MCC-SVN02A-EN

Models

Cooling Only

MCC 518 ZB

MCC 524 ZB

MCC 530 ZB

MCC 536 ZB

MCC 048 ZB

October 2007

Installation Manual

Split System,

18,000 - 48,000 Btu/h

Under ceiling T ype

MCC Series 50 Hz

CASSETTE

MCC-SVN02A-EN

General Information

General Information

This Installation Manual is given as a

guide to good practice in the

installation by the installer of MCC

mini-split system. Installation

procedur es should be performed in

the sequence that they appear in this

manual.

For installing the unit to operate

properly and r eliably, it must be

installed in accor dance with these

instructions. Also, the services of a

qualied service technician should be

employed, thr ough the maintenance

contract with a r eputable ser vice

company .

Read this Installation Manual

completely befor e installing the

air conditioning system.

About this Manual

Cautions appear at appr opriate

places in this Installation Manual.

Your personal safety and the pr oper

operation of this machine r equire that

you follow them car efully.

The T rane Company assumes no

liability for installations or servicing

performed by unqualied personnel.

All phases of the installation of this air

conditioning system must conform to

all national, pr ovincial, state and local

codes.

About the Unit

These MCC units ar e assembled,

pressur e tested, dehydrated, char ged

and run tested befor e shipment. The

information contained in this manual

applies to MCC units ar e designed to

operate in cooling mode only .

Trane MCC series of fer ceiling

mounted installation to leave the oor

space unclutter ed, and equipped with

LCD wir eless r emote contr ol.

Reception

On ar rival, inspect the unit befor e

signing the delivery note. Specify any

damage of the unit on the delivery

note, and send a r egister ed letter of

protest to the last carrier of the goods

within 72 hours of delivery . Notify the

dealer at the same time.

The unit should be totally inspected

within 7 days of delivery . If any

concealed damage is discover ed,

send a r egister ed letter of pr otest to

the carrier within 7 days of delivery

and notify the dealer .

Wa rning

Warnings ar e pr ovided at appr opriate

places in this manual to indicate to

installers, operators and service

personnel of potentially hazar dous

situations which, if not avoided,

COULD r esult in death or serious

injury.

Caution

Cautions ar e provided at appr opriate

places in this manual to indicate to

installers, operators, and service

personnel of potentially hazar dous

situations which, if not avoided, MA Y

result in minor or moderate injury or

malfunction of the unit.

Your personal safety and the pr oper

operation of this unit r equire that you

follow them car efully. The T rane

Company assumes no liability for

installations or servicing performed by

unqualied personnel.

Wa rranty

Warranty is based on the general

terms and conditions by country . The

warranty is void if the equipment is

modied or r epair ed without the

written appr oval of The T rane

Company , if the operating limits ar e

exceeded or if the contr ol system or

the electrical wiring is modied.

Damage due to inappr opriate

installation, lack of knowledge or

failure to comply with the

manufactur er’s instructions, is not

cover ed by the warranty obligation.

If the installation does not conform to

the rules described in Installation

Manual, it may entail cancellation of

warranty and liabilities by The T rane

Company .

Important

This document is customer pr operty

and is to r emain with unit. Please

place in service information pack upon

completion of work.

These instructions do not cover all

variations in systems, nor do they

provide for every possible contingency

to be met in connection with

installation.

Should further information be desir ed

or should par ticular pr oblems arise

which ar e not cover ed suf ciently in

this manual, the matter should be

referred to your authorized T rane

dealer.

