Page 1

Product Catalog

Direct-Fired Make-Up

Air Units

DFIA

DFOA

November 2009

MUA-PRC007-EN

Page 2

Introduction

Why use Trane Makeup Air Units…

Trane’s innovative Direct Fired gas heating systems add warm, fresh and clean air to your work

environment for about 20 precent less than the operation and maintenance costs of indirect gas

heat.

• Heats Without Complications: The Direct Fired gas heating system heats efficiently and cost-

• Replaces Indoor Air: The Direct Fired gas heating system replaces indoor air that can become

• Provides Ventilation: Fresh air is available simply by turning off the heating section.

• Cleans and Tempers Incoming Air: The optional filter bank removes airborne particles, and

• Trane offers two styles of Direct Fired gas heating systems:

What Is Make-Up Air?

Make-up air is an outside air supply that is brought in to relieve “air starvation.” Without make-up

air, a building is under a “negative” condition and the following will occur:

• Backdrafts in natural flues, ventilators and stacks.

• Reduced air volume handled by the exhaust fans and subsequently inadequate removal of

• Dispersal of contaminants throughout the work area by high velocity cross-currents from

• Uncomfortable and unhealthy working conditions.

• Pilot outages.

effectively using no heat exchanger.

chemical laden in an industrial process or commercial cooling application.

cleaned air is heated to create a more refreshing and comfortable indoor environment.

– Indoor units (DFIA)

– Large outdoor units (DFOA)

contaminants.

uncontrolled outside air sources.

When Is It Required?

Make-up air is required whenever exhaust fans are used. This need for a building “air change”

arises when there are:

• Processes which generate contaminants in the form of noxious fumes or dust.

• Activities which create excessive heat or undesirable odors.

• Hazardous material storage areas.

• Ventilation requirements for a building’s inhabitants.

• State and local code requirements.

Why Use Make-Up Air Units?

Outside air should not be allowed to drift in through windows, door cracks and other openings,

creating a strain on the heating system. Outside air should be controlled, tempered and

coordinated with the exhaust by a make-up air unit. The latter is reliable, efficient and does not

disrupt building activities.

Why Use Direct Gas-Firing?

Maximum economy is realized with direct gas-firing because the incoming air is heated directly in

the burner chamber. This provides 100 percent efficiency (92 percent sensible, 8 percent latent)

while eliminating a heat exchanger or combustion chamber that could burn out or corrode.

Trane direct-fired units are factory tested, include the necessary controls for operating the system

and generally cost less than alternate systems.

© 2009 Trane All rights reserved MUA-PRC007-EN

Page 3

Introduction

Installation is simple since the unit, (when shipping permits), is shipped as a complete package.

The burner is fully modulating, with a minimum firing rate of four percent of full input. This

characteristic results in just the right amount of heat under all operating conditions.

Industry Approval

ETL Labeling Requirements

A DFOA/DFIA unit can bear the ETL label if:

• The unit airflow is within the SCFM range shown in Tabl e 3 , p . 18 (DFIA) and Table 12, p. 33

(DFOA).

• The fuel is natural gas with a temperature rise not greater than 130°F or the fuel is LP and the

temperature rise not greater than 100°F.

• The motor is a single speed motor, or if the motor is a two speed motor, the burner will operate

in only one of the two speeds (high or low speed).

• Unit components are standard (there are exceptions to this).

• If the unit has return air, the unit must have a mixing box with the AdaptAire airflow station.

Maximum Emission Levels:

• If the unit has an ETL label, the maximum levels of the products of combustion meet

ANSI Z83.18 which are:

• Carbon Dioxide 4000 ppm

• Carbon Monoxide 5 ppm

• Aliphatic Aldehydes 1 ppm

• Nitrogen Dioxide 0.50 ppm

CETL Labeling Requirements (Canada)

A DFOA/DFIA unit will have a CETL label if the unit meets the first five items of “ETL Labeling

Requirements” (above), AND the unit does not have return air.

Trademarks

Trane and the Trane logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

MUA-PRC007-EN 3

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The Need for Make-Up Air Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

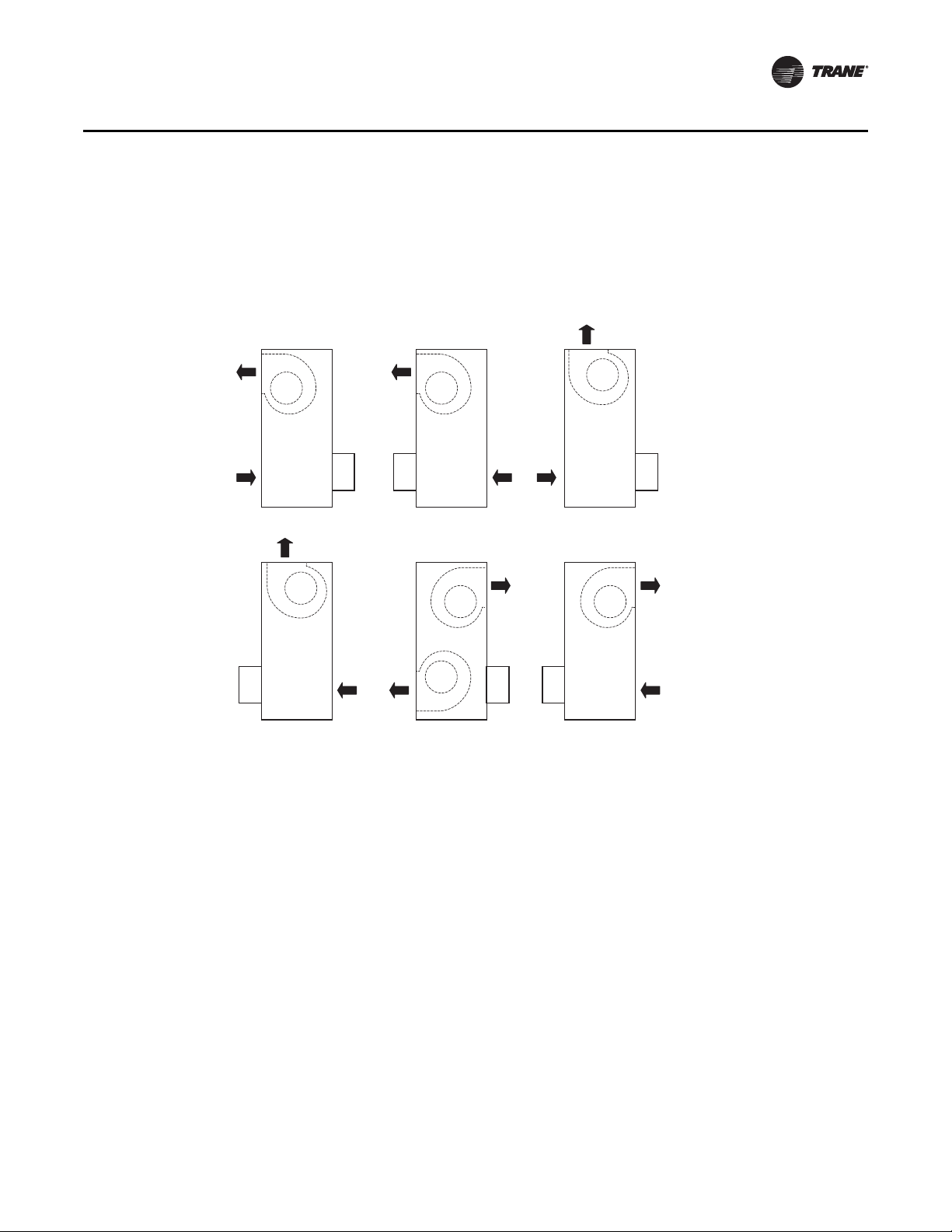

Unit Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Horizontal Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vertical Configurations (DFOA only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vertical Configurations (DFIA only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

DFIA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Outdoor Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

What Fuel to Use? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Burner Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reliable Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Equipment Approval Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Special Construction Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DFOA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Basic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gas-Fired Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Motorized 75/25 Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mixing Box—Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mixing Box—Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mixing Box—Building Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Motorized Inlet Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Exhaust Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4 MUA-PRC007-EN

Page 5

UV Flame Sensor (UV Mini-Peeper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Optional Gas Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Factory Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Additional Options* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Additional Factory Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Field Installed Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

MUA-PRC007-EN 5

Page 6

Application Considerations

The Need for Make-Up Air Units

When more air is exhausted from a building than is supplied by the mechanical systems, the

building is under a “negative” condition. Air will leak into the building through cracks, windows,

and doors.

• Make-up air units are typically used to compensate for air being exhausted from a building or

other structure.

• Application for closed systems such as ovens or paint booths (consult home office).

• For use as a door heater where outside air is heated and not prevented from infiltrating.

• The DFOA/DFIA can be used as an air handler, no burner section. Can also be used with DX,

electric, CW, HW and steam coils. Contact your Trane representative.

