Page 1

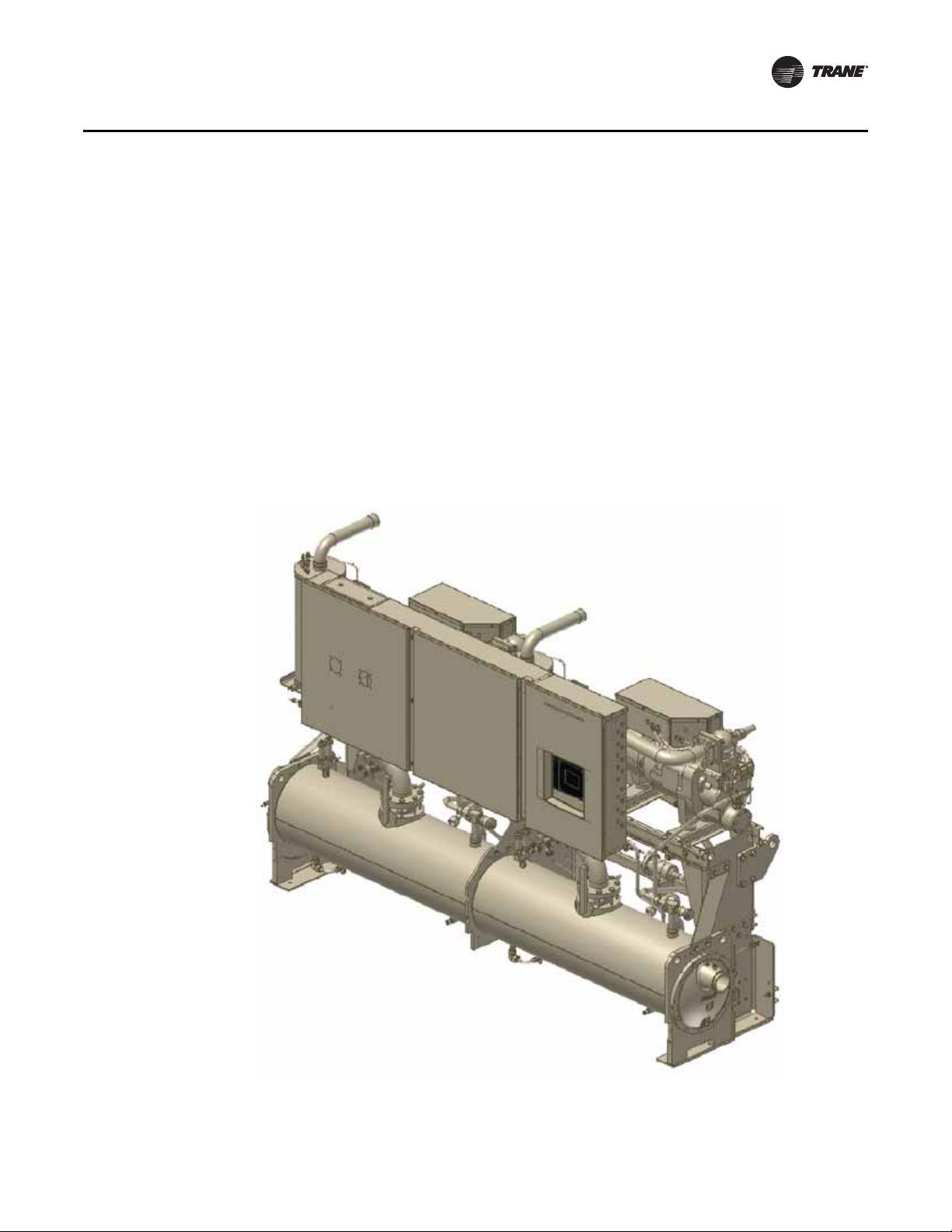

Product Catalog

Series R™ Helical Rotary

Liquid Chillers

70-250 Tons Model RTWD Water-Cooled

70-200 Tons Model RTUD Condenserless

Made in USA

February 2010

RLC-PRC029-EN

Page 2

Introduction

To meet a wide range of applications in the 70–250 ton water-cooled market, Trane is proud to

introduce the model RTWD helical-rotary liquid chiller. To meet a wide range of applications in the

70-200 ton condenserless market, Trane is offering the RTUD condenserless chiller. The

introduction of this next-generation chiller is an exciting step forward in application versatility, ease

of installation, control precision, reliability, energy-efficiency, and operational cost-effectiveness.

The new chiller is designed to deliver proven Series R performance, plus all the benefits of an

advanced heat transfer design with two low-speed, direct-drive compressors.

Important Design Advances and New Features

• Higher full-load energy efficiency that meets ASHRAE 90.1 and reduces both operating and life-

• Variable evaporator flow compensation for improved control stability with energy saving

• Single chiller time of day scheduling communication option for easier control of small jobs.

• Dual independent refrigerant circuits.

• HFC-134a optimized design.

The industrial-grade design of the Series R helical-rotary chiller is ideal for both industrial and

commercial markets, in applications such as office buildings, hospitals, schools, retail buildings,

and industrial facilities. The reliable compressors, wide operating temperature range, advanced

controls, electronic expansion valve, short anti-recycle timers, and industry-leading efficiencies

mean that this latest Trane Series R chiller is the perfect choice for tight temperature control in

almost any application temperatures, and under widely varying loads.

cycle costs.

variable flow applications.

© 2009 Trane All rights reserved RLC-PRC029-EN

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

RLC-PRC029-EN 3

Page 4

Features and Benefits

Reliability

• The Trane helical rotary compressor is a proven design resulting from years of research and

thousands of test hours, including extensive testing under extraordinarily severe operating

conditions.

• Trane is the world’s largest manufacturer of large helical rotary compressors, with more than

240,000 compressors installed worldwide.

• Direct drive, low-speed compressors—a simple design with only four moving parts—provides

maximum efficiency, high reliability, and low maintenance requirements.

• Suction gas-cooled motor stays at a uniformly low temperature for long motor life.

• Electronic expansion valve, with fewer moving parts than alternative valve designs, provides

highly reliable operation.

High Performance

• Advanced design enables chilled water temperature control to ±0.5°F (0.28°C) for flow changes

up to 10 percent per minute, plus handling of flow changes up to 30 percent per minute for

variable flow applications.

• Two minute stop-to-start and five minute start-to-start anti-recycle timer allows tight chilled

water temperature control in constant or transient low-load applications.

• High compressor lift capabilities for use with heat recovery and waterside heat pump

applications allows highly efficient system design with minimal operational concerns.

• Tight water temperature control extends to operation of multiple chillers in parallel or series

configurations, offering further system design flexibility for maximum efficiency.

• Optional LonTalk/Tracer Summit communications interface provides excellent, trouble-free

inter operability.

Life Cycle Cost-Effectiveness

• Precise compressor rotor tip clearance ensures optimal efficiency.

• Condenser and evaporator tubes use the latest heat transfer technology for increased

efficiency.

• Electronic expansion valve enables exceptionally tight temperature control and extremely low

superheat, resulting in more efficient full-load and part-load operation than previously

available.

• Chilled water reset based on return water temperature is standard.

• Electrical current-limiting is available as an option.

4 RLC-PRC029-EN

Page 5

Application Versatility

• Industrial/low temperature process cooling – Excellent operating temperature range and

precise control capabilities enable tight control with single chiller or series configuration.

• Ice/thermal storage – Specifiers and operators benefit from dual setpoint control and industry-

leading temperature, efficiency, and control capabilities, plus outstanding support through

partnership with Calmac, a strong Trane partner providing proven installation examples,

templates, and references that minimize design time and energy costs.

• Heat recovery – Maximum condenser temperature exceeds those of previous technologies,

providing hot water and tight control that minimizes operating costs for the chilled water plant

and boiler/hot water heater, while also providing consistent dehumidification.

• Water to water heat pump – For multi-chiller systems where there is a base or year-round

heating load the RTWD can be used as a water side heat pump by utilizing ground or surface

water as a heat source. Leaving condenser temperature control option allows for the chiller to

be used and controlled primarily for the heat produced in the condenser.

• Dry Cooler – Allows for use with a closed condenser loop system that minimizes the potential

for cross-contamination of the condenser loop.

• Variable primary flow – Variable evaporator flow compensation allows multi-chiller systems to

vary the flow of water throughout the entire system (from the evaporator through the cooling

coils). This feature also provides additional system efficiency as the number of pumps and the

flow rate in the system are reduced. Standard 2 pass or optional 3 pass evaporator allows for

a wider range of flow capabilities.

• Series chiller configuration – For two-chiller systems all the system water passes through the

evaporators and/or condensers of both chillers to take advantage of system efficiency gains due

to thermodynamic staging as well as downsizing the upstream chiller.

• EarthWise system – Low flow and high temperature differential installations allow for reduced

pump and cooling-tower energy by decreasing the amount of water flow pumped through the

system. This results in downsizing of all HVAC and ancillary equipment which provides

installation and operational savings.

Features and Benefits

RLC-PRC029-EN 5

Page 6

Features and Benefits

Simple, Economical Installation

• All units fit through standard double-width doors and most units fit through single width doors.

Units are designed with bolt-together construction for disassembly to fit through smaller

openings.

• Small footprint saves valuable equipment room space and alleviates access concerns for most

retrofit jobs.

• Lightweight design simplifies rigging requirements, further reducing installation time

requirements and costs.

• Full factory refrigerant and oil charges reduce required field labor, materials, and installation

cost (RTWD). An optional nitrogen charge can reduce the time and labor for projects expecting

dis-assembly.

• Optional integrated forklift channels on the unit base allow for easy movement of the chiller at

the job site.

• Single or dual point power connection options simplify overall installation.

• Unit-mounted starter eliminates additional job site installation considerations and labor

requirements.

• Trane CH530 controls easily interface with Tracer Summit

automation systems through single twisted-pair wire.

• Trane has conducted extensive factory testing during manufacturing, and also offers options

for in-person and/or documented system performance verification.

™

,LonTalk™, or BACnet™ building

6 RLC-PRC029-EN

Page 7

Precision Control

• Microprocessor-based Trane CH530 controls monitor and maintain optimal operation of the

chiller and its associated sensors, actuators, relays, and switches, all of which are factoryassembled and extensively tested.

• Easy interface with computers hosting LonTalk/Tracer Summit/BACnet building automation/

energy management systems allows the operator to efficiently optimize comfort system

performance and minimize operating costs.

• Proportional Integral Derivative (PID) control strategy ensures stable, efficient chilled water

temperature, maintaining ±1°F (0.56°C) by reacting to instantaneous load changes.

• Adaptive Control™attempts to maintain chiller operation under adverse conditions, when

many other chillers might simply shut down. This is accomplished by unloading the

compressor due to high condensing pressure, low suction pressure and/or overcurrent.

• EMC certification ensures trouble-free use of electronic devices around the chiller.

• Easy-to-use operator interface displays all operating and safety messages, with complete

diagnostics information, on a easily readable panel with a scrolling touch-screen display.

• New variable evaporator flow compensation maintains improved control stability of the

leaving water temperature.

