Page 1

Product Catalog

VariTrane™ Products

Parallel and Series Fan-Powered

VPCF, VPWF, VPEF, VSCF, VSWF, VSEF,

LPCF, LPWF, LPEF, LSCF, LSWF, LSEF

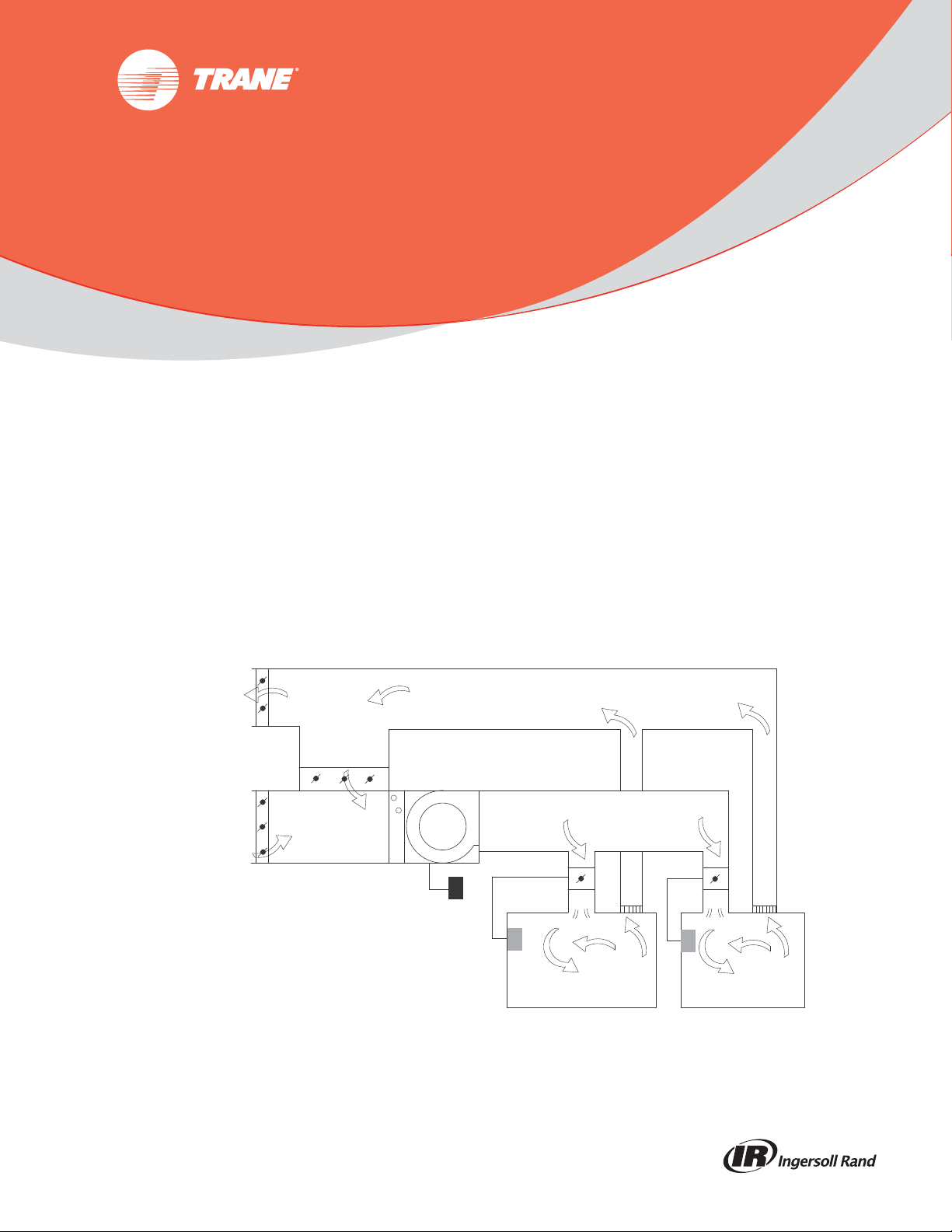

Variable-Air-Volume (VAV) System

EA

OA

cooling

coil

variable-

speed drive

supply

fan

thermostat

PA

RA

VAV

box

SA

July 2013

VAV-PRC012-EN

Page 2

Introduction

Fan-powered units offer energy savings due to intermittent fan control.The fan energizes only in

heating mode when the space needs heat. Additional energy savings are obtained by using warm

plenum air forfree reheat. Motor heat is never wasted in parallel units.Theyare an excellent choice

when minimal zone heating is needed.

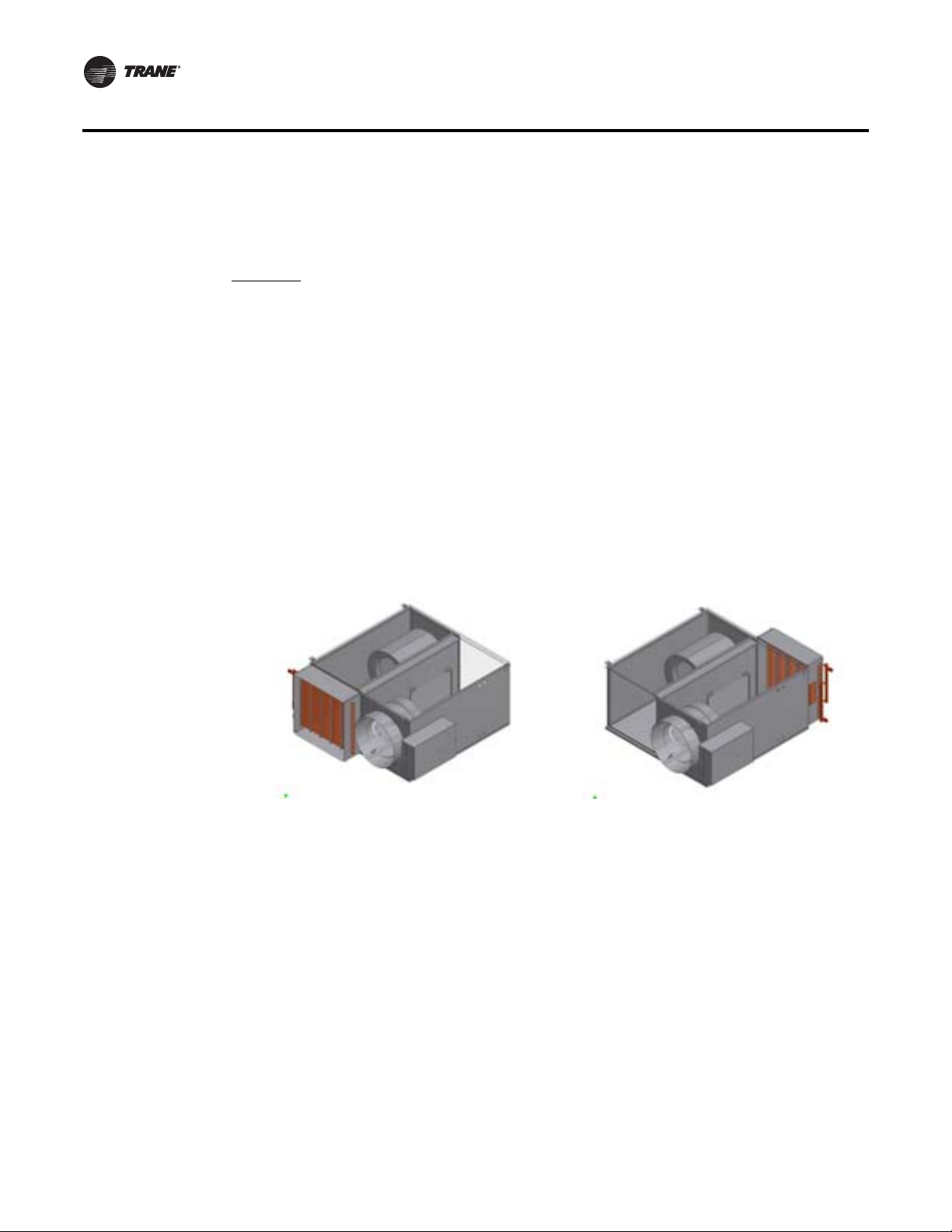

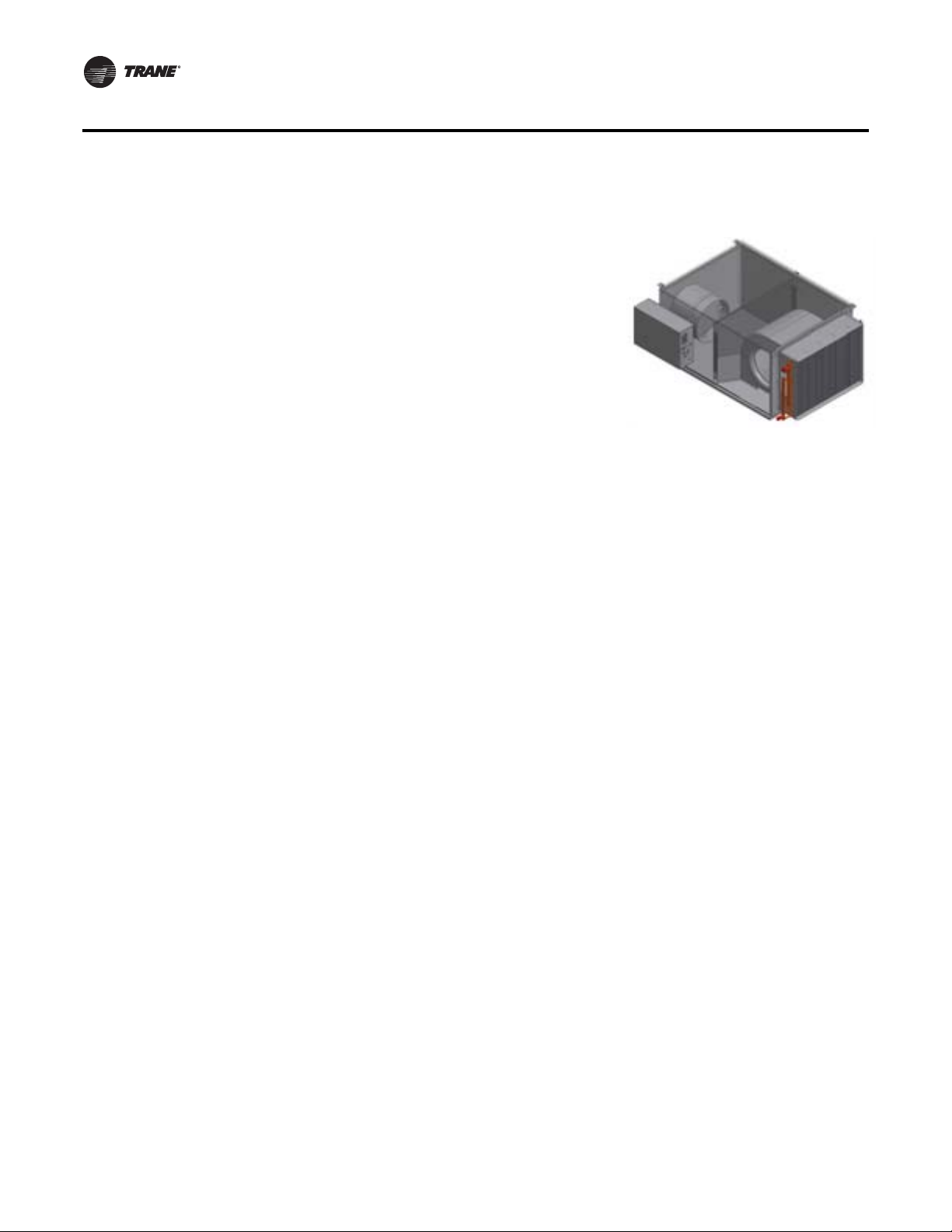

Figure 1. Parallel fan-powered terminal unit (L) & series fan-powered terminal units (R)

Figure 2. Low height series: LSCF (L) & low height series: LSWF (R)

Figure 3. Low height series: LSEF (L) & low height parallel: LPCF (R)

Figure 4. Low height parallel: LPWF (L) & low height parallel: LPEF (R)

Revision Summary

VAV-PRC012-EN (16 Jul 2013). Updated proportional water valve design.

VAV-PRC012-EN (27 June 2013). Updated controls information. Updated dimensions for units

with attenuators.

Trademarks

Earthwise, VariTrane, VariTrac,Trane and theTrane logo are trademarks of Trane in the United

States and other countries. All trademarks referenced in this document are the trademarks of their

respective owners.

BACnet is a registered trademark of American Society of Heating, Refrigerating and AirConditioning Engineers (ASHRAE); LONMARK and LonTalk are registered trademarks of Echelon

Corporation.