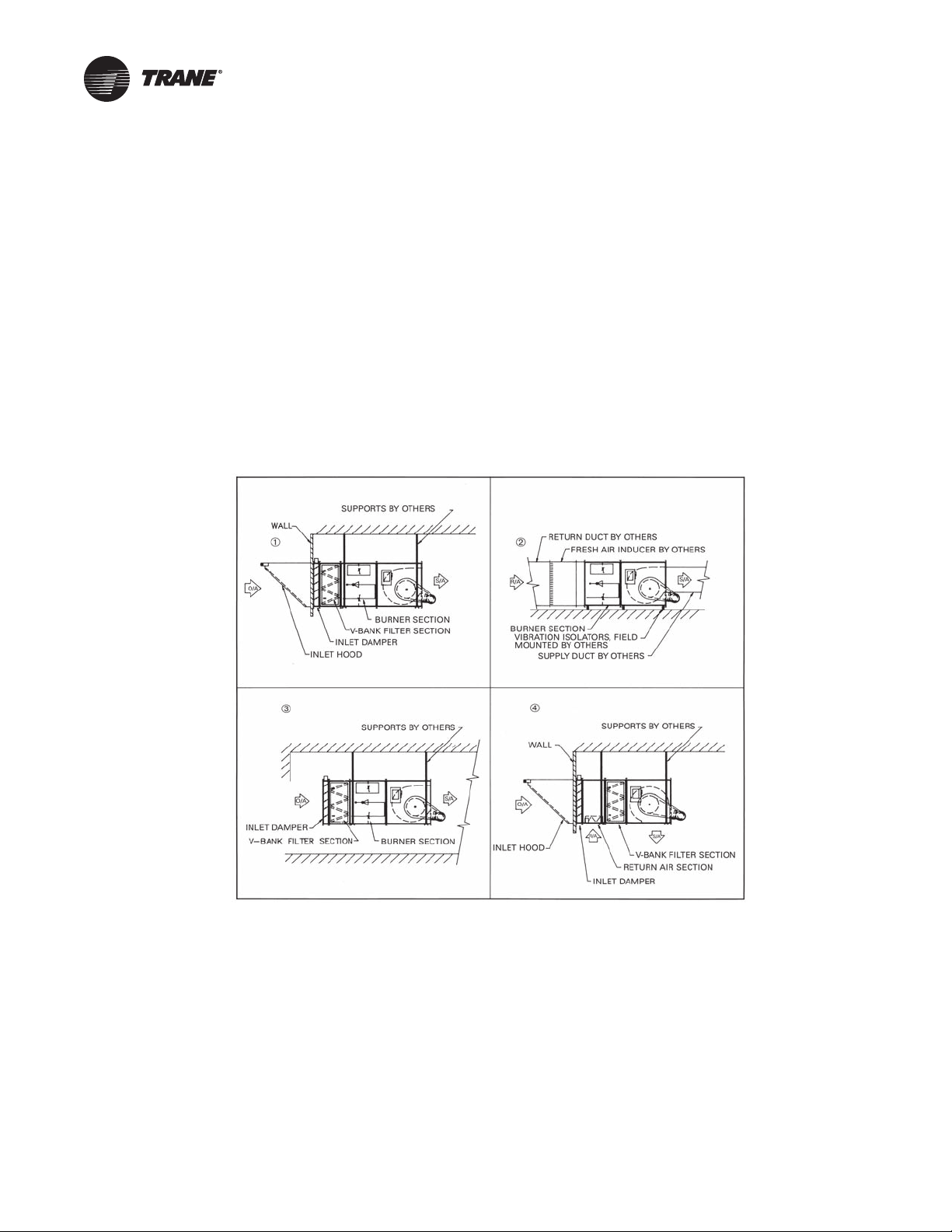

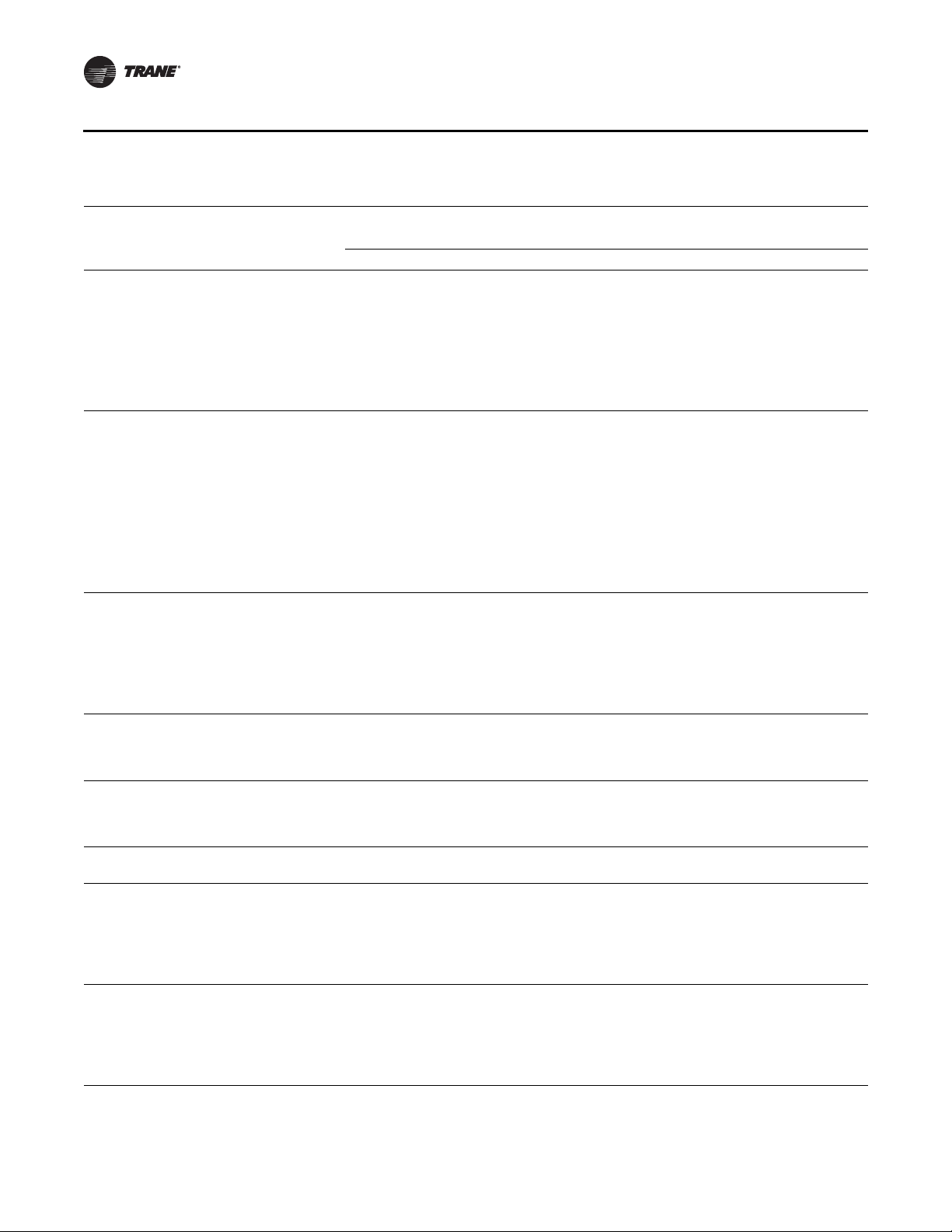

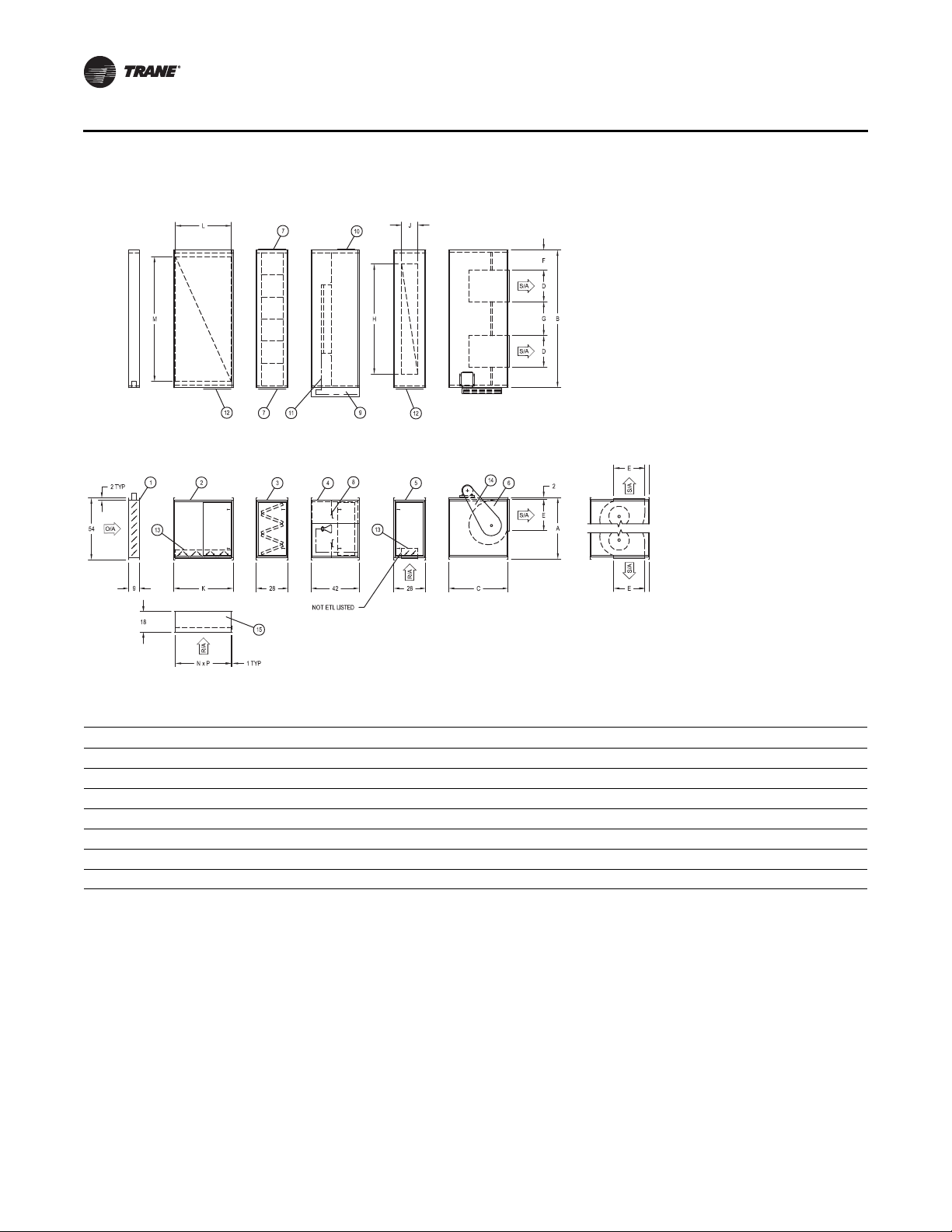

Figure 1. Application and various modular arrangements (DFIA only)

Outdoor Units

Outdoor make-up air units are the most common approach to relieving negative pressure inside

commercial and industrial facilities. All units offer the advantage of a full support system that is

watertight, provides a plenum for return air, and has easily accessible piping and electrical

connections.

When a negative condition exists:

• Flues and stacks may experience a backdraft and cause dangerous contaminants to remain in

the occupied space. In the case of flues, the products of combustion may condense and corrode

the equipment.

• Under negative conditions, the exhaust system sees a greater static pressure. The capacity of

each fan is reduced and this results in an inadequate removal of contaminants.

6 MUA-PRC007-EN

Page 7

• Drafts and cross-currents will increase in a negative condition, causing an uncomfortable or

What Fuel to Use?

The most common fuel for heating make-up air is natural gas. This is because 100 percent of the

energy goes into the air stream (92 percent sensible, 8 percent latent). Direct firing eliminates the

need for heat exchangers or combustion chambers that can corrode or leak. Natural gas is often

the least expensive fuel and is usually readily available.

Note: Selected horizontal and vertical units are available with special coil options (DX, chilled

Application Considerations

unhealthy work environment.

water, steam or electric).

MUA-PRC007-EN 7

Page 8

Selection Procedure

Calculating Total External Static Pressure to Determine Fan Motor Horsepower. To

determine the fan motor horsepower, use the following steps:

1. Select Unit

– Determine cabinet size and cfm

2. Determine Static Pressure of Optional Accessories

– Add the static pressures of the optional accessories.

3. Determine External Static Pressure

– Calculate external static pressure of system due to ductwork, grilles, etc. This is the static

pressure external to the DFIA/DFOA unit and is up to the system designer to determine.

4. Calculate Total External Static Pressure

– Add the static pressures of the optional accessories to the external static pressure to

determine total external static pressure.

5. Use the Tabl e 1 , p . 1 6 (DFIA) and Table 10, p. 31 (DFOA) to determine the fan motor horsepower.

Example:

1. Specification calls for a 40,000 cfm unit. Select a size 225.

2. Unit will require an inlet hood, inlet damper and a v-bank filter. Therefore,the static pressure

of the optional accessories is 0.51 in. wc.

Fresh air inlet hood and birdscreen 0.13 in. wc

Motor operated inlet damper 0.13 in. wc

V-bank filter section 0.25 in. wc

Static pressure of optional accessories 0.51 in. wc

3. Engineer has determined that the external static pressure due to the ductwork is 0.75 in. wc.

4. Static Pressure of optional accessories 0.51 in. wc

External static pressure 0.75 in. wc

Total External Static Pressure 1.26 in. wc

5. For a size 225 unit at 40,000 cfm and 1.26 in. total external static pressure, a 30 hp fan motor will

be required.

8 MUA-PRC007-EN

Page 9

Burner Selection Procedure

For DFIA selections, use Tab l e 3 , p . 18, and select next size larger available burner. For DFOA

selections, use Table 12, p. 33.

Note: Table is based on an entering air temperature of -40°F.

Example: an 80°F temperature rise is desired for 18000 scfm.

The table shows a MBh input of 1788 MBh.

Select the 1925 MBh input burner (Digit 14, 15 = AH)

OR

Use the following formula:

MBh input = (0.6210 x scfm x TR)

(0.6210 X ) / (460 + TR + EAT)

where:

TR = Temperature Rise (Desired leaving air temperture – entering air temperature)

EAT = Temperature Rise (Desired leaving air temperture – entering air temperature)

Selection Procedure

(460 + 80 + 10)

Example: A desired leaving air temperature of 90°F is required for 18000 scfm.

The entering air temperature is 10°F.

Temperature rise (TR) = 90 – 10 = 80°F

MBh input = (0.6210 x 18000 x 80)

(460 + 80 + 10)

Select the 1650 MBh input burner (Digit 14, 15 = AG)

= 1626 MBh input

MUA-PRC007-EN 9

Page 10

Unit Configuration

Fan Arrangement #4

Side Discharge

Fan Arrangement #6

Side Discharge

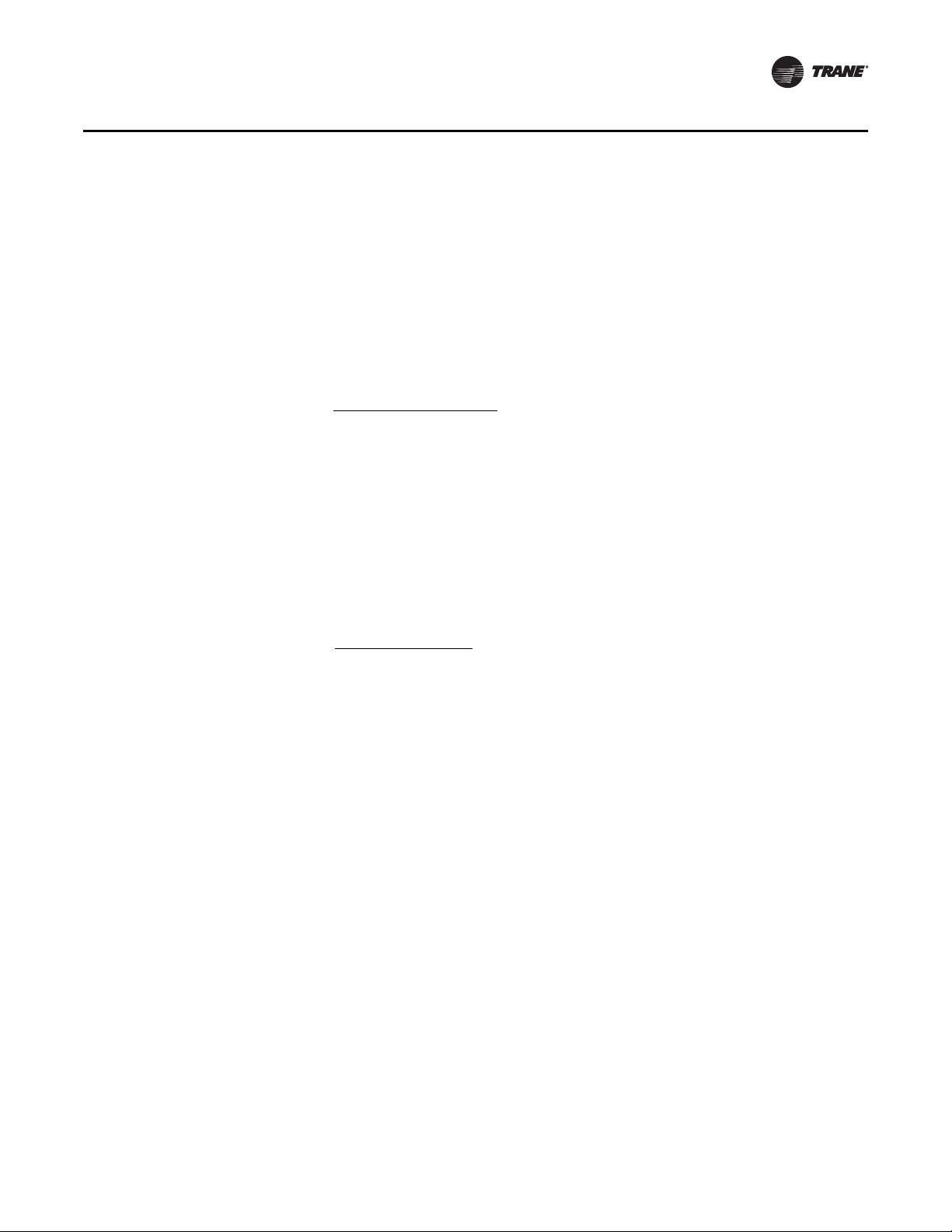

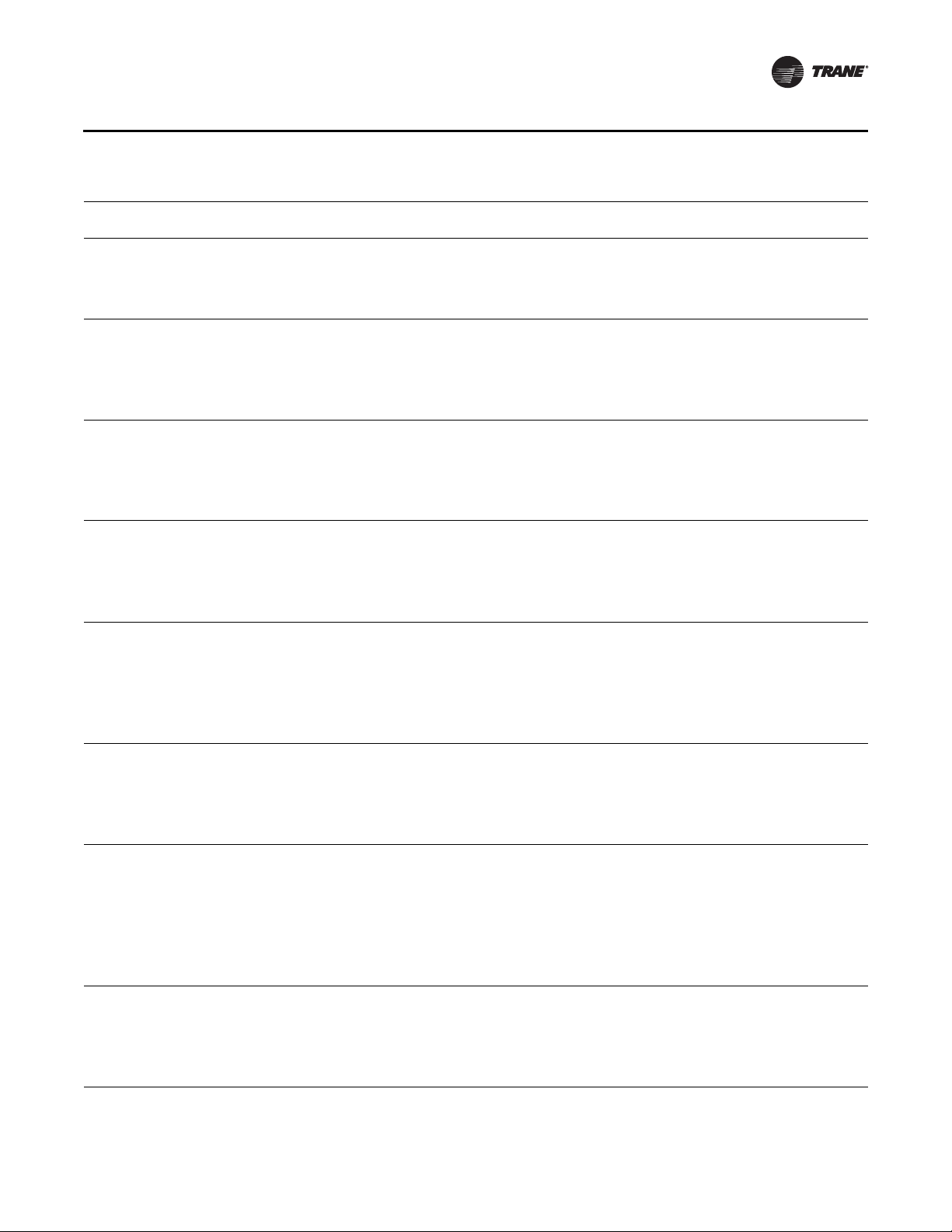

Horizontal Configurations

For all arrangements shown, controls, gas piping and fan motor are on the near side. Selected

horizontal units are available with special options — cooling coils (DX, chilled water), steam and

electric coils, no burner section. Contact your Trane representative for availability and pricing.