Features and Benefits

RLC-PRC029-EN 7

Page 8

Application Considerations

Condenser Water Temperatures

With the model RTWD chiller, condenser head pressure control is necessary only if the unit starts

with entering condenser water temperatures below 55°F (12.8°C), or between 45°F (7.2°C) and 55°F

(12.8°C), when a temperature increase of 1°F (0.56°C) per minute to 55°F (12.8°C) is not possible.

When the application requires startup temperatures below the prescribed minimums, a variety of

system implementation options are available including the use of a 2- or 3-way valve or tower

bypass to maintain the required system refrigerant differential pressure.

• To control a 2-way or 3-way valve, select the Condenser Regulating Valve Control option for the

Trane CH530 controls. This option enables the CH530 controls to send a signal for opening and

closing the valve as necessary to maintain chiller differential refrigerant pressure. The 2-way

valves are available as a ship-with option.

• Tower bypass may also be a valid control method if the chiller temperature requirements can

be maintained and the loop is small.

The minimum acceptable refrigerant pressure differential between condenser and evaporator is 25

psid (1.7 bars) at all load conditions in order to ensure adequate oil circulation. Condenser leaving

water temperature must be 17°F (9.5°C) higher than evaporator leaving water temperature within

2 minutes of startup. A 25°F (13.9°C) temperature difference must be maintained thereafter [this

differential requirement is lessened by 0.25°F (0.14°C) for every 1°F (0.56°C) that the condenser

leaving water temperature is above 55°F (12.8°C)].

Trane Series R chillers start and operate successfully and reliably over a range of load conditions

with controlled condenser pressure. Reducing the condenser water temperature is an effective

method of lowering chiller power input required, but the ideal temperature for optimizing total

system power consumption will depend on the overall system dynamics. From a system

perspective, some improvements in chiller efficiency may be offset by the increased tower fan and

pumping costs required to achieve the lower tower temperatures. Contact your local Trane systems

solution provider for more information on optimizing system performance.

Variable Evaporator Flow and Short Evaporator Water Loops

Variable evaporator flow is an energy-saving design strategy which has quickly gained acceptance

as advances in chiller and controls technology have made it possible. With its superior unloading

compressor design and advanced Trane CH530 controls, the RTWD/RTUD has excellent capability

to maintain leaving water temperature control within +/-0.5°F (0.28°C), even for systems with

variable evaporator flow.

Some basic rules should be followed whenever using these system design and operational savings

methods with the RTWD/RTUD. The proper location of the chilled water temperature control sensor

is in the supply (outlet) water. This location allows the building to act as a buffer, and it assures a

slowly changing return water temperature. If there is insufficient water volume in the system to

provide an adequate buffer, temperature control can be lost, resulting in erratic system operation

and excessive compressor cycling. To ensure consistent operation and tight temperature control,

the chilled water loop should be at least two minutes. If this recommendation cannot be followed,

and tight leaving water temperature control is necessary, a storage tank or larger header pipe

should be installed to increase the volume of water in the system.

8 RLC-PRC029-EN

Page 9

For variable primary flow applications, the rate of chilled water flow change should not exceed 10

percent of design per minute to maintain +/-0.5°F (0.28°C) leaving evaporator temperature control.

For applications in which system energy savings is most important and tight temperature control

is classified as +/-2°F (1.1°C), up to 30 percent change in flow per minute are possible. Flow rates

should be maintained between the minimum and maximum allowed for any particular chiller

configuration.

For applications designed to operate with changes in the water flow rate, the new evaporator waterflow compensation improves the ability of the chiller to respond to increasing or decreasing water

flow. This new standard control feature works by varying the leaving evaporator temperature

control gains in response to changes in evaporator water flow. By measuring the refrigerant flow

in each circuit and using this value to calculate the resulting waterside temperature drop, the CH530

can estimate the water flow rate through the evaporator.

Series Chiller Arrangements

Another energy-saving strategy is to design the system around chillers arranged in series, on the

evaporator, condenser, or both. It is possible to operate a pair of chillers more efficiently in a series

chiller arrangement than in a parallel arrangement. It is also possible to achieve higher enteringto-leaving chiller differentials, which may, in turn, provide the opportunity for lower chilled water

design temperature, lower design flow, and resulting installation and operational cost savings

(including downsizing a chiller).

The Trane screw compressor also has excellent “lift” capabilities which afford an opportunity for

savings on the evaporator and condenser water loops. Like series arrangements on the evaporator,

series arrangements on the condenser may enable savings. This approach may allow reductions

in pump and tower installation and operating costs.

Maximizing system efficiency requires that the designer balance performance considerations for

all system components; the best approach may or may not involve multiple chillers, or series

arrangement of the evaporators and/or condensers. This ideal balance of design integrity with

installation and operating cost considerations should be researched by consulting a Trane systems

solutions provider and applying the Trace™ building energy and economic analysis program.

Application Considerations

Water-to-Water Heat Pump

The RTWD can be used as a water side heat pump by using ground or surface water as a heat

source. Leaving condenser water control option provides the ability to control the heating setpoint.

Local regulation concerning limitation on minimum/maximum rejected water temperature needs

to be checked before using this method.

Dry Cooler

The RTWD can be used with dry coolers. Generally this application is selected to minimize the

spread of airborne contaminates associated with open tower systems. In addition, other drawbacks

of cooling towers are avoided: water consumption, production of vapor, need of water treatment,

etc. Another benefit of dry coolers is the ability to operate in low ambient conditions. With the use

of a third party heat exchanger this design can also be used to provide free cooling to the chilled

water loop during cold weather.

RLC-PRC029-EN 9

Page 10

Application Considerations

heat

exchanger

heating

loads

T1

V2

V1

T2

controller

condenser

evaporator

cooling-tower

pump

cooling

loads

chilled-water

pump

condenser-water

pump

cooling

tower

controller

no flow

warmer flow

cooler flow

LEGEND

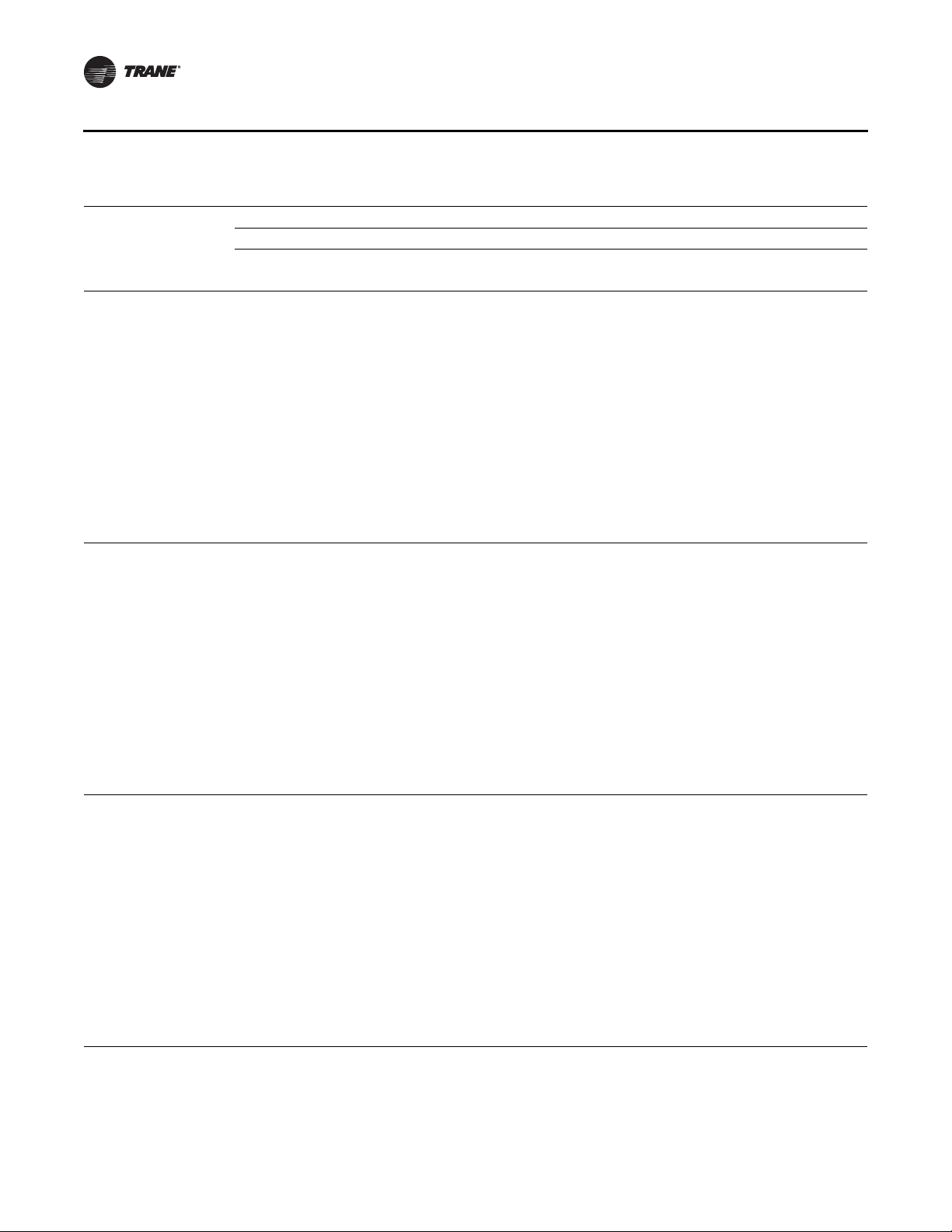

Heat Recovery

At a time when energy costs are high and continue to rise, reducing energy usage has become

increasingly important. By using a RTWD chiller with heat recovery, utilization of energy can be

improved by using heat from the condenser that would otherwise be wasted.

The use of heat recovery should be considered in any building with simultaneous heating and

cooling requirements or in facilities where heat can be stored and used at a later time. Buildings

with high year-round internal cooling loads are excellent opportunities for heat recovery. Heat

recovery can be accomplished with the RTWD by recovering heat from the water leaving the

standard condenser and using it in conjunction with a third party heat exchanger.

Water Treatment

The use of untreated or improperly treated water in chillers may result in scaling, erosion,

corrosion, and algae or slime buildup. It is recommended that the services of a qualified water

treatment specialist be engaged to determine what treatment, if any, is advisable.

Water Pumps

Where noise limitation and vibration-free operation are important, Trane strongly encourages the

use of 1750-rpm (60 Hz) [1450-rpm (50 Hz)] pumps. Specifying or using 3600-rpm (60 Hz) [3000-rpm

(50 Hz)] condenser water and chilled water pumps must be avoided, because such pumps may

operate with objectionable levels of noise and vibration. In addition, a low frequency beat may

occur due to the slight difference in operating rpm between 3600-rpm (60 Hz) [3000-rpm (50 Hz)]

water pumps and Series R chiller motors.

Note: The chilled water pump must not be used to stop the chiller.

10 RLC-PRC029-EN

Page 11

Acoustic Considerations

For chiller sound ratings, installation tips, and considerations on chiller location, pipe isolation, etc.,

refer to the Water-Cooled Series R Chillers Sound Ratings and Installation Guide.

Remote Condenser

The installation of a split system offers a good economic alternative to satisfy the chilled water

demand for cooling a building, particularly in the case of new construction.

The choice of a complete Trane system, including the compressor chiller and the condenser offers

the designer, installer and owner the advantages of an optimized selection and undivided

responsibility for the design, the quality and the operation of the complete system.

