Trane AAM8A0A24V21CA, AAM8A0C36V31CA, TAM8A0A24V21CA, AAM8A0C48V41CA, TAM8A0C36V31CA Field Reference Data

...Page 1

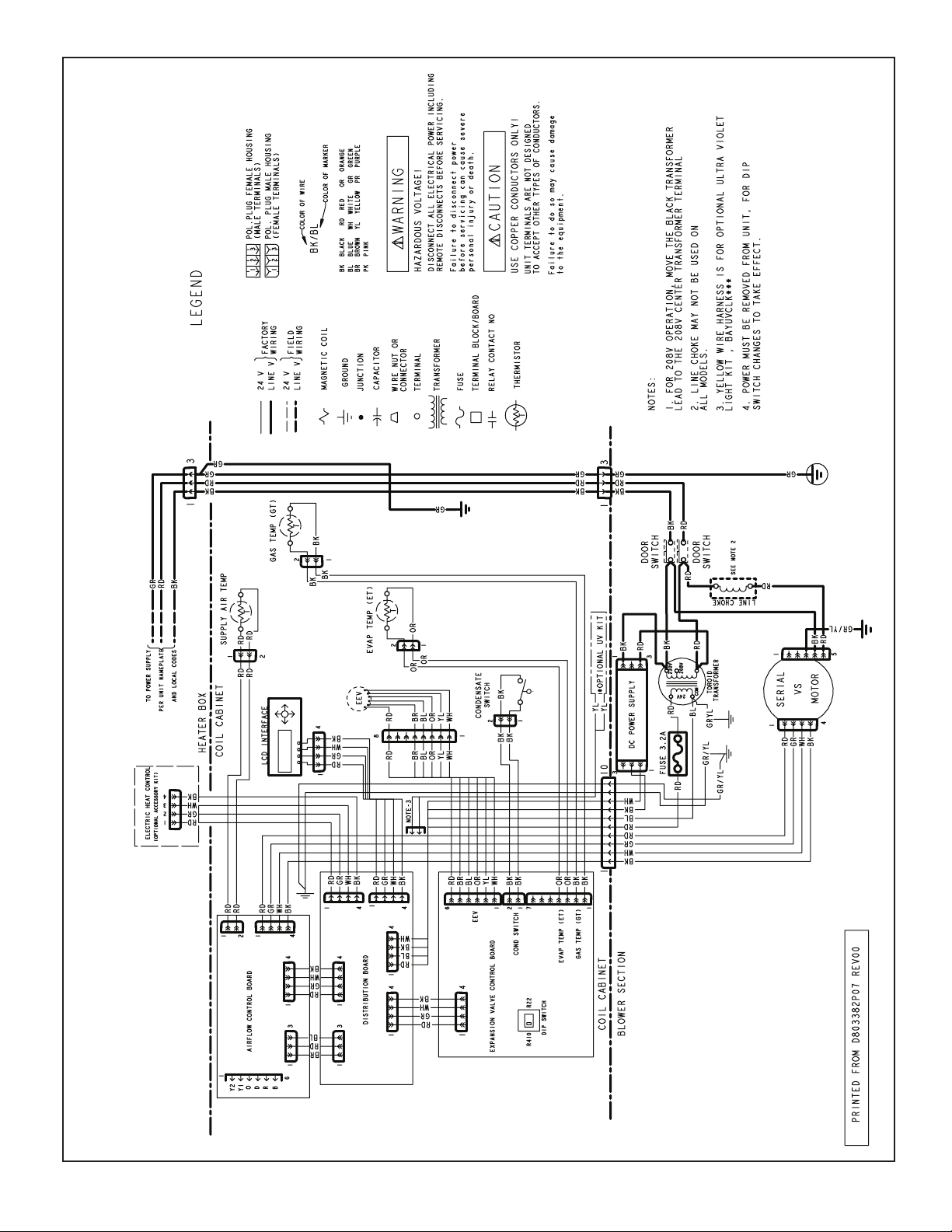

HAZARDOUS VOLTAGE - DISCONNECT POWER BEFORE SERVICING

WARNING:

HyperionFieldReferenceDataTAM8

▲

WARNING

!

▲

WARNING

!

▲

WARNING

!

Air Handler - Convertible

Models: Series 8 Air Handlers 2-5 Ton

*AM8A0A24V21CA, *AM8A0B30V21CA

*AM8A0C36V31CA, *AM8A0C42V31CA

*AM8A0C48V41CA, *AM8A0C60V51CA

* May be "A" or "T"

For use with BAYEV or BAYW series heaters ONLY

IMPORTANT --- This document contains a wiring diagram and service information. This is customer property and is to remain with this unit.

Please return to service information pack upon completion of work.

SAFETY HAZARD! This information is intended for use

by individuals possessing adequate backgrounds of electrical and

mechanical experience. Any attempt to repair a central air conditioning product may result in personal injury and/or property damage.

The manufacture or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection

with its use.

LIVE ELECTRICAL COMPONENTS! During instal-

lation, testing, servicing, and troubleshooting of this product, it may

be necessary to work with live electrical components. Failure to follow all electrical safety precautions when exposed to live electrical

components could result in death or serious injury.

NOTE: This unit as shipped is ONLY compatible with

Trane and American Standard communicating thermostats

and outdoor units. (24VAC thermostats cannot be used)

With the addition of a BAYCC24VK01 accessory, this unit

can be compatible with a 24VAC single or multistage heat

pump or air conditioner.

PRESSURIZED REFRIGERANT! SYSTEM CONTAINS

OIL AND REFRIGERANT UNDER HIGH PRESSURE. RECOVER

REFRIGERANT TO RELIEVE PRESSURE BEFORE OPENING THE

SYSTEM.

DO NOT USE NON-APPROVED REFRIGERANTS OR REFRIGERANT

SUBSTITUTES OR REFRIGERANT ADDITIVES.

Note: This unit is certified to UL 1995.

The interior cabinet wall meets the following:

- UL94-5VA Flame Class Listed

- UL723 Steiner Tunnel Listed for 25/50 Flame/

Smoke

- UL746C Listed for Exposure to Ultraviolet Light,

Water Exposure and Immersion

Table of Contents

Product Specifications. .................................................................................................... 2

Wiring Diagram. ............................................................................................................... 3

Sequence of Operation. ................................................................................................... 4

Control Layout - Refrigerant Dip Switch .......................................................................... 6

Airflow Performance. ........................................................................................................ 7

Heater Attribute Data. .................................................................................................... 13

Control Layout - LEDs. ...................................................................................................16

Alert Codes. ................................................................................................................... 22

EEV Test Procedures. .................................................................................................... 23

EVC Thermal Resistance and Voltage Table. ................................................................ 24

AFC Supply Air Temperature Sensor Table. ...................................................................25

Display Assembly Menus. .............................................................................................. 26

Troubleshooting. ............................................................................................................ 32

NOTICE: Since the manufacturer has a policy of continuous product and product data improvement, it reserves the right to change design and specifications without notice.

© 2011 Trane

Page 2

MODEL

RATED VOLTS/PH/HZ.

RATINGS 1

INDOOR COIL — Type

Rows — F.P.I.

Face Area (sq. ft.)

Tube Size (in.)

Refrigerant Control

Drain Conn. Size (in.) 2

DUCT CONNECTIONS

INDOOR FAN — Type

Diameter-Width (In.)

No. Used

Drive - No. Speeds

CFM vs. in. w.g.

No. Motors — H.P.

Motor Speed RPM

Volts/Ph/Hz

F.L. Amps

FILTER

Filter Furnished?

Type Recommended

No.-Size-Thickness

REFRIGERANT

Ref. Line Connections

Coupling or Conn. Size — in. Gas

Coupling or Conn. Size — in. Liq.

DIMENSIONS

Crated (In.)

Uncrated

WEIGHT

Shipping (Lbs.) / Net (Lbs.)

*AM8A0A24V21CA

200-230/1/60

See O.D. Specifications

Plate Fin

3/4 NPT

See Outline Drawing

Centrifugal

Direct - Variable

See Fan Performance Table

Variable ECM

208-230/1/60

Throwaway

1 - 16 X 20 - 1 in.

R-410A

H x W x D

51 x 20 x 24.5

49.9 x 17.5 x 21.8

126/116

PRODUCT SPECIFICATIONS

*AM8A0B30V21CA

See O.D. Specifications

3 - 14

3.67

3/8

EEV

See Outline Drawing

11 X 8

1

See Fan Performance Table

1 - 1/2

3.0

No

Brazed

3/4

3/8

200-230/1/60

Plate Fin

3 - 14

5.04

3/8

EEV

3/4 NPT

Centrifugal

11 X 10

1

Direct - Variable

1 - 1/2

Variable ECM

208-230/1/60

3.0

No

Throwaway

1 - 20 X 20 - 1 in.

R-410A

Brazed

3/4

3/8

H x W x D

56.8 x 23.5 x 24.5

55.7 x 21.3 x 21.8

150/138

*AM8A0C36V31CA

200-230/1/60

See O.D. Specifications

Plate Fin

3 - 14

5.50

3/8

EEV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - Variable

See Fan Performance Table

1 - 1/2

Variable ECM

208-230/1/60

3.0

No

Throwaway

1 - 22 X 20 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

58 x 25.5 x 24.5

56.9 x 23.5 x 21.8

157/146

MODEL

RATED VOLTS/PH/HZ.

RATINGS 1

INDOOR COIL — Type

Rows — F.P.I.

Face Area (sq. ft.)

Tube Size (in.)

Refrigerant Control

Drain Conn. Size (in.) 2

DUCT CONNECTIONS

INDOOR FAN — Type

Diameter-Width (In.)

No. Used

Drive - No. Speeds

CFM vs. in. w.g.

No. Motors — H.P.

Motor Speed RPM

Volts/Ph/Hz

F.L. Amps

FILTER

Filter Furnished?

Type Recommended

No.-Size-Thickness

REFRIGERANT

Ref. Line Connections

Coupling or Conn. Size — in. Gas

Coupling or Conn. Size — in. Liq.

DIMENSIONS

Crated (In.)

Uncrated

WEIGHT

Shipping (Lbs.) / Net (Lbs.)

* May be "A" or "T"

1 These Air Handlers are AHRI certified with various Split System Air Conditioners and Heat Pumps (AHRI STANDARD 210/240).

2 3/4" Male Plastic Pipe (Ref.: ASTM 1785-76)

*AM8A0C42V31CA

200-230/1/60

See O.D. Specifications

Plate Fin

4 - 14

5.04

3/8

EEV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - Variable

See Fan Performance Table

1 - 1/2

Variable ECM

208-230/1/60

3.0

No

Throwaway

1 - 22 X 20 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

58 x 25.5 x 24.5

56.9 x 23.5 x 21.8

162/150

*AM8A0C48V41CA

200-230/1/60

See O.D. Specifications

Plate Fin

4 - 14

5.96

3/8

EEV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - Variable

See Fan Performance Table

1 - 3/4

Variable ECM

208-230/1/60

4.2

No

Throwaway

1 - 22 X 20 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

62.8 x 25.5 x 24.5

61.7 x 23.5 x 21.8

174/162

PRODUCT SPECIFICATIONS

*AM8A0C60V51CA

200-230/1/60

See O.D. Specifications

Plate Fin

4 - 14

5.96

3/8

EEV

3/4 NPT

See Outline Drawing

Centrifugal

11 X 10

1

Direct - Variable

See Fan Performance Table

1 - 1

Variable ECM

208-230/1/60

5.5

No

Throwaway

1 - 22 X 20 - 1 in.