Figure 2. Horizontal configurations

Fan Arrangement #1

Top Discharge (For outdoor only)

Fan Arrangement #2

Side Discharge

Vertical Configurations (DFOA only)

For all arrangements shown, the gas piping and controls are on the near side. Selected vertical units

are available with special options — steam and electric coils, no burner section.

Figure 3. Vertical configuration (DFOA only)

Fan Arrangement #3

Bottom Discharge

10 MUA-PRC007-EN

Page 11

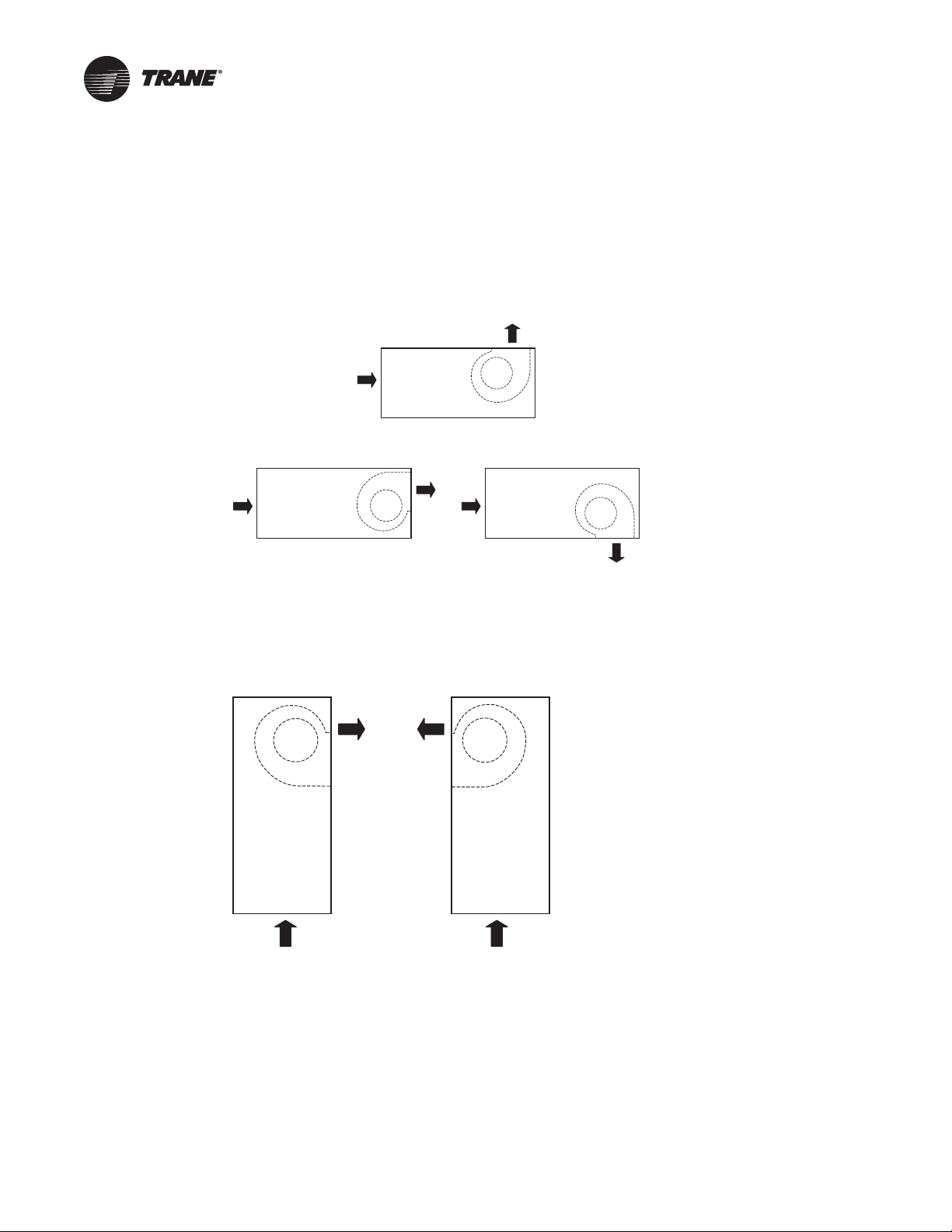

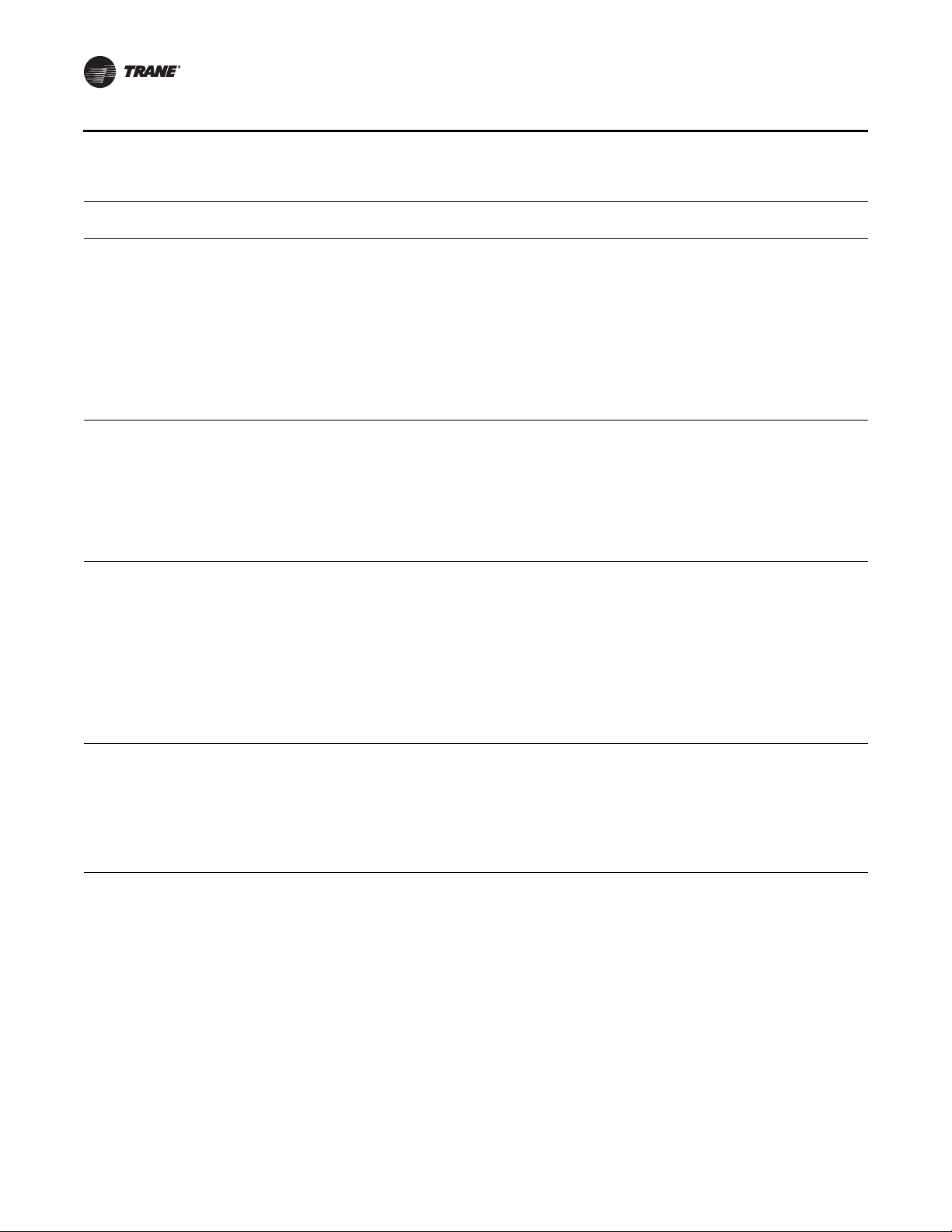

Vertical Configurations (DFIA only)

Fan Arrangement #9

Side Discharge

Fan Arrangement #6

Top Discharge

EC

EC

Fan Arrangement #8

Side Discharge

Fan Arrangement #5

Side Discharge

EC

EC

Fan Arrangement #7

Top Discharge

Fan Arrangement #4

Side Discharge

EC

EC

For all arrangements shown, the gas piping is on the near side. The electric control cabinet (EC) and

disconnect are on the side opposite the air entering side. Selected vertical units are available with

special options – steam and electric coils, no burner section. Contact your Trane representative for

availability.

Figure 4. Vertical configurations (DFIA only)

Unit Configuration

MUA-PRC007-EN 11

Page 12

DFIA

Model Number Descriptions

Digit 1, 2, 3 — Unit Description

DFI = Direct fired indoor unit

Digit 4 — Development

Sequence

A = First Generation

Digit 5 — Unit Size

109 120 215 225

112 122 218 230

115 125 220

118 130 222

Digit 8 —Burner Section

0 = No Burner Section

1 = Burner Section

Digit 9 —Main Power Supply

A = 115/60/1 D = 208/60/3

B = 230/60/1 E = 230/60/3

C = 208/60/1 F = 460/60/3

Digit 10 — Design Sequence

H = Eighth Design

Digit 11 — Fuel

N= Natural Gas

P=LP (Propane) Gas

Digit 12 — Gas Control Option

E = Modulating Discharge Temp

Control (MDT)

F = Modulating Room Temp Control

(MRT)

G = Modulating Room Temp Control

& Pro Room Sensor (MRT Pro)

H = Modulating Room Temp Control

& BACview

Digit 13 — Gas Train Approvals

0 = No Selection

1=Standard Gas Train

3 = IRI Gas Train Approval (ETL)

4 = FM Gas Train Approval (ETL)

5 = IRI Gas Train Approval (No ETL)

6 = FM Gas Train Approval (No ETL)

®

(MRT Expert)

Digit 14, 15 — Burner Input

Rating (Natural Gas/Propane)

00 = No Burner Input Selection

AA = 275/225 MBh

AB = 550/450 MBh

AC = 825/885 MBh

AE = 1100/1125 MBh

AF = 1375/1350 MBh

AG = 1650/1575 MBh

AH = 1925/1800 MBh

AJ = 220 0/2025 MBh

AK = 2475/2475 MBh

AL = 2750/2700 MBh

AN = 3025/2925 MBh

AP = 3300/3150 MBh

AQ = 3575/3375 MBh

AR = 3850/3825 MBh

AT = 4125/4050 MBh

AV = 4400/4275 MBh

AW = 4675/4500 MBh

AX = 4950/4950 MBh

AY = 5225/5175 MBh

AZ = 5500/5400 MBh

A1 = 5775/5624 MBh

A2 = 6050/5850 MBh

A3 = 6325/6075 MBh

A4 = 660 0/6525 MBh

A5 = 6875/6750 MBh

A6 = 7150/6975 MBh

A7 = 7425/7425 MBh

A8 = 770 0/7650 MBh

A9 = 7975 MBh

BA = 8250 MBh

BB = 8525 MBh

BC = 8800 MBh

BD = 9075 MBh

Digit 16 — Blower Motor

Horsepower

0 = No Selection J = 10 hp

B = 3/4 hp K = 15 hp

C=1 hp L=20 hp

D = 1-1/2 hp M = 25 hp

E=2 hp P=30 hp

F=3 hp Q=40 hp

G= 5 hp R= 50 hp

H = 7-1/2 hp T = 60 hp

Digit 17 — Motor Speed and

Starter

0 = No Selection

1 = Single Speed odp 1800 rpm

2 = Single Speed tefc 1800 rpm

3 = Single Speed Ener. Effic odp

4 = Single Speed Ener. Effic tefc

5 = 2s1w odp 1800/900 rpm

6 = 2s2w odp 1800/1200 rpm

Digit 18 — Fan Arrangement

1 = Horizontal Arrangement 1 Top

2 = Horizontal Arrangement 2 Side

3 = Horizontal Arrangement 3 Bottom

4 = Vertical Arrangement 4 Side

5 = Vertical Arrangement 5 Side

6 = Vertical Arrangement 6 Top

7 = Vertical Arrangement 7 Top

8 = Vertical Arrangement 8 Side

9 = Vertical Arrangement 9 Side

Digit 20 — V-Bank Filter Section

0 = No V-Bank Filter Section

A = V-Bank Section with Permanent

Filters

B = V-Bank Section without

Permanent Filters

C = V-Bank Section with TA Filters

D = V-Bank Section with Pleated

Filters

Digit 21 — Dampers/Mixing Box

0 = No Damper/Mixing Box Selected

(No ETL)

A = Motorized Return Air Damper

(No ETL)

B = Motorized Damper 75/25 (No ETL)

C = Mixing Box - Temperature Control

(No ETL)

D = Mixing Box - Building Press

Control (No ETL)

E = Mixing Box - Manual Control

(No ETL)

F = Mixing Box with Airflow

Station - Manual Control (ETL)

G = Mixing Box with Airflow

Station - Temp Control (ETL)

H = Mixing Box with Airflow

Station - Bldg. Press Control (ETL)

Digit 22, 23 — Controls Opposite

from Standard

** = Standard Controls

AA = Controls Opposite from Standard

Digit 24, 25 — Motorized Inlet

Damper

** = No Motorized Inlet Damper

AB = Motorized Inlet Damper

Digit 26, 27 —Insulation

AC = Insulation on Entire Unit

(Include Filter)

Digit 28, 29 —115V Duplex

Service Receptable with Trans.