Remote condensers should be located as close as possible to the chiller to ensure minimum

pressure drops of discharge refrigerant. If non-Trane condensers are provided, a subcooling circuit

must be provided in order to achieve cataloged performances.

Application Considerations

RLC-PRC029-EN 11

Page 12

Model Number Descriptions

Digits 01, 02, 03, 04 – Chiller

Model

RTWD = Water-Cooled Series R™ Chiller

RTUD = Compressor Series R Chiller

Digit 05, 06, 07 – Unit Nominal

Tonnage

060 = 60 Nominal Tons

070 = 70 Nominal Tons

080 = 80 Nominal Tons

090 = 90 Nominal Tons

100 = 100 Nomi nal Tons

110 = 11 0 No mi na l To ns

120 = 120 Nominal Tons

130 = 130 Nominal Tons

140 = 140 Nominal Tons

150 = 150 Nominal Tons

160 = 160 Nominal Tons

180 = 180 Nominal Tons

200 = 200 Nominal Tons

220 = 220 Nominal Tons

250 = 250 Nominal Tons

Digit 08 – Unit Voltage

A = 200/60/3

B = 230/60/3

D = 380/60/3

E = 400/50/3

F = 460/60/3

G = 575/60/3

Digit 09 – Manufacturing Plant

2 = Pueblo, USA

Digit 10, 11 – Design Sequence

** = First Design, etc. increment when

parts are affected for service purposes

Digits 12 – Unit Type

1 = Standard Efficiency/Performance

2 = High Efficiency/Performance

3 = Premium Efficiency/Performance

Digit 13 – Agency Listing

0 = No Agency Listing

A = UL Listed to US and Canadian Safety

Standards

Digit 14 – Pressure Vessel Code

1 = ASME Pressure Vessel Code

3 = Chinese Code-Imported Pressure

Ves sel

S = Special

Digit 15 – Unit Application

A = Std Condenser <=95°F/35°C Entering

Water Temperature

B = High Temperature Condenser >95°F/

35°C Entering Water Temperature

C = Water-to-Water Heat Pump

D = Remote Condenser by Trane

E = Remote Condenser by Others

Digit 16 – Pressure Relief Valve

1 = Single Relief Valve

2 = Dual Relief Valve with 3-Way Isolation

Val ve

Digit 17 – Water Connection Type

A = Grooved Pipe Connection

Digit 18 – Evaporator Tubes

A = Internal and External Enhanced Evap

Tub e

Digit 19 – Number of Evap

Passes

1 = 2 Pass Evaporator

2 = 3 Pass Evaporator

Digit 20 – Evaporator Water Side

Pressure

A = 150 psi/10.5 bar Evaporator Water

Pressure

Digit 21 – Evaporator

Application

1 = Standard Cooling

2 = Low Temperature

3 = Ice Making

Digit 22 – Condenser Tubes

X = Remote Condenser

A = Enhanced Fin - Copper

B = Internally Enhanced 90/10 CuNi Fin

Digit 23 – Condenser Water Side

Pressure

0 = Remote Condenser

1 = 150 psi/10.5 Bar Condenser Water

Pressure

Digit 24 – Compressor Starter

Typ e

Y = Wye-Delta Closed Transition Starter

X = Across-the-Line Starter

Digit 25 – Incoming Power Line

Connection

1 = Single Point Power Connection

2 = Dual Point Power Connection

Digit 26 – Power Line

Connection Type

A = Terminal Block Connection for

Incoming Lines

B = Mechanical Disconnect Switch

D = Circuit Breaker

E = High Fault Rated Panel with Circuit

Breaker

Digit 27 – Under/Over Voltage

Protection

0 = No Under/Over Voltage Protection

1 = Under/Over Voltage Protection

Digit 28 – Unit Operator

Interface

A = Dyna-View/English

B = Dyna-View/Spanish

C = Dyna-View/Spanish-Mexico

D = Dyna-View/French

E = Dyna-View/German

F = Dyna-View/Dutch

G = Dyna-View/Italian

H = Dyna-View/Japanese

J = Dyna-View/Portuguese-Portugal

K = Dyna-View/Portuguese-Brazil

L = Dyna-View/Korean

M = Dyna-View/Thai

N = Dyna-View/Simplified Chinese

P = Dyna-View/Traditional Chinese

R = Dyna-View/Russian

T = Dyna-View/Polish

U = Dyna-View/Czech

V = Dyna-View/Hungarian

W = Dyna-View/Greek

X = Dyna-View/Romanian

Y = Dyna-View/Swedish

12 RLC-PRC029-EN

Page 13

Model Number Descriptions

Digit 29 – Remote Interface

(Digital Comm)

0 = No Remote Digital Communication

1 = LonTalk/Tracer Summit Interface

2 = Time of Day Scheduling

Digit 30 – External Water &

Current-Limit Setpoint

0 = No External Water & Current-Limit

Setpoint

A = External Water & Current-Limit

Setpoint - 4–20 mA

B = External Water & Current-Limit

Setpoint - 2–10 Vdc

Digit 31 – Ice Making

0 = No Ice Making

A = Ice Making with Relay

B = Ice Making without Relay

Digit 32 – Programmable Relays

0 = No Programmable Relays

A = Programmable Relays

Digit 33 – Condenser Refrigerant

Pressure Output Option

0 = No Condenser Refrigerant Output

1 = Condenser Water Control Output

2 = Condenser Pressure (%HPC) Output

3 = Differential Pressure Output

Digits 34 – Outdoor Air Temp

Sensor

0 = No Outdoor Air Temp Sensor

A = Outdoor Air Temp Sensor-CWR/Low

Ambient

Digit 35 – Condenser Leaving

Hot Water Temp Control

0 = No Condenser Leaving Hot Water

Tem p Co n t ro l

1 = Condenser Leaving Hot Water Temp

Control

Digit 36 – Power Meter

0 = No Power Meter

P = Power Meter

Digit 37 – Motor Current Analog

Output (%RLA)

0 = No Motor Current Analog Output

1 = Motor Current Analog Output

Digit 38 – A/C Fan Control

0 = No Fan Controls (RTWD)

A = Fan Control By Others

B = Integral Fan Controls

Digit 40 – Installation

Accessories

0 = No Installation Accessories

A = Elastomeric Isolators

B = Flanged Water Connection Kit

C = Isolators & Flanged Water Connection

Kit

Digit 41 – Flow Switch

0 = No Flow Switch

1 = 150 psi NEMA 1; Flow Switch x 1

2 = 150 psi NEMA 1; Flow Switch x 2

3 = 150 psi NEMA 4; Flow Switch x 1

4 = 150 psi NEMA 4; Flow Switch x 2

Digit 42 – 2-Way Water

Regulating Valve

0 = No 2-Way Water Regulating Valve

A = 3” 150 psi/88.9 mm 10.5 bar 115 V

B = 3” 150 psi/88.9 mm 10.5 bar 220 V

C = 4” 150 psi/114.3 mm 10.5 bar 115 V

D = 4” 150 psi/114.3 mm 10.5 bar 220 V

Digit 44 – Insulation

0 = No Insulation

1 = Factory Insulation - All Cold Parts

2 = Insulation for High Humidity

Digit 45 – Factory Charge

0 = Full Factory Refrigerant Charge

(R134a)

1 = Nitrogen Charge

Digit 46 – Base Rail Forklifting

0 = No Base Rail Forklifting

B = Base Rail Forklifting

Digit 47 – Label and Literature

Language

B = Spanish

D = English

E = French

G = Chinese - Traditional

Digit 48 – Special

0 = None

S = Special

Digit 49 – 55

0 = None

Digit 56 – Shipping Package

0 = No Skid (Standard)

1 = Skid

2 = Shrink Wrap

3 = Skid + Shrink Wrap

Digit 59 – Performance Test

Options

0 = No Performance Test

C = 1 Point Test with Report

D = 2 Point Test with Report

E = 3 Point Test with Report

F = 4 Point Test with Report

G = Witness 1 Point Test with Report

H = Witness 2 Point Test with Report

J = Witness 3 Point Test with Report

K = Witness 4 Point Test with Report

RLC-PRC029-EN 13

Page 14

General Data

Table 1. General Data – RTWD – 60 Hz – standard efficiency

Size 80 90 100 110 120 130 140

Compressor

Quantity 2222222

Evaporator

2 Pass Arrangement

Water Conn. SizeNPS4444555

mm 100 100 100 100 125 125 125

Water Storage (gal) 11.2 11.2 12.6 14.0 15.2 16.2 17.7

(L) 42.2 42.2 47.6 53.0 57.4 61.5 66.8

Minimum Flow (gpm) 77 77 89 101 101 110 122

(L/s) 4.9 4.9 5.6 6.3 6.3 6.9 7.6

Maximum Flow (gpm) 281 281 325 368 368 400 444

(L/s) 17.8 17.8 20.5 23.2 23.2 25.3 28.0

3 Pass Arrangement

Water Conn. SizeNPS3333444

mm 80 80 80 80 100 100 100

Water Storage (gal) 11.2 11.2 12.6 14.0 15.2 16.2 17.7

(L) 42.2 42.2 47.6 53.0 57.4 61.5 66.8

Minimum Flow(gpm)52525967677381

(L/s) 3.2 3.2 3.7 4.2 4.2 4.6 5.1

Maximum Flow (gpm) 187 187 216 244 244 266 295

(L/s) 11.8 11.8 13.6 15.5 15.5 16.8 18.6

Condenser

Water Conn. SizeNPS5555555

mm 125 125 125 125 125 125 125

Water Storage (gal) 12.4 14.2 16.0 16.9 18.5 18.5 20.9

(L) 46.8 53.6 60.4 63.8 70.1 70.1 79.2

Minimum Flow (gpm) 83 99 115 124 135 135 156

(L/s) 5.2 6.2 7.3 7.8 8.5 8.5 9.8

Maximum Flow (gpm) 301 361 421 451 491 491 572

(L/s) 19.0 22.8 26.6 28.5 31.0 31.0 36.1

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 2222222

Refrigerant Charge (lb) 114.6/114.6 114.6/114.6 112.4/114.6 112.4/112.4 132.3/132.3 130.1/130.1 127.9/132.3

(kg) 52/52 52/52 51/52 51/51 60/60 59/59 58/60

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

14 RLC-PRC029-EN

Page 15

General Data

Table 2. General Data – RTWD – 60 Hz – high efficiency

Size 80 90 100 110 120 130

Compressor

Quantity 222222

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 4 4 4 5 5 5

mm 100 100 100 125 125 125

Water Storage (gal) 9.8 11.9 12.8 15.3 16.4 17.3

(L) 37.0 45.2 48.3 57.9 62.3 65.4

Minimum Flow (gpm) 72 92 100 112 123 130

(L/s) 4.5 5.8 6.3 7.0 7.7 8.2

Maximum Flow (gpm) 263 336 364 409 448 476

(L/s) 16.6 21.2 23.0 25.8 28.3 30.0

3 Pass Arrangement

Water Conn. Size NPS 3 3 3 4 4 4

mm 80 80 80 100 100 10 0

Water Storage (gal) 9.8 11.9 12.8 15.3 16.4 17.3

(L) 37.0 45.2 48.3 57.9 62.3 65.4

Minimum Flow(gpm)486167758287

(L/s) 3.0 3.9 4.2 4.7 5.1 5.5

Maximum Flow (gpm) 175 223 242 271 298 316

(L/s) 11.1 14.1 15.3 17.2 18.8 20.0

Condenser

Water Conn. Size NPS 5 5 5 5 5 5

mm 125 125 125 125 125 125

Water Storage (gal) 11.9 12.7 14.9 16.6 17.2 18.0

(L) 45.1 48.1 56.3 62.7 65.2 68.3

Minimum Flow (gpm) 87 95 117 130 136 145

(L/s) 5.5 6.0 7.4 8.1 8.6 9.1

Maximum Flow (gpm) 317 347 427 473 498 528

(L/s) 20.0 21.9 27.0 29.9 31.4 33.3

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222

Refrigerant Charge (lb) 99.2/99.2 97/97 123.5/125.7 123.5/123.5 121.3/121.3 119/119