R-410A

Brazed

7/8

3/8

H x W x D

62.8 x 25.5 x 24.5

61.7 x 23.5 x 21.8

175/163

TAM82

Page 3

WIRING DIAGRAM FOR *AM8 AIR HANDLERS

5. ET WIRING MAY BE BROWN OR ORANGE.

TAM83

Page 4

SEQUENCE OF OPERATION FOR *AM8

AM8 Sequence of Operation

Abbreviations

• AFC = Airow Control

• EVC = Expansion Valve Control

• EEV = Electronic Expansion Valve

• EHC = Electric Heat Control

• HHC= Hydronic Heat Control

This unit as shipped is ONLY compatible with Trane

and American Standard communicating thermostats and OD units. (24VAC thermostats cannot be

used)

With the addition of a BAYCC24VK01 accessory, this

unit can be compatible with a 24VAC single or

multistage heat pump or air conditioner.

The installing and servicing technician should have an

understanding of the sequence of operation to be

able to properly setup and diagnose functions of

the air handler.

See unit, auxiliary heat, and field wiring diagrams

for additional information.

Continuous Fan

IMPORTANT: If the indoor air exceeds 60% relative

humidity or simply feels uncomfortably humid, it is

recommended that the indoor fan only be used in

the AUTO mode.

1. When a fan request is received from the thermostat, the AFC sends a command to the serial

communicating blower motor to run. Airflow can be

adjusted through the thermostat

2. Humidity Control – When enabled in the thermostat, this feature will disable any blower off delays

and disable continuous fan mode when the humidity is above the dehumidification setpoint. This will

help prevent coil condensation from being evaporated back into the air stream.

Cooling mode

1. When a request for 1st stage cooling is received,

the AFC sends a command to the serial communicating blower motor to run at 1st stage cooling

airflow. (Delay profiles from the thermostat may

change blower motor timing and actual airflow

demand)

TAM84

2. The EVC will receive input from the two temperature sensors and start to control 1st stage superheat.

3. When a request for 2nd stage cooling is received,

the AFC sends a command to the serial communicating blower motor to run at 100 % cooling

airflow.

4. The EVC will now control superheat for 2nd stage.

5. When a request for cooling is removed, the AFC will

turn off the blower motor after any user selected

fan-off delays have expired.

NOTE: Delay profiles from the thermostat may change

blower motor timing and actual airflow demand

Heatpump (compressor only)

1. When a request for 1st stage heat is received, the

AFC sends a command to the serial communicating blower motor to run at 1st stage heating

airflow.

2. Humidifier contacts close

3. The EVC will drive the EEV to the heating position

and refrigerant will flow in the reverse cycle.

4. When a request for 2nd stage mechanical heat is

received, the AFC sends a command to the serial

communicating blower motor to run at 100 % heating airflow.

5. When a request for heatpump is removed, the humidifier contacts open and the AFC will turn off the

blower motor after any user selected fan-off delays

have expired.

NOTE: Delay profiles from the thermostat may change

blower motor timing and actual airflow demand

Electric Heat

1. When a request for electric heat is received, the

AFC communicates to the EHC how much demand for auxiliary heat is being requested

2. The EHC determines the number of elements that

will be used for this request and sends a message

to the AFC for proper airflow. (The EHC determines the amount of heat available per stage by

either factory programming or by the kw jumper

position)

3. The AFC sends a command to the serial communicating blower motor to run proper airflow and close

the blower interlock relay on the EHC.

4. Humidifier contacts close.

5. As demand from the thermostat increases, the EHC

will communicate to the AFC the required airflow

when energizing additional relays.

Page 5

NOTE: The EHC has “lead-lag or rotating” logic built in

that energizes the electric heat relays based upon

cycle counts. To verify operation of all heating

elements, switch thermostat to Emergency Heat

and raise the setpoint of the thermostat at least 5

degrees above the actual room temperature.

Hydronic Heat

1. When the request for hydronic heat is received, the

AFC communicates to the HHC how much auxiliary heat is being requested

2. The HHC will close the K1 relay contacts that enable the boiler or circulating pump to start.

3. The HHC sends a signal to the AFC when the inlet

water temperature reaches 100 degrees for a

maximum of 60 seconds, and then determines the

amount of airflow needed for the heat demand.

4. The AFC sends a command to the serial communicating blower motor to run at the requested CFM.

5. Humidifier contacts close.

6. As demand from the thermostat increases, the

HHC will communicate to the AFC matching airflow requirements.

Defrost

1. The OD unit will initiate defrost and send a message to the AFC.

2. The AFC will communicate to the EVC that the OD

is in defrost and the EVC will start to control the

correct superheat.

3. Electric or hydronic heat will be energized to help

temper the air. (Auxiliary heat options for defrost

can be adjusted through the Display Assembly

Configuration Menu)

Optional Condensate Switch

1. An optional OEM Condensate Switch can be installed within the unit. This switch is only available

through the National Distribution Center or Global

Parts.

2. OEM Condensate Switch contacts are Normally

Open and will close when water level inside the

unit rises. A closed switch will de-energize the OD

unit.

3. The OEM Condensate Switch is only operational

during the cooling mode and is not operational

during heating or defrost modes.

Note: Standard aftermarket condensate switches

(Normally Closed) can be wired in series with the

“External Switch” contacts on the AFC.

Important: The switch action must be selected in the

Configuration Menu section of the Display Assembly to either “Disable Cool” or “Disable All”.

Freeze Protection

1. The EVC control has the ability to sense when the

indoor coil is beginning to ice. If this event should

occur, the AFC will send a message to de-energize

the OD unit.

2. The indoor blower motor will continue running to aid

in defrosting the coil.

3. After 5 minutes, the OD will be turned back on.

(*CONT900 and the 1st release of the *ZONE950

will disable the indoor blower motor and OD unit for

30 minutes)

Unit Test Mode

Unit Test Mode will exit if any demand is given to the

unit.

To enter Unit Test Mode:

1. Set System Switch on comfort control to Off

2. Scroll to the Control Menu on the Display Assembly

3. Scroll down to the Unit Test selection and push the

“Enter” key

Sequence of Unit Test Mode (OD unit is not ener-

gized during the Unit Test Mode)

1. EVC drives the EEV motor to the 1st stage position

for 5 seconds

2. EVC drives the EEV motor to the 2nd stage position

for 5 seconds

3. AFC energizes the blower at 50% and then continues to ramp until it reaches 100% cooling airflow.

4. Humidifier contacts close when the blower starts

5. EHC energizes the circuit relay(s) for 5 seconds

each in 5 second intervals.

6. All relays de-energize and the blower shuts off five

seconds after the last bank of heat is energized.

7. HHC energizes its K1 relay that interfaces with

the boiler system or circulating pump. The blower

continues to run for 30 seconds and then K1 relay

contacts open and the blower shuts off.

If an error occurs during the Unit Test Mode, the Fault

LED will flash a code and continue the test.

TAM85

Page 6

Fault Reporting

Control boards in this unit store active and historical

faults. Each control board will report active faults

continuously and will report the last four faults

stored after a power cycle of the unit. See Fault

Table section for list of fault codes

The active and historical faults can also be accessed

through the Alert Menu in the Display Assembly.

Clearing Fault History

Option 1:

a) Scroll to the Alert Menu in the Display Assembly

b) Scroll to the Alert History section.

c) Scroll to the Clear History selection and push the

Enter key. At the “Are You Sure” question, push the

Enter again.

Option 2:

a) Press and hold the Unit Test Button for 10-12 sec-

onds.

b) Release the Unit Test button and “wait” 5 seconds.

c) Cycle 230VAC power to the unit. (the blower panel

can be removed to achieve this)

CLEAR HISTORY? ↕

YES

Unit Test Button

J6

J11

Airflow Control (AFC)

<ENTER>

24 VAC

TEST

J4

13.8 VDC

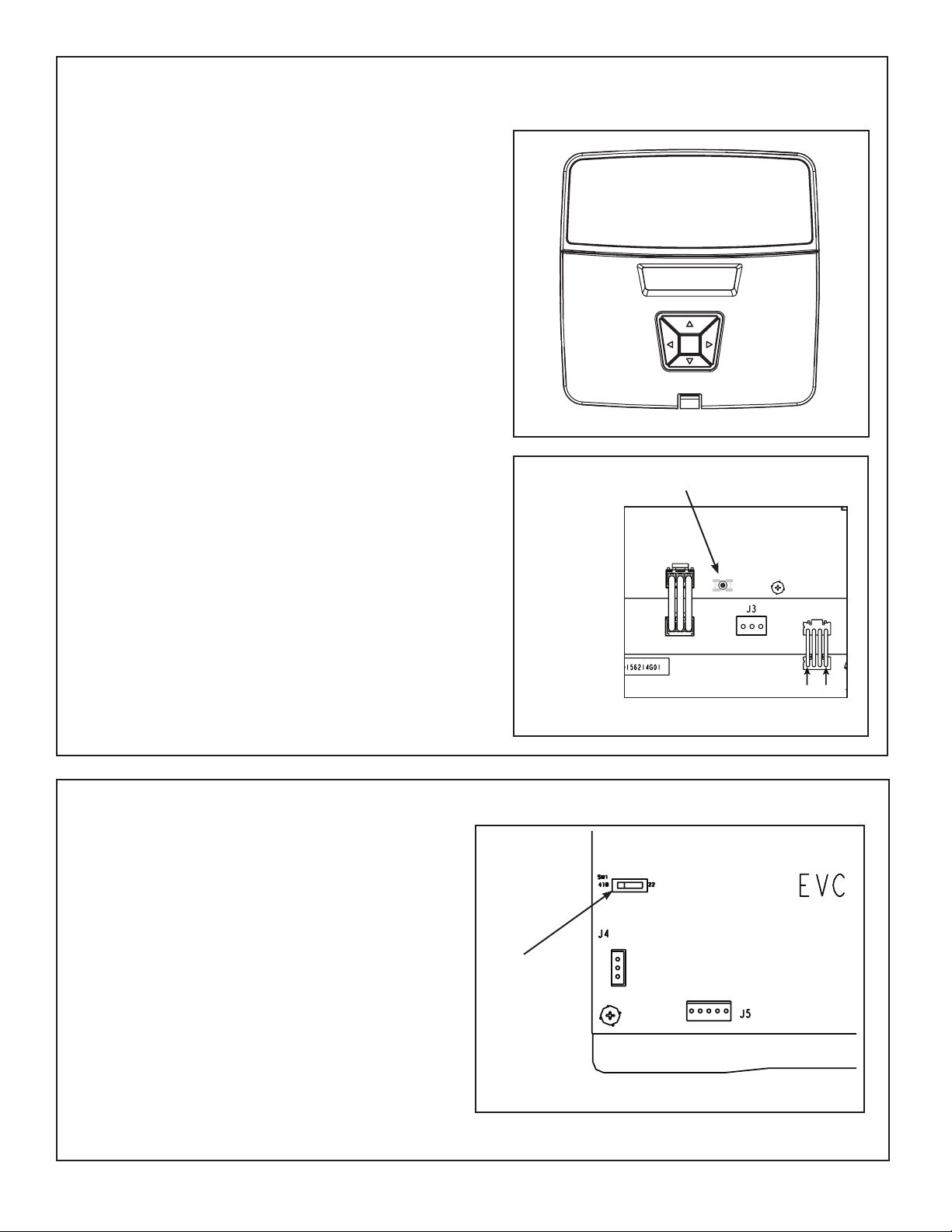

Control Layout - Refrigerant Dip Switch

Refrigerant Switch SW1

• Set the system refrigerant to either R-410A or R-22

using the Refrigerant Switch located on the Expansion Valve Control board (EVC) in the Control Pocket.

• Factory default is R-410A.