© 2013Trane All rights reserved VAV-PRC012-EN

Page 3

Table of Contents

Features and Benefits ..............................................5

Agency Certifications ..............................................13

Model Number Descriptions ........................................15

Selection Procedure ...............................................17

Performance Data ................................................24

Parallel Fan-Powered Terminal Units .............................. 24

Series Fan-Powered Terminal Units ............................... 35

Low Height Parallel Fan-Powered Terminal Units .................... 47

Low Height Series Fan-Powered Terminal Units ..................... 53

Electrical Data ....................................................59

Parallel Fan-Powered Terminal Units .............................. 59

Series Fan-Powered Terminal Units ............................... 63

Low Height Parallel Fan-Powered Terminal Units .................... 68

Low Height Series Fan-Powered Terminal Units ..................... 70

Acoustics Data ...................................................76

Parallel Fan-Powered Terminal Units .............................. 76

Series Fan-Powered Terminal Units ............................... 85

Low Height Parallel Fan-Powered Terminal Units .................... 92

Low Height Series Fan-Powered Terminal Units ..................... 98

Dimensional Data ................................................103

Parallel Fan-Powered Terminal Units ............................. 103

Series Fan-Powered Terminal Units .............................. 109

Low Height Parallel Fan-Powered Terminal Units ................... 123

Low Height Series Fan-Powered Terminal Units .................... 134

Mechanical Specifications: Fan-Powered ............................142

DDC Controls ...................................................147

Control Logic ................................................. 147

DDC Remote Heat Control Options ............................... 148

Tracer™ UC400 and UC210 Programmable BACnet Controllers ....... 152

Trane DDC VAV Controller Logic ................................. 154

Flow Tracking Control .......................................... 157

Tracer™ Programmable BACnet Controller — Unit Control Module .... 158

Trane LonMark DDC VAV Controller .............................. 160

Trane DDC VAV Controller Logic ................................. 162

VAV-PRC012-EN 3

Page 4

Flow Tracking Control .......................................... 165

LonMark™ Direct Digital Controller—Unit Control Module ........... 166

Direct Digital Controller—Unit Control Module ..................... 169

Wireless Comm Interface (WCI) .................................. 170

Wireless Receiver/Wireless Zone Sensor .......................... 172

DDC Zone Sensor ............................................. 173

CO

Wall Sensor and Duct CO2Sensor ............................ 174

2

DDC Zone Sensor with LCD ..................................... 176

Zone Occupancy Sensor ........................................ 177

Factory or Field Wired Auxiliary Temperature Sensor ............... 178

Control Relay ................................................. 178

Two-Position Water Valve ...................................... 179

Proportional Water Valve ....................................... 180

Differential Pressure Transducer ................................. 181

Transformers ................................................. 182

Trane Actuator – 90 Second at 60 Hz Drive Time .................... 183

Belimo Actuator – 95 Second Drive Time .......................... 184

Trane Spring Return Actuator ................................... 185

VariTrane DDC Retrofit Kit ...................................... 186

Retrofit Kit Actuator ........................................... 186

Silicon-Controlled Rectifier (SCR) ................................ 187

Pneumatic Controls ............................................ 188

Controls Specifications ......................................... 203

Application Considerations ........................................208

VAV System .................................................. 208

Parallel vs. Series ............................................. 211

Low-Temperature Air .......................................... 213

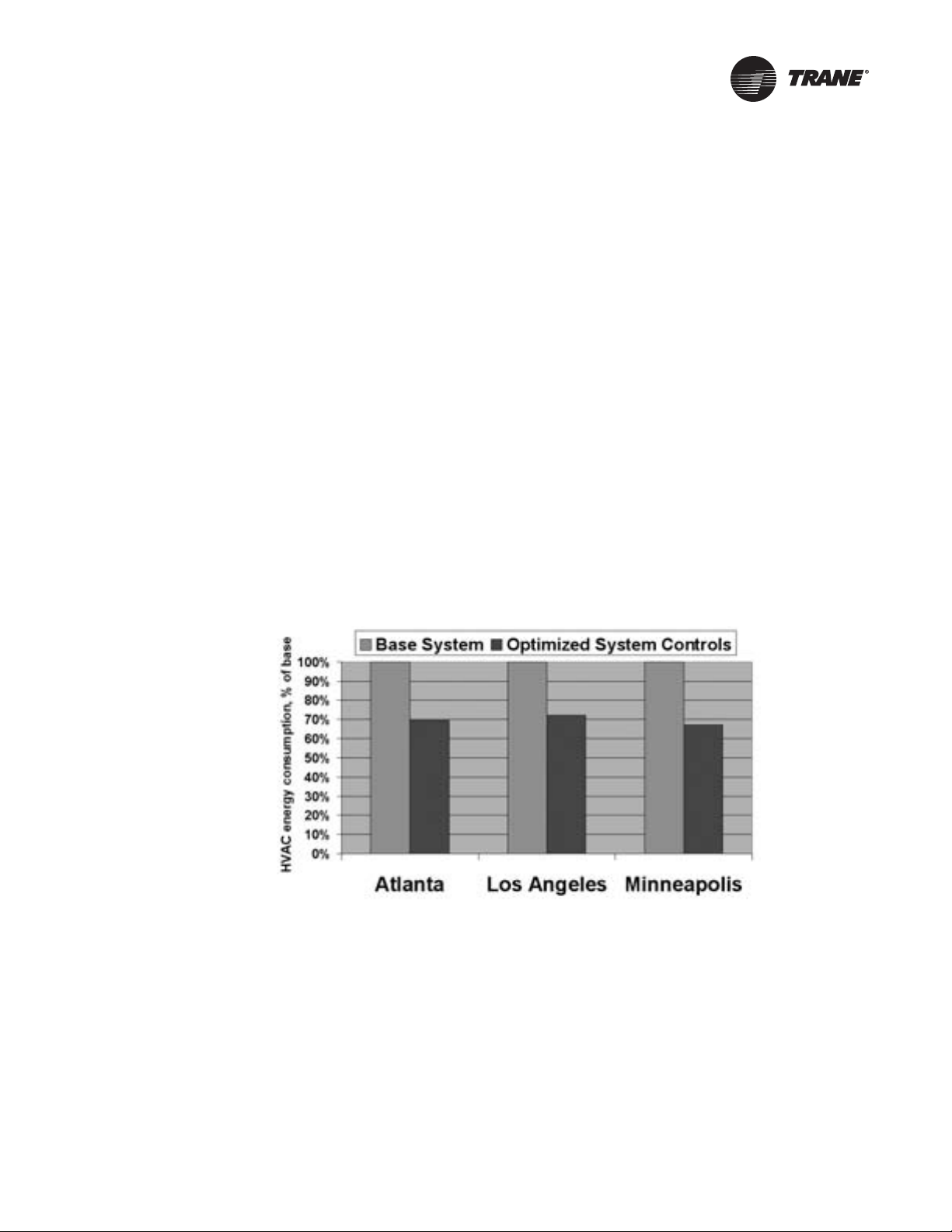

Energy Savings & System Controls ............................... 216

Control Types ................................................ 218

Flow Measurement and Control ................................. 221

Reheat Options ............................................... 224

Insulation .................................................... 226

Acoustics .................................................... 226

Duct Design .................................................. 230

Best Practices ................................................. 231

Unit Conversions .............................................. 232

Additional VAV System and Product References .................... 233

4 VAV-PRC012-EN

Page 5

Features and Benefits

VariTrane™– VAV Leadership

VariTrane variable-air-volume (VAV) units lead the industry in quality and reliability and are

designed to meet the specific needs of today’s applications.This generation of VariTrane units

builds upon the history of quality and reliability and expands the products into the most complete

VAV offering in the industry.

Parallel Fan-powered units offer energy savings due to intermittent fan control.The fan

energizes only inheating mode when the space needsheat. Additional energysavings are obtained

by using warm plenum air for free reheat. Motor heat is never wasted in parallel units.They are

an excellent choice when minimal zone heating is needed.

Series fan-powered units have fans which are always energized in occupied mode.They are

common in applications such as conference rooms, cafeterias, etc., that desire constant airflow

rates at all conditions.

Low-height parallel units provide the energy savings of an intermittent fan with the flexibility

of an 11"–11.5” casing height.This is a good choice for tight plenum spaces.

Low-height series units have been used for years in projects with strict plenum height

requirements. Units

are available in 11.0" height.

Energy Efficient Earthwise™ Systems

Figure 5. Rooftop VAV (office building)

A significant consumer of energy in commercial buildings is heating and air conditioning. One of

the most energy-efficient HVAC solutions is theVAV system.This inherent system efficiency, along

with high-quality, affordable DDC controls, has steadily increased demand forVAV systems over

the years. VAV systems save significant energy, are able to deliver the required amount of

ventilation air, and provide reliable occupant comfort.

Energy saving featuresmust go beyond a simple VAV unit to incorporate VAV unit level and system

level control strategies like:

• Ventilation Optimization-Combines demand-controlled ventilation (using either a time-of-day

schedule, an occupancy sensor, or a carbon dioxide sensor) at the zone level with ventilation

reset at the system level to deliver the required amount of outdoor air to each zone, while

minimizing costly over-ventilation.

VAV-PRC012-EN 5

Page 6

Features and Benefits

S

Q

s

r

y

u

g

l

• Fan Pressure Optimization- reduces supply fan energy by as much as 40% by intelligently

• Night setback reduces energy consumption during unoccupied periods by raising or lowering

• Supply AirTemperature Reset-reduces overall system energy use (balancing reduced cooling

• Electrically Commutated Motors (ECM) improve the efficiency of fan-powered VAV units.

• LowTemperatureAir Distribution can decrease overall system energy use by reducing airflows

To determine the potential energy savings a VAV system can bring to your applications,Trane

offers energy-modeling software like System Analyzer™ andTRACE 700

introduced into the HVAC industry in 1972, the HVAC design and analysis program was the first of

its kind and quickly became a defacto industry standard. It continues to grow with the industry

meeting requirements for ASHRAE Standard 140, ASHRAE 90.1, and the LEED® Green Building

Rating System and has now been approved by the IRS to certify energy savings for building

owners. Contact your localTrane Sales Engineer for additional information.

reducing the pressure in the air distribution system to the lowest possible level without

impacting occupant comfort.

space temperature setpoints.

and reheat energy with increasedfan energy)by raising thesupply airtemperature at part load,

while avoiding elevated space humidity levels.

and the fan energy needed to move that air through the system.

®

. WhenTRACE™ was

Control Flexibility—Trane

factory installs more VAV

controllers than any other

manufacturer in the

industry. In addition to

Trane DDC controls and

simple factory-mounting

of non-Trane VAV controllers,

Trane now offers a LonMark™

controller that is completely

factory-commissioned to

maximize installation quality

and system reliability. Labor

savings are maximized with

Trane factory-commissioned

controllers.

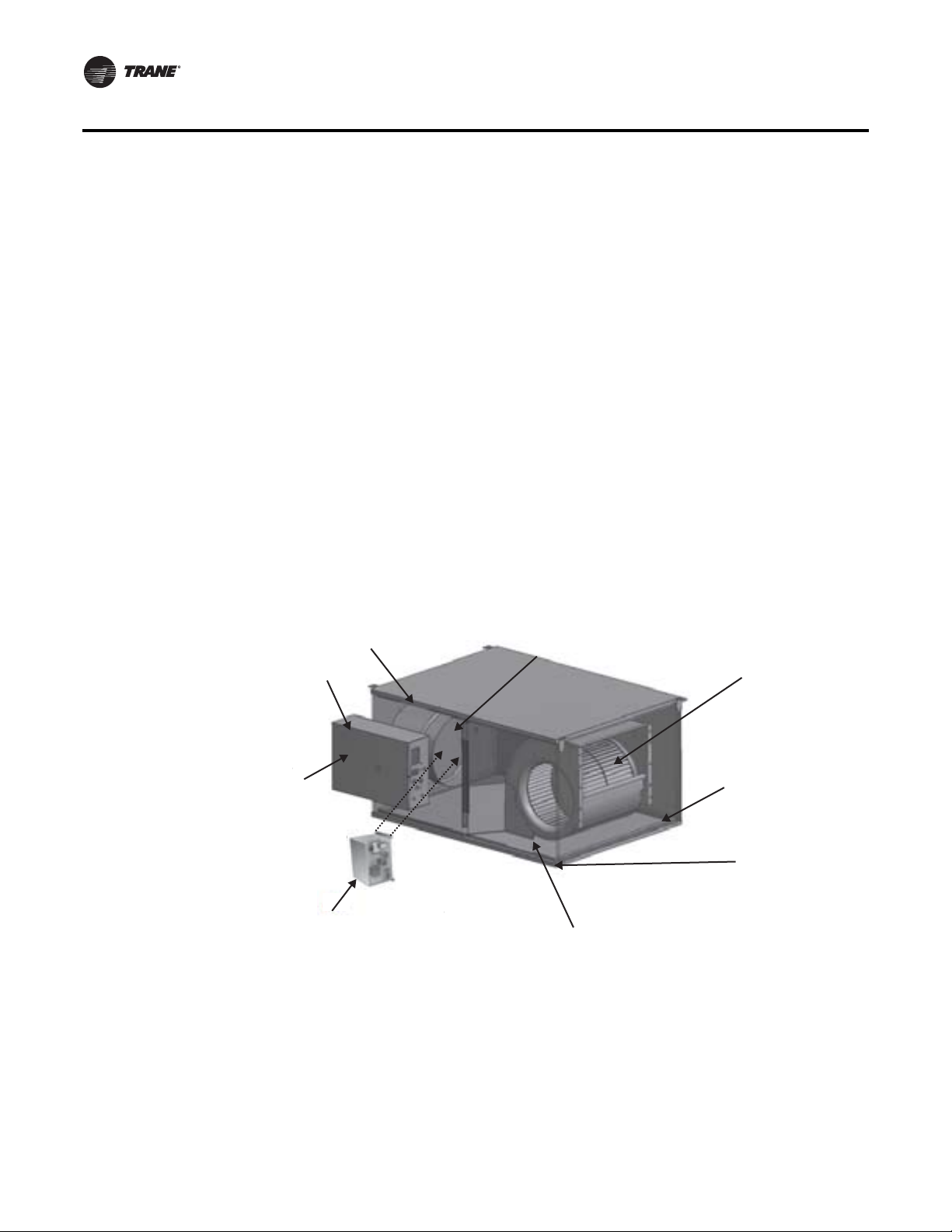

Service Friendly:

* Internal shaft visible

through control box

cover sight hole for

blade orientation

verification.

