Page 1

Installation

Operation

Maintenance

UniTrane® Fan-Coil Room Conditioners

Force Flo™ Cabinet Heaters

Sizes 02-12

Low Vertical Fan-Coils

Sizes 03-06

Models

“LO” Design Sequence and Later

April 2000

UNT-IOM-6

Supercedes UNT-IOM-5

Page 2

Table of Contents

General Information3

Cabinet Styles4

Model Number Description6

Receiving and Handling9

Jobsite Storage10

Installation Considerations11

Service Access12

Installation Checklist13

Vertical Units15

Installing the Unit15

Horizontal Units16

External Insulating Require-

ments20

Startup Checklist20

Units with Hydronic Coil Connec-

tions Only21

Piping21

Units with Steam Coils22

Factory Piping Package Connec-

tions24

Installing the Auxiliary Drain

Pan25

Condensate Overflow Detection

Device26

Automatic Changeover Sensor26

Automatic Electric Heat Lockout

Switch (Fan-coil) 27

Ductwork Recommendations32

Duct Connections32

Supply Power Wiring33

Electrical Connections33

Wall Mounted Control Interconnec-

tion Wiring35

Electrical Grounding Restric-

tions35

Fan Mode Switch 36

Installation36

Installing Wall Mounted Con-

trols36

Zone Sensor Installation37

Fan Mode Switch39

Tracer® ZN.010 and ZN.51040

Thermostat Module Operating

Information41

Binary Inputs42

Binary Outputs43

Analog Inputs44

Fan Mode Switch44

Zone Sensors44

Supply Fan Operation45

LED Activity46

Troubleshooting46

Yellow COMM LED47

Manual Output Test48

Diagnostics50

Resetting Diagnostics51

Troubleshooting 53

Tracer® ZN.52059

Troubleshooting83

Troubleshooting85

Tracer® Communication Wiring

88

Service Communication Wiring

89

Wall-Mounted Zone Sensor

Module89

TUC Human Interface90

Cooling and Heating Operation92

TUC Sequence of Operation92

Fan Mode Operation93

Entering Water Temperature

Sampling Function94

2-Pipe with Auxiliary Electric Heat

(Fan-coils)94

Fresh Air Damper Options95

BIP4: Low Temperature Detection

Option97

BIP3: Condensate Overflow

Detection Device97

BIP4: Smoke Input98

BIP1: External Interlock98

BIP3: Occupied/Unoccupied

Mode98

BIP2: Motion Detection99

Autocycle Test99

Reading Diagnostics 101

Reading the Operating Machine

State 102

Reading the Operating Control

Mode104

Resetting Diagnostics107

Diagnostics107

Unit Mode Listed as Standby108

Troubleshooting 109

Maintenance Procedures116

Periodic Maintenance Check-

list116

Maintenance116

Inspecting and Cleaning Drain

Pans118

Winterizing the Coil 120

Inspecting and Cleaning Coils121

Inspecting and Cleaning the

Internal Insulation on Fan-

Coils123

Inspecting and Cleaning the

Fan124

Fan Board Assembly Removal126

Factory Piping Packages128

Appendix128

Typical Wiring Diagrams129-134

2 UNT-IOM-6

Page 3

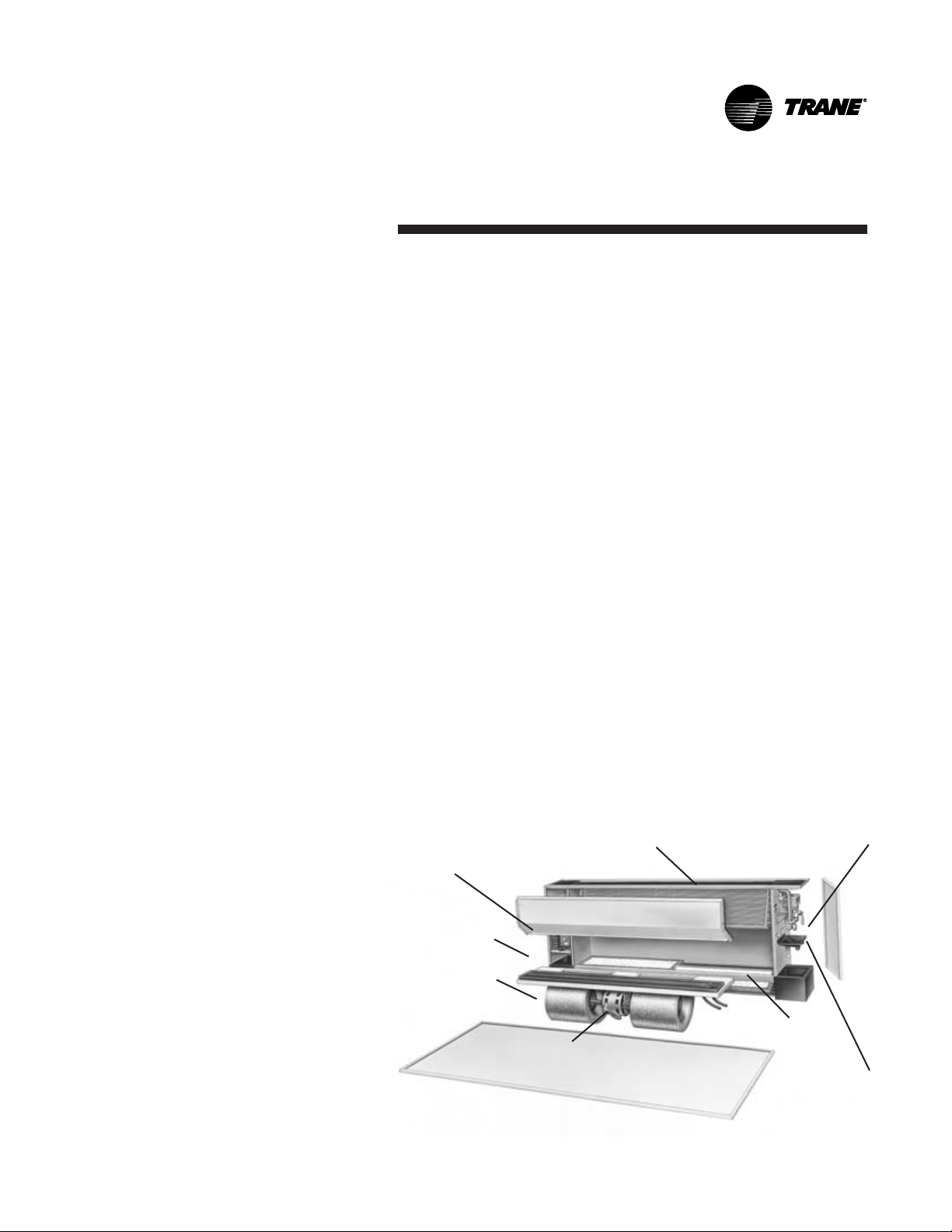

General Information

UniTrane® fan-coil and Force Flo cabinet heaters units are single

room units with load capabilities of 200 to 1200 cfm. See Figure 1

for unit components. Fan-coil units are available as 2-pipe with or

without electric heat (one hydronic circuit) or 4-pipe (two hydronic

circuits). Force Flo units feature 2-pipe hydronic coils, electric heat

only, or steam only. Also, units feature a variety of factory piping

packages. See the Appendix on page 100 for more information on

available factory-installed piping packages.

®

Three control options are available with the UniTrane

Force Flo cabinet heater units.

1. fan mode switch

®

2. Tracer

ZN.010 and ZN.510, ZN.520

3. terminal unit controller (TUC)

All control options are available as unit or wall mounted. Units with a

®

Tracer

ZN.010, ZN.510, ZN.520 or TUC also feature a split combina-

tion: unit mounted fan mode switch with a wall mounted setpoint dial.

The Tracer® controllers (ZN.010, ZN.510 and ZN.520) utilize binary

outputs to operate 2-position control valves, supply fan/s, 2-position

dampers, and electric heat.

fan-coil and

The TUC utilizes binary outputs to control the fan and optional

auxiliary heat. In addition, it operates 2-position or 3 wire floating

point control valves and the fresh air damper.

Available supply and return openings vary with each cabinet style. In

addition, a fresh air opening with either a manual or motorized air

damper is an available option. See pages 4-5 for available cabinet

styles.

Control panel

*Main drain pan

Supply fan(s)

Fan motor(s)

*Featured on fan-coils only

Figure 1. Main components of a fan-coil or cabinet heater unit.

