Page 1

Trane Horizon

®

Absorption Series

Single-Stage Hot Water or

Steam-Fired Absorption Water Chillers

500-1350 Tons

Built for Industrial and Commercial Applications

ABS-PRC001-ENJune 2003

Page 2

Introduction

Hybrid Chiller Plant

A chiller plant design that allows the

operator to choose between multiple

energy sources is referred to as a hybrid

design. Hybrid chiller plants are

receiving increasing attention as

valuable options for facility owners.

There are various types of hybrid plant

designs. They encompass different

combinations of electric chillers and

other chiller types, including gas or

steam absorption chillers. The

advantages of having a choice of energy

sources will become even more viable

as we move further into the new

millennium.

Today we hear about utility deregulation.

For the first time, building owners can

negotiate power supply and natural gas

contracts with their traditional supplier,

as well as with new suppliers in the

market. The fuel-switching flexibility of

the hybrid plant puts the owner in a

much stronger negotiating position.

Similarly, many electric utilities offer

attractive off-peak or dual fuel electric

rates for applications which are not

operating during peak electric system

demand, most commonly in the

summer months. This represents an

opportunity for building owners who can

switch to a gas or steam system.

ABS-PRC001-EN© 2003 American Standard Inc. All rights reserved.

Page 3

Contents

Trane Horizon® Absorption

Series

Trane has led in absorption chiller design

and manufacturing for four consecutive

decades. In fact, Trane is the only North

American chiller manufacturer to

commercialize double-effect absorption,

over 25 years ago. With over 10,000

absorption chillers manufactured and

shipped, Trane serves the commercial,

industrial and process worldwide

markets. Microelectronic controls,

adaptive frequency drives and smart

purge systems have modernized the

technology, making it more capable,

more reliable and, in many applications,

more economical.

Performance

• Produces colder chilled water to 40°F

[4.4°C].

• Starts with low 55°F [12.8°C] towerwater temperatures.

• Operates reliably with low 65°F [18.3°C]

tower-water temperatures.

Easier Installation

• Rigging eyes built-in as standard.

• Shell disassembly option.

• Crossover pipe and steam valve

available as an option.

Reliability

• Adaptive microprocessor controls.

• 50,000 hours life-extended pumps.

• Constructed of corrosion-resistant alloy

materials.

Design Diversity

• Marine water boxes on cooling-water

connections available as an option.

• Custom design options available.

Introduction

Features and Benefits

Component Identification, Typical Single-Stage

Steam Illustration, Refrigerant Cycle Overview

Application Considerations

Operating Limits, Sound, Water Flow/Treatment,

Combination Systems, Multiple Machines

Selection Procedure

Computer Selection Procedure, Tube Fouling,

Product Coding Description

Performance Data

Capacity/COP/Steam Rate/Flow Rate, Pressure Drop

Tables, Capacity vs. Chilled Water Supply Temperature,

Energy Input vs. Capacity, Pressure Drop vs. Flow Rate

Electrical Data

Controls Data

Dimensions and Weights

Physical Dimensions, Weights, Connection Sizes,

Refrigerant Charging, Separated Machine Sections,

Foundation Support, Rigging/Service Clearances,

Chiller Isolation, Insulation Lengths

Jobsite Connections

Typical Piping

2

4

8

9

12

17

20

24

34

ABS-PRC001-EN

Mechanical Specifications

Standard/Optional/Design Special Features

Standard Conversion Table

40

42

43

3

Page 4

Features and

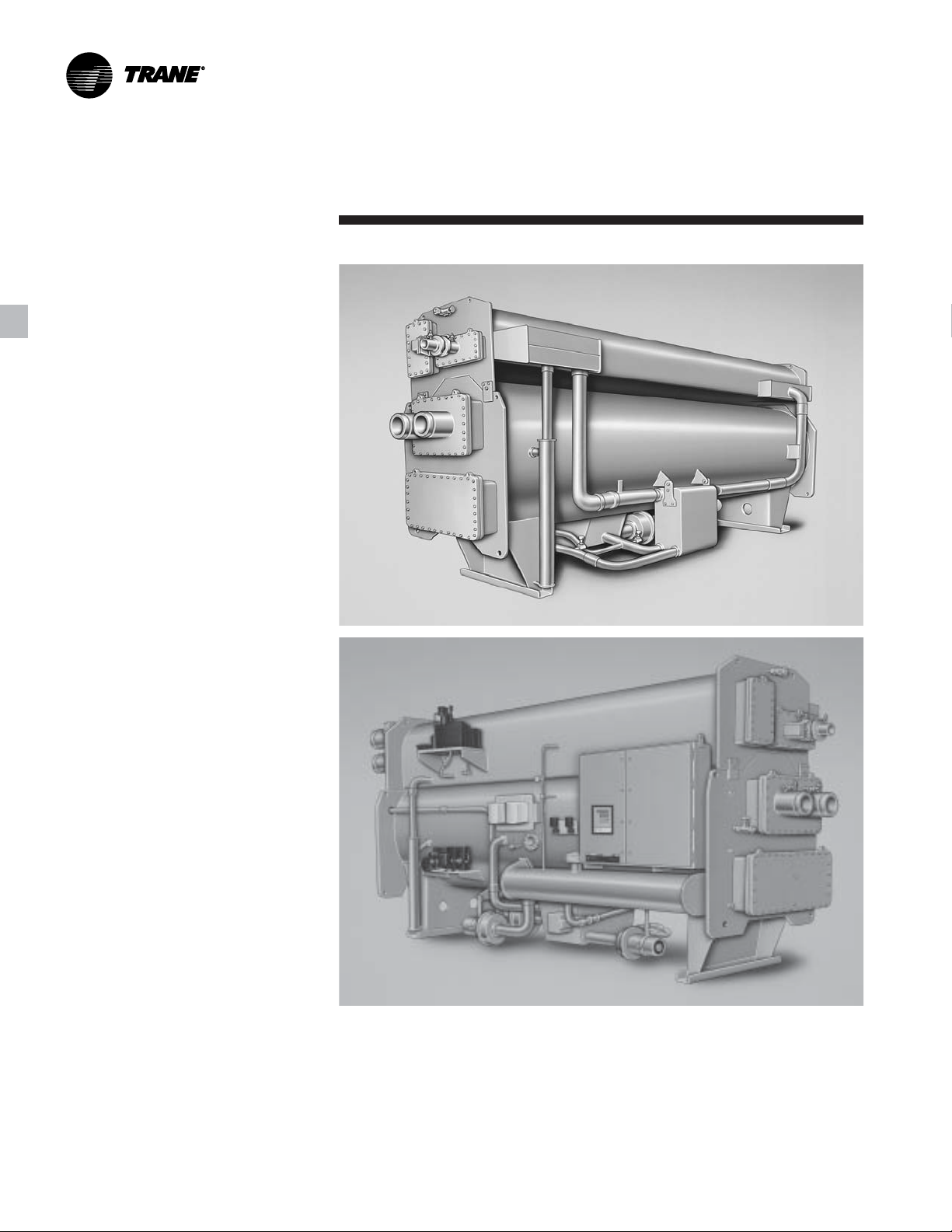

Trane Horizon® Absorption

Series, Single-Stage Hot

Water- or Steam-Fired

Absorption Water Chillers,

500-1350 Tons

Technology You Can Trust

In the early 1990’s, with the assistance of

the Gas Research Institute, Trane began

developing an innovative series of

absorption chillers. In 1995, Horizon

chillers began shipping from the Trane

manufacturing facility in La Crosse,

Wisconsin. The Horizon chiller is so

advanced, it redefined industry

standards for absorption system

integrity. Horizon chiller performance,

efficiency and reliability far exceed that

of past and present absorption chillers.

Dynamic By Design

Because uninterrupted chiller service is

critical to your operation, Horizon chillers

are designed to make chilled water

reliably, even in the harshest industrial

application. Water-tower systems and

load requirements can challenge the

long-term operation of many standardgrade chillers. The industrial-grade

construction of the Horizon chiller

accounts for varying load and watertemperature changes, as well as dirty

tower water. They are built with

corrosive-resistant alloy metals, and

precision welded in an ISO 9001 qualitycertified facility. Only extended-life

pumps, valves and water boxes are

manufactured into their design. For

further dynamics, Horizon UCP2

adaptive microprocessor controls react

precisely to system diversification.

Quality construction, long-life

components and adaptive controls are

what make the Horizon dynamic by

design.

Operates With Energy-Saving,

Low-Pressure Steam or Hot Water

The Horizon family includes a singlestage, hot water- or steam-fired chiller

line. Able to produce chilled water in the

range of 40 to 60°F [4.4 to 15.6°C], these

machines use 12 psig [0.83 bar] lowgrade steam or 270°F [132°C] hot water.

Benefits

Making chilled water from these

comparatively low-temperature inputs is

particularly important for energy

conserving applications, such as wasteheat recovery, co-generation equipment

and solar-energy-powered cooling.

General

Using refrigerant water helps eliminate

refrigerant management or availability

concerns. Additionally, absorption

technology reduces the use of electric

energy.

ABS-PRC001-EN4

Page 5

Features and

Sophisticated Reliability

Horizon controls meet specifications for

stand alone or hybrid chiller control.

UCP2 adaptive controls are critical to

reliable operation. Trane controls are

compatible with Integrated Comfort

Systems (ICS), and are easily integrated

into the Tracer

plant system controllers with a single

twisted-pair communications cable.

Ideal for Process and Commercial

Applications

With Horizon chillers, the application

possibilities for the absorption machine

are expanded. Capabilities such as lower

tower flow, variable evaporator flow,

lower chilled-water temperatures and

advanced control capabilities make the

single-stage Horizon absorption chiller

ideal for both process and comfort

applications.

When Long-lived Reliability

Is Important

Trane has been a long-time proponent of

the use of high-quality materials in

absorption chiller designs. The lithium

bromide temperatures and water

refrigerant, typical of all absorbers, can

more quickly corrode lower-grade metals

in the presence of air. Trane recommends

and uses industrial-grade materials to

provide long-lived, reliable cooling.

®

family of flexible chiller-

™

Benefits

A Global Network of

Absorption Expertise

When you specify a Trane Horizon

chiller, you’re getting the knowledge,

expertise and assistance of a pool of

experts that have decades of absorption

expertise. Making The Trane Company

part of your management team gives

you access to refrigeration, air

conditioning and facility control-system

applications specialists, and a unique

breadth of innovative solutions to satisfy

your facilities needs for today and

tomorrow.