AJ = 115V Duplex Service Receptacle

with Trans.

Digit 30, 31 — Painted Cabinet

AZ = Painted Cabinet

DIGIT 32, 33 — UV Flame Sensor

AL = Ultraviolet (UV) Flame Sensor

12 MUA-PRC007-EN

Page 13

Digit 34, 35 —Clogged Filter

Indicator

AN = Clogged Filter Indicator

Digit 36, 37— Exhaust Interlock

AP = Exhaust Interlock

Digit 38, 39 — Interlocking Relay

AQ = Interlocking Relay

Digit 40, 41 — Omit Disconnect

Switch

DS = Disconect Switch

AT = Omit Disconnect Switch

Digit 42, 43 — High Gas Pressure

Regulator

CA = High Gas Press Reg 0.5–1 psi

AV = High Gas Press Reg –5 psi

AW = High Gas Press Reg 5–10 psi

BH = High Gas Press Reg Over 10 psi

Digit 44, 45 — Adjustable Drive

AX = Adjustable Drive

Digit 46, 47 — Low Gas Pressure

Burner

BJ = Low Gas Pressure Burner

Digit 48, 49 — Vibration Options

A5 = Vibration Feet

A6 = Vibration Hangers

Digit 50, 51 — Control Options

BD = 7-Day Time Clock

BG = On/off Night Setback Thermostat

BF = BACview

®

Remote Panel

Digit 52, 53 — Discharge Louver

AY = Discharge Louver

0=None

DFIA

MUA-PRC007-EN 13

Page 14

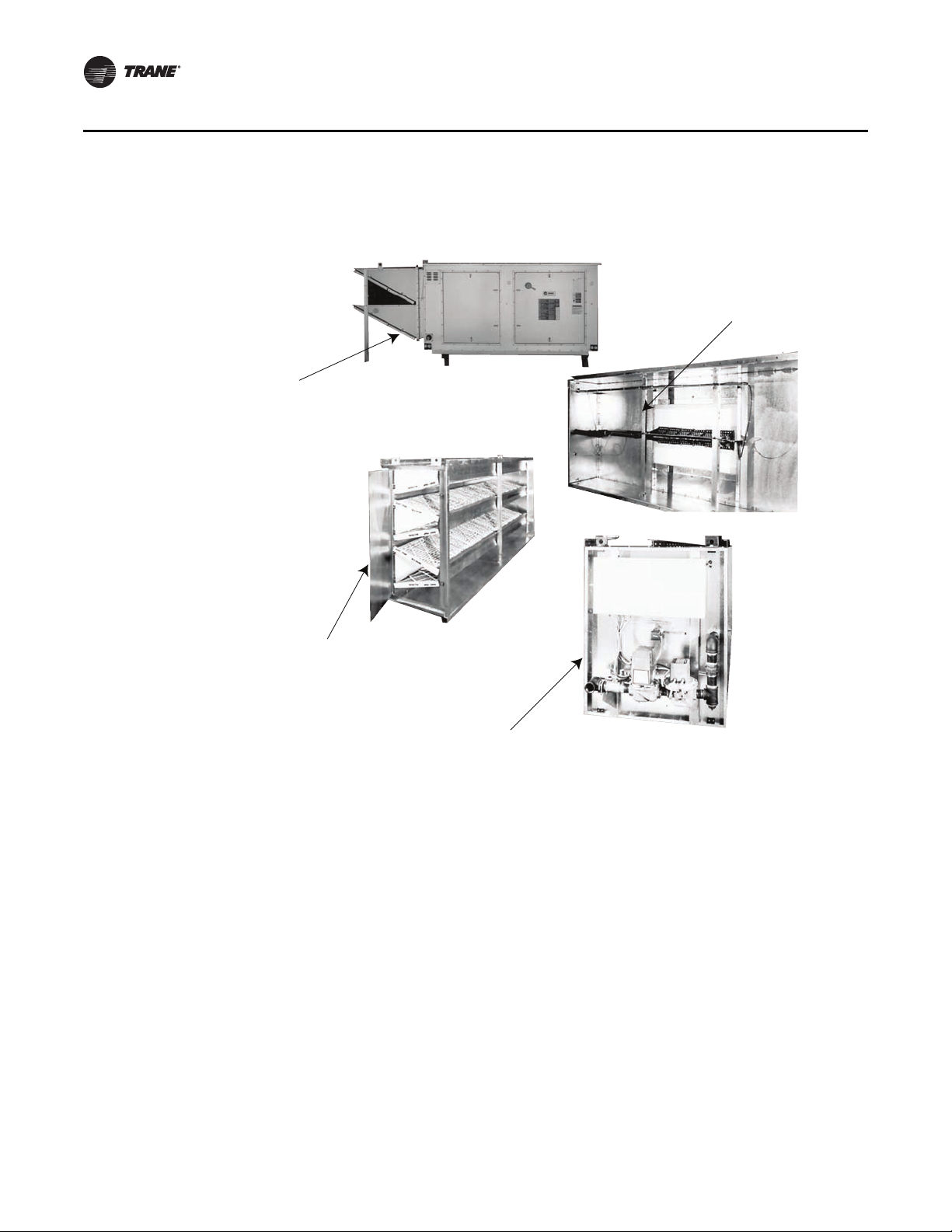

DFIA

Discharge fan section

Gas burner section

V-bank Filter with hinged access door

Gas manifold and control cabinet

Features and Benefits

Figure 5. DFIA features and benefits

14 MUA-PRC007-EN

Feature: Basic unit is factory assembled and wired.

Benefit: Reduces field installation cost.

Feature: Factory tested.

Benefit: Eliminates majority of field start-up problem caused by defective controls.

Feature: Adjustable motor mount.

Benefit: Belt tension can be field adjusted for maximum belt life.

Feature: All fuses factory furnished.

Benefit: Delay at start-up eliminated.

Feature: Return air cycle capability.

Benefit: Return air cycle results in fuel economy for pressurized heating systems and eliminates

need for two-speed fan operation. Minimizes heating cost.

Feature: No flues or stacks are used.

Benefit: Eliminates backdraft and dangerous contaminants from entering the space.

Page 15

Reliable Operation

The standard unit includes all of the controls needed for trouble-free operation.

If the designer does not utilize a master panel for consolidating mechanical equipment, an optional

remote control station should be ordered.

This device includes switches and signal lights for operating the make-up air unit and monitoring

its performance from any convenient location.

While rare, malfunctions can occur because a belt breaks, local power is interrupted or a

component fails. If this should happen, the unit’s control system is designed to take over. Its

overlapping fail-safe protective devices will turn on an alarm light and prevent burner operation

until the problem has been corrected.

Because of this attention to detail, combustion will be clean and odorless under the most adverse

conditions. The incoming “make-up air” will be at least five times purer than the requirements set

down by the U.S. Bureau of Standards.

Equipment Approval Options

Owners and specifiers have three very important reasons for wanting equipment approvals. One

reason is to establish a manufacturer’s reliability.

A second looks for conformance with equipment standards if any have been established for the

particular product. And finally, there may be requirements set down by an industrial user’s

insurance carrier.

Trane has gone to great lengths to satisfy these needs. In the first case, reliability is established for

our standard unit through conservative design and the use of U.L. listed components.

For industrial applications, the unit can also be furnished with special gas controls to comply with

FM or IRI. The latter is available for applications where the exact insurance approval agency has

not been established.

DFIA

Special Construction Features

• External bearings for easy service and lubrication.

• External motor for ease of service and belt maintenance.

• Hollow fan shaft on double blower models eliminate the need for a center bearing which is

difficult to service.

• Enlarged filter sections increasing filter life and reducing service time.

• Hinged filter access door.

• Service platform available as an option for easy maintenance on suspended units.

MUA-PRC007-EN 15

Page 16

DFIA

Performance Data

Table 1. Direct-Fired Indoor Air (DFIA) unit—General data

Unit Size 109 112 115 118 120 122 125 130 215 218 220 222 225 230

Airflow

Min. Airflow (cfm) 1600 3250 4 500 6500 9000 11000 14000 22000 9000 12500 18000 25000 30000 44000

Max. Airflow (cfm) 3000 4250 6 000 8500 11000 15000 20000 30000 12000 17000 26000 31000 46000 64000

Fan

Quantity - Wheel Size 1 - 9 1 - 12 1 - 15 1 - 18 1 - 20 1 - 22 1 - 25 1 - 30 2 - 15 2 - 18 2 - 20 2 - 22 2 - 25 2 - 30

Motor (hp) 1–5 1.5–5 2–7.5 3–10 5–10 5–15 7.5–20 10–30 5–15 7.5–20 7.5–25 15–30 15–50 20–60

Filters, 2-in

Quantity 4 4 9 9 10 10 24 24 18 18 35 35 42 42

Size (in) 20x20 20x20 20x16 20x16 20x25 20x25 20x16 20x16 20x15 20x15 20x16 20x16 20x20 20x20

Table 2. Direct-Fired Indoor Air (DFIA) unit—Performance data

Models

DFI

109 1–9

112 1–12

115 1–15

118 1–18

120 1–20

Note: Use the following static pressures for the optional accesso ries:

1. Motor Operated Inlet Damper: 0.13 in. wc

2. V-Bank Filter Section: 0.25 in. wc

3. Mixing Box: 0.40 in. wc

4. Discharge Louver: 0.13 in. wc

Blower

Size (in.)

Std Air

at 70

1600 1914 1111————

1900 2273 1 1 1-1/2 1-1/2 1-1/2 1-1/2 2 —

2200 2632 1-1/2 1-1/2 1-1/2 1-1/2 2 2 2 3

2600 3110 22223333

3000 3589 33333335

3250 2257 1-1/2 2222333

3500 2431 22223335

3750 2604 22333335

4000 2778 33333355

4250 2951 33333555

4500 2239 2233335—

5000 2488 33333555

5500 2736 33335555

6000 2985 35555557-1/2

6500 2265 35555557-1/2

7000 2439 5555557-1/27-1/2

7500 2613 555557-1/27-1/27-1/2

8000 2787 55557-1/27-1/27-1/27-1/2

8500 2962 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 10

9000 2143 55557-1/27-1/27-1/2—

9500 2262 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 —

10000 2381 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 10

10500 2500 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10

11000 2619 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10 10

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Total External Static Pressure (in. wc)

Horsepower

16 MUA-PRC007-EN

Page 17

Table 2. Direct-Fired Indoor Air (DFIA) unit—Performance data (continued)

DFIA

Models

DFI

122 1–22

125 1–25

130 1–30

215 2–15

218 2–18

220 2–20

Note: Use the following static pressures for the optional accesso ries:

1. Motor Operated Inlet Damper: 0.13 in. wc

2. V-Bank Filter Section: 0.25 in. wc

3. Mixing Box: 0.40 in. wc

4. Discharge Louver: 0.13 in. wc

Blower

Size (in.)

Std Air

at 70

11000 2157 5 5 7 -1/2 7-1/2 7-1/2 7-1/2 10 —

12000 2353 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10 15

13000 2549 7-1/2 7-1/2 7-1/2 10 10 10 10 15

14000 2745 7-1/2 10 10 10 10 15 15 15

15000 2941 — 10 10 10 15 15 15 15

14000 2086 7-1/2 7-1/2 7-1/2 7-1/2 10 — — —

15000 2235 7-1/2 7-1/2 7-1/2 10 10 10 15 —

16000 2385 7-1/2 7-1/2 7-1/2 10 10 15 15 —

18000 2683 10 10 10 10 15 15 15 15

20000 2981 15 15 15 15 15 15 15 20

22000 2486 10 10 10 15 15 15 15 —

24000 2581 10 15 15 15 15 15 20 20

26000 2796 15 15 15 15 20 20 20 25

28000 3011 15 15 15 20 20 20 20 25

30000 3226 20 20 20 20 20 25 25 30

9000 2239 55555———

9500 2363 55557-1/27-1/2——

10000 2488 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 —

10500 2612 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 —

11000 2736 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10

11500 2861 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10 10

12000 2985 7-1/2 7-1/2 7-1/2 7-1/2 10 10 10 15

12500 2178 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 — — —

13000 2265 7-1/2 7-1/2 7-1/2 7-1/2 10 10 — —

14000 2439 7-1/2 7-1/2 7-1/2 10 10 10 15 —

15000 2613 7-1/2 10 10 10 10 15 15 15

16000 2787 10 10 10 10 15 15 15 15

17000 2962 10 10 10 15 15 15 15 20

18000 2143 7-1/2 10 10 10 15 15 15 —

19000 2262 10 10 10 10 15 15 15 —

20000 2381 10 10 10 15 15 15 15 20

21000 2500 10 15 15 15 15 15 20 20

22000 2619 15 15 15 15 15 15 20 20

23000 2738 15 15 15 15 15 20 20 20

24000 2857 15 15 15 15 20 20 20 25

25000 2976 15 15 15 20 20 20 20 25

26000 3095 15 20 20 20 20 20 25 25

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Total External Static Pressure (in. wc)

Horsepower

MUA-PRC007-EN 17

Page 18

DFIA

Table 2. Direct-Fired Indoor Air (DFIA) unit—Performance data (continued)

Models

DFI

222 2-22

225 2-25

230 2-30

Note: Use the following static pressures for the optional accesso ries:

1. Motor Operated Inlet Damper: 0.13 in. wc

2. V-Bank Filter Section: 0.25 in. wc

3. Mixing Box: 0.40 in. wc

4. Discharge Louver: 0.13 in. wc

Blower

Size (in.)

