Page 1

Split System Heat Pumps

Split System Heat Pumps

7½ - 20 Tons - 60 Hz

Air Handlers

5-20 Tons - 60 Hz

February 2008 SSP-PRC001-EN

Page 2

Introduction

Split System Heat Pump

Units Designed With

Your Needs In Mind.

The Trane reputation for quality and

reliability in air conditioning is

apparent with Odyssey™ light

commercial split systems. These

Trane systems are designed to meet

your job requirements every

time...and at a competitive price.

Odyssey has Trane quality and

reliability built-in. Couple that with

outstanding efficiency, flexibility and

installation ease, and you have an

unbeatable combination for years of

worry-free service and operation.

Manufacturing Control

Trane’s exclusive control over the

design and manufacturing of all

major components is unique in the

industry. This approach assures total

control over both the quality and

reliability of these components and

allows us to custom match

components to deliver the best in

split system performance.

Standardized Cabinets

In addition, all cabinets have been

standardized. When you are

servicing an outdoor unit or an air

handler, all components are in the

same location from unit to unit.

Filters

The 5, 7½ and 10 ton air handlers are

supplied with 1" throwaway filters as

standard. The filter racks were

designed to easily convert for

installation of 2" filters. The 15 and

20 ton air handlers have 2" filters as

standard.

Figure 1.

Designing the Details

Careful attention was given to

designing the details — from control

wiring to the access panels. Odyssey

units feature time-saving colored

and numbered wiring and

removable panels which allow

complete access to all major

components and controls. All

outdoor units feature external high

and low pressure switches for easy

diagnosing and servicing of the unit.

Service valves with gauge ports are

provided on all units.

2 SSP-PRC001-EN

Page 3

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features and Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Model Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Jobsite Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

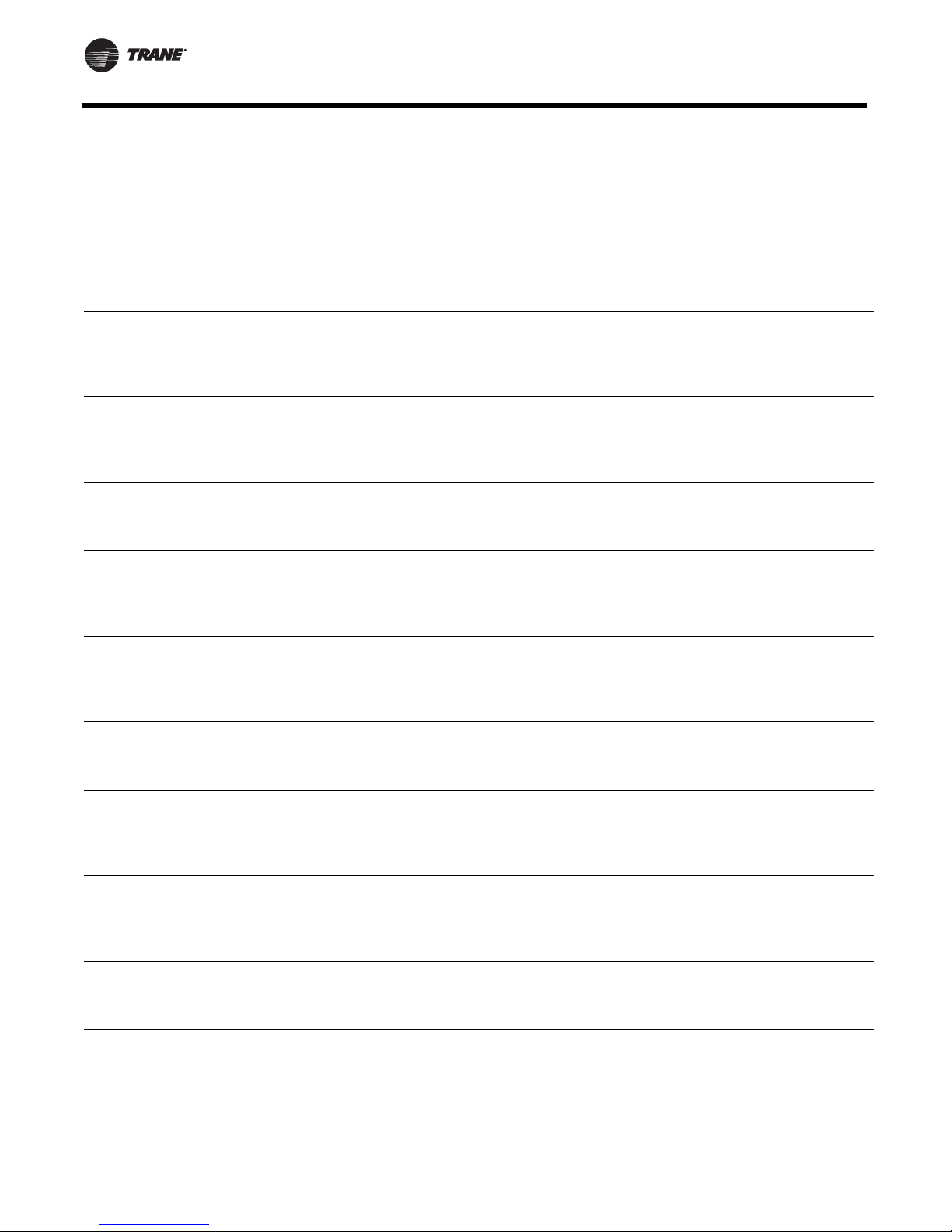

Typical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SSP-PRC001-EN 3

Page 4

Features and Benefits

Condensing Units Options

The 7½ and 10-ton single

compressor models feature single

refrigeration circuitry, lowering job

installation costs by requiring only

one set of refrigerant lines. These

units are ideal for low cost, new

construction, building renovation

and unit replacement jobs.

In addition, Odyssey includes 15 and

20-ton dual compressor units to give

true stand-by protection; if one

compressor fails, the second will

automatically start-up. Also, the first

compressor can be serviced without

shutting down the unit since the

refrigerant circuits are independent.

Dual compressors also provide high

energy savings. Most buildings are

designed for peak load requirements

even though the building typically

operates at less than peak load.

During light load conditions only one

compressor functions to maintain

the space comfort, reducing energy

use. For instance, the EER of the 15

ton unit at ARI conditions is 10.1 and

at part load conditions it is 11.6.

Trane split systems have been

specified in thousands of

applications. You’ll find Odyssey will

win you even more jobs with its

compact, manageable cabinet which

will save time and money for rigging

and installation and permit Trane to

replace almost any unit —

effortlessly.

Each heat pump unit can operate to

50°F as standard in the cooling

mode. An accessory Head Pressure

Control gives you the capability to

operate to 0°F. All heat pumps offer

these accessories:

• Head Pressure Control

• Coil Guard Kits

• Isolators - both Rubber-in-Shear

and Spring Type

• Anti-Short-Cycle Kit

• Time Delay Relay

Air Handlers Offer More

Flexibility

Flexibility is a key to meeting

changing market requirements.

Odyssey split systems offer not only

heat pumps, but also convertible air

handlers.

The air handlers can be installed

either vertically in a mechanical

room or horizontally above a ceiling

— and it doesn’t require any removal

of panels to make either airflow

application work.

Figure 2.

These air handlers have a double

sloped condensate drain pan that

allows for either airflow

configuration. The drain pan can

easily be removed for cleaning.

All the air handlers feature factoryinstalled belt drive and ball bearing

evaporator fans with adjustable

sheaves for maximum airflow

performance. In fact, the standard

motor on the 10-ton air handler will

deliver 4000 cfm at 1.4" ESP. Plus

oversized motors are available for

higher static applications.

4 SSP-PRC001-EN

Page 5

Features and Benefits

Odyssey’s air handler versatility is

further increased by a complete line

of accessories designed to match and

install smoothly:

• Discharge Plenum and Grille

• Return Grille

• Subbase

• Electric Heaters

• High Static Evaporator Motor

• Isolators both Rubber-in-Shear

and Spring Type

• A full line of Thermostats

• Outdoor Thermostat

Figure 3.

Odyssey — A Complete

Split System

Odyssey delivers the flexibility to

select a complete system that meets

your particular job requirements.

Air handlers are designed, tested and

rated with outdoor units to let you

select the proper match between

capacity and load. Also, these

matched systems can be quickly

engineered for specific applications

using Trane’s computerized selection

and load programs.

Odyssey Lowers Installation Costs

Your installation costs are reduced

with Odyssey Split. Both outdoor

units and air handlers are factory

packaged and assembled so jobsite

installation is quick and easy. You get

a complete system, with all the

components, controls and the

internal wiring, factory-installed for a

smooth jobsite start-up.

Unlike some competitive models the

following components are factoryinstalled in Trane air handlers:

• Single Point Power Entry

• Blower Wheel and Housing

• Evaporator Motor with Sheaves

and Pulleys

• Low Voltage Terminal Board

•Transformer

• Contactor

• Fan Relay

• DX Coil with complete

Refrigeration Circuitry

• Expansion Valve and Check

Valves

There’s no need to install

components and put together the air

handler on the job. This provides you

with less labor cost and fewer

chances for installation errors which

cause callbacks. All this means

saving you money both in

replacement and new construction

applications.

Figure 4.

SSP-PRC001-EN 5

Page 6

Application Considerations

Application of this product should be

within the catalogued airflow and

performance considerations.