Hydronic coil

Throwaway filter

Piping package

*Auxiliary

drain pan

UNT-IOM-6 3

Page 4

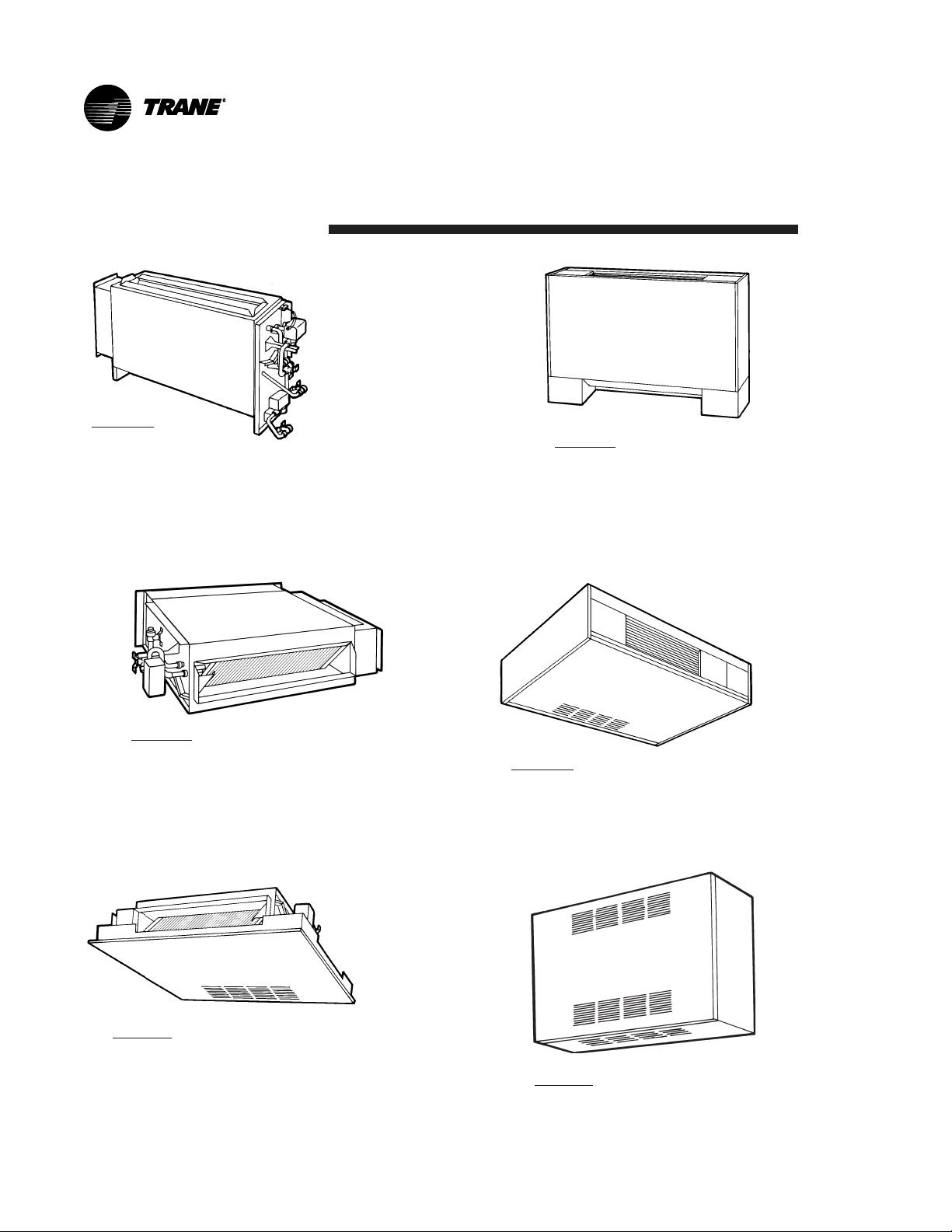

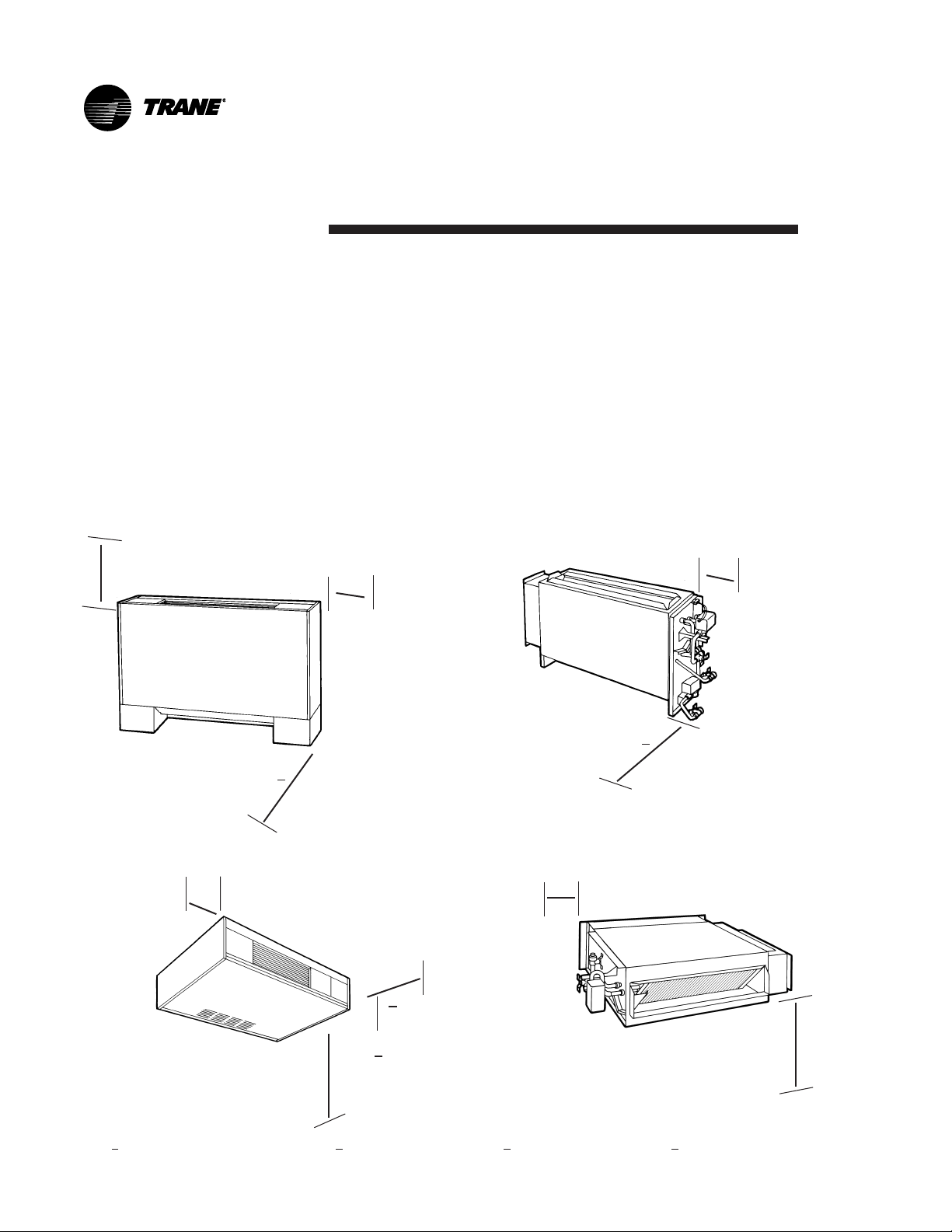

Model A

Vertical Concealed

Cabinet Styles

Model B

Vertical Cabinet

Model C

Horizontal Concealed

Model E

Horizontal Recessed

4 UNT-IOM-6

Model D

Horizontal Cabinet

Model F

Wall Hung Cabinet**

Page 5

Model H

Vertical Recessed

Model J

Vertical Slope Top Cabinet

Model K

Low Vertical Concealed*

Model M

Inverted Vertical Cabinet**

*Fan-coil only

**Force Flo cabinet heater only

Model L

Low Vertical Cabinet*

Model N

Inverted Vertical Recessed**

UNT-IOM-6 5

Page 6

Model Number

Description

Each UniTrane® fan-coil and Force Flo cabinet heater has a

multiple character model number unique to that particular unit. To

determine a units specific

options, reference the model

number on the unit nameplate

on the fan scroll. The unit

nameplate also identifies the

serial number, sales order

number, and installation and

operating specifications. See

Figure 2 for the nameplate

location.

Reference pages 7-8 for a

detailed explanation of the

model number.

Complete the installation checklist on page 13 to ensure proper and

safe operation.

Figure 2. The unit nameplate is

on the fan scroll.

6 UNT-IOM-6

Page 7

Model Number Description

Digits 1 & 2 Unit Type

FC

FF

Digit 3 Model

A Vertical concealed

B Vertical cabinet

C Horizontal concealed

D Horizontal cabinet

E Horizontal recessed

F Vertical wall hung*

H Vertical recessed

J Vertical slope top

K Low vertical concealed

L Low vertical cabinet

M Inverted vertical cabinet*

N Inverted vertical recessed*

Digit 4 Development Sequence

B

Digits 57 Unit Size

020 200 cfm

030 300 cfm

040 400 cfm

060 600 cfm

080 800 cfm

100 1000 cfm

120 1200 cfm

Digit 8 Unit Voltage

1 115/60/1

2 208/60/1

3 277/60/1

4 230/60/1

5 208/60/3

6 230/6j0/3

7 480/60/3

8 110-120/50/1

9 220-240/50/1

A 220-240/50/3

B 380-415/50/3

Digit 9 Piping System Placement

A W/o piping, RH conn.,

w/o aux. drain pan

B W/o piping, LH conn.,

w/o aux. drain pan

C W/o piping, RH conn.,

w/ aux. drain pan

D W/o piping, LH conn.,

w/ aux. drain pan

E W/o piping, RH conn.,

w/o aux. drain pan,

ext. end pocket

F W/o piping, LH conn.,

w/o aux. drain

G W/o piping, RH conn.,

w/ aux. drain pan,

ext. end pocket

H W/o piping, LH conn.,

w/ aux. drain pan, ext. end

pocket

J With piping, RH

K With piping, LH

L With piping, RH, ext. end pocket

M With piping, RH, ext. end pocket

Digits 10 & 11 Design Sequence

LO

Digit 12 Inlet

A Front toe space

B Front bar grille

C Front stamped louver

D Bottom stamped louver

E Bottom toe space

F Back duct collar

G Open return

H Back stamped louver

Digit 13 Fresh Air Damper

0 None

A Manual, bottom opening

B Manual, back opening

C Manual, top opening

D Auto, 2 pos., bottom opening

E Auto, 2 pos., back opening

F Auto, 2 pos. top opening

G Auto, economizer,

bottom opening

H Auto, economizer, back opening

J Auto, economizer, top opening

K No damper, bottom opening

L No damper, back opening

M No damper, top opening

Digit 14 Outlet

A Front duct collar

B Front bar grille

C Front stamped louver

D Front quad grille

E Bottom duct collar

F Bottom stamped louver

G Top quad grille

H Top bar grille

J Top duct collar

K Bottom bar grille

Digit 15 Color

0 None

1 Deluxe beige

2 Soft dove

3 Cameo white

4 Driftwood grey

5 Stone grey

6 Rose mauve

Digit 16 Tamperproof Locks

& Leveling Feet

0 None

A Keylock panel

B Keylock access door

C Keylock panel & access door

D Leveling feet

E Keylock panel with leveling feet

F Keylock access door

w/leveling feet

G Keylock panel & access door

w/leveling feet

Digit 17 Motor

A Free discharge

B High static

Digit 18 Coil

A 2 row cooling/heating

B 3 row cooling/heating

C 4 row cooling/heating

D 2 row cooling, 1 row heating

E 2 row cooling, 2 row heating

F 3 row cooling, 1 row heating

G 2 row cooling or heating only

H 3 row cooling or heating only

J 4 row cooling or heating only

K 2 row cooling/heating, elec. heat

L 3 row cooling/heating, elec. heat

M 4 row cooling/heating, elec. heat

N Electric heat only, 1 stage

P 2 row cooling/heating,

1 row heating

Q 2 row cooling/heating,

2 row heating

R 3 row cooling/heating,

1 row heating

U Electric heat only, 2 stage

V Electric heat only, low kw, 1 stage

W Steam coil

Digit 19 Coil Fin Series

2 144

Digit 20 Air Vent

A Automatic

M Manual

Digits 21, 22, & 23 Electric Heat kW

[208 V kW derate in brackets]

000 None

010 1.0 [0.75]

015 1.5 [1.1]

020 2.0 [1.5]

025 2.5 [1.9]

030 3.0 [2.2]

040 4.0 [3.0]

045 4.5 [3.3]

050 5.0 [3.7]

060 6.0 [4.4]

070 7.0 [5.3]

075 7.5 [5.7]

080 8.0 [6.0]

100 10.0

105 10.5 [7.9]

110 11.0 [9.0]

120 12.0

135 13.5 [10.2]

150 15.0

180 18.0 [13.5]

200 20.0 [15.0]

*Force Flo cabinet heater only

UNT-IOM-6 7

Page 8

Digit 24 Reheat

0 None

A Steam

B Hot water

Digit 25 Disconnect Switch

0 None

D With disconnect

Digit 26 Filter

0 None

11 TA

2 1 TA pltd. media

3 1 TA + 1 extra

4 1 TA pltd. media + 1 extra

5 1 TA + 2 extra

6 1 TA pltd. media + 2 extra

7 1 TA + 3 extra

8 1 TA pltd. media + 3 extra

Digit 27 Main Control Valve

0 None

A 2 way, 2 pos., N.O. (25 psig)

B 3 way, 2 pos., N.O. (30 psig)

C 2 way, 2 pos., N.C. (25 psig)

D 3 way, 2 pos., N.C. (15 psig)

E 2 way, 2 pos., N.O. (50 psig)

F 3 way, 2 pos., N.O. (50 psig)

G 2 way, 2 pos., N.C. (50 psig)

H 3 way, 2 pos., N.C. (50 psig)

J 2 way, mod., Cv = 0.7 (50 psig)

K 3 way, mod., Cv = 0.7 (50 psig)

L 2 way, mod., Cv = 1.5 (50 psig)

M 3 way, mod., Cv = 1.5 (50 psig)

N 2 way, mod., Cv = 2.5 (50 psig)

P 3 way, mod., Cv = 2.5 (50 psig)

Q 2 way, mod., Cv = 4.0 (50 psig)

R 3 way, mod., Cv = 4.0 (50 psig)

Digit 28 Auxiliary Control Valve

0 None

A 2 way, 2 pos., N.O. (25 psig)

B 3 way, 2 pos., N.O. (30 psig)

C 2 way, 2 pos., N.C. (25 psig)

D 3 way, 2 pos., N.C. (15 psig)

E 2 way, 2 pos., N.O. (50 psig)

F 3 way, 2 pos., N.O. (50 psig)

G 2 way, 2 pos., N.C. (50 psig)

H 3 way, 2 pos., N.C. (50 psig)

J 2 way, mod., Cv = 0.7 (50 psig)

K 3 way, mod., Cv = 0.7 (50 psig)

L 2 way, mod., Cv = 1.5 (50 psig)

M 3 way, mod., Cv = 1.5 (50 psig)

N 2 way, mod., Cv = 2.5 (50 psig)

P 3 way, mod., Cv = 2.5 (50 psig)

Q 2 way, mod., Cv = 4.0 (50 psig)

R 3 way, mod., Cv = 4.0 (50 psig)

Digit 29 Piping Package

0 None

A Ball valve supply & return

B Ball valve supply & manual circuit

setter return

C Ball valve supply & auto circuit

setter

D Ball valve supply & return

w/strainers & unions

E Ball valve supply & manual circuit

setter w/strainers & unions

F Ball valve supply & auto circuit

setter w/strainers & unions

Digit 30 Control Type

A Fan Speed Switch

C TUC

D TUC w/Trane ICS

E Tracer

F Tracer

®

ZN.010

®

ZN.510

G Tracer® ZN.520

Digit 31 Control Options

D Unit mtd. fan mode switch (OHML)

K Wall mtd. fan mode switch (OHML)