Std Air

at 70

25000 2451 15 15 15 15 20 20 20 25

26000 2549 15 15 15 20 20 20 20 25

27000 2647 15 15 15 20 20 20 25 25

28000 2745 15 20 20 20 20 25 25 30

29000 2843 20 20 20 20 25 25 25 30

30000 2941 20 20 20 20 25 25 25 30

31000 3039 20 20 20 25 25 25 30 30

30000 2235 15 15 15 15 20 20 — —

32000 2385 15 15 15 20 20 25 25 —

34000 2534 15 20 20 20 20 25 25 30

36000 2683 20 20 20 20 25 25 30 30

38000 2832 20 20 20 25 25 30 30 40

40000 2981 20 25 25 25 30 30 30 40

42000 3130 25 25 25 30 30 30 40 40

44000 3279 25 30 30 30 40 40 40 40

46000 3428 30 30 30 40 40 40 40 50

44000 2366 20 20 20 25 25 30 — —

48000 2581 20 25 25 25 30 30 40 —

52000 2796 25 25 30 30 40 40 40 50

56000 3011 30 30 30 40 40 40 40 50

60000 3226 30 40 40 40 40 50 50 50

64000 3441 40 40 40 50 50 50 50 60

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Total External Static Pressure (in. wc)

Horsepower

Table 3. Direct-Fired Indoor Air (DFIA) unit—Burner selection table (MBh)

DFIA Model

109

112

18 MUA-PRC007-EN

CFM Std. Air

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

1600 142 159 175 191 206 221 235

1900 169 189 208 227 245 262 279

2200 195 219 241 263 284 304 323

2600 231 258 285 311 335 359 382

3000 266 298 329 358 387 414 440

3250 288 323 356 388 419 449 477

3500 311 348 384 418 451 483 514

3750 333 373 411 448 483 518 550

4000 355 397 438 478 516 552 587

4250 377 422 466 508 548 587 624

Page 19

Table 3. Direct-Fired Indoor Air (DFIA) unit—Burner selection table (MBh) (continued)

DFIA Model

115

118

120

122

125

130

215

218

CFM Std. Air

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

4500 399 447 493 537 580 621 661

5000 444 497 548 597 644 690 734

5500 488 546 603 657 709 759 807

6000 532 596 658 717 773 828 881

6500 577 646 712 776 838 897 954

7000 621 696 767 836 902 966 1027

7500 616 704 792 880 968 1057 1101

8000 710 795 877 955 1031 1104 1174

8500 754 845 932 1015 1096 111733 1248

9000 798 894 986 1057 1160 1242 1321

9500 798 894 986 1057 1160 1242 1321

10000 887 994 1096 1194 1289 1380 1468

10500 863 986 1109 1233 1356 1479 1541

11000 976 1039 1205 1314 1418 1518 1615

11000 976 1039 1205 1314 1418 1518 1615

12000 1065 1192 1315 1433 1547 1656 1761

13000 1153 1292 1425 1553 1676 1794 1908

14000 1242 1391 1534 1672 1804 1932 2055

15000 1331 1409 1644 1791 1933 2070 2202

14000 1242 1391 1534 1672 1804 1932 2055

15000 1331 1409 1644 1791 1933 2070 2202

16000 1419 1590 1753 1911 2062 2208 2349

17000 1508 1689 1863 2030 2191 2346 2495

18000 1597 1788 1973 2150 2320 2484 2642

20000 1774 1987 2192 2388 2578 2760 2936

22000 1952 2186 2411 2627 2836 3036 3229

24000 2129 2385 2630 2866 3093 3312 3523

26000 3207 2583 2849 3105 3351 3588 3816

28000 2484 2782 3069 3344 3609 3864 4110

30000 2661 2981 3288 3583 3867 4140 4404

9000 798 894 986 1057 1160 1242 1321

9500 798 894 986 1057 1160 1242 1321

10000 887 994 1096 1194 1289 1380 1468

10500 863 986 1109 1233 1356 1479 1541

11000 976 1039 1205 1314 1418 1518 1615

11500 1020 1143 1260 1373 1482 1587 1688

12000 1065 1192 1315 1433 1547 1656 1761

13000 1153 1292 1452 1553 1676 1794 1908

14000 1242 1319 1534 1672 1804 1932 2055

15000 1331 1490 1644 1791 1933 2070 2202

16000 1419 1590 1753 1911 2062 2208 2349

17000 1508 1689 1863 2030 2191 2346 2495

DFIA

MUA-PRC007-EN 19

Page 20

DFIA

Table 3. Direct-Fired Indoor Air (DFIA) unit—Burner selection table (MBh) (continued)

DFIA Model

220

222

225

230

CFM Std. Air

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

18000 1597 1788 1973 2105 2320 2484 2642

19000 1686 1888 2082 2269 2449 2622 2789

20000 1774 1987 2192 2388 2578 2760 2936

21000 1726 1972 2219 2465 2712 2958 3082

22000 1952 2186 2411 2627 2836 3036 3229

23000 2040 2285 2521 2747 2964 3174 3376

24000 2129 2385 2630 2866 3093 3312 3523

25000 2218 2484 2740 2986 3222 3450 3670

26000 2307 2583 2849 3105 3351 3588 3816

25000 2218 2484 2740 2986 3222 3450 3670

26000 2307 2583 2849 3105 3351 3588 3816

27000 2395 2683 2959 3224 3480 3726 3963

28000 2484 2782 2069 3344 3609 3864 4110

29000 2573 2881 3064 3404 3745 4085 4257

30000 2465 2817 3178 3463 3738 4002 4257

31000 2750 3080 3397 3702 3996 4278 4550

30000 2661 2981 3288 3583 3867 4140 4404

32000 2839 3180 3507 3822 4124 4416 4697

34000 3016 3378 3726 4060 4382 4692 4991

36000 3194 3577 3945 4299 4640 4968 5284

38000 3371 3776 4164 4538 4898 5544 5578

40000 3549 3974 4384 4777 5156 5520 5871

42000 3451 3944 4437 4930 5423 5917 6165

44000 3903 4372 4822 5255 5671 6072 6458

46000 4081 4571 5041 5494 5929 6348 6752

44000 3903 4372 4822 5255 5671 6072 6458

48000 4258 4769 5260 5732 6187 6624 7046

52000 4613 5167 5699 6210 6702 7176 7633

56000 4968 5564 6317 6688 7218 7728 8220

60000 5323 5962 6575 7165 7733 8280 8807

64000 5678 6359 7014 7643 8249 8832 9394

20 MUA-PRC007-EN

Page 21

Dimensions

Plain View

Front View

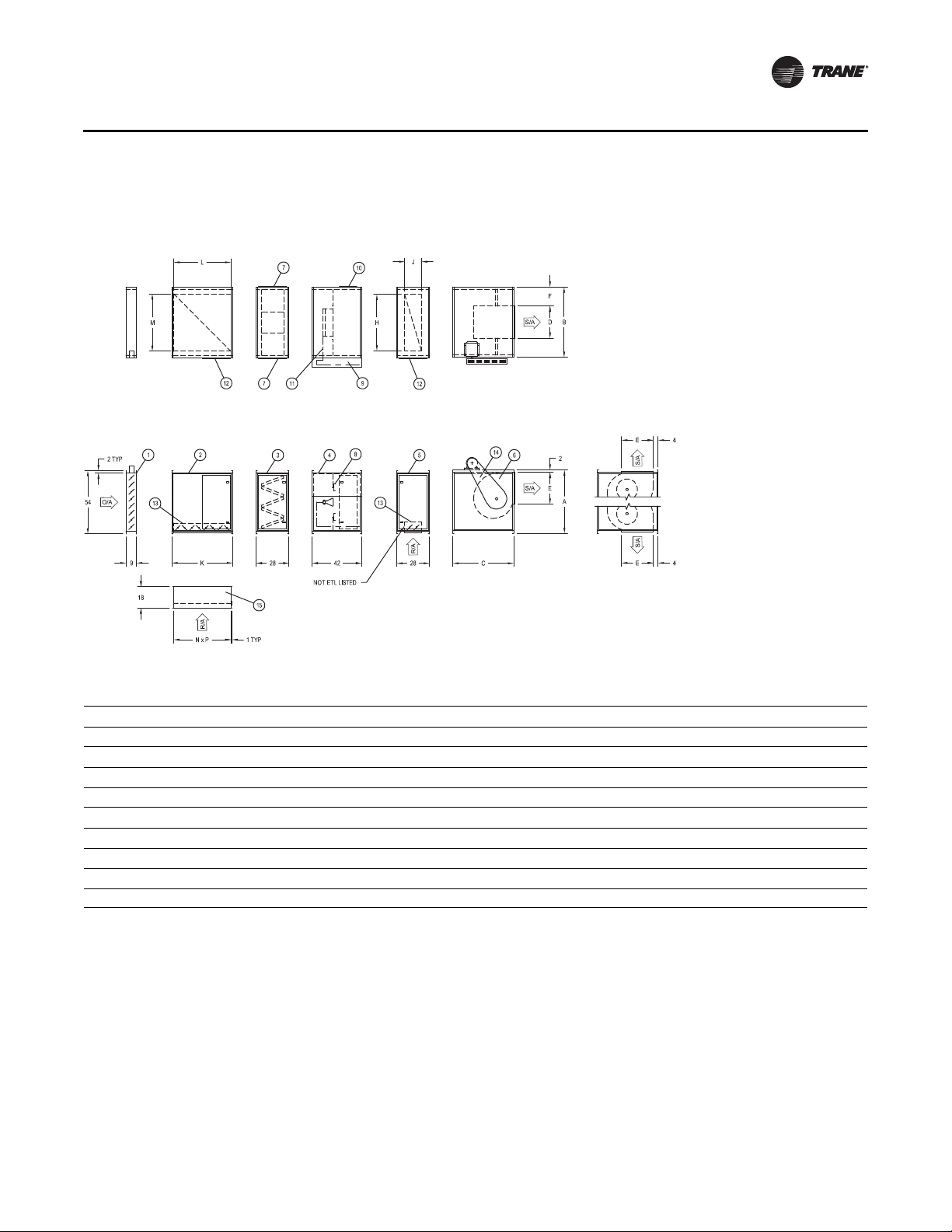

Figure 6. Horizontal arrangement single blower

DFIA

Unit Components

1. Inl e t d am per

2. R/A section (before

Burner)

3. V-bank

4. Burner section

5. R/A section (after

burner)

6. Blower section

7. Filter access

8. Adjustable profile

9. Control cabinet

10. Access door (piping

compartment)

11. Gas piping manifold

12. R/A acces

13. Return air damper

14. Belt guard

Table 4. Dimensions for horizontal arrangement—Single blower DFIA

Model A B C D E F H J K L M N P

109 29 45 33 12 10-1/2 16-1/2 30 8-1/4 28 23-3/4 34 25-1/8 34-1/2

112 29 45 33 15-3/4 13-3/8 14-5/8 30 8-1/4 28 23-3/4 34 25-1/8 34-1/2

115 37-1/4 51 43 18-3/4 16 16-1/8 30 14-1/4 43 39-3/4 40 40-1/4 40-1/2

118 37-1/4 51 43 22 19 14-1/2 30 14-1/4 43 39-3/4 40 40-1/4 40-1/2

120 54 60 52 24-7/8 24-7/8 17-9/16 48 14-1/4 52 48-3/4 49 49-1/8 49-1/2

122 54 60 52 27-3/8 27-3/8 16-5/16 48 14-1/4 52 48-3/4 49 49-1/8 49-1/2

125 66 72 60 31-3/8 31-3/8 20-5/16 60 20-1/4 52 48-3/4 61 49-1/8 61-1/2

130 66 72 60 36-7/8 36-7/8 17-9/16 60 20-1/4 52 48-3/4 61 49-1/8 61-1/2

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 21

Page 22

DFIA

Plan View

Front View

Figure 7. Horizontal arrangement twin blowers

Unit Components

1. Inlet damper

2. R/A section (before

Burner)

3. V-bank

4. Burner section

5. R/A section (after burner)

6. Blower section

7. Filter access

8. Adjustable profile

9. Control cabinet

10. Access door (piping

compartment)

11. Gas piping manifold

12. R/A acces

13. Return air damper

14. Belt guard

Table 5. Dimensions for horizontal arrangement—Single blower DFIA

Model A B C D E F G H J K L M N P

215 37-1/4 93 43 18-3/4 16 16-1/8 22-1/2 79 10 43 39-3/4 82 40-1/4 82-1/2

218 37-1/4 93 43 22 19 13-1/4 22-1/2 79 10 43 39-3/4 82 40-1/4 82-1/2

220 54 120 52 24-7/8 24-7/8 20-1/4 29-5/8 96 14-1/4 52 48-3/4 109 49-1/8 109-1/2

222 54 120 52 27-3/8 27-3/8 14-1/2 29-5/8 96 14-1/4 52 48-3/4 109 49-1/8 109-1/2

225 66 144 60 31-3/8 31-3/8 21-3/4 37-5/8 120 20-1/4 52 48-3/4 133 49-1/8 133-3/8

230 66 144 60 36-7/8 36-7/8 18-5/8 33 120 20-1/4 52 48-3/4 133 49-1/8 133-3/8

Note: All dimensions in inches subject to manufacturing tolerances.