• Note: The power must be shut off and then re-applied

in order for the EVC to recognize the change.

TAM86

SW1 Dip

Switch

Electronic Expansion Valve Control (EVC)

Page 7

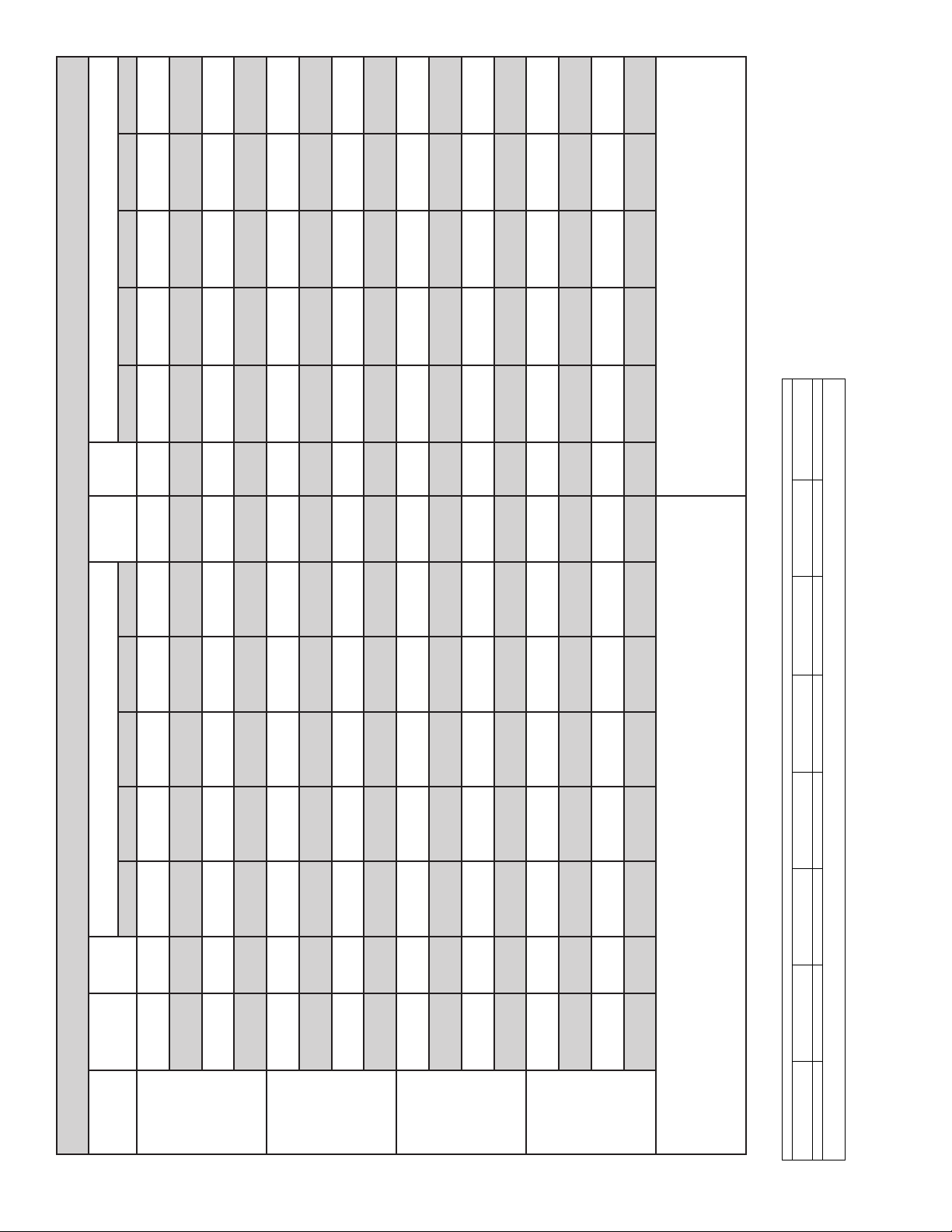

291

A

A

A

A

A

A

A

A

A

X

134

329

101

76

400

49

425

EXTERNAL STATIC PRESSURE

22

416

CFM

Watts

Powe r

Airflow

290

HEATING

AIRFLOW

CFM/ton

SETTING

434

152

507

129

542

101

69

550

37

532

CFM

Watts

350

CFM/ton

614

197

658

169

679

136

99

680

62

660

CFM

Watts

430

CFM/ton

650

208

690

180

709

145

710

108

69

690

CFM

Watts

450

CFM/ton

527

172

582

147

608

116

82

613

48

593

CFM

Watts

290

CFM/ton

679

218

716

189

734

153

734

115

75

714

CFM

Watts

350

CFM/ton

849

290

874

254

884

213

881

168

862

122

CFM

Watts

430 †

CFM/ton

889

310

912

273

921

231

917

184

899

136

CFM

Watts

450

CFM/ton

707

229

742

198

758

162

757

122

81

738

CFM

Watts

290

CFM/ton

864

297

888

261

898

220

895

174

876

127

CFM

Watts

350

CFM/ton

418

1066

375

1084

326

1089

272

1083

215

1064

CFM

Watts

430

CFM/ton

453

1116

410

1133

360

1139

304

1133

244

1115

CFM

Watts

450

CFM/ton

859

295

883

259

894

217

890

172

871

125

CFM

Watts

290

CFM/ton

401

1041

358

1059

310

1064

257

1058

202

1040

CFM

Watts

350

CFM/ton

470

1138

478

1220

487

1300

432

1302

368

1291

CFM

Watts

430

CFM/ton

462

1128

468

1208

476

1286

483

1360

422

1355

CFM

Watts

450

CFM/ton

4. Torque mode will reduce airflow when static is above approximately

0.3” water column.

5. All heating modes default to Constant CFM.

6. Cooling airflow values are with wet coil, no filter

BAYEVBC20BK1A

BAYEVCB15LG3A

279 / NA

133 / NA

439 / NA

154 / NA

559 / NA

181 / NA

653 / NA

209 / NA

531 / NA

174 / NA

681 / 383

219 / 145

787 / 561

261 / 183

888 / 689

310 / 225

709 / 473

229 / 162

863 / 680

297 / 221

989 / 821

367 / 280

451 / 354

858 / 674

295 / 219

399 / 307

485 / 408

464 / 464

1120 / 1120

465 / 399

469 / 469

1203 / 1203

339 / NA

102 / NA

514 / NA

131 / NA

612 / 325

155 / 101

694 / 494

181 / 128

588 / 241

149 / 95

720 / 534

190 / 137

818 / 666

228 / 174

913 / 777

274 / 214

745 / 596

199 / 153

890 / 770

262 / 211

1009 / 901

1113 / 961

327 / 270

409 / 345

1132 / 1034

1039 / 877

885 / 764

259 / 209

1058 / 953

1154 / 1046

358 / 297

1205 / 1115

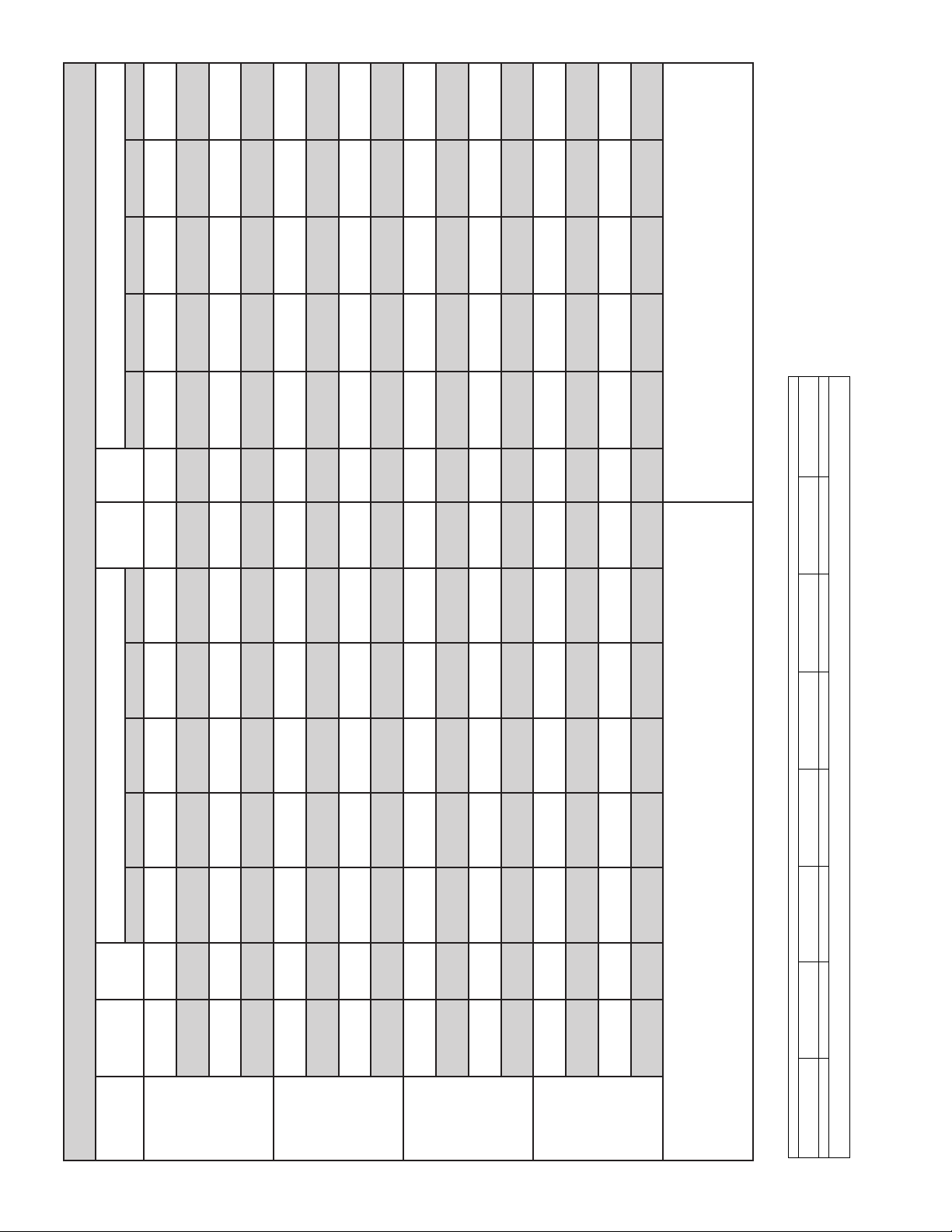

*AM8A0A24 AIRFLOW PERFORMANCE

BAYEVAC10LG3AA BAYEVBC15BK1A

77 / NA

102 / 73

408 / NA

CONSTANT CFM MODE / CONSTANT TORQUE MODE

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Powe r

Airflow

SETTING

AIRFLOW

COOLING

548 / 373

50 / 48

431 / 412

555 / 541

22 / 40

419 / 554

534 / 638

CFM

CFM

Watts

290

350

CFM/ton

123 / 96

636 / 513

70 / 67

88 / 85

639 / 626

37 / 56

52 / 71

617 / 705

CFM

Watts

Watts

400

CFM/ton

CFM/ton

714 / 613

714 / 703

692 / 770

CFM

450

117 / 90

146 / 119

614 / 481

83 / 80

108 / 105

617 / 605

69 / 89

48 / 67

595 / 688

CFM

Watts

Watts

290

CFM/ton

CFM/ton

738 / 643

154 / 127

832 / 751

737 / 727

115 / 112

829 / 821

75 / 96

716 / 792

809 / 877

CFM

CFM

Watts

350

400 †

CFM/ton

190 / 161

924 / 852

231 / 200

147 / 144

920 / 913

185 / 182

103 / 125

900 / 964

136 / 161

CFM

Watts

Watts

450

CFM/ton

CFM/ton

762 / 692

163 / 141

901 / 845

761 / 769

123 / 125

897 / 907

81 / 108

740 / 829

878 / 957

CFM

CFM

Watts

290

350

CFM/ton

220 / 196

281 / 255

1017 / 967

175 / 178

231 / 236

1012 / 1023

127 / 158

178 / 215

993 / 1070

CFM

Watts

Watts

400

CFM/ton

CFM/ton

359 / 330

896 / 840

1139 / 1095

1133 / 1148

1115 / 1193

CFM

450

218 / 194

304 / 312

893 / 902

173 / 176

244 / 290

873 / 953

125 / 156

CFM

Watts

Watts

290

CFM/ton

CFM/ton

310 / 282

1065 / 1018

1059 / 1072

1041 / 1118

CFM

350

415 / 386

1214 / 1175

257 / 264

358 / 368

1210 / 1227

202 / 242

295 / 347

1194 / 1271

CFM

Watts

Watts

400

CFM/ton

CFM/ton

476 / 476

1284 / 1284

483 / 491

1360 / 1373

422 / 476

1355 / 1421

CFM

Watts

450

CFM/ton

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

BAYEVAC10LG1A

BAYEVAC10BK1A

MINIMUM HEATER AIRFLOW CFM - HEATER MATRI

BAYEVAC08LG1A

BAYEVAC08BK1A

BAYEVAC05LG1A

BAYEVAC05BK1A

(TONS)