V Unit mtd. zone sensor, w/SP

rotary, & fan mode switch

(OAHML),

W Wall mtd. zone sensor w/

SP rotary, & fan mode switch

(OAHML),

X Unit mtd. fan mode switch, wall

mtd. setpoint dial zone sensor

Digit 32-34 Future Control Options

Digit 35 Control Function 3

0 None

2 Condensate overflow detection

Digit 36 Control Function 4

0 None

2 Low temperature detection

Digits 37 & 38 Future Control Options

Digit 39 Recessed Options

0 None

A Stand. 5/8 recessed panel

B 2 projection panel

C 2.5 projection panel

D 3 projection panel

E 3.5 projection panel

F 4 projection panel

G 4.5 projection panel

H 5 projection panel

J 5.5 projection panel

K 6 projection panel

L 2 falseback

M 3 falseback

N 4 falseback

P 5 falseback

Q 6 falseback

R 7 falseback

T 8 falseback

Digit 40 Main Auto Circuit Setter GPM

0 None

A 0.5

B 0.75

C 1.0

D 1.5

E 2.0

F 2.5

G 3.0

H 3.5

K 4.5

L 5.0

M 6.0

N 7.0

P 8.0

Q 9.0

R 10.0

T11.0

U 12.0

J 4.0

Digit 41 Auxiliary Auto Circuit Setter GPM

0 None

A 0.5

B 0.75

C 1.0

D 1.5

E 2.0

F 2.5

G 3.0

H 3.5

K 4.5

L 5.0

M 6.0

N 7.0

P 8.0

Q 9.0

R 10.0

T11.0

U 12.0

J 4.0

Digit 42 Subbase

0 None

A 2 height

B 3 height

C 4 height

D 5 height

E 6 height

F 7 height

Digit 43 Recessed Flange

0 None

A Recessed flange

Digit 44 Wallbox

0 None

A Anodized

8 UNT-IOM-6

Page 9

Receiving and Handling

UniTrane® fan-coil and Force Flo cabinet heaters ship in individual

cartons for maximum protection during shipment and for handling and

storage ease. Each carton has tagging information such as the

model number, sales order number, serial number, unit size, piping

connections, and unit style to help properly locate the unit in the floor

plan. If specified, the unit will ship with tagging designated by the

customer.

Complete the following checklist before accepting delivery of units to

detect any shipping damage.

o 1. Inspect each piece of the shipment before accepting it.

Check for rattles, bent carton corners, or other visible indications of

shipping damage.

o 2. If the carton appears damaged, open it immediately and

inspect the contents before accepting. Do not refuse the shipment.

Make specific notations concerning the damage on the freight bill.

Check the unit casing, fan rotation, coils, condensate pan, filters, and

all options or accessories.

o 3. Inspect the unit for concealed damage and missing compo-

nents soon after delivery and before storing. Report concealed

damage to the delivering carrier within the allotted time after

delivery (check with the carrier on the allotted time to submit a

claim).

o 4. Do not move damaged material from the receiving location if

possible. It is the receivers responsibility to provide reasonable

evidence that concealed damage did not occur after delivery.

o 5. Do not continue to unpack shipment if it appears damaged.

Retain all internal packing, cartons, and crate. Take photos of the

damaged material if possible.

o 6. Notify the carriers terminal of damage immediately by phone

and mail. Request an immediate joint inspection of the damage by

the carrier and consignee.

o 7. Notify the Trane sales representative of the damage and

arrange for repair. Have the carrier inspect the damage before beginning any repairs to the unit.

UNT-IOM-6 9

Page 10

Jobsite Storage

This unit is intended for indoor use only. To protect the unit from

damage due to the elements and prevent it from possibly becoming a

contaminant source for IAQ problems, store the unit indoors. If indoor

storage is not possible, the Trane Company makes the following

provisions for outdoor storage:

1. Place the unit(s) on a dry surface or raised off the ground to assure

adequate air circulation beneath unit and to assure that no portion of

the unit contacts standing water at any time.

2. Cover the entire unit with a canvas tarp only. Do not use clear,

black or plastic tarps as they may cause excessive moisture condensation and equipment damage.

Note: Wet interior unit insulation can become an amplification site for

microbial growth (mold), which may cause odors and health-related

indoor air quality problems. If there is visable evidence of microbial

growth (mold) on the interior insulation, remove and replace the

insulation prior to operating the system. Refer to the Inspecting and

Cleaning the Internal Insulation section on page 123 for more

information.

10 UNT-IOM-6

Page 11

Installation

Considerations

Complete the following checklist before installing the unit.

o 1. Clearances

Allow adequate space for free air circulation, service clearances,

piping and electrical connections, and any necessary ductwork. For

specific unit dimensions, refer to the submittals. Allow clearances

according to local and national electric codes. See the following

section on Service Access and refer to Figure 3 on page 12 for

recommended service and operating clearances. Provide removable

panels for concealed units.

o 2. Structural Support

The floor should be strong enough to adequately support floor

mounted units. The installer is responsible to supply adequate

support rods for installation of ceiling units.

o 3. Level

If necessary, prepare the floor or ceiling to ensure the unit installation

is level (zero tolerance) in both horizontal axis to allow proper

operation.

Set the unit level using the chassis end panels as a reference point.

Do not use the coil or drain pan as the reference point since the coil

is pitched and the drain pan has an inherent positive slope to provide

proper drainage.

o 4. Condensate Line

A continuous pitch of 1 inch per 10 feet of condensate line run is

necessary for adequate condensate drainage.

o 5. Wall and Ceiling Openings

Recessed units only:

Refer to the submittal for specific dimensions of wall or ceiling

openings before attempting to install the unit.

Horizontal concealed units only:

The installation of horizontal concealed units must meet the requirements of the National Fire Protection Association (N.F.P.A.) Standard 90A or 90B concerning the use of concealed ceiling spaces as

return air plenums.

o 6. Exterior

Touch up painted panels if necessary. If panels need paint, sanding

is not necessary. However, clean the surface of any oil, grease, or

dirt residue so the paint will adhere. Purchase factory approved touch

up epoxy paint from your local Trane Service Parts Center and apply.

UNT-IOM-6 11

Page 12

Service

Access

24 in.

Vertical or Low

Vertical Cabinet

A

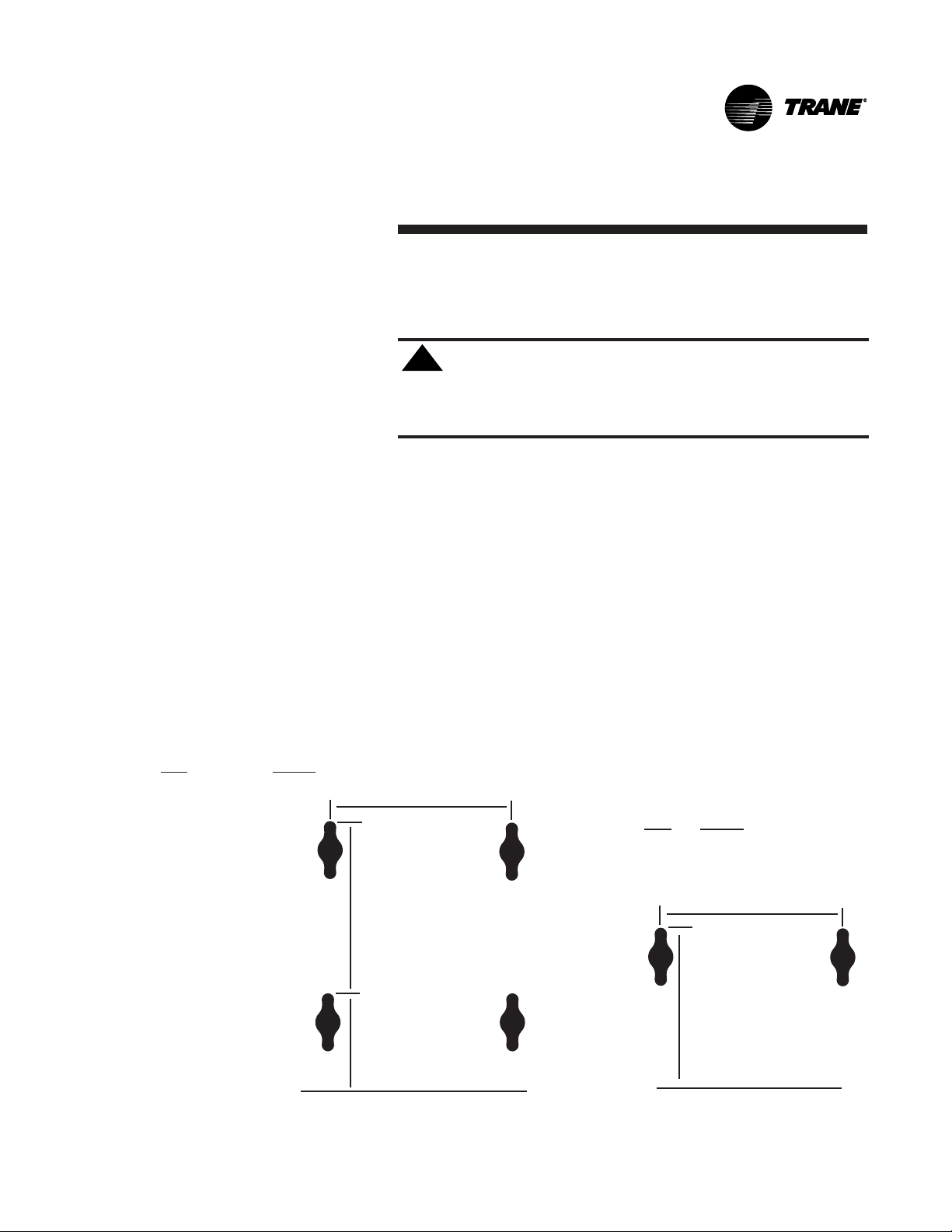

Service access is available from the front on vertical units and from

the bottom on horizontal units. Cabinet and recessed units have

removable front or bottom panels to allow access into the unit. See

Figure 3 for recommended service and operating clearances.

Units have either right or left hand piping. Reference piping locations

by facing the front of the unit (airflow discharges from the front). The

control panel is always on the end opposite the piping.

The unit has a modular fan board assembly that is easy to remove.

Also, the main drain pan is easily removable for cleaning. See the

Maintenance section beginning on page 88 for more details on

servicing.

8.5 in.

12 in.

both sides

both sides

Vertical or Low Vertical

Concealed or Vertical

Recessed

3 in.

A

36 in.

12 in.

both sides

24 in.

C

28 in.

6 in.

B

Horizontal

Cabinet

A- Front Access or Front Free Discharge B- Control Access Door C- Front Free Discharge D- Back Louvered Return

Figure 3. Recommended Service and Operating Clearances

12 UNT-IOM-6

8.5 in.

both sides

Horizontal Concealed

or Recessed

28 in.

Page 13

Installation Checklist

The following checklist is only an abbreviated guide to the detailed

installation procedures given in this manual. Use this list to ensure all

necessary procedures are complete. For more detailed information,

refer to the appropriate sections in this manual.

WARNING: Allow rotating fan to stop before

!

servicing equipment. Failure to do so may cause severe

personal injury or death.

o 1. Inspect the unit for shipping damage.

o 2. Level installation location to support the unit weight ad-

equately. Make all necessary wall or ceiling openings to allow

adequate air flow and service clearances.

o 3. Ensure the unit chassis is level.

CAUTION: The unit must be installed level (zero

!

tolerance) in both horizontal axis for proper operation.

Failure to do so may result in condensate management

problems such as standing water inside the unit. Standing water and wet surfaces may result in microbial

growth (mold) in the drain pan that may cause unpleasnt

odors and serious health-related indoor air quality problems.

o 4. Secure the unit and any accessory items properly to the

wall or ceiling support rods.

o 5. Complete piping connections correctly.

o 6. Check field sweat connections for leaks and tighten the

valve stem packing, if necessary.

o 7. Install the auxiliary drain pan properly under piping package

on fan-coil units.

o 8. Pitch condensate drain line 1 inch drop per 10 feet of line

run on fan-coil units.