22 MUA-PRC007-EN

Page 23

Figure 8. Single blower vertical units

VST Discharge

Plan View

Side View

Front View

DFIA

Unit Components

1. Inlet damper

2. R/A section (before burner)

3. V-bank

4. Burner section

5. R/A section (after burner)

6. Blower section

7. Filter access

8. Adjustable profile

9. Control cabinet

10. Access door (piping compartment)

11. Gas piping manifold

12. R/A acces

13. Return air damper

14. Belt guard

15. Screen

Table 6. Dimensions for single blower vertical units—DFIA

Model A B C D E F H J K L M N PN Q R S

109 29 45 33 12 10-1/2 16-1/8 30 8-1/4 28 23-3/4 34 25-1/8 34-1/2 36 32 17-1/4

112 29 45 33 15-3/4 13-3/8 14-5/8 30 8-1/4 28 23-3/4 34 25-1/8 34-1/2 36 32 17-1/4

115 37-1/4 51 43 18-3/4 16 16-1/8 29-5/8 14-1/4 43 39-3/4 40 40/4 40-1/2 36 32 17-1/4

118 37-1/4 51 43 22 19 14-1/2 30 14-1/4 43 39-3/4 40 40-1/4 40-1/2 36 32 20

120 54 60 52 24-7/8 24-7/8 17-9/16 48 14-1/4 52 48-3/4 49 49-1/8 49-1/2 48 44 20

122 54 60 52 27-3/8 27-3/4 16-5/16 48 14-1/4 52 48-3/4 49 49-1/8 49-1/2 48 44 20

125 66 72 60 31-3/4 31-3/8 20-5/16 60 20-1/4 52 48-3/4 61 49-1/8 61-1/2 48 44 21

130 66 72 60 36-7/8 36-7/8 17-9/16 60 20-1/4 52 48-3/4 61 49-1/8 61-1/2 48 44 21

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 23

Page 24

DFIA

VST Discharge

Plan View

Side View

Front View

Figure 9. Twin blower models vertical units

Unit Components

1. Inlet damper

2. R/A section (before

burner)

3. V-bank

4. Burner section

5. R/A section (after

burner)

6. Blower section

7. Filter access

8. Adjustable profile

9. Control cabinet

10. Access door

11. Gas piping manifold

12. R/A acces

13. Return air damper

14. Belt guard

15. Screen

Table 7. Dimensions for twin blower vertical units—DFIA

Model A B C D E F G H J K L M N P Q R S

215 37-1/4 93 43 18-3/4 16 16-1/8 22-1/2 79 10 43 39-3/4 82 40-1/4 82-1/2 36 32 18-1/2

218 37-1/4 93 43 22 19 13-1/4 22-1/2 79 10 43 39-3/4 82 40-1/4 82-1/2 36 32 22

220 54 120 52 24-7/8 24-7/8 20-1/4 29-5/8 96 14-1/4 52 48-3/4 109 49-1/8 109-1/2 48 44 22

222 54 120 52 27-3/8 27-3/8 17-3/4 29-5/8 96 14-1/4 52 48-3/4 109 49-1/8 109-1/2 48 44 23-1/2

225 66 144 60 31-3/8 31-3/8 21-3/4 37-5/8 120 20-1/4 52 48-3/4 133 49-1/8 133-1/2 48 44 32-3/4

230 66 144 60 36-7/8 36-7/8 18-5/8 33 120 20-1/4 52 48-3/4 133 49-1/8 133-1/2 48 44 32-3/4

Note: All dimensions in inches subject to manufacturing tolerances.

24 MUA-PRC007-EN

Page 25

Figure 10. DFIA Accessories dimensional data

Return air Probe Box

DFIA

Table 8. DFIA Accesories dimensional data

Model A B C D E

109–112 2 ft 5 in 3 ft 9 in 1 ft 5-3/8 in 1 ft 2-3/8 in 2 ft 4 in

115–118 3 ft 1-1/4 in 4 ft 3 in 1 ft 11 in 1 ft 8-3/8 in 3 ft 7 in

120–122 4 ft 6 in 5 ft 0 in 2 ft 4-1/2 in 3 ft 3-1/4 in 4 ft 4 in

125–130 5 ft 6 in 6 ft 0 in 3 ft 4-1/8 in 3 ft 3-1/4 in 4 ft 4 in

215–218 3 ft 1-1/4 in 7 ft 9 in 5 ft 7-3/4 in 1 ft 8-3/8 in 3 ft 7 in

220–222 4 ft 6 in 10 ft 0 in 7 ft 1-3/4 in 3 ft 3-1/4 in 4 ft 4 in

225–230 5 ft 6 in 12 ft 0 in 9 ft 1/8 in 3 ft 3-3/4 in 4 ft 4 in

MUA-PRC007-EN 25

Page 26

DFIA

RETURN AIR

Weights

Figure 11. DFIA approximate weights

Table 9. DFIA Approximate weights

Unit Size

109 350 180 55 165 104 260 104 70 67 149 67 67

112 350 180 55 165 104 260 104 70 67 149 67 67

115 535 210 70 185 178 375 116 80 94 253 94 94

118 535 210 70 185 178 375 116 80 94 253 94 94

120 916 420 120 275 2809 550 151 110 159 439 159 159

122 916 420 120 275 280 550 151 110 159 439 159 159

125 1262 570 155 310 386 700 208 125 224 590 224 224

130 1262 570 155 310 386 700 208 125 224 590 224 224

215 912 500 125 275 217 510 141 150 158 438 158 158

218 912 500 125 275 217 510 141 150 158 438 158 158

220 1501 625 233 410 420 725 226 215 268 697 268 268

222 1501 625 233 410 420 725 226 215 268 697 268 268

225 2117 845 340 500 560 1010 302 230 388 953 388 388

230 2117 845 340 500 560 1010 302 230 388 953 388 388

(a)When a mixing box option is ordered, these three accessory weights need to be totaled: Inlet Damper, V-Bank Filter, and Return Air (After Burner).

Section

Blower

Support

Stand

Vertical

(a)

Inlet

Damper

V-Bank

)

Filter

(a

Air

(Before

Burner)

Burner

Section

Return

Return

(a)

Air

(After

Burner)

Discharg

e Louver A B C D

26 MUA-PRC007-EN

Page 27

DFOA

Model Number Descriptions

Digit 1, 2, 3 — Unit Type

DFO= Direct-Fired Outdoor Unit

Digit 4 — Development

Sequence

A = First Generation

Digit 5, 6, 7 — Unit Size

109 118 220 230

112 215 222

115 218 225

Digit 8 — Main Power Supply

A = 115/60/1 D = 208/60/3

B = 230/60/1 E = 230/60/3

C = 208/60/1 F = 460/60/3

Digit 9 — Fuel

N= Natural Gas

P=LP (Propane) Gas

Digit 10 — Design Sequence

H = Eighth Design

Digit 11 — Gas Control Option

E = Modulating Discharge Temp

Control

F = Modulating Room Temp Control

G = Modulating Room Temp Control

& Pro Room Sensor

H = Modulating Room Temp Control

& BACview

Digit 12 — Gas Train Approvals

0 = No Selection

1=Standard Gas Train

3 = IRI Gas Train Approval (ETL)

4 = FM Gas Train Approval (ETL)

5 = IRI Gas Train Approval (No ETL)

6 = FM Gas Train Approval (No ETL)

®

Digit 13 — Burner Input Rating

(Natural/Propane)

AA = 275/225 MBh

AB = 550/450 MBh

AC = 825/675 MBh

AE = 1100/1125 MBh

AF = 1375/1350 MBh

AG = 1650/1575 MBh

AH = 1925/1800 MBh

AJ = 220 0/2025 MBh

AK = 2475/2475 MBh

AL = 2750/2700 MBh

AN = 3025/2925 MBh

AP = 3300/3150 MBh

AQ = 3575/3375 MBh

AR = 3850/3825 MBh

AT = 4125/4050 MBh

AV = 4400/4275 MBh

AW = 4675/4500 MBh

AX = 4950/4950 MBh

AY = 5225/5175 MBh

AZ = 5500/5400 MBh

A1 = 5775/5624 MBh

A2 = 6050/5850 MBh

A3 = 6325/6075 MBh

A4 = 660 0/6525 MBh

A5 = 6875/6750 MBh

A6 = 7150/6975 MBh

A7 = 7425/7425 MBh

A8 = 770 0/7650 MBh

A9 = 7975 MBh

Digit 15 — Blower Motor

Horsepower

0 = No Selection J = 10 hp

B = 3/4 hp K = 15 hp

C=1 hp L=20 hp

D = 1-1/2 hp M = 25 hp

E=2 hp P=30 hp

F=3 hp Q=40 hp

G= 5 hp R= 50 hp

H = 7-1/2 hp T = 60 hp

Digit 16 — Motor Speed and

Starter

0 = No Selection

1 = Single Speed odp 1800 rpm

2 = Single Speed tefc 1800 rpm

3 = Single Speed Ener. Effic odp

4 = Single Speed Ener. Effic tefc

5 = 2s1w odp 1800/900 rpm

6 = 2s2w odp 1800/1200 rpm

Digit 17 — Fan Arrangement

2 = Horizontal Arrangement 2, Front

3 = Horizontal Arrangement 3,

Bottom

4 = Vertical Arrangement 4, Side

6 = Vertical Arrangement 6, Side

Digit 18— Inlet Hood and

Birdscreen

O = No Inlet Hood and Birdscreen

A = Inlet Hood/Birdscreen with

Permanent Filters

B = Inlet Hood/Birdscreen without

Permanent Filters

Digit 19 — V-Bank Filter Section

0 = No V-Bank Filter Section

A = V-Bank Section with Permanent

Filters

B = V-Bank Section without

Permanent Filters

C = V-Bank Section with TA Filters

D = V-Bank Section with Pleated

Filters

Digit 20 — Damper/Mixing Box

0 = No Damper/Mixing Box Selected

(No ETL)

A = Motorized 75/25 Damper

(Manual Control)

B = Motorized Damper 75/25

(Bldg Press Control)

C = Mixing Box - Temperature Control

(No ETL)

D = Mixing Box - Building Press

Control (No ETL)

E = Mixing Box - Manual Control

(No ETL)

F = Mixing Box with Airflow

Station - Manual Control (ETL)

G = Mixing Box with AIrflow

Station - Temp Control (ETL)

H = Mixing Box with Airflow

Station - Bldg Press Control (ETL)

Digit 21 — Controls Opposite

from Standard

0 = Standard Controls

A = Controls Opposite from Standard

Digit 22 — Motorized Inlet

Damper

0 = No Motorized Inlet Damper

B = Motorized Inlet Damper

Digit 23 — Motorized Outlet

Damper

0 = No Motorized Outlet Damper

C = Motorized Outlet Damper

Digit 24 — Insulation

D = Insulation on Entire Unit

Digit 25 — Internal Blower/Motor

Isolation

F = Internal Blower/Motor Isolation

Digit 26 — Extended Grease

Lines

G = Extended Grease Lines

Digit 27 — 115V Duplex Service

Receptable

K=115 Volt Duplex Service Receptacle

MUA-PRC007-EN 27

Page 28

DFOA

Digit 28 — Painted Basic Unit

and Accessories

M = Painted Basic Unit and

Accessories

Digit 29 — UV Flame Sensor

N = UV Flame Sensor

Digit 30 — Clogged Filter

Indicator

P = Clogged Filter Indicator

Digit 31 — Exhaust Interlock

Q = Exhaust Interlock

Digit 32 — Interlocking Relay

R = Interlocking Relay

Digit 33 — Omit Disconnect

Switch

DS = Disconect Switch

V = Omit Disconnect Switch

Digit 34 — High Gas Pressure

Regulator

7 = High Gas Press Reg 0.5–1 psi

W = High Gas Press Reg 1–5 psi

X = High Gas Press Reg 5–10 psi

6 = High Gas Press Reg Over 10 psi

Digit 35 — Adjustable Drive

Y = Adjustable Drive

Digit 36 — Low Gas Pressure

Burner

8 = Low Gas Pressure Burner

Digit 37 — Vibration Options

Z Vibration Feet—Full Unit

Digit 38 — Control Options

2 = 7-Day Time Clock

5 = On/Off Night Setback Thermostat

7 = BACview

Digit 39 — Discharge Louver

M = Discharge Louver

Digit 40 — Separator for Unit

Model Number

# = Separator for AOS Model

Number

Digit 41 — Roofcurbs

A = Curb for Basic Frame, No

Return Air

B = Curb for Basic Frame Return

Air Downstream

C = Curb for Basic Frame with

Mixing Box

®

Remote Panel

28 MUA-PRC007-EN

Page 29

Features and Benefits

DFOA

MUA-PRC007-EN 29

Page 30

DFOA

Basic Unit

Feature: Casing with galvanized finish.

Benefit: Rust problem is greatly reduced.

Feature: Watertight construction.

Benefit: Designed for indoor or outdoor mounting.

Feature: Access doors are hinge mounted with industrial type hardware.

Benefit: Provides simple access to service compartments without removing sheet metal screws

and panels.

Feature: Adjustable motor mount

Benefit: Belt tension can be field adjusted for maximum belt life and for motor speed adjustment

Feature: Basic unit is factory assembled and wired.

Benefit: Reduces field installation cost.

Feature: All fuses factory furnished.

Benefit: Delay at start-up eliminated.

Feature: Factory tested before being shipped.

Gas-Fired Unit

Benefit: Eliminates majority of field start-up problems caused by defective controls.

Feature: Many units bear the ETL label.

Benefit: Meets certain specification requirements.

Feature: Optional temperature control systems available.

Benefit: Select system to satisfy application.

Feature: Optional dual fuel gas manifold.

Benefit: Standby flexibility in case natural gas supply is interrupted.

Feature: Optional construction provides returnair cycle.

Benefit: Maximum 80 percent return air cycle results in fuel economy for pressurized heating

systems and eliminates need for two-speed fan operation. Minimizes heating costs.

30 MUA-PRC007-EN

Page 31

Performance Data

Table 10. Direct-Fired Outdoor Air (DFOA) unit—General data

Unit Size 109 112 115 118 215 218 220 222 225 230

Airflow

Min. Airflow (cfm) 1600 3250 4500 6500 9000 12500 18000 25000 30000 44000

Max. Airflow (cfm) 3000 4250 6000 8500 12000 17000 26000 31000 46000 64000

Fan

Quantity - Wheel Size 1 - 9 1 - 12 1 - 15 1 - 18 2 - 15 2 - 18 2 - 20 2 - 22 2 - 25 2 - 30

Motor (hp) 1–5 1.5–5 2–7.5 3–10 5–15 7.5–20 7.5–25 15–30 15–50 20–60

Filters, 2-in V-Bank Filter

Quantity 9999181825253636

Size (in) 20x15 20x15 20x15 20x15 20x15 20x15 20x20 20x20 20x25 20x25

Inlet Hood and Birdscreen

Quantity 4488161618186666

Size 20x16 20x16 20x16 20x16 20x16 20x16 20x25 20x25 20x15 20x15

Table 11. Direct-Fired Outdoor Air (DFOA) unit—Performance data

DFOA

Models

DFO

109 1–9

112 1–12

115 1–15

Note: External Pressure Drop in inches of water. Add pressure drop of the optional accessories, if used, to the pressure drop of the duct work:

1. Fresh Air Inlet Hood and Birdscreen: 13 in. wc

2. Fresh Air Inlet Hood with Filters: 25 in. wc

3. Motor Operated Inlet Damper: 13 in. wc

4. Motor Operated Discharge Damper: 50 in. wc

5. V-Bank Filter Section: 25 in. wc

6. Mixing Box: 40 in. wc

7. Discharge Louver: 13 in. wc

Blower

Size (in.)