(kg) 45/45 44/44 56/57 56/56 55/55 54/54

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

RLC-PRC029-EN 15

Page 16

General Data

Table 3. General Data – RTWD – 60 Hz – high efficiency (continued)

Size 150 160 180 200 220 250

Compressor

Quantity 222222

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 5 5 5 5 6 6

mm 125 125 125 125 150 150

Water Storage (gal) 19.2 20.3 22.3 24.2 28.6 31.8

(L) 72.6 77.0 84.5 91.5 108.3 120.3

Minimum Flow (gpm) 141 151 170 187 211 240

(L/s) 8.9 9.5 10.7 11.8 13.3 15.1

Maximum Flow (gpm) 515 554 621 683 772 879

(L/s) 32.5 35.0 39.2 43.1 48.8 55.5

3 Pass Arrangement

Water Conn. Size NPS 4 4 4 4 4 4

mm 100 100 100 100 100 100

Water Storage (gal) 18.8 20.0 22.0 23.8 27.9 31.0

(L) 71.2 75.6 83.2 90.1 105.5 117.5

Minimum Flow (gpm) 94 101 113 124 141 160

(L/s) 5.9 6.4 7.1 7.8 8.9 10.1

Maximum Flow (gpm) 343 369 414 455 515 586

(L/s) 21.7 23.3 26.2 28.7 32.5 37.0

Condenser

Water Conn. Size NPS 6 6 6 6 6 6

mm 150 150 150 150 150 150

Water Storage (gal) 21.6 22.9 24.6 26.2 31.1 39.2

(L) 81.7 86.8 93.0 99.2 117.8 148.3

Minimum Flow (gpm) 160 173 190 206 245 326

(L/s) 10.1 10.9 12.0 13.0 15.4 20.5

Maximum Flow (gpm) 583 634 694 754 895 1192

(L/s) 36.8 40.0 43.8 47.6 56.5 75.3

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222

Refrigerant Charge (lb) 134.5/143.3 141.1/141.1 138.9/138.9 136.7/136.7 178.6/185.2 180.8/180.8

(kg) 61/65 64/64 63/63 62/62 81/84 82/82

Oil Charge (qt) 10.5/12.4 12.4/12.4 12.4/12.4 12.4/12.4 12.4/12.4 12.4/12.4

(L) 9.9/11.7 11.7/11.7 11.7/11.7 11.7/11.7 11.7/11.7 11.7/11.7

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

16 RLC-PRC029-EN

Page 17

Table 4. General Data – RTWD – 60 Hz – premium efficiency

Size 150 160 180 200

Compressor

Quantity 2222

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 6 6 6 6

mm 150 150 150 150

Water Storage (gal) 27.8 27.8 29.3 31.3

(L) 105.1 105.1 110.9 118.3

Minimum Flow (gpm) 175 175 187 202

(L/s) 11.0 11.0 11.8 12.7

Maximum Flow (gpm) 638 638 683 739

(L/s) 40.3 40.3 43.1 46.7

3 Pass Arrangement

Water Conn. Size NPS 4 4 4 4

mm 100 100 100 100

Water Storage (gal) 27.1 27.1 28.6 30.6

(L) 102.4 102.4 108.3 115.7

Minimum Flow (gpm) 117 117 125 135

(L/s) 7.3 7.3 7.8 8.5

Maximum Flow (gpm) 425 425 455 492

(L/s) 26.9 26.9 28.7 31.1

Condenser

Water Conn. Size NPS 6 6 6 6

mm 150 150 150 150

Water Storage (gal) 30.0 30.0 32.9 32.9

(L) 113.4 113.4 124.4 124.4

Minimum Flow (gpm) 206 206 231 231

(L/s) 13.0 13.0 14.6 14.6

Maximum Flow (gpm) 754 754 845 845

(L/s) 47.6 47.6 53.3 53.3

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a

# Refrig Circuits 2 2 2 2

Refrigerant Charge (lb) 174.2/183.0 183.0/183.0 180.8/180.8 178.6/178.6

(kg) 79/83 83/83 82/82 81/81

Oil Charge (qt) 10.5/12.4 12.4/12.4 12.4/12.4 12.4/12.4

(L) 9.9/11.7 11.7/11.7 11.7/11.7 11.7/11.7

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

General Data

RLC-PRC029-EN 17

Page 18

General Data

Table 5. General Data – RTUD – 60 Hz

Size 80 90 100 110 120 130

Compressor

Quantity 222222

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 4 4 4 5 5 5

mm 100 100 100 125 125 125

Water Storage (gal) 9.8 10.6 12.0 14.0 15.3 15.3

(L) 37.1 40.2 45.3 53.0 58.0 58.0

Minimum Flow (gpm) 77 79 91 99 111 111

(L/s) 4.9 5.0 5.7 6.2 7.0 7.0

Maximum Flow (gpm) 281 291 335 363 408 408

(L/s) 17.7 21.2 23.0 25.8 28.3 30.0

3 Pass Arrangement

Water Conn. Size NPS 3 3 3 4 4 4

mm 80 80 80 100 100 10 0

Water Storage (gal) 9.5 10.3 11.6 13.7 15.1 15.1

(L) 36.0 39.0 44.0 52.0 57.0 57.0

Minimum Flow(gpm)515361667474

(L/s) 3.2 3.3 3.8 4.2 4.7 4.7

Maximum Flow (gpm) 187 194 224 242 272 272

(L/s) 11.8 12.2 14.1 15.3 17.2 17.2

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222

Refrigerant Charge (lb) 50/50 49/49 47/47 65/65 64/64 64/64

(kg) 22.7/22.7 22.2/22.2 21.3/21.3 29.5/29.5 29.0/29.0 29.0/29.0

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9

Discharge Connection

Liquid Connection Diameter (inch) 1.1 1.1 1.1 1.4 1.4 1.4

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

Diameter

(inch)2.12.12.12.62.62.6

18 RLC-PRC029-EN

Page 19

General Data

Table 6. General Data – RTUD – 60 Hz (continued)

Size 150 160 180 200 220 250

Compressor

Quantity 222222

Evaporator

2 Pass Arrangement

Water Conn. Size NPS 5 5 5 5 5 5

mm 125 125 125 125 125 125

Water Storage (gal) 16.5 19.2 19.2 20.3 22.3 24.2

(L) 62.4 72.6 72.6 77.0 84.5 91.5

Minimum Flow (gpm) 122 140 140 151 169 186

(L/s) 7.7 8.8 8.8 9.5 10.7 11.7

Maximum Flow (gpm) 447 514 514 553 620 681

(L/s) 28.2 32.4 32.4 34.9 39.1 43.0

3 Pass Arrangement

Water Conn. Size NPS 4 4 4 4 4 4

mm 100 100 100 100 100 100

Water Storage (gal) 16.1 18.8 18.8 20.0 22.0 23.8

(L) 61.0 71.2 71.2 75.6 83.2 90.1

Minimum Flow (gpm) 81 94 94 100 112 124

(L/s) 5.1 5.9 5.9 6.3 7.1 7.8

Maximum Flow (gpm) 298 343 343 368 413 454

(L/s) 18.8 21.6 21.6 23.2 26.1 28.6

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222

Recommended Refrigerant

Discharge Connection

Liquid Connection Diameter (inch) 1.4 1.4 1.4 1.4 1.4 1.6

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

3. Condenserless chiller is not factory charged, the refrigerant must be purchased and charged in the field.

Charge¹,³

Oil Charge¹ (qt) 10.5/10.5 10.5/10.5 10.5/12.4 12.4/12.4 12.4/12.4 12.4/12.4

Diameter

(lb) 62/62 66/66 66/66 66/66 63/63 61/61

(kg) 28.1/28.1 29.9/29.9 29.9/29.9 29.9/29.9 28.6/28.6 27.7/27.7

(L) 9.9/9.9 9.9/9.9 9.9/11.7 11.7/11.7 11.7/11.7 11.7/11.7

(inch)2.63.13.13.13.13.1

RLC-PRC029-EN 19

Page 20

General Data

Table 7. General Data – Condenser by Trane – 60 Hz

Size 80 90 100 110 120 130

Condenser

Condenser Quantity 111111

Fins/Inch 12 10 10 12 8 10

Coil Length (inch) 162 216 216 216 270 270

(mm) 4115 5486 5486 5486 6858 6858

Coil Width(inch)858585858585

(mm) 2159 2159 2159 2159 2159 2159

Number of Rows 334444

Condenser Fans

Fan Quantity 6 8 8 8 10 10

Diameter (inch) 30 30 30 30 30 30

(mm) 762 762 762 762 762 762

Nominal RPM (rpm) 850 850 850 850 850 850

Air Flow (cfm) 56,646 78,280 72,248 69 ,280 94,490 90,310

Tip Speed (fpm) 6676 6676 6676 6676 6676 6676

Motor HP(hp)1.51.51.51.51.51.5

General

Recommended Refrigerant

Discharge/Liquid Connection

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Condenser is not factory charged, the refrigerant must be purchased and charged in the field.