* Same-side NEC jumpback clearance—

provides all high- and low-voltage

components on the same side

to minimize field labor.

* SQ fan-powered units have

improved accessability to

internal components. Sliding

panels are standard which

improve safety and allow

servicing with a single

technician.

Accurate Flow Ring—Housed

and recessed within the air

valve to provide flow ring

handling/shipping protection.

The patented flow ring provides

unmatched airflow measurement

accuracy.

Optional Narrow Corridor unit

configuration — designed to minimize building

material expenses by squeezing more into less space.

Meets all NEC jumpback clearance requirements

for these extra-tight areas. Narrow Corridor

Configuration not pictured here. Refer to Series

Fan-Powered dimensional data for reference drawings.

Rugged Air Valve—Trane air

valves are heavy gage steel

with a continuously welded

seam to limit inlet deformation.

This provides consistent and

repeatable airflow across

the flow ring with performance you

can count on.

Full Range of Insulation—Whether seeking optimal acoustical perf

or cleanability, Trane has a complete line of insulation options, inc

double-wall, matte-faced, foil-faced, closed cell, etc.

Technologically Advanced "

Units— New super-quiet (S

fan/motor/wheel assemblie

engineered as an air delive

system to provide the most

efficient design available in

industry. For quiet comfort

can trust, rely on Trane SQ

Tough Interlocking Panels— Ru

and rigidity are assured with Tra

patent-pending interlocking pan

Superior Metal Encapsulated

VariTrane Units are complete

encapsulated edges to arrest

fibers and prevent erosion in

6 VAV-PRC012-EN

Page 7

Construction

Features and Benefits

UL-listed products—

Safety and reliability are vital in commercial construction. AllVariTrane units are completely listed

in accordance with UL -1995 as terminal units.This listing includes the VAV terminal with electric

heaters. Additionally, all insulation materials pass UL 25/50 smoke and flame safety standards.

AHRI Certified Performance—

All VariTrane units are AHRI certified. AHRI 880 guarantees the pressure drop, flow performance,

and acoustical performance provided is reliable and has been tested in accordance with industry

accepted standards. AHRI 885 uses AHRI 880 performance and applies accepted industry methods

to estimate expected “NC” sound levels within the occupied space.

Casing Design—

Interlocking Panels—VariTrane products are manufactured in the most state-of-the-art VAV facility

in the world.The patent-pending interlocking panels are designed using integral I-beam

construction technology.This limits deformation and creates tremendous product rigidity. An

additional benefit is a smooth unit exterior with few exposed screws—ideal for exposed ceiling

applications. VariTrane units are designed for use in systems that operate up to 5" w.c. of inlet

pressure.

Metal Encapsulated Edges—AllVariTrane unitsare complete

with encapsulated edges to arrest cut fibers and prevent

insulation erosion into the airstream.This is the standard of

care in applications concerned with fiberglass erosion or

projects with either double-wall or externally wrapped duct

work.

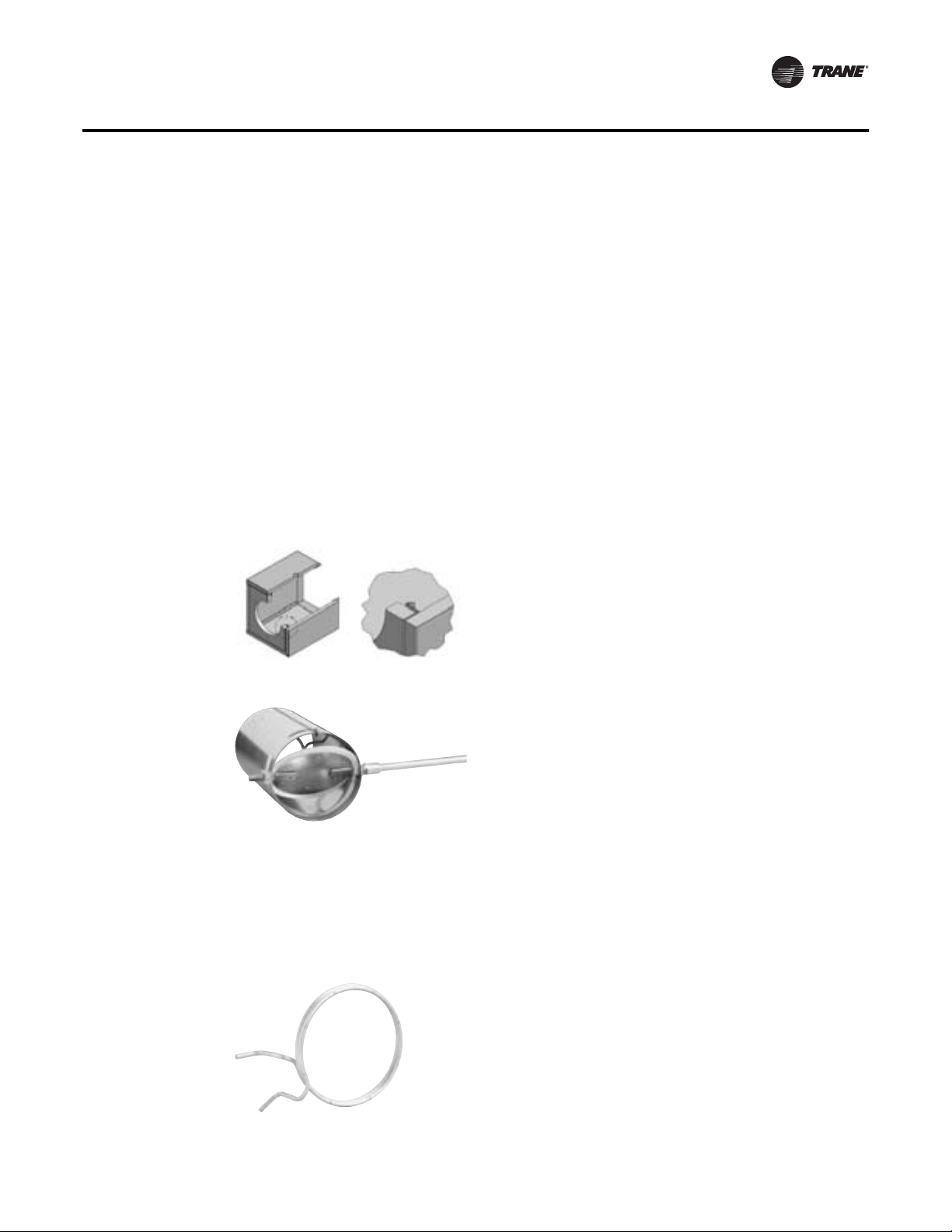

TheTrane Air Valve—is at the heart of VariTrane terminal

units.This is where airflow is measured and controlled.

Repeatability and ruggedness is vital.VariTrane products are

the most rugged and reliable available.

18-gage Cylinder—limits deformation or damage during shipment and job site handling, and

provides even airflow distribution across the flow ring for unmatched airflow measurement

accuracy.

Continuously Welded Seam — an automated weld process creates the highest quality continuous

seam, which is “right” every time.The welded seam improves air valve rigidity and creates

consistent and repeatable airflow across the flow measurement device.The result is a truly round

cylinder every time, with no flat spots caused by lower quality crimping and riviting technologies.

Flow Ring—TheTrane flow ring is time tested to perform under the

most demanding conditions. Additionally,Trane’s patented flow ring

is recessed within the air valve cylinder to reduce the potential for

damage during job site handling and installation.

VAV-PRC012-EN 7

Page 8

Features and Benefits

External Shaft—The simple design provides controller flexibility and is designed to facilitate

actuator field replacement.

Position Indicator—The position indicator shows current air valve position to aid in system

commissioning. Many times this can be seen from the floor without climbing a ladder.

ExternalActuator—This feature increases serviceability,control system compatibility,and actuator

clutch access for simplified commissioning.

Indoor Air Quality (IAQ) Features

The oil embargo ofthe early1970s created an energy crisis,which resulted in tighter buildings,and

reduced ventilation rates. A fallout issue of tighter building construction was poor indoor air

quality.This heightened IAQ awareness. IAQ issues have been featured in publications from the

smallest towns to the largest cities. System design should consider applicable ventilation and IAQ

standards.(See your localTrane Sales Engineer or visit

Good indoor air quality results from units and systems which:

• Provide the required amount of ventilation air to each zone during all operating conditions

• Limit particulates from entering occupied spaces

• Allow proper access for periodic cleaning.

www.trane.com for additional information).

Note: Access made easy on new VariTrane units, as shown on this Series Fan-Powered unit.

VariTrane units are designed with simplified access and a full line of insulation options including:

Matte-faced—Typical industry standard with reduced first cost.

Closed-cell—This insulation has anR-value andperformance equivalent to matte-faced insulation.

The main difference is the reduction of water vapor transmission. Closed-cell is designed for use

in installations with a high chance of waterformation. (It has been usedto coat the exterior of chiller

evaporator barrels for many years.)

Foil-faced—A fiberglass insulation with a thin aluminum coating on the air stream side to prevent

fibers frombecoming airborne.The aluminum lining is acceptable for many applications, however

it is not as rugged as double-wall

Double-wall—Premium insulation often used in many health care applications with insulation

locked between metal liners.This eliminates the possibility for insulation entering the airstream

and allows for unit interior wipe-down as needed.

VariTrane VAV units are the most prepared IAQ units in the industry.

The end result is areliable product designed for peak performance, regardless of jobsite conditions

or handling.

8 VAV-PRC012-EN

Page 9

Tracer™ Building Automation System

Tracer Building Automation System assures comfort within your building. Building controls have

a bigger job descriptionthan theydid afew years ago. It’s no longer enough tocontrol heatingand

cooling systems and equipment. Sophisticated buildings require smarter technology that will

carry into the future. Tracer™ controls provide the technology platform – mobile, easy-to-use,

cloud-based, scalable and open - for the next generation of data-driven, technology-enabled

services that are creating high performance buildings. With aTraneTracer Building Automation

System, you’ll:

• Reduce operating costs through energy management strategies

• Consistently provide occupant comfort

• Enjoy reliable operation with standard, pre-engineered and pretested applications

• Easily troubleshoot and monitor either on site or from a remote location

• Reduce installation time and simplify troubleshooting

Whether factory-mounted or field-installed,Trane offers a wide range of controllers to suit virtually

any application.These unitsare compatible witha variety of building typesand can be usedfor new

construction or renovation.Through extensive usability testing internally and with building

operators, we’ve designed our controls for real world ease of use.

(Additional control options and sequence-of-operations are located in the “Controls” section.)

Trane VAV UCM DDC Controller

Features and Benefits

DDC (communicating electronic)—DDC

controllers are today’s industrystandard. DDC

controllers provide system-level data used to

optimize overall SYSTEM performance.

Variables such as occupied/unoccupied,

minimum and maximum cfm and

temperature, valve position, ventilation

fraction, etc. are available on a simple twistedshielded wire pair. For additional information,

see “Industry Issues: Energy Efficiency”.

Note: One of many Trane DDC Control Options which are factory-installed, wired, calibrated, and fully tested before shipment.

Trane DDC controllers provideTrane-designed solid-state electronics intended specifically forVAV

temperature control in space comfort applications. DDC control capabilities include:

• Pressure-independent (PI) operation—Provides airflow required by the room thermostat to

maintain occupant comfort.The controller automatically adjusts valve position to maintain

required airflow. Minimum and maximum airflow is factory-set and field-adjustable.

• Factory-set airflow and temperature setpoints

• Most advanced system integration in the industry.

Tracer VV550 LonTalk™ Controllers

LonTalk™ Controller

Trane now offers a full line of LonTalk™

controllers designed for simple integration

into ANY system which can communicate via

the LonMark Space Comfort Control (SCC)

protocol.These controllers are also

completely factory-commissioned.

VAV-PRC012-EN 9

Page 10

Features and Benefits

Tracer BACnet™ Controllers

Trane now offers a full line of BACnet controllers designed for simple integration into any system

which can communicate via the BACnet protocol.These controllers are factory-commissioned and

shipped ready to be installed.

UC210 BACnet Controller

Trane Wireless Comm Interface (WCI)

WCI controller

Provides wireless communication between theTracer SC,

Tracer Unit Controllers, and BACnet™ Communication

Interface (BCI) modules.

TheTrane WCI is the perfect alternative to Trane’s BACnet

wired communication links (for example – Comm links

between aTracer SC andTracer UC400).

Eliminating communication wire used between terminal

products, zone sensors, and system controllers has substantial

benefits.

• Installation time and associated risks are reduced.

• Projects are completed with fewer disruptions.

• Future re-configurations, expansions, and upgrades are

easier and more cost effective.

UC400 BACnet Controller

Trane Wireless Zone Sensor

Wireless Zone Sensor

Provides wireless communication between theUnit Controller

and the zone sensor.This is an alterntive to the wired zone

sensor when access and routing of communicaiton cable is an

issue. It also allows very flexible mounting and relocation of

zone sensors

10 VAV-PRC012-EN

Page 11

Pneumatic Controller

Pneumatic Controller

Binary Input Controller

Features and Benefits

Pneumatic—Pneumatic controllers provide

proven reliability and performance. A full line

of options provide:

• Highest quality PVR available, which

maximizes zone temperature control.