UNT-IOM-6 13

Page 14

o 9. Complete condensate drain line connections on fan-coil

units.

o 10. Install automatic changeover sensor option on the

supply water line.

o 11. Install automatic electric heat lockout switch option on

the supply water line.

o 12. Install condensate overflow switch option correctly on

the auxiliary drain pan.

o 13. Install the low temperature detection device option correctly.

o 14. Complete all necessary duct connections.

o 15. Complete all interconnection wiring for the wall mounted fan

mode switch or zone sensor per the wiring schematic and guidelines

established in the Wall Mounted Control Interconnection Wiring

section on page 35.

o 16. Install the wall mounted fan mode switch, or zone sensor

module options properly.

o 17. Connect electrical supply power according to the NEC and

unit wiring diagrams.

o 19. Remove any miscellaneous debris, such as sheetrock, that

may have infiltrated the unit during construction.

o 20. Replace the air filter as required.

14 UNT-IOM-6

Page 15

Installing the Unit

Before beginning installation, refer to Table 1 on page 17 for unit

weights and Figure 3 on page 12 for service and operating clearances.

In addition, refer to the unit submittal for installation details.

CAUTION: Do not allow electrical wire to fall

!

between the unit and installation surface. Failure to

comply may cause electrical shorts or difficulty in accessing wires.

Vertical Units

Cabinet & Concealed Units

Size L (in.)

02 21 1/4

03 21 1/4

04 26 1/4

06 35 3/4

08 44 1/4

10 63 1/4

12 63 1/4

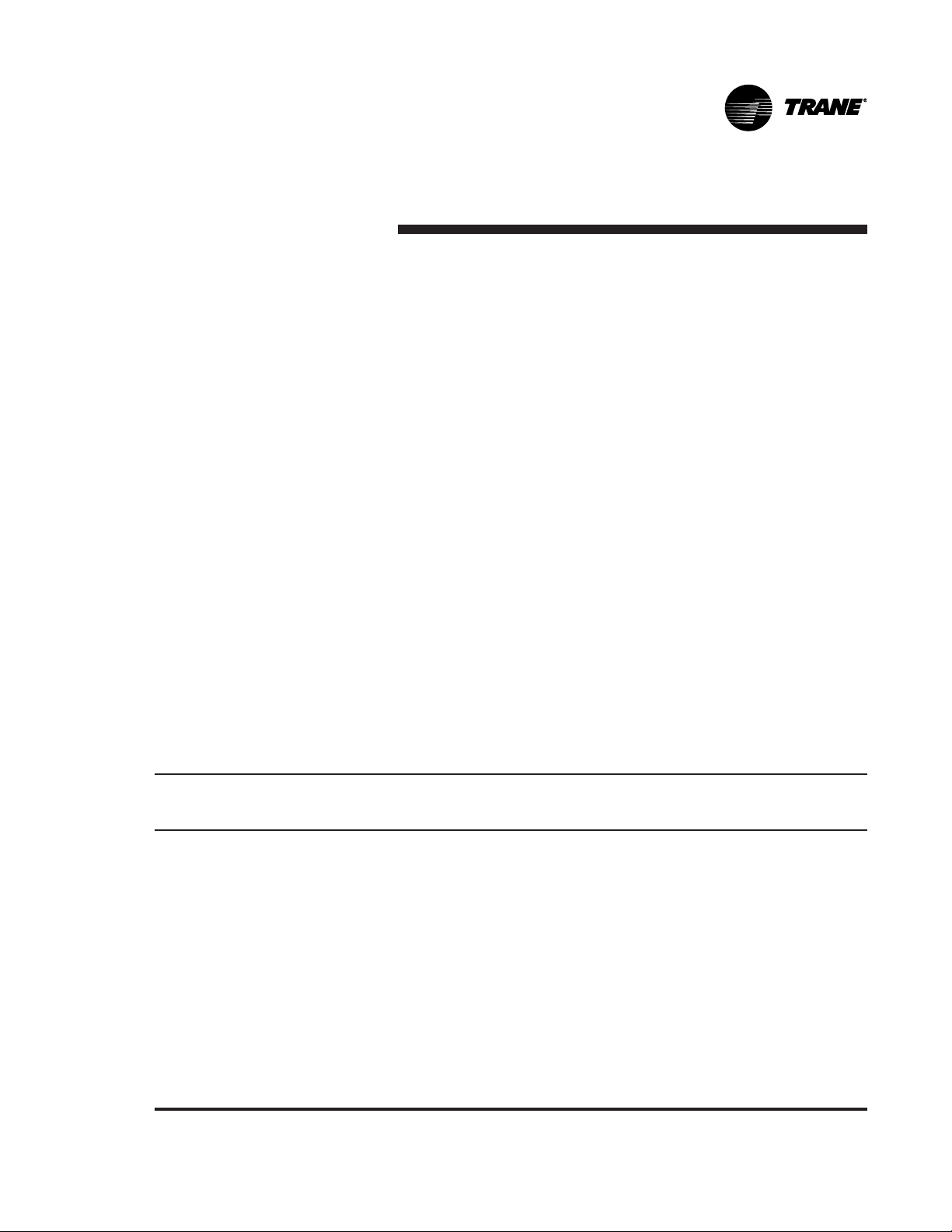

Install vertical units in an upright position using the 5/8 inch diameter

double key slot hanger holes, located on the back of unit. The hanger

holes allow a maximum shank size of 5/16 inch diameter threaded

rods or lag screws (installer provides). Follow the installation procedure below.

1. Prepare wall openings for recessed units. Reference unit submittal

for each unit size dimensions.

2. If the unit has leveling legs, adjust them correctly to level unit.

3. Mark the position of the keyslot hanger holes on the wall according

to the dimensions given in Figure 4 for each unit size. Align the

hole locations evenly.

L

15.5 in.

Low Vertical Cabinet & Concealed

Size L (in.)

03 26 1/4

04 35 3/4

06 44 1/4

L

12.19 in.

7.5 in.

Floor Level

Figure 4. Keyslot Hanger Hole Locations

UNT-IOM-6 15

Floor Level

Page 16

4. Insert the threaded rods or lag screws in the wall before setting the

unit in place.

5. Remove the front panel (cabinet unit only) by lifting it upward.

6. Position the hanger holes, located on the back of the unit, over the

rod or lag screw heads, pushing the unit downward to properly

position.

7. Complete piping and wiring connections, in addition to any necessary ductwork to the unit as instructed in the following sections.

Ensure that the auxiliary drain pan is in position on fan-coil units.

8. Install the front panel before starting the unit.

On cabinet units, replace the front panel by aligning the bottom tabs

on the unit with the respective slots on the panel bottom. Align the

top edge of the unit with the panel.

On recessed units, install the front panel by aligning and locking

together the interlocking support channel of the panel and unit. While

holding the panel against the unit, tighten the screws at the top of the

panel until it fits tight against the units front. Do not over tighten the

screws.

CAUTION: All unit panels and filters must be in

!

place prior to unit start-up. Failure to have panels and

filters in place may cause motor overload.

Horizontal Units

16 UNT-IOM-6

Install horizontal units suspended from the ceiling using the four 5/8

inch diameter double key slot hanger holes, located on the top of the

unit. The hanger holes allow a maximum shank size of 5/16 inch

diameter threaded rods or lag screws (installer provided). Follow the

installation procedure below.

Note: Follow the requirements of National Fire Protection Association

(NFPA) Standard 90A or 90B, concerning the use of concealed

ceiling spaces as return air plenums.

1. Prepare the ceiling opening for recessed units. Reference the unit

submittals for each unit size dimensions.

Page 17

2. Position and install the suspension rods or a suspension device

(supplied by installer) according to the unit size dimensions in

Figure 4 on page 15. Also refer to the weight range chart given in

Table 1.

3. On cabinet units, remove the bottom panel by using a 5/32 inch

Allen wrench to unscrew fasteners. Swing the panel down and lift

outward.

4. Level the unit by referencing the chassis end panels. Adjust the

suspension device.

5. Complete piping and wiring connections, in addition to any neces

sary ductwork as instructed in the following sections. Ensure that

the auxiliary drain pan is in position on fan-coil units.

6. Install the bottom panel before starting the unit.

7. Ensure condensate drain line is pitched 1 inch per 10 feet of pipe

away from fan-coil unit.

Table 1. Unit Operating Weights, pounds (kg)

Unit Cabinet Concealed Recessed Low Vertical Low Vertical

Size Models Models Models Cabinet Models Concealed

Models

02 84 (38) 68 (31) 68 (31) NA NA

03 84 (38) 68 (31) 68 (31) 112 (51) 96 (44)

04 112 (51) 96 (44) 78 (35) 139 (63) 123 (56)

06 139 (63) 123 (56) 118 (54) 148 (67) 131 (59)

08 148 (67) 131 (59) 129 (59) NA NA

10 200 (91) 182 (83) 243 (110) NA NA

12 200 (91) 182 (83) 243 (110) NA NA

Note: All weights are approximate. Individual weights may vary depending upon the units options.

UNT-IOM-6 17

Page 18

Cabinet units:

Install the bottom panel by placing the hinged end on the units hinged

end (always at the return end of the unit). See Figure 4 on page 15 for

keyslot hanger hole locations. Swing the panel upward into position.

Tighten the panel to the unit with the fasteners provided. Do not overtighten the fasteners.

Recessed units:

See Figure 5 on page 19 and follow the procedure below.

· Insert the mounting bolts through the panel brackets of the trim ring

and secure to the hanger holes on the unit. Tighten the mounting

bolts to pull the trim ring snug against the finished ceiling.

· Install the bottom panel by placing the hinged end on the trim ring

hinged end (always at the units return end).

· Adjust the inner duct of the expansion collar (on units with a bottom

return) to ensure a tight fit against the insulation located on the

perimeter of the bottom panels return louver.

· Safety chain assembly: close s-hook on each end of chain. Insert s hooks through holes in unit and door. Close s-hook on door.

· Insert retaining screws through bottom panel door and place

retaining rings on screws.

· Swing the bottom panel upward into position. Hook the safety chain

to the bottom panel and the unit. Tighten the panel to the unit with

the fasteners provided. Do not over tighten the removable front

access panel.

CAUTION: All unit panels and filters must be in

!

place prior to unit start-up. Failure to have panels and

filters in place may cause motor overload.

Note: The trim ring assembly cannot accomodate unlevel ceilings.

18 UNT-IOM-6

Page 19

Figure 5. Trim ring assembly installation.

UNT-IOM-6 19

Page 20

Startup Checklist

o 1. Ensure all panels are in place.

o 2. Tighten unions adequately if unit has a factory deluxe piping

package.

o 3. Properly vent the hydronic coil to allow water flow through the

unit.

o 4. Set water flow to the unit properly if unit piping has the circuit

setter valve.

o 5. Check strainers (if supplied) for debris after applying system

water.

o 6. Install the auxiliary drain pan and route the main drain pan

hoses to the auxiliary drain pan on vertical fan-coil units.

o 7. Ensure all grille options are in place.

External Insulating

Requirements

o 8. Ensure the air filter is in place.

o 9. Set the damper position to allow the fresh air requirement on

units with a fresh air damper.

Note: Some circumstances may require the unit to run before building

construction is complete. These operating conditions may be beyond

the design parameters of the unit and may adversely affect the unit.

Insulate all cold surfaces to prevent condensation. Moisture mixed

with accumulated dirt and organic matter may create an amplification

site for microbial growth (mold) causing unpleasant odors and healthrelated indoor air quality (IAQ) problems.

The Trane Company recommends field-insulation of the following

areas to prevent potential condensate and IAQ problems:

1. Supply and return water piping connections

2. Condensate drain lines and connections

3. Fresh air intake duct connections

4. Discharge duct connections

5. Wall boxes

20 UNT-IOM-6

Page 21

Piping

Units with

Hydronic Coil

Connections Only

Piping Considerations

Before installing field piping to the coil, consider the following .

· All coil connections are 5/8 inch O.D. (or 1/2 inch nominal) female

copper connections.

· The supply and return piping should not interfere with the auxiliary

drain pan or condensate line. See Connecting the Condensate

Drain section on page 25 for more detailed information.

· The installer must provide adequate piping system filtration and

water treatment.

· Condensate may be an issue (fan-coils only) if field piping does not

have a control valve.