OUTDOOR

MULTIPLIER

1.5 tons

2 tons †

2.5 tons

3 tons

NOTES:

1. * Models start with "A" or "T"

2. † Factory Setting

3. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

*AM8A0A24V21SAA 638/713 638/900 675/900 600/713 -- -- --

MODEL NO.

AM8A0A24 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

TAM87

Page 8

A

A

A

A

A

A

A

A

A

X

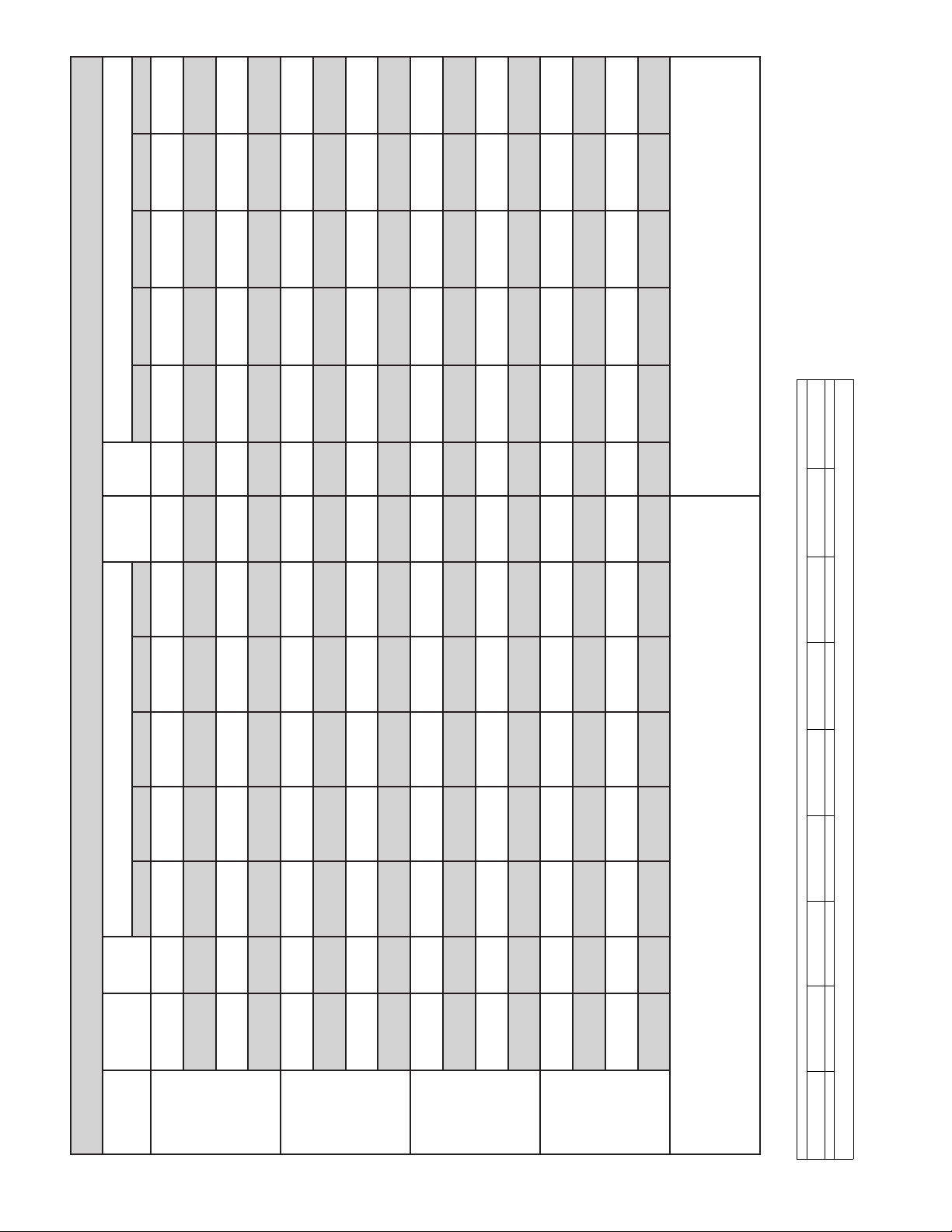

301

130

97

350

69

393

44

437

EXTERNAL STATIC PRESSURE

21

485

CFM

Watts

Powe r

Airflow

290

HEATING

AIRFLOW

CFM/ton

SETTING

458

146

489

115

85

517

56

545

29

574

CFM

Watts

350

CFM/ton

614

177

636

143

653

108

75

669

42

683

CFM

Watts

430

CFM/ton

649

186

669

151

685

115

80

698

45

709

CFM

Watts

450

CFM/ton

533

160

560

127

95

582

64

604

35

625

CFM

Watts

290

CFM/ton

678

193

696

157

710

120

84

722

49

731

CFM

Watts

350

CFM/ton

853

248

864

205

869

161

871

116

73

868

CFM

Watts

430 †

CFM/ton

895

263

905

219

908

172

908

126

80

902

CFM

Watts

450

CFM/ton

706

201

723

164

736

126

88

746

52

753

CFM

Watts

290

CFM/ton

869

254

879

210

884

165

884

120

75

881

CFM

Watts

350

CFM/ton

342

1078

290

1087

234

1084

176

1074

119

1057

CFM

Watts

430

CFM/ton

366

1128

314

1139

255

1136

194

1125

133

1104

CFM

Watts

450

CFM/ton

863

252

874

208

879

164

880

118

74

877

CFM

Watts

290

CFM/ton

330

1053

279

1061

224

1058

168

1049

112

1034

CFM

Watts

350

CFM/ton

446

1271

398

1300

337

1309

267

1298

193

1271

CFM

Watts

430

CFM/ton

472

1314

427

1350

369

1368

299

1363

221

1338

CFM

Watts

450

CFM/ton

4. Torque mode will reduce airflow when static is above approximately

0.35” water column.