Pressure-independent operation

• AllVariTrane pneumatic controllers use the

patented flow sensor input to provide the

most accurate performance available.

Integration Options (Interfacing with other control systems) - Trane offers three ways to

interface with other control systems.

1. UseTrane LonMark, factory-commissioned VAV controllers

2. UseTrane Binary Input Controller (BIC). BIC allows system control through binary logic.This

means that a control system on an existing campus, or those seeking “Analog noncommunicating control” can control aTrane DDCVAV unit viabasic binarycontact closures, like

relays, etc.This can be a cost effective interface option where a fullTrane DDC VAV System is

not available.

3. UseTrane BACnet™ factory-commissioned VAV controllers.

Factory-installed vs. Factory-commissioned:

The terms factory-installedand factory-commissioned are often used interchangeably.Trane takes

great pride in being the industry leader in factory-commissioned DDC controllers. Table

differentiates these concepts.

Factory-commissioned controllers provide thehighest quality and most reliable units for your VAV

system. Additional testing verifies proper unit operation including occupied/unoccupied airflow,

temperature setpoints, communication link functionality, and output device functionality.The

benefits of factory-commissioning are standard on VariTrane terminal units withTrane DDC

controls.This means that factory-commissioned quality on VariTrane VAV units is now available

on ANY manufacturer’s control system that can communicate using the LonMark Space Comfort

Control (SCC) protocol. (See Controls section for complete listing of variables which are

communicated.

Table 1. Factory-installed vs. factory-commissioned

Factory-installed Factory-commissioned

Transformer installed (option) X X

Wires terminated in reliable/consistent setting X X

Controller mounted XX

Electric heat contactors and fan relay wired X X

VAV-PRC012-EN 11

Page 12

Features and Benefits

Table 1. Factory-installed vs. factory-commissioned

Factory-installed Factory-commissioned

Testing of electric heat contactors and fan relay X

Controller addressing and associated testing X

Minimum & Maximum airflows settings (occupied/unoccupied) X

Minimum & Maximum temperature setpoints (occupied/unoccupied) X

Minimum ventilation requirements X

Thumbwheel enable/disable X

Heating offset X

Wireless communications modules (WCI) X X

Wireless zone sensor X

Indoor Air Quality Management During Construction

LEED wrap option is a pressure sensitive

covering that prevents contamination of the

VAV box during the construction phase. It is

utilized to seal all openings without

constraining the installation process.

Trane VAV Systems - Proven Performance

Trane is the industry leader in VAV systems, including factory-commissioned controls and

integration with other control systems.This leadership began with customers seeking the most

reliable VAV products in the industry.The solution was factory-commissioned controls (see

Factory-installed vs. Factory-commissioned). Since then, it has blossomed to include optimized

system control strategies.

Control strategies are often made more complicated than necessary. VariTrane DDC controls

simplify control strategies by pre-engineeringcontrol logic and sequencinginto the controller.This

information is available via a twisted-shielded wire pair, and accessible via aTraneTracer™ SC

building automation system. Data is easily accessed via a computer workstation.

Optimized system control strategies, such as ventilation optimization, fan-pressure optimization,

and optimal start/stop, are pre-engineered in VariTrane™ unit-level DDC controllers and theTracer

SC building automation system.

This allows aTrane VAV system to meet or exceed the latest ASHRAE 90.1 Energy Efficiency

standards. Pre-engineered controls allow consistent, high quality installations which are very

repeatable.The end result is PROVEN control strategies you can rely on to perform. For more

information on these and other control strategies, contact your localTrane Sales Office, or visit

www.trane.com.

PurchasingVAV controllers and VAV hardware from a single manufacturer provides a single

contact for all HVAC system related questions.

12 VAV-PRC012-EN

Page 13

Agency Certifications

There are numerous regulationsand standardsin theindustry thatdetermine theconstruction and

performance parameters for VAV terminal units. Some of the more important of those standards

and regulations are listed below, along with a brief description of what each one addresses.

American Society of Heating, Refrigerating and Air-conditioning Engineers

(ASHRAE) - 41.1

ASHRAE - 41.2

ASHRAE - 41.3

These standards specify methods for temperature measurement (41.1), laboratory airflow

measurement (41.2), and pressure measurement (41.3).While none of these standards specifically

discusses VAV air terminals, they discuss topics that are aspects of terminal box systems.

Therefore, some engineers will include these standards in their specifications as a primer on

accepted measurement techniques.

ASHRAE - 62

This standard specifies theminimum ventilationrates andindoor air qualitythat areacceptable for

occupied spaces.

ASHRAE - 111

This standard calls out procedures to be followed for testing and balancing HVAC systems. It

includes descriptions of the equipment used, procedures followed, and field changes that must be

made when a system is balanced.

Air-Conditioning, Heating and Refrigeration Institute (AHRI)

AHRI 880

This standard sets forth classifications, performance testing requirements, and test results

reporting requirements for air terminal units.The standard contains very detailed procedures that

are to be followed for the testing and certification program associated with this standard.This is

one of the most commonly referenced standards in the VAV terminal unit industry.The AHRI-880

certification program is designed to police the accuracy of documented performance for terminal

units.The certification program requires a sampling of at least four units be tested annually.The

tested units are chosen at random by AHRI and sent to an independent laboratory for the testing.

The performance is tested at one specific operating condition.The operating characteristics tested

include discharge and radiated sound power (for the damper and, in the case of fan-powered

boxes, the fan), wide-open damper pressure drop, and fan motor amp draw. VariTrane terminal

units are certified according to AHRI-880.

AHRI 885

This document provides a procedure to estimate sound pressure levels in an occupied space.The

standard accounts for the amount of sound pressure in the space due to the VAV air terminal,

diffusers and their connecting low pressure ductwork. While sound generated from the central

system fan andductwork may be a significant factor in determining thesound pressure level in the

room, this standarddoes not address those factors. It focusessolely onthe VAVterminal and items

downstream of it.This standard is related to AHRI-880 by using sound power determined using

AHRI-880 methodology as a starting point for the AHRI-885 procedure.

Underwriter’s Laboratory (UL) 1995

Underwriter’s Laboratory is an independent testing agency that examines products and

determines if those products meet safety requirements. Equipment manufacturers strive to meet

UL guidelines and obtain listing and classifications for their products because customers recognize

UL approval as a measure of a safely designed product. VariTrane VAV air terminals are listed

per UL-1995, Heating and Cooling Equipment.The terminals are listed as an entire assembly.

VAV-PRC012-EN 13

Page 14

Agency Certifications

National Fire Protection Association

NFPA 70

This standard is also known as the National Electrical Code (NEC).The Code gives standards for

installation of wiring and electrical equipment for most types of commercial and residential

buildings. It is often referred to inVAV air terminal specifications when fan-powered boxes, electric

heat or electric controls are included.

NFPA 90A

This standard does not speak directly to VAV air terminals but does discuss central system

considerations pertaining to a fire and/or smoke condition.The standard discusses safety

requirements in design and construction that should be followed to keep the air-handling system

from spreading a fire or smoke.The standard specifies practices that are intended to stop fire and

smoke from spreading through a duct system, keep the fire-resistive properties of certain building

structures (fire walls, etc.) intact, and minimize fire ignition sources and combustible materials.

14 VAV-PRC012-EN

Page 15

Model Number Descriptions

Digit 1, 2—Unit Type

VP = VariTrane™ Fan-Powered Parallel

VS = VariTrane Fan-Powered Series

LP = VariTrane Fan-Powered

Low-Height Parallel

LS = VariTrane Fan-Powered

Low-Height Series

Digit 3—Reheat

C = Cooling Only

E = Electric Heat

W = Hot Water Heat

Digit 4—Development Sequence

F = Sixth

Digit 5, 6—Primary Air Valve

05 = 5" inlet (350 max cfm)

06 = 6" inlet (500 max cfm)

08 = 8" inlet (900 max cfm)

10 = 10" inlet (1400 max cfm)

12 = 12" inlet (2000 max cfm)

14 = 14" inlet (3000 max cfm)

16 = 16" inlet (4000 max cfm)

RT = 8" x 14" inlet (1800 max CFM)

Note: 10, 12, 14, 16 Not Available on Low-

Height

Digit 7, 8—Secondary Air Valve

00 = N/A

Digit 9—Fan

P = 02SQ fan (500 nominal cfm)

Q = 03SQ fan (1100 nominal cfm)

R = 04SQ fan (1350 nominal cfm)

S = 05SQ fan (1550 nominal cfm)

T = 06SQ fan (1850 nominal cfm)

U = 07SQ fan (2000 nominal cfm)

V = 08SQ Fan (500 nominal cfm)

W = 09SQ Fan (900 nominal cfm)

X = 10SQ Fan (1800 nominal cfm)

Digit 10, 11—Design Sequence

** = Factory assigned

Digit 12, 13, 14, 15—Controls

DD01= Cooling Only Control

DD02= N.C. On/Off Hot Water

DD03= Prop. Hot Water

DD04= Staged On/Off E-Heat

DD05= Pulse Width Mod of E-Heat

DD07= N.O. On/Off Hot Water

DD11= VV550 DDC Controller - Cooling

Only

DD12= VV550 DDC Ctrl w/N.C. On/Off

HW Valve

DD13= VV550 DDC Ctrl w/Prop. HW

Valve

DD14= VV550 DDC Ctrl - On/Off

Electric Heat

DD15= VV550 DDC Ctrl w/Pulse Width

Modulation

DD17= VV550 DDC Ctrl w/N.O. On/Off

HW Valve

DD23= VV550 DDC- Basic plus- Local

(Electric heat- PWM) Remote

(Staged EH)

DD28= VV550 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

DD29= VV550 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

DD30= VV550 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

DD31= VV550 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

DD32= VV550 DDC-Basic plus- Local

(Electric heat- Staged) Remote

(Staged EH)

DD41= UC400 DDC-Basic (No water or

electric heat)

DD42= UC400 DDC-Basic (Water heat-

Normally Closed- 2 position)

DD43= UC400 DDC-Basic (Water heat-

Modulating)

DD44= UC400 DDC-Basic (Electric heat-

staged)

DD45= UC400 DDC-Basic (Electric heat-

PWM)

DD47= UC400 DDC-Basic (Water heat-

Normally Opened- 2 position)

DD53= UC400 DDC-Basic plus- Local

(Electric heat- PWM) Remote

(Staged EH)

DD58= UC400 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.O. 2-position)

DD59= UC400 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.C. 2-position)

DD60= UC400 DDC-Basic plus- Local

(Water heat- N.O. 2-position)

Remote (Water- N.C. 2-position)

DD61= UC400 DDC-Basic plus- Local

(Water heat- N.C. 2-position)

Remote (Water- N.O. 2-position)

DD62= UC400 DDC-Basic plus- Local

(Electric heat- Staged) Remote

(Staged EH)

DD65= Basic (Electric Heat- Modulating

SCR)

DD66= Basic plus – Local (Electric heat –

Modulating SCR) Remote

(Staged EH)

DD71= UC210 DDC-Basic

(Cooling only)

DD72= UC210 DDC-Basic

(Water heat-nc 2pos)

DD73= UC210 DDC-Basic

(Water heat-Modulating)

DD74= UC210 DDC-Basic

(Electric heat-staged)

DD75= UC210 DDC-Basic

(Electric heat-pwm)

DD77= UC210 DDC-Basic

(Water heat-NO 2pos)

DD83= UC210 DDC-Basic+ Local

(Electric heat-pwm)

Remote (Staged)

DD84= UC210 DDC-Basic+ Local

(Water heat Modulating)

Remote (Water-NC 2pos)

DD85= UC210 DDC-Basic+ Local

(Water heat Modulating)

Remote (Water-NO 2pos)

DD86= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-Modulating)

DD87= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-Modulating)

DD88= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-NO 2pos)

DD89= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-NC 2pos)

DD90= UC210 DDC-Basic+ Local

(Water heat NO 2pos)

Remote (Water-NC 2pos)

DD91= UC210 DDC-Basic+ Local

(Water heat NC 2pos)

Remote (Water-NO 2pos)

DD92= UC210 DDC-Basic+ Local

(Electric heat-staged)

Remote (Staged)

DD95= UC210 DDC-Ctrl w/Modulating

SCR

DD96= UC210 DDC-SpaceTemp Ctrl w/

Local SCR & Remote Stge Elec

Heat

DD00= Trane Actuator Only

ENCL= Shaft Only in Enclosure

ENON= Shaft Out Side for Electric Units

FM00= Other Actuator and Control

FM01= Trane supplied actuator,

other control

PN00= N.O. Actuator and Linkage Only

PN05= N.O. 3000 Series, RA Stat

PN51= Pneumatic normally open

w/3011,DPS fan

PN52= Pneumatic normally open

w/3011, DPM fan

PNON= Shaft Out Side for Pneumatic

Units

N.C. = Normally-closed

N.O. = Normally-opened

DA Stat = Direct-acting pneumatic t-stat

(by others)

RA Stat = Reverse-acting pneumatic

t-stat (by others)

PN = Pneumatic

FM = Factory installation of customer-

supplied controller

PVR = Pneumatic Volume Regulator

Digit 16—Insulation

A = 1/2” Matte-faced

B = 1" Matte-faced

D = 1" Foil-faced

F = 1" Double-wall

G = 3/8” Closed-cell

Digit 17—MotorType

D = PSC Motor

E = High-efficiency motor (ECM)