Charge¹

Diameters

(lbs) 40/40 52/52 68/68 68/68 85/85 85/85

(kg) 18.1/18.1 23.6/23.6 30.8/30.8 30.8/30.8 38.6/38.6 38.6/38.6

(inch)2.12.12.12.12.12.1

(mm) 54 54 54 54 54 54

20 RLC-PRC029-EN

Page 21

General Data

Table 8. General Data – Condenser by Trane – 60 Hz (continued)

Size 150 160 180 200 220 250

Condenser

Condenser Quantity 222222

Fins/Inch¹ 8/12 12/12 12/8 8/8 8/10 10/10

Coil Length¹ (inch) 162/162 162/162 162/216 216/216 216/216 216/216

4115/4115 4115/4115 4115/5486 5486/5486 5486/5486 5486/5486

Coil Width¹ (inch) 85/85 85/85 85/85 85/85 85/85 85/85

2159/2159 2159/2159 2159/2159 2159/2159 2159/2159 2159/2159

Number of Rows 3/3 3/3 3/3 3/3 3/4 4/4

Condenser Fans

Fan Quantity¹ 6/6 6/6 6/8 8/8 8/8 8/8

Diameter (inch) 30 30 30 30 30 30

Nominal RPM (rpm) 850 850 850 850 850 850

Air Flow¹ (cfm)

Tip Speed (fpm) 6676 6676 6676 6676 6676 6676

Motor HP(hp)1.51.51.51.51.51.5

60,954/

56,646

General

Recommended Refrigerant

Discharge/Liquid Connection

1. Data containing information on two condens ers is shown as cond 1/cond 2.

2. Data containing information on two circuits is shown as circuit 1/circuit 2.

3. Condenser is not factory charged, the refrigerant must be purchased and charged in the field.

Charge²,³

Diameters

(lbs) 76/76 76/76 76/101 101/101 101/134 134/134

(kg) 34.5/34.5 34.5/34.5 34.5/45.8 45.8/45.8 45.8/60.8 60.8/60.8

(inch) 2.125 2.125 2.125 2.125 2.125 2.125

(mm) 54 54 54 54 54 54

56,646/

56,646

56,646/

81,272

81,272/

81,272

81,272/

72,248

72,248/

72,248

RLC-PRC029-EN 21

Page 22

General Data

Table 9. General Data – RTWD – 50 Hz – standard efficiency

Size 70 80 90 100 110 120 130 140 150

Compressor

Quantity 222222222

Evaporator

2 Pass Arrangement

Water Conn. SizeNPS444445555

(mm) 100 100 100 100 100 125 1 25 125 125

Water Storage (gal) 11.2 12.6 14.0 14.0 14.0 16.2 17.7 17.7 19.1

(L) 42.2 47.6 53.0 53.0 53.0 61.5 66.8 66.8 72.2

Minimum Flow (gpm) 77 89 101 101 101 110 122 122 133

(L/s) 4.9 5.6 6.3 6.3 6.3 6.9 7.6 7.6 8.4

Maximum Flow (gpm) 281 324 368 368 368 400 444 444 487

(L/s) 17.8 20.5 23.2 23.2 23.2 25.3 28.0 28.0 30.8

3 Pass Arrangement

Water Conn. SizeNPS333334444

(mm) 80 80 80 80 80 100 100 100 100

Water Storage (gal) 11.2 12.6 14.0 14.0 14.0 16.2 17.7 17.7 19.1

(L) 42.2 47.6 53.0 53.0 53.0 61.5 66.8 66.8 72.2

Minimum Flow(gpm)525967676773818189

(L/s) 3.2 3.7 4.2 4.2 4.2 4.6 5.1 5.1 5.6

Maximum Flow (gpm) 187 216 244 244 244 266 295 295 324

(L/s) 11.8 13.6 15.5 15.5 15.5 16.8 18.6 18.6 20.5

Condenser

Water Conn. SizeNPS555555555

(mm) 125 125 125 125 125 125 125 125 125

Water Storage (gal) 12.4 14.2 16.0 16.9 16.9 18.5 20.9 20.9 22.4

(L) 46.8 53.6 60.4 63.8 63.8 70.1 79.2 79.2 84.8

Minimum Flow (gpm) 83 99 115 124 124 135 156 156 170

(L/s) 5.2 6.2 7.3 7.8 7.8 8.5 9.8 9.8 10.7

Maximum Flow (gpm) 301 361 421 451 451 491 571 571 622

(L/s) 19.0 22.8 26.6 28.5 28.5 31.0 36.1 36.1 39.3

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 222222222

Refrigerant Charge (lb)

(kg) 52/52 51/51 50/50 50/51 51/51 59/59 58/58 58/60 59/59

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9 9.9/9.9

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

114.6/

114.6

112.4/

112.4

110.2/

110.2

110.2/

112.4

112.4/

112.4

130.1/

130.1

127.9/

127.9

127.9/

132.3

130.1/

130.1

22 RLC-PRC029-EN

Page 23

General Data

Table 10. General Data – RTWD – 50 Hz – high efficiency

Size 60 70 80 90 100 110 120

Compressor

Quantity 2222222

Evaporator

2 Pass Arrangement

Water Conn. SizeNPS4445555

(mm) 100 100 100 125 125 125 125

Water Storage (gal) 9.8 10.6 11.9 15.3 15.3 16.4 17.3

(L) 37.0 40.2 45.2 57.9 57.9 62.3 65.4

Minimum Flow (gpm) 72 80 92 112 112 123 130

(L/s) 4.5 5.0 5.8 7.0 7.0 7.7 8.2

Maximum Flow (gpm) 263 291 336 408 408 448 476

(L/s) 16.6 18.4 21.2 25.8 25.8 28.3 30.0

3 Pass Arrangement

Water Conn. SizeNPS3334444

(mm) 80 80 80 100 100 100 100

Water Storage (gal) 9.8 10.6 11.9 15.3 15.3 16.4 17.3

(L) 37.0 40.2 45.2 57.9 57.9 62.3 65.4

Minimum Flow(gpm)48536175758287

(L/s) 3.0 3.3 3.9 4.7 4.7 5.1 5.5

Maximum Flow (gpm) 175 193 223 271 271 298 316

(L/s) 11.1 12.2 14.1 17.2 17.2 18.8 20.0

Condenser

Water Conn. SizeNPS5555555

(mm) 125 125 125 125 125 125 125

Water Storage (gal) 11.9 11.9 13.8 15.3 16.6 16.6 18.0

(L) 45.1 45.1 52.2 58.1 62.7 62.7 68.3

Minimum Flow (gpm) 87 87 106 117 130 130 145

(L/s) 5.5 5.5 6.7 7.4 8.1 8.1 9.1

Maximum Flow (gpm) 317 317 387 427 473 473 528

(L/s) 20.0 20.0 24.5 27.0 29.9 29.9 33.3

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 2222222

Refrigerant Charge (lb) 99.2/99.2 99.2/99.2 97/97 121.3/121.3 121.3/123.5 121.3/121.3 119/119

(kg) 45/45 45/45 44/44 55/55 55/56 55/55 54/54

Oil Charge (qt) 7.2/7.2 7.2/7.2 7.2/7.2 7.2/7.2 7.2/10.5 10.5/10.5 10.5/10.5

(L) 6.8/6.8 6.8/6.8 6.8/6.8 6.8/6.8 6.8/9.9 9.9/9.9 9.9/9.9

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

RLC-PRC029-EN 23

Page 24

General Data

Table 11. General Data – RTWD – 50 Hz – high efficiency (continued)

Size 130 140 160 180 200 220 250

Compressor

Quantity 2222222

Evaporator

2 Pass Arrangement

Water Conn. SizeNPS5555666

(mm) 125 125 125 125 150 150 150

Water Storage (gal) 19.2 20.3 22.3 24.2 28.6 29.9 31.8

(L) 72.6 77.0 84.5 91.5 108.3 113.3 120.3

Minimum Flow (gpm) 141 152 170 187 211 224 240

(L/s) 8 .9 9.5 10.7 11.8 13.3 14.1 15.1

Maximum Flow (gpm) 515 554 621 683 773 817 879

(L/s) 32.5 35.0 39.2 43.1 48.8 51.6 55.5

3 Pass Arrangement

Water Conn. SizeNPS4444444

(mm) 100 100 100 100 100 100 100

Water Storage (gal) 18.8 20.0 22.0 23.8 27.9 29.2 31.0

(L) 71.2 75.6 83.2 90.1 105.5 110.5 117.5

Minimum Flow (gpm) 94 101 114 125 141 149 160

(L/s) 5 .9 6.4 7.1 7.8 8.9 9.4 10.1

Maximum Flow (gpm) 344 370 415 456 515 545 586

(L/s) 21.7 23.3 26.2 28.7 32.5 34.4 37.0

Condenser

Water Conn. SizeNPS6666666

(mm) 150 150 150 150 150 150 150

Water Storage (gal) 21.6 22.9 24.6 26.2 31.1 31.1 35.2

(L) 81.7 86.8 93.0 99.2 117.8 117.8 133.3

Minimum Flow (gpm) 160 173 190 206 245 245 286

(L/s) 10.0 10.9 12.0 13.0 15.4 15.4 18.0

Maximum Flow (gpm) 583 634 694 755 895 895 1046

(L/s) 36.8 40.0 43.8 47.6 56.5 56.5 66.1

General Unit

Refrigerant Type R-134a R-134a R-134a R-134a R-134a R-134a R-134a

# Refrig Circuits 2222222

Refrigerant Charge (lb) 134.5/134.5 132.3/136.7 134.5/134.5 132.3/136.7 178.6/178.6 176.4/183.0 180.8/180.8

(kg) 61/61 60/62 61/61 60/62 81/81 80/83 82/82

Oil Charge (qt) 10.5/10.5 10.5/10.5 10.5/10.5 10.5/12.4 12.4/12.4 12.4/12.4 12.4/12.4

(L) 9.9/9.9 9.9/9.9 9.9/9.9 9.9/11.7 11.7/11.7 11.7/11.7 11.7/11.7

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

24 RLC-PRC029-EN

Page 25

Table 12. General Data – RTWD – 50 Hz – premium efficiency

Size 160 180 200

Compressor

Quantity 222

Evaporator

2 Pass Arrangement

Water Conn. SizeNPS666

(mm) 150 150 150

Water Storage (gal) 29.3 31.3 31.8

(L) 110.9 118.3 120.3

Minimum Flow (gpm) 187 202 240

(L/s) 11.8 12.7 15.1

Maximum Flow (gpm) 683 739 879

(L/s) 43.1 46.7 55.5

3 Pass Arrangement

Water Conn. SizeNPS444

(mm) 100 100 100

Water Storage (gal) 28.6 30.6 31.0

(L) 108.3 115.7 117.5

Minimum Flow (gpm) 125 135 160

(L/s) 7.8 8.5 10.1

Maximum Flow (gpm) 455 492 586

(L/s) 28.7 31.1 37.0

Condenser

Water Conn. SizeNPS666

(mm) 150 150 150

Water Storage (gal) 30.0 34.5 39.2

(L) 113.4 130.6 148.3

Minimum Flow (gpm) 206 245 326

(L/s) 13.0 15.4 20.5

Maximum Flow (gpm) 754 895 1192

(L/s) 47.6 56.5 75.3

General Unit

Refrigerant Type R-134a R-134a R-134a

# Refrig Circuits 2 2 2

Refrigerant Charge (lb) 176.4/176.4 174.2/178.6 176.4/174.2

(kg) 80/80 79/81 80/79

Oil Charge (qt) 10.5/10.5 10.5/12.4 12.4/12.4

(L) 9.9/9.9 9.9/11.7 11.7/11.7

1. Data containing information on two circuits is shown as circuit 1/circuit 2.

2. Flow limits are for water only.

General Data

RLC-PRC029-EN 25

Page 26

Performance Data

Table 13. Performance Data - RTWD - 60 Hz - standard efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving

Water Temp

(°F)