5. All heating modes default to Constant CFM.

6. Cooling airflow values are with wet coil, no filter

BAYEVBC20BK1A

BAYEVCB15LG3A

279 / NA

130 / NA

449 / NA

146 / NA

554 / NA

164 / NA

647 / NA

186 / NA

528 / NA

159 / NA

676 / NA

193 / NA

788 / NA

97 / NA

338 / NA

484 / NA

115 / NA

582 / NA

132 / NA

151 / 91

557 / NA

669 / 231

157 / 94

127 / NA

696 / 299

226 / NA

803 / 463

186 / 115

704 / NA

895 / 394

264 / 138

907 / 621

219 / 141

723 / 409

201 / NA

869 / 401

254 / 139

164 / 105

881 / 625

211 / 142

307 / 177

1001 / 609

1128 / 784

258 / 180

1010 / 777

1141 / 925

366 / 226

863 / 391

252 / 138

314 / 227

875 / 619

209 / 140

330 / 195

1053 / 681

1196 / 886

279 / 197

1063 / 836

1217 / 1016

403 / 261

471 / 347

1311 / 1086

352 / 261

427 / 345

1350 / 1201

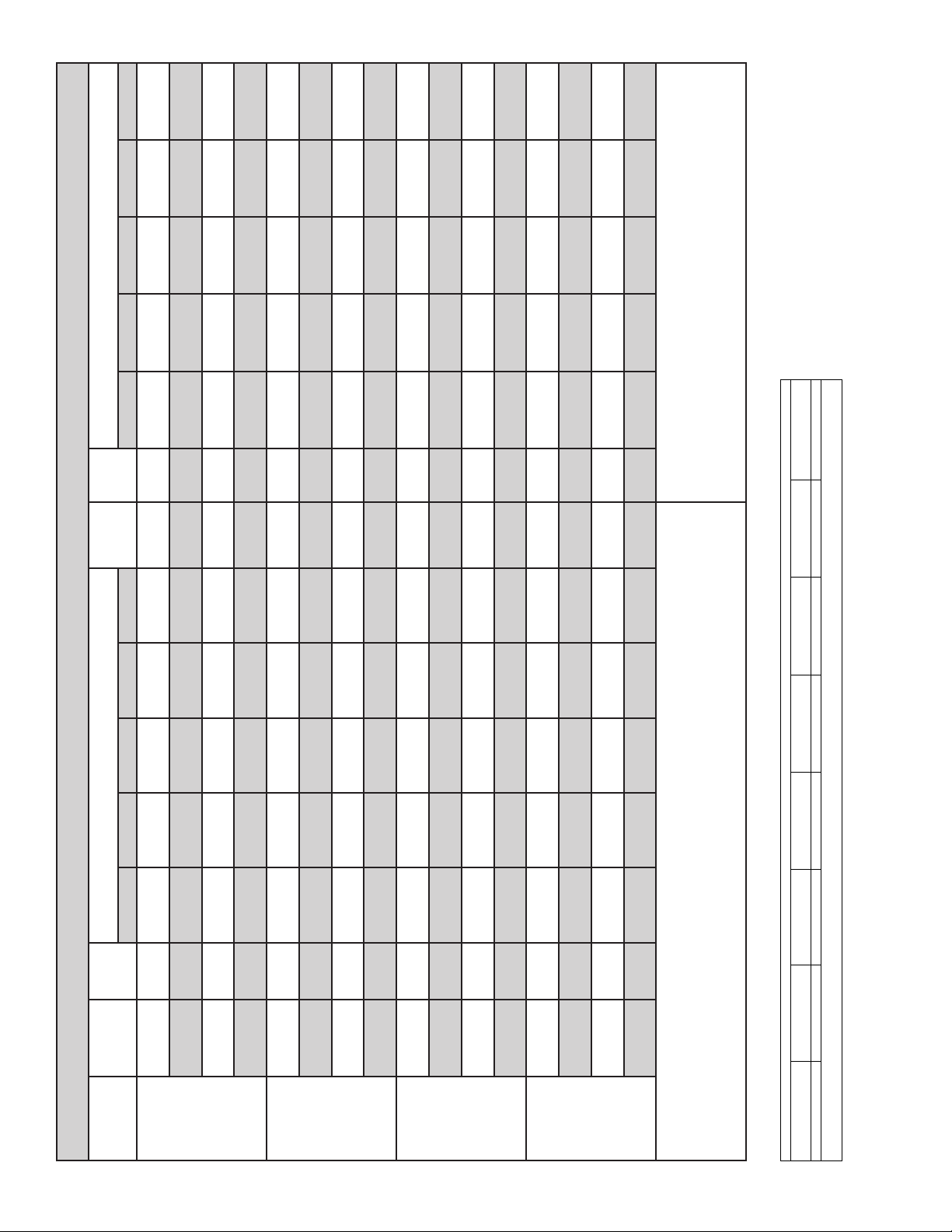

*AM8A0B30 AIRFLOW PERFORMANCE

85 / 60

69 / NA

388 / NA

CONSTANT CFM MODE / CONSTANT TORQUE MODE

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Powe r

Airflow

SETTING

AIRFLOW

COOLING

515 / 270

44 / 42

438 / 406

546 / 523

21 / 30

490 / 587

578 / 672

CFM

CFM

Watts

290

350

CFM/ton

99 / 72

605 / 413

56 / 54

67 / 65

626 / 607

29 / 39

37 / 48

646 / 738

CFM

Watts

Watts

400

CFM/ton

CFM/ton

686 / 520

700 / 683

712 / 803

CFM

450

95 / 69

115 / 86

582 / 380

80 / 77

64 / 62

605 / 585

45 / 59

35 / 46

628 / 721

CFM

Watts

Watts

290

CFM/ton

CFM/ton

121 / 91

712 / 552

812 / 668

84 / 81

724 / 708

818 / 803

49 / 62

734 / 824

819 / 908

CFM

CFM

Watts

350

400 †

CFM/ton

145 / 112

911 / 775

173 / 136

103 / 100

910 / 896

126 / 122

63 / 79

80 / 99

904 / 993

CFM

Watts

Watts

450

CFM/ton

CFM/ton

737 / 617

126 / 102

886 / 778

89 / 91

748 / 760

887 / 899

52 / 71

755 / 870

883 / 996

CFM

CFM

Watts

290

350

CFM/ton

165 / 137

206 / 173

1010 / 908

120 / 123

153 / 156

1004 / 1016

75 / 100

101 / 131

991 / 1107

CFM

Watts

Watts

400

CFM/ton

CFM/ton

256 / 218

881 / 773

1139 / 1041

1126 / 1141

1106 / 1226

CFM

450

164 / 136

194 / 199

882 / 894

119 / 121

74 / 99

133 / 172

879 / 992

CFM

Watts

Watts

290

CFM/ton

CFM/ton

224 / 189

1061 / 960

1052 / 1065

1036 / 1153

CFM

350

291 / 251

1217 / 1126

168 / 172

224 / 231

1202 / 1221

113 / 146

158 / 203

1179 / 1304

CFM

Watts

Watts

400

CFM/ton

CFM/ton

370 / 333

1369 / 1302

300 / 311

1365 / 1391

222 / 282

1338 / 1471

CFM

Watts

450

CFM/ton

BAYEVAC10LG3AA BAYEVBC15BK1A

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

BAYEVAC10LG1A

BAYEVAC10BK1A

MINIMUM HEATER AIRFLOW CFM - HEATER MATRI

BAYEVAC08LG1A

BAYEVAC08BK1A

BAYEVAC05LG1A

BAYEVAC05BK1A

(TONS)

OUTDOOR

MULTIPLIER

1.5 tons

2 tons †

2.5 tons

3 tons

NOTES:

1. * Models start with "A" or "T"

2. † Factory Setting

3. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

*AM8A0B30V21SAA 723/808 723/1020 765/1020 680/808 765/1063 850/1105 --

MODEL NO.

AM8A0B30 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

TAM88

Page 9

A

A

A

A

A

A

A

A

A

X

551

153

551

119

87

557

58

574

EXTERNAL STATIC PRESSURE

31

607

CFM

Watts

Powe r

Airflow

290

HEATING

AIRFLOW

CFM/ton

SETTING

695

185

14

695

697

111

77

705

44

721

CFM

Watts

350

CFM/ton

845

277

844

186

843

144

843

102

62

847

CFM

Watts

420

CFM/ton

908

248

906

204

903

159

900

115

72

900

CFM

Watts

450

CFM/ton

723

192

722

154

724

117

81

730

47

744

CFM

Watts

290

CFM/ton

882

239

880

196

878

153

876

110

68

878

CFM

Watts

350

CFM/ton

307

1062

257

1060

205

1052

152

1046

101

1033

CFM

Watts

420

CFM/ton

340

1138

288

1137

232

1128

175

1116

119

1102

CFM

Watts

450

CFM/ton

877

238

875

195

873

151

871

108

67

873

CFM

Watts

290

CFM/ton

307

1062

257

1060

205

1052

152

1043

101

1033

CFM

Watts

350

CFM/ton

405

1270

351

1277

289

1270

224

1253

158

1231

CFM

Watts

420 †

CFM/ton

448

1348

397

1365

334

1365

264

1349

192

1324

CFM

Watts

450

CFM/ton

292

1026

248

1024

197

1017

141

1005

93

1002

CFM

Watts

290

CFM/ton

388

1236

333

1239

272

1230

209

1215

148

1199

CFM

Watts

350

CFM/ton

476

1394

456

1468

395

1484

327

1480

246

1452

CFM

Watts

420

CFM/ton

469

1383

476

1505

451

1573

385

1584

306

1573

CFM

Watts

450

CFM/ton

4. Torque mode will reduce airflow when static is above approximately

0.35” water column.

5. All heating modes default to Constant CFM.

6. Cooling airflow values are with wet coil, no filter

BAYEVBC20BK1A

BAYEVCB15LG3A

556 / NA

153 / NA

741 / NA

553 / NA

119 / NA

740 / 297

195 / NA

805 / 374

213 / 128

156 / 90

803 / 554

172 / 122

725 / 30

909 / 485

245 / 142

906 / 636

201 / 137

723 / 413

191 / 156

935 / 488

254 / 143

153 / 101

931 / 639

209 / 138

282 / 196

1011 / 731

1138 / 823

234 / 189

1008 / 848

1136 / 933

334 / 222

879 / 480

235 / 141

281 / 215

876 / 632

192 / 136

328 / 196

369 / 278

1123 / 731

1213 / 984

275 / 189

313 / 269

1120 / 848

1212 / 1086

441 / 321

293 / 184

1028 / 687

1352 / 1091

386 / 312

244 / 178

1024 / 808

1364 / 1189

422 / 262

471 / 386

1301 / 942

1386 / 1228

369 / 254

422 / 377

1311 / 1046

1410 / 1324

470 / 443

1379 / 1334

477 / 434

1499 / 1429

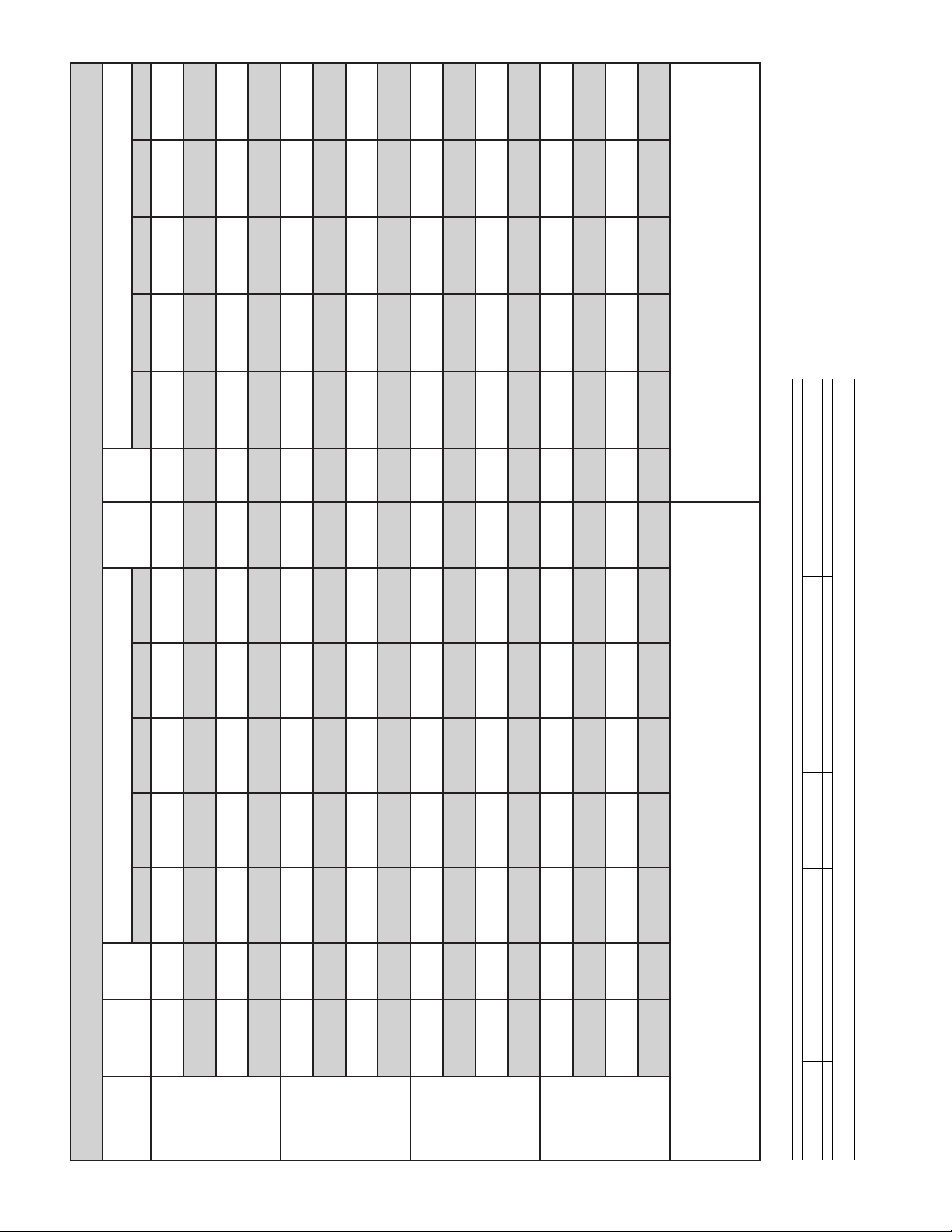

*AM8A0C36 AIRFLOW PERFORMANCE

86 / 62

118 / 85

556 / 321

739 / 530

802 / 707

81 / 77

744 / 706

803 / 846

47 / 63

759 / 858

812 / 974

CFM

CFM

Watts

370

400

CFM/ton

132 / 115

92 / 103

54 / 85

Watts

CFM/ton

CONSTANT CFM MODE / CONSTANT TORQUE MODE

57 / 58

573 / 573

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

610 / 758

CFM

Powe r

290

SETTING

30 / 47

Watts

CFM/ton

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Airflow

AIRFLOW

COOLING

115 / 96

902 / 774

156 / 129

723 / 602

79 / 86

899 / 903

112 / 116

729 / 761

69 / 96

45 / 71

746 / 903

900 / 1024

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

927 / 776

163 / 130

1001 / 961

923 / 905

117 / 116

944 / 1070

73 / 97

922 /1026

988 / 1175

CFM

CFM

Watts

370

400

CFM/ton

184 / 177

225 / 202

1127 / 1040

134 / 160

168 / 183

1114 / 1143

86 / 137

112 / 159

1100 / 1243

CFM

Watts

Watts

450

CFM/ton

CFM/ton

872 / 771

148 / 128

1112 / 961

871 / 900

105 / 115

1099 / 1070

64 / 96

874 / 1022

1087 / 1175

CFM

CFM

Watts

290

370 †

CFM/ton

220 / 177

253 / 254

1202 / 1185

163 / 160

192 / 233

1188 / 1280

109 / 137

132 / 207

1170 / 1373

CFM

Watts

Watts

400

CFM/ton

CFM/ton

321 / 296

193 / 167

1016 / 925

1360 / 1284

251 / 275

1344 / 1377

1322 / 1465

CFM

450

138 / 150

1009 / 1037

90 / 128

181 / 247

1006 / 1144

CFM

Watts

Watts

290

CFM/ton

CFM/ton

306 / 239

360 / 361

1306 / 1146

1416 / 1416

238 / 219

289 / 338

1404 /1505

1290 / 1244

170 / 193

213 / 310

1266 / 1338

1378 / 1591

CFM

CFM

Watts

Watts

370

400

CFM/ton

CFM/ton

451 / 419

1572 / 1519

385 / 396

1585 / 1607

307 / 367

1575 / 1691

CFM

Watts

450

CFM/ton

BAYEVAC10LG3AA BAYEVBC15BK1A

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

BAYEVAC10LG1A

BAYEVAC10BK1A

MINIMUM HEATER AIRFLOW CFM - HEATER MATRI

BAYEVAC08LG1A

BAYEVAC08BK1A

BAYEVAC05LG1A

BAYEVAC05BK1A

(TONS)

OUTDOOR

MULTIPLIER

2 tons

2.5 tons

3 tons †

3.5 tons

NOTES:

1. * Models start with "A" or "T"

2. † Factory Setting

3. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

*AM8A0C36V31SAA 876/979 876/1236 927/1236 824/979 927/1288 1030/1339 1236/1442

MODEL NO.