VAV-PRC012-EN 15

Page 16

Model Number Descriptions

Digit 18—Motor Voltage

1 = 115/60/1

2 = 277/60/1

3 = 347/60/1

4 = 208/60/1

5 = 230/50/1

Digit 19—Outlet Connection

1 = Flanged

2 = Slip & Drive

Digit 20—Attenuator

0 = No Attenuator

W = With Attenuator

Digit 21—Water Coil

0 = None

1 = 1-Row–Plenum inlet installed RH

2 = 2-Row–Plenum inlet installed RH

3 = 1-Row–Discharge installed, LH

4 = 1-Row–Discharge installed, RH

5 = 2-Row–Discharge installed, LH

6 = 2-Row–Discharge installed, RH1

A = 1-Row–Premium water coil inlet

B = 2-Row–Premium water coil inlet

C = 1-Row–Premium hot coil

on discharge, LH

D = 1-Row–Premium hot coil

on discharge, RH

E = 2-Row–Premium hot coil

on discharge, LH

F = 2-Row–Premium hot coil

on discharge, RH

Note: 1- and 2-row not available with

Low-Height

Digit 22—Electrical Connections

L = Left (Airflow hitting you in the

face)

R = Right (Airflow hitting you in the

face)

W = Narrow Corridor LH, Hi-Volt Inlet

Facing

X = Narrow Corridor RH, Hi-Volt Inlet

Facing

Note: (W & X) Fan Powered Series Only

Digit 23—Transformer

0 = N/A (provided as standard)

Digit 24—Disconnect Switch

0 = None

W = With

Electric Reheat w/ door interlocking

power disconnect, Cooling Only and

Water Reheat w/ toggle disconnect

Digit 25—Power Fuse

0 = None

W = With

Digit 26—Electric Heat Voltage

0 = None

A = 208/60/1

B = 208/60/3

C = 240/60/1

D = 277/60/1

E = 480/60/1

F = 480/60/3

G = 347/60/1

H = 575/60/3

J = 380/50/3

K = 120/60/1

Note: K not available with Low Height

Digit 27, 28, 29—Electric Heat

kW

000 = None

050 = 0.5 kW

010 = 1.0 kW

015 = 1.5 kW

260 = 26.0 kW

Note: Electric Heat Voltage -

0.5 to 8.0 kW–½ kW increments

8.0 to 18.0 kW –1 kW increments

18.0 to 46.0 kW–2 kW increments

Digit 30—Electric Heat Stages

0 = None

1 = 1 Stage

2 = 2 Stages Equal

3 = 3 Stages Equal

Note: 3 not available with Low Height

Digit 31—Contactors

0 = None

1 = 24-volt magnetic

2 = 24-volt mercury

3 = PE with magnetic

4 = PE with mercury

5 = SCR heat UC400

6 = SCR heat FMTD/ENCL/DD00

Note: SCR cannot be selected with the

following configuration:

• KW > 10, 208 volt 3 phase, Low

Height

• KW > 22, 480 volt 3 phase, Low

Height

• Voltage = 575 volt

Digit 32—Airflow Switch

0 = None

W = With

Digit 33—Not Used

0 = N/A

Digit 34—Actuator

0 = Standard

A = Belimo actuator

Digit 35—Wireless Sensors

0 = None

1 = Factory Mounted Wireless

Receiver (Sensor Assembly)

2 = Wireless Comm Interface

Modular FM

Note: All sensors selected in accessories

Digit 36—Pre-Wired Factory

Solutions

0 = None

1 = Factory Mounted DTS

2 = HW Valve Harness

3 = Both DTS & HW Valve Harness

16 VAV-PRC012-EN

Page 17

Selection Procedure

This section describes elements and process required to properly select fan-powered VAV

terminals, and includes a specificexamples. Selection procedure is iterativein naturewhich makes

computer selection desirable. Selection of fan-powered VAV terminals involves four elements:

• Air valve selection

• Heating coil selection

• Fan size and selection

• Acoustics

Note: Use the same procedures for selecting Low-Height Fan-Powered Units.

Air Valve Selection

Provided in the Performance Data—Air Pressure Requirements section of the catalog is the unit air

pressure drop at varying airflows.To select an air valve, determine the airflow required at design

cooling. Next, select an air valve diameter that will allow proper airflow modulation, (a velocity of

1600 – 2000 FPM is recommended). Keep in mind that modulation below 300 FPM is not

recommended. Proper selection requires defining the minimum valve airflow (in either heating

or cooling) and maintaining at least 300 FPM through the air valve.The minimum is typically set

based on ventilation requirements. If zone ventilation does not come through the VAV unit, a

minimum valve position can also be zero.

Heating Coil Selection

Supply Air Temperature

The first step required when selecting a heating coil is to determine the heating supply air

temperature to the space, calculated using the heat transfer equation. A recommended value is

90°F, although values between 85°F and 95°F are common. Discharge air temperatures that exceed

20 degrees above space temperature are not recommended for proper diffuser operation. Air

temperature difference is defined as the heating supply air temperature to the space minus the

winter room design temperature.The zone design heat loss rate is denoted by the letter Q. Supply

air temperature to the space equals the leaving air temperature (LAT) for the terminal unit.

Coil Leaving Air Temperature

Once the terminal unit LAT is determined, the heating requirements for the coil can be calculated.

The leaving air temperature for the coil of a parallel fan-powered terminal unit varies based on the

type of unit installed heat being selected. Series unit leaving air temperatures do not vary because

in each case the coil is located on the unit discharge.

Electric coil LAT equals terminal unitLATbecause the coil is located on the unit discharge.Hot water

coils can be located on either the discharge or, for maximum system efficiency, the plenum inlet

when located on the entering air side of the fan. Coil LAT is calculated using a mixing equation.

Given the unitheating airflow and LAT, minimum primary airflow atits supplyair temperature,and

the volume of heated plenum air, the leaving air temperature for the hot water coil can be

determined (see the unit selection example that follows for more details).

Coil Entering Air Temperature

The entering air temperature (EAT) to the coil also varies based on the coil position on the unit for

parallel units.The unit heat is mounted on the discharge of a series unit.Therefore the EAT equals

the temperature of blended primary and plenum air.

Parallel electric coils are mounted on the unit discharge. Hot water coils can be mounted on the

discharge or on the plenum inlet. Plenum inlet mounting creates a more efficientVAV system.This

is because the parallel fan is energized only when in heating mode, and thus, when in cooling

mode, the water coil is not in the airstream.

The EAT for discharge mounted coils equals the temperature of blended primary air and plenum

air. For plenum inlet mounted water coils, the EAT equals the plenum air temperature.

VAV-PRC012-EN 17

Page 18

Selection Procedure

Capacity Requirement

Once both coil EAT and LAT are determined, the heat transfer (Q) for the coil must be calculated

using the heat transfer equation. For electric heat units, the Q value must be converted from Btu

to kW for heater selection.The required kW should be compared to availability charts in the

performance data section for the unit selected. For hot water heat units, reference the capacity

charts in the performance data section for the required heat transfer Q and airflow to pick the

appropriate coil.

Fan Size and Selection

Fan Airflow

Fan airflow is determined by calculating thedifference between the unitdesign heating airflowand

minimum primary airflow.

Fan External Static Pressure

Fan external static pressure is the total resistance experienced by the fan, which may include

downstream ductwork and diffusers, heating coils, and sound attenuators. As total airflow varies

so will static pressure, making calculation of external static pressure dependent on unit type.

In many applications of parallel terminals,a minimumprimary airflow mustbe maintainedto meet

ventilation requirements.This primary airflow contributes to the total resistance experienced by

the fan and should be accounted for in all components downstream of the fan itself, including

electric coils. Hot water coils positioned on the fan inlet are not affected by the additional primary

airflow.The static pressure resistance experienced by the fan due to the hot water coil is based on

fan airflow only, not the total heating airflow.

With series fan-powered terminal units, all airflowpasses through the fan. External static pressure

requirements are the sum of the individual component pressure retirements at the design airflow

of the unit.

Acoustics

Fan Motor Type

The fan motor type that will be used for the unit will need to be known before fan selection can

begin.The ECM motor offers more efficient operation than the standard single-speed PSC motor

and will use different fan curves. Because series fans operate in both heating and cooling mode,

payback is typically 2–3 years for the premium ECM option. Refer to the Features and Benefits

section to determine which motor is more appropriate for the unit

Selection

Once fan airflow and external static pressure are determined, reference the fan curves in the

performance data section. Cross plot both airflow and external static pressure on each applicable

graph. A selection between the minimum and maximum airflow ranges for the fan is required.

It is common to identify more than one fan that can meet the design requirements.Typically,

selection begins with the smallest fan available to meet capacity. If this selection does not meet

acoustical requirements, upsizing the fan andoperating it at aslower speed can be donefor quieter

operation.

Air Valve Generated Noise

To determine the noise generated by the air valve, two pieces of information are required; design

airflow and design air pressure drop.The design air pressure drop is determined by taking the

difference between design inlet and static pressure (the valve’s most over-pressurized condition)

and external static pressure at design cooling flow.This represents a worst-case operating

condition for the valve.

18 VAV-PRC012-EN

Page 19

Fan Generated Noise

To determine fan noise levels, fan airflow, external static pressure and speed information is

required.

Evaluation Elements

For parallel fan-powered terminal units, the air valve and fan operation must be evaluated

separately because these operations are not simultaneous. For Series fan-powered units, the air

valve and fan are evaluated together because they have simultaneous operation. Access the

appropriate acoustics table(s)of the catalog and determine the sound power and NC predictionfor

both the discharge and radiated paths. It is important to understand that discharge air noise is

generally not a concern with fan-powered terminals. Radiated noise from the unit casing typically

dictates the noise level of the space. If the entire unit or any element of it is generating noise in

excess of the NoiseCriteria requirements, thesize of theappropriate portion of theterminal should

be increased. Because the selection procedure is iterative, care should be taken by the designer to

confirm that the change in selection does not affect other elements of the unit or system design.

Selection Example—ParallelWith Hot Water Heat

Air Valve Selection

Design Cooling Airflow:1000 cfm

Minimum Ventilation Airflow: 200 cfm

Maximum Unit APD: 0.25 in. wg

Choose 10" air valve

Check – Is minimum airflow above 300 FPM? Guidelines, FPP 8)

A 10" air valve is selected with unit pressure drop = 0.01 in. wg

Selection Procedure

Heating Coil Selection

Required Information:

Zone design heat loss: 20000 Btu

Unit heating airflow: 600 cfm

Winter room design temp.: 68ºF

Coil entering water temp.: 180ºF

Minimum primary airflow: 200 cfm

Fan Airflow: 400 cfm

Plenum temperature: 70ºF

Coil flow rate: 2 gpm

Primary air temperature: 55ºF

Heat Transfer Equation (Btu)

Q = 1.085 x Cfm x DTemperature

For the heating zone, the temperature difference is the zone supply air temperature (SAT) minus

the winter room design temperature.

18000 Btu = 1.085 x 600 x (SAT - 68ºF)

SAT = 95.6ºF

Because the designer chose to maximize system efficiency by having the hot water coil on the

plenum inlet, the unit supply air temperature is equal to the mix of the heated plenum air from the

fan and the minimum primary airflow.

600 cfm x 95.6ºF =

200 cfm x 55ºF +

(600 cfm - 200 cfm) x Coil LAT

Coil LAT = 116ºF

VAV-PRC012-EN 19

Page 20

Selection Procedure

For the heating coil, the temperature difference is the calculated coil LAT minus the coil EAT

(Plenum AirTemperature).

CoilQ=1.085 x 400 x (116-70) = 19,964 Btu = 19.96 Mbh

Coil Performance Table

Selection:

Size 02SQ fan, 1-row coil with 2 gpm =20.53 Mbh (at 400 cfm)

1-row coil with 2 gpm = 2.57 ftWPD

Fan Selection

Required Information:

Design airflow: 400 cfm

Downstream static pressure at design airflow: 0.25 in. wg

Fan external static pressure equals downstream static pressure (ductwork and diffusers) plus coil

static pressure.The coil static pressure that the fan experiences is at the fan airflow (400 cfm).The

downstream static pressure the fan experiences is at fan airflow plus minimum primary airflow.

The sum of fan airflow and minimum primary airflow (600 cfm) is less than design airflow (1000

cfm) and therefore the 0.25 in. wg downstream static pressure at design airflow must be adjusted

for the lower heating airflow.

Parallel Fan-Powered Unit with Water Coil (2 Options)

Plenum Inlet Mounted

Using Fan LawTwo:

Heating Downstream Static Pressure = (600/1000)2 x 0.25 = .09 in. wg

A size 02SQ fan has the capability to deliver approximately 650 cfm at 0.09 downstream static

pressure. If an attenuator is required, use the attenuator air pressure drop tables to define

additional fan static pressure.

Acoustics

Required Information:

Design inlet static press.: 1.0 in. wg

NC criteria: NC-35

The selection is a VPWF Parallel Fan-poweredTerminal Unit, 10" primary, parallel fan size 02SQ,

with a 1-row hot water coil.

Determine the casing radiated noise level because it typically dictates the sound level (NC) of the

space. With a parallel unit, two operating conditions must be considered, design cooling and

design heating.

Discharge Mounted

20 VAV-PRC012-EN

Page 21

Selection Procedure

Design Cooling (1000 cfm). Radiated valve typically sets the NC for parallel units incooling mode.