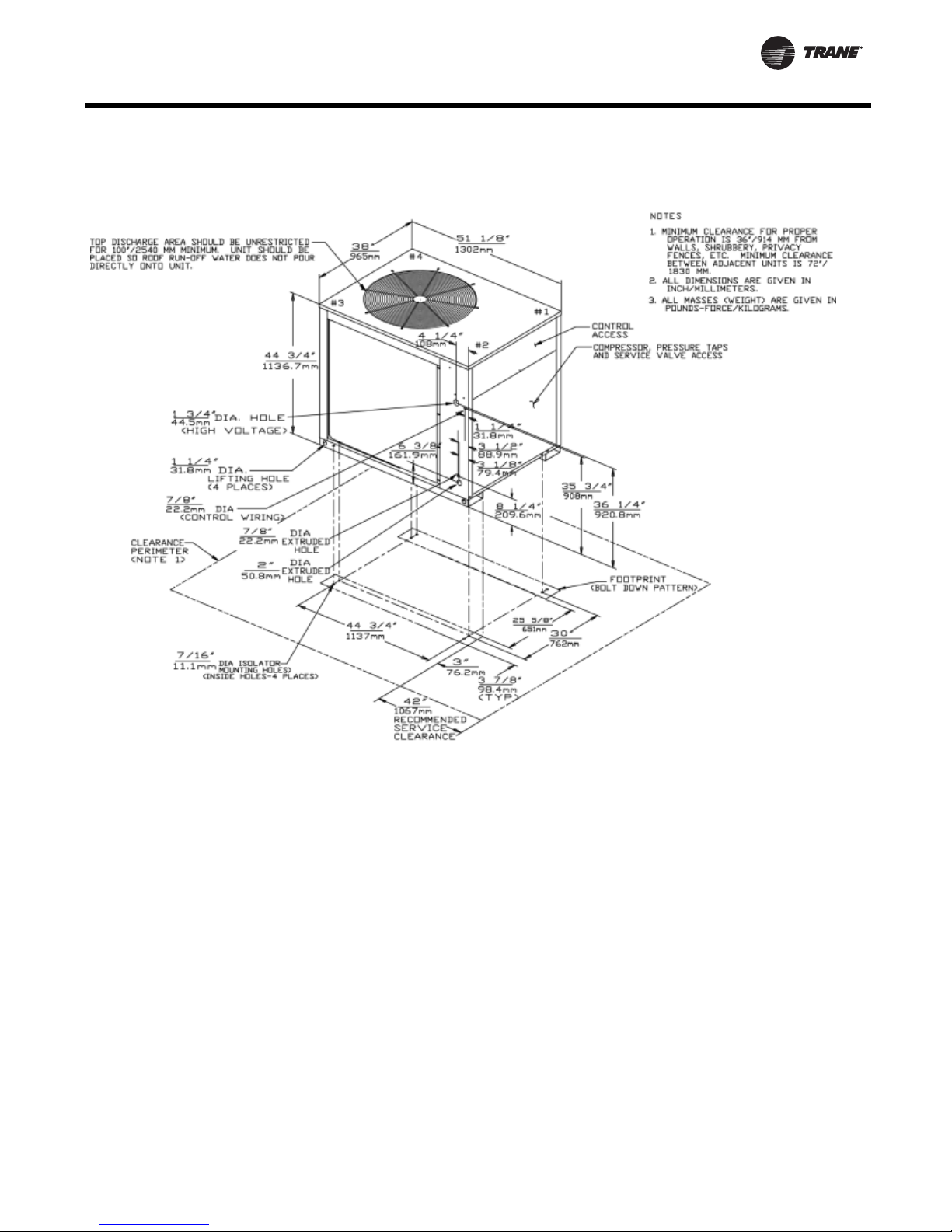

Clearance Requirements

The recommended clearances

identified with unit dimensions

should be maintained to assure

adequate serviceability, maximum

capacity and peak operating

efficiency. Actual clearances which

appear inadequate should be

reviewed with a local Trane

Representative.

180° Blower Rotation

The 5, 7½ and 10 ton air handler

blower section can be rotated 180° to

change the discharge pattern. This

modification must be done in the

field and requires an additional kit.

See unit installer's guide.

Low Ambient Cooling

As manufactured, these units can

operate to 50°F in the cooling mode

of operation. An accessory head

pressure control will allow operation

to 0°F outdoor ambient. When using

these units with control systems

such as bypass changeover Variable

Air Volume, make sure you consider

the requirement for a head pressure

control to allow low ambient

cooling.

Figure 5. Typical Horizontal Air Handler Application

Figure 6. Typical Split System Application

6 SSP-PRC001-EN

Page 7

Application Considerations

Figure 7. Typical Vertical Air Handler Application

SSP-PRC001-EN 7

Page 8

Selection Procedure

Cooling Capacity

Step 1.

Calculate the building’s total and

sensible cooling loads at design

conditions.

Step 2.

Size the equipment using Tab l e 3 .

Match the cooling loads at design

conditions.

Example: The following are the

building cooling requirements:

a. Electrical Characteristics:

460/60/3

b. Summer Design Conditions:

Entering Evaporator Coil:

80°F DB/67°F WB Outdoor

Ambient: 95°F

Total Cooling Load: 90 MBh

c. Sensible Cooling Load: 64

MBh

d. Airflow: 3000 cfm

External Static Pressure:

0.77 inches of water gauge

Tab le 3 shows that TWA090A4 with

TWE090A has a gross cooling

capacity of 91.1 MBh and 65.9 MBh

sensible capacity at 95°F DB ambient

and 3000 cfm with 80°F DB/67°F WB

air entering the evaporator.

To find the net cooling capacities, fan

motor heat must be subtracted.

Determine the total unit static

pressure:

External Static Duct System 0.77 in.

Standard Filter 1 in. 0.10 in.

Supplementary Electric Heat 0.23 in.

Total Static Pressure 1.10 in.

Note: The Evaporator Fan

Performance Table has

included the effect of a 1 in.

filter already. Therefore, the

actual Total Static Pressure is

1.10 - 0.10 = 1.0 0 in. Wit h

3000 cfm and 1.00 in.,

Ta b le 1 7 shows a 1.17 bhp.

Note: The formula below the table

can be used to calculate Fan

Motor Heat:

3.5 X bhp = MBh

3.5 X 1.17 = 4.09 MBh

Net Total Cooling Capacity =

91.1 MBh - 4.09 = 87.01 MBh

Net Sensible Cooling Capacity =

65.9 MBh - 4.09 = 61.81 MBh

Heating Capacity

Step 1.

Calculate the building heating load

using the Trane calculation form or

any other standard accepted

method.

Step 2.

Size the equipment using Tab le 11 to

match the heating loads at design

conditions. The following are

building heating requirements:

a. Total Heating Load: 95.0 MBh

b. Outdoor Ambient (Winter):

17°F DB

c. Indoor Return Temperature:

70°F DB

d. Airflow: 3000 cfm

Ta b le 11 indicates the mechanical

heating portion of the heat pump will

provide 54.8 MBh for the winter

design conditions.

Step 3.

Because 54.8 MBh is less than the

building’s required heating capacity,

a supplementary heater must be

selected. 95.0 - 54.8 = 40.2 MBh

minimum heater capacity.

From Table 32, the 14.96 kW heater

has a capacity of 51,058 Btu/h.

From Table 37, the 14.96 kW heater

at 460V indicates the heater model

number is BAYHTRL415A.

This heater will be adequate to cover

the residual heat capacity needed for

the application.

Air Delivery Selection

External static pressure drop

through the air distribution system

has been calculated to be 0.77 in. of

water gauge.

From Table 31 static pressure drop

through the electric heater is 0.12 in.

of water (0.77 + 0.12 = .89 in.)

Enter Tab l e 17 for TWE090A4 at 3000

cfm and .90 static pressure. The

standard motor at 790 RPM will give

the desired airflow.

8 SSP-PRC001-EN

Page 9

Model Number Description

Split System Heat Pump Model Nomenclature

TWA 0 9 0 A 3 00 A A

123 45 6 7 8 910 11 12

Digits 1,2,3 - Product Type

TWA = Split System Heat Pump

Digits 4,5,6 - Nominal Gross Cooling

Capacity (MBh)

090 = 7 1/2 Tons

120 = 10 Tons

180 = 15 Tons

240 = 20 Tons

Digits 7 - Major Development

Sequence

A = Single Compressor

B = Dual Compressor

Digits 8 - Electrical Characteristics

1 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

W = 575/60/3

Digits 9,10 - Factory Installed

Options

00 = Packed Stock

0S = Black Epoxy Coated Coil

Digits 11 - Minor Design Sequence

A = Current Design Sequence

Digits 12 - Service Digit

A = Current Service Digit

Air Handler Model Nomenclature

TWE 0 9 0 A 1 00 A A

123 45 6 7 8 910 11 12

Digits 1,2,3 - Product Type

TWE = Split System Heat Pump/

Cooling Air Handler

Digits 4,5,6 - Nominal Gross Cooling

Capacity (MBh)

060 = 5 Tons

090 = 7½ Tons

120 = 10 Tons

180 = 15 Tons

240 = 20 Tons

Digits 8 - Electrical Characteristics

1 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

W = 575/60/3

Digits 9,10 - Factory Installed

Options

00 = Packed Stock

Digits 11 - Minor Design Sequence

A = Current Design Sequence

Digits 12 - Service Digit

A = Current Service Digit

Digits 7 - Refrigerant Circuit

A = Single

B = Dual

SSP-PRC001-EN 9

Page 10

General Data

Table 1. General Data — Heat Pumps

7½ Tons 10 Tons 15 Tons 20 Tons

Single Compressor

TWA090A3,A4,AW

Cooling Performance

(i)

Gross Cooling Capacity

Matched Air Handler 91,000 124,000 182,000 240,000

Matched Heat Pump Only

ARI Net Cooling Capacity

(iv)

EER

(ii)

(iii)

91,000 124,000 182,000 240,000

89,000 120,000 176,000 234,000

Matched Air Handler 10.1 10.1 9.9 9.3

Heat Pump Only 11.5 11.1 10.9 10.3

Integrated Part Load Value

(v)

- - 11.0 10.5

System/Condensing Unit Power (kW) 8.70/7.95 11.91/11.07 17.77/16.62 24.99/23.20

Heating Performance

ARI Heating and Matched Air Handler

High Temperature Capacity 87,000 122,000 168,000 234,000

System kW/COP 7.68/3.3 10.82/3.2 16.10/3.1 22.42/3.1

Low Temperature Capacity 55,000 80,000 106,000 154,000

System kW/COP 6.73/2.4 9.62/2.4 14.16/2.2 19.54/2.30

Compressor

TM

No./Type 1/Trane 3-D

Scroll 1/Trane 3-DTM Scroll 2/Trane 3-DTM Scroll 2/Trane 3-DTM Scroll

No. Motors/HP 1/7.5 1/10 2/7.5 2/10

Motor RPM 3450 3450 3450 3450

Sound Rating (BELS)

System Data

(vii)

(vi)

8.8 8.8 8.8 8.8

No. Refrigerant Circuits 1 1 2 2

Suction Line (in.) OD 1 3/8 1 3/8 1 3/8 1 3/8

Liquid Line (in.) OD 1/2 1/2 1/2 1/2

Outdoor Coil - Type Plate Fin Plate Fin Plate Fin Plate Fin

Tube Size (in.) OD .375 .375 .375 .375

Face Area (sq ft) 19.2 29.5 38.5 50.2

Rows/FPI 2/18 2/18 2/18 2/18

Refrigerant Control Expansion Valve Expansion Valve Expansion Valve Expansion Valve

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter (in.) 1/26 1/28 2/26 2/28

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct1

CFM 5890 8200 11,780 16,240

No. Motor/HP 1/.50 1/1.00 2/.50 2/1.00

Motor RPM 1100 1100 1100 1100

Refrigerant Charge (Field Supplied)

(lbs of R-22)

(i)

(ii)

(iii)

(iv)

(v)

(vi)

(vii)

(viii)

(viii)

Cooling Performance is ra ted at 95°F ambient, 80°F enterin g dry bulb , 67°F ente ring wet bu lb. Gross c apacity doe s not inclu de t he effect of fan motor

heat. ARI capacity is net and includes the effect of fan motor heat. Certified in accordance with the Unitary Large Equipment certification program,

which is based on ARI Standard 340/360-00.

Condensing unit only gross cooling capacity rated at 45°F saturated suction temperature and at 95°F ambient.

ARI net cooling capacity is calculated with matched blower coil and 25 feet of 1 3/8" or 1/2" OD interconnecting tubing.

EER is rated at ARI conditions and in accordance with DOE test procedures.

Integrated part load value is based on ARI Standard 340/360-00. Units are rated at 80°F ambient, 80°F entering dry bulb (DB), and 67°F entering

wet bulb (WB) at ARI rated cfm.

Sound rating shown is tested in accordance with ARI Standard 270 or 370.

Refer to refrigerant piping applications manual for line sizing and line length.

Refrigerant (operating) charge is for c ondens ing uni t (all circui ts) wi th matchi ng bl ower co ils and 25 feet of inter connec ting refrigerant lines. All units

are supplied with a small nitrogen holding charge only.