Standard Specification For

Single-Stage Horizon Chillers

• C.O.P. 0.70

• Victaulic

• Fully-automatic purge system

• Industrial-grade tubes

— Generator .028" wall, 90/10

— Evaporator .025" wall copper

— Absorber 500-800 tonnages .022"

— Condenser .028• wall copper

• Advanced cycle-management system

with Adaptive Frequency

solution control

• 150 psig [10.3 bar] evaporator, absorber

and condenser sections

• Industrial-grade energy valve

• Rigging eyes for easy installation

• Advanced microprocessor control

system with adaptive control functions

• 2-line, 40-character clear-language

interface to unit functions and

diagnostic information

• Fixed and floating generator tube

supports prevent thermal stress

• Efficient stainless steel brazed plate

solution heat exchanger

• Long-life solution pumps

• Molybdate inhibitor system

• Factory-installed and-commissioned

controls

• Individually replaceable tubes

• Removable absorber and evaporator

spray trees

™

water connections

Cupro-nickel

(enhanced)

wall 95/5 Cupro-nickel 975-1350

tonnages .028" wall copper

™

drive

General

Optional Specification For

Single-Stage Horizon Chillers

• Removable absorber and evaporator

spray trees150 psig [10.3 bar] raised

face flanges for the evaporator,

condenser, and absorber water

connections

• Disassembled unit — eases

disassembly and reassembly of major

components at the job site

• Lithium bromide filter

• Condenser and absorber marine style

water boxes

• Factory installed cooling-water

crossover pipe absorber to condenser

• Factory mounted energy valve

• Choice of tube materials and other

chiller options

• Stainless steel evaporator pan

Absorption Cooling —

A Sound Decision

Life-cycle costing has become a primary

concern for chiller buyers who have

long-term investment opportunity in

mind. Changes in the distribution and

pricing of electricity have made the

absorption water chiller a popular choice

when alternative energy use makes

sense. Ask your local Trane

representative for a comprehensive

analysis of your facility, and the energysaving opportunities Trane offers for the

design of Heating, Ventilating and Air

Conditioning systems and controls.

ABS-PRC001-EN

5

Page 6

Features and

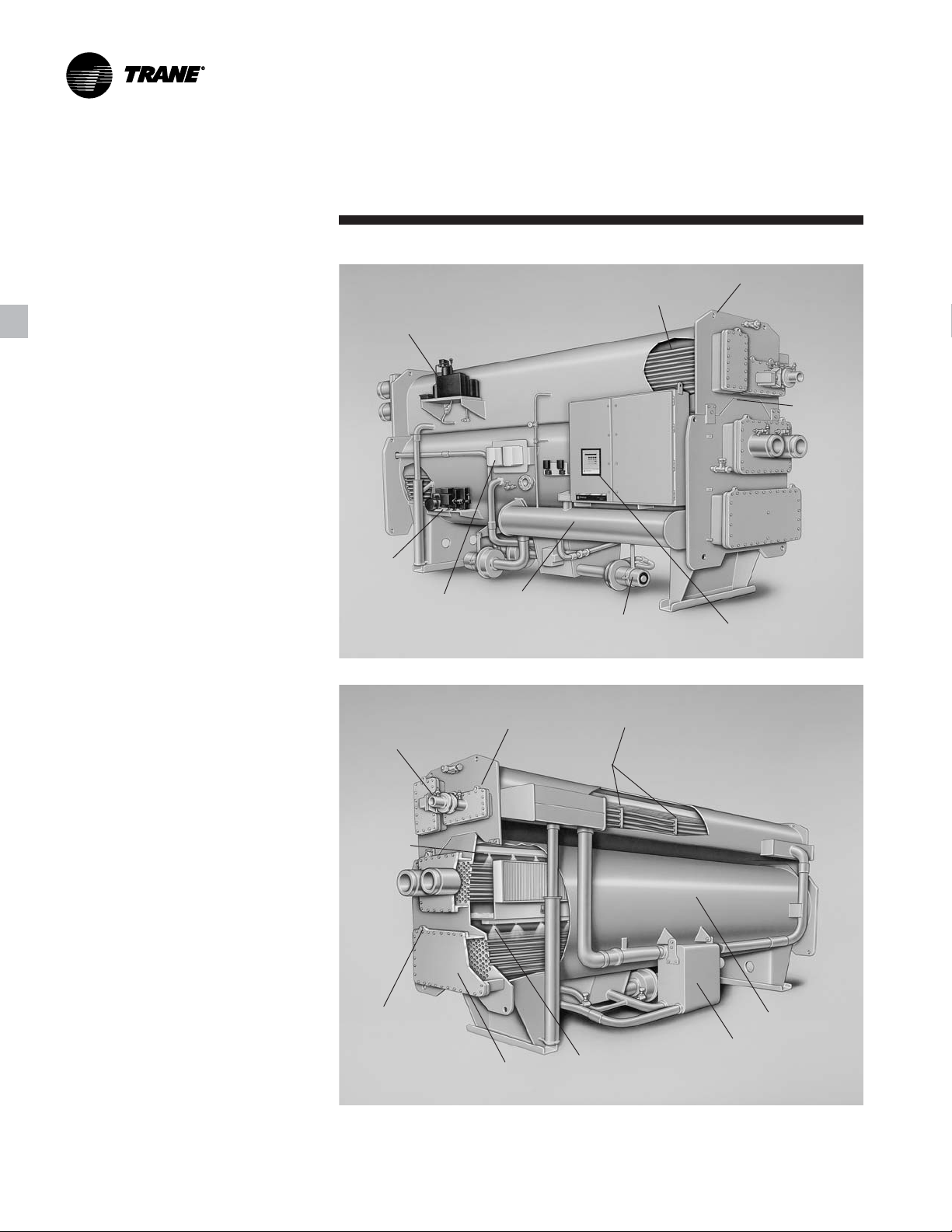

Component

Benefits

Fully-Automatic

Purge System

Vacuum

Pump

Solution Pump

Variable-Frequency

Drive

Refrigerant

Storage Tank

Identification

Condenser

Section

Long Life Hermetic

Solution Pumps

Rigging Eyes For

Easier Installation

Separable

Shell

Design

™

UCP2

Microprocessor

Control System

Industrial-Grade

Energy Valve

Evaporator

Spray Tree

Lifting Eyes on

Water Box Covers

ASME-Rated

Generator

Absorber Section

Fixed and floating tube supports

Industrial-grade tubes

Absorber

Spray Tree

Efficient Stainless-Steel

Solution Heat Exchanger

Evaporator

Section

ABS-PRC001-EN6

Page 7

Features and

Refrigeration

Horizon Single-Stage

Absorption Refrigeration Cycle

Refrigeration Cycle

This is an example of typical machine

operation at a standard rating point

condition (i.e., 85°F [29.4°C] tower, 44°F

[6.7°C] leaving chilled water) at full load.

Dilute solution has a relatively high

refrigerant content and low lithium

bromide content. An intermediate

solution is a mixture of dilute and

concentrated solutions. A concentrated

solution is one with a relatively low

refrigerant content and high lithium

bromide content.

Generator (1)

Dilute solution is pumped into the

generator, where it is boiled by the

steam or hot water in the tube bundle,

creating refrigerant vapor. The

refrigerant vapor flows to the condenser

(2). The now-concentrated solution

flows by gravity, through the solution

heat exchanger to the absorber spray

system, where it is mixed with dilute

solution from the absorber and sprayed

on the absorber tube bundle.

Condenser (2)

Refrigerant vapor, produced by the

generator, enters the condenser and

changes to a liquid through

condensation. The heat of condensation

is rejected to the cooling water inside the

tube bundle.

Evaporator (3)

The liquid refrigerant leaves the

condenser through a J tube, where the

pressure/temperature is reduced

through expansion for delivery to the

evaporator at 41°F [5°C]. System water

runs through the tube bundle where its

heat is transferred to the refrigerant,

causing the refrigerant to vaporize/boil.

The refrigerant vapor flows to the

slightly lower pressure in the absorber.

Absorber (4)

Refrigerant vapor is absorbed by the

lithium bromide solution. The now-dilute

solution is pumped through the solution

heat exchanger and on to the generator.

The heat of vapor absorption is rejected

via the cooling water inside the tube

bundle.

Benefits

Figure FB-1. Single-stage absorption refrigeration cycle

(1) Solution 215°F [102°C], Vapor 207°F [97°C]

(6)

Absorption Process (5)

Solution (concentrated) enters the spray

system from the generator and enters

the spray system, wetting the tubes and

providing a liquid surface for the

refrigerant vapor (from the evaporator)

to absorb into the lithium bromide

solution. The solution temperature/

concentration sprayed in the absorber

controls the absorber pressure, thereby

controlling the evaporator refrigerant

temperature.

Cycle

(5) Entering

Solution Heat Exchanger (6)

Solution flows through the heat

exchanger to be preheated, reducing the

heat energy required to induce boiling

within the generator, and to decrease the

temperature of the solution being

returned to the absorber, thus

decreasing the load on the cooling

tower.

(2) Refrigerant 100°F [38°C], Entering/

Leaving Cooling Water

94°F/102°F [34°C/39°C]

(3)

Entering/Leaving System

Water 54°F/44°F [12°C/7°C],

Evaporator Pump

Refrigerant 41°F [5°C]

(4) Leaving Solution 107°F

[42°C], Entering/Leaving

Cooling Water 85°F/94°F

Solution

120°F [49°C]

[29°C/34°C]

ABS-PRC001-EN

7

Page 8

Application

General

The Horizon single-stage steam-fired or

hot water absorption chiller is designed

to provide 40°F to 60°F [4.4°C to 15.6°C]

chilled water, for comfort or process

cooling applications, within all three

market segments – commercial,

industrial and institutional. They are

most-often used where an economic

analysis of fuel costs versus electrical

rates indicates an operating cost

advantage.

In many process applications, they can

be utilized to convert excess heat energy

to provide chilled water for process or

comfort applications.

Operating Limits

Trane single-stage absorption chillers

operate with nominal 12 psig [0.83 bar]

steam or nominal 270°F [132°C] hot

water. In all applications, superheat

should be limited so steam temperature

does not exceed 340°F [171°C].

Waterflows that are within the limits

indicated on the appropriate selection

table will ensure tube water velocities

not exceeding 10 feet per second

[3.05 m/sec] in copper tubes and 11 feet

per second [3.35 m/sec] in cupronickel

tubes. Changes in condenser water

temperature should not exceed

1°F per minute in the range from 75°F to

95°F [23.9°C to 35°C].

Sound and Vibration

Absorption units are well-suited for

areas where low sound levels are

required. The Trane Horizon single-stage

steam absorption chiller will operate

under normal load conditions at less

than 85 dBA sound pressure level.

During operation there is no vibration of

any components that could be

damaging to the chiller or that could

transmit objectionable sound or

vibration to the building.