Std Air

at 70

1600 1915 1 1 1 1 — — — —

1800 2155 1 1 1-1/2 1-1/2 1-1/2 1-1/2 — —

2000 2390 1-1/2 1-1/2 1-1/2 1-1/2 1-1/2 2 2 —

2250 2690 1-1/2 1-1/2 1-1/2 2 2 2 2 3

2500 2990 2 2 2 2 2 3 3 3

2750 3290 2 2 2 3 3 3 3 3

3000 3585 3 3 3 3 3 3 5 5

3250 2180 1-1/2 2 2 2 3 3 3 3

3500 2360 2 2 2 3 3 3 3 5

3750 2540 2 2 3 3 3 3 3 5

4000 2720 3 3 3 3 3 3 5 5

4250 2900 3 3 3 3 3 5 5 5

4500 2190 2 2 3 3 3 3 5 —

5000 2430 3 3 3 3 3 5 5 5

5500 2670 3 3 3 5 5 5 5 5

6000 2910 3 5 5 5 5 5 5 7-1/2

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Total External Static Pressure (in. wc)

Horsepower

MUA-PRC007-EN 31

Page 32

DFOA

Table 11. Direct-Fired Outdoor Air (DFOA) unit—Performance data (continued)

Models

DFO

118 1–18

215 2–15

218 2–18

220 2–20

222 2–22

Note: External Pressure Drop in inches of water. Add pressure drop of the optional accessories, if used, to the pressure drop of the duct work:

1. Fresh Air Inlet Hood and Birdscreen: 13 in. wc

2. Fresh Air Inlet Hood with Filters: 25 in. wc

3. Motor Operated Inlet Damper: 13 in. wc

4. Motor Operated Discharge Damper: 50 in. wc

5. V-Bank Filter Section: 25 in. wc

6. Mixing Box: 40 in. wc

7. Discharge Louver: 13 in. wc

Blower

Size (in.)

Std Air

at 70

6500 2215 3 5 5 5 5 5 5 7-1/2

7000 2390 5 5 5 5 5 5 7-1/2 7-1/2

7500 2565 5 5 5 5 5 7-1/2 7-1/2 7-1/2

8000 2740 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2

8500 2915 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10

9000 2190 5 5 5 5 5 — — —

9500 2310 5 5 5 5 7-1/2 7-1/2 — —

10000 2430 5 5 5 7-1/2 7-1/2 7-1/2 7-1/2 —

10500 2550 5 5 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 —

11000 2670 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10

11500 2790 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 10 10 10

12000 2910 7-1/2 7-1/2 7-1/2 7 -1/2 10 10 10 15

12500 2125 7-1/2 7-1/2 7-1/2 7-1/2 7-1/2 — — —

13000 2215 7-1/2 7-1/2 7-1/2 7-1/2 10 10 — —

14000 2390 7-1/2 7-1/2 7-1/2 10 10 10 15 —

15000 2565 7-1/2 10 10 10 10 15 15 15

16000 2740 10 10 10 10 15 15 15 15

17000 2915 10 10 10 15 15 15 15 20

18000 2140 7-1/2 10 10 10 15 15 15 —

19000 2260 10 10 10 10 15 15 15 —

20000 2380 10 10 10 15 15 15 15 20

21000 2500 10 15 15 15 15 20 20 20

22000 2620 15 15 15 15 15 15 20 20

23000 2740 15 15 15 15 15 20 20 20

24000 2860 15 15 15 15 20 20 20 25

25000 2980 15 15 15 20 20 20 20 25

26000 3100 15 20 20 20 20 20 25 25

25000 2450 15 15 15 15 20 20 20 25

26000 2550 15 15 15 20 20 20 20 25

27000 2650 15 15 15 20 20 20 25 25

28000 2750 15 20 20 20 20 25 25 30

29000 2850 20 20 20 20 25 25 25 30

30000 2950 20 20 20 20 25 25 25 30

31000 3050 20 20 20 25 25 25 30 30

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Horsepower

Total External Static Pressure (in. wc)

32 MUA-PRC007-EN

Page 33

Table 11. Direct-Fired Outdoor Air (DFOA) unit—Performance data (continued)

DFOA

Models

DFO

225 2–25

230 2–30

Note: External Pressure Drop in inches of water. Add pressure drop of the optional accessories, if used, to the pressure drop of the duct work:

1. Fresh Air Inlet Hood and Birdscreen: 13 in. wc

2. Fresh Air Inlet Hood with Filters: 25 in. wc

3. Motor Operated Inlet Damper: 13 in. wc

4. Motor Operated Discharge Damper: 50 in. wc

5. V-Bank Filter Section: 25 in. wc

6. Mixing Box: 40 in. wc

7. Discharge Louver: 13 in. wc

Blower

Size (in.)

Std Air

at 70

30000 2235 15 15 15 15 20 20 — —

32000 2385 15 15 15 20 20 20 25 —

34000 2535 15 20 20 20 20 25 25 30

36000 2685 20 20 20 20 25 25 30 30

38000 2835 20 20 20 25 25 30 30 40

40000 2985 20 25 25 25 30 30 30 40

42000 3135 25 25 25 30 30 40 40 40

44000 3285 25 30 30 30 40 40 40 40

46000 3430 30 30 30 40 40 40 40 50

44000 2365 20 20 20 25 25 30 — —

48000 2580 20 25 25 25 30 30 40 —

52000 2800 25 25 30 30 40 40 40 50

56000 3020 30 30 30 40 40 40 40 50

60000 3240 40 40 40 40 40 50 50 50

64000 3440 40 40 40 50 50 50 50 60

CFM

FPM

Outlet

Velocity

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2

Horsepower

Table 12. Direct-Fired Outdoor Air (DFOA) unit—Burner selection table (MBh)

Total External Static Pressure (in. wc)

DFOA Model

109

112

115

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

1600 142 159 175 191 206 221 235

1800 160 179 179 215 232 248 264

2000 177 199 219 239 258 276 294

2250 200 224 247 269 290 311 330

2500 222 248 274 299 322 345 367

2750 244 273 201 328 354 380 404

3000 266 298 329 358 387 414 440

3250 288 323 356 388 419 449 477

3500 311 348 384 418 451 483 514

3750 333 373 411 448 483 518 550

4000 355 397 438 478 516 552 587

4250 377 422 466 508 548 587 624

4500 399 447 493 537 580 621 661

5000 444 497 548 597 644 690 734

5500 488 546 603 657 709 759 807

6000 533 596 658 717 773 828 881

MUA-PRC007-EN 33

CFM Std. Air

Page 34

DFOA

Table 12. Direct-Fired Outdoor Air (DFOA) unit—Burner selection table (MBh) (continued)

DFOA Model

118

215

218

220

222

225

CFM Std. Air

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

6500 577 646 712 776 838 897 954

7000 621 697 767 836 902 966 1027

7500 665 745 822 896 967 1035 1101

8000 710 795 877 955 1031 1104 1174

8500 754 845 932 1015 1096 1173 1248

9000 798 894 986 1057 1160 1242 1321

9500 843 944 1041 1135 1224 1311 1394

10000 887 994 1096 1194 1289 1380 1468

10500 932 1043 1151 1254 1353 1449 1541

11000 976 1039 1205 1314 1418 1518 1615

11500 1020 1143 1260 1373 1482 1587 1688

12000 1065 1192 1315 1433 1547 1656 1761

12500 1109 1242 1370 1493 1611 1725 1835

13000 1153 1292 1452 1553 1676 1794 1908

14000 1242 1391 1534 1672 1804 1932 2055

15000 1331 1490 1644 1791 1933 2070 2202

16000 1419 1590 1753 1911 2062 2208 2349

17000 1508 1689 1863 2030 2191 2346 2495

18000 1597 1788 1973 2105 2320 2484 2642

19000 1686 1888 2082 2269 2449 2622 2789

20000 1774 1987 2192 2388 2578 2760 2936

21000 1863 2087 2301 2508 2707 2898 3082

22000 1952 2186 2411 2627 2836 3036 3229

23000 2040 2285 2521 2747 2964 3174 3376

24000 2129 2385 2630 2866 3093 3312 3523

25000 2218 2484 2740 2986 3222 3450 3670

26000 2307 2583 2849 3105 3351 3588 3816

25000 2218 2484 2740 2986 3222 3450 3670

26000 2307 2583 2849 3105 3351 3588 3816

27000 2395 2683 2959 3224 3480 3726 3963

28000 2484 2782 3069 3344 3609 3864 4110

29000 2573 2881 3178 3463 3738 4002 4257

30000 2661 2981 3288 3583 3867 4140 4404

31000 2750 3080 3397 3702 3996 4278 4550

30000 2661 2981 3288 3583 3867 4140 4404

32000 2839 3180 3507 3822 4124 4416 4697

34000 3016 3378 3726 4060 4382 4692 4991

36000 3194 3577 3945 4299 4640 4968 5284

38000 3371 3776 4164 4538 4898 5544 5578

40000 3549 3974 4384 4777 5156 5520 5871

42000 3762 4173 4603 5016 5413 5796 6165

44000 3903 4372 4822 5255 5671 6072 6458

46000 3780 4320q 4860 5400 5940 6480 7046

34 MUA-PRC007-EN

Page 35

Table 12. Direct-Fired Outdoor Air (DFOA) unit—Burner selection table (MBh) (continued)

DFOA

DFOA Model

230

CFM Std. Air

70° 70° Rise 80° Rise 90° Rise 100° Rise 110° Rise 120° Rise 130° Rise

44000 3903 4372 4822 5255 5671 6072 6458

48000 4258 4769 5260 5732 6187 6624 7046

52000 4273 4883 5494 6104 6715 7325 8807

56000 4968 5564 6317 6688 7218 7728 8220

60000 5323 5962 6575 7165 7733 8280 8807

64000 5678 6359 7014 7643 8249 8832 9394

MUA-PRC007-EN 35

Page 36

DFOA

Front View

side discharge

Right Hand Shown

Left is opposite

Front View

bottom discharge

Dimensions

Figure 12. Single blower sizes 109–130

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit base

11. Manifold

compartment

Table 13. Dimensions for DFOA single blower sizes 109–130

Model A B C D E F G H J

109 36 52 77 17-13/16 10-3/8 15-1/8 14-7/16 11-9/16 19

112 36 52 77 17-13/16 13-9/16 13-9/16 14-7/16 11-9/16 19

115 36 52 77 23-15/16 16 12-3/8 19-7/8 8-5/8 19

118 36 52 77 23-15/16 19 12-3/8 19-7/8 6-15/16 19

120 48 78 96 29-1/2 24-7/8 13-3/16 28-1/4 10-5/32 19

122 48 78 96 29-1/2 27-3/8 13-3/16 28-1/4 11-13/32 19

125 60 91 96 38-7/8 31-3/8 17-9/16 37-3/4 11-13/16 12-5/16

130 60 91 96 38-7/8 36-7/8 17-9/16 37-3/4 14-7/16 12-5/16

Model K L M P R S T U V

109 14-1/4 14-1/2 11-15/16 27-3/4 32 54 20-1/4 42 22

112 14-1/4 12-1/2 15-15/16 27-3/4 32 54 20-1/4 42 22

115 14-1/4 11-1/8 18-15/16 27-3/4 32 54 20-1/4 42 22

118 14-1/4 7-7/8 22-1/16 27-3/4 32 54 20-1/4 42 22

120 14-1/4 12-1/8 25-1/16 48 38-1/2 60 20-1/4 68 22

122 14-1/4 12-3/8 27-9/16 48 38-1/2 60 20-1/4 68 22

125 20-1/4 15-1/8 31-1/2 49 53 65 26-1/2 81 28

130 20-1/4 15-3/8 37 49 53 65 26-1/2 81 28

Note: All dimensions in inches subject to manufacturing tolerances.

36 MUA-PRC007-EN

Page 37

Figure 13. Twin blower sizes 215–230

Plan View

Front View

(side discharge)

Right Hand Shown

left is opposite

Front View

(bottom discharge)

DFOA

Unit Components

1. Centrifugal supply

fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit base

11. Manifold

compartment

12. Airflow station

(required ETL listed

Return Air Unit)

Table 14. Dimensions for DFOA twin blower sizes 215–230

Model A B C D E F G H I J

215 36 94 77 23-15/16 16 12-3/8 19-7/8 6-15/16 22-1/4 19

218 36 94 77 23-15/16 19 12-3/8 19-7/8 6-15/16 16 19

220 48 130 96 29-7/16 24-7/8 13-3/16 28-1/4 11-7/16 29-5/8 19

222 48 130 96 29-7/16 27-3/8 13-3/16 28-1/4 11-7/16 24-5/8 19

225 60 154 96 38-7/8 31-3/8 17-9/16 37-3/4 14-7/16 37-5/8 12-5/16

230 60 154 96 38-7/8 36-7/8 17-9/16 37-3/4 14-7/16 26-5/8 12-5/16

Model K L M N P R S T U V

215 14-1/4 7-7/8 18-15/16 14 65-3/4 32 54 20-1/4 84 22

218 14-1/4 7-7/8 22-1/16 14 65-3/4 32 54 20-1/4 84 22

220 14-1/4 12-3/8 25-1/16 22-5/8 87-3/8 44-1/2 60 20-1/4 120 22

222 14-1/4 12-3/8 27-9/16 22-5/8 87-3/8 44-1/2 60 20-1/4 120 22

225 20-1/4 15-3/8 31-1/2 24-5/8 111-3/8 56-1/2 65 26-1/2 144 28

230 20-1/4 15-3/8 37 24-5/8 111-3/8 56-1/2 65 26-1/2 144 28

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 37

Page 38

DFOA

Front View

(side discharge)

Right Hand Side

left is opposite

Front View

(bottom discharge)

Figure 14. Twin blower sizes 233 and 240

.

Unit Components

1. Centrifugal supply

fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit bas e

11. M a n i f o l d

compartment

12. Airflow station

(required ETL listed

Return Air Unit)

Table 15. Dimensions for DFOA twin blower sizes 233 and 240

Model A B C D E F G H I J K

233 68 175 117 43-3/4 43-1/16 19-7/16 44 16-1/16 36 20 20-1/4

240 79-1/4 210 131 55-3/4 41 33 42 19-1/16 39-7/8 20 20-1/4

Model

233 17 39-7/8 34-1/8 45 130 56-1/2 70 31-1/4 163 28 72

240 20 53-7/8 38 45 166 51-1/2 70 31-1/4 198 28 86

Note: All dimensions in inches subject to manufacturing tolerances.