18.00 31.50 36.00 48.50

Single Compressor

TWA120A3,A4,AW

Dual Compressor

TWA180B3,B4,BW

Dual Compressor

TWA240B3,B4,BW

10 SSP-PRC001-EN

Page 11

General Data

Table 2. General Data - Air Handlers

5 Tons 7½ Tons 10 Tons

Single Circuit

TWE060A1

A3, A4, AW

Dual Circuit

(i)

,

TWE060B1, B3,

B4

System Data

No. Refrigerant Circuits 1 2 1 2 1 1

Suction Line (in.) OD 1 1/8 3/4 1 3/8 1 1/8 1 3/8 1 3/8

Liquid Line (in.) OD 3/8 5/16 1/2 3/8 1/2 1/2

Indoor Coil - Type Plate Fin Plate Fin Plate Fin Plate Fin Plate Fin Plate Fin

Tube Size (in.) .375 .375 .375 .375 .375 .375

Face Area (sq. ft.) 5.0 5.0 8.1 8.1 11.2 11.2

Rows/FPI 3/12 3/12 3/12 3/12 4/12 4/12

Refrigerant Control Expansion Valve Expansion Valve Expansion Valve Expansion Valve Expansion Valve Expansion Valve

Drain Connection Size (in.) 1 PVC 1 PVC 1 PVC 1 PVC 1 PVC 1 PVC

Indoor Fan - Type Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal

No. Used/Diameter x Width (in.) 1/12 x 12 1/12 x 12 1/15 x 15 1/15 x 15 1/15 x 15 1/15 x 15

Drive Type/No. Speeds Belt/Adjustable Belt/Adjustable Belt/Adjustable Belt/Adjustable Belt/Adjustable Belt/Adjustable

CFM 2000 2000 3000 3000 4000 4000

No. Motors 1 1 1 1 1 1

Motor HP - Standard/Oversized .75/1.00 .75/1.00 1.50/2.00 1.50/2.00 2.00 2.00/3.00

Motor RPM 1725 1725 1725 1725 1725 1725

Motor Frame Size 56 56 56H 56H 56HZ 56HZ

Filters - Type/Furnished Throwaway/Yes Throwaway/Yes Throwaway/Yes Throwaway/Yes Throwaway/Yes Throwaway/Yes

(No.)/Size Recommended (1) 16x20x1 (1) 16x20x1 (3) 16x25x1 (3) 16x25x1 (4) 16x25x1 (4) 16x25x1

(1) 20x20x1 (1) 20x20x1

10 Tons 15 Tons 20 Tons

Dual Circuit

Dual Circuit

TWE120B1

(iv)

TWE120B3

B4, BW

System Data

No. Refrigerant Circuits 2 2 2 2 2

Suction Line (in.) OD 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

Liquid Line (in.) OD 3/8 3/8 3/8 1/2 1/2

Indoor Coil - Type Plate Fin Plate Fin Plate Fin Plate Fin Plate Fin

Tube Size (in.) .375 .375 .375 .375 .375

Face Area (sq. ft.) 11.2 11.2 11.2 16.3 21.6

Rows/FPI 4/12 4/12 4/12 3/12 3/12

Refrigerant Control Expansion Valve Expansion Valve Expansion Valve Expansion Valve Expansion Valve

Drain Connection Size (in.) 1 PVC 1 PVC 1 PVC 1 PVC 1 PVC

Indoor Fan - Type Centrifugal Centrifugal - Centrifugal Centrifugal

No. Used/Diameter x Width (in.) 1/15x15 1/15x15 - 2/15x15 2/15x15

Drive Type/No. Speeds Belt/Adjustment Belt/Adjustment - Belt/Adjustment Belt/Adjustment

CFM 4000 4000 - 6000 8000

No. Motors 1 1 - 1 1

Motor HP - Standard/Oversized 2.00/- 2.00/3.00 - 3.00/5.00 5.00/7.50

Motor RPM 1725 1725 - 1735/1750 1750/3470

Motor Frame Size 56HZ 56HZ - 145T 184T

Filters - Type/Furnished Throwaway/Yes Throwaway/Yes Throwaway/

(No.)/Size Recommended (4) 16x25x1 (4) 16x25x1 (4) 16x25x1 (8) 15x20x2 (4) 16x25x2

(i)

TWE60A1 has motor RPM of 3450 for oversized motor.

(ii)

Ships wired for 208-230/60/3. Field convertible to 460/60/3.

(iii)

TWE120A1 does not have an oversized motor option.

(iv)

TWE120B1 does not have an oversized motor option.

(v)

Coil has filter rack as standard, but no filters. When us ing this coil as a duct coi l, use below s ize recommended. Filters for coil no t recommen ded when

using coil with upflow gas furnaces.

Single Circuit

TWE090A1,

(ii)

,

Dual Circuit

TXE120B500B

A3

(ii)

Yes

, AW

(v)

Dual Circuit

TWE090B1,

(ii)

B3

Dual Circuit

TWE180B3, B4,

BW

Single Circuit

TWE120A1

Dual Circuit

TWE240B3, B4,

BW, E3, E4, EW

Throwaway/Yes Throwaway/Yes

(4) 16x20x2

Single Circuit

TWE120A3

(iii)

(ii)

AW

,

SSP-PRC001-EN 11

Page 12

Performance Data

Table 3. Gross Cooling Capacities (MBh) 7½ Tons TWA090A Heat Pump with 7½ TWE090A Air Handler

Ambient Temperature

85 95 105

Entering WB

CFM Air

flow

2700 75 84.1 67.2 92.8 56.3 102.1 37.7 81.2 65.7 89.5 55.0 98.5 36.4 78.0 64.2 86.1 53.6 94.8 35 .2

3000 75 87.5 70.3 94.4 54.8 103.7 38.4 82.7 68.8 91.1 53.4 100.0 37.1 79.4 67.2 87.5 51.9 96.1 35.7

3300 75 87.0 73.3 95.7 56.6 104.9 39.0 83.9 71.7 92.3 55.2 101.2 37.6 80.6 70.1 88.6 53.7 97.3 36.2

3600 75 88.2 76.1 96.8 58.3 106.0 39.5 85.0 74.6 93.3 56.9 102.2 38.1 81.6 73.0 89.6 55.4 98.2 36.7

CFM Air

flow

2700 75 74.7 62.5 82.4 52.1 90.9 33.8

3000 75 75.9 65.6 83.7 50.4 92.2 34.3

3300 75 77.1 68.5 84.8 52.2 93.3 34.8

3600 75 78.1 71.3 85.7 53.9 94.1 35.3

Notes:

1. Dry coil condition. Total gross capacity (MBh) shown to the left is not applicable. In this case the Sensible Heat Capacity (SHC) is the total capacity.

2. All temperatures are in °F.

3. All capacities shown are gross and have not considered indoor fan heat.

4. To obtain net cooling capacities, subtract indoor fan heat.

5. MBH = Total Gross Cooling Capacity

6. SHC = Sensible Heat Capacity

Ent

DB °F

80 84.6 78.6 93.0 64.5 102.1 49.6 81.8 77.2 89.8 63.2 98.5 48.3 78.8 75.7 86.3. 61.7 94.8 46.9

85 86.9 86.9 93.1 75.8 102.2 61.3 84.4 84.4 89.9 74.4 98.7 60.0 81.7 81.7 86.4 72.9 95.0 58.6

90 91.2 91.2 93.7 87.3 102.3 72.9 88.7 88.7 90.6 85.9 98.7 71.5 86.0 86.0 87.3 84.5 95.1 70.0

80 86.5 82.9 94.6 67.5 103.7 51.2 83.6 81.4 91.1 65.9 100.0 499 80.5 79.9 87.6 64.4 96.2 48.5

85 89.6 89.6 94.7 79.7 103.8 64.0 87.1 87.1 91.4 78.3 100.2 62.6 84.3 84.3 87.9 76.7 96.4 61.3

90 94.1 94.1 95.7 92.4 92.4 103.9 76.4 91.5 92.5 91.0 100.3 75.0 88.6 88.6 88.7 88.7 96.5 73.6

80 88.1 87.0 95.8 70.1 105.0 52.8 84.7 84.7 92.4 68.6 101.2 51.4 81.9 81.9 88.8 67.0 97.4 50.0

85 92.0 92.0 96.1 83.4 105.1 66.5 89.3 89.3 92.8 82.0 101.4 65.2 86.4 86.4 89.2 80.4 97.6 63.8

90 96.6 96.6 97.5 97.2 105.2 79.9 93.9 93.9 93.9 93.9 101.5 78.5 90.9 90.9 91.0 91.9 97.7 77.0

80 89.3 89.3 96.9 72.7 106.1 54.2 86.6 86.6 93.4 71.2 102.3 52.9 83.7 83.7 89.8 69.6 98.3 51.5

85 94.1 94.1 97.4 87.0 106.2 69.0 91.3 91.3 94.0 85.6 102.5 67.6 88.3 88.3 90.4 84.0 98.4 66.1

90 98.9 98.9 98.9 98.9 106.4 83.2 96.0 96.0 96.1 96.1 102.6 81.8 92.9 92.9 93.0 93.0 98.7 80.3

Ent

DB °F

80 75.6 74.1 82.6 60.0 91.0 45.5

85 78.9 78.9 82.9 71.3 91.1 57.2

90 83.1 83.1 84.0 83.0 91.3 68.5

80 77.0 77.0 83.9 62.8 92.3 47.1

85 81.3 81.3 84.3 75.2 92.5 59.9

90 85.6 85.6 85.7 85.7 92.6 72.1

80 78.9 78.9 85.0 65.4 93.4 48.6

85 83.3 83.3 85.6 78.9 93.6 62.4

90 87.8 87.8 87.9 87.9 93.7 75.5

80 80.6 80.6 85.9 68.0 94.3 50.1

85 85.1 85.1 86.7 82.5 94.4 64.6

90 89.7 89.7 89.8 89.8 94.8 78.8

61 67 73 61 67 73 61 67 73

MBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHC

Ambient Temperature

115

Enter WB

61 67 73

MBH SHC MBH SHC MBH SHC

12 SSP-PRC001-EN

Page 13

Performance Data

10 Tons Gross Cooling Capacities

Table 4. Gross Cooling Capacities (MBh) 10 Ton TWA120A Heat Pump with 10 Ton TWE120A Air Handler

Ambient Temperature

85 95 105

Entering WB

CFM Air

flow

3600 75 114.6 90.1 126.2 76.3 138.8 51.1 110.6 88.1 121.8 74.5 134.0 49.4 106.2 85.9 117.1 72.6 128.9 47.7

4000 75 116.7 94.0 128.5 73.3 114.1 52.1 112.5 91.9 123.9 71.4 136.1 50.4 108.1 86.7 119.1 69.3 130.8 48.5

4400 75 118.5 97.7 130.3 75.5 142.9 53.0 114.2 95.6 125.6 73.6 137.8 51.1 109.6 93.4 120.7 71.6 132.4 49.2

4800 75 120.0 101.3 131.9 77.7 144.5 53.6 115.6 99.1 127.1 75.7 139.4 51.7 111.1 96.9 122.1 73.7 133.8 49.8

CFM Air

flow

3600 75 101.7 83.6 112.2 70.6 123.4 45.8

4000 75 103.5 87.5 114.0 67.2 125.2 46.5

4400 75 105.0 91.1 115.5 69.4 126.7 47.1

4800 75 106.3 94.7 116.7 71.5 128.0 47.7

Notes:

1. Dry coil condition. Total gross capacity (MBh) shown to the left is not applicable. In this case the Sensible Heat Capacity (SHC) is the total capacity.