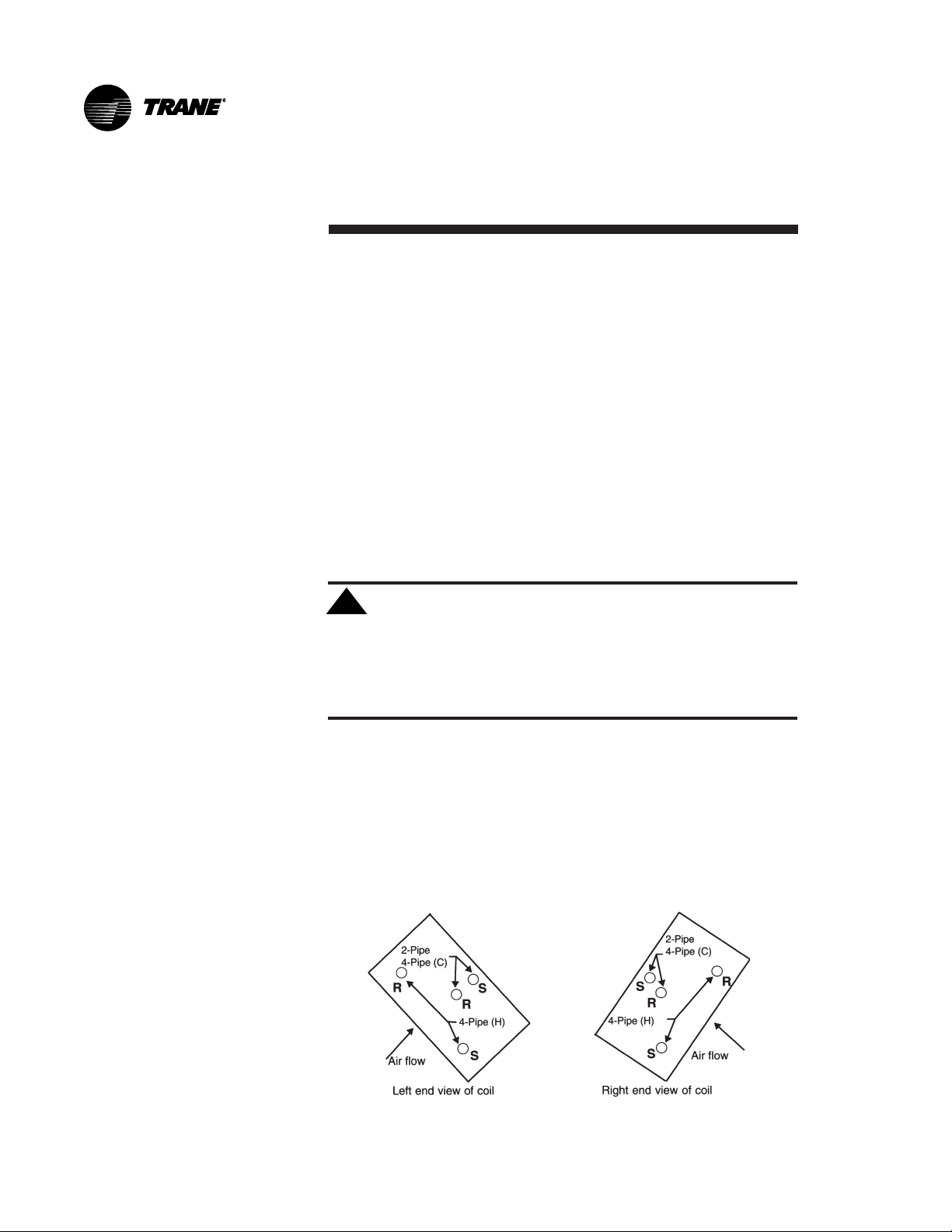

Refer to Figure 6 for supply and return header locations.

CAUTION: When using a field supplied piping

!

package in a fan-coil unit, allow sufficient room to install

the auxiliary drain pan. In addition, piping package must

not extend over edges of auxiliary drain pan.

S

R

S

2-Pipe

4-Pipe (C)

R

Air flow

2-Pipe

4-Pipe (C)

R

Air flow

Left end view of coil

Figure 6. Supply and return header locations on the hydronic

coil.

Connecting field piping to coil:

1. Slide a 1/2 inch sweat connection coupling (installer provided) onto

the coil headers.

2. Remove the auxiliary drain pan, if it is in place, to prevent exposure

to dripping solder or excessive temperatures.

UNT-IOM-6 21

S

R

4-Pipe (H)

S

4-Pipe (H)

Right end view of coil

Page 22

Units with Steam

Coils

Note: For vertical fan-coil units, push the main condensate drain

hose and overflow condensate drain hose through to the inside of the

chassis end panel to prevent them from being burned when making

sweat connections. Be sure to pull the hoses back through and route

to the auxiliary drain pan when the end panel has cooled.

3. Solder the joint using bridgit lead-free solder (ASTM B32-89) to

provide a watertight connection. Avoid overheating factory soldered

joints when soldering field connections to the coil to prevent

leakage from occurring.

4. Insulate all piping to coil connections as necessary after connections are complete.

Note: Maintain a minimum distance of one foot between the reduction

fitting for the 1/2 inch diameter line and the fan-coil unit piping

connections.

Install the auxiliary drain pan, which ships in the accessory packet

CAUTION: In all steam coil installations, the con-

!

densate return connections must be at the low point of

the coil to ensure condensate flows freely from the coil

at all times. Failure to do so may cause physical coil

damage from water hammer, unequal thermal stresses,

freeze-up and/or corrosion.

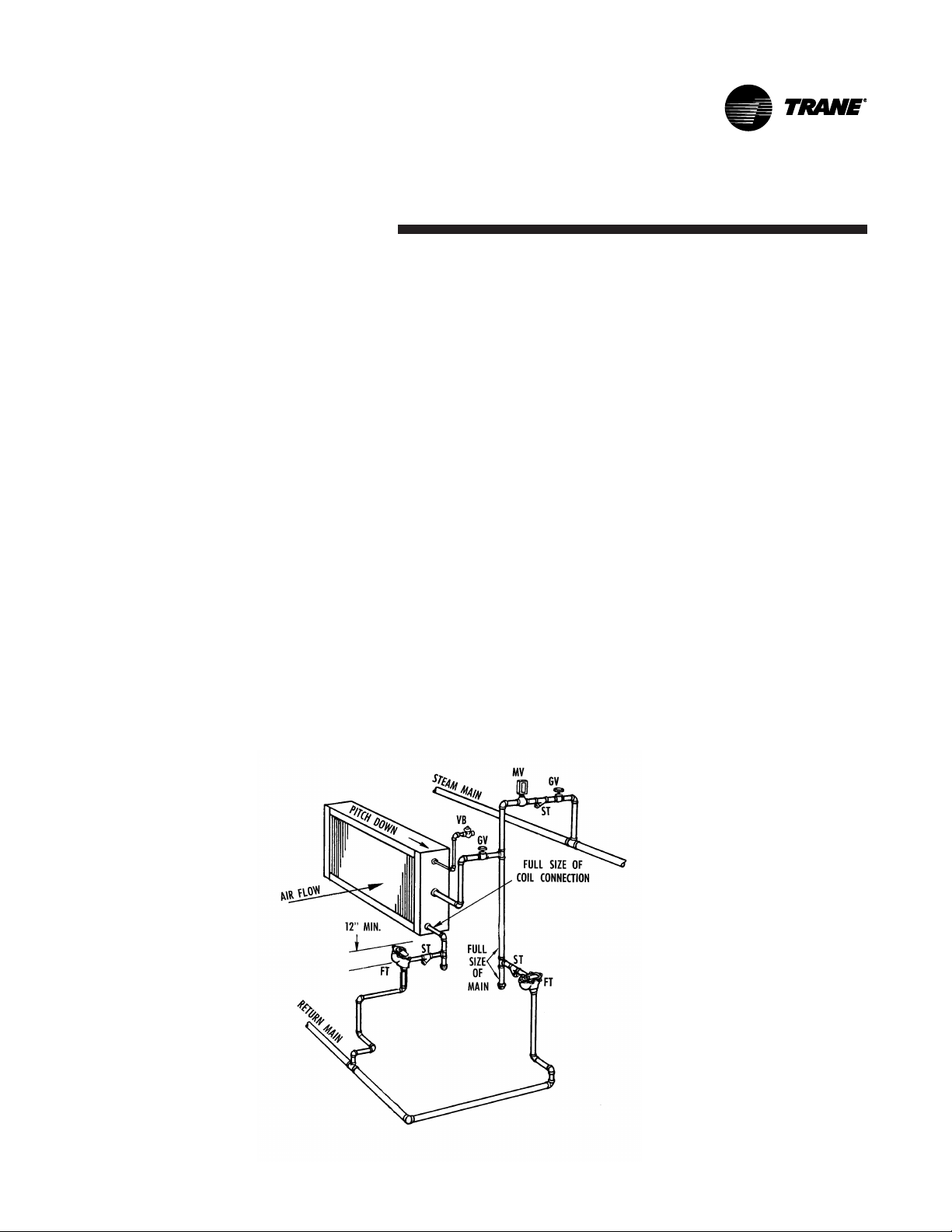

1. Make piping connections to the steam coil as shown in Figure 7.

Cap the unused connection.

2. The coil is already pitched within the unit to provide proper pitch to

drain condensate out of the coil. Ensure that the unit has been

properly leveled. Refer to page 13 for unit leveling instructions.

3. Install a 1/2 inch, 15-degree swing check vacuum breaker in the

unused condensate return tapping as close as possible to the coil.

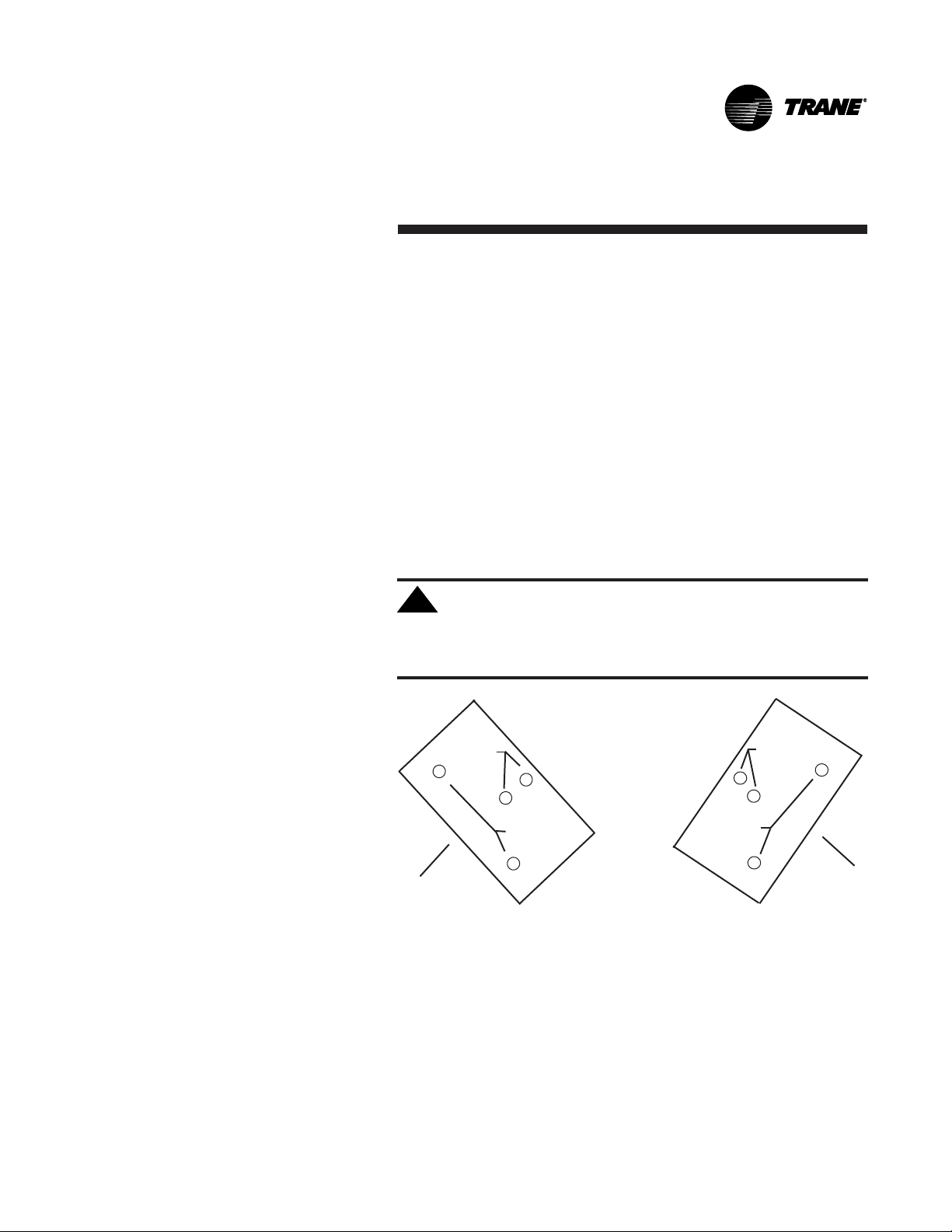

Figure 7. Steam coil header ports. The center port is the supply

connection. The return port is below the supply. The top port

must be closed off.