38 MUA-PRC007-EN

LMNOPSRSTUVW

Page 39

Figure 15. Vertical models sizes 109–130

Front View

Side view

Right Hand Shown

Left is opposite

DFOA

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold

compartment

Table 16. Dimensions vertical models sizes 109–130

Model A B C D E F G H J K L M

109 42 52 77 135 10-3/8 15-1/8 22 36 14-1/2 11-15/16 20-1/4 42

112 42 52 77 135 13-9/16 13-9/16 22 36 12-1/2 15-15/16 20-1/4 42

115 42 52 77 135 16 12-3/8 22 36 11-1/8 18-15/16 20-1/4 42

118 42 52 77 135 19 12-3/8 22 36 7-7/8 22-1/16 20-1/4 42

120 56 78 96 166 24-7/8 13-3/16 22 48 12-3/8 25-1/16 20-1/4 68

122 56 78 96 166 27-3/8 13-3/16 22 48 12-3/8 27-9/16 20-1/4 68

125 68 91 96 172 31-3/8 17-9/16 28 48 15-3/8 31-1/2 26-1/2 81

130 68 91 96 172 36-7/8 17-9/16 28 48 15-3/8 37 26-1/2 81

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 39

Page 40

DFOA

Front View

Side Discharge

Side View

Right Hand Shown

Left is opposite

Figure 16. Vertical models sizes 109–130 with mixing box

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold

compartment

12. Airflow station

(required ETL listed

return air unit)

Table 17. Dimensions for vertical models sizes 109–130 with mixing box

Model A B C D E F G H L M T U

109 42 52 77 167 10 3/8 15 1/8 54 36 14 1/2 11 15/16 20 1/4 42

112 42 52 77 167 13 9/16 13 9/16 54 36 12 1/2 15 15/16 20 1/4 42

115 42 52 77 167 16 12 3/8 54 36 11 1/8 18 15/16 20 1/4 42

118 42 52 77 167 19 12 3/8 54 36 7 7/8 22 1/16 20 1/4 42

120 56 78 96 204 24 7/8 13 3/16 60 48 12 3/8 25 1/16 20 1/4 68

122 56 78 96 204 27 3/8 13 3/16 60 48 12 3/8 27 9/16 20 1/4 68

125 68 91 96 209 31 3/8 17 9/16 65 48 15 3/8 31 1/2 26 1/2 81

130 68 91 96 209 36 7/8 17 9/16 65 48 15 3/8 37 26 1/2 81

Note: All dimensions in inches subject to manufacturing tolerances.

40 MUA-PRC007-EN

Page 41

Figure 17. Vertical models sizes 215–230

Front View

(side discharge)

Right Hand Shown

left is opposite

Side View

DFOA

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold

compartment

12. Airflow station

(required ETL listed

return air unit)

Table 18. Dimensions for vertical models sizes 215-230

Model A B C D E F G H I J K L M P

215 42 94 77 135 16 12-3/8 22 36 22-1/4 19 14-1/4 7-7/8 18-15/16 65-3/4

218 42 94 77 135 19 12-3/8 22 36 16 19 14-1/4 7-7/8 22-1/16 65-3/4

220 56 130 96 166 24-7/8 13-3/16 22 48 29-5/8 19 14-1/4 12-3/8 25-1/16 87-3/8

222 56 130 96 166 27-3/8 13-3/16 22 48 24-5/8 19 14-1/4 12-3/8 27-9/16 87-3/8

225 68 154 96 172 31-3/8 17-9/16 28 48 37-5/8 12-5/16 20-1/4 15-3/8 31-1/2 111-3/8

230 68 154 96 172 36-7/8 17-9/16 28 48 26-5/8 12-5/16 20-1/4 15-3/8 37 111-3/8

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 41

Page 42

DFOA

Front View

(side discharge)

Side View

Right Hand Shown

Left is opposite

SEPERATE HERE

FOR SHIPPING

Figure 18. Vertical models sizes 215–230 with mixing box

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control cabinet

access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold compartment

12. Airflow station (required ETL

listed return air unit)

Table 19. Dimensions for vertical models sizes 215–230 with mixing box

Model A B C D E F G H I L M T U

215 42 94 77 167 16 12-3/8 54 36 22-1/4 7-7/8 18-15/16 20-1/4 84

218 42 94 77 167 19 12-3/8 54 36 16 7-7/8 22-1/16 20-1/4 84

220 56 130 96 204 24-7/8 13-3/16 60 48 29-5/8 12-3/8 25-1/16 20-1/4 120

222 56 130 96 204 27-3/8 13-3/16 60 48 24-5/8 12-3/8 27-9/16 20-1/4 120

225 68 154 96 209 31-3/8 17-9/16 65 48 37-5/8 15-3/8 31-1/2 26-1/2 144

230 68 154 96 209 36-7/8 17-9/16 65 48 26-5/8 15-3/8 37 26-1/2 144

Note: All dimensions in inches subject to manufacturing tolerances.

42 MUA-PRC007-EN

Page 43

Front View

(side discharge)

Right Hand Shown

Left is opposite

Side View

Figure 19. Vertical models sizes 233 and 240

DFOA

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold

compartment

Table 20. Dimensions vertical models sizes 233 and 240

Model A B C D E F I J K L M O P W

233 76 175 117 205 43-1/16 19-7/16 36 20 20-1/4 17 39-7/8 45 130 72

240 87-1/4 210 131 219 41 33 39-7/8 20 20-1/4 20 53-7/8 45 166 86

Note: All dimensions in inches subject to manufacturing tolerances.

MUA-PRC007-EN 43

Page 44

DFOA

Front View

(side discharge)

Right Hand Shown

Left is opposite

Side View

Figure 20. Vertical models 233 and 240 with mixing box

Unit Components

1. Centrifugal supply fan

2. Fan motor

3. Line burner

4. Control cabinet

5. Hinged control

cabinet access door

6. Observation port

7. Access door

8. Access door (piping

compartment)

9. Lifting lug

10. Unit support stand

11. Manifold

compartment

Table 21. Dimensions for vertical models 233 and 240 with mixing box

Model A B C D E F I L M T U W

233 76 175 117 247 43-1/16 19-7/16 36 17 39-7/8 31-1/4 163 72

240 87-1/4 210 131 261 41 33 39-7/8 20 58-7/8 31-1/4 198 86

Note: All dimensions in inches subject to manufacturing tolerances.

44 MUA-PRC007-EN

Page 45

Figure 21. DFOA Accessories dimensional data

DFOA

Table 22. DFOA Accessories dimensional data

Model A B C D E F G H J K L M

109–112 3’ 0” 3’ 11-1/4” 1’ 5-7/16” 1’ 8-13/16” 1’ 10” 5’ 1-3/4” 2’ 8-1/4” 3’ 7-1/8” 1’ 9” 1’ 11” 4’ 4” 4’ 6”

914 1200 443 529 559 1568 819 1095 533 584 1321 1372

115–118 3’ 0” 3’ 11-1/4” 1’ 10-7/8” 2’ 2-15/16” 1’ 10” 5’ 1-3/4” 2’ 8-1/4” 3’ 7-1/8” 2’ 0” 1’ 11” 4’ 4” 4’ 6”

914 1200 581 684 559 1568 819 1095 610 660 1321 1372

215–218 3’ 0” 7’ 7-1/2” 1’ 10-7/8” 5’ 4-7/8” 1’ 10” 5’ 1-3/4” 2’ 8-1/4” 7’ 3-3/8” 2’ 0” 1’ 11” 7’ 10” 4’ 6”

914 2324 581 1648 559 1568 819 2219 610 660 2388 1372

220–222 4’ 0” 8’ 5-5/8” 2’ 7-1/4” 7’ 0-1/2” 1’ 10” 5’ 5-3/4” 3’ 8-1/4” 8’ 1-1/2” 3’ 9” 2’ 7” 10’ 10” 5’ 0”

1219 2581 794 2146 559 1670 1124 2477 1143 787 3302 1524

225–230 5’ 0” 10’ 1-3/8” 3’ 4-3/4” 8’ 9-3/8” 2’ 4” 7’ 2-1/8” 4’ 8-1/4” 9’ 9-1/4” 3’ 9” 3’ 4-3/4” 12’ 10” 5’ 5”

1524 3083 1035 2677 711 2188 1429 2978 1143 1035 3912 1651

Model R / A / ID

109–118 3’ 6” x 1’ 8-1/4” (1067 x 514)

215–218 7’ x 1’ 8-1/4” (2134 x 514)

220–222 0’ x 1’ 8-1/4” (3048 x 514)

225–230 12’ x 2’ 2-1/2” (3658 x 673)

MUA-PRC007-EN 45

Page 46

DFOA

Roof curbs for 100% make-up air units

Figure 22. Single blower roof curb dimensions

Table 23. Dimensions for single blower roof curb model sizes 109–118

Model A B C D E

109 10-3/8” 1’ 0-3/8” 11-15/16” 11-3/4” 1’ 10-13/16”

264 314 303 298 579

112 1’ 1-9/16” 10-13/16” 1’ 3-15/16” 9-3/4” 1’ 8-13/16”

344 275 405 248 529

115 1’ 4” 9-5/8” 1’ 6-15/16” 8-3/8” 1’ 7-3/16”

406 244 481 213 487

118 1’ 7” 9-5/8” 1’ 10-1/16” 5-1/8” 1’ 7-5/16”

483 244 560 130 491

46 MUA-PRC007-EN

Page 47

Roof curbs for 100% make-up air units

Figure 23. Double blower roof curb dimensions

DFOA

Table 24. Double blower roof curb dimensions for model sizes 215–230

Model A B C D E F G H J K

215 1’ 4” 9-5/8” 1’ 6-15/16” 5-1/8” 1’ 10-1/4” 1’ 11-1/4” 6’ 3” 5’ 11-1/2” 7’ 8” 7’ 4-1/2”

406 244 481 130 565 591 1905 1816 2337 2248

218 1’ 7” 9-5/8” 1’ 10-1/16” 5-1/8” 1’ 4” 1’ 11-1/4” 6’ 3” 5’ 11-1/2” 7’ 8” 7’ 4-1/2”

483 244 560 130 406 591 1905 1816 2337 2248

220 2’ 0-7/8” 10-7/16” 2’ 1-1/16” 9-5/8” 2’ 5-5/8” 2’ 11-1/8” 7’ 10” 7’ 6-1/2” 10’ 8” 10’ 4-1/2”

632 265 637 244 752 892 2388 2299 3251 3162

222 2’ 3-3/8” 10-7/16” 2’ 3-9/16” 9-5/8” 2’ 0-5/8” 2’ 11-1/8” 7’ 10” 7’ 6-1/2” 10’ 8” 10’ 4-1/2”

695 265 700 244 625 892 2388 2299 3251 3162

225 2’ 7-3/8” 1’ 2-13/16” 2’ 7-1/2” 1’ 0-5/8” 3’ 1-5/8” 2’ 11-1/4” 7’ 10” 7’ 6-1/2” 12’ 8” 12’ 4-1/2”

797 376 800 321 956 895 2388 2299 3861 3772

230 3’ 0-7/8” 1’ 2-13/16” 3’ 1” 1’ 0-5/8” 2’ 2-5/8” 2’ 11-1/4” 7’ 10” 7’ 6-1/2” 12’ 8” 12’ 4-1/2”

937 376 940 321 676 895 2388 2299 3861 3772

Notes:

1. Curb to be shipped loose and assembled in the field.

2. Curb must be square and level

3. Curb requires intermediate structural support and is not to be corner post mounted.

4. Gaskets to be shipped with unit.

5. Bolting accessories shipped with curb.

6. Curb drawings shown are for units which have controls on the “standard” side.

7. Available on horizontal units only.

MUA-PRC007-EN 47

Page 48

DFOA

Roof curbs for units with return air opening downsteam of burner

Figure 24. Roof curb dimensions for single blower models sizes 109–118

Table 25. Dimensions for roof curb single blower models sizes 109–118

Model A B C D E

109 10-3/8” 1’ 0-3/8” 11-15/16” 11-3/4” 1’ 10-13/16”

264 314 303 298 579

112 1’ 1-9/16” 10-13/16” 1’ 3-15/16” 9-3/4” 1’ 8-13/16”

344 275 405 248 529

115 1’ 4” 9-5/8” 1’ 6-15/16” 8-3/8” 1’ 7-3/16”

406 244 481 213 487

118 1’ 7” 9-5/8” 1’ 10-1/16” 5-1/8” 1’ 7-5/16”

483 244 560 130 491

48 MUA-PRC007-EN

Page 49

Roof curbs for units with return air opening downstream of burner

Figure 25. Roof curb dimensions for double blower models sizes 215–230

DFOA

Table 26. Roof curb dimensions for double blower models sizes 215–230

Model A B C D E F G

215 1’ 4” 9-5/8” 1’ 6-15/16” 5-1/8” 1’ 10-1/4” 1’ 11-1/4” 6’ 3”

406 244 481 130 565 591 1905

218 1’ 7” 9-5/8” 1’ 10-1/16” 5-1/8” 1’ 4” 1’ 11-1/4” 6’ 3”

483 244 560 130 406 591 1905

220 2’ 0-7/8” 10-7/16” 2’ 1-1/16” 9-5/8” 2’ 5-5/8” 2’ 11-1/8” 7’ 10”

632 265 637 244 752 892 2388

222 2’ 3-3/8” 10-7/16” 2’ 3-9/16” 9-5/8” 2’ 0-5/8” 2’ 11-1/8” 7’ 10”

695 265 700 244 625 892 2388

225 2’ 7-3/8” 1’ 2-13/16” 2’ 7-1/2” 1’ 0-5/8” 3’ 1-5/8” 2’ 11-1/4” 7’ 10”

797 376 800 321 956 895 2388

230 3’ 0-7/8” 1’ 2-13/16” 3’ 1” 1’ 0-5/8” 2’ 2-5/8” 2’ 11-1/4” 7’ 10”

937 376 940 321 676 895 2388

Model H J K L M W

215 5’ 11-1/2” 7’ 8” 7’ 4-1/2” 5’ 5-3/4” 1’ 4-1/4” 1’ 2-1/4”

1816 2337 2248 1670 413 362

218 5’ 11-1/2” 7’ 8” 7’ 4-1/2” 5’ 5-3/4” 1’ 4-1/4” 1’ 2-1/4”

1816 2337 2248 1670 413 362

220 7’ 6-1/2” 10’ 8” 10’ 4-1/2” 7’ 3-3/8” 1’ 4-1/4” 1’ 2-1/4”

2299 3251 3162 2219 413 362

222 7’ 6-1/2” 10’ 8” 10’ 4-1/2” 7’ 3-3/8” 1’ 4-1/4” 1’ 2-1/4”

2299 3251 3162 2219 413 362

225 7’ 6-1/2” 12’ 8” 12’ 4-1/2” 9’ 3-3/8” 9-9/16” 1’ 8-1/4”

2299 3861 3772 2829 243 514

230 7’ 6-1/2” 12’ 8” 12’ 4-1/2” 9’ 3-3/8” 9-9/16” 1’ 8-1/4”

2299 3861 3772 2829 243 514

MUA-PRC007-EN 49

Page 50

DFOA

Roof curbs for units with mixing box

Figure 26. Roof curb dimensions for single blower units with mixing box