2. All temperatures are in °F.

3. All capacities shown are gross and have not considered indoor fan heat.

4. To obtain net cooling capacities, subtract indoor fan heat.

5. MBH = Total Gross Cooling Capacity

6. SHC = Sensible Heat Capacity

Ent

DB °F

80 115.0 104.8 126.4 85.8 138.8 66.4 111.1 102.8 122.0 83.9 134.0 64.6 106.9 100.7 117.3 81.9 128.9 62.6

85 117.1 117.1 126.5 100.7 138.8 81.2 113.7 113.7 122.0 98.6 134.0 79.3 110.1 110.1 117.4 96.5 129.0 77.4

90 122.7 122.7 126.9 115.2 138.9 95.9 119.2 119.2 122.7 113.2 134.2 94.0 115.5 115.5 118.2 111.1 129.1 92.1

80 117.5 110.2 128.6 89.5 141.1 68.5 113.4 108.1 124.0 87.6 136.1 66.6 109.2 106.0 119.2 85.5 130.8 64.6

85 120.7 120.7 128.6 105.4 141.1 84.5 117.1 117.1 124.1 103.4 136.2 82.6 113.4 113.4 119.3 101.2 131.0 80.7

90 126.6 126.6 129.5 121.4 141.2 100.5 122.9 122.9 125.2 119.4 136.3 98.6 119.1 119.1 120.7 117.3 131.1 96.6

80 119.7 115.3 130.4 93.0 142.9 70.4 115.6 113.2 125.8 91.0 137.8 68.5 11.3 111.1 120.8 89.0 132.5 66.5

85 123.9 123.9 130.5 110.0 143.0 87.7 120.2 120.2 125.9 107.9 138.0 85.8 116.3 116.3 121.1 105.8 132.6 83.8

90 129.9 129.9 131.9 127.4 143.1 104.8 126.1 126.1 127.5 125.4 138.1 102.9 122.2 122.2 122.0 122.0 132.7 100.9

80 121.7 120.2 132.0 96.3 144.5 72.2 116.7 116.7 127.2 94.4 139.3 70.3 112.8 112.8 122.2 92.3 133.9 68.3

85 126.7 126.7 132.2 114.4 144.6 90.7 122.9 122.9 127.6 112.4 139.5 88.8 118.8 118.8 122.7 110.3 134.0 86.8

90 132.9 132.9 134.1 133.2 144.7 109.0 129.0 129.0 128.9 128.9 138.5 106.9 124.9 124.9 124.8 124.8 134.1 104.8

Ent

DB °F

80 102.6 98.5 112.4 79.8 123.5 60.6

85 106.3 106.3 112.5 94.3 123.6 75.3

90 111.7 111.7 113.5 109.0 123.7 90.0

80 104.9 103.8 114.2 83.4 125.3 62.6

85 109.5 109.5 114.4 99.0 125.4 78.6

90 115.0 115.0 115.9 115.2 125.5 94.5

80 106.5 106.5 115.7 86.8 126.8 64.5

85 112.2 112.2 116.1 103.6 126.9 81.7

90 117.9 117.9 117.8 117.8 126.9 98.5

80 108.7 108.7 116.9 89.8 128.0 66.2

85 114.6 114.6 117.6 108.0 128.2 84.7

90 120.5 120.5 120.4 120.4 128.2 102.6

61 67 73 61 67 73 61 67 73

MBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHCMBHSHC

Ambient Temperature

115

Enter WB

61 67 73

MBH SHC MBH SHC MBH SHC

SSP-PRC001-EN 13

Page 14

Performance Data

15 Tons Gross Cooling Capacities

Table 5. Gross Cooling Capacities (MBh) 15 Tons TWA180B Heat Pump with 15 Tons TWE180B Air Handler

Ambient Temperature

85 95 105

Entering WB

CFM Air

flow

5400 75 167.8 134.1 185.1 112.3 203.6 75.2 161.9 131.2 178.6 109.7 196.4 72.7 155.5 128 171.6 106.9 188.9 70.1

6000 75 170.9 140.3 188.3 109.4 206.8 76.7 164.8 137.3 181.5 106.6 199.3 74.1 158.3 134.2 174.4 103.7 191.6 71.3

6600 75 173.5 146.3 190.9 113 209.3 77.8 167.2 143.2 184 110.2 201.7 75.1 160.5 140 176.7 107.3 193.9 72.3

7200 75 175.7 152 193.1 116.5 211.5 78.8 169.4 148.9 186.1 113.7 203.7 76 162.6 145.6 178.6 110.7 195.8 73.3

CFM Air

flow

5400 75 148.8 124.7 164.3 104 181.1 67.5

6000 75 151.3 130.8 166.9 100.7 183.7 68.5

6600 75 153.5 136.6 169.1 104.2 185 .8 69.5

7200 75 155.5 142.2 170.9 107.7 187.6 70.4

Notes:

1. Dry coil condition. Total gross capacity (MBh) shown to the left is not applicable. In this case the Sensible Heat Capacity (SHC) is the total capacity.

2. All temperatures are in °F.

3. All capacities shown are gross and have not considered indoor fan heat.

4. To obtain net cooling capacities, subtract indoor fan heat.

5. MBH = Total Gross Cooling Capacity

6. SHC = Sensible Heat Capacity

Ent

DB °F

80 168.7 157 185.4 128.9 203.7 99.1 163 154.1 178.9 126.2 196.5 96.4 156.9 151.1 171.8 122.9 189.1 93.7

85 173.3 173.31 185.7 151.5 203.9 122.5 168.4 168.41 179.2 148.6 196.8 119.8 163 163.01 172.3 145.5 189.4 117.1

90 182 182.01 186.8 174.4 204.1 145.5 176.9 176.91 180.6 171.6 197 142.7 171.4 171.41 174 168.7 189.6 139.8

80 172.3 165.5 188.4 134.5 206.8 102.3 166.5 162.6 181.7 131.6 199.5 99.7 160.3 159.5 174.7 128.5 191.8 96.9

85 178.8 178.81 188.9 159.2 207.1 127.9 173.6 173.61 182.3 156.3 199.8 125.2 168 168.01 175.3 153.2 192.2 122.5

90 187.9 187.91 190.7 184.5 207.3 152.7 182.5 182.51 184.4 181.7 200 149.9 176.8 176.81 176.9 176.91 192.5 146.9

80 175.6 173.7 191.1 139.9 209.4 105.4 169 169.01 184.3 137 201.9 102.7 163.3 163.31 177 133.8 194.1 100

85 183.6 183.61 191.7 166.7 209 .8 133 178.1 178.11 184.9 163.7 202.3 130.3 172.3 172.31 177.9 160.6 194.3 127.2

90 192.9 192.91 194.3 194.31 210 159.6 187.3 187.31 187.5 187.51 202.6 156.7 181.4 181.41 181.6 181.61 194.9 153.8

80 178.2 178.21 193.4 145.1 211.6 108.4 172.7 172.71 186.4 142.1 204 105.7 166.9 166.91 179 139 196.1 102.9

85 187.8 187.81 194.2 173.9 212 138 182.1 182.11 187.4 170.9 204.2 134.8 176.1 176.11 180.2 167.8 196.4 131.8

90 197.4 197.41 197.5 197.51 212.3 166.3 191.6 191.61 191.7 191.71 204.7 163.4 185.4 185.41 185.6 185.61 196.9 160.4

Ent

DB °F

80 150.4 147.9 164.6 119.8 181.4 90.8

85 157.3 157.31 165.1 142.4 181.8 114.3

90 165.7 165.71 167.2 165.6 182 136.8

80 153.5 153.51 167.2 125.3 184 94.1

85 162.1 162.11 168 150 184.4 119.7

90 170.8 170.81 171 171.01 184.7 144

80 157.3 157.31 169.5 130.6 186.2 97.2

85 166.2 166.21 170.5 157.5 186.4 124.2

90 175.2 175.21 175.4 175.41 187 150.8

80 160.7 160.71 171.3 135.7 188 100.1

85 169.8 169.81 172.8 164.6 188.4 128.8

90 179.1 179.11 179.3 179.31 188.9 157.4

61 67 73 61 67 73 61 67 73

MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC

Ambient Temperature

115

Enter WB

61 67 73

MBH SHC MBH SHC MBH SHC

14 SSP-PRC001-EN

Page 15

Performance Data

20 Tons Gross Cooling Capacities

Table 6. Gross Cooling Capacities (MBh) 20 Tons TWA240B Heat Pump with 20 Ton TWE240B Air Handler

Ambient Temperature

85 95 105

Entering WB

CFM Air

flow

7200 75 223.8 177.3 246 148.8 269.9 99.5 215.5 173.1 237 145.1 260.1 96.1 206.9 168.8 227.5 141.3 249.8 92.5

8000 75 227.8 185.1 250.2 143.9 274.2 101.4 219.3 180.8 240.9 139.9 264.1 98 210.4 176.4 231.1 135.9 253.4 94.1

8800 75 231.2 192.5 253.6 148.3 277.7 103 222.4 188.2 244.1 144.4 267.4 99.3 213.4 183.7 234.1 140.3 256.4 95.3

9600 75 234 199.6 256.5 152.6 280.7 104.3 225.2 195.2 246.8 148.6 270.1 100.5 216 190.8 236.7 144.5 258.9 96.5

CFM Air

flow

7200 75 198 164.3 217.7 137.3 238.9 88.8

8000 75 201.2 171.9 221 131.7 242.2 90

8800 75 204 179.2 223.7 136.1 244.9 91.2

9600 75 206.6 186.2 226.1 140.3 247 .2 92.4

Notes:

1. Dry coil condition. Total gross capacity (MBh) shown to the left is not applicable. In this case the Sensible Heat Capacity (SHC) is the total capacity.