22 UNT-IOM-6

Page 23

4. Vent the vacuum breaker line to atmosphere or connect it into the

return main at the discharge side of the steam trap.

5. Pitch all steam supply and return mains down a minimum of 1 inch

per 10 feet in the direction of flow.

6. Do not drain the steam mains or take-off through the coils. Drain

the mains ahead of the coils through a steam trap to the return line.

7. Overhead returns require 1 psig of pressure at the steam trap

discharge for each 2-foot elevation to ensure continuous condensate

removal.

8. Proper steam trap selection and installation is necessary for

satisfactory coil performance and service life. For installation, use the

following steps:

a. Locate the steam trap discharge at least 12 inches below the

condensate return connection. This provides sufficient hydrostatic

head pressure to overcome trap losses and ensure complete condensate removal.

b. Trane Company recommends using flat and thermostatic traps

because of gravity drain and continuous discharge operation.

c. Use float and thermostatic

traps with atmospheric pressure

gravity condensate return, with

automatic controls or where the

ST = Strainer

FT = Float and

thermostatic

steam trap

MV = Manual

air vent

GV= Gate valve

VB = Vacuum

breaker, 15°

swing check

valve

possibility of low pressure supply

steam exists.

d. Always install strainers as

close as possible to the trap inlet

side.

Reference Figure 8 for an example of a properly piped steam

coil.

Figure 8. Example of typical piping to the steam coil.

UNT-IOM-6 23

Page 24

Factory Piping

Package

Connections

Before installing water piping supply and return lines to factory

piping package, note the following items.

· All piping connections are 5/8 inch O.D. (1/2 inch nominal) female

copper connections.

Piping Considerations

Connecting Water Piping to

Factory Piping Package

· The fan-coil supply and return piping should not interfere with the

auxiliary drain pan or condensate line. See Connecting the

Condensate Drain section on page 25 for more information.

· The installer must provide adequate piping system filtration and

water treatment.

· If the unit has a factory deluxe piping package, the piping includes

a strainer with a 20 mesh size screen, which allows minimal

protection from debris. Therefore, clean the strainer regularly.

NOTE: Maintain a minimum distance of one foot between the

reduction fitting for the 1/2 inch diameter line and the fan-coil piping

connections.

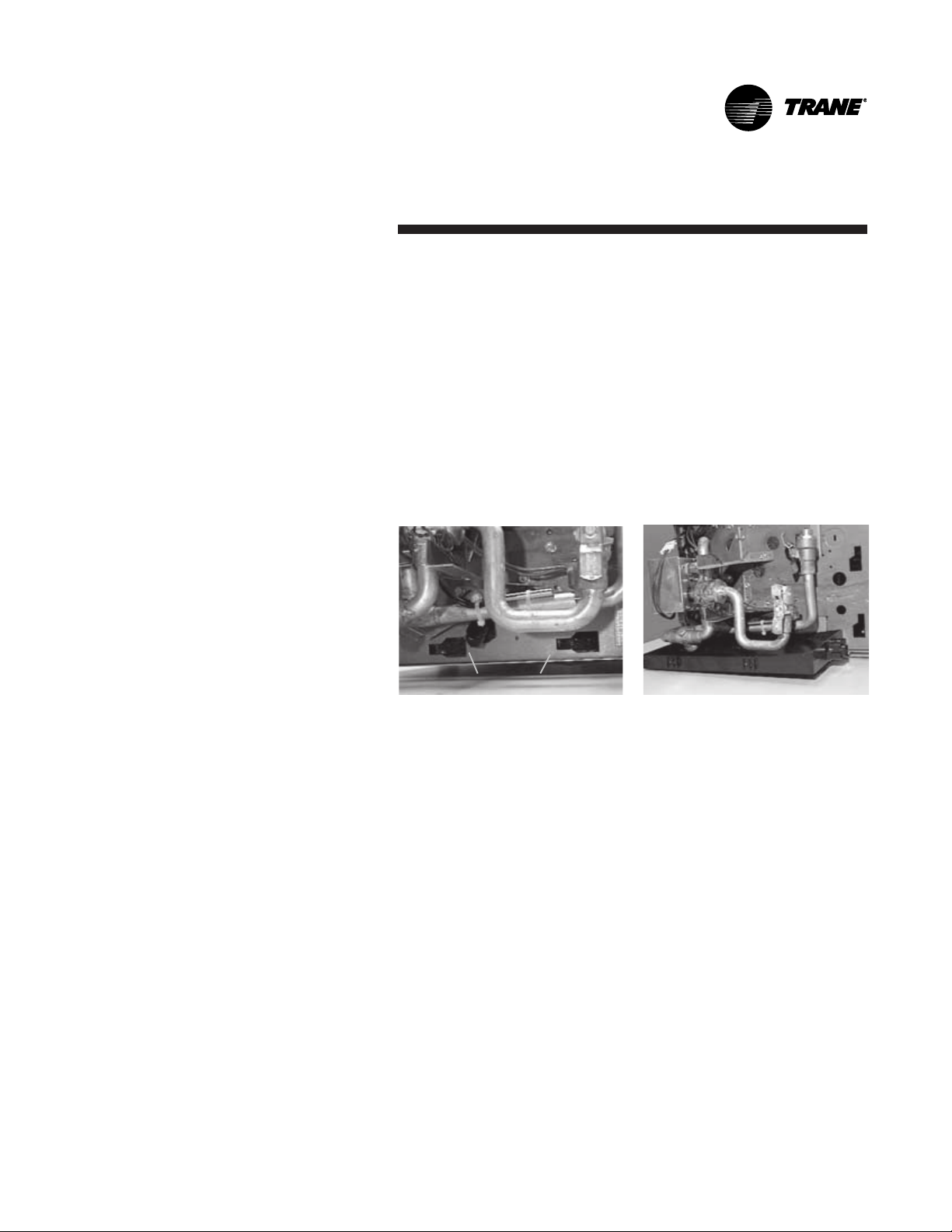

1. The factory piping package ships with brackets to adequately

support the piping during shipment. Remove these brackets before

connecting water piping to the unit. See Figure 9.

2. Close the piping end valves to the fully open position to prevent

damage to the valve seat during brazing.

3. Remove the auxiliary drain pan, if it is in place, to prevent exposure to dripping solder or excessive temperatures.

4. Solder water piping connections to supply and return end

connections. Avoid overheating

factory soldered joints to

prevent the possibility of

leakage.

5. Insulate fan-coil piping to

auxiliary drain pan connections

and any piping that is not above

the auxiliary drain pan.

Figure 9. Remove the shipping

brackets which support the

factory piping package before

connecting piping.

24 UNT-IOM-6

Page 25

Installing the

Auxiliary Drain

Pan

The auxiliary drain pan ships loose with a fan-coil unit with factory

piping. To install the auxiliary drain pan, insert the tabs, located on

the side of the drain pan, into the slots located in the chassis end

panel. Slide the pan into the narrow groove section to lock into place.

See Figures 10 and 11. Make sure the auxiliary pan is pushed all the

way into the fully locked position.

Note: The function of the auxiliary drain pan is to collect condensate

from the main drain pan and the factory installed piping package only.

It also provides a convenient field connection for the condensate

drain line for units without factory piping. Moreover, the auxiliary drain

pan may not be adequate to collect condensate from a field-installed

piping package. Apply additional insulation as needed.

Connecting the

Condensate Drain

Figure 10. Insert the auxiliary

drain pan tabs into these slots

in the fan-coil chassis end

panel.

1. De-burr the pipe end before making the connection to the drain pan.

2. Connect a 7/8 inch O.D. copper pipe or tube, with a 0.20 inch wall

thickness, to the auxiliary drain pan. This should be a mechanical

connection that allows easy removal of the auxiliary drain pan when

servicing the piping end pocket.

3. Slide the copper pipe over the drain pan nipple and tighten the

collar on the pipe with a hose clamp (installer supplied).

Maintain a continuous drain line pitch of 1 inch per 10 feet of drain line

run to provide adequate condensate drainage. Extend the drain line

straight from the drain pan a minimum distance of 6 inches before

making any turns. The installer must provide proper support for the

drain line to prevent undue stress on the auxiliary drain pan.

Install a secondary overflow drain line if necessary by punching out

the overflow drain nipple on the auxiliary drain pan. Next, place a 3/8

Figure 11. The horizontal

auxiliary drain pan in its

installed position.

UNT-IOM-6 25

Page 26

inch inside diameter flexible plastic tube over the nipple and secure

with a field supplied hose clamp.

Note: The installer is responsible for adequately insulating field

piping. See the External Insulating Requirements section on page 20

for more information.

Condensate

Overflow

Detection Device

Automatic

Changeover

Sensor

The condensate overflow detection device is an option on fan-coil

units with either a Tracer

The float switch, mounting bracket, and coiled leads ship attached

inside the piping end pocket of the unit. Install the switch by placing

the hole or slot in the bracket over the condensate overflow drain (of

the auxiliary drain pan) with the switch float extending over the pan.

Secure the drain pan by attaching the pans bracket with the factory

provided clip. See Figures 12 and 13.

Figure 12. Condensate

overflow switch installed in a

vertical auxiliary drain pan.

Two-pipe changeover units with either the Tracer

ZN.520 or TUC control have an automatic changeover sensor that

determines heating or cooling mode based on the supply water

temperature. On units with a factory piping package, the factory

straps the changeover sensor to the piping supply water pipe. See

Figure 14 on page 27.

®

ZN.010, ZN.510, ZN.520 or TUC control.

Figure 13. Condensate

overflow switch installed in a

horizontal auxiliary drain pan.

®

ZN.010, ZN.510,

If the unit does not have a factory piping package, the factory attaches the sensor and coiled lead wires to the piping side end panel.

The installer should attach the sensor parallel to and in direct contact

with the supply water pipe.

Note: The installer is responsible to ensure the changeover sensor is

installed in a location that can sense active water temperature.

Otherwise, the unit may fail to sense the correct operating mode and

disable temperature control.

26 UNT-IOM-6

Page 27

When using field supplied 3-way valves, position the changeover

sensor upstream of the valve on the supply water pipe.

Recommendation: When using field supplied 2-way control

valves, attach the changeover sensor in a location that will

detect an active water temperature. The unit must always be

able to sense the correct

system water temperature,

regardless of the control valve

position.

Note: The maximum length of

the automatic changeover wire

cannot exceed 10 feet from the

control panel. If the sensor

extends beyond the unit chassis,

use shielded conductors to

eliminate radio frequency

interference (RFI).

Figure 14. The changeover

sensor strapped to the supply

water pipe.

Automatic Electric

Heat Lockout

Switch (Fan-coil)

Two-pipe fan-coil units with auxiliary electric heat have an automatic

electric heat lockout switch that disengages the electric heat when

hydronic heat enables. If the unit has a factory piping package and

electric heat, the factory attaches the switch to the supply water

pipe. When the lockout switch detects the supply water temperature

above 95° F, it disengages the

electric heat. This eliminates

electric heat and hydronic heat

working simultaneously.

If the fan-coil unit does not have

a factory piping package, the

factory attaches the switch and

coiled lead wires to the piping

side end panel. The installer

should position the lockout

switch on the supply water line of

the unit by sliding its spring

connector over the pipe.

See Figure 15.

Figure 15. Units with electric

heat have an electric heat

lockout switch on the supply

water pipe.

UNT-IOM-6 27

Page 28

Venting the Hydronic

Coil

The hydronic coil contains a vent, either manual or automatic, to

release air from the unit. This vent is not sufficient for venting the

water piping system in the building.

Locate the coil air vent on the piping side, above the coil connections

on the unit. Perform the following steps to vent the coil after installing

the unit. See Figure 16.

1. Pressurize the building piping system with water and vent any

trapped air at system vents.

2. For units with manual air vents, back the set screw out to expel air

from the unit and then re-tighten the set screw.

The automatic air vent should require no adjustment for the coil to

vent. However, if the coil does not vent immediately, unscrew the outer

portion of the fitting to expel air from the port.

If debris has become trapped in the vent, completely remove the outer

portion of the fitting and clean.