40

42

44

Unit kW kW kW

Size Tons Input EER kW/ton Tons Input EER kW/ton Tons Input EER kW/ton

80

90

100

110

120

130

140

80

90

100

110

120

130

140

80

90

100

110

120

130

140

75.6 49.6 18.2 0.661 70.8 56.0 15.1 0.796 65.7 63.4 12.4 0.971

86.4 56.5 18.2 0.659 81.3 63.7 15.2 0.789 75.9 72.2 12.6 0.956

98.8 65.1 18.1 0.663 93.0 73.8 15.0 0.798 86.7 83.9 12.3 0.973

112.0 73.8 18.1 0.662 105.2 83.8 15.0 0.800 98.1 95.6 12.3 0 .979

122.7 79.6 18.4 0.652 115.3 90.2 15.3 0.786 107.5 102.7 12.5 0.959

130.5 85.0 18.3 0.654 122.7 96.3 15.2 0.788 114.4 109.5 12.5 0.960

142.5 93.3 18.2 0.658 134.0 105.5 15.2 0.790 125.1 119.8 12.5 0.961

78.7 49.9 18.8 0.640 73.8 56.2 15.6 0.768 68.5 63.6 12.8 0.935

89.7 56.9 18.8 0.639 84.6 64.0 15.7 0.762 79.0 72.4 13.0 0.921

102.7 65.5 18.7 0.642 96.7 74.1 15.6 0.770 90.3 84.1 12.8 0.936

116.3 74.2 18.7 0.641 109.4 84.2 15.5 0.773 102.1 95.9 12.7 0.943

127.6 80.1 19.0 0.631 120.0 90.6 15.8 0.758 112.0 103.0 13.0 0.923

135.7 85.5 19.0 0.633 127.7 96.7 15.8 0.761 119.2 109.8 13.0 0.924

148.2 93.9 18.9 0.636 139.5 106.0 15.7 0.763 130.3 120.1 13.0 0.925

81.8 50.3 19.4 0.620 76.7 56.6 16.2 0.742 71.3 63.8 13.3 0.901

93.2 57.3 19.4 0.620 87.9 64.4 16.3 0.737 82.2 72.6 13.5 0.888

106.6 66.0 19.3 0.622 100.5 74.4 16.1 0.745 93.9 84.3 13.3 0.902

120.8 74.7 19.3 0.621 113.7 84.5 16.1 0.747 106.3 96.1 13.2 0.908

132.6 80.6 19.6 0.611 124.9 91.1 16.4 0.733 116.6 103.4 13.5 0.890

141.0 86.1 19.6 0.614 132.8 97.2 16.3 0.735 124.2 110.2 13.5 0.891

154.1 94.6 19.5 0.616 145.2 106.6 16.3 0.737 135.7 120.5 13.5 0.891

75 85 95

26 RLC-PRC029-EN

Page 27

Performance Data

Table 13. Performance Data - RTWD - 60 Hz - standard efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving

Water Temp

(°F)

46

48

50

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator fouling

factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

6. Interpolation between points is permissible. Extrapolation is not permitted.

Unit kW kW kW

Size Tons Input EER kW/ton Tons Input EER kW/ton Tons Input EER kW/ton

80

90

100

110

120

130

140

80

90

100

110

120

130

140

80

90

100

110

120

130

140

85.0 50.7 20.0 0.601 79.8 56.9 16.7 0.718 74.2 64.1 13.8 0.869

96.7 57.8 19.9 0.602 91.2 64.7 16.8 0.714 85.4 72.8 14.0 0.857

110.7 66.4 19.9 0.604 104.4 74.8 16.7 0.721 97.6 84.6 13.8 0 .871

125.3 75.2 19.9 0.603 118.1 84.9 16.6 0.722 110.5 96.5 13.7 0.876

137.7 81.2 20.2 0.593 129.8 91.6 16.9 0.709 121.4 103.8 14.0 0.858

146.5 86.8 20.2 0.595 138.1 97.8 16.9 0.711 129.2 110.6 14.0 0.860

160.1 95.3 20.1 0.598 150.9 107.2 16.8 0.713 141.2 120.9 14.0 0.859

88.2 51.1 20.6 0.584 82.9 57.2 17.3 0.695 77.2 64.4 14.3 0.839

100.3 58.3 20.5 0.585 94.7 65.1 17.3 0.692 88.8 73.1 14.5 0.828

114.8 66.9 20.5 0.587 108.3 75.2 17.2 0.698 101.5 85.0 14.3 0.841

130.0 75.7 20.5 0.585 122.6 85.4 17.2 0.700 114.8 96.8 14.2 0.846

143.0 81.9 20.8 0.576 134.8 92.2 17.5 0.687 126.3 104.2 14.5 0.829

152.0 87.5 20.8 0.578 143.4 98.4 17.4 0.689 134.4 111.2 14.5 0.830

166.2 96.1 20.7 0.580 156.8 107.8 17.4 0.690 146.8 121.4 14.5 0.830

91.5 51.5 21.1 0.568 86.1 57.6 17.8 0.674 80.3 64.7 14.8 0.811

104.0 58.8 21.1 0.569 98.3 65.6 17.9 0.672 92.2 73.5 15.0 0.802

119.0 67.5 21.0 0.570 112.4 75.7 17.7 0.677 105.4 85.3 14.8 0.813

134.7 76.3 21.1 0.569 127.2 85.9 17.7 0.678 119.3 97.2 14.7 0.818

148.3 82.6 21.4 0.560 140.0 92.8 18.0 0.666 131.2 104.7 15.0 0.801

157.8 88.3 21.3 0.562 149.0 99.1 18.0 0.668 139.6 111.7 14.9 0.803

172.5 96.9 21.3 0.564 162.9 108.5 17.9 0.669 152.6 122.0 15.0 0.802

75 85 95

RLC-PRC029-EN 27

Page 28

Performance Data

Table 14. Performance Data - RTWD - 60 Hz - high efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving Water

Temp (°F)

38

40

42

Unit kW kW kW

Size Tons input EER kW/ton Tons input EER kW/ton Tons input EER kW/ton

80

90

100

110

120

130

150

160

180

200

220

250

80

90

100

110

120

130

150

160

180

200

220

250

80

90

100

110

120

130

150

160

180

200

220

250

77.1 48.5 18.9 0.634 72.2 54.7 15.7 0.763 66.9 61.9 12.9 0.931

89.9 56.0 19.1 0.627 84.5 63.0 16.0 0.750 78.7 71.2 13.2 0.910

103.5 64.1 19.2 0.624 97.1 72.5 16.0 0.750 90.4 82.3 13.1 0.915

117.3 72.3 19.4 0.620 110.0 82.0 16.0 0.749 102.3 93.4 13.1 0.917

124.9 77.1 19.3 0.621 117.2 87.4 16.0 0.749 109.1 99.5 13.1 0.916

132.6 81.7 19.4 0.619 124.6 92.5 16.1 0.746 116.1 105.3 13.2 0.911

144.6 90.3 19.1 0.628 135.9 102.3 15.9 0.756 126.8 116.3 13.0 0.921

157.7 98.3 19.2 0.626 148.4 111.2 16.0 0.752 138.4 126.4 13.1 0.916

172.1 106.1 19.4 0.619 162.0 119.7 16.2 0.741 151.4 135.8 13.3 0.900

187.0 113.8 19.7 0.610 176.3 128.1 16.5 0.729 165.0 145.1 13.6 0.882

204.7 128.5 19.1 0.630 193.0 144.9 15.9 0.753 180.7 164.2 13.2 0.911

225.0 141.5 19.0 0.631 212.0 159.6 15.9 0.754 198.4 180.8 13.1 0.913

80.3 48.8 19.6 0.613 75.3 54.9 16.3 0.735 69.8 62.1 13.4 0.895

93.6 56.4 19.8 0.607 88.0 63.3 16.6 0.724 82.0 71.4 13.7 0.875

107.8 64.5 19.9 0.603 101.2 72.8 16.6 0.723 94.3 82.5 13.7 0.879

122.1 72.7 20.0 0.599 114.7 82.3 16.6 0.721 106.8 93.6 13.6 0.880

130.0 77.5 20.0 0.599 122.2 87.7 16.6 0.721 113.9 99.7 13.7 0.879

138.1 82.1 20.1 0.598 129.9 92.8 16.7 0.718 121.1 105.5 13.7 0.874

150.5 90.8 19.8 0.606 141.6 102.6 16.5 0.727 132.2 116.5 13.6 0.884

164.2 98.8 19.9 0.604 154.6 111.6 16.6 0.724 144.4 126.6 13.6 0.879

179.1 106.7 20.1 0.598 168.8 120.2 16.8 0.714 157.9 136.1 13.9 0.865

194.6 114.5 20.3 0.590 183.6 128.7 17.1 0.703 172.0 145.5 14.1 0.848

213.0 129.3 19.7 0.609 201.0 145.5 16.5 0.726 188.4 164.6 13.7 0.876

234.2 142.4 19.7 0.610 220.9 160.2 16.5 0.727 206.9 181.2 13.7 0.878

83.5 49.1 20.2 0.593 78.4 55.2 16.9 0.709 72.8 62.3 13.9 0.861

97.3 56.9 20.4 0.588 91.6 63.7 17.2 0.699 85.5 71.6 14.2 0.842

112.1 65.0 20.6 0.583 105.4 73.1 17.2 0.697 98.3 82.7 14.2 0.845

127.0 73.2 20.7 0.580 119.4 82.6 17.3 0.695 111.4 93.8 14.2 0.846

135.3 78.0 20.7 0.580 127.2 88.0 17.3 0.695 118.7 99.9 14.2 0.845

143.7 82.6 20.8 0.578 135.3 93.2 17.3 0.692 126.3 105.7 14.3 0.840

156.6 91.3 20.5 0.586 147.5 103.0 17.1 0.701 137.8 116.7 14.1 0.850

170.8 99.4 20.5 0.584 161.0 112.0 17.2 0.698 150.5 126.8 14.2 0.845

186.3 107.4 20.7 0.578 175.8 120.7 17.4 0.689 164.5 136.5 14.4 0.832

202.4 115.3 21.0 0.572 191.1 129.3 17.7 0.679 179.2 146.0 14.7 0.817

221.5 130.2 20.3 0.590 209.2 146.2 17.1 0.701 196.3 165.1 14.2 0.843

243.6 143.4 20.3 0.590 230.0 160.9 17.1 0.702 215.6 181.7 14.2 0.845

75 85 95

28 RLC-PRC029-EN

Page 29

Table 14. Performance Data - RTWD - 60 Hz - high efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving Water

Temp (°F)