Considerations

Chiller Installation

The following should be considered

when installing an absorption chiller:

• Rigging and service clearances

• Foundation support

• Chiller isolation for sound/vibration

reduction

• Condensate handling

• Steam supply control

• Condenser-water temperature control

• Chilled-water flow control

• Chilled- and condenser-water flow limit

• Generator hot-water application

Cooling-Tower Water Flow

The ARI standard gpm/ton for singlestage absorption chillers is 3.6, however,

lower flow through the condenser and

absorber section will present an

opportunity for a smaller tower, smaller

piping, and smaller condenser pump.

For more information on lower flows in

the cooling tower water circuit, refer to

the appropriate Trane engineering

bulletin, available from your local Trane

representative.

Water Treatment

The use of untreated or improperly

treated water may result in scaling,

erosion, and corrosion, algae or slime. It

is recommended that the services of a

qualified water-treatment specialist be

used to determine what treatment, if

any, is advisable. The Trane Company

assumes no responsibility for the results

of untreated or improperly treated water.

Combination Systems

Peak energy savings can be achieved

when using a combination of electric

chillers and absorption chillers for air

conditioning loads. The absorption

chiller is used to shave seasonal, billable

peak-power demands during summer

operation, and the electric chiller is run

below the allowed demand limit,

reducing costly demand charges. Trane

offers both electric chillers and

absorption chillers with the unit control

panel (UCP2) as standard. Although the

General

chillers have different features and

modes of operation, the chiller control

panel looks and acts the same when

used with any chiller model. Each

control panel is programmed to monitor

the particular chiller for which it was

designed, however, maintenance and

service personnel only need to become

familiar with one control panel.

Combined with a Trane Tracer

chiller plant has almost unlimited

operational flexibility, and all equipment

is supplied from a single source.

Multiple Machine Installations

The Trane absorption machine can be

applied to series or parallel chilled-water

flow, depending upon the design

requirement. The arrangement that is

best for an individual system should be

based on an analysis of system water

and temperature rise requirements,

system and machine pressure-drop

characteristics, and installation cost.

Parallel flow allows minimum chilledwater pressure drop through the

machines. However, with one machine

“off,” it is not usually possible to

maintain the design chilled-water

temperature unless one machine is

isolated with shut off valves and the

chilled-water flow decreased.

Series flow permits design chilled-water

temperature at light loads with one

machine “off.” However, at all operating

conditions, the chilled-water pressure

drop through the machine is high.

Accurate chilled-water temperatures can

be maintained on individual machines

between 100 percent and 10 percent of

nominal chiller load, which allows for a

wide range of control options. Each

chiller has a stand-alone control system

to manage the desired water

temperature, and also the ability to

receive remote commands to support

various system demands from a control

center. This versatility of control makes

the management of more than one

machine relatively easy.

®

system, a

ABS-PRC001-EN8

Page 9

Selection Procedure

Selection Procedure

Absorption refrigeration machines are

usually selected to provide the required

refrigeration capacity with the smallest

practical machine of sufficient size.

Machine size is based on chilled-water

flow rates and temperatures specified for

the air side of the system.

Total air-conditioning system first cost

can be minimized by a careful analysis of

system operating parameters. The effect

of flow rates and temperatures, on both

the building air side and the refrigeration

machine selections, should be

investigated to determine which system

represents the best investment for the

owner.

The information on the following pages

provides performance data, at ARI

standard conditions, for capacity in tons,

efficiency, flow rates and water pressure

drops. All capacities are in accordance

with the expected ARI 560 Standard

revision, and are based on fouling

factors of .0001 for the evaporator

waterside tubing and .00025 for the

absorber and condenser tubing.

Standard Fouling

Unit performance at non-standard

fouling factors may vary from standard

performance. Fouling factors estimate

the heat transfer penalty that coincides

with the effect of typical fouling in

evaporator and absorber/condenser

(cooling) water circuits. All selections

should use the standard fouling factor to

more accurately estimate the chiller

performance in an equipment room and

to comply with ARI 560.

ARI Standard Fouling Factors

Evaporator Condenser/Absorber

English Units – hr-ft2-F/Btu

0.0001 0.00025

SI Units – m2-K/kW

0.018 0.044

Additional Fouling

Any selection that uses a fouling factor

greater than 0.0001 for the evaporator

tubes, and 0.00025 for the condenser/

absorber tubes, is a more conservative

estimate that should only be used if

there is an abnormal amount of fouling

contaminants in the water systems. The

ARI 560 Standard defines “additional

fouling” as “Conditions such as water

hardness, organic material, suspended

solids and/or water velocity may

necessitate the use of a greater field

fouling allowance than that provided in

the Standard Rating of equipment.” The

Trane single-stage Horizon Selection

program should be used to determine

the effect of nonstandard fouling factors.

The following guidelines can be used for

estimation prior to the selection:

ARI Standard Fouling Factors For

Additional Fouling

Evaporator Condenser/Absorber

English Units – hr-ft2-F/Btu

0.0002 0.00026 – 0.00075

SI Units – m2-K/kW

0.035 0.046

Part Load Performance

The Horizon

®

single-stage absorption

chiller exhibits excellent part-load

performance characteristics. Air

conditioning system loads are usually

significantly less than full-load design

conditions. Therefore, the absorption

chiller operates at full load a small

percentage of the time. Part-load

absorption chiller operation is normally

associated with reduced tower-water

temperatures. At part-load operation, the

heat rejected to the cooling tower is less

than at full-load operation. Also, partload operation is typically associated

with reduced outside wet-bulb

temperatures, resulting in improved

cooling tower performance. The net

result of less heat rejection and lower

wet-bulb temperature is cooler tower

water entering the chiller and improved

unit performance.

Final Selection

A final selection must be done by the

local Trane sales engineer using the

Trane Horizon

®

Single-Stage Absorption

Selection Program. For applications

higher than 1600 feet [500 meters] above

sea level, final selection requires review

by Absorption Product Marketing. Prior

to accessing the computer selection

program, the following data inputs

should be tabulated:

• Temperature or pressure of the hot

water or steam

• Two of the following three values must

be provided

1

:

– Evaporator Delta-T

– Evaporator Flow

– Cooling Capacity

• Leaving-Evaporator Water Temperature

• Entering-Absorber Water Temperature

• Cooling Water Flow

• Chilled water and tower water fouling

factors

Other options that may also be selected

are:

• Type and thickness of tube material

• Type of solution flowing through the

evaporator and tower loop

1

Any limitations or restrictions should

2

.

also be given (i.e., pressure drop, gpm

etc.).

2

Absorption chillers can be selected with

a wide variety of media other than

water (evaporator and absorber/

condenser, or both). For media other

than water, contact the local Trane sales

office for chiller selections and

information.

ABS-PRC001-EN

9

Page 10

Selection

Product Coding

Procedure

Selection

Product Coding Description

The coding block precisely identifies all

characteristics of any Horizon® Single-Stage

Steam-Fired or Hot Water Absorption Chiller.

Table S-1. Product coding description

MODL Absorption Unit Model

ABSD Single Stage Absorption

NTON Unit Nominal Tonnage

500 500 Nominal Tons

600 600 Nominal Tons

700 700 Nominal Tons

800 800 Nominal Tons

975 975 Nominal Tons

1100 1100 Nominal Tons

1225 1225 Nominal Tons

1350 1350 Nominal Tons

VOLT Unit Voltage

190 190 Volt - 50 HZ

200 200 Volt - 60 HZ

220 220 Volt - 50 HZ

230 230 Volt - 60 HZ

380 380 Volt - 50 HZ

415 415 Volt - 50 HZ

460 460 Volt - 60 HZ

575 575 Volt - 60 HZ

ENSR Unit Energy Source

STM Steam Energy Source

HOTW Hot Water Energy Source

ENPR Unit Energy Pressure

50 Steam Energy Pressure - 50 PSIG

ASME Required

150 Hot Water Energy Pressure - 150

PSIG - ASME Required

400 Hot Water Energy Pressure – 400

PSIG - ASME Required

PVCN Pressure Vessel Construction

STD Standard Construction

Standard construction (includes

ASME LTGN)

PURG Purge System

AUTO Automatic Purge System

LGTM Generator Tubes

SB04 .028 Wall 90-10 CUNI Smooth

Surface

SB05 .035 Wall 90-10 CUNI Smooth

Surface

SB06 .049 Wall 90-10 CUNI Smooth

Surface

SB16 .028 wall 409 SST smooth surface

CDTM Condenser Tubes

SB09 .028 Wall Copper Smooth Surface

SB10 .035 Wall Copper Smooth Surface

SB04 .028 Wall 90-10 CUNI Smooth

Surface

SB05 .035 Wall 90-10 CUNI Smooth

Surface

SB06 .049 Wall 90-10 CUNI Smooth

Surface

SB17 .028w 316L SST Smooth Surface

Description

EVTM Evaporator Tubes

ES12 .025 Wall Copper Enhanced Surface

ES11 .025 Wall 90-10 CUNI Enhanced

Surface

ES05 .035 Wall 90-10 CUNI Enhanced

Surface

ABTM Absorber Tubes

SB00 .022 Wall 95-5 CUNI Smooth Surface

SB01 .028 Wall 95-5 CUNI Smooth Surface

SB02 .035 Wall 95-5 CUNI Smooth Surface

SB03 .049 Wall 95-5 CUNI Smooth Surface

SB04 .028 Wall 90-10 CUNI Smooth

Surface

SB05 .035 Wall 90-10 CUNI Smooth

Surface

SB06 .049 Wall 90-10 CUNI Smooth

Surface

SB09 .028 Wall Copper Smooth Surface

SB17 .028 Wall 316L SST Smooth Surface

GNWA LTGN - Generator Water Box

Arrangement

GN02 1-Pass Non-Marine RF Flange

GN04 2-Pass Non-Marine RF Flange

CAWA Condenser and Absorber Water Box

Arrangement

CA17 150 PSI Marine Victaulic

CA18 150 PSI Marine RF Flange

CA19 150 PSI Non-Marine Victaulic

CA20 150 PSI Non-Marine RF Flange

EVWA Evaporator Water Box Arrangement

EV31 1-Pass 150 PSI Non-Marine Victaulic

EV32 1-Pass 150 PSI Non-Marine RF Flange

EV01 2-Pass 150 PSI Non-Marine Victaulic

EV02 2-Pass 150 PSI Non-Marine RF Flange

CAWC Condenser and Absorber Water

Connections

RERE In right-hand end – out right-hand

end (700, 800, 1000, 1100, 1200 tons)

LELE In left-hand end – out left-hand end

(500 tons)

LERE In left-hand end – out right-hand end

(600 and 900 tons)