2. All temperatures are in °F.

3. All capacities shown are gross and have not considered indoor fan heat.

4. To obtain net cooling capacities, subtract indoor fan heat.

5. MBH = Total Gross Cooling Capacity

6. SHC = Sensible Heat Capacity

Ent

DB °F

80 224.8 206.8 246.2 169 269.9 130 216.8 202.6 237.3 165.1 260.1 126.2 208.5 198.4 227.9 161 2 49.8 122.3

85 229.6 229.61 246.4 198.1 270 159.6 222.6 222.61 237.5 194 260.3 155.8 215.3 215.31 228.1 189.7 250 151.9

90 240.5 240.51 247.6 227.3 270 .3 189 233.4 233.41 238.9 223.2 260.6 185.2 225.9 225.91 230 219.1 250.3 181.3

80 229.4 217.4 250.4 176.3 274.1 134 221.2 213.2 241.2 172.4 264.1 130.3 212.8 208.9 231.2 167.9 253.4 126.3

85 236.4 236.41 250.6 207.6 274.3 166.2 229.3 229.31 241.4 203.5 264.3 162.4 221.6 221.61 231.9 199.2 253.7 158.5

90 247.9 247.91 252.5 239.7 274.6 198.2 240.4 240.41 243.8 235.6 264.4 193.9 232.6 232.61 234.7 231.4 253.8 189.7

80 233.5 227.6 253.9 183.3 277.6 137.8 225.3 223.4 244.2 178.8 267.3 134.1 215.8 215.81 234.3 174.5 256.5 130.1

85 242.5 242.51 254.2 216.8 277.9 172.5 235 235.01 244.9 212.7 267.6 168.7 227.1 227.11 235.2 208.4 256.8 164.7

90 254.3 254.31 257 251.7 278 206.3 246.5 246.51 248.2 247.6 267.8 202.3 238.4 238.41 238.2 238.21 257 198.1

80 235.8 235.81 256.6 189.4 280.7 141.5 228.3 228.31 247 185.2 270.1 137.7 220.3 220.31 236.9 180.9 259 133.7

85 247.9 247.91 257.4 225.8 280.9 178.6 240.1 240.11 248 221.6 270.5 174.7 231.9 231.91 238.2 217.2 259.4 170.7

90 260 260.01 259.7 259.71 281.1 214.5 252 252.01 251.8 251.81 270.7 210.4 243.5 243.51 243.4 243.41 259.6 206.2

Ent

DB °F

80 199.9 194.1 218.1 156.9 238.9 118.3

85 207.7 207.71 218.4 185.3 239.2 147.8

90 218 218.01 220.7 214.8 239.3 176.7

80 203 203.01 221.2 163.5 242.3 122.3

85 213.6 213.61 222 194.8 242.6 154.4

90 224.3 224.31 224.1 224.11 242.8 185.4

80 207.8 207.81 224 170.1 245 126

85 218.8 218.81 225.1 204 245.4 160.6

90 229.8 229.81 229.6 229.61 245.6 193.7

80 212 212.01 226.4 176.4 247.3 129.6

85 223.3 223.31 228 212.8 247.7 166.6

90 234.6 234.61 234.5 234.51 248 201.7

61 67 73 61 67 73 61 67 73

MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC MBH SHC

Ambient Temperature

115

Enter WB

61 67 73

MBH SHC MBH SHC MBH SHC

SSP-PRC001-EN 15

Page 16

Performance Data

7½ Tons Gross Cooling Capacities and Capacity Curves

Table 7. Gross Cooling Capacities (MBh) 7½ Tons TWA090A Heat Pump Only

Suction Temperature (°F)

Outdoor

Temp (°F)

Head press PSIG 168 173 179 185 191 197

65

75

85

95

105

115

Notes:

1. Performance data calculated at 15°F subcooling and 20°F superheat and does not include capacity loss due to refrigerant lines.

Cap. Btuh/1000 81 89 97.2 105.8 114.5 123.4

Unit kW 5.56 5.69 5.83 5.97 6.13 6.28

Head press PSIG 194 199 205 211 217 224

Cap. Btuh/1000 77.8 85.3 93.1 101.1 109.4 117.8

Unit kW 6.09 6.23 6.38 6.54 6.7 6.87

Head press PSIG 221 227 234 240 247 254

Cap. Btuh/1000 74.1 81.3 88.7 96.3 104.2 112.3

Unit kW 6.71 6.87 7.03 7.2 7.38 7.56

Head press PSIG 252 258 265 272 279 286

Cap. Btuh/1000 70.3 77.1 84.1 91.4 98.9 106.7

Unit kW 7.43 7.6 7.77 7.95 8.14 8.33

Head press PSIG 285 292 299 306 314 322

Cap. Btuh/1000 66.1 72.6 79.3 86.3 93.5 101.1

Unit kW 8.23 8.41 8.6 8.79 8.98 9.18

Head press PSIG 321 328 336 343 351 360

Cap. Btuh/1000 61.8 67.9 74.3 81 88.1 95.5

Unit kW 9.12 9.32 9.51 9.71 9.91 10.12

30 35 40 45 50 55

Figure 8. Capacity Curves 7½ Tons TWA090A Heat Pump Only

16 SSP-PRC001-EN

Page 17

Performance Data

10 Tons Gross Cooling Capacities and Capacity Curves

Table 8. Gross Cooling Capacities (MBh) 10 Tons TWA120A Heat Pump Only

Suction Temperature (°F)

Outdoor

Temp (°F)

Head press PSIG 167 172 178 183 189 195

65

75

85

95

105

115

Notes:

1. Performance data calculated at 15°F subcooling and 20°F superheat and does not include capacity loss due to refrigerant lines.

Cap. Btuh/1000 110.6 121.1 132.1 143.7 155.9 168.6

Unit kW 7.87 8.04 8.22 8.41 8.61 8.83

Head press PSIG 192 197 202 208 214 221

Cap. Btuh/1000 105.4 115.4 126.1 137.3 149.1 161.4

Unit kW 8.56 8.75 8.95 9.16 9.38 9.62

Head press PSIG 219 224 230 236 243 250

Cap. Btuh/1000 100 109.6 119.9 130.7 142 153.9

Unit kW 9.38 9.59 9.82 10.05 10.3 10.55

Head press PSIG 248 254 260 267 274 281

Cap. Btuh/1000 94.5 103.7 113.5 123.8 134.7 146.1

Unit kW 10.35 10.58 10.82 11.07 11.59

Head press PSIG 281 287 293 300 307 315

Cap. Btuh/1000 88.8 97.6 107 116.8 127.1 137.8

Unit kW 11.45 11.7 11.96 12.22 12.48 12.74

Head press PSIG 316 322 329 336 343 351

Cap. Btuh/1000 83.1 91.4 100.3 109.6 119.2 129.2

Unit kW 12.69 12.95 13.21 13.48 13.73 13.98

30 35 40 45 50 55

Figure 9. Capacity Curves 10 Tons TWA120A Heat Pump Only

SSP-PRC001-EN 17

Page 18

Performance Data

15 Tons Gross Cooling Capacities and Capacity Curves

Table 9. Gross Cooling Capacities (MBh) 15 Tons TWA180B Heat Pump Only

Suction Temperature (°F)

Outdoor

Temp (°F)

Head press PSIG 168 173 179 185 191 197

65

75

85

95

105

115

Notes:

1. Performance data calculated at 15°F subcooling and 20°F superheat and does not include capacity loss due to refrigerant lines.

Cap. Btuh/1000 161.3 177.1 193.6 210.6 228.1 245.8

Unit kW 10.9 11.16 11.43 11.71 12.01 12.32

Head press PSIG 193 199 205 211 217 224

Cap. Btuh/1000 154.9 169.9 185.5 201.5 218 234.8

Unit kW 11.94 12.22 12.51 12.82 13.14 13.47

Head press PSIG 221 227 233 240 247 254

Cap. Btuh/1000 147.7 162 176.8 192.1 207.8 224

Unit kW 13.16 13.46 13.78 14.11 14.46 14.81

Head press PSIG 252 258 265 272 279 286

Cap. Btuh/1000 140.1 153.7 167.8 182.4 197.5 213.1

Unit kW 14.56 14.89 15.23 15.59 15.95 16.32

Head press PSIG 285 292 299 306 313 321

Cap. Btuh/1000 131.9 144.8 158.2 172.2 186.8 202.1

Unit kW 16.14 16.49 16.85 17.23 17.61 18

Head press PSIG 321 328 335 343 351 360

Cap. Btuh/1000 123.3 135.5 148.3 161.8 176 190.9

Unit kW 17.88 18.25 18.64 19.03 19.43 19.83

30 35 40 45 50 55

Figure 10. Capacity Curves 15 Tons TWA180B Heat Pump Only

18 SSP-PRC001-EN

Page 19

Performance Data

20 Tons Gross Cooling Capacities and Capacity Curves

Table 10. Gross Cooling Capacities (MBh) 20 Tons TWA240B Heat Pump Only

Suction Temperature (°F)

Outdoor

Temp (°F)

Head press PSIG 183 190 196 203 211 219

65

75

85

95

105

115

Notes:

1. Performance data calculated at 15°F subcooling and 20°F superheat and does not include capacity loss due to refrigerant lines.

Cap. Btuh/1000 217.4 237.4 258.4 280.5 303.5 327.5

Unit kW 16.09 16.51 16.96 17.44 17.96 18.5

Head press PSIG 209 216 223 231 239 248

Cap. Btuh/1000 206.8 226 246.3 267.6 290 313.3

Unit kW 17.58 18.05 18.56 19.11 19.68 20.28

Head press PSIG 238 245 253 261 270 279

Cap. Btuh/1000 196 214.4 233.9 254.5 276 298.3

Unit kW 19.35 19.88 20.44 21.03 21.65 22.27

Head press PSIG 269 277 285 294 303 313

Cap. Btuh/1000 185 202.6 221.3 240.9 261.4 282.6

Unit kW 21.39 21.97 22.57 23.2 23.83 24.47

Head press PSIG 304 312 320 329 339 349

Cap. Btuh/1000 173.8 190.6 208.4 227.1 246.5 266.5

Unit kW 23.68 24.31 24.95 25.6 26.24 26.87

Head press PSIG 341 349 358 368 378 388

Cap. Btuh/1000 162.4 178.5 195.4 213 231.2 249.9

Unit kW 26.23 26.89 27.56 28.22 28.86 29.46

30 35 40 45 50 55

Figure 11. Capacity Curves 20 Tons TWA240B Heat Pump Only

SSP-PRC001-EN 19

Page 20

Performance Data

7½, 10 Tons Gross Heating Capacities

Table 11. Gross Heating Capacities (MBh) 7½ Tons TWA090A Heat Pump with 7½ Tons TWE090A Air Handler at 3000 CFM

Heating Capacity (BTUH/1000)

Outdoor Temp

(°F)

-18 35.2 32 30.9 30.1 5.4 5.9 6.2 6.5

-13 36.8 34 33.1 32.5 5.5 6 6.3 6.6

-8 38.7 36.4 35.7 35.2 5.6 6.1 6.4 6.7

-3 41.1 39.2 38.7 38.3 5.7 6.2 6.5 6.8

2 44.1 42.5 42 41.8 5.8 6.3 6.6 6.9

7 47.5 46.3 45.9 45.7 5.9 6.5 6.8 7.1

12 51.3 50.3 50 49.9 6 6.6 6.9 7.2

17 55.6 54.8 54.5 54.3 6.2 6.7 7.1 7.4

22 60.3 59.6 59.3 59.1 6.3 6.9 7.2 7.6

27 65.5 64.7 64.4 64.2 6.4 7 7.4 7.7

32 71 70.2 69.9 69.6 6.6 7.2 7.5 7.9

37 76.7 75.8 75.4 75 6.7 7.4 7.7 8.1

42 82.7 81.7 81.2 80.7 6.9 7.5 7.9 8.3

47 89 87.8 87.3 86.7 7 7.7 8.1 8.5

52 95.7 94.4 93.7 93.1 7.2 7.9 8.3 8.7

57 102.7 101.2 100.5 99.7 7.3 8 8.4 8.9

62 109.9 108.2 107.4 106.6 7.5 8.2 8.6 9.1

67 117.3 115.5 114.6 113.8 7.7 8.4 8.8 9.3

72 124.8 122.9 122 121.1 7.9 8.6 9 9.5

Notes:

1. Rated with 25 feet of 13/8" suction and ½" liquid line.

at Indicated Indoor Dry Bulb Temperature

60 70 75 80 60 70 75 80

at Indicated Indoor Dry Bulb Temperature

Total Power in kW

Table 12. Gross Heating Capacities (MBh) 10 Tons TWA120A Heat Pump with 10 Tons TWE120A Air Handler at 4000 CFM

Heating Capacity (BTUH/1000)

Outdoor Temp

(°F)

-18 29.9 42.3 46.5 49.9 7.4 8.4 9 9.5

-13 39.4 47.5 50.6 53 7.7 8.6 9.1 9.6

-8 46.9 52.6 54.8 56.7 7.9 8.8 9.2 9.7

-3 53.7 57.8 59.4 60.7 8.1 9 9.4 9.9

2 60.3 63.1 64.2 65 8.3 9.1 9.6 10

7 66.9 68.6 69.2 69.7 8.5 9.3 9.7 10.2

12 73 .4 74.3 74.6 74.7 8.7 9.5 9.9 10.3

17 80.2 80.3 80.2 80.2 8.9 9.6 10.1 10.5

22 87 .1 86.6 86.3 86 9 9.8 10.2 10.7

27 94 .2 93.2 92.6 92.2 9.2 10 10.4 10.9

32 101.7 100.2 99.5 98.9 9.4 10.2 10.6 11.1

37 109.1 107.2 106.4 105.6 9.5 10.4 10.9 11.4

42 116.7 114.4 113.5 112.7 9.7 10.6 11.1 11.6

47 124.6 122.1 121.1 120.1 9.9 10.8 11.3 11.9

52 132.8 130.1 129 127.9 10.1 11.1 11.6 12.1

57 141.1 138.3 137.1 136 10.4 11.3 11.9 12.4

62 149.6 146.7 145.3 144.1 10.6 11.6 12.1 12.7

67 158.3 155.2 153.8 152.5 10.9 11.9 12.4 13.1

72 167.4 164.1 162.6 161.2 11.2 12.2 12.8 13.4

Notes:

1. Rated with 25 feet of 1 3/8" suction and ½" liquid line.

at Indicated Indoor Dry Bulb Temperature

60 70 75 80 60 70 75 80

at Indicated Indoor Dry Bulb Temperature

Total Power in kW

20 SSP-PRC001-EN

Page 21

Performance Data

15, 20 Tons Gross Heating Capacities

Table 13. Gross Heating Capacities (MBh) 15 Tons TWA180B Heat Pump with 15 Tons TWE180B Air Handler at 6000 CFM

Heating Capacity (BTUH/1000)

Outdoor Temp

(°F)

18 71 65.3 63.5 62.2 11.6 12.6 13.1 13.5

-13 73.8 69 67.5 66.5 11.8 12.7 13.2 13.8

-8 77.4 73.4 72.2 71.5 11.9 12.9 13.5 14

-3 81.8 78.7 77.8 77.3 12.1 13.2 13.7 14.3

2 87 84.6 84 83.7 12.3 13.4 14 14.6

7 93.1 91.2 90.8 90.7 12.6 13.6 14.2 14.9

12 100 98.6 98.3 98 .3 12.8 13.9 14.5 15.2

17 107.8 106.7 106.4 106.5 13 14.2 14.8 15.5

22 116.5 115.5 115.3 115.3 13.3 14.5 15.1 15.8

27 126 125.1 124.9 124.8 13.6 14.8 15.5 16.2

32 136.3 135.4 135.1 134.9 13.9 15.1 15.8 16.6

37 146.8 145.8 145.4 145 14.1 15.4 16.1 16.9

42 157.9 156.7 156.1 155.6 14.4 15.8 16.5 17.3

47 169.7 168.2 167.5 166.8 14.7 16.1 16.9 17.7

52 182.2 180.4 179.6 178.8 15.1 16.5 17.2 18.1

57 195.2 193.2 192.2 191.2 15.4 16.8 17.6 18.5

62 208.7 206.4 205.3 204.2 15.7 17.2 18 18.9

67 222.6 220 218.8 217.6 16.1 17.6 18.4 19.3

72 237 234.2 232.9 231 .7 16.5 18 18.8 19.7

Notes:

1. Rated with 25 feet of 1 3/8" suction and ½" liquid line.

at Indicated Indoor Dry Bulb Temperature

60 70 75 80 60 70 75 80

at Indicated Indoor Dry Bulb Temperature

Total Power in kW

Table 14. Gross Heating Capacities (MBh) 20 Tons TWA240B Heat Pump with 20Tons TWE240B Air Handler at 8000 CFM

Heating Capacity (BTUH/1000)

Outdoor Temp

(°F)

-18 64.1 89.6 97.7 103.6 14.7 17.1 18.3 19.4

-13 81.2 97.6 103.4 107.6 15.4 17.4 18.5 19.5

-8 94.5 106.1 110.1 113.1 15.9 17.8 18.8 19.8

-3 106.6 114.7 117.5 119.5 16.3 18.1 19.1 20.1

2 118.3 123.8 125.6 126.9 16.7 18.5 19.4 20.4

7 130.1 133.4 134.5 135.1 17.1 18.8 19.7 20.7

12 141.9 143.6 144 144.2 17.5 19.2 20.1 21.1

17 154.1 154.4 154.4 154.2 17.9 19.6 20.5 21.6

22 166.7 166 165.5 165 18.2 20 21 22

27 179.9 178.3 177.6 176.8 18.6 20.4 21.4 22.5

32 193.7 191.5 190.5 189.5 19 20.9 21.9 23.1

37 207.6 204.8 203.6 202.5 19.4 21.4 22.4 23.6

42 221.9 218.8 217.4 216.2 19.9 21.9 23 24.2

47 237 233.5 232 230.7 20.4 22.4 23.6 24.8

52 253 249.3 247.6 246.2 20.9 23 24.2 25.5

57 269.6 265.7 263.9 262.3 21.4 23.6 24.9 26.2

62 286.8 282.6 280.6 278.9 22 24.3 25.5 26.9

67 304.4 299.9 297.8 295.8 22.7 25 26.3 27.6

72 322.8 317.9 315.6 313.4 23.4 25.8 27 28.4

Notes:

1. Rated with 25 feet of 1 3/8" suction and ½" liquid line.

at Indicated Indoor Dry Bulb Temperature

60 70 75 80 60 70 75 80

at Indicated Indoor Dry Bulb Temperature

Total Power in kW

SSP-PRC001-EN 21

Page 22

Performance Data

Evaporator Fan Performance, Low Static Fan Drive, 5 Tons

Table 15. Evaporator Fan Performance 5 Ton TWE060A, TWE060B - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00" 1.10" 1.20"

CFM RPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHP

.75 HP Standard Motor & Field Supplied Low Static Drive

1600 578 0.34 625 0.38 676 0.43 727 0.48 778 0.52 828 0.57 879 0.62 930 0.67 963 0.70 995 0.74 1028 0.77 1060 0.8

1700 601 0.35 648 0.4 696 0.44 744 0.49 792 0.54 841 0.59 889 0.64 937 0.69 971 0.73 1005 0.77 1039 0.81 1073 0.84

1800 625 0.36 671 0.41 716 0.46 762 0.51 807 0.56 853 0.61 898 0.66 944 0.71 979 0.76 1015 0.8 1050 0.84 1085 0.88

1900 642 0.4 687 0.45 731 0.5 776 0.55 820 0.6 865 0.66 909 0.71 951 0.75 987 0.80 1023 0.84 1059 0.89 1095 0.93

2000 659 0.44 703 0.49 746 0.54 790 0.6 833 0.65 877 0.7 920 0.75 957 0.8 994 0.84 1031 0.89 1069 0.93 1106 0.98

2100 674 0.48 722 0.54 770 0.6 817 0.65 857 0.7 897 0.75 936 0.8 973 0.85 1009 0.89 1046 0.94 1082 0.99 1119 1.04

2200 689 0.52 741 0.59 793 0.65 845 0.71 881 0.76 917 0.8 953 0.85 989 0.9 1024 0.95 1060 1 1096 104 — —

2300 710 0.57 761 0.63 812 0.7 863 0.76 897 0.81 932 0.86 966 0.91 1001 0.96 1035 1 — — — — — —

2400 730 0.61 780 0.68 830 0.75 880 0.82 913 0.87 946 0.91 979 0.96 1013 1.01 — — — — — — — —

1 HP Oversized Motor & Sheaves

Notes:

1. Data includes pressure drop due to wet coil and 1" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably and

continuously at all cataloged condit ions. Using the full horsepower range of our fan motors as shown in our tabular data will not r esult in nuisance

tripping or premature motor failure. Our product’s warranty will not be affected.

(i)

Field Supplied Low Static Drive (use Table 16)

(i)

.75 HP Standard Motor & Sheaves

Table 16. Low Static Fan Drive 5 Ton TWE060A, TWE060B Air Handler

Motor Sheave Turns Open Nominal RPM

0 752

1 708

2 663

3 619

4 574

5 530

(i)

Field supplied components required:

Blower Sheave: Fixed Pitch (7.8 inch Pitch Diameter)

Blower Sheave: 0.625 inch Bore, Single Groove, "A" Belt

Belt: A48

(i)

22 SSP-PRC001-EN

Page 23

Performance Data

Evaporator Fan Performance, Low Static Fan Drive, 7½ Tons

Table 17. Evaporator Fan Performance 7 1/2 Ton TWE090A, TWE090B - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00"

CFM RPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHP

1.5 HP Standard Motor & Field Supplied

2400 429 0.45 475 0.51 522 0.58 569 0.65 6 15 0.71 662 0.78 708 0.84 755 0.91 783 0.98 811 1.05

2550 453 0.48 496 0.55 539 0.61 582 0.68 626 0.74 669 0.81 712 0.87 756 0.94 785 1 814 1.08

2700 476 0.52 516 0.58 556 0.65 596 0.71 636 0.77 676 0.83 716 0.9 758 0.96 787 1.02 816 1.11

2850 500 0.55 537 0.62 573 0.68 610 0.74 646 0.8 683 0.86 720 0.92 759 0.99 788 1.05 819 1.14

3000 524 0.59 557 0.65 590 0.71 624 0.77 6 57 0.83 690 0.89 723 0.95 760 1.01 790 1.07 821 1.17

3150 546 0.62 577 0.68 609 0.75 640 0.81 6 72 0.87 703 0.94 735 1.00 768 1.07 798 1.15 829 1.25

3300 568 0.65 598 0.72 628 0.79 657 0.85 6 87 0.92 717 0.99 746 1.05 776 1.12 807 1.22 837 1.33

3450 589 0.67 618 0.75 647 0.83 676 0.91 7 05 0.99 733 1.07 762 1.15 791 1.23 820 1.33 849 1.42

3600 611 0.69 639 0.79 666 0.88 694 0.97 7 22 1.06 750 1.16 778 1.25 806 1.34 834 1.43 862 1.51

1.10" 1.20" 1.30" 1.40" 1.50" 1.60" 1.70" 1.80"

CFM RPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHP

2400 840 1.11 868 1.18 896 1.25 924 1.32 9 52 1.39 890 1.46 1009 1.52 1037 1.59

2550 843 1.15 872 1.23 901 1.31 930 1.38 9 59 1.46 988 1.54 1016 1.61 1045 1.69

2700 846 1.19 876 1.28 905 1.36 935 1.45 9 65 1.53 995 1.62 1024 1.7 1054 1.79

2850 849 1.23 880 1.33 910 1.42 941 1.51 971 1.6 1002 1.7 1032 1.79 1063 1.88

3000 853 1.27 884 1.37 915 1.48 946 1.58 9 78 1.68 1009 1.78 1040 1.88 1071 1.98

3150 860 1.35 891 1.45 922 1.56 958 1.66 984 1.76 1014 1.86 1044 1.94 — —

3300 868 1.43 898 1.54 929 1.64 959 1.74 990 1.85 1020 1.95 1049 2.01 — —

3450 879 1.52 908 1.61 937 1.71 966 1.8 995 1.9 1025 2 ————

3600 890 1.6 918 1.69 945 1.78 973 1.87 1001 1.96 ——————

Notes:

1. Data includes pressure drop due to wet coil and 1" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably and

continuously at all cataloged condit ions. Using the full horsepower range of our fan motors as shown in our tabular data will not r esult in nuisance

tripping or premature motor failure. Our product’s warranty will not be affected.