MCC-SVN02A-EN

3

Contents

4

MCC-SVN02A-EN

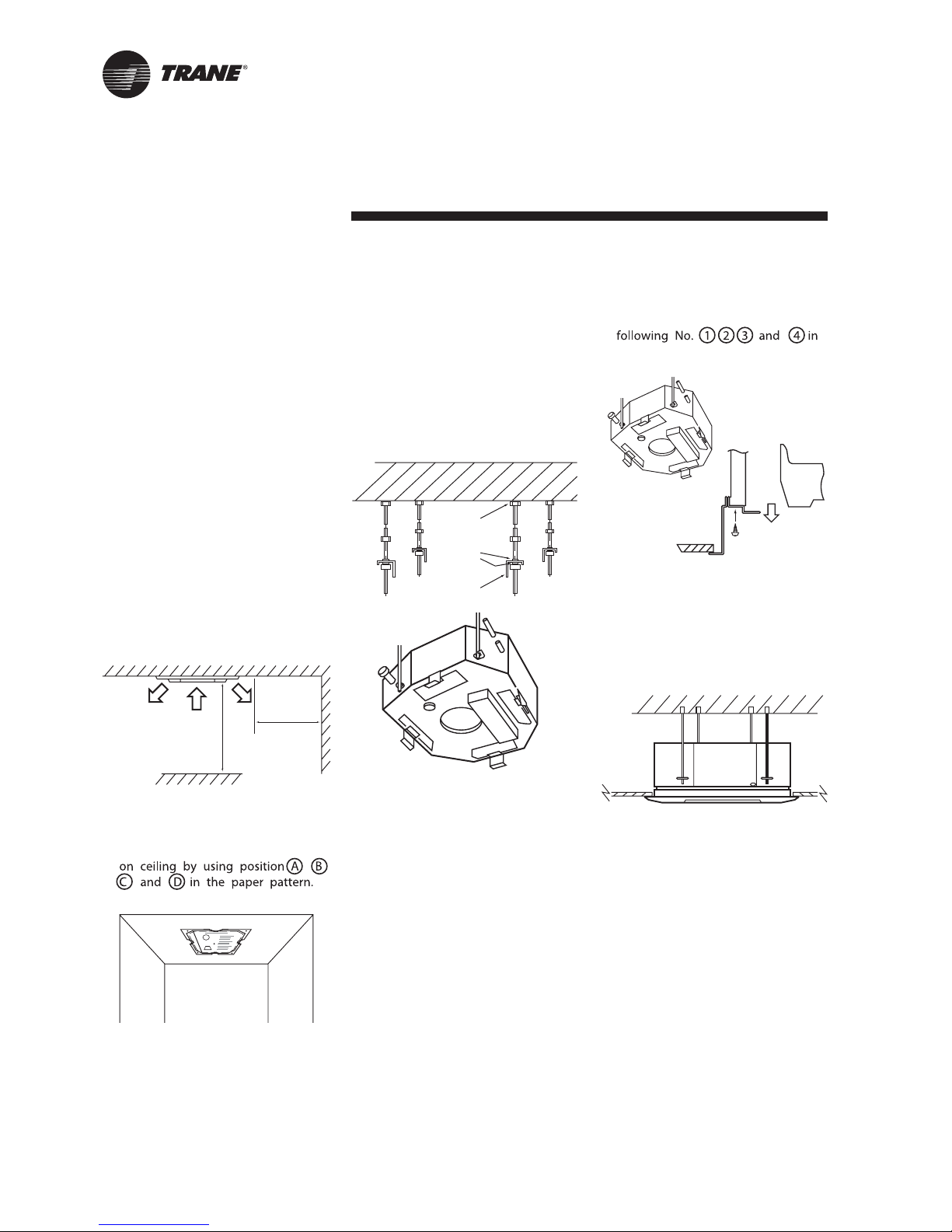

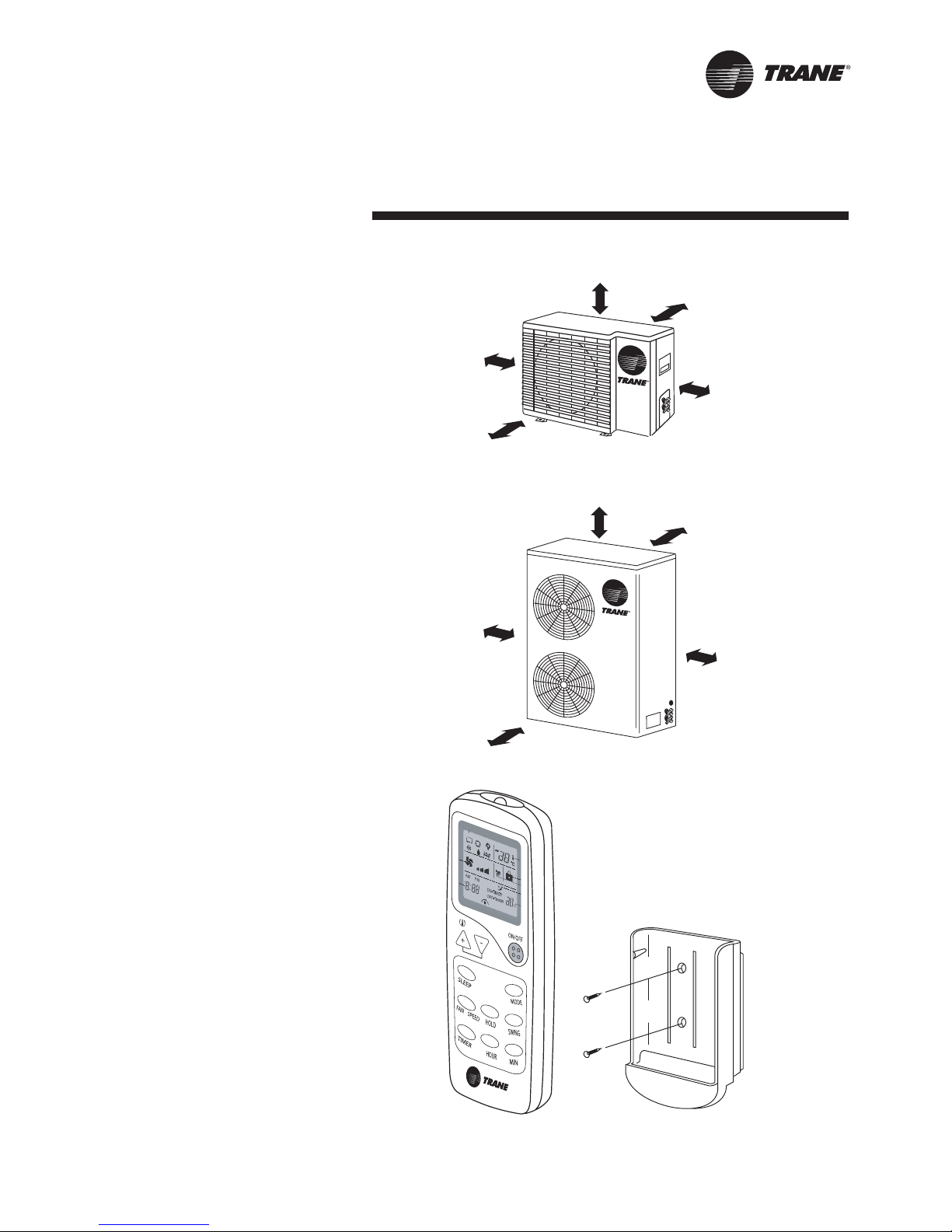

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

more than

100 cm.

more than

100 cm.

Lock Nut

Washers

Suspension

Bracket

Cross Section

of Air Outlet

Indoor Unit Installation

Where to install Indoor Unit

• There should not be any heat

source or steam near the unit.

• There should not be any obstacles

to prevent the air circulation.

• A place where air circulation in the

room will be good.

• A place where drainage can be

easily obtained.

• A place where noise prevention is

taken into consideration.

• Do not install the unit near the

door way.

Indoor Unit Installation

• Select the location where a space

is more than 100 cm. as shown in

gure 1 also ensure that the

position dose not interfere with

light tting, sprinkle head, etc.

• Determine the ceiling hole by using

the paper pattern.

- Determine the mounting position

• Hang the four mounting rods to the

positions marked as picture shown

in gure 3 (using twelve nuts and

eight washers to support the

suspension brackets). Suspend

the unit to the mounting rods.

Lock the nuts, ensure for good

drainage, and check whether the

unit is on horizontal level by using

leveling guage.

• Install the leveling metal plate to

adjust the gap between the unit

and a ceiling, xing the screws

paper pattern.