EVWC Evaporator Water Connections

LEBK Inlet Connection Left Back

LEFR Inlet Connection Left Front

REBK Inlet Connection Right Back

REFR Inlet Connection Right Front

LEND In left end, out the other end

REND In right end, out the other end

CAFT Condenser and Absorber Water Box

Fluid Type

WTR Water

EGLY Ethylene Glycol Solution

PGLY Propylene Glycol Solution

EVFT Evaporator Water Box Fluid Type

WTR Water

EGLY Ethylene Glycol Solution

PGLY Propylene Glycol Solution

ABS-PRC001-EN10

Page 11

Selection

Product Coding

Procedure

EVLV Unit Energy Valve

BF02 2-Way 3" 150# Wafer Btrfly

BF03 2-Way 4" 150# Wafer Btrfly

BF04 2-Way 6" 150# Wafer Btrfly

BF05 2-Way 8" 150# Wafer Btrfly

BF22 3-Way 3" 150# Flanged tee Wafer

Btrfly

BF23 3-Way 4" 150# Flanged tee Wafer

Btrfly

BF24 3-Way 6" 150# Flanged tee Wafer

Btrfly

BF32 3-Way 3" 300# Flanged tee Wafer

Btrfly

BF33 3-Way 4" 300# Flanged tee Wafer

Btrfly

BF34 3-Way 6" 300# Flanged tee Wafer

Btrfly

BF42 2-Way 3" 150# Flanged Btrfly

BF43 2-Way 4" 150# Flanged Btrfly

BF44 2-Way 6" 150# Flanged Btrfly

BF45 2-Way 8" 150# Flanged Btrfly

VB01 2-Way 2" 150# Wafer V-Ball

VB02 2-Way 3" 150# Wafer V-Ball

VB03 2-Way 4" 150# Wafer V-Ball

VB11 2-Way 2" 300# Wafer V-Ball

VB12 2-Way 3" 300# Wafer V-Ball

VB13 2-Way 4" 300# Wafer V-Ball

VB41 2-Way 2" 150# Flanged V-Ball

VB42 2-Way 3" 150# Flanged V-Ball

VB43 2-Way 4" 150# Flanged V-Ball

EVIN Unit Energy Valve Installation

FLD Field-installed Energy Valve

FACT Factory-installed Energy Valve

EVPN Evaporator Pan construction

STD Evaporator Pan – Steel

SSTL Evaporator Pan – Stainless Steel

UPNT Unit Paint

SFPT Standard Factory Paint – Entire Unit

CSPT Customer Specified Paint – Entire

Unit

WCNM Water Chiller Nameplate

SNMP Standard ABS Water Chiller

Nameplate

BNMP Decorative Brass ABS Water Chiller

Nameplate

SPKG Unit Shipping Package

DAU Domestic – Assembled Unit

DDG Domestic – 2-Piece Disassembled

Unit

DAGF Domestic – Assembled - 2-Piece Field

Disassembly

EAU Export – Assembled Unit

EDG Export – 2-Piece Disassembled Unit

EAGF Export – Assembled - 2-Piece Field

Disassembly

Description

ELPP Electrical Protection Package

SELP Standard Electrical Package

PPCO Control Panel Power Connection

CB Circuit Breaker

FDS Fused Disconnect Switch

NFDS Non-Fused Disconnect Switch

TB Terminal Block

LCLD Local Clear Language Display

CLDC Clear Language Display – Complex

Character

CLDO Clear Language Display – Suitable for

Outdoor Use

TRIM Tracer Interface Control Module

TRMI Tracer 100 Interface Module (com3)

TRMS Tracer Summit Interface Module

(com4)

PRIM Printer Interface Control Module

YES Printer Interface Module

ACWR Ambient Chilled Water Reset

YES Ambient Chilled Water Reset

WVUO Under/Over Phase Voltage

Protection

YES Under/over Voltage Protection

CTWF Chiller/Tower Water Flow Display

YES Differential Water Pressure

Transducers

OPTM Options Control Module

YES Options Module

AFDS Adjustable frequency drive

YES Frequency drive

FLSW Flow Switches

1FS1 150 PSI NEMA 1 Flow Switch

- QTY of 1

1FS2 300 PSI NEMA 1 Flow Switch

- QTY of 1

1FS3 150 PSI NEMA 4 Flow Switch

- QTY of 1

1FS4 300 PSI NEMA 4 Flow Switch

- QTY of 1

2FS1 150 PSI NEMA 1 Flow Switch

- QTY of 2

2FS2 300 PSI NEMA 1 Flow Switch

- QTY of 2

2FS3 150 PSI NEMA 4 Flow Switch

- QTY of 2

2FS4 300 PSI NEMA 4 Flow Switch

- QTY of 2

LBMF Lithium Bromide Filter

Yes Lithium Bromide Filter

UINS Unit Insulation

CINS Cold Unit Insulation Only

CRPI Condenser Cross-Over pipe

Yes Condenser cross-over pipe,

factory installed

ABS-PRC001-EN

11

Page 12

Performance Data

Table PD-1. Performance data at ARI conditions

Capacity of Rate Flow Rate Press. Drop Flow Rate Press. Drop

Coefficient Steam Chilled Water Cond/Abs Water

Model (Tons) Performance (lbm/ton/hr) (gpm) (ft Wtr) (gpm)*** (ft Wtr)

ABSD500 571 0.71 17.71 1366 19.7 1800 27.4

ABSD600 670 0.72 17.45 1603 30.2 2160 26.6

ABSD700 738 0.71 17.68 1766 22.3 2520 12.2

ABSD800 859 0.72 17.62 2054 32.6 2880 16.6

ABSD975 998 0.71 17.91 2387 18.8 3510 33.5

ABSD1100 1105 0.70 17.98 2643 24.6 3960 20.1

ABSD1225 1238 0.70 17.95 2960 32.7 4410 25.7

ABSD1350 1371 0.71 17.90 3279 42.2 4860 32.2

* 3.6 gpm/nominal ton, Pstm = 12 psig, TctwS = 85°F, TcwS = 44°F, TcwR = 54°F, 0.0001 evap fouling,

0.00025 cond/abs fouling

Coefficient Steam Chilled Water Cond/Abs Water

Capacity of Rate Flow Rate Press. Drop Flow Rate Press. Drop

Model (kW) Performance (kg/kW-hr) (m

ABSD500 2008 0.71 2.28 310 6.0 409 8.3

ABSD600 2356 0.72 2.25 364 9.2 491 8.1

ABSD700 2595 0.71 2.28 401 6.8 572 3.7

ABSD800 3021 0.72 2.27 466 9.9 654 5.1

ABSD975 3510 0.71 2.31 542 5.7 797 10.2

ABSD1100 3886 0.70 2.32 600 7.5 899 6.1

ABSD1225 4354 0.70 2.31 672 10.0 1002 7.8

ABSD1350 4821 0.71 2.31 745 12.9 1104 9.8

** 0.23 m3/nominal kWh, Pstm = 0.83 bar, TctwS = 29.4°C, TcwS = 6.67°C, TcwR = 12.2°C, 0.018 evap fouling,

0.044 cond/abs fouling

English Units*

SI Units**

3

/hr) (m wg) (m3/hr) (m wg)

ABS-PRC001-EN12

Page 13

Performance

Data

Figure PD-1. ABSD 500-800 capacity vs. chilled-water supply temperature at various

cooling-water supply temperatures

Figure PD-2. ABSD 975-1350 capacity vs. chilled water supply temperature at various