(i)

Field Supplied Low Static Drive (use Table 18)

Low Static Drive

External Static Pressure (Inches of Water Gauge)

2 HP Oversized Motor & Sheaves

(i)

1.5 HP Standard Motor & Sheaves

1.5 HP Standard Motor & Low Static Drive Kit

1.5 HP Standard Motor &

Sheaves

Table 18. Low Static Fan Drive 7½ Tons TWE090A, B Air Handler

Field Supplied Low Static Fan Drive

7½ Tons TWE090A, B Air Handler

Motor Sheave

Turns Open

0 598 0 733

1 563 1 690

2 528 2 647

3 493 3 604

4 458 4 561

5 422 5 518

(i)

Field supplied components required:

Blower Sheave: Fixed Pitch (9.8 inch Pitch Diameter), Blower Sheave: 1.00 inch Bore,

Single Groove, "A" Belt. Belt: A55

Nominal

(i)

RPM

SSP-PRC001-EN 23

Low Static Fan Drive Accessory Kit

7½ Tons TWE090A, B Air Handler

Motor Sheave

Turns Open

Nominal

RPM

Page 24

Performance Data

Evaporator Fan Performance, Low Static Fan Drive, 10 Tons

Table 19. Evaporator Fan Performance 10 Tons TWE120A1, TWE120B1 - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00" 1.20" 1.40" 1.60"

CFM RPM BHP RPM BHP R PM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2 HP Standard Motor and Field Supplied

3200 — — — — 570 0.67 603 0.75 636 0.83 670 0.91 703 1.00 736 1.08 756 1.14 784 1.2 838 1.32 890 1.49 942 1.66

3400 — — 560 0.71 592 0.79 623 0.88 652 0.95 685 1.04 716 1.12 743 1.18 762 1.24 790 1.3 844 1.43 895 1.59 948 1.8

3600 557 0.77 583 0.84 613 0.92 643 1.01 667 1.07 700 1.16 730 1.23 750 1.27 768 1.34 797 1.41 850 1.55 900 1.69 954 1.94

3800 579 0.94 605 1.01 634 1.09 663 1.18 683 1.24 710 1.29 738 1.37 762 1.42 785 1.49 813 1.56 861 1.72 911 1.87 — —

4000 602 1.11 628 1.17 656 1.26 683 1.35 698 1.4 720 1.43 747 1.5 773 1.58 801 1.64 829 1.71 872 1.89 922 2.04 — —

4200 626 1.23 651 1.31 677 1.4 703 1.48 714 1.53 741 1.59 765 1.66 790 1.72 815 1.81 841 1.9 888 2.08 — — — —

4400 649 1.36 674 1.45 698 1.53 723 1.62 729 1.65 761 1.76 784 1.81 807 1.87 830 1.98 852 2.09 ——————

4600 669 1.52 692 1.62 714 1.69 735 1.77 747 1.82 782 1.92 798 1.99 815 2.06 — — — — ——————

4800 689 1.69 711 1.79 729 1.85 746 1.92 764 1.98 802 2.09 — — — — — — — — ——————

Notes:

1. Data includes pressure drop due to wet coil and 1" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably and

continuously at all cataloged condit ions. Using the full horsepower range of our fan motors as shown in our tabular data will not r esult in nuisance

tripping or premature motor failure. Our product’s warranty will not be affected.

(i)

Field Supplied Low Static Drive (use Table 2 0)

Low Static Drive

(i)

2 HP Standard Motor and Sheaves

Table 20. Low Static Fan Drive 10 Tons TWE120A1, TWE120B1 - Air Handler

Motor Sheave Turns Open Nominal RPM

0 745

1 706

2 666

3 627

4 588

5 549

(i)

Field supplied components required:

Blower Sheave: Fixed Pitch (8.8 inch Pitch Diameter)

Blower Sheave: 1.00 inch Bore, Single Groove, "A" Belt

Belt: A54

(i)

24 SSP-PRC001-EN

Page 25

Performance Data

10 Tons Evaporator Fan Performance

Table 21. Evaporator Fan Performance 10 Tons TWE120A3, AW; TWE120B3, BW - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00"

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2 HP Standard Motor & Field Supplied

3200 — — — — 570 0.67 603 0.75 636 0.83 670 0.91 703 1.00 736 1.08 756 1.14 784 1.2

3400 — — 560 0.71 592 0.79 623 0.88 652 0.95 685 1.04 716 1.12 743 1.18 762 1.24 790 1.3

3600 557 0.77 583 0.84 613 0.92 643 1.01 667 1.07 700 1.16 730 1.23 750 1.27 768 1.34 797 1.41

3800 579 0.94 605 1.01 634 1.09 663 1.18 683 1.24 710 1.29 738 1.37 762 1.42 785 1.49 813 1.56

4000 602 1.11 628 1.17 656 1.26 683 1.35 698 1.40 720 1.43 747 1.5 773 1.58 801 1.64 829 1.71

4200 626 1.23 651 1.31 677 1.4 703 1.48 714 1.53 741 1.59 765 1.66 790 1.72 815 1.81 841 1.9

4400 649 1.36 674 1.45 698 1.53 723 1.62 729 1.65 761 1.76 784 1.81 807 1.87 830 1.98 852 2.09

4700 669 1.52 792 1.62 714 1.69 735 1.77 747 1.82 782 1.92 798 1.99 815 2.06 837 2.18 862 2.29

4800 689 1.69 711 1.79 729 1.85 746 1.92 764 1.98 802 2.09 812 2.17 822 2.24 844 2.39 872 2.48

External Static Pressure (Inches of Water Gauge)

1.20" 1.40" 1.60" 1.80" 2.00" 2.20" 2.40"

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

2 HP Standard Motor & Sheaves

3200 838 1.32 890 1.49 942 1.66 1001 1.84 1051 2.03 1106 2.24 1162 2.44

3400 844 1.43 895 1.59 948 1.80 1009 1.98 1057 2.17 1111 2.37 1165 2.57

3600 850 1.55 900 1.69 954 1.94 1016 2.13 1065 2.31 1115 2.51 1167 2.7

3800 861 1.72 911 1.87 959 2.15 1024 2.35 1070 2.54 1120 2.73 1169 2.92

4000 872 1.89 922 2.04 965 2.36 1031 2.57 1077 2.76 1124 2.95 — —

4200 888 2.08 941 2.29 984 2.54 1039 2.73 1083 2.91 1129 3.10 — —

4400 904 2.27 960 2.53 1003 2.71 1047 2.89 1090 3.06 ————

4700 922 2.45 979 2.67 1020 2.86 1061 3.06 ——————

4800 939 2.64 997 2.8 1036 3.02 ————————

Notes:

1. Data includes pressure drop due to wet coil and 1" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably and

(i)

3 HP Oversized Motor & Sheaves

continuously at all cataloged condit ions. Using the full horsepower range of our fan motors as shown in our tabular data will not r esult in nuisance

tripping or premature motor failure. Our product’s warranty will not be affected.

Field Supplied Low Static Drive (use Table 2 2)

Low Static Drive

(i)

3 HP Oversized Motor & Sheaves

2 HP Standard Motor & Sheaves

s

Table 22. Low Static Fan Drive 10 Tons TWE120A3, AW; BE, BW Air Handler

Motor Sheave Turns Open Nominal RPM

0 745

1 706

2 666

3 627

4 588

5 549

(i)

Field supplied components required:

Blower Sheave: Fixed Pitch (8.8 inch Pitch Diameter)

Blower Sheave: 1.00 inch Bore, Single Groove, "A" Belt

Belt: A54

SSP-PRC001-EN 25

(i)

Page 26

Performance Data

Evaporator Fan Performance, Low Static Fan Drive, 15 Tons

Table 23. Evaporator Fan Performance 15 Tons TWE180B - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00" 1.20

CFM RPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHPRPMBHP

3 HP Standard Motor and Field Supplied Low Static Drive

4500 637 1.4 662 1.44 687 1.49 701 1.53 717 1.58 732 1.63 747 1.64 754 1.65 782 1.67 817 1.76 873 1.96

4800 642 1.42 667 1.51 692 1.54 706 1.63 722 1.64 737 1.65 752 1.66 767 1.68 795 1.73 831 1.82 887 2.02

5100 647 1.45 672 1.52 697 1.57 713 1.66 726 1.68 740 1.70 761 1.72 783 1.77 811 1.85 843 1.96 900 2.19

5400 652 1.47 677 1.54 702 1.6 719 1.69 730 1.72 742 1.75 769 1.78 798 1.87 827 1.98 856 2.09 914 2.37

5700 653 1.48 679 1.56 706 1.67 725 1.75 741 1.80 758 1.84 786 1.92 815 2.02 843 2.14 872 2.27 932 2.57

6000 655 1.49 681 1.59 709 1.74 731 1.8 752 1.87 774 1.94 803 2.05 831 2.17 860 2.29 889 2.44 950 2.78

6300 658 1.51 687 1.63 716 1.79 741 1.89 765 1.98 792 2.09 823 2.22 853 2.35 883 2.49 913 2.64 974 2.96

6600 663 1.54 693 1.68 723 1.84 750 1.97 778 2.09 811 2.24 843 2.39 875 2.53 906 2.69 936 2.84 997 3.15

6900 670 1.62 700 1.77 735 1.98 767 2.15 799 2.29 832 2.44 865 2.61 900 2.79 934 2.98 967 3.16 1019 3.48

7200 677 1.7 707 1.86 747 2.12 785 2.33 819 2.49 853 2.65 888 2.83 926 3.05 963 3.27 997 3.49 1041 3.81

External Static Pressure (Inches of Water Gauge)

1.40" 1.60" 1.80" 2.00" 2.20" 2.40"

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

3 HP Standard Motor and

4500 929 2.19 986 2.46 1035 2.74 1084 3.01 1132 3.28 - 4800 943 2.29 999 2.56 1046 2.83 1095 3.11 1143 3.38 - 5100 957 2.48 1012 2.76 1058 3.04 1105 3.31 1152 3.57 - 5400 972 2.67 1024 2.96 1070 3.24 1116 3.51 - - - 5700 990 2.89 1038 3.18 1083 3.46 1127 3.74 - - - 6000 1008 3.11 1052 3.39 1096 3.68 1138 3.96 - - - 6300 1025 3.3 1069 3.61 1113 3.92 1152 4.21 - - - 6600 1042 3.49 1087 3.83 1130 4.16 - - - - - 6900 1063 3.81 1107 4.15 1146 4.49 - - - - - 7200 1085 4.14 1127 4.47 - - - - - - - -

Notes:

1. Data includes pressure drop due to wet coil and 2" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’ s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably

and continuously at all catalog ed con ditio ns. U sing t he ful l hor sepow er r an ge o f our fan mo tors as sho wn in ou r tabu lar d ata will not result

in nuisance tripping or premature motor failure. Our product’s warranty will not be affected.