AM8A0C36 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

TAM89

Page 10

A

A

A

A

A

A

A

A

A

X

734

209

890

738

170

894

740

130

894

90

741

744

51

892

889

EXTERNAL STATIC PRESSURE

259

215

169

123

76

308

1016

160

1019

209

1018

156

1016

103

1006

366

1140

313

1144

256

1142

196

1135

136

1124

885

889

889

887

884

257

214

168

121

75

330

1066

280

1069

227

1067

171

1062

115

1053

403

1212

349

1219

289

1218

225

1209

160

1196

480

1342

430

1366

367

1371

295

1363

220

1347

315

1031

327

1173

214

1033

160

1028

107

1020

417

1236

362

1244

301

1243

236

1234

169

1220

475

1355

458

1411

395

1421

322

1416

244

1440

463

1315

473

1434

474

1545

428

1592

347

1589

383

1174

330

1179

271

1177

209

1169

147

1157

475

1335

458

1411

395

1421

322

1416

244

1400

462

1313

471

1431

474

1545

444

1615

363

1615

452

1297

458

1411

462

1528

453

1629

430

1716

CFM

CFM

Watts

Powe r

Airflow

290

350

HEATING

AIRFLOW

CFM/ton

SETTING

739 / NA

207 / NA

741 / 342

168 / 106

944 / 458

947 / 655

*AM8A0C42 AIRFLOW PERFORMANCE

742 / 591

127 / 102

CONSTANT CFM MODE / CONSTANT TORQUE MODE

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Powe r

Airflow

946 / 823

87 / 94

743 / 764

942 / 956

48 / 77

747 / 905

937 / 1072

CFM

CFM

Watts

CFM

Watts

Watts

400

CFM/ton

CFM/ton

273 / 155

302 / 177

1019 / 586

227 / 155

253 / 178

1022 / 760

179 / 151

201 / 173

1020 / 903

129 / 139

148 / 159

1014 / 1027

80 / 118

95 / 138

1006 / 1136

CFM

Watts

Watts

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

357 / 223

889 / 341

1142 / 768

1146 / 911

1143 / 1035

1135 / 1146

1122 / 1247

CFM

254 / 143

303 / 224

892 / 590

209 / 139

245 / 216

891 / 763

163 / 136

185 / 200

889 / 904

116 / 125

70 / 106

125 / 176

885 / 1026

CFM

Watts

Watts

CFM

CFM

Watts

Watts

350

400

CFM/ton

CFM/ton

350 / 217

393 / 256

1128 / 747

1215 / 868

297 / 218

337 / 255

1131 / 893

1221 / 999

240 / 210

276 / 246

1128 / 1019

1218 / 1115

181 / 195

212 / 229

1120 / 1132

1208 / 1220

121 / 171

147 / 204

1108 / 1233

1194 / 1316

CFM

CFM

Watts

Watts

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

469 / 334

308 / 182

1034 / 609

1352 / 1061

413 / 331

259 / 183

1037 / 779

1368 / 1175

348 / 320

206 / 178

1034 / 919

1371 / 1279

275 / 300

1361 / 1374

1343 / 1463

CFM

152 / 164

1028 / 1041

99 / 142

200 / 272

1020 / 1149

CFM

Watts

Watts

CFM

CFM

Watts

Watts

350

400 †

CFM/ton

CFM/ton

441 / 303

1304 / 981

1315 / 1110

1314 / 1218

1304 / 1317

1287 / 1408

CFM

480 / 364

1369 / 1124

384 / 301

440 / 361

1415 / 1233

320 / 291

374 / 348

1421 / 1334

250 / 272

300 / 328

1413 / 1427

179 / 245

221 / 299

1395 / 1514

CFM

Watts

Watts

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

468 / 477

383 / 249

1174 / 848

1350 / 1326

477 / 472

319 / 248

1181 / 981

1474 / 1425

467 / 458

1576 / 1518

1593 / 1605

1584 / 1687

CFM

259 / 239

1178 / 1098

399 / 435

197 / 222

1169 / 1205

313 / 405

135 / 197

1156 / 1302

CFM

Watts

Watts

CFM

CFM

Watts

Watts

350

400

CFM/ton

CFM/ton

470 / 429

1319 / 1248

1445 / 1350

1496 / 1445

1500 / 1534

1487 / 1618

CFM

463 / 463

1301 / 1301

481 / 425

472 / 472

1423 / 1423

441 / 411

475 / 475

1543 / 1543

369 / 389

443 / 464

1614 / 1646

288 / 359

363 / 433

1616 / 1728

CFM

Watts

Watts

CFM

Watts

4. Torque mode will reduce airflow when static is above approximately

450

CFM/ton

453 / 453

1273 / 1273

460 / 460

1393 / 1393

465 / 465

1514 / 1514

456 / 456

1621 / 1621

432 / 432

1711 / 1711

CFM

Watts

0.35” water column.

5. All heating modes default to Constant CFM.

6. Cooling airflow values are with wet coil, no filter

MINIMUM HEATER AIRFLOW CFM - HEATER MATRI

BAYEVBC20BK1A

BAYEVCB15LG3A

BAYEVAC10LG3AA BAYEVBC15BK1A

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

BAYEVAC10LG1A

BAYEVAC10BK1A

BAYEVAC08LG1A

BAYEVAC08BK1A

COOLING

OUTDOOR

290

SETTING

AIRFLOW

(TONS)

MULTIPLIER

370

CFM/ton

CFM/ton

400

CFM/ton

2.5 tons

450

CFM/ton

290

CFM/ton

370

CFM/ton

400

3 tons

450

CFM/ton

CFM/ton

290

CFM/ton

370 †

CFM/ton

400

450

CFM/ton

3.5 tons †

290

CFM/ton

CFM/ton

370

CFM/ton

400

4 tons

450

CFM/ton

CFM/ton

NOTES:

1. * Models start with "A" or "T"

2. † Factory Setting

3. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

BAYEVAC05LG1A

BAYEVAC05BK1A

*AM8A0C42V31SAA 978/1093 978/1380 1035/1380 920/1093 1035/1438 1150/1495 1380/1610

MODEL NO.

AM8A0C42 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

TAM810

Page 11

864

A

A

A

A

230

883

197

893

159

900

EXTERNAL STATIC PRESSURE

Airflow

118

72

893

CFM

Watts

Powe r

290

HEATING

AIRFLOW

CFM/ton

SETTING

295

1049

257

1062

213

1070

164

1073

112

1068

CFM

Watts

350

CFM/ton

359

1196

315

1206

266

1212

212

1212

154

1207

CFM

Watts

400

CFM/ton

436

1344

387

1352

331

1354

270

1352

206

1344

CFM

Watts

450

CFM/ton

281

1014

244

1028

202

1037

154

1040

103

1034

CFM

Watts

290

CFM/ton

371

1220

326

1230

276

1236

221

1235

162

1229

CFM

Watts

350

CFM/ton

465

1394

413

1400

356

1403

293

1400

226

1392

CFM

Watts

400

CFM/ton

577

1567

521

1574

457

1576

386

1572

310

1561

CFM

Watts

450

CFM/ton

341

1157

299

1168

251

1174

198

1176

141

1168

CFM

Watts

290

CFM/ton

465

1394

413

1400

356

1403

293

1400

226

1392

CFM

Watts

350

CFM/ton

595

1591

538

1599

474

1601

402

1597

325

1586

CFM

Watts

400 †

CFM/ton

655

1667

665

1766

620

1800

544

1801

459

1794

CFM

Watts

450

CFM/ton

403

1301

355

1309

310

1311

252

1310

189

1302

CFM

Watts

290

CFM/ton

563

1569

505

1575

439

1575

367

1570

290

1557

CFM

Watts

350

CFM/ton

659

1701

663

1794

594

1801

515

1799

428

1789

CFM

Watts

400

CFM/ton

628

1660

634

1757

643

1863

656

1975

605

2018

CFM

Watts

450

CFM/ton

6. If the air handler is applied in downflow or horizontal configurations, the

airflow should not exceed 2000 CFM. Airflow above 2000 CFM could result in

water blow-off.