cooling water supply temperatures

ABS-PRC001-EN

13

Page 14

Performance

Data

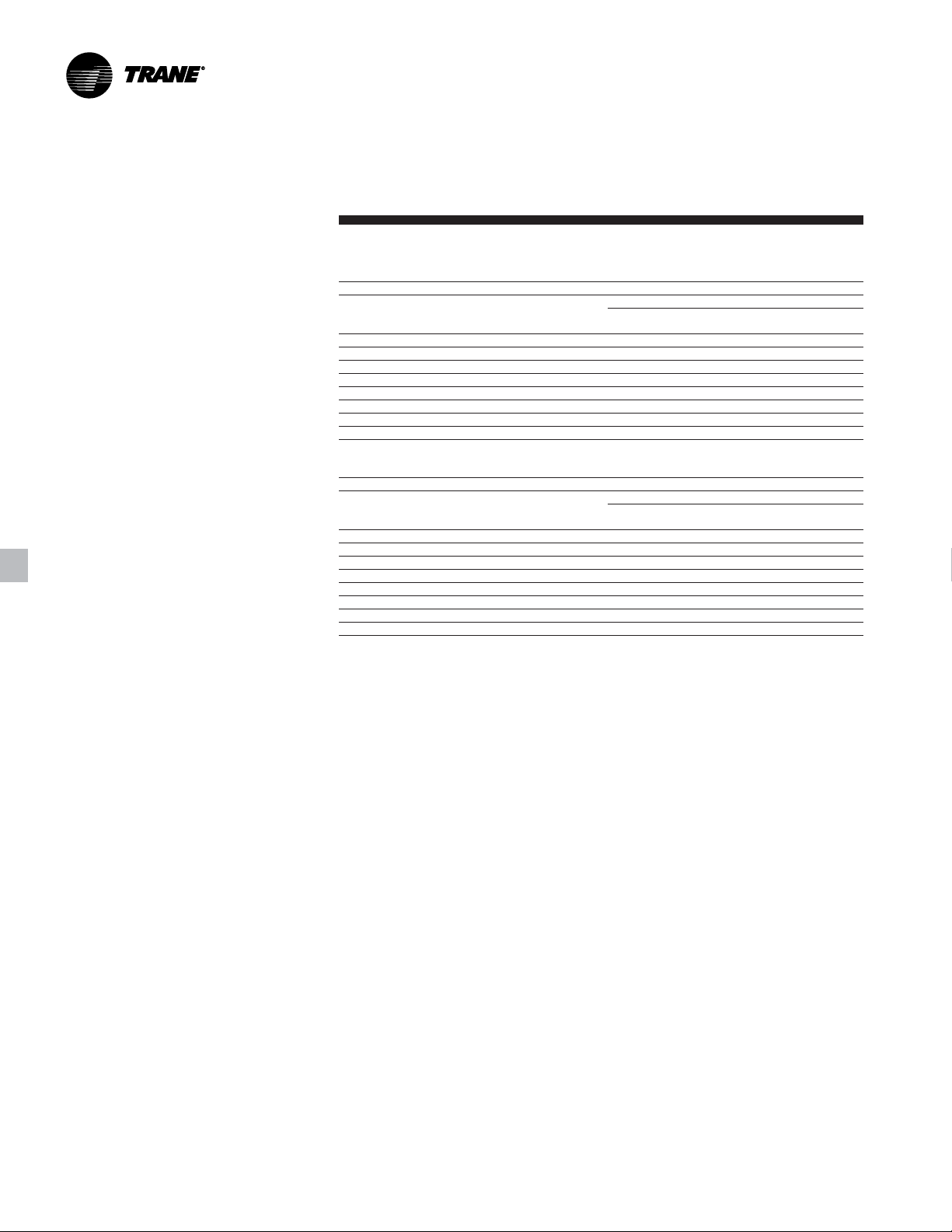

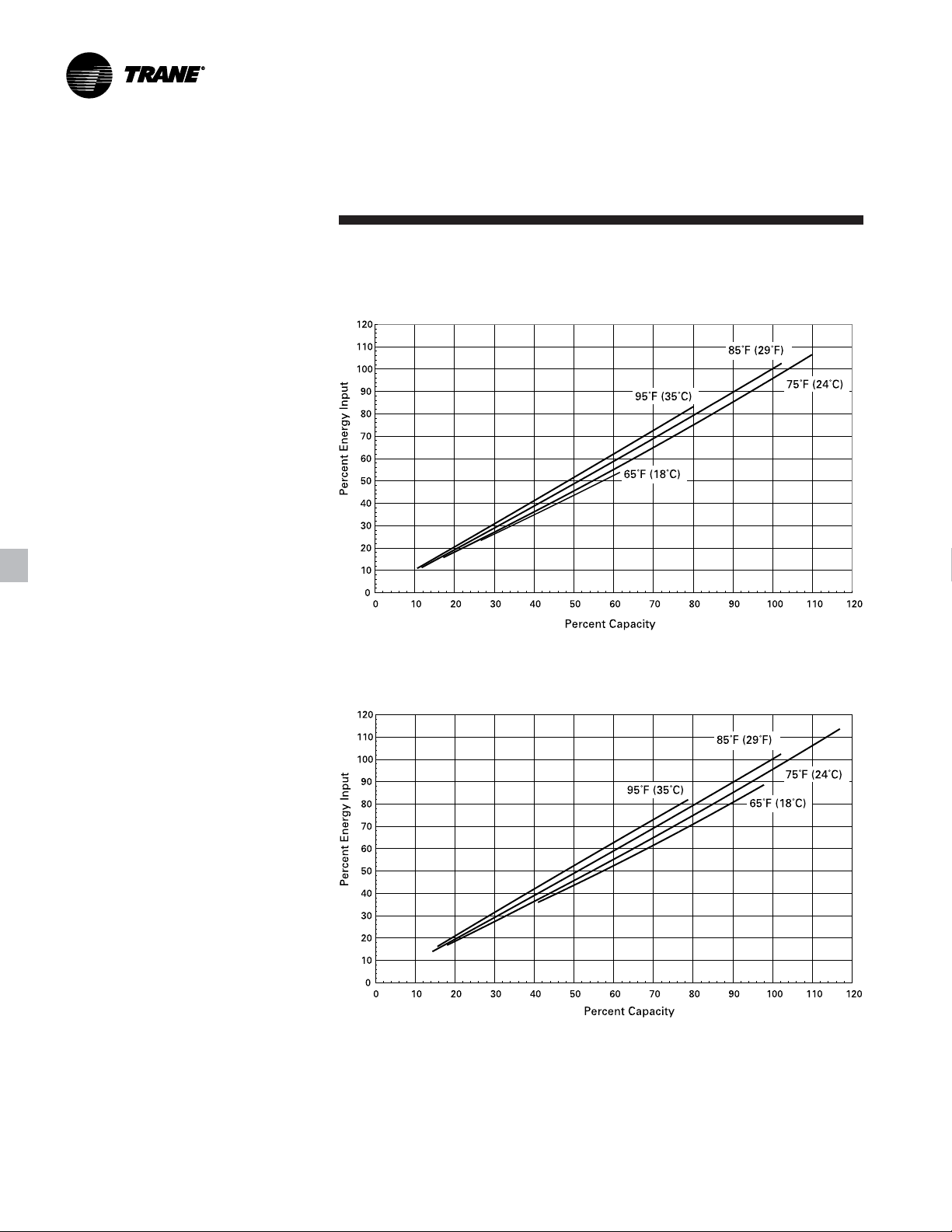

Figure PD-3. ABSD 500-800 part load performance - energy input vs. capacity at various

cooling water supply temperatures:

chilled water supply temperature = 44°F (7°C)

Figure PD-4. ABSD 975-1350 part load performance - energy input vs. capacity at various

cooling water supply temperatures:

chilled water supply temperature = 44°F (7°C)

ABS-PRC001-EN14

Page 15

Performance

Pressure Drop vs.

Data

Figure PD-5. ABSD 500-800 pressure drop vs. chilled water flow rate – English and SI Units

Water Flow Rate

Figure PD-6. ABSD 975-1350 pressure drop vs. chilled water flow rate – English and SI Units

ABS-PRC001-EN

15

Page 16

Performance

Pressure Drop vs.

Data

Figure PD-7. ABSD 500-800 pressure drop vs. cooling water flow rate – English and SI Units

Water Flow Rate

Figure PD-8. ABSD 975-1350 pressure drop vs. cooling water flow rate – English and SI Units

ABS-PRC001-EN16

Page 17

Electrical Data

Electrical Data

Factory-wired and-mounted power control includes main power connections. Total kW includes solution and refrigerant pump,

motors, purge pump motor and control panel. Units may be supplied for operation on 230,460 or 575 volt, 3-phase, 60-hertz

power, or 190, 220, 380 or 415 volt, 3-phase, 50-hertz power.

Table ED-1. Electrical data

Model Voltage FLA HP kW Amps MCA Amps

500 200 69.0 13.0 9.7 10.0 86 90

thru 230 60.0 13.0 9.7 8.7 75 80

600 460 30.0 13.0 9.7 4.4 37 40

700 200 90.0 17.5 13.0 10.0 109 110

thru 230 78.0 17.5 13.0 8.7 94 100

800 460 39.0 17.5 13.0 4.4 47 50

975 230 78.0 17.5 13.0 8.7 94 100

1100 200 96.0 20.0 14.9 10.0 115 125

thru 230 84.0 20.0 14.9 8.7 100 110

1350 460 42.0 20.0 14.9 4.4 50 60

Model Voltage FLA HP kW Amps MCA Amps

500 190 62.0 13.0 9.7 10.5 79 80

thru 220 52.4 13.0 9.7 9.1 67 70

600 380 30.0 13.0 9.7 5.3 38 40

700 190 67.0 15.5 11.6 10.5 85 90

thru 220 57.4 15.5 11.6 9.1 73 80

800 380 33.0 15.5 11.6 5.3 42 45

975 190 80.0 17.5 13.0 10.5 98 100

1100 190 85.0 20.0 14.9 10.5 103 110

thru 220 73.0 20.0 14.9 9.1 89 90

1350 380 42.0 20.0 14.9 5.3 51 60

Supply Total Motor Total Motor Control Circuit Max Fuse Size

575 25.0 13.0 9.7 3.5 31 35

575 32.0 17.5 13.0 3.5 39 40

200 90.0 17.5 13.0 10.0 109 110

460 39.0 17.5 13.0 4.4 47 50

575 32.0 17.5 13.0 3.5 39 40

575 34.0 20.0 14.9 3.5 41 45

Supply Total Motor Total Motor Control Circuit Max Fuse Size

415 27.5 13.0 9.7 4.8 35 35

415 30.5 15.5 11.6 4.8 39 40

220 68.0 17.5 13.0 9.1 84 90

380 39.0 17.5 13.0 5.3 48 50

415 36.0 17.5 13.0 4.8 44 45

415 39.0 20.0 14.9 4.8 47 50

60 Hertz, 3-Phase

50 Hertz, 3-Phase

ABS-PRC001-EN

17

Page 18

Electrical

Data

Wiring

ABS-PRC001-EN18

Page 19

Electrical

Data

Wiring

ABS-PRC001-EN

19

Page 20

Controls Data

Setting The Standards

Trane set the standard for unit

microprocessor controls in 1985 with the

first generation of Unit Control Panel.

Associated with this standard have been:

• Proportional Integral Derivative (PID)

control strategies, which provide stable

operation and high accuracy for better

performance, along with feed forward

plus;

• Adaptive Control

™

to keep the chiller

“on line” and at the same time keep the

chiller away from a major failure;

• Software based safeties that do not

depend on electromechanical hardware

– hardware that means questionable

reliability and added cost;

• Operator interface that accesses chiller

information and control adjustments at

the front of the panel.

™

UCP2

UCP2 adds more flexibility, more

reliability and better system performance

than even our most demanding

customers expect.

Flexibility

Trane offers the ability to adapt to

changes easily and effectively without

adding prohibitive cost. To provide

flexibility, the controller responds to a

wide variety of needs for:

• System Designs, including equipment,

operating conditions and controls

variations that are either existing or

being considered for new installations.

Key to designing non-traditional

systems is the ability to evaluate the

cost and reliability issues of these

systems in comparison to the more

traditional systems. Trane recommends

the use of C.D.S. Network Equipment

Economics, the Trane Applications

Manuals and consultation with a Trane

sales engineer for help in this analysis.

• System Upgrades, including the ability

to accommodate changes in the chilledwater system design or equipment

room requirements, or to

accommodate new technologies that

become available.

• Modular structure of the UCP2 makes it

possible for the designer to select the

system controls and associated

interfaces to Tracer

®

(or other building

automation systems) that are required

for the chiller plant design. With this

modular concept, capability can be

added or upgraded at any time, with

only temporary interruption of chilledwater production.

• The operator can quickly program a

Custom Report — so that only what are

considered to be the most frequently

accessed/important reports are

available — at any time, right at the

front of the panel.

• With easy front panel programmability

of Daily, Service Start-up and Machine

Configuration settings and setpoints,

the operator, serviceman and system

designer can customize the use of the

micro controller to unique conditions of

the chiller plant — whether the purpose

of chilled water is for comfort cooling or

for process cooling.

• All data that is necessary for the safe

operation and easy serviceability of the

chiller is provided as standard on all

Horizon

®

absorption chillers. Options

are available that provide additional

controls/data that are required for: an

industrial/process system design,

applications outside of the typical

chilled water system design, the need

for redundant machine protection or the

desire for more system information.

ABS-PRC001-EN20

Page 21

Controls Data

Reliability

To most people, reliability means

“dependability — giving the same result

on successive trials.” To our customers,

however, it has come to mean “keep

chilled water flowing.” In other words,

“when I turn the switch on, cold water

comes out.” In order to do this, the

micro controller must be aware of what

is happening in the system. But more

importantly, it must be able to make

decisions and adjustments to keep the

chiller running as long as possible, even

when non-standard conditions exist —

conditions such as bad power, bad water

(flow, temperature, fouling) or system

component failure. Also, the Trane UCP2

panel continuously monitors for

noncondensables and purges

automatically.