The closest tabulated condition (1100 cfm at 1.0 in. wg ISP) has an NC=31. (A more accurate

selection can be done viaTOPSS electronic selection program.):

Table 2. Selection Program Output (Radiated Valve):

Octave Band 2 3 4 5 6 7 NC

Sound Power 65 60 53 48 41 32 30

Design Heating (200 cfm valve, 400 cfm fan, 0.25 in. wg DSP). Radiated fan typically sets the NC

for parallel units in heating mode.The closest cataloged condition (430 fan cfm , 0.25 in. wg DSP)

has an NC=32. (A more accurate selection can be done viaTOPSS electronic selection program.)

Table 3. Selection Program Output (Radiated Fan):

Octave Band 2 3 4 5 6 7 NC

Sound Power 66 58 56 52 48 41 31

The predicted NC level for design cooling is NC-30 and for design heating is NC-31. If the catalog

path attenuation assumptions are acceptable, this unit meets all of the design requirements and

the selection process is complete.

Computer Selection

The advent of personal computers has served to automate many processes that were previously

repetitive and time-consuming. One of those tasks is the proper scheduling, sizing, and selection

of VAV terminal units.Trane has developed a computer program to perform these tasks.The

software is called theTrane Official Product Selection System (TOPSS).

TheTOPSS program will take the input specifications and output the properly sizedVariTrane VAV

terminal unit along with the specific performance for that size unit.

The program has several required fields, denoted by red shading in theTOPSS screen, and many

other optional fields to meet the criteria you have. Required values include maximum and

minimum airflows, control type, and model. If selecting models with reheat, you will be required

to enter information to make that selection also.The user is given the option to look at all the

information for one selection on one screen or as a schedule with the other VAV units on the job.

The user can select single-duct, dual-duct, and fan-poweredVAV boxes with the program, as well

as most otherTrane products, allowing you to select all yourTrane equipment with one software

program.

The program will also calculate sound power datafor the selected terminal unit.The usercan enter

a maximum individual sound level for each octave bandor a maximum NC value.The program will

calculate acoustical data subject to default or user supplied sound attenuation data.

Schedule View

The program has many time-saving features such as:

• Copy/Paste from spreadsheets like Microsoft® Excel

• Easily arranged fields to match your schedule

• Time-saving templates to store default settings

The user can also export the Schedule View to Excel to modify and put into a CAD drawing as a

schedule.

Specific details regarding the program, its operation, and how to obtain a copy of it are available

from your localTrane sales office.

VAV-PRC012-EN 21

Page 22

Selection Procedure

Selection Example—Series With Hot Water Heat and ECM

Air Valve Selection

Required Information: Design cooling airflow: 1000 cfm

Minimum ventilation airflow: 200 cfm

Maximum unit APD: 0.40 in. wg

A 10" air valve is selected.

Check–is minimum airflow above 300 FPM?

Answer–Yes. Minimum cfm allowable = 165 cfm. (See

General Data—Valve/Controller Guidelines pp FPS 8).

The 03SQ fan will be used in this instance. By interpolating,

you can choose a 10" air valve with wide-open air pressure

drop of 0.32 in. wg.

Heating Coil Selection

Required Information: Zone design heat loss: 30000 Btu

Design heating airflow: 1000 cfm

Winter room design temp.: 68ºF

Coil entering water temp.: 180ºF

Minimum primary airflow: 200 cfm

Plenum temperature: 70ºF

Primary air temperature: 55ºF

Coil flow rate: 2 gpm

HeatTransfer Equation (Btu)Q=1.085 x Cfm x Temperature

For the heating zone, the temperature difference is the zone supply air temperature (SAT) minus

the winter room design temperature.

30000 Btu = 1.085 x 1000 x (SAT-68°F)

SAT = 96ºF

Because the hot water coil is on the unit discharge of a series fan-powered unit, the unit supply air

temperature is equal to the coil LAT. Coil entering air temperature (EAT) is a mix of plenum air and

the minimum primary airflow.

1000 cfm x Coil EAT = 200 cfm x 55ºF + (1000 cfm - 200 cfm) x 70ºF

Coil EAT = 67ºF

For the heating coil, the temperature difference is the calculated coil LAT minus the coil EAT

(Plenum AirTemperature).

Coil Q =1.085 x 1000 x (96-70) = 31,465 Btu

On a series unitthe hot water coilis locatedon thedischarge, so the totalheating airflow, 1000 cfm,

passes through the coil.

Coil Performance Table

Selection:

Performance:

Size 03SQ fan, 1-row coil at 2 gpm = 32.23 MBh

1-row Coil at 2 gpm= 0.83 ftWPD

Fan Selection

Required Information. Fan airflow: 1000 cfm

Downstream static pressure at design airflow: 0.25 in. wg

A size 03SQ fan can operateat upto 1150 cfm (1-row coil) or 1100 (2-row coil) and 0.25" downstream

static pressure. Inlet and coil selections should be verified withTOPSS electronic selections.

22 VAV-PRC012-EN

Page 23

Selection Procedure

If an attenuator is required, use attenuator air pressure drop tables to define additional fan static

pressure.

Acoustics

Required Information. Design inlet static press: 0.75 in. wg

NC criteria (general office space): NC-40

The selection is aVSWF Series Fan-PoweredTerminal Unit, 10" primary, series fan size 03SQ, with

a 1-row hot water coil.

Determine the casing radiated noise level because it typically dictates the sound level

(NC) of the space. With a series unit, the air valve and fan operate simultaneously, so the chart

for air valve and fan sound data must be consulted.

The results in the below table are for the acoustics value of a size 10" air valve with a size 03SQ fan.

The predicted NC level for design conditions is NC-38.

Octave Band 2 3 4 5 6 7 NC

Sound Power 70 65 63 61 59 59 38

Note: Ensure water coil acoustical impact is considered. For this example, the appurtenance effect

adds one (1) NC to fan-only radiated sound. Because this does not set NC for this selection,

it can be overlooked.The addition of an attenuator (see same appurtenance effect tables

reduces the NC four (4) points, resulting in a final selection NC = 30 (if required).

Note: Do not overlook the water coil impact on acoustics. A good rule of thumb is that it will add

1 to 2 NC to “fan only” radiated sound for most applications.

Computer Selection

The advent of personal computers has served to automate many processes that were previously

repetitive and time-consuming. One of those tasks is the proper scheduling, sizing, and selection

of VAV terminal units.Trane has developed a computer program to perform these tasks.The

software is called theTrane Official Product Selection System (TOPSS).

TheTOPSS program will take the input specifications and output the properly sizedVariTrane VAV

terminal unit along with the specific performance for that size unit.

The program has several required fields, denoted by red shading in theTOPSS screen, and many

other optional fields to meet the criteria you have. Required values include maximum and

minimum airflows, control type, and model. If selecting models with reheat, you will be required

to enter information to make that selection also.The user is given the option to look at all the

information for one selection on one screen or as a schedule with the other VAV units on the job.

User can select single-duct, dual-duct, and fan-powered VAV boxes with the program, as well as

most otherTrane products, allowing selection of allTrane equipment with one software program.

The program will also calculate sound power datafor the selected terminal unit.The usercan enter

a maximum individual sound level for each octave bandor a maximum NC value.The program will

calculate acoustical data subject to default or user supplied sound attenuation data.

Schedule View

The program has many time-saving features such as:

• Copy/Paste from spreadsheets like Microsoft® Excel

• Easily arranged fields to match your schedule

• Time-saving templates to store default settings

User can also export Schedule View to Excel to modify and put into a CAD drawing as a schedule.

Specific details regarding program, its operation, and how to obtain a copy of it are available from

your localTrane sales office.

VAV-PRC012-EN 23

Page 24

Performance Data

Parallel Fan-PoweredTerminal Units

Table 4. Primary airflow control factory setting-I-P

Control Type

Direct Digital

Control/ UCM

Pneumatic with

Volume

Regulator

Note: Maximum airflow must be greater than or equal to minimum airflow.

Size (in.)

5

6

8

10

12

14

16

5

6

8

10

12

14

16

Table 5. Primary airflow control factory settings – SI

Air Valve

Control Type

Direct Digital

Control/ UCM

Pneumatic with

Volume

Regulator

Note: Maximum airflow must be greater than or equal to minimum airflow.

Air Valve

Size (in.)

5

6

8

10

12

14

16

5

6

8

10

12

14

16

Maximum

Valve Cfm

350

500

900

1400

2000

3000

4000

350

500

900

1400

2000

2885

3785

Maximum

Valve L/s

165

236

425

661

944

1416

1888

165

236

425

661

944

1362

1787

Maximum

Controller Cfm

40-350

60-500

105-900

165-1400

240-2000

320-3000

420-4000

63-350

73-500

134-900

215-1400

300-2000

408-2887

536-3789

Maximum

Controller L/s

19-165

28-236

50-425

77-661

111-944

151-1416

198-1888

30-165

35-236

63-425

102-661

141-944

193-1363

253-1788

Minimum

Controller Cfm

0, 40-350

0, 60-500

0, 105-900

0, 165-1400

0, 240-2000

0, 320-3000

0, 420-4000

0, 63-350

0, 73-500

0, 134-900

0, 215-1400

0, 300-2000

0, 408-2887

0, 536-3789

Minimum

Controller L/s

0, 19-350

0, 28-236

0, 50-425

0, 77-661

0, 111-944

0, 151-1416

0, 198-1888

0, 30-165

0, 35-236

0, 63-425

0, 102-661

0, 141-944

0, 193-1363

0, 253-1788

Constant Volume

Cfm

40-350

60-500

105-900

165-1400

240-2000

320-3000

420-4000

63-350

73-500

134-900

215-1400

300-2000

408-2887

536-3789

Constant

Volume L/s

19-350

28-236

50-425

77-661

111-944

151-1416

198-1888

30-165

35-236

63-425

102-661

141-944

193-1363

253-1788

Table 6. Unit air pressure drop – in. wg (I-P)

Fan/Inlet Size Airflow Cfm Cooling Only Fan/Inlet Size Airflow Cfm Cooling Only

02SQ-05

02SQ-06

Note: Unit pressure drops do not include hot water coil or attenuator pressure drops.

02SQ-08

40

150

250

350

60

200

350

500

105

350

600

900

0.01

0.03

0.08

0.17

0.01

0.05

0.17

0.35

0.01

0.03

0.09

0.21

04SQ-14

05SQ-10

05SQ-12

320

1200

2100

3000

165

550

950

1400

240

750

1350

2000

24 VAV-PRC012-EN

0.01

0.01

0.01

0.01

0.01

0.01

0.02

0.05

0.01

0.01

0.01

0.01

Page 25

Performance Data

Table 6. Unit air pressure drop – in. wg (I-P) (continued)

Fan/Inlet Size Airflow Cfm Cooling Only Fan/Inlet Size Airflow Cfm Cooling Only

02SQ-10

03SQ-06

03SQ-08

03SQ-10

03SQ-12

04SQ-08

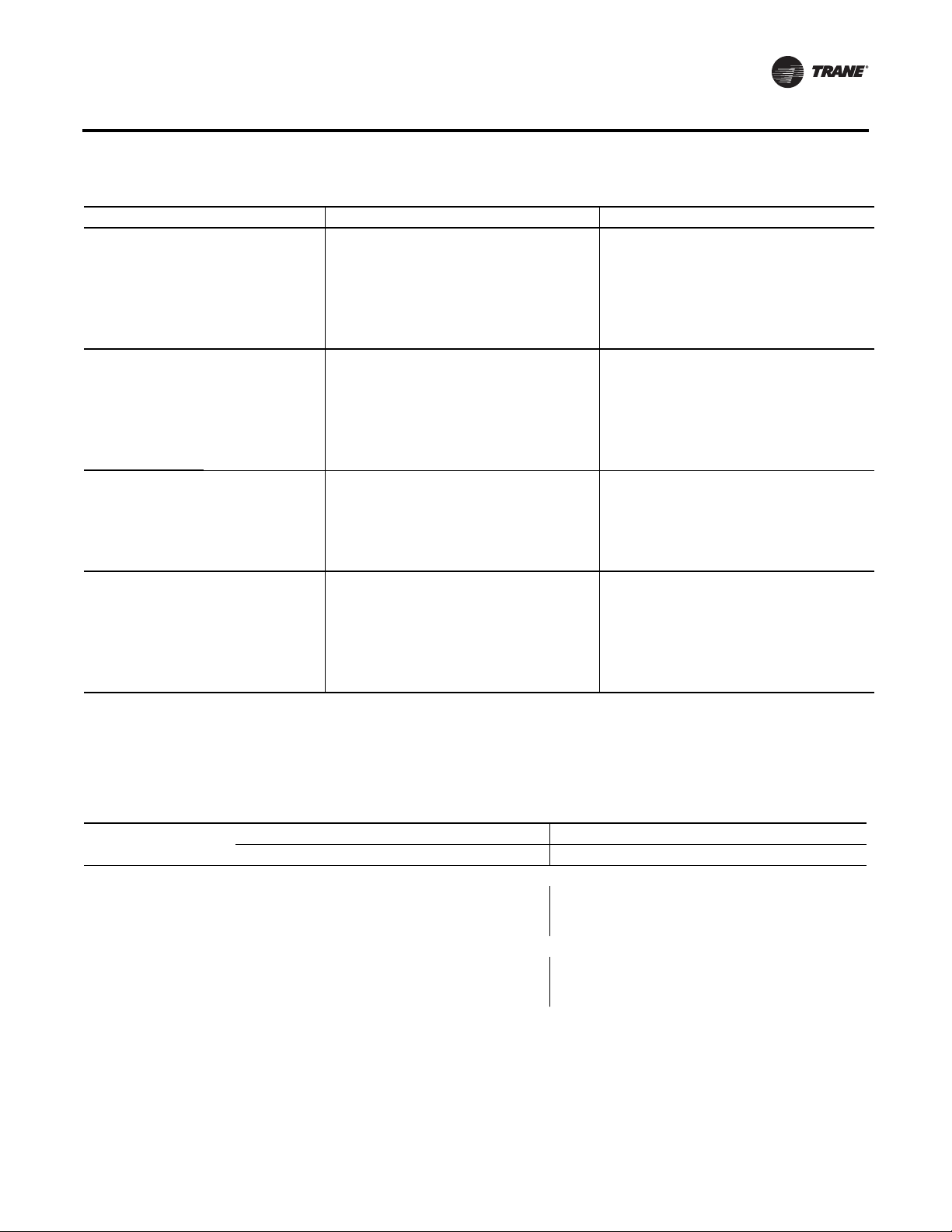

04SQ-10

04SQ-12

Note: Unit pressure drops do not include hot water coil or attenuator pressure drops.