Figure 16. The hydronic coil air vent is above the coil

connections. A horizontal unit is on the left and a vertical on

the right.

28 UNT-IOM-6

Page 29

Balancing The Manual

Circuit Setter Valve

The manual circuit setter valve is an optional end valve supplied on

the return pipe of the factory piping package. The valve allows the

operator to regulate water flow through the hydronic coil, balance the

water flow through the unit with other units in the piping system, and

serves as a shutoff or end valve. See Figure 17.

Follow the procedure below to set maximum water flow through the

coil.

1. Establish water flow through the coil. Perform an open override of

the valve if the control valve is closed to the coil, either manually or

®

by Tracer

.

If the piping package has 2-position, normally closed valves:

Drive open the valve using a 24V signal.

If the piping package has 2position, normally open

valves:

Manually drive open the valve by

removing power to the valve.

If the piping package has

modulating valves:

To manually drive the valve open,

depress the button stem on top

of the valve and push the lever

located on the side of the valve to

Figure 17. Manual circuit setter

valve.

the full open position.

2. For presetting, use the appropriate valve curve shown in Figure 19

on page 30 to determine which setting is necessary to achieve the

appropriate pressure drop.

3. Carefully remove the Schrader pressure port connection caps on

the manual circuit setter, since they will be at the same temperature

as the pipeline.

4. Bleed all air from the hoses and meter before reading the pressure

drop. Refer to the gauge operating instructions.

5. Adjust the circuit setter valve by turning the valve stem until the

appropriate pressure drop is achieved. See Figure 18 on page 30.

6. After achieving the proper setting, slightly loosen the two socket

head cap screws and rotate the memory stop around until it

touches the back side of the indicator. Then tighten the screws to

UNT-IOM-6 29

Page 30

securely set the open memory position. The memory stop indicates

the last set open position.

7. If using a 3-way valve: close the control valve to the coil, with the

differential pressure meter still

connected. This will divert flow to

the bypass side of a 3-way valve.

Adjust the balancing fitting to

obtain the same pressure drop

across the circuit setter valve as

in step 2 when the control valve

was open to the coil.

Figure 18. Close-up view of

manual circuit setter valve.

Figure 19. Setting the manual circuit setter valve, differential

pressure vs. flow.

30 UNT-IOM-6

Page 31

Balancing The Automatic Circuit Setter

Valve

The automatic flow valve is an

optional end valve on the return of

the factory piping package.

See Figure 20. The valve regulates water flow through the coil

to a specific (gpm) flow rate, as

ordered by the customer.

The automatic flow valve controls

to the specified flow rate, provided that the pressure drop

across the valve is within a

certain range. To verify that the

valve is operating properly, remove the protective caps from the P/T

ports and measure the pressure drop across the valve with a differential pressure meter. Carefully remove the P/T port connection caps,

since they will be at the same temperature as the pipeline. The

reading should be within the given ranges in Table 2. If the pressure

drop is not within the ranges listed, the valve will not control water

flow. If the valve orifice becomes clogged with debris, remove water

from piping and then remove the cap of the valve body and push on

the piston to dislodge any foreign matter. If this is not successful,

remove the cartridge and clean.

Figure 20. Automatic circuit

setter valve.

Table 2. Automatic Circuit Setter Flow Rate Range.

Valve gpm Pressure Drop Range (psig)

0.5 to 8.0 2 to 32

9 to 12 5 to 50

Replace the cartridge in the field without breaking the piping line to

furnish a higher or lower gpm. To do this, remove the water from the

system. Remove the cap assembly containing the plug from the valve

body. Grasp the cartridge by the piston to remove. Install a different

spring if the pressure drop range of the valve is being changed also.

UNT-IOM-6 31

Page 32

Duct Connections

The units airflow configuration varies dependent on the model and

options ordered. A one-inch duct collar is provided on units with a

ducted return and/or discharge to attach ductwork to the unit.

The Trane Company recommends using galvanized sheet metal

ductwork with fan-coil and cabinet heater units. Slide the sheetmetal

duct over the duct collar flange of the unit, seal the joint and fasten

with sheetmetal screws.

Note: Do not run screws through the removable front panel on concealed units.

Install all air ducts according to National Fire Protection Association

standards for the Installation of Air Conditioning and Ventilating

Systems (NFPA 90A and 90B).

Ductwork

Recommendations

Follow the general recommendations listed below when installing

ductwork for the unit.

· Discharge ductwork should run in a straight line, unchanged in size

or direction, for a minimum equivalent distance of 3 fan diameters

from the unit (approximately 20 inches).

· When making duct turns and transitions avoid sharp turns and use

proportional splits, turning vanes, and air scoops when necessary.

· When possible, construct, and orient supply ductwork turns in the

same direction as the fan rotation.

32 UNT-IOM-6

Page 33

Electrical Connections

Supply Power

Wiring

Refer to the unit nameplate to obtain the minimum circuit ampacity

(MCA) and maximum fuse size (MFS) or maximum circuit breaker

(MCB) to properly size field supply wiring and fuses or circuit breakers. See Figure 2 on page 6 to reference the nameplate location.

Refer to the unit operating voltage listed on the unit wiring schematic,

submittal, or nameplate. Reference the wiring schematic for specific

wiring connections.

WARNING: Hazardous voltage! Disconnect all

!

electric power including remote disconnects before

servicing. Failure to do so may cause severe personal

injury or death.

Wiring diagrams are attached to the unit in a plastic bag and can be

be easily removed for reference. Wiring schematics are attached as

follows:

· Vertical cabinet & recessed units:

Schematics are on the inside of the front panel. See Figure 21.

· Vertical concealed & all horizontal units:

Locate schematics on the fan and motor panel of unit. See Figure 22.

CAUTION: Use copper conductors only! Unit

!

terminals are not designed to accept other types of

conductors. Failure to do so may cause damage to the

equipment.

Figure 21. Locate the wiring

schematic on the inside of the

front panel of vertical cabinet

and recessed units.

Figure 22. Locate the wiring

schematic on the fan and

motor panel of vertical

concealed and all horizontal

units. (This unit is turned on

it's side.)

UNT-IOM-6 33

Page 34

All field wiring should conform

to NEC and all applicable

state and local code requirements.

The control panel box is

always on the end opposite

the piping connections.

Access the control box by

removing the two screws that

secure the front cover. If the

unit has a terminal unit control

board (TUC), remove the screw

in the top right corner of the

panel. This will allow the panel

to pivot downward to provide

access to the electrical

components. See Figure 23.

WARNING: Insulate all power wire from sheetmetal

!

Figure 23. The terminal unit

control (TUC) board pivots

downward to provide service

access.

ground. Failure to do so may cause electrical shorts

resulting in personal injury or death.

Units have one of three different connection points, depending on the

unit type and options.

1. Power & ground inside of control box:

®

If the unit has a fan mode switch, Tracer

ZN.010 or ZN.510 control

without a disconnect switch, the power leads and capped ground

wire are inside the control panel.

2. Power & ground inside the junction box:

If the unit has a TUC control without a disconnect switch, the power

leads and capped ground wire are inside the junction box on the

control panel.

3. Power wired to switch on junction box & ground inside of junction

box:

If the unit has a disconnect switch, the power leads wire to the

junction box switch on the control panel. Pull the capped

ground wire into the junction box.

34 UNT-IOM-6

Page 35

Electrical

Grounding

Restrictions

All sensor and input circuits are normally at or near ground (common)

potential. When wiring sensors and other input devices to the Tracer

ZN.010, ZN.510, ZN.520 or TUC, avoid creating ground loops with

grounded conductors external to the unit control circuit. Ground loops

can affect the measurement accuracy of the controller.

CAUTION: Unit transformer IT1 provides power to

!

fan-coil unit only. Field connections to the transformer

IT1 may create immediate or premature unit component

failure.

All input/output circuits (except isolated relay contacts and optically

isolated inputs) assume a grounded source, either a ground wire at

the supply transformer to control panel chassis, or an installer

supplied ground.

Note: Do not connect any sensor or input circuit to an external ground

connection.

®

Wall Mounted

Control

Interconnection

Wiring

The installer must provide interconnection wiring to connect wall

mounted devices such as a fan mode switch or zone sensor module.

Refer to the unit wiring schematic for specific wiring details and pointto-point wiring connections. Dashed lines indicate field wiring on the

unit wiring schematics. All interconnection wiring must conform to

NEC Class 2 wiring requirements and any state and local requirements. Refer to Table 3 for the wire size range and maximum wiring

distance for each device.

Recommendation: Do not bundle or run interconnection wiring

in parallel with or in the same conduit with any high-voltage

wires (110V or greater). Exposure of interconnection wiring to

high voltage wiring, inductive loads, or RF transmitters may

cause radio frequency interference (RFI). In addition, improper

separation may cause electrical noise problems. Therefore, use

shielded wire (Beldon 83559/83562 or equivalent) in applications

that require a high degree of noise immunity. Connect the shield

to the chassis ground and tape at the other end.

Table 3. Maximum Wiring Distances, ft (m)

Device Wire Size Range

Max. Wiring Distance

Fan Mode Switch 14 - 22 AWG

500 (152.4)

Zone Sensor Module 16 - 22 AWG

200 (60.96)

UNT-IOM-6 35

Page 36

Installing Wall Mounted Controls

Wall mounted controls, which include the fan mode switch and the

zone sensor module, ship loose inside the unit accessory bag.

Position the controller on an inside wall 3 to 5 feet above the floor and

and at least 18 inches from the nearest outside wall. Installing the

controller at a lower height may give the advantage of monitoring the

temperature closer to the zone, but it also exposes the controller to

airflow obstructions. Ensure that air flows freely over the controller.

Avoid mounting the controller in an area subject to the following

conditions:

· Dead spots such as behind doors or in corners that do not allow

free air circulation.

· Air drafts from stairwells, outside doors, or unsectioned hollow

walls.

· Radiant heat from the sun, fireplaces, appliances, etc.

Fan Mode Switch

Installation

Figure 24. Fan Mode Switch

· Airflow from adjacent zones or other units.

· Unheated or uncooled spaces behind the control, such as outside

walls or unoccupied spaces.

· Concealed pipes, air ducts, or chimneys in partition spaces behind

the controller.

The fan mode switch ships loose inside the unit accessory bag.

Follow the steps below to install the fan mode switch.

Items needed:

2 x 4 electrical junction box

1.Remove the brown wire if not using a field-supplied damper.

Remove the terminals, cut and strip wires as required for installation.

2.Level and position a 2 x 4 electrical junction box. Follow the

instructions given in the Interconnection Wiring section and route the

wires as shown in the wiring diagram. Refer to the typical wiring

diagram on page 101 or to the unit specific diagram on the unit.

3.Position the fan mode switch over the junction box with the two

screws supplied.

36 UNT-IOM-6

Page 37

Zone Sensor

Installation

Follow the procedure below to install the zone sensor module.

Reference Figure 25 on page 38 when installing the wall mounted

zone sensor.

1. Note the position of the setpoint adjustment knob and gently pry

the adjustment knob from the cover using the blade of a small

screwdriver.

2. Insert the screwdriver blade behind the cover at the top of the

module and carefully pry the cover away from the base.

3. To install the zone sensor module without a junction box

(directly to the wall):

a. Using the module base as a template, mark the the rectangular

cutout for the control wiring and module installation holes. Ensure

the base is level.

b. Set the base aside and make the cutout. Then, drill two 3/16

inch diameter holes approximately 1 inch deep. Insert and fully

seat the plastic anchors.

c. Pull the control wires through the cutout and attach the module

to the wall using the screws provided.

4. To install the zone sensor module to a standard junction box:

a. Level and install a 2 inch x 4 inch junction box (installer

supplied) vertically on the wall.

b. Pull the control wires through the cutout. Attach the module to

the wall using the screws provided.

5. Strip the insulation on the interconnection wires back 0.25 inch

and connect to TB1. Screw down the terminal blocks.

6. Replace the zone sensor cover and adjustment knob.

Before beginning installation, follow the wiring instructions in the Wall

Mounted Control Interconnection Wiring section on page 34. Also,

refer to the unit wiring schematic for specific wiring details and point

connections.

If installing a TUC zone sensor, see the TUC sections regarding

communication wiring beginning on page 60 for more detailed information.

UNT-IOM-6 37

Page 38

Wall mounted zone sensor

Model # Digit 31 = W

Figure 25. Wall mounted zone sensor dimensions.