• With Enhanced Adaptive Control

controller does everything it can to

avoid taking the chiller offline.

— Senses evaporator temperature

limit and high temperature limit

— Displays a warning message about

the potential condition/safety trip

— Takes the following corrective action

sequentially as the condition

worsens:

- limits loading

- prevents further loading

- unloads until condition improves

- takes chiller offline

• With more diagnostics and diagnostic

history that are time/date stamped and

with help messages, the operator or

serviceman can take faster and more

effective corrective action.

™

the

System Performance

“Chilled Water System” encompasses

many levels of control: Standalone

Chiller, Chiller Plant, Applied System,

Central Building Automation System.

However, regardless of the system level

being designed, the unit controls

become critical, not just in making every

level operate reliably but also in

facilitating optimal performance. UCP2

provides more capability and more

intelligence to make this operation/

optimization possible.

Panel Features:

The absorption chiller Unit Control Panel

(UCP2) incorporates the following

features and components:

Control Functions

• Smart dilution-cycle duration based on

system requirements

• Adaptive evaporator leaving-fluid

temperature control

• Low evaporator-temperature limit

• High solution-temperature limit

• Solution flow control via AFD

• Soft loading

• Nuisance trip prevention via Adaptive

Control

• Chilled-water reset

• Optimum concentration control

• Crystallization recovery via SDR

ABS-PRC001-EN

21

Page 22

Controls Data

Safeties

• Smart shutdown sequence: condenser/

absorber loss of flow

• Low condenser/absorber water

temperature

• High-pressure cutout

• Evaporator leaving-fluid temperature

cutout

• Motor current overload

• High motor-winding temperature

• Over/under voltage (optional)

• Purge limit

• Sensor failure detection

Monitored Points

Chiller information is available at the

operator interface via a clear language

display. Access to the information is

through four dedicated report keys:

Customer, Chiller, Cycle and Pump/

Purge.

Customer Report

User-defined custom report (operator

may choose up to 20 points from a list of

over 100 choices).

Chiller Report

Status, fluid temperatures, and setpoints:

• Operating mode (i.e. run status)

• Chilled-water setpoint

• Evaporator entering/leaving water

temperatures

• Absorber entering/leaving water

temperatures

• Condenser leaving-water temperature

outdoor air temperature

• Evaporator leaving-water temperature

• Chilled-water reset

Cycle Report

Refrigerant temperatures and pressures:

• Solution temperature leaving generator

• Solution temperature entering

generator

• Generator-leaving concentration

• Generator cutout and monitor

temperature

• Crystallization detection temperature

• Crystallization trip temperature

• Saturated condenser refrigerant

temperature

• Absorber-entering concentration

• LiBr crystallization margin

• Solution temperature entering absorber

• Absorber spray temperature

• Solution temperature leaving absorber

• Saturated evaporator refrigerant

temperature

• Evaporator leaving-water temperature

• Evaporator entering-water temperature

• Absorber entering-water temperature

• Absorber leaving-water temperature

• Condenser leaving-water temperature

• Solution pump auto/manual speed

command

• Energy input auto/manual/slaved

reported command

• Steam Supply Pressure

• Generator Steam Pressure

Pump/Purge Report

• Solution pump

— Counters for starts and hours

— Motor phase currents

— Motor phase voltages (optional)

• Purge Pump

— Operating mode and status

— Refrigerant suction temperature

— Pumpout rate

— Total pumpout time

— Service log

ABS-PRC001-EN22

Page 23

Controls Data

Diagnostics

The absorption chiller Unit Control Panel

(UCP2) provides over 70 different

diagnostics such as:

• Water and refrigerant/solution

temperatures out of range

• Loss of system waterflows

• Sensor and switch faults

• Overload trips

• Over/under voltage (optional)

• Crystallization recovery

• Emergency stop

• Loss of communication to other

modules

• Motor abnormal

Operator Interface

The Trane Horizon

®

steam-fired

absorption chiller control panel, UCP2, is

easy to use, understand, access

information, read, change setpoints,

diagnose problems, maintain, and to

reset after shutdown.

Convenience

Enunciation of all information is at the

front panel display (including power,

voltage, amps, purge pressures, and

number of starts data). Messages are

displayed using clear language.

Readability

• Two-line, 40-character display that is

easy to read from within a 60-degree

angle

• LCD backlight so that the display can be

read in a variety of equipment-room

lighting

• Seven languages available

• Metric (SI) units available

• Complete character human interface

available

Ease of Use

• Keypad programmability — no manual

switches or setpoint potentiometers

• Logically arranged report groups with

report header and setpoint groups

• Selectable security

• Variable points updated every two

seconds

• Messages that direct user to problem

source via a menu item

Trane ICS Compatibility

The Trane absorption chiller control

panel, UCP2, is 100 percent compatible

with the Trane Integrated Comfort

systems, ICS, UCP2 easily integrates into

the Tracer

®

family of flexible chiller-plant

™

system controllers with a single twistedwire pair communications cable.

For more information on the Trane

absorption chiller unit control panel,

please contact your local Trane sales

engineer.

ABS-PRC001-EN

23

Page 24

Dimensions

Physical

ABSD 500, 600, 700, 800

Physical Dimensions

English and SI Units

and Weights

This section provides the overall dimensions of the Horizon absorption chiller.

See unit submittal drawings for configured water nozzle connection dimensions.

A 500 Ton 2 pass absorber and condenser is illustrated. All catalog dimensional

drawings are subject to change. Current submittal drawings should be referred to for

detailed dimensional information. Contact the local Trane sales office for submittal

and template information.

Table DW-1. Dimensional data

Unit A B C D E F

500 13’-9½” 14’-5½” 1’-73/8” 17’-9¾” 14’-21/8” 8’-07/8”

600 16’-5½” 17’-1½” 1’-87/8” 20’-7¼” 16’-101/8” 10’-87/8”

700 19’-13/8” 19’-9½” 1’-87/8” 23’-3¼” 19’-61/8” 13’-111/8”

800 21’-93/8” 22’-5½” 1’-87/8” 25’-11¼” 22’-21/8” 16’-107/8”

Unit A B C D E F

500 4204 4407 492 5429 4321 2461

600 5017 5220 530 6280 5134 3273

700 5826 6033 530 7093 5947 4245

800 6639 6845 530 7906 6760 5153

Dimensions

English Units

SI Units

ABS-PRC001-EN24

Page 25

Dimensions

Physical

Table DW-2. English to SI Units

Cross Reference

Conversion Chart

English Units SI Units

1 7/8" 48

2" 51

1' 0 5/16" 313

1' 1 1/2" 343

1’ 1 9/16” 344

1' 3 1/2" 394

1' 8" 508

1' 8 7/8" 530

1' 11 9/16" 598

2' 0 1/2" 622

2' 8" 813

2' 8 5/8" 829

3' 1" 940

3' 1 3/4" 959

3’ 1 13/16” 960

3' 5 7/8" 1064

3' 6" 1067

3' 9" 1143

4' 0 1/8" 1222

4' 6" 1372

4' 9" 1448

5' 3 7/8" 1622

6' 3" 1905

7' 4" 2235

7' 5 7/16" 2272

8' 6 1/16" 2593

9' 5 1/`16" 2886

9' 6 9/16" 2910

(Ft. to mm)

and Weights

Dimensions

ABS-PRC001-EN

25

Page 26

Dimensions

Physical

ABSD 975, 1100, 1225, 1350

Physical Dimensions

English and SI Units

and Weights

This section provides the overall dimensions of the Horizon absorption chiller.

See unit submittal drawings for configured water nozzle connection dimensions. All

catalog dimensional drawings are subject to change. Current submittal drawings

should be referred to for detailed dimensional information. Contact the local Trane

sales office for submittal and template information.

Table DW-3. Dimensional data

Unit A B D E F

975 17' - 7 1/2" 18' - 0" 21' - 8" 17' - 3" N/A

1100 19' - 7 1/2" 20' - 0" 23' - 8" 19' - 3" N/A

1225 21' - 7 1/2" 22' - 0" 25' - 8" 21' - 3" N/A

1350 23' - 7 1/2" 24' - 0" 27' - 8" 23' - 3" N/A

Unit A B D E F

975 5372 5486 6604 5258 N/A

1100 5982 6096 7214 5868 N/A

1225 6591 6705 7823 6477 N/A

1350 7201 7315 8433 7087 N/A

Dimensions

English Units

SI Units

ABS-PRC001-EN26

Page 27

Dimensions

Physical

Table DW-4. English to SI Units

Cross Reference

Conversion Chart

English Units SI Units

4' - 2 1/16" 50

2" 51

3 1/4" 83

9 1/2" 241

10 1/16" 256

1' - 2 3/4" 375

1' - 3 1/2" 394

1' - 4 7/16" 418

1' - 9 7/8" 556

2' - 3 5/8" 702

3' - 3 1/8" 994

3' - 4" 1016

3' - 6" 1067

3' - 8" 1118

4' - 6" 1372

5' - 1 15/16" 1573

5' - 2 7/16" 1586

5' - 9 3/4" 1772

6' - 0" 1829

6' - 9 7/8" 2080

7' - 4 1/8" 2238

8' - 2 5/16" 2497

8' - 4 1/4" 2546

8' - 10 5/8" 2708

9' - 6 9/16" 2910

9' - 7 11/16" 2938

11' - 6 1/4" 3512

11' - 7 1/2" 3543

(Ft. to mm)

and Weights

Dimensions

ABS-PRC001-EN

27

Page 28

Dimensions

Disassembly

Separated Machine Sections

Disassembled machines can ship to the

job site in two main sections, the

evaporator/ absorber as a section and

the low temperature generator/

condenser as a separate section. Contact

the local Trane sales office for current

submittal information.

and Weights

Figure DW-1. Disassembly options – right end view

Options

Table DW-5. Disassembly and center of gravity dimensions

Unit Size 500 600 700 800 975 1100 1225 1350

A 5’ 11¼” 5’ 11¼” 5’ 11¼” 5’ 11¼” 8'-2 3/8” 8'-2 3/8” 8'-2 3/8” 8'-2 3/8”

B 3’ 5 5/8” 3’ 5 5/8” 3’ 5 5/8” 3’ 5 5/8” 3'-11¼” 3'-11¼” 3'-11¼” 3'-11¼”

C 3’ 9 3/8” 3’ 10” 3’ 10 1/8” 3’ 10 3/8” 4'-8 ¾" 4'-8 ¾" 4'-8 ¾" 4'-8 ¾"

D* 7’ 3” 7’ 3” 7’ 3” 7’ 3” 8'-2 5/8" 8'-2 5/8" 8'-2 5/8" 8'-2 5/8"

E 3’ 2 5/8” 3’ 2 5/8” 3’ 2 5/8” 3’ 2 5/8” 4'-2 3/8" 4'-2 3/8" 4'-2 3/8" 4'-2 3/8"

F 6’ 0 3/8” 6’ 0 3/8” 6’ 0 3/8” 6’ 0 3/8” 7'-7" 7'-7" 7'-7" 7'-7"

G 2’ 9” 2’ 9” 2’ 9” 2’ 9” 3'-8 1/2" 3'-8 1/2" 3'-8 1/2" 3'-8 1/2"

H 1’ 6½” 1’ 6½” 1’ 6½” 1’ 6 ½” 2'-0 3/8" 2'-0 3/8" 2'-0 3/8" 2'-0 3/8"

A 1810 1810 1810 1810 2499 2499 2499 2499

B 1057 1057 1057 1057 1200 1200 1200 1200

C 1153 1168 1172 1178 1441 1441 1441 1441

D 2210 2210 2210 2210 2505 2505 2505 2505

E 981 981 981 981 1280 1280 1280 1280

F 1838 1838 1838 1838 2311 2311 2311 2311

G 838 838 838 838 1130 1130 1130 1130

H 470 470 470 470 619 619 619 619

*Indicates overall height of chiller. The top of the evaporator shell is the highest point on chiller sizes 975-1350 tons. The top of the control panel is the highest point on chillers 800 tons and

below.