165

550

950

1400

60

200

350

500

105

350

600

900

165

550

950

1400

240

750

1350

2000

105

350

600

900

165

550

950

1400

240

750

1350

2000

0.01

0.01

0.01

0.01

0.01

0.06

0.19

0.40

0.01

0.03

0.08

0.20

0.01

0.01

0.02

0.05

0.01

0.01

0.01

0.01

0.01

0.03

0.08

0.20

0.01

0.01

0.02

0.05

0.01

0.01

0.01

0.01

05SQ-14

06SQ-10

06SQ-12

06SQ-14

06SQ-16

07SQ-10

07SQ-12

07SQ-14

07SQ-16

320

1200

2100

3000

165

550

950

1400

240

750

1350

2000

320

1200

2100

3000

420

1600

2800

4000

165

550

950

1400

240

750

1350

2000

320

1200

2100

3000

420

1600

2800

4000

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

Table 7. Coil air pressure drop – in. wg (I-P)

Fan Size Airflow Cfm 1-Row HW (in. wg) 2-Row HW (in. wg)

02SQ

03SQ

04SQ

05SQ

06SQ

07SQ

Note: HW Coil Only pressure drops do not include unit pressure drop.

100

200

300

400

500

250

500

750

1000

1250

1400

600

900

1200

1500

1800

2000

0.00

0.01

0.01

0.02

0.02

0.01

0.02

0.04

0.07

0.10

0.12

0.02

0.04

0.06

0.09

0.12

0.15

VAV-PRC012-EN 25

0.00

0.01

0.02

0.03

0.05

0.02

0.04

0.08

0.13

0.19

0.23

0.04

0.07

0.11

0.16

0.22

0.27

Page 26

Performance Data

Table 8. Attenuator air pressure drop (I-P)

Fan Size Plenum Cfm Attenuator Fan Size Plenum Cfm Attenuator

02SQ

03SQ

04SQ

Note: Plenum cfm = (Fan cfm)

50

200

350

500

650

750

50

250

500

750

1000

1200

50

300

600

900

1200

1450

0.00

0.00

0.01

0.02

0.04

0.06

0.00

0.00

0.00

0.00

0.01

0.06

0.00

0.01

0.02

0.03

0.05

0.06

05SQ

06SQ

07SQ

50

300

600

900

1200

1550

50

500

900

1300

1650

1900

50

500

1000

1500

2000

2500

0.00

0.00

0.02

0.06

0.13

0.24

0.00

0.01

0.03

0.06

0.10

0.14

0.00

0.01

0.04

0.08

0.15

0.25

Table 9. Attenuator air pressure drop (SI)

Fan Size Plenum L/s Attenuator Fan Size Plenum L/s Attenuator

02SQ

03SQ

04SQ

Note: Plenum cfm = (Fan cfm)

24

94

165

236

307

354

24

118

236

354

472

566

24

142

283

425

566

684

10

14

14

11

14

0

0

2

5

0

0

0

0

2

0

3

5

8

05SQ

06SQ

07SQ

24

142

283

425

566

731

24

236

425

613

779

897

24

236

472

708

944

1180

0

1

5

15

32

61

0

2

7

15

26

35

0

2

9

21

38

62

Table 10. Coil air pressure drop – Pa (SI)

Fan Size Airflow L/s 1-Row HW (Pa) 2-Row HW (Pa)

02SQ

03SQ

04SQ

05SQ

200

300

400

500

600

118

236

354

472

590

661

0

1

2

4

6

2

5

10

17

25

31

26 VAV-PRC012-EN

1

3

5

8

12

4

11

21

33

47

57

Page 27

Performance Data

Table 10. Coil air pressure drop – Pa (SI)

06SQ

07SQ

Note: HW Coil Only pressure drops do not include unit pressure drop.

900

1200

1500

1800

2150

2500

5

9

15

22

30

36

Table 11. Unit air pressure drop-Pa (SI)

Fan/Inlet Size Airflow L/s Cooling Only Fan/Inlet Size Airflow L/s Cooling Only

19

02SQ-05

02SQ-06

02SQ-08

02SQ-10

03SQ-06

03SQ-08

03SQ-10

03SQ-12

04SQ-08

04SQ-10

04SQ-12

Note: Unit pressure drops do not include hot water coil or attenuator pressure drops.

71

118

165

28

94

165

236

50

165

283

425

78

260

448

661

28

94

165

236

50

165

283

425

78

260

448

661

113

354

637

944

50

165

283

425

78

260

448

661

113

354

637

944

2

7

20

41

2

13

41

86

2

8

23

51

2

2

2

3

2

15

48

99

2

6

21

49

2

2

6

13

2

2

2

2

2

6

21

49

2

2

6

13

2

2

2

2

04SQ-14

05SQ-10

05SQ-12

05SQ-14

06SQ-10

06SQ-12

06SQ-14

06SQ-16

07SQ-10

07SQ-12

07SQ-14

07SQ-16

151

566

991

1416

78

260

448

661

113

354

637

944

151

566

991

1416

78

260

448

661

113

354

637

944

151

566

991

1416

198

755

1321

1888

78

260

448

661

113

354

637

944

151

566

991

1416

198

755

1321

1888

10

18

28

41

56

67

2

2

2

2

2

2

6

13

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

VAV-PRC012-EN 27

Page 28

Performance Data

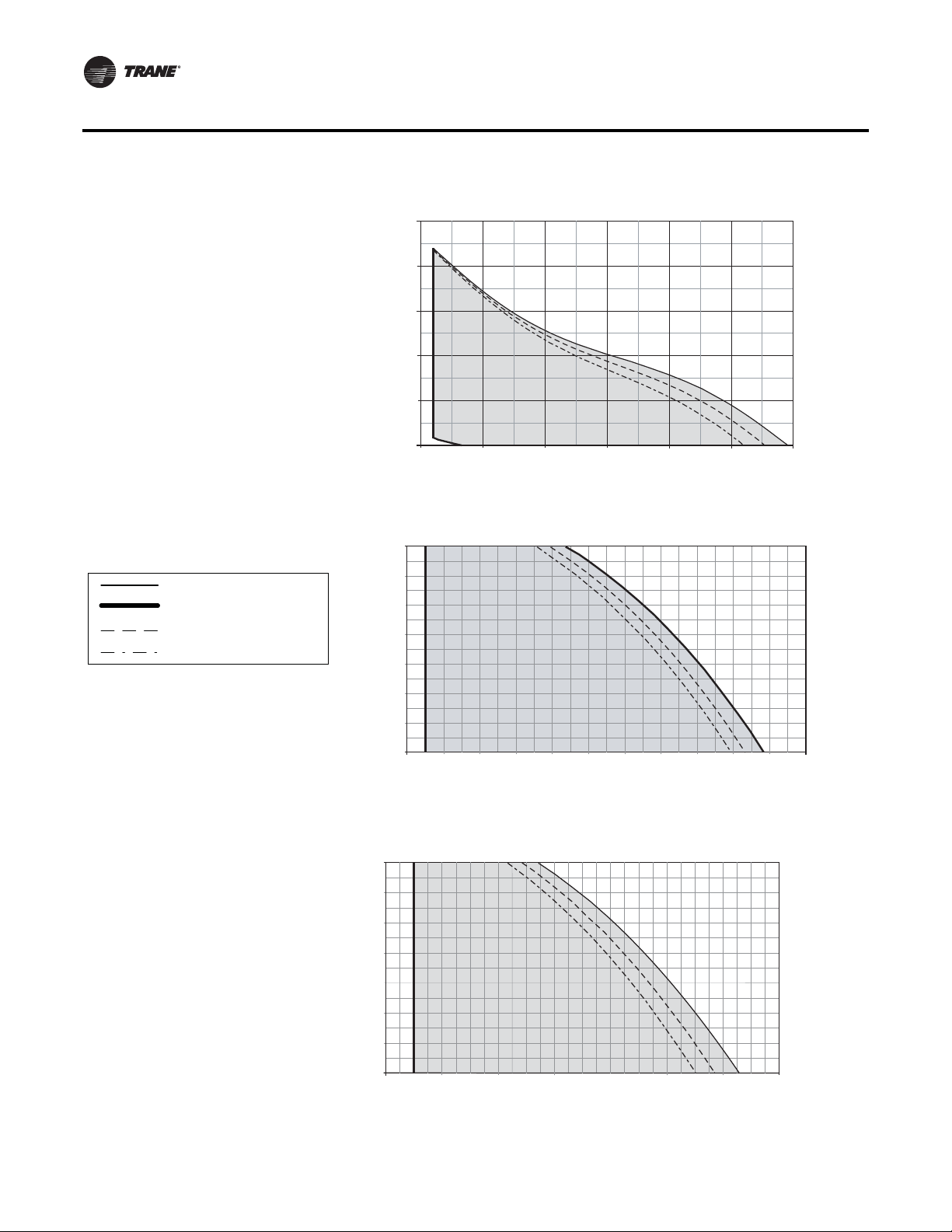

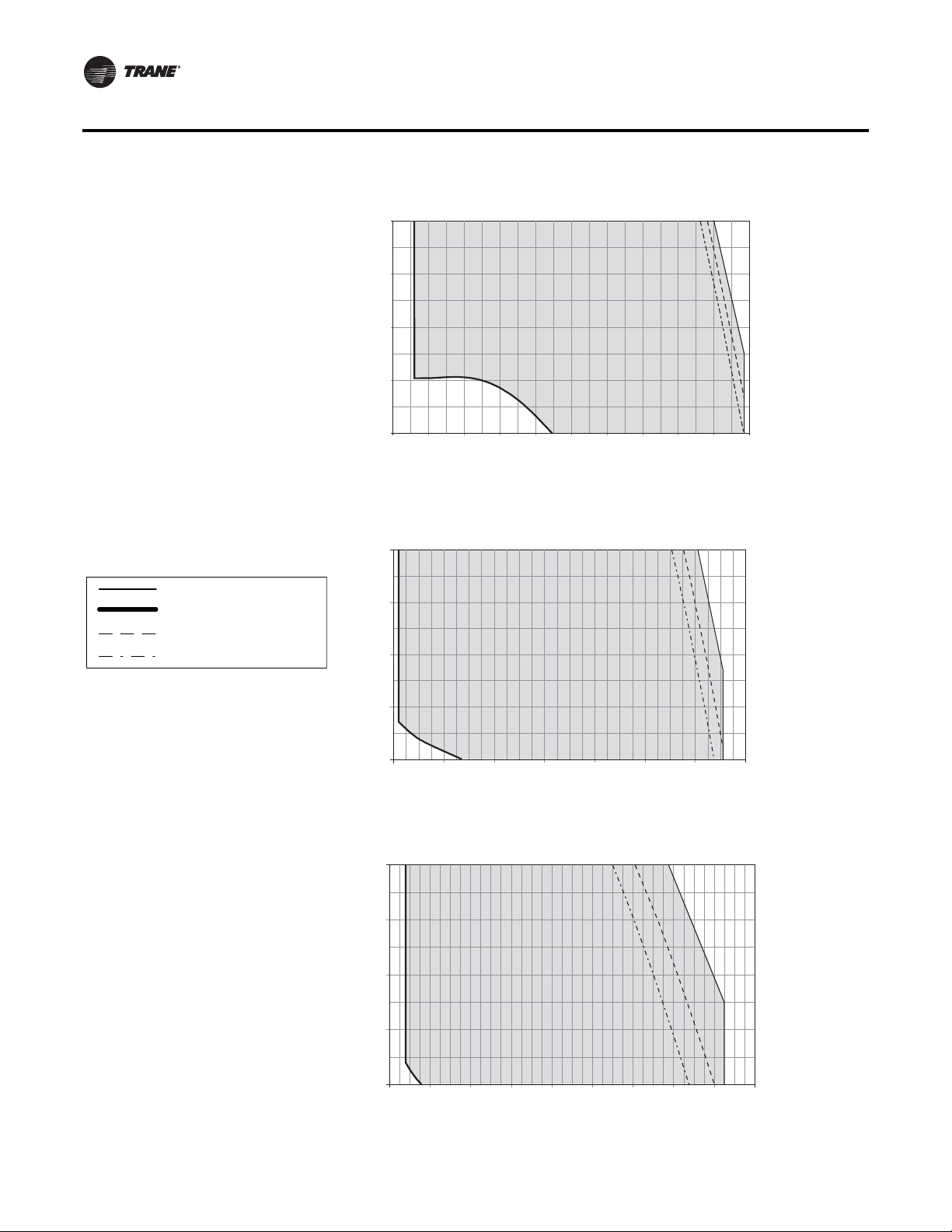

VPCF and VPEF maximum

Minimum

1-row coil maximum

2-row coil maximum

Note: When attenuator is required, add inlet

attenuator pressure to discharge static

pressure for final fan performance.