• Remove four screws (M8). Fix the

front panel with the units by tighten

up four screws (M8).

Caution: Over tightening the screws

will distort the front panel.

MCC-SVN02A-EN

5

Figur e 6

Figur e 7

more than 10 cm.

more than 10 cm.

more than 10 cm.

more than 70 cm.

more than 35 cm.

more than 30 cm.

more than 10 cm.

more than 30 cm.

more than 120 cm.

more than 35 cm.

Wir eless Remote Control

Figur e 8

Outdoor Unit Installation

Wher e to install Outdoor

Unit

• The foundation must be solid

enough to bear the weight and

vibration of the unit.

• The space ar ound the unit is

adequate for ventilation.

• The location is not close to any

amable gases.

• The location is sufciently isolated

so that the running noise and the

hot exhaust air do not disturb the

users or their neighbors.

• Easy access to check and to

maintain.

• Ensur e the spaces indicated by

arrows fr om the wall, ceiling, fence,

or other obstacles.

Caution

Installation in the following places may

cause pr oblems. If it is unavoidable to

use such places, consult with your

distributor or dealer .

• A place with machine oil.

• A saline place such as a place very

close to a seashore.

• A place with sulphur gas.

• A place where high-fr equency

waves are generated by radio

equipment, welder and medical

equipment.

Remote Contr ol

Installation

Locate and attach the wireless

remote contr ol as follows:

• Do not place the remote control

near heat sources or expose to

the direct rays of the sun.

• Do not expose the remote control

to the indoor unit’s supply air

stream.

• Do not place in a conned space.

• Attach the remote control holder

as shown in gure 8.

6

MCC-SVN02A-EN

Figure 15

Figure 10

Figure 9

Figure 11

Figure 12

Figure 13

Copper

tubing

Reamer

Before

After

Flare nut

Flare tool

Copper

tubing

Apply refrigerant

lubricant here

Flare nut

Union

epols a eviG

Figure 14

Drain hose

Connection of Refrigerant Tubing

and Condensate Drain Piping

Deburring

Connecting the unit with aring

procedure

1. Flaring (If piping is procured or cut

at the site). Cut the copper tube to

the required length with a tube

cutter. It is recommended to cut

approx. 30-50 cm. longer than the

tubing length you estimate.

2. Hold each pipe downward when

cutting and remove burrs at the

end of the copper tube with a tube

reamer or le. This process is

important and should be done

carefully to make a good are

(Figure 9 and Figure 10).

A good are should have the

following characteristics:

- Inside surface is glossy and

smooth.

- Edge is smooth.

- Tapered sides are of uniform length.

Bending

5. When bending the tube, be careful

not to crush it. To prevent crushing

of the tube, bend it gently and do

not bend the tube at a radius

curvature of less than 100 mm.

6. If the copper tube is bent or pulled

too often, it will become sti. Do

not bend the pipe more than three

times at one place.

Cautions before Connecting

Tubes Tightly

7. Be sure to apply a sealing cap

or water-proof tape to prevent

dust or water from getting into

the tubes before they are used.

8. Be sure to apply refrigerant

lubricant to the matching surfaces

of the are and union before

connecting them together. This

is eective for reducing gas leaks

(Figure 12).

10. Tighten the are nut to the

specied tightening torque with

torque wrench and adjustable

wrench.

Condensate Drain Piping

- The drain hose should run straight

down the wall to a level where the

runo will not stain the wall.

- There should be no traps. Avoid

putting the end of the hose in

water.

- To conveniently drain the system,

the drain hose must slant

downward, with a slope of at least

1 : 50 to prevent leakage as shown

in gure 14.

When reaming, hold the tube end

downward and be sure that no

copper scraps fall into the tube.

3. Remove the are nut from the

unit and be sure to mount it on

the copper tube.

4. Make a are at the end of copper

tube with a are tool (Figure 11).

Connection

9. For proper connection, align the

union tube and are tube straight

with each other, then screw in the

are nut lightly at rst to obtain a

smooth match (Figure 13).

- When the drain hose is placed in

the room, insulate the hose with

foam polyethylene to avoid

damage to the ceiling or furniture.