English Units

SI Units (mm)

ABS-PRC001-EN28

Page 29

Dimensions

Foundation Support

The foundation must be level, smooth,

and capable of supporting the machine

weight. The machine legs should be

positioned over isolation pads. A

housekeeping pad or support rail is

recommended to elevate the machine

for maintenance. Any foundation pad

should provide adequate structural

support and keep the installed machine

level within 1/16-inch [1.6 mm] by length

and width for reliable operation.

Leveling marks on the evaporator and

absorber tube sheet can be used to

check the machine after it is positioned

on the pad.

Chiller Isolation

Isolation pads are provided with each

unit. The purpose of the isolation pad is

to distribute the machine weight and

minimize sound and vibration

transmission through the building

structure.

and Weights

Figure DW-2. Typical machine rigging points

Rigging

ABS-PRC001-EN

Figure DW-3. Unit anchoring detail – all sizes

29

Page 30

Dimensions

Service

Figure DW-4. Service clearances

and Weights

Clearances

ABS-PRC001-EN30

Page 31

Dimensions

Service

and Weights

Table DW-6. Service clearances

Unit Size 500 600 700 800 975 1100 1225 1350

A 33' - 10 1/4" 39' - 2 1/4" 44' - 6 1/4" 49' - 10 1/4" 40' - 11 7/8" 44' - 11 7/8" 48' - 11 7/8" 52' - 11 7/8"

B 10' - 1" 12' - 9" 15' - 5" 18' - 1" 13' - 4 1/8" 15' - 4 1/8" 17' - 4 1/8" 19' - 4 1/8"

C 11' - 3 7/8" 13' - 11 7/8" 16' - 7 7/8" 19' - 3 7/8" 15' - 1" 17' - 1" 19' - 1" 21' - 1"

D 6' - 0" 6' - 0" 6' - 0" 6' - 0" 5' - 7 3/8" 5' - 7 3/8" 5' - 7 3/8" 5' - 7 3/8"

E 5' - 3" 5' - 3" 5' - 3" 5' - 3" 5' - 3 1/2" 5' - 3 1/2" 5' - 3 1/2" 5' - 3 1/2"

F 8' - 6" 8' - 6" 8' - 6" 8' - 6" 9' - 10 7/8" 9' - 10 7/8" 9' - 10 7/8" 9' - 10 7/8"

G 13' - 9" 13' - 9" 13' - 9" 13' - 9" 15' - 2 3/8" 15' - 2 3/8" 15' - 2 3/8" 15' - 2 3/8"

H 5' - 7" 5' - 7" 5' - 7" 5' - 7" 5' - 7 3/8" 5' - 7 3/8" 5' - 7 3/8" 5' - 7 3/8"

J 4' - 1" 4' - 1" 4' - 1" 4' - 1" 5' - 4 1/4" 5' - 4 1/4" 5' - 4 1/4" 5' - 4 1/4"

K5

L 10 3/4" 10 3/4" 10 3/4" 10 3/4" 16" 16" 16" 16"

M 10 1/2" 10 1/2" 10 1/2" 10 1/2" 10" 10" 10" 10"

N 3' - 0" 3' - 0" 3' - 0" 3' - 0" 4' - 4" 4' - 4" 4' - 4" 4' - 4"

P 4' - 9" 4' - 9" 4' - 9" 4' - 9" 6' - 0" 6' - 0" 6' - 0" 6' - 0"

Unit Size 500 600 700 800 975 1100 1225 1350

A 10319 11944 13570 15196 12494 13713 14932 16151

B 3073 3886 4699 5512 4067 4677 5286 5896

C 3451 4264 5077 5890 4597 5207 5817 6426

D 1829 1829 1829 1829 1711 1711 1711 1711

E 1600 1600 1600 1600 1613 1613 1613 1613

F 2591 2591 2591 2591 3019 3019 3019 3019

G 4191 4191 4191 4191 4632 4632 4632 4632

H 1702 1702 1702 1702 1711 1711 1711 1711

J 1245 1245 1245 1245 1632 1632 1632 1632

K 137 137 137 137 203 203 203 203

L 273 273 273 273 406 406 406 406

M 267 267 267 267 254 254 254 254

N 914 914 914 914 1321 1321 1321 1321

P 1448 1448 1448 1448 1829 1829 1829 1829

3

/8"5

3

/8"5

3

/8"5

English Units

3

/8"8"8"8"8"

SI Units (mm)

Clearances

Rigging and Service Clearances

Service clearance is required on all sides

of the machine. Pay particular attention

to the control panel door clearance and

the clearance at one end for tube service.

Figure DW-4 and Table DW-6 illustrate

the recommended clearances for normal

service and tube replacement. When

sufficient overhead clearance exists, we

recommend placing a 6-8 inch

(150-200 mm) extension underneath the

machine legs for additional access under

the chiller.

Overhead lift is the recommended

method when moving a machine.

Before lifting the machine, determine the

approximate location of the center of

gravity.

ABS-PRC001-EN

31

Page 32

Dimensions

Cold

Low Temperature Insulation (Cold

Insulation Type)

Cold insulation can be ordered as a

factory-installed option. The quantity

and the areas to be covered are

illustrated in Table DW-7 and

Figure DW-5.

and Weights

Figure DW-5. Cold insulation

Insulation

Table DW-7. Cold insulation area and length

Refrigerant Storage Tubesheets

Tank Circuit Evaporator Shell & Water Boxs 2" Pipe 4.50" Pipe

500T 45.01 sq. ft 500T 97.65 sq. ft 500T-800T 99.74 sq. ft 500T-800T 11.19 LN FT 500T-800T 2.625 LN FT

600T 55.53 sq. ft 600T 115.87 sq. ft

700T 66.04 sq. ft 700T 134.12 sq. ft

800T 76.55 sq. ft 800T 152.32 sq. ft

Refrigerant Storage Tubesheets

Tank Circuit Evaporator Shell & Water Boxs 3.50" Pipe 4.00" Pipe 4.50" Pipe

975T-1350T 64.876 sq. ft 975T 154.24 sq. ft 975T-1350T 164.32 sq. ft 975T-1350T 5.97 LN FT 975T-1350T 2.92 LN FT 975T-1350T 2.24 LN FT

Refrigerant Storage Tubesheets

Tank Circuit Evaporator Shell & Water Boxs 2" Pipe 4.50" Pipe

500T 4.18 sq. m 500T 9.07 sq. m 500T-800T 9.27 sq. m 500T-800T 3411 mm 500T-800T 800 mm

600T 5.16 sq. m. 600T 10.76 sq. m.

700T 6.14 sq. m. 700T 12.46 sq. m.

800T 7.11 sq. m. 800T 14.15 sq. m.

Refrigerant Storage Tubesheets

Tank Circuit Evaporator Shell & Water Boxs 3.50" Pipe 4.00" Pipe 4.50" Pipe

975T-1350T 6.03 sq. m 975T 14.33 sq. m 975T-1350T 15.27 sq. m 975T-1350T 1820 mm 975T-1350T 890 mm 975T-1350T 683 mm

1100T 171.58 sq. ft

1225T 188.91 sq. ft

1350T 206.26 sq. ft

1100T 15.94 sq. m.

1225T 17.55 sq. m.

1350T 19.16 sq. m.

English Units

SI Units

ABS-PRC001-EN32

Page 33

Dimensions

Weights and

and Weights

Table DW-8. Weights and connection sizes

Model [lbm] [lbm] [in] [in] [lbm] [gal]

ABSD 500 22900 31800 8 8 3620 150

ABSD 600 25500 35700 8 8 4040 190

ABSD 700 28000 40100 10 10 4620 230

ABSD 800 30600 44200 10 10 5140 270

ABSD 975 36305 49910 12 12 5080 162

ABSD 1100 38769 53487 12 12 5499 179

ABSD 1225 41450 57262 12 12 5880 197

ABSD 1350 43941 60776 12 12 6215 213

Model [kg] [kg] [mm] [mm] [kg] [l]

ABSD 500 10400 14400 203 203 1642 568

ABSD 600 11500 16200 203 203 1833 719

ABSD 700 12700 18200 254 254 2096 871

ABSD 800 13900 20100 254 254 2331 1022

ABSD 975 16468 22639 305 305 2304 613

ABSD 1100 17585 24262 305 305 2494 679

ABSD 1225 18802 25974 305 305 2667 745

ABSD 1350 19931 27568 305 305 2819 805

Shipping Operating Evap Cond/Abs 54.7% Brine Refrigerant

Shipping Operating Evap Cond/Abs 54.7% Brine Refrigerant

Weights Connection Sizes Unit Charging

Weights Connection Sizes Unit Charging

English Units

SI Units

Connection Sizes

ABS-PRC001-EN

33

Page 34

Job Site

Steam Supply and

Steam Supply

Figure JC-1 illustrates a typical steamsupply piping illustration that includes

the appropriate hardware.

The steam supply piping should be

designed in accordance with good

design practice, providing strainers,

unions and gate valves for ease of

operation and maintenance. A properly

sized steam-modulating valve, based on

design flow and pressure drop

requirements, is provided by The Trane

Company.