Pa In. wg

0.60

150

0.50

125

0.40

100

0.30

75

Discharge Static Pressure

0.20

50

0.10

25

Pa In. wg

0.80

199

0.70

174

0.60

150

0.50

125

0.40

100

0.30

75

0.20

50

Discharge Static Pressure

0.10

25

200 300 400 500

94 142 189 236

100

47

(57 L/s)

120 cfm min

(118 L/s)

250 cfm min

Parallel 02SQ—PSC

200 300 400

94

142

189 236

Airflow

Parallel Fan Size 03SQ—PSC

700

600

330

283

Airflow

800

378

900

425

500

1000

472

1100

519

1200

566

700600

Cfm

330283

L/s

1300

Cfm

614

L/s

Pa

In. wg

199

0.80

174

0.70

150

0.60

125

0.50

0.40

100

0.30

75

Discharge Static Pressure

0.20

50

0.10

25

200 400 600 800 1000 1200 1400 1600

300 cfm min

94

(142 L/s)

189

Parallel 04SQ—PSC

283

378 472 566

661

755

Cfm

L/s

Airflow

28 VAV-PRC012-EN

Page 29

Performance Data

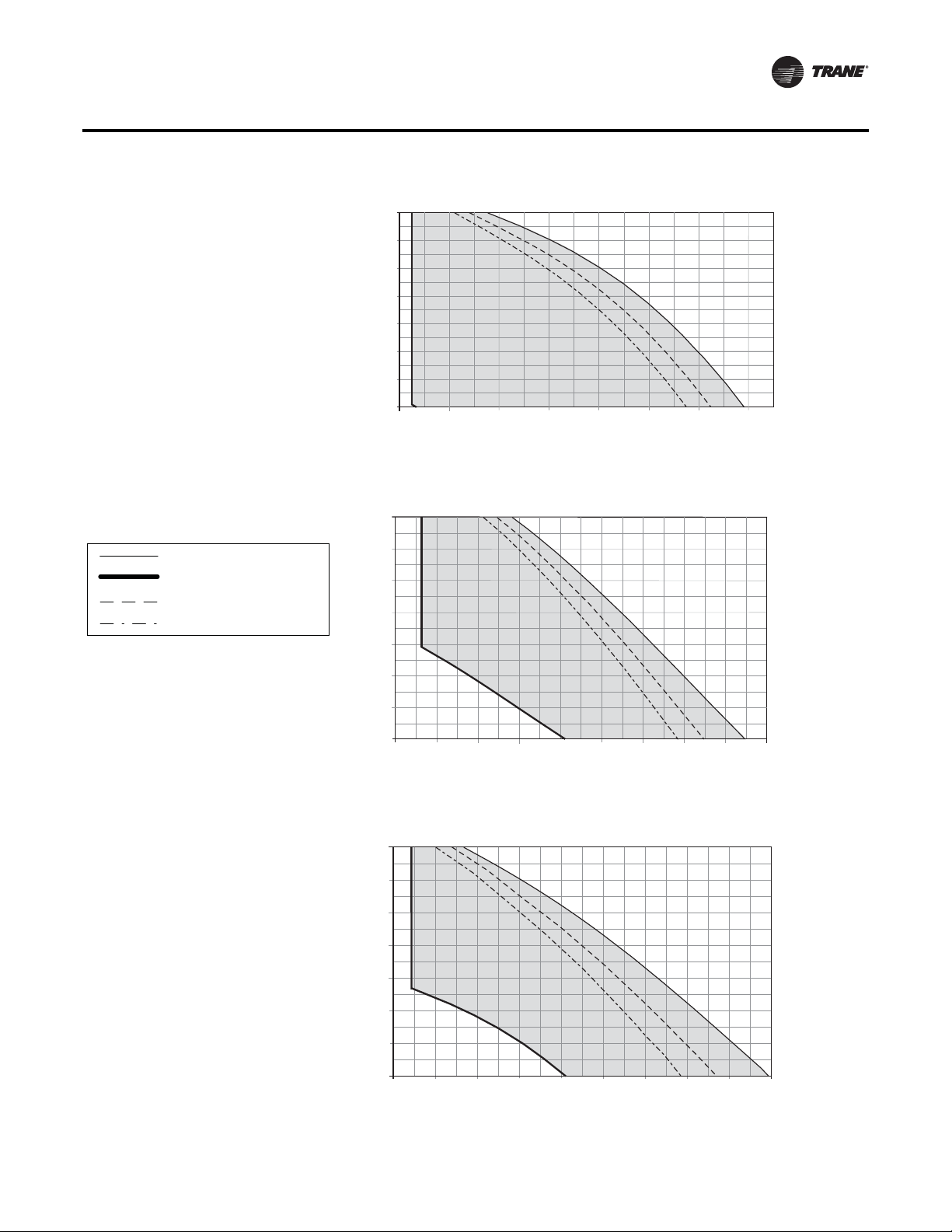

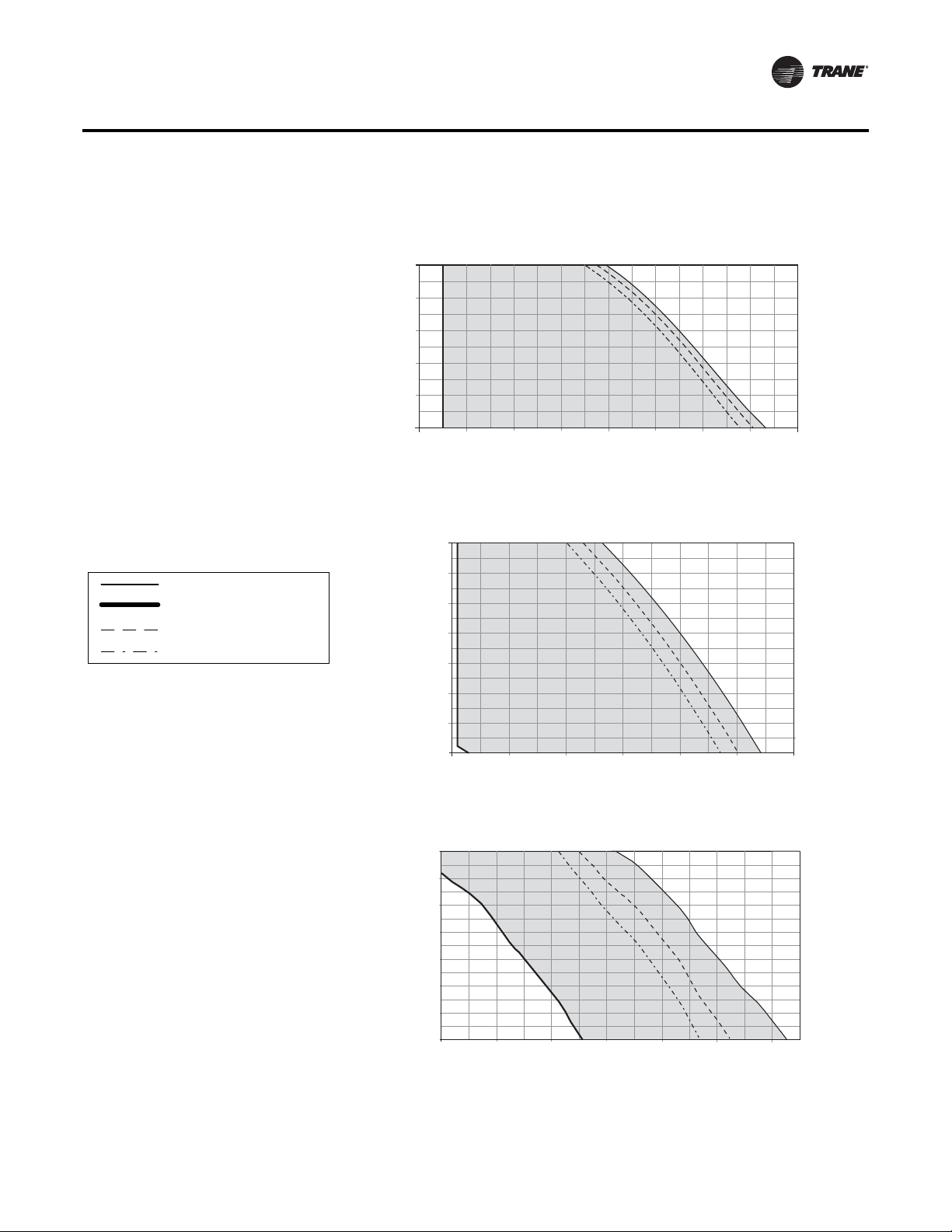

VPCF and VPEF maximum

Minimum

1-row coil maximum

2-row coil maximum

Note: When attenuator is required, add inlet

attenuator pressure to discharge static

pressure for final fan performance.

Pa In. wg

0.80

199

174

0.70

0.60

150

125

0.50

0.40

100

75

0.30

Discharge Static Pressure

50

0.20

0.10

25

Pa In. wg

199

0.80

0.70

174

150

0.60

0.50

125

0.40

100

0.30

75

Discharge Static Pressure

50

0.20

(165 L/s)

350 cfm min

300 500 700 900 1100 1300 1500 1700

142

236 330

(250 L/s)

530 cfm min

Parallel 05SQ—PSC

425

519

Airflow

Parallel 06SQ—PSC

614

708

802

Cfm

L/s

25

0.10

400

600 800 1000

283

189

378

1200

566 850

1600 1800 2000 2200

1400

755661472

944

1038

Cfm

L/s

Airflow

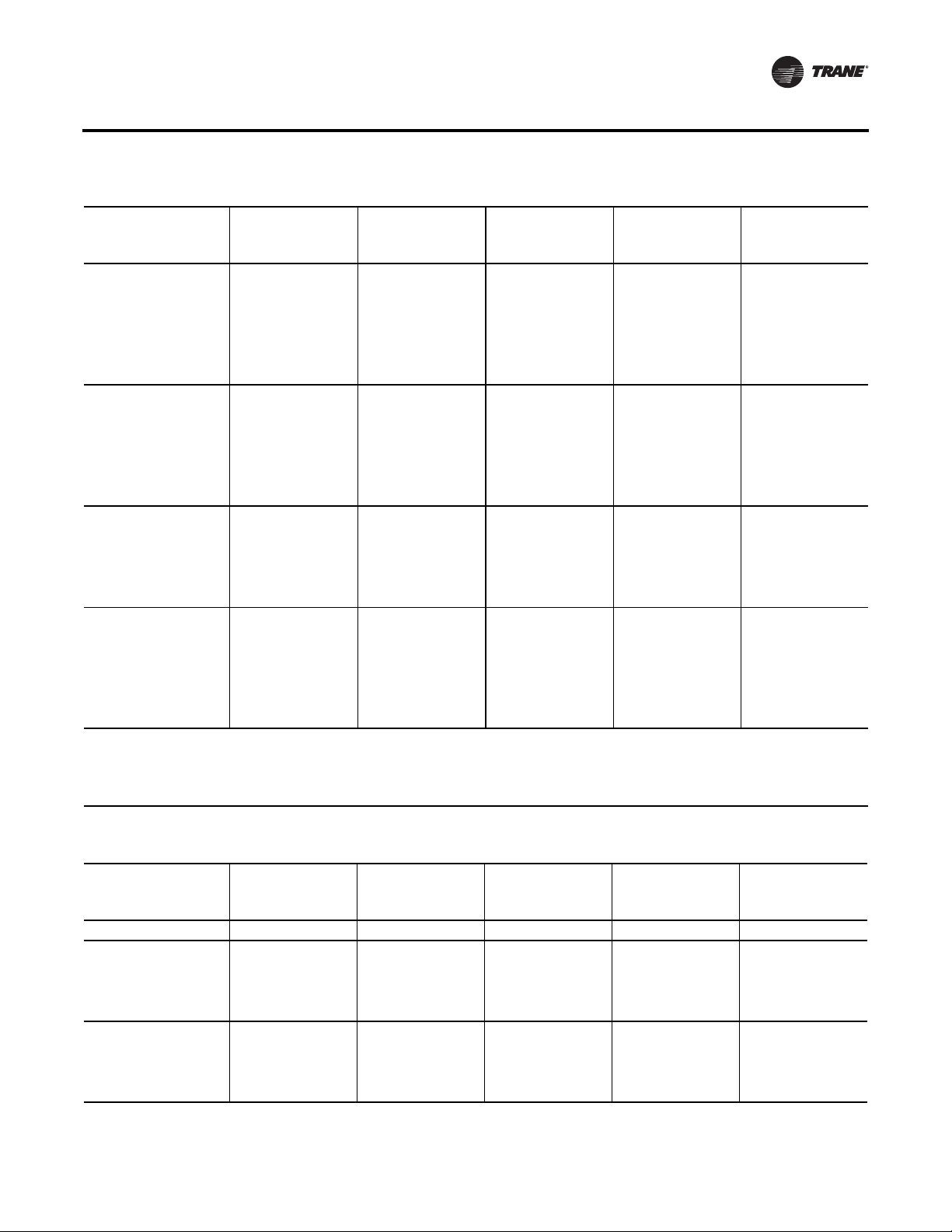

Pa In. wg

0.80

199

0.70

174