- After completing installation of

refrigerant lines, wiring and drain

connections, bind the tubing,

wiring and drain hose (check if

local codes permit binding) into a

bundle by using tape at 100 or

200 mm (4" to 8") intervals. Make

sure the drain hose is at the bottom

of the bundle (Figure 15).

MCC-SVN02A-EN

7

Leak Check and System Evacuation

Leak Check

After the connection operation of

refrigerant lines to both the outdoor

and indoor unit is completed, the eld

brazed connections must be checked

for leaks. Pressurize the system

through the service valve with dry

nitrogen to 250 psi. Use soap

bubbles or other leak-checking

methods to ensure that all eld joints

are leak free. If not, release pressure,

repair and repeat leak test.

System Evacuation

1. After completion of leak check,

evacuate the system.

2. Attach appropriate hoses from

manifold gauge to gas and liquid

line pressure taps.

Note: Unnecessary switching of

hoses can be avoided and

complete evacuation of all lines

leading to sealed system can be

accomplished with manifold

center hose and connecting

branch hose to a cylinder of

R-22 and vacuum pump.

3. Attach center hose of manifold

gauges to vacuum pump.

4. Evacuate the system to hold a

350 micron vacuum.

5. Close o valve to vacuum pump

and observe the micron gauge.

If gauge pressure rised above

500 microns in one (1) minute,

then evacuation is incomplete or

the system has a leak.

6. If vacuum gauge does not rise

above 500 microns in one (1)

minute, the evacuation should

be complete.

7. With vacuum pump and micron

gauge blanked o, open valve on

R-22 cylinder and allow refrigerant

pressure to build up to about 40

psig.

8. Close valve on the R-22 supply

cylinder. Close valves on manifold

gauge set and remove refrigerant

charging hoses from liquid and

gas gauge ports.

9. Leak test the entire system. Using

proper procedures and caution,

repair any leaks found and repeat

the leak test.

Refrigerant Charging Procedure

Charge refrigerant through the gauge

port on the liquid line until pressure at

gauge is up to 120-150 psi. Once the

charge enters the system, backseat

(open) the liquid line service valve and

disconnect the charging line and

replace the cap on the gauge port.

Gaseous Charging

This procedure is accomplished

with the unit operating. Electrical

connections must be complete.

Do not proceed until the system is

ready to operate.

Procedure

1. Connect R-22 drum with gauge

manifold to the Schrader valves

(pressure taps) on the compressor

discharge and suction lines.

2. Turn on power to the unit. Allow

the system to run for ve to ten

minutes to stabilize operating

conditions.

3. Once proper airow is established,

observe the suction and head

pressure gauges on the gauge

manifold. Pressure reading should

fall approximately at the normal

points. Add or remove refrigerant

(gas only) as required to obtain

correct head and suction pressures.

Check suction line superheat and

condenser sub-cooling to ensure

the unit is operating properly.

4. Disconnect all power to the unit.

5. Remove the charging system from

the unit and close the opening in

the bottom of the control box with

the pivotal cover before attempting

to replace access panel.