7. All heating modes default to Constant CFM.

8. Cooling airflow values are with wet coil, no filter

229 /

871 / 445

886 / 622

195 / 137

*AM8A0C48 AIRFLOW PERFORMANCE

896 / 767

900 / 897

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

894 / 1018

CFM

Powe r

290

SETTING

157 / 130

114 / 114

69 / 91

Watts

CFM/ton

CONSTANT CFM MODE / CONSTANT TORQUE MODE

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Airflow

AIRFLOW

COOLING

292 / 194

354 / 249

1053 / 738

1199 / 926

252 / 192

309 / 244

1065 / 859

1208 / 1029

208 / 180

259 / 229

1072 / 972

1213 / 1128

158 / 160

203 / 206

1073 / 1078

1212 / 1222

106 / 132

145 / 176

1205 /1314

1067 / 1180

CFM

CFM

Watts

Watts

350

400

CFM/ton

CFM/ton

427 / 313

279 / 182

1018 / 690

1346 / 1098

377 / 305

240 / 181

1031 / 817

1353 / 1190

320 / 289

197 / 170

1038 / 934

1355 / 1280

259 / 264

149 / 150

1352 / 1367

1041 / 1044

98 / 123

193 / 232

1343 / 1451

1034 / 1149

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

365 / 259

1224 / 955

1232 / 1056

1236 / 1153

1235 / 1246

1228 / 1336

CFM

350

455 / 336

1395 / 1154

319 / 253

402 / 328

1401 / 1244

268 / 238

343 / 311

1403 / 1331

212 / 215

280 / 286

1399 / 1415

212 253

152 / 185

1389 / 1498

CFM

Watts

Watts

400

CFM/ton

CFM/ton

563 / 432

336 / 242

1160 / 905

1568 / 1351

505 / 422

293 / 237

1575 / 1434

1170 / 1010

439 / 404

244 / 223

1575 / 1514

1175 / 1109

367 / 377

191 / 200

1570 / 1592

1175 / 1205

290 / 343

133 / 170

1558 / 1669

1168 / 1298

CFM

CFM

Watts

Watts

450

290

CFM/ton

CFM/ton

455 / 346

580 / 459

1395 / 1177

1593 / 1401

402 / 338

521 / 450

1401 / 1266

1600 / 1483

343 / 321

455 / 431

1403 / 1352

1601 / 1562

280 / 295

382 / 546

1399 / 1436

1595 / 1639

212 / 262

303 / 370

1389 / 1517

1583 / 1714

CFM

CFM

Watts

Watts

400

350 †

CFM/ton

CFM/ton

660 / 601

1698 / 1625

1793 / 1701

1808 / 1775

1800 / 1848

1790 / 1918

CFM

450

404 / 302

1302 / 1071

663 / 592

355 / 294

1309 / 1165

594 / 573

300 / 278

1312 / 1256

515 / 546

241 / 253

1310 / 1344

429 / 511

177 / 222

1301 / 1429

CFM

Watts

Watts

290

CFM/ton

CFM/ton

563 / 444

660 / 601

1568 / 1373

1698 / 1625

505 / 434

663 / 592

1575 / 1455

1793 / 1701

439 / 415

594 / 573

1575 / 1535

1801 / 1775

367 / 389

515 / 546

1570 / 1613

1800 / 1848

290 / 354

429 / 511

1558 / 1688

1790 / 1918

CFM

CFM

Watts

Watts

350

400

CFM/ton

CFM/ton

631 / 631

1651 / 1651

637 / 637

1749 / 1749

645 / 645

1857 / 1857

656 / 656

1973 / 1973

605 / 605

2018 / 2018

CFM

Watts

450

CFM/ton

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

MINIMUM HEATER AIRFLOW CFM - HEATER MATRIX

BAYEVAC10LG1AA BAYEVAC10LG3AA BAYEVBC15BK1AA BAYEVCB15LG3AA BAYEVBC20BK1AA BAYEVCC25BK1AA

BAYEVAC10BK1A

BAYEVAC08LG1AA

BAYEVAC08BK1A

1063/1188 1063/1500 1125/1500 1000/1188 1125/1563 1250/1625 1500/1750 1625/1813

BAYEVAC05LG1AA

BAYEVAC05BK1A

(TONS)

OUTDOOR

MULTIPLIER

TAM811

3 tons

3.5 tons

4 tons †

4.5 tons**

1. * Models start with "A" or "T"

2. † Factory Setting

3. ** Not an actual OD size

4. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

5. Torque mode will reduce airflow when static is above approximately 0.4” water column.

*AM8A0C48V41SA

MODEL NO.

AM8A0C48 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

Page 12

283

A

1045

247

1063

203

1071

151

1065

EXTERNAL STATIC PRESSURE

95

1039

CFM

Watts

Powe r

Airflow

290

HEATING

AIRFLOW

CFM/ton

SETTING

363

1248

321

1263

270

1270

213

1266

150

1247

CFM

Watts

350

CFM/ton

439

1409

392

1421

337

1426

274

1423

206

1407

CFM

Watts

400

CFM/ton

529

1569

476

1578

416

1582

348

1578

274

1564

CFM

Watts

450

CFM/ton

337

1187

297

1203

248

1210

192

1206

131

1185

CFM

Watts

290

CFM/ton

439

1409

392

1421

337

1426

274

1423

206

1407

CFM

Watts

350

CFM/ton

543

1592

490

1601

428

1604

360

1600

285

1587

CFM

Watts

400

CFM/ton

671

1782

611

1788

543

1788

467

1783

385

1770

CFM

Watts

450

CFM/ton

396

1322

352

1336

300

1342

240

1338

174

1321

CFM

Watts

290

CFM/ton

529

1569

476

1578

416

1582

348

1578

274

1564

CFM

Watts

350

CFM/ton

671

1782

611

1788

543

1788

467

1783

385

1770

CFM

Watts

400 †

CFM/ton

856

2011

788

2014

711

2011

626

2003

534

1989

CFM

Watts

450

CFM/ton

463

1454

415

1466

358

1471

294

1467

224

1452

CFM

Watts

290

CFM/ton

636

1734

578

1740

511

1741

437

1736

357

1723

CFM

Watts

350

CFM/ton

833

1985

766

1988

690

1985

606

1978

515

1964

CFM

Watts

400

CFM/ton

2186

1023

2252

1016

934

2252

842

2245

741

2232

CFM

Watts

450

CFM/ton

6. If the air handler is applied in downflow or horizontal configurations, the

airflow should not exceed 2000 CFM. Airflow above 2000 CFM could result in

water blow-off.

7. All heating modes default to Constant CFM.

8. Cooling airflow values are with wet coil, no filter

283 / 165

1046 / 607

1314 / 945

247 / 175

1066 / 799

1329 / 1068

*AM8A0C60 AIRFLOW PERFORMANCE

203 / 168

EXTERNAL STATIC PRESSURE (Constant CFM / Constant Torque)

Powe r

Airflow

AIRFLOW

1075 / 941

151 / 148

1068 / 1056

0.1 0.3 0.5 0.7 0.9 0.1 0.3 0.5 0.7 0.9

94 / 119

1040 / 1151

CFM

Watts

290

CFM/ton

SETTING

1336 / 1174

1332 / 1264

1312 / 1343

CFM

370

CONSTANT CFM MODE / CONSTANT TORQUE MODE

COOLING

392 / 251

440 / 325

1410 / 1154

349 / 250

393 / 319

1423 / 1256

296 / 235

337 / 301

1429 / 1346

236 / 210

274 / 273

1425 / 1426

171 / 178

206 / 238

1408 / 1496

CFM

Watts

Watts

400

CFM/ton

CFM/ton

529 / 407

337 / 233

1189 / 887

1569 / 1343

477 / 398

1580 / 1432

1584 / 1512

1579 / 1585

1565 / 1650

CFM

450

297 / 234

1206 / 1018

416 / 378

248 / 220

1213 / 1128

348 / 348

192 / 196

1208 / 1223

274 / 312

131 / 164

1186 / 1304

CFM

Watts

Watts

290

CFM/ton

CFM/ton

479 / 334

543 / 430

1482 / 1177

1592 / 1399

430 / 327

490 / 420

1495 / 1277

1602 / 1475

372 / 308

429 / 399

1499 / 1365

1606 / 1554

306 / 280

360 / 369

1495 / 1444

1602 / 1625

235 / 245

285 / 332

1480 / 1514

1587 / 1689

CFM

CFM

Watts

Watts

370

400

CFM/ton

CFM/ton

671 / 546

1782 / 1597

1788 / 1675

1789 / 1747

1784 / 1813

1770 / 1873

CFM

450

397 / 292

1323 / 1069

612 / 534

353 / 288

1338 / 1179

543 / 512

300 / 271

1345 / 1274

468 / 481

240 / 245

1340 / 1358

386 / 443

174 / 211

1322 / 1431

CFM

Watts

Watts

290

CFM/ton

CFM/ton

582 / 417

1653 / 1363

1662 / 1451

1665 / 1530

1660 / 1602

1646 / 1667

CFM

370 †

671 / 546

1781 / 1597

527 / 407

612 / 534

1788 / 1675

463 / 386

543 / 512

1789 / 1747

392 / 357

468 / 481

1784 / 1813

315 / 320

386 / 443

1770 / 1873

CFM

Watts

Watts

400

CFM/ton

CFM/ton

855 / 716

2009 / 1842

2013 / 1913

2012 / 1980

2004 / 2042

1989 2099

CFM

450

463 / 356

1455 / 1231

788 / 703

415 / 348

1468 / 1327

712 / 681

358 / 329

1473 / 1413

627 / 650

294 / 301

1469 / 1489

535 / 612

224 / 265

1452 / 1557

CFM

Watts

Watts

290

CFM/ton

CFM/ton

708 / 515

1831 / 1544

1837 / 1624

1837 / 1698

1831 / 1765

1817 / 1826

CFM

370

832 / 695

1983 / 1814

647 / 503

766 / 682

1987 / 1886

576 / 481

690 / 660

1986 / 1953

499 / 451

607 / 629

1978 / 2015

415 / 451

516 / 590

1964 / 2073

CFM

Watts

Watts

400

CFM/ton

CFM/ton

1024 / 941

2185 / 2104

1015 / 930

2252 / 2171

934 / 908

2252 / 2233

842 / 879

2245 / 2292

741 / 842

2231 / 2347

CFM

Watts

450

CFM/ton

SEE AIR HANDLER NAMEPLATE

WITHOUT HEAT PUMP / WITH HP

MINIMUM HEATER AIRFLOW CFM - HEATER MATRIX

BAYEVAC10LG1AA BAYEVAC10LG3AA BAYEVBC15BK1AA BAYEVCB15LG3AA BAYEVBC20BK1AA BAYEVCC25BK1AA

BAYEVAC10BK1AA

BAYEVAC08LG1AA

BAYEVAC08BK1AA

1063/1188 1063/1500 1125/1500 1000/1188 1125/1563 1250/1625 1500/1750 1625/1813

BAYEVAC05LG1AA

BAYEVAC05BK1AA

(TONS)

OUTDOOR

MULTIPLIER

TAM812

3.5 tons

4 tons

4.5 tons **†

5 tons

1. * Models start with "A" or "T"

2. † Factory Setting

3. ** Not an actual OD size

4. Status LED will blink once per 100 CFM requested. In torque mode, actual airflow may be lower.

5. Torque mode will reduce airflow when static is above approximately 0.4" water column.

*AM8A0C60V51SA

MODEL NO.

AM8A0C60 Minimum Heating Airflow Settings

NOTE: Minimum auxiliary heating airflow is automatically configured by the air

handler model and the auxiliary heater model number. This is not field adjustable.

Page 13

A

A

A

AM8 HEATER ATTRIBUTE DATA

Heater Attribute Data

*AM8A0A24V21SA

240 Volt

Heater Model No.

No Heater 0 - - 3.0** 4 15 - - 3.0** 4 15

BAYEVAC05++1 1 4.80 16400 20.0 29 30 3.60 12300 17.3 25 25

BAYEVAC08++1 1 7.68 26200 32.0 44 45 5.76 19700 27.7 38 40

BAYEVAC10++1 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 32 35 7.20 24600 20.0 28 30

Note: * May be "A" or "T"

Note: ** Motor Amps

Heater Model No.

No Heater 0 - - 3.0** 4 15 - - 3.0** 4 15

BAYEVAC05++1 1 4.80 16400 20.0 29 30 3.60 12300 17.3 25 25

BAYEVAC08++1 1 7.68 26200 32.0 44 45 5.76 19700 27.7 38 40

BAYEVAC10++1 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 32 35 7.20 24600 20.0 28 30

BAYEVBC15LG3 1-3 PH 14.40 42000 34.6 47 50 10.80 36900 30.0 41 45

BAYEVBC15BK1 - Circuit 1 1

BAYEVBC15BK1 - Circuit 2

Note: * May be "A" or "T"

Note: ** Motor Amps

1 MCA and MOP for circuit 1 contains the motor amps

No. of

Circuits

No. of

Circuits

2

Capacity Minimum

kW BTUH kW BTUH

Capacity Heater

kW BTUH kW BTUH

9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

Heater

mps per

Circuit

240 Volt

mps per

Circuit

Circuit

Ampacity

Heater Attribute Data

*AM8A0B30V21SA

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Maximum

Overload

Protection

Capacity Heater

Capacity

208 Volt

Amps per

Circuit

208 Volt

Heater

Amps per

Circuit

Minimum

Circuit

Ampacity

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Maximum

Overload

Protection

Heater Attribute Data

*AM8A0C36V31SA

240 Volt 208 Volt

Heater Model No.