Split-mounted option:

Wall mounted setpoint dial with unit

mounted fan mode switch

Model # Digit 31 = X

Figure 26. Resistance temperature curve for the zone sensor, entering water temperature sensor,

and discharge air sensor.

38 UNT-IOM-6

Page 39

Fan Mode Switch

Manual Fan Mode Switch

The manual fan mode switch is available for fan-coil units that do not

have Trane factory-mounted control packages. This four-position

switch (off-hi-med-lo) allows manual fan mode selection and is

available unit or wall mounted.

The unit-mounted option (Digit 31 = D) operates on line voltage. The

wall-mounted option (Digit 31 = K) is low-voltage and has three 24 volt

relays using a factory-wired transformer and relays to control the fan

motor.

Sequence of Operations

Off: Fan is turned off, two-position damper option spring-returns

closed.

Hi, Med, Lo: Fan runs continuously at the selected speed. The twoposition damper option opens to an adjustable mechanical stopposition.

UNT-IOM-6 39

Page 40

Tracer® ZN.010

and ZN.510

Tracer® ZN.010 and ZN.510

The Tracer® ZN.010

is a stand-alone

device that controls

fan-coils and cabinet

heaters. The Tracer

ZN.510 can be

stand-alone or utilize

peer-to-peer communications. The

controller is easily

accessible in the

control end panel for

service. The control

end panel is on the

end of the unit

opposite the piping.

Reference Figure 27.

®

Figure 27. The Tracer ZN.010 board.

Sequence of Operations

Off: Fan is off; control valves and fresh air damper option close. Low

air temperature detection option is still active.

Auto (Fan Cycling): Fan and fresh air damper cycle with control

valve option to maintain setpoint temperature. In cooling mode, the

fan cycles from off to medium and in heating mode it cycles from off

to low. When no heating or cooling is required, the fan is off and the

fresh air damper option closes.

Low/Med/High (Continuous Fan): Fan operates continuously while

control valve option cycles to maintain setpoint temperature. Fresh

air damper option is open.

40 UNT-IOM-6

Page 41

Tracer® ZN.010

and ZN.510

Operating

Information

Power-Up Sequence

Entering Water

Temperature

Sampling Function

When 24 VAC power is initially applied to the Tracer® ZN.010 or

ZN.510, the following sequence occurs:

1. All outputs are controlled off.

2. Tracer

initial values.

3. The random start time (0-25 seconds) expires.

4. Normal operation begins.

Both Tracer

sampling function to test for the correct water temperature for the unit

operating mode. For all applications not involving changeover, the

water temperature does not effect the unit operation.

The entering water temperature sampling function opens the main

hydronic valve, waits no more than three minutes to allow the water

temperature to stabilize, then measures the entering water temperature to see if the correct water temperature is available.

The entering water must be five degrees or more above the space

temperature to allow hydronic heating and five degrees or more below

the space temperature to allow hydronic cooling.

If the correct water temperature is available, the unit begins normal

heating or cooling operation. If the measured entering water temperature is too low or high, the controller closes the valve and waits 60

minutes before attempting to sample the entering water. Reference

Table 4.

®

ZN.010 and ZN.510 reads all input values to detemine

®

ZN.010 and ZN.510 use an entering water temperature

Table 4. Unit Mode as Related to Water Temperature

Unit Type EWT Sensor Required? Coil Water Temperature

2-pipe changeover Yes

4-pipe changeover Yes

2-pipe heating only No

2-pipe cooling only No

4-pipe heat/cool No

UNT-IOM-6 41

· Can cool if:

space temp - EWT

· Can heat if:

EWT - space temp

· Can cool if:

space temp - EWT

· Can heat if:

EWT - space temp

Hot water assumed

Cold water assumed

·Cold water assumed in main coil

·Hot water assumed in aux. coil

³ 5 deg F

³ 5 deg F

³ 5 deg F

³ 5 deg F

Page 42

Tracer® ZN.010

and ZN.510

Binary Inputs

BIP1: Low

Temperature

Detection

Option

BIP2: Condensate

Overflow Detection

Option

The factory hard wires the low temperature detection sensor to binary

input #1 (BIP1) on the Tracer

defaults normally closed (N.C.), and will trip off the unit on a low

temperature diagnostic when detecting low temperature. In addition,

the Tracer

Note: See the Diagnostics section on page 50 for more information.

The factory hard wires the condensate overflow sensor to binary input

#2 (BIP2) on the Tracer

normally closed (N.C.), and will trip off the unit on a condensate

overflow diagnostic if condensate reaches the trip point. In addition,

the Tracer

Reference Table 6 for the Tracer

outputs.

®

ZN.010 and ZN.510 control unit devices as listed below:

Fan: Off

Valves: Open

Electric heat: Off

Damper: Closed

®

ZN.010 and ZN.510 control unit devices as listed below:

Fan: Off

Valves: Closed

Electric heat: Of

®

ZN.010 and ZN.510. The sensor

®

ZN.010 and ZN.510. The sensor defaults

®

ZN.010 and ZN.510s six binary

BIP3: Occupancy

Sensor

42 UNT-IOM-6

Binary input #3 (BIP3) on Tracer® ZN.010 and ZN.510 is available for

field- wiring an occupancy sensor, such as a binary switch or a

timeclock, to detect occupancy. The sensor can be either normally

open or normally closed. Reference Table 5 on page 43.

Page 43

Tracer® ZN.010

and ZN.510

Table 5. Occupancy Sensor State Table

Sensor Type Sensor Position Unit Occupancy Mode

Normally Open Open Occupied

Normally Open Closed Unoccupied

Normally Closed Open Unoccupied

Normally Closed Closed Occupied

Binary Outputs

Table 6. Binary Outputs

Binary Output Description Pin

BOP1 Fan high speed J1-1

BOP2 Fan medium speed J1-2

BOP3 Fan low speed J1-4

BOP4 Main valve J1-5

BOP5 Auxiliary valve/electric heat J1-6

BOP6 2-position fresh air damper J1-7

Notes:

1. In a four-pipe application, BOP4 is used for cooling and BOP5 is

used for heating.

2. If no valves are ordered with the unit, the factory default for the

Tracer

BOP4 configured as normally closed

BOP5 configured as normally open

3. If the fresh air damper option is not ordered on the unit, BOP6 will

be configured as none.

®

ZN.010 and ZN.510 controller are:

UNT-IOM-6 43

Page 44

Tracer® ZN.010

and ZN.510

Analog Inputs

Table 7. Analog Inputs Available

Analog Input Description Application

Zone Space temperature Space temperature detection

Set Local setpoint Thumbwheel setpoint

Fan Fan mode input Zone sensor fan switch

Analog input 1 (AI1) Entering water temperature Entering water temperature detection

Analog input 2 (AI2) Discharge air temperature Discharge air temperature detection

Notes:

1.The zone sensor, entering water temperature sensor, and the discharge air temperature sensor are

10KW thermistors. Figure 26 on page 38 provides the resistance-temperature curve for these

thermistors.

2. Zone Sensor:

Wall mounted sensors include a thermistor soldered to the sensors circuit board

Unit mounted sensors include a return air sensor in the units return air stream.

3. Changeover units include an entering water temperature sensor.

Both Tracer® ZN.010 and ZN.510 accept a maximum of five analog

inputs. Reference Table 7.

Zone Sensors

Fan Mode Switch

44 UNT-IOM-6

The zone sensors available with the Tracer® ZN.010 and ZN.510

provide up to three different inputs

1. Space temperature measurement (10K thermistor)

2. Local setpoint

3. Fan mode switch

Wall mounted zone sensors include a thermistor as a component of

the internal printed circuit board. Unit mounted zone sensors use a

sensor placed in the units return air stream.

Each zone sensor is equipped with a thumbwheel for setpoint

adjustment.

The zone sensor may be equipped with a fan mode switch. The fan

mode switch offers selections of off, low, medium, high, or auto.

Reference Table 8 on page 45 for fan mode operation.

Page 45

Tracer® ZN.010

and ZN.510

Supply Fan

Operation

Table 8. Fan Mode Operation

Heating Mode Cooling Mode

Fan Mode Occupied Unoccupied Occupied Unoccupied

Off Off Off Off Off

Low Low Off/high (3) Low Off/high (3)

Medium Medium Off/high (3) Medium Off/high (3)

High High Off/high (3) High Off/high (3)

Auto

Continuous Heat default Off/high (3) Cool default Off/high (3)

CyclingOff/heat default Off/high (3) Off/cool default Off/high (3)

Notes:

1. During the transition from off to any fan speed but high, Tracer

starts the fan on high speed and runs for three seconds before transitioning to the selected speed (if it

is other than high). This provides enough torque to start all fan motors from the off position.

The Tracer® ZN.010 and ZN.510 will operate in either continuous fan

or fan cycling mode. The fan cycles when the fan mode switch is

placed in auto. The fan runs continuous when placed in the high,

medium, or low position. Use Rover, installation and service tool,

to change the auto defaults.

®

ZN.010 and ZN.510 automatically

2. When the heating output is controlled off, ZN.010 and ZN.510 automatically controls the fan on for

an additional 30 seconds. This delay allows the fan to dissipate any residual heat from the heating source,

such as electric heat.

3. Whenever two states are listed for the fan:

The first state (off) applies when there is not a call for heating or cooling.

The second state (varies) applies when there is a call for heating or cooling.

The heat default is factory configured for low fan speed, and the cool default is medium.

Table 9. Valid Operating Range and Factory Default Setpoints

Setpoint/Parameter Default Setting Valid Operating Range

Unoccupied cooling setpoint 85° F 40 to 115° F

Occupied cooling setpoint 74° F 40 to 115° F

Occupied Heating setpoint 71° F 40 to 115° F

Unoccupied heating setpoint 60° F 40 to 115° F

Cooling setpoint high limit 110° F 40 to 115° F

Cooling setpoint low limit 40° F 40 to 115° F

Heating setpoint high limit 105° F 40 to 115° F

Heating setpoint low limit 40° F 40 to 115° F

Power up control wait 0 sec 0 to 240 sec

UNT-IOM-6 45

Page 46

Yellow COMM LED

Red SERVICE LED

Tracer® ZN.010

and ZN.510

Troubleshooting

Green STATUS LED

LED Activity

Red Service LED

Table 10. Red Service LED Activity

Red LED Blink Activity

LED off continuously when power

is applied to the controller

LED on continuously, even when

power is applied to the controller

LED flashes once every second

Figure 28. The Tracer ZN.010 board.

Description

Normal operation

Someone is pressing the service button or the controller has failed.

Use Rover, Tranes service tool, to restore the unit to normal

operation. Refer to the Rover product literature for more information.

46 UNT-IOM-6

Page 47

Tracer® ZN.010

and ZN.510

Green STATUS LED

Table 11. Green STATUS LED Activity

Green LED Blink Activity Description

LED on continuously Power on (normal operation)

LED blinks once Manual output test mode

LED blinks twice Manual output test mode, with one or more diagnos-

LED blinks (1/4 second on, 1/4 second

off for 10 seconds) Wink mode

LED off · Power off

Note: The wink feature allows the identification of a particular controller. When sending a request from a

device, such as Rover, the controller will wink to indicate it received the signal.

The green LED normally indicates whether the controller is powered

on (24 VAC supplied). Reference Table 11.

tic present

· Abnormal condition

· Test button is pressed

Yellow COMM LED

Table 12. Yellow COMM LED Activity

Yellow LED Blink Activity Description

LED off continuously The controller is not detecting any communication.

(Normal for units in standalone applications)

LED blinks The controller detects communication.

LED on continuously Abnormal condition

UNT-IOM-6 47

Page 48

Tracer® ZN.010

and ZN.510

Manual Output

Test

Manual Output Test

Procedure

The purpose of the manual output test sequence is to verify output

and end device operation. Use the manual output test to:

· Verify output wiring and operation without using Rover,

service tool.

· Force the water valve to open and balance the hydronic system.

Note: The manual output test is not an automatic cycle. You must

press the Test button to proceed through each step.

The controller observes all diagnostics that occur during the test

sequence. Although an automatic diagnostic reset sequence exists

as part of the controllers normal operation, the automatic diagnostic

reset feature is not active during the test sequence.

If left in an individual test step, the controller remains in test mode

for 60 minutes and then exits to normal operation.

Many service calls are due to unit diagnostics. The test sequence

resets unit diagnostics and attempts to restore normal unit operation