Liquid pressure

Suction pressure

Vacuum pump

R-22

Service hose

Liquid line

Suction

line

Electrical connection

Figure 16

MCC-SVN02A-EN

9

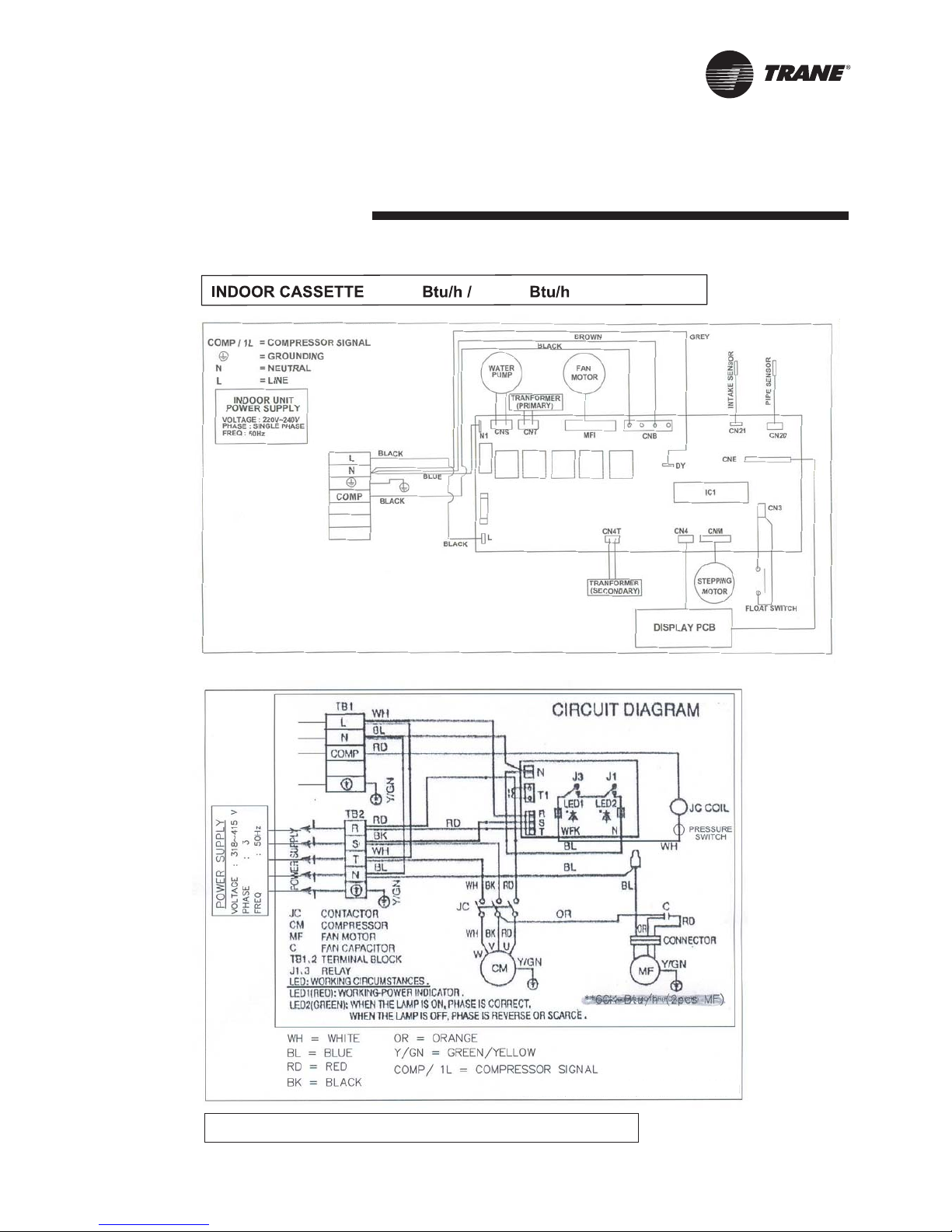

Wiring Diagram

OUTDOOR CASSETTE 18000 Btu/h & 24000 Btu/h

220-240/1/50 Hz

380-420/3/50 Hz

MCC518-048ZB

MCC-SVN02A-EN

10

Wiring Diagram

OUTDOOR CASSETTE 30000 Btu/h

MCC-SVN02A-EN

11

Wiring Diagram

OUTDOOR CASSETTE 36,000 Btu/h & 48,000 Btu/h

36,000 48,000

12

MCC-SVN02A-EN

MCC518ZB MCC524ZB MCC530ZB MCC536ZB MCC048ZB

A. Height above ceiling

B. Height above suspension brackets

C. Height of condensate drain above ceiling

D. Pipe exit position

Model

950

390

340

512

330

370

350

CEILING HOLES 860-890

418

785

drainpipe outlet

850

60

main cable entry

B

C

D

22

refrigerant pipe

Dimensional Data

A

230 230 230 290 290

100 100 100 150 150

200 200 200 200 200

150 150 150 150 150

MCC-SVN02A-EN

13

Notes

Trane has a policy of continuous product and product data implement and reserves the

right to change design and specications without notice.

New

Loading...

Loading...