No Heater 0 - - 3.0** 4 15 - - 3.0** 4 15

BAYEVAC05++1 1 4.80 16400 20.0 29 30 3.60 12300 17.3 25 25

BAYEVAC08++1 1 7.68 26200 32.0 44 45 5.76 19700 27.7 38 40

BAYEVAC10++1 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 32 35 7.20 24600 20.0 28 30

BAYEVBC15LG3 1-3 PH 14.40 42000 34.6 47 50 10.80 36900 30.0 41 45

BAYEVBC15BK1 - Circuit 1 1

BAYEVBC15BK1 - Circuit 2

BAYEVBC20BK1 - Circuit 1 1

BAYEVBC20BK1 - Circuit 2

Note: * May be "A" or "T"

Note: ** Motor Amps

1 MCA and MOP for circuit 1 contains the motor amps

No. of

Circuits

2

2

Capacity Heater

kW BTUH kW BTUH

9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

mps per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Capacity Heater

Amps per

Circuit

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

TAM813

Page 14

A

A

A

AM8 HEATER ATTRIBUTE DATA

Heater Attribute Data

*AM8A0C42V31SA

240 Volt

Heater Model No.

No Heater 0 - - 3.0** 4 15 - - 3.0** 4 15

BAYEVAC05++1 1 4.80 16400 20.0 29 30 3.60 12300 17.3 25 25

BAYEVAC08++1 1 7.68 26200 32.0 44 45 5.76 19700 27.7 38 40

BAYEVAC10++1 1 9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 32 35 7.20 24600 20.0 28 30

BAYEVBC15LG3 1-3 PH 14.40 42000 34.6 47 50 10.80 36900 30.0 41 45

BAYEVBC15BK1 - Circuit 1 1

BAYEVBC15BK1 - Circuit 2

BAYEVBC20BK1 - Circuit 1 1

BAYEVBC20BK1 - Circuit 2

Note: * May be "A" or "T"

Note: ** Motor Amps

1 MCA and MOP for circuit 1 contains the motor amps

Heater Model No.

No Heater 0 - - 4.2** 5 15 - - 4.2** 5 15

BAYEVAC05++1 1 4.80 16400 20.0 30 30 3.60 12300 17.3 27 30

BAYEVAC08++1 1 7.68 26200 32.0 45 45 5.76 19700 27.7 40 40

BAYEVAC10++1 1 9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 34 35 7.20 24600 20.0 30 30

BAYEVBC15LG3 1-3 PH 14.40 42000 34.6 48 50 10.80 36900 30.0 42 45

BAYEVBC15BK1 - Circuit 1 1

BAYEVBC15BK1 - Circuit 2

BAYEVBC20BK1 - Circuit 1 1

BAYEVBC20BK1 - Circuit 2

BAYEVCC25BK1 - Circuit 1 1

BAYEVCC25BK1 - Circuit 2

BAYEVCC25BK1 - Circuit 3

Note: * May be "A" or "T"

Note: ** Motor Amps

1 MCA and MOP for circuit 1 contains the motor amps

Heater Model No.

No Heater 0 - - 5.5** 7 15 - - 5.5** 7 15

BAYEVAC05++1 1 4.80 16400 20.0 30 30 3.60 12300 17.3 27 30

BAYEVAC08++1 1 7.68 26200 32.0 45 45 5.76 19700 27.7 40 40

BAYEVAC10++1 1 9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

BAYEVAC10LG3 1-3 PH 9.60 32800 23.1 34 35 7.20 24600 20.0 30 30

BAYEVBC15LG3 1-3 PH 14.40 42000 34.6 48 50 10.80 36900 30.0 42 45

BAYEVBC15BK1 - Circuit 1 1

BAYEVBC15BK1 - Circuit 2

BAYEVBC20BK1 - Circuit 1 1

BAYEVBC20BK1 - Circuit 2

BAYEVCC25BK1 - Circuit 1 1

BAYEVCC25BK1 - Circuit 2

BAYEVCC25BK1 - Circuit 3

Note: * May be "A" or "T"

Note: ** Motor Amps

1 MCA and MOP for circuit 1 contains the motor amps

No. of

Circuits

2

2

No. of

Circuits

2

2

3

No. of

Circuits

2

2

3

Capacity Heater

kW BTUH kW BTUH

9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

9.60 32800 40.0 54 60 7.20 24600 34.6 47 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

Capacity Heater

kW BTUH kW BTUH

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

Capacity Heater

kW BTUH kW BTUH

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

9.60 32800 40.0 55 60 7.20 24600 34.6 49 50

9.60 32800 40.0 50 50 7.20 24600 34.6 43 45

4.80 16400 20.0 25 25 3.60 12300 17.3 22 25

Minimum

mps per

Circuit

Ampacity

Heater Attribute Data

*AM8A0C48V41SA

240 Volt 208 Volt

Minimum

mps per

Circuit

Ampacity

Heater Attribute Data

*AM8A0C60V51SA

240 Volt 208 Volt

Minimum

mps per

Circuit

Ampacity

Circuit

Circuit

Circuit

Maximum

Overload

Protection

Maximum

Overload

Protection

Maximum

Overload

Protection

Capacity Heater

Capacity Heater

Capacity Heater

Notes:

1. See Product Data or Air Handler nameplate for approved combinations of Air Handlers and Heaters

2. Heater model numbers may have additional suffix digits.

TAM814

208 Volt

Amps per

Circuit

Amps per

Circuit

Amps per

Circuit

Minimum

Circuit

Ampacity

Minimum

Circuit

Ampacity

Minimum

Circuit

Ampacity

Maximum

Overload

Protection

Maximum

Overload

Protection

Maximum

Overload

Protection

Page 15

WHEEL

BLOWER HOUSING

BELLY BAND

MOTOR

A

A is determined per chart

Wheel is centered in

Blower Housing

SUBCOOLING ADJUSTMENT

Indoor Unit Model No. Outdoor Unit Model No. Subcooling

*AM8A0B30V21CA 4A6H6024E, 4TWX6024E 9°

*AM8A0C36V31CA 4A6H6036E, 4TWX6036E 10°

*AM8A0C48V41CA 4A6H6048E, 4TWX6048E 8°

*AM8A0B30V21CA 4A7A6024E, 4TTX6024E 8°

*AM8A0C36V31CA 4A7A6036E, 4TTX6036E 8°

*AM8A0C48V41CA 4A7A6048E, 4TTX6048E 8°

*AM8A0B30V21CA 4TWZ0024A, 4A6Z0024A 9°

*AM8A0C36V31CA 4TWZ0036A, 4A6Z0036A 10°

*AM8A0C48V41CA 4TWZ0048A, 4A6Z0048A 12°

*AM8A0B30V21CA 4TTZ0024A, 4A7Z0024A 9°

*AM8A0C36V31CA 4TTZ0036A, 4A7Z0036A 11°

*AM8A0C48V41CA 4TTZ0048A, 4A7Z0048A 13°

* May be “A” or “T”

All other matches must be charged per the nameplate charging instructions.

DISTANCE FROM BELLY BAND TO SHAFT FACE OF MOTOR FOR MINIMUM VIBRATION

MODEL DIM "A"

*AM8A0A24V21CA 2-3/8

*AM8A0B30V21CA 2-3/8

*AM8A0C36V31CA 2-3/8

*AM8A0C42V31CA 2-3/8

*AM8A0C48V41CA 2-3/8

*AM8A0C60V51CA 2-3/8

* May be "A" or" T"

TAM815

Page 16

Air Handler Control Panel - LEDs

Airflow Control (AFC)

J8

13.8 VDC

From DC Power Supply

24 VAC

From Transformer

J10

HUM

J7 - Motor

BM LED

J8

J2

J9 - EHC/HHC

13.8 VDC

13.8 VDC

Unit Test

TEST

J6

J5

J4

24 VAC

J11

J1

13.8 VDC

To EEV Stator

J2

J10 - Display Assembly

Distribution

Board

To Internal

J6

Condensate

Switch (Optional)

ET Sensor

J3

GT Sensor

See Table

Electronic Expansion Valve Control (EVC)

COMM LED

UNIT

BM

B

D

R

O

Y1

Y2

WIRE

TIE

STATUS

LED

STATUS

COMM

UNIT

LED

FAULT

FAULT

LED

TAM816

STATUS

LED

UNIT

STATUS

UNIT

LED

FAULT

FAULT

LED

OPEN

SW1

R410A / R22

TEST

CLOSE

OPEN

TEST

CLOSE

J4

Page 17

AFC BM (Bit Master) LED (GREEN LED)

Airflow Control (AFC)

J7 - Motor

J10

TEST

Unit Test

24 VAC

J4

J8

J9 - EHC/HHC

13.8 VDC

J8

J2

13.8 VDC

r

AFC BM LED

Solid ON

Normal operation

Description

AFC COMM LED (AMBER LED)

WIRE

TIE

HUM

AFC COMM LED

Device count

Number of communicating devices*

Description

* Examples: communicating thermostat, communicating air cleaner, etc.

AFC STATUS CODES (GREEN LED)

AFC STATUS LED

ON SOLID Power up and during last 4 fault history sequence

1 Flash (per second) Stand-by or idle

Multiple Flash CFM demand - 1 flash per 100 cfm

Description

AFC UNIT LED (BLUE LED)

UnitLED

1Flash

Rapid

SOLIDON

Off

Normal(1flashevery4seconds)

CommunicationBusyError(2flashespersecond)

CommunicationscannotbeestablishedwiththeAFC

NoPower

Description

STATUS

LED

UNIT

LED

FAULT

LED

Y2

Y1

O

D

R

B

BM

COMM

STATUS

UNIT

FAULT

BM LED

COMM LED

J6

AFC FAULT CODES (RED LED)

AFC Fault

LED Description

OFF No Fault

SolidOn Internal control failure

1 24VAC fuse blown

2

3

4 Blower communication error (Status LED will be ON solid)

5

6

8

11

12

NOTES:

TAM817

PM Data Corrupt or Missing / Motor Mismatch

Communication error 3

Internal communication error (refer to Unit LED on EVC, EHC, HHC) (1)(2)

Indoor coil air sensor error

Twinning erro

EVC has detected a fault condition (refer to Fault LED on EVC)

EHC / HHC has detected a fault condition (refer to Fault LED on EHC / HHC)

1) If Unit LED on AFC is flashing 2 times/second, AFC is causing the error.

2) Unit LED on suspect control will flash 2 times/second on the suspect control.

3) Error is associated with the ComfortLink

All LED's will be off if power is not applied.

TM

II or AccuLinkTM communcating bus.

Page 18

EVC STATUS CODES (GREEN LED)

A

A

y

EVC STATUS LED (Non Heat Pump Systems)

Flash

1 Cool mode selected / No active call

2 Active call for 1st stage cooling

3

NOTE:

ctive call for 2nd stage cooling (1)

(1) Single stage OD systems will report 2nd stage flash codes

EVC STATUS LED (Heat Pump Systems)

Flash

1 Cool mode selected / No active call

2 Active call for 1st stage cooling or defrost

3 Active call for 2nd stage cooling or defrost (1)

4 Heat mode selected or Thermostat system switch off

5 Active call for 1st stage heating

6

NOTE:

ctive call for 2nd stage heating (1)

(1) Single stage OD systems will report 2nd stage flash codes

EVC UNIT LED (BLUE LED)

STATUS

LED

UNIT

LED

FAULT

LED

SW1

R410A / R22

J4

OPEN

TEST

CLOSE

J11

STATUS

UNIT

FAULT

EVC

OPEN

TEST

CLOSE

UnitLED

1Flash

Rapid

SOLIDON

Off