44

46

Unit kW kW kW

Size Tons input EER kW/ton Tons input EER kW/ton Tons input EER kW/ton

80

90

100

110

120

130

150

160

180

200

220

250

80

90

100

110

120

130

150

160

180

200

220

250

86.9 49.5 20.9 0.574 81.6 55.5 17.5 0.685 75.9 62.5 14.5 0.829

101.2 57.3 21.0 0.571 95.3 64.0 17.7 0.676 89.1 71.9 14.8 0.812

116.6 65.5 21.2 0.565 109.8 73.5 17.8 0.673 102.5 83.0 14.8 0.813

132.1 73.7 21.4 0.561 124.3 83.0 17.9 0.671 116.1 94.1 14.7 0.814

140.7 78.5 21.4 0.561 132.5 88.4 17.9 0.671 123.8 100.2 14.8 0.813

149.4 83.2 21.5 0.559 140.8 93.6 18.0 0.668 131.6 106.0 14.9 0.808

162.8 91.9 21.2 0.567 153.5 103.4 17.7 0.677 143.6 117.0 14.7 0.818

177.6 100.0 21.2 0.565 167.6 112.5 17.8 0.674 156.7 127.1 14.8 0.813

193.7 108.1 21.4 0.560 182.9 121.3 18.0 0.665 171.4 136.9 15.0 0.801

210.4 116.2 21.6 0.554 198.8 130.0 18.3 0.656 186.6 146.6 15.2 0.788

230.2 131.2 21.0 0.572 217.6 147.0 17.7 0.677 204.3 165.7 14.8 0.813

253.2 144.4 21.0 0.572 239.2 161.8 17.7 0.678 224.5 182.3 14.8 0.814

90.3 49.9 21.5 0.557 84.8 55.8 18.1 0.662 79.0 62.7 15.0 0.799

105.2 57.9 21.7 0.554 99.1 64.5 18.3 0.654 92.7 72.2 15.3 0.783

121.2 66.0 21.9 0.548 114.2 73.9 18.4 0.651 106.7 83.3 15.3 0.784

137.2 74.3 22.1 0.544 129.3 83.5 18.5 0.649 120.9 94.4 15.3 0.785

146.2 79.1 22.1 0.544 137.8 88.9 18.5 0.648 128.9 100.5 15.3 0.783

155.3 83.8 22.1 0.542 146.5 94.1 18.6 0.645 137.1 106.3 15.4 0.778

169.1 92.5 21.8 0.549 159.6 103.9 18.4 0.654 149.5 117.3 15.2 0.788

184.5 100.6 21.9 0.548 174.3 113.0 18.4 0.651 163.1 127.4 15.3 0.783

201.2 108.9 22.1 0.543 190.2 121.9 18.7 0.643 178.4 137.4 15.5 0.772

218.6 117.2 22.3 0.538 206.7 130.8 18.9 0.635 194.2 147.2 15.8 0.760

239.0 132.2 21.6 0.555 226.1 147.8 18.3 0.655 212.5 166.3 15.3 0.784

263.1 145.5 21.6 0.555 248.8 162.6 18.3 0.655 233.7 182.9 15.3 0.784

75 85 95

Performance Data

RLC-PRC029-EN 29

Page 30

Performance Data

Table 14. Performance Data - RTWD - 60 Hz - high efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving Water

Temp (°F)

48

50

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator fouling

factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

6. Interpolation between points is permissible. Extrapolation is not permitted.

Unit kW kW kW

Size Tons input EER kW/ton Tons input EER kW/ton Tons input EER kW/ton

80

90

100

110

120

130

150

160

180

200

220

250

80

90

100

110

120

130

150

160

180

200

220

250

93.7 50.3 22.2 0.541 88.2 56.1 18.7 0.641 82.2 63.0 15.6 0.771

109.2 58.4 22.3 0.538 103.0 64.9 18.9 0.634 96.4 72.5 15.9 0.756

125.9 66.5 22.6 0.532 118.7 74.4 19.0 0.630 111.1 83.6 15.9 0.756

142.5 74.8 22.7 0.528 134.4 83.9 19.1 0.628 125.8 94.8 15.9 0.757

151.8 79.7 22.7 0.528 143.3 89.4 19.1 0.627 134.2 100.9 15.9 0.755

161.4 84.4 22.8 0.526 152.3 94.6 19.2 0.624 142.7 106.7 16.0 0.750

175.6 93.2 22.5 0.533 165.9 104.5 19.0 0.632 155.5 117.7 15.8 0.759

191.5 101.3 22.6 0.531 181.1 113.5 19.1 0.629 169.7 127.8 15.9 0.755

208.9 109.7 22.8 0.527 197.6 122.6 19.3 0.623 185.5 137.9 16.1 0.745

226.9 118.2 23.0 0.523 214.8 131.7 19.5 0.615 201.9 147.8 16.3 0.734

248.1 133.3 22.3 0.539 234.9 148.7 18.9 0.635 221.0 167.0 15.8 0.758

273.2 146.8 22.3 0.539 258.5 163.6 18.9 0.635 243.0 183.6 15.8 0.757

97.3 50.7 22.8 0.525 91.6 56.5 19.3 0.621 85.5 63.3 16.1 0.744

113.3 59.0 22.9 0.524 107.0 65.4 19.5 0.615 100.3 72.9 16.4 0.731

130.6 67.1 23.2 0.517 123.3 74.9 19.7 0.610 115.6 84.0 16.4 0.730

147.8 75.5 23.4 0.513 139.6 84.5 19.7 0.608 130.9 95.2 16.4 0.731

157.6 80.4 23.4 0.512 148.9 89.9 19.8 0.607 139.6 101.3 16.5 0.729

167.6 85.1 23.5 0.510 158.3 95.2 19.9 0.604 148.4 107.1 16.6 0.724

182.2 93.9 23.2 0.517 172.4 105.0 19.6 0.612 161.7 118.1 16.4 0.733

198.7 102.0 23.3 0.515 188.1 114.1 19.7 0.609 176.4 128.2 16.5 0.729

216.8 110.6 23.4 0.512 205.3 123.4 19.9 0.603 192.9 138.5 16.7 0.720

235.5 119.3 23.6 0.508 223.1 132.6 20.1 0.596 209.9 148.6 16.9 0.710

257.3 134.5 22.9 0.524 243.8 149.7 19.5 0.615 229.6 167.8 16.4 0.732

283.5 148.0 22.9 0.524 268.4 164.6 19.5 0.615 252.6 184.4 16.4 0.732

75 85 95

30 RLC-PRC029-EN

Page 31

Performance Data

Table 15. Performance Data - RTWD - 60 Hz - premium efficiency - I-P units

Condenser Entering Water Temperature (°F)

Evaporator

Leaving Water

Temp (°F)