A hand valve in the steam supply piping

is recommended when the machine will

be out of operation for an extended

period. The modulating steam valve

may experience a small amount of

leakage during shutdown. This leakage

may result in heating of the equipment

room unless the machine is properly

isolated with a hand valve.

In all applications, it is recommended

that the steam supply pressure to the

control valve inlet not exceed design to

ensure that the valve closes properly. If

steam supply pressures exceed design, a

pressure reducing station should be

used to control the steam pressure to the

valve.

The unit control has adjustable features

that minimize steam draw on start-up.

The adjustable steam-control feature

allows the user to adapt the machine to

the available steam source capability.

Connections

Figure JC-1. Typical steam supply piping

Table JC-1. Steam supply and condensate return piping responsibilities

Energy Valve X X

T-Type Strainer, Flanged connections, gate valve, drip leg

w/dirt pocket, float and thermostatic trap, pressure gauge vent X X

and valve, pressure reducing valve, pressure gauge, relief valve

check valve, connecting piping.

Rupture Disk Assembly X X

Rupture Disk Piping X X

Item Trane Other Trane Other

Condensate Piping

Material Provided By Installed By

ABS-PRC001-EN34

Page 35

Job Site

Steam Supply and

Connections

Condensate Handling

Figure JC-1 illustrates a typical

condensate system consisting of steam

traps, condensate receivers and

condensate pumps. Such systems

provide the most economical method for

returning condensate to a boiler.

Properly-sized float and thermostatic

traps are required for proper operation.

The use of bucket traps is not

recommended.

Trane absorption machines use steamthrottling control. A maximum of three

percent of the condensate may flash to a

vented receiver at full load. This flashing

decreases as the load decreases, and is

virtually nonexistent below 70 percent

load. When the machine is operating at

less than 70 percent load, the pressure in

the generator tube bundle may be below

atmospheric pressure. The temperature

of the condensate leaving the machine

under these conditions is less than 212°F

[100°C], so flashing does not occur.

A subcooler may be installed ahead of

the receiver to cool the condensate to a

temperature below the saturation

temperature at atmospheric pressure,

thus eliminating flashing entirely. It is

recommended that a cooling medium,

such as boiler feed water, be used to

keep this energy within the system. The

pressure drop through the subcooler

should be minimized.

Figure JC-1 indicates an equalizer line

installed to avoid condensate backup in

the machine. The swing check opens if a

vacuum develops within the tube bundle

under part-load operation.

This prevents development of a lower

pressure in the concentrator than at the

outlet of the trap.

Condensate Piping

Packaged Condensate Systems

Several manufacturers have available

packaged condensate-pump systems,

designed for various condensate

temperatures. A decision regarding the

use of these systems with a Trane

absorption machine should be based on

a thorough economic analysis of the

particular installation. The following

factors should be considered:

1. Condensate may flash in the receiver

less than 20 percent of the total

operating time in a typical installation.

The amount of condensate that may

flash varies from a maximum of three

percent at full load, to none at less

than 70 percent load. A subcooler can

be used to eliminate the small amount

of flashing that may occur when the

machine is operating under heavy

load.

2. The condensate system must prevent

condensate from backing up into the

machine at part load when the

pressure in the generator tube bundle

is below atmospheric pressure.

3. The condensate system must not

draw supply steam through the

machine. This reduces the machine

efficiency and may offset any potential

energy savings that might otherwise

be realized by the use of the

condensate return system. Also,

reduced tube life would result due to

erosion.

If the decision is made to use a packaged

condensate-pump system, follow the

manufacturer’s recommendations

regarding its application.

ABS-PRC001-EN

35

Page 36

Job Site

Hot Water

Hot Water Piping

The hot water system must be designed

such that it will avoid fluctuations in the

pressure differences across the control

valve. Trane absorption chillers for use

with hot water may be used at an

entering hot-water temperature of 270°F

[132°C] or below. Piping for a typical hot

water installation using a temperature of

270°F [132°C] or less is shown in Figure

JC-2. In this arrangement, a three-way

energy valve is used to control capacity

by varying the quantity of hot water

flowing through the chiller, while

maintaining a constant supply and

return flow rate. As shown in Figure

JC-3, a two-way energy valve can also

be used where the return and supply

flow rates can vary. The generator

design is rated to 150 psig [10.3 bars]

with a 400 psig [27.6 bars] optional

design available.

When the supply-water temperature

exceeds 270°F [132°C], a separate

circulating pump is recommended in a

run-around loop as shown in Figure

JC-4. The hot water for the absorption

machine should be taken from a header

installed between the hot-water supply

and return mains. The flow of hot water

through the machine is held constant,

but the temperature of the circulating

water is varied to meet load

requirements by modulating the amount

of high-temperature supply water added

to the loop. This is done by installing a

two-way modulating valve at the loop

outlet. The valve responds to the chilledwater temperatures, but limits the water

temperature entering the machine to a

maximum of 270°F [132°C].

Hot Water Valves

Trane provides hot-water temperaturecontrol valves with the machine for

installation by the contractor at the job

site. These valves are selected by The

Trane company based on data provided

by the contractor (*i.e. water flow to be

used and the design pressure-drop

across the valve.)

It is desirable to use the smallest valve,

with the highest pressure drop,

appropriate to the design water flow and

allowable pressure drop in the system.

The smaller the valve, the better the

control.

Connections

Figure JC-2. Hot water supply piping – 270°F and below with 3-way energy valve

Figure JC-3. Hot water supply piping – 270°F and below with 2-way energy valve

Piping

ABS-PRC001-EN36

Page 37

Job Site

Hot Water

Connections

Figure JC-4. Hot water supply temperature piping above 270°F

Piping

Table JC-2. Hot water supply piping responsibilities

Energy Valve (2-Way/3-Way) X X

Gate valve, balance valve, Y-type strainer w/valve,

bypass circuit, check valve, thermometer, pressure gauge, X X

vent shutoff valve, union or flanged connection circulating pump

Rupture Disk Assembly X X

Rupture Disk Piping X X

Item Trane Other Trane Other

Material Provided By Installed By

ABS-PRC001-EN

37

Page 38

Job Site

Cooling

Cooling Water Piping

The cooling water piping design for the

Horizon series of absorption chillers

differs from conventional reciprocating

or centrifugal systems, in that cooling

water passes through the absorber

section of the machine prior to entering

the condenser.

The Horizon Single Stage absorption

chiller is designed to start and operate

with cooling-water temperatures as low

as 55°F [12.8°C]. In typical applications,

the machine is selected on the basis of

the cooling-water temperature that will

be available at full-load and at the design

outside conditions. In air conditioning

applications utilizing a cooling tower, this

is usually 85°F [29.4°C].

With a cooling tower sized at design

conditions, the temperature of the

cooling-water supply to the unit will

decrease with any decrease in cooling

load or outside wet-bulb temperature.

The lower cooling-water temperature

would normally tend to increase the

capacity potential of the unit. In the

Trane design, the UCP2 adaptive

controls will limit the energy input of the

machine based on the entering cooling

water temperature, thereby preventing

overfiring of the machine.

In typical air-conditioning applications,

precise cooling-water temperature

control is not required. In process

applications, however, where extremely

close control of leaving chilled-water is

required, it is recommended that a tower

valve be used to maintain cooling-water

temperature at a specified temperature.

Constant cooling-water temperature

allows the unit control valve to more

precisely control leaving chilled-water

temperature. Also, in applications where

well water or other cooling water will be

available at a temperature below 65°F

[18.3°C], a control valve is recommended

to maintain the temperature at 65°F

[18.3°C] or above. Changes in condenser

water temperature should not exceed

1°F per minute in the range of 75°F to

95°F [23.9 to 35°C].

Figure JC-5 illustrates a typical airconditioning installation without a

cooling-tower control valve. Figure JC-6

illustrates typical cooling-water piping in

applications where a three-way valve

may be required. Figure JC-7 illustrates

typical cooling-water piping utilizing well

or river water.

Connections

Figure JC-5. Cooling-water piping with cooling tower

Figure JC-6. Cooling-water piping, three-way mixing valve

Water Piping

ABS-PRC001-EN38

Page 39

Job Site

Cooling

Connections

Figure JC-7. Cooling-water piping with well or river water

Table JC-3. Condenser/absorber piping responsibility

Item Trane Other Trane Other

Crossover Pipe (factory installed X (factory installed

Flow Switch (optional) X X

Balancing valve, gate valve, thermometer

(optional), pressure gauge vent and shutoff X X

valve, Victaulic or flange connection, pipe stub,

strainer, pump.

Water Piping

Material Provided By Installed By

option) (option)

X or X or

X or

ABS-PRC001-EN

39

Page 40

Mechanical Specifications

General

The unit is a complete, single-effect

steam- or hot-water-fired absorption

chiller package, built in an ISO 9001

environment. The chiller consists of

generator/condenser section,

evaporator/absorber section, controls,

pumps, heat exchanger, and energy

control valve. All units are of hermetic

design, factory-assembled and-leaktested prior to shipment. Units can be

separated and shipped disassembled for

rigging purposes. Unit controls are

factory mounted and wired, including

microelectronic control panel, sensors

and purge system. An energy valve can

be factory mounted and wired as an

option on steam-fired units. The unit is

painted prior to shipping with two coats

of a water-base air-dry primer. Standard

method of shipment is by truck.

Generator/CondenserEvaporator/Absorber

The shell material is carbon steel. The

standard generator tube material is

cupro-nickel, the evaporator is copper,

absorber is cupro-nickel or copper and

the condenser is copper. Tubes are

mechanically rolled into the tube sheets

and are replaceable from either end.

The condenser, evaporator and absorber

tube supports are fixed. The generator

consists of fixed and floating tube

supports to allow for even tube

expansion. Solution spray systems are

replaceable from one end of the unit

without sacrificing the hermetic integrity

of the unit.

Design working pressure for the water

boxes is 150 psig [10.3 bars]. All tube

bundles are tested at 150 percent of

design working pressure. All water

boxes have gasketed, removable covers

for access. Optional marine-type water

boxes can be provided on the condenser

and absorber. Water connections are

provided with either victaulic or raisedface flanged connections.

Heat Exchangers

A brazed-plate solution heat exchanger

is provided to reduce energy use and

improve unit performance. Heat

exchanger surfaces are 300 series

stainless steel.

Pumps

Solution and refrigerant are circulated by

means of three hermetic, single-stage

centrifugal pumps. The pump impellers

are cast iron, with a steel shaft supported

by two tapered carbon bearings. The

bearings are lubricated and the motor is

cooled via the pumped fluid. Adjustablefrequency drives are provided on the

generator pump and absorber pump to

provide solution flow control.

Automatic Purge System

The purge system utilizes an eductor for

moving noncondensables to the

condenser, Purifier

noncondensables in an external storage