38

40

42

44

46

48

50

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator fouling

factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

6. Interpolation between points is permissible. Extrapolation is not permitted.

Unit kW kW kW

Size Tons input EER kW/ton Tons input EER kW/ton Tons input EER kW/ton

150

160

180

200

150

160

180

200

150

160

180

200

150

160

180

200

150

160

180

200

150

160

180

200

150

160

180

200

149.9 88.3 20.3 0.592 140.7 99.9 16.8 0.713 131.0 113.5 13.8 0.870

163.7 96.5 20.3 0.592 153.8 109.1 16.9 0.712 143.3 123.8 13.8 0.867

178.0 104.2 20.4 0.588 167.4 117.4 17.1 0.704 156.2 133.1 14.0 0.854

193.1 112.3 20.6 0.583 181.9 126.2 17.2 0.696 170.0 142.8 14.2 0.842

156.3 88.8 21.0 0.571 146.9 100.2 17.5 0.685 136.9 113.7 14.4 0.833

170.6 97.1 21.0 0.571 160.5 109.4 17.5 0.684 149.6 124.0 14.4 0.831

185.5 104.8 21.2 0.567 174.6 117.8 17.7 0.677 163.1 133.3 14.6 0.820

201.2 113.1 21.3 0.564 189.6 126.8 17.9 0.671 177.5 143.2 14.8 0.809

162.9 89.4 21.8 0.551 153.3 100.6 18.2 0.659 143.0 113.9 15.0 0.799

177.7 97.6 21.8 0.552 167.4 109.8 18.2 0.659 156.2 124.2 15.0 0.798

193.1 105.5 21.9 0.548 182.1 118.3 18.4 0.652 170.2 133.7 15.2 0.787

209.5 113.9 22.0 0.546 197.6 127.4 18.6 0.647 185.1 143.7 15.4 0.778

169.6 89.9 22.5 0.533 159.8 101.0 18.9 0.635 149.2 114.1 15.6 0.768

185.0 98.2 22.5 0.533 174.4 110.3 18.9 0.635 162.9 124.4 15.7 0.766

201.0 106.2 22.6 0.530 189.7 118.9 19.1 0.629 177.5 134.0 15.8 0.757

218.1 114.8 22.7 0.528 205.8 128.2 19.2 0.625 193.0 144.2 16.0 0.749

176.5 90.6 23.3 0.515 166.4 101.5 19.6 0.612 155.6 114.4 16.3 0.738

192.4 98.9 23.3 0.516 181.6 110.8 19.6 0.612 169.8 124.8 16.3 0.737

209.1 107.0 23.4 0.514 197.5 119.6 19.8 0.607 185.0 134.5 16.5 0.729

226.9 115.9 23.4 0.512 214.3 129.0 19.9 0.604 201.1 144.8 16.6 0.722

183.6 91.2 24.0 0.499 173.3 102.0 20.3 0.591 162.2 114.8 16.9 0.710

200.0 99.6 24.0 0.500 189.0 111.3 20.3 0.591 176.9 125.1 16.9 0.709

217.4 107.9 24.1 0.498 205.5 120.3 20.4 0.587 192.7 135.0 17.1 0.703

235.9 116.9 24.1 0.498 223.0 129.9 20.5 0.584 209.4 145.5 17.2 0.697

190.8 92.0 24.8 0.484 180.3 102.6 21.0 0.571 168.9 115.2 17.5 0.684

207.7 100.3 24.8 0.485 196.6 111.9 21.0 0.571 184.2 125.6 17.6 0.684

225.8 108.8 24.8 0.484 213.7 121.0 21.1 0.568 200.6 135.6 17.7 0.678

245.1 118.1 24.8 0.483 231.9 130.8 21.2 0.566 217.9 146.3 17.8 0.673

75 85 95

RLC-PRC029-EN 31

Page 32

Performance Data

Table 16. Part Load Performance – 60 Hz – standard efficiency – I-P units

IPLV

Unit Size % Load Tons kW EER kW/ton EER kW/ton

100 76.7 57.0 16.2 0.742

80

90

100

110

120

130

140

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator

fouling factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

75 57.5 35.2 19.6 0.611

50 38.4 19.3 23.9 0.502

25 19.2 11.6 19.9 0.602

100 87.9 64.8 16.3 0.737

75 65.9 39.7 19.9 0.603

50 43.9 22.3 23.7 0.508

25 22.0 13.4 19.7 0.609

100 100.5 74.8 16.1 0.745

75 75.3 46.4 19.5 0.615

50 50.2 25.6 23.6 0.509

25 25.1 16.7 18.0 0.538

100 113.8 84.9 16.1 0.747

75 85.3 53.0 19.3 0.622

50 56.9 28.7 23.8 0.505

25 28.4 17.3 19.7 0.609

100 124.8 91.5 16.4 0.733

75 93.6 57.5 19.5 0.614

50 62.4 31.1 24.1 0.498

25 31.2 17.6 21.3 0.563

100 132.8 97.6 16.3 0.735

75 99.6 61.5 19.4 0.618

50 66.4 33.6 23.7 0.506

25 33.2 20.9 19.1 0.630

100 145.2 107.0 16.3 0.737

75 108.9 68.6 19.0 0.630

50 72.6 36.1 24.1 0.497

25 36.3 20.9 20.8 0.576

21.6 0.557

21.5 0.558

21.6 0.554

21.3 0.563

21.8 0.551

21.3 0.564

21.5 0.558

32 RLC-PRC029-EN

Page 33

Performance Data

Table 17. Part Load Performance – RTWD – 60 Hz – high efficiency – I-P units

IPLV

Unit Size % Load Tons kW EER kW/ton EER kW/ton

100 81.6 55.9 17.5 0.685

80

90

100

110

120

130

150

160

180

75 61.2 34.5 21.3 0.563

50 40.8 19.0 25.8 0.465

25 20.4 11.5 21.3 0.562

100 95.3 64.4 17.8 0.676

75 71.5 39.5 21.7 0.552

50 47.7 22.2 25.8 0.466

25 23.8 13.2 22.0 0.555

100 109.8 73.9 17.8 0.673

75 82.3 45.7 21.6 0.556

50 54.9 24.9 26.5 0.453

25 27.4 13.3 24.7 0.483

100 124.3 83.4 17.9 0.671

75 93.2 52.1 21.5 0.559

50 62.2 28.3 26.4 0.455

25 31.1 17.0 22.0 0.548

100 132.5 88.8 17.9 0.671

75 99.3 55.9 21.3 0.563

50 66.2 30.5 26.0 0.460

25 33.1 17.2 23.1 0.520

100 140.8 94.0 18.0 0.668

75 105.6 59.4 21.4 0.562

50 70.4 32.4 26.0 0.461

25 35.2 20.3 20.8 0.576

100 153.5 103.8 17.7 0.677

75 115.1 66.7 20.7 0.580

50 76.8 35.9 25.7 0.468

25 38.4 20.4 22.6 0.533

100 167.6 112.9 17.8 0.674

75 125.7 73.0 20.7 0.580

50 83.8 38.8 25.9 0.463

25 41.9 24.9 20.2 0.594

100 182.9 121.7 18.0 0.666

75 137.2 78.1 21.1 0.569

50 91.4 41.7 26.3 0.456

25 45.7 25.2 21.8 0.551

23.3 0.515

23.5 0.511

24.1 0.497

23.7 0.506

23.6 0.508

23.4 0.514

23.1 0.519

22.9 0.523

23.5 0.511

RLC-PRC029-EN 33

Page 34

Performance Data

Table 17. Part Load Performance – RTWD – 60 Hz – high efficiency – I-P units

IPLV

Unit Size % Load Tons kW EER kW/ton EER kW/ton

100 198.8 130.4 18.3 0.656

200

220

250

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator

fouling factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

75 149.1 83.2 21.5 0.558

50 99.4 45.8 26.0 0.460

25 49.7 28.4 21.0 0.571

100 217.6 147.4 17.7 0.677

75 163.2 95.0 20.6 0.582

50 108.8 52.5 24.9 0.483

25 54.4 28.6 22.8 0.526

100 239.3 162.2 17.7 0.678

75 179.4 106.1 20.3 0.591

50 119.6 56.2 25.5 0.470

25 59.8 35.9 20.0 0.599

23.5 0.511

22.8 0.527

22.6 0.531

Table 18. Part Load Performance – RTWD – 60 Hz – premium efficiency – I-P units

IPLV

Unit Size % Load Tons kW EER kW/ton EER kW/ton

100 159.8 101.4 18.9 0.635

150

160

180

200

1. Rated in accordance with AHRI Standard 550/590, based on evaporator temperature drop of 10°F, 3 gpm/ton on the condenser, evaporator

fouling factor of 0.0001°F·ft²·h/Btu and condenser fouling factor of 0.00025°F·ft²·h/Btu.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. EER – Energy Efficiency Ratio (Btu/W·h). Power inputs include compressors and control power.

75 119.8 65.1 22.1 0.543

50 79.9 34.4 27.9 0.430

25 39.9 20.3 23.6 0.509

100 174.4 110.7 18.9 0.635

75 130.8 71.5 22.0 0.547

50 87.2 37.9 27.6 0.434

25 43.6 24.7 21.2 0.566

100 189.7 119.3 19.1 0.629

75 142.3 76.5 22.3 0.538

50 94.8 40.5 28.1 0.427

25 47.4 25.2 22.6 0.530

100 205.8 128.6 19.2 0.625

75 154.4 81.9 22.6 0.531

50 102.9 44.9 27.5 0.437

25 51.5 28.2 21.9 0.547

24.8 0.483

24.4 0.492

24.9 0.482

24.7 0.486

34 RLC-PRC029-EN

Page 35

Performance Data

Table 19. Performance Data - RTWD - 60 Hz - standard efficiency - SI units

Condenser Entering Water Temperature (°C)

Evaporator

Leaving Water

Temperature

(°C)

Unit Size Cooling input COP Cooling input COP Cooling input COP

80

90

100

5

110

120

130

140

80

90

100

7

110

120

130

140

80

90

100

9

110

120

130

140

1. Rated in accordance with AHRI Standard 550/590, based on an evaporator temperature drop of 5.6°C, 0.054 L/s per kW on the condenser, evaporator

fouling factor of 0.01761°K·m³/kW and condenser fouling of 0.044025°K·m³/kW.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. COP–Coefficient of Performance. Power inputs include compressors and control power.

6. Interpolation between points is permissible. Extrapolation is not permitted.

kW kW kW kW kW kW

268.0 50.9 5.2 252.5 56.8 4.4 235.9 63.5 3.7

306.2 58.0 5.2 289.8 64.7 4.5 272.4 72.3 3.7

350.3 66.9 5.2 331.3 74.9 4.4 311.1 84.0 3.7

396.8 75.8 5.2 375.0 85.1 4.4 352.0 95.7 3.7

435.0 81.8 5.3 411.1 91.6 4.5 386.0 102.9 3.7

462.6 87.3 5.3 437.4 97.7 4.5 410.9 109.6 3.7

505.4 95.9 5.2 477.9 107.1 4.4 449.0 120.0 3.7

287.5 51.6 5.5 271.2 57.3 4.7 253.9 63.9 3.9

327.8 58.8 5.5 310.6 65.2 4.7 292.5 72.6 4.0

375.0 67.7 5.5 355.2 75.5 4.7 334.2 84.4 3.9

424.8 76.6 5.5 402.1 85.7 4.7 378.2 96.2 3.9

466.4 82.8 5.6 441.4 92.4 4.8 415.2 103.5 4.0

496.0 88.4 5.6 469.6 98.6 4.7 441.9 110.3 4.0

542.1 97.0 5.6 513.4 108.0 4.7 483.0 120.6 4.0

307.7 52.3 5.8 290.7 57.9 5.0 272.6 64.4 4.2

350.2 59.6 5.8 332.3 65.9 5.0 313.4 73.2 4.3

400.7 68.5 5.8 380.1 76.2 5.0 358.3 85.0 4.2

453.8 77.6 5.8 430.3 86.5 5.0 405.5 96.8 4.2

499.1 83.9 5.9 473.1 93.4 5.0 445.8 104.3 4.3

530.8 89.6 5.9 503.3 99.7 5.0 474.4 111.2 4.3

580.4 98.4 5.9 550.3 109.2 5.0 518.4 121.5 4.3

25 30 35

RLC-PRC029-EN 35

Page 36

Performance Data

Table 20. Performance Data - 60 Hz - RTWD - high efficiency - SI units

Condenser Entering Water Temperature (°C)

Evaporator

Leaving Water

Temperature

(°C)

Unit Size Cooling input COP Cooling input COP Cooling input COP

80

90

100

110

120

5

130

150

160

180

200

220

250

80

90

100

110

120

7

130

150

160

180

200

220

250

80

90

100

110

120

9

130

150

160

180

200

220

250

1. Rated in accordance with AHRI Standard 550/590, based on an evaporator temperature drop of 5.6°C, 0.054 L/s per kW on the condenser, evaporator

fouling factor of 0.01761°K·m³/kW and condenser fouling of 0.044025°K·m³/kW.

2. Performance is based on 2 pass evaporator configuration.

3. Consult Trane representative for additional performance information.

4. kW input is for compressors only.

5. COP–Coefficient of Performance. Power inputs include compressors and control power.

6. Interpolation between points is permissible. Extrapolation is not permitted.

kW kW kW kW kW kW

284.6 50.1 5.6 268.3 55.7 4.8 250.9 62.2 4.0

331.9 57.9 5.7 313.8 64.2 4.9 294.6 71.5 4.1

382.1 66.3 5.7 361.0 73.8 4.9 338.8 82.6 4.1

432.9 74.7 5.8 408.9 83.5 4.9 383.6 93.7 4.1

461.1 79.6 5.8 435.7 89.0 4.9 409.0 99.8 4.1

489.8 84.4 5.8 463.1 94.2 4.9 435.1 105.6 4.1

533.8 93.3 5.7 505.2 104.1 4.8 474.9 116.6 4.1

582.6 101.5 5.7 551.6 113.2 4.9 518.4 126.7 4.1

635.5 109.5 5.8 602.2 121.9 4.9 566.9 136.3 4.1

690.5 117.5 5.9 654.8 130.5 5.0 617.5 145.7 4.2

755.7 132.8 5.7 717.0 147.6 4.8 676.4 164.9 4.1

830.9 146.2 5.7 788.0 162.5 4.8 743.0 181.4 4.1

305.5 50.7 6.0 288.4 56.2 5.1 270.2 62.6 4.3

356.1 58.7 6.0 337.1 64.9 5.2 317.0 72.0 4.4

410.2 67.1 6.1 388.1 74.5 5.2 364.9 83.1 4.4

464.6 75.6 6.1 439.6 84.2 5.2 413.3 94.2 4.4

494.9 80.5 6.1 468.5 89.7 5.2 440.7 100.3 4.4

525.8 85.3 6.1 498.0 94.9 5.2 468.7 106.1 4.4

572.8 94.2 6.1 542.9 104.8 5.2 511.2 117.1 4.4

625.1 102.5 6.1 592.8 114.0 5.2 558.0 127.1 4.4

681.7 110.8 6.1 647.0 122.9 5.2 610.1 137.0 4.4

740.6 119.0 6.2 703.3 131.8 5.3 664.3 146.7 4.5

810.1 134.4 6.0 769.7 148.9 5.2 727.2 165.9 4.4

891.4 148.0 6.0 846.4 163.9 5.2 799.3 182.4 4.4

327.2 51.4 6.3 309.4 56.8 5.4 290.4 63.0 4.6

381.3 59.7 6.3 361.5 65.7 5.5 340.5 72.6 4.7

439.4 68.0 6.4 416.5 75.3 5.5 392.3 83.7 4.7

497.4 76.6 6.5 471.6 85.0 5.5 444.3 94.8 4.7

530.2 81.6 6.5 502.8 90.5 5.5 473.8 100.9 4.7

563.5 86.4 6.5 534.5 95.8 5.6 503.9 106.7 4.7

613.4 95.3 6.4 582.3 105.7 5.5 549.1 117.7 4.6

669.2 103.7 6.4 635.7 114.9 5.5 599.3 127.8 4.7

729.9 112.2 6.5 693.7 124.1 5.6 655.1 137.9 4.7

792.9 120.8 6.5 753.9 133.3 5.6 713.1 147.9 4.8

866.7 136.3 6.3 824.5 150.5 5.5 780.3 167.1 4.7

954.3 150.0 6.3 907.3 165.6 5.5 858.1 183.7 4.7

25 30 35

36 RLC-PRC029-EN

Page 37

Performance Data

Table 21. Performance Data - RTWD - 60 Hz - premium efficiency - SI units

Condenser Entering Water Temperature (°C)

Evaporator

Leaving Water

Temperature

(°C)

Unit Size Cooling input COP Cooling input COP Cooling input COP

150

5

160

180

200

150

7

160

180

200

150

9

160

180

200