(i)

Field Supplied Low Static Drive (use Table 24)

Sheaves

5 HP Oversized Motor and Sheaves

(i)

3 HP Standard Motor and Sheaves

5 HP Oversized Motor and Sheaves

Table 24. Low Static Fan Drive 15 Ton TWE180B Air Handler

Motor Sheave Turns Open Nominal RPM

0 776

1 748

2 720

3 692

4 663

5 635

6 607

(i)

Field supplied components required:

Motor Sheave: Variable Pitch (4.3-5.5 inch Pitch Diameter),

0.875 inch Bore, Single Groove, "B" Belt.

Blower Sheave: Fixed Pitch (12.4 inch Pitch Diameter),

1.4375 inch Bore, Single Groove, "B" Belt.

Belt: B67

26 SSP-PRC001-EN

(i)

Page 27

Performance Data

Evaporator Fan Performance, Low Static Fan Drive, 20 Tons

Table 25. Evaporator Fan Performance 20 Ton TWE240B - Air Handler

External Static Pressure (Inches of Water Gauge)

.10" .20" .30" .40" .50" .60" .70" .80" .90" 1.00"

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

5 HP Standard Motor & Field Supplied Low Static Drive

6400 — — — — 570 1.41 612 1.57 654 1.7 696 1.83 743 2.06 781 2.25 808 2.4 835 2.55

6800 — — — — 593 1.58 635 1.74 677 1.90 722 2.08 762 2.29 794 2.46 820 2.61 846 2.76

7200 — — 573 1.58 615 1.75 657 1.92 700 2.09 747 2.33 781 2.52 806 2.66 831 2.81 856 2.96

7600 — — 603 1.84 651 1.98 694 2.15 731 2.38 766 2.57 795 2.74 819 2.88 844 3.02 869 3.17

8000 585 1.97 633 2.11 686 2.21 730 2.39 761 2.66 785 2.81 809 2.95 832 3.09 857 3.23 882 3.37

8400 619 2.2 657 2.35 710 2.54 752 2.73 778 2.94 801 3.09 823 3.23 848 3.39 873 3.55 899 3.71

8800 652 2.43 680 2.60 733 2.86 773 3.07 794 3.22 816 3.36 837 3.50 863 3.68 889 3.86 915 4.04

9200 682 2.76 723 2.98 760 3.19 790 3.37 811 3.52 834 3.68 858 3.84 884 4.01 909 4.2 932 4.4

9600 711 3.08 766 3.36 787 3.52 807 3.67 828 3.82 852 3.99 878 4.17 904 4.35 929 4.53 949 4.75

External Static Pressure (Inches of Water Gauge)

1.20" 1.40" 1.60" 1.80" 2.00" 2.20" 2.40" 2.60"

CFM RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

5 HP Standard Motor & Sheaves 7.5 HP Oversized Motor & Sheaves

6400 883 2.86 930 3.16 976 3.52 1021 3.89 1066 4.26 1111 4.62 1156 4.99 1201 5.36

6800 894 3.07 941 3.4 986 3.78 1030 4.16 1075 4.55 1119 4.93 1164 5.31 — —

7200 904 3.29 951 3.65 995 4.04 1039 4.44 1083 4.84 1127 5.23 1171 5.63 — —

7600 919 3.55 963 3.94 1007 4.34 1050 4.75 1093 5.16 1136 5.57 1179 5.98 — —

8000 933 3.8 975 4.23 1018 4.65 1060 5.07 1103 5.49 1145 5.91 1187 6.34 — —

8400 947 4.14 989 4.57 1032 5.01 1074 5.44 1117 5.87 1159 6.31 1200 6.73 — —

8800 960 4.47 1002 4.92 1045 5.36 1087 5.81 1130 6.26 1172 6.70 ————

9200 975 4.83 1016 5.28 1058 5.73 1099 6.17 1141 6.62 1182 7.07 ————

9600 990 5.2 1030 5.65 1071 6.09 1111 6.54 1152 6.99 1192 7.43 ————

Notes:

1. Data includes pressure drop due to wet coil and 2" filter.

2. Fan motor heat (MBh) = 3.15 x BHP.

3. Trane’s factory supplied motors, in commercial equipment, are definite purpose motors, specifically designed and tested to operate reliably and

continuously at all cataloged condit ions. Using the full horsepower range of our fan motors as shown in our tabular data will not r esult in nuisance

tripping or premature motor failure. Our product’s warranty will not be affected.

(i)

Field Supplied Low Static Drive (use Table 2 6)

(i)

5 HP Standard Motor & Low Static Drive Kit

5 HP Standard Motor & Sheaves

Table 26. Low Static Fan Drive 20 Tons TWE240B/TWE240E Air Handler

Field Supplied Low Static Fan Drive

20 Tons TWE240B/TWE240E Air Handler

Motor Sheave

Turns Open

0 712 0 857

1 686 1 831

2 660 2 805

3 634 3 779

4 609 4 753

5 583 5 727

6 557 6 701

(i)

Field supplied components required:

Motor Sheave: Variable Pitch (4.3-5.5 inch

Pitch Diameter) 1.125 inch Bore, Single Groove, "B" Belt.

Blower Sheave: Fixed Pitch (13.4 inch Pitch Diameter),

1.4375 inch Bore, Single Groove, "B" Belt.

Belt: B67

Nominal

RPM

SSP-PRC001-EN 27

(i)

Low Static Fan Drive Accessory Kit

20 Tons TWE240B/TWE240E Air Handler

Motor Sheave

Turns Open

Nominal

RPM

Page 28

Performance Data

5-20 Tons Motor and Fan Speed, Electric Heat Discharge Plenum and Grille Airflow

Table 27. Standard Motor and Sheave/Fan Speed (RPM) - Air Handler

Sheave Position

Tons Unit Model No.

5

7 1/2

TWE060A

TWE060B

TWE090A

TWE090B

(i)

(i)

(ii)

(ii)

TWE120A1, B1

10

TWE120A3, AW

TWE120B3, BW

15 TWE180B

20 TWE240B

(i)

Factory setting is 3.0 turns open.

(ii)

Factory setting is 4.5 turns open.

(iii)

Factory setting is 4.0 turns open.

(iv)

Factory setting is 6.0 turns open.

(iv)

/TWE240E

(ii)

(iii)

(ii)

(ii)

(iv)

Open

- 714 773 833 892 952 1011

- 726 787 847 908 968 1029

- 702 760 819 877 936 994

- 710 761 812 863 913 964

760 795 831 866 902 937 862 894 926 958 990 1022 1054

Table 28. Oversized Motor and Sheave/Fan Speed (RPM) - Air Handler

6 Turns

Tons Unit Model No.

TWE060A1,B1 - 828 897 966 1035 1104 1173

5

TWE060A3,A4,AW - 863 934 1006 1078 1150 1222

TWE060B3,B4,BW

7½

10

TWE090A1 - 845 915 986 1056 1127 1197

TWE090A3,AW - 847 908 968 1029 1089 1150

TWE120A3,AW

TWE120B3,BW

TWE120A3,AW

TWE120B3,BW

(i)

(i)

(ii)

(ii)

15 TWE180B 946 981 1016 1052 1087 1122 1157

20 TWE240B/TWE240E - 991 1040 1091 1140 1190 1239

(i)

High Static Motor with 6 1/2" Fan Sheave.

(ii)

High Static Motor with 8" Fan Sheave.

6 Turns

Open

- 915 969 1023 1077 1131 1185

- 733 776 819 863 906 949

5 Turns

Open

5 Turns

Open

4 Turns

Open

4 Turns

Open

3 Turns

Open

Sheave Position

3 Turns

Open

2 Turns

Open

2 Turns

Open

1 Turns

Open Closed

1 Turns

Open Closed

Table 29. Electric Heat Discharge Plenum and Grille Airflow (CFM)

Tons Unit Model No. Model No. Minimum Maximum

TWE060A1, B1 BAYHTRL117A 2000 2400

5

TWE060A3, B3 BAYHTRL315A 2000 2400

TWE060A4, B4 BAYHTRL415A 2000 2400

TWE090A1, B1 BAYHTRL117A 3000 3600

7 1/2

TWE090A3, B3 BAYHTRL315A 2625 3600

TWE090A3, B3 BAYHTRL415A 2625 3600

TWE120A1, B1 BAYHTRL117A 3500 4800

10

15

20

(i)

When wired for 460 Volt.

TWE120A3, B3 BAYHTRL315A 4000 4800

TWE120A3, B3

(i)

TWE180B3 BAYHTRM330A 5250 7200

TWE180B4 BAYHTRM430A 5250 7200

TWE240B3/TWE240E3 BAYHTRM330A 7000 9600

TWE240B4/TWE240E4 BAYHTRM430A 7000 9600

28 SSP-PRC001-EN

Electric Heater Airflow (CFM)

BAYHTRL123A 3375 3600

BAYHTRL325A 3000 3600

BAYHTRL425A 2625 3600

BAYHTRL123A 4000 4800

BAYHTRL325A 3500 4800

BAYHTRL415A 3500 4800

BAYHTRL425A 3500 4800

Page 29

Performance Data

Discharge Plenum and Grille Assembly Throw Distance

Table 30. Discharge Plenum and Grille Assembly Throw Distance (ft) — Air Handler

Louver Angle Deflection Position

Tons Model No. CFM Straight 20° 40° 55°

1600 42 31 26 20

TWE060A 1800 46 37 29 22

5

TWE060B 2000 48 43 33 24

2200 51 50 36 25

2400 54 57 39 29

2400 52 43 35 29

TWE090A 2700 55 48 38 31

7½

10

15

20

Notes:

1. Throw distance values are based on a terminal velocity of 75 FPM.

2. Throw distance values at other terminal velocities may be established by multiplying throw

distances in the table above by throw factor

Terminal

Velocity

50 FPM x 1.50

100 FPM x .75

150 FPM x .50

TWE090B 3000 58 53 42 32

3300 62 57 46 35

3600 66 60 50 37

3200 56 46 38 30

TWE120A 3600 62 51 42 33

TWE120B 4000 66 57 47 35

4400 71 62 52 38

4800 76 67 56 42

4900 47 38 32 25

TWE180B 5400 52 44 37 29

6000 57 49 41 32

6600 61 53 43 34

7200 65 57 46 35

6400 56 46 38 30

TWE240B/ 7200 62 51 42 33

TWE240E 8000 66 57 47 35

8800 71 62 52 38

9600 76 67 56 42

Throw

Factor

SSP-PRC001-EN 29

Page 30

Performance Data

5-20 Tons Static Pressure Drop, Auxiliary Heat Capacity

Table 31. Static Pressure Drop Through Accessories (inches of water column)

Tons Unit Model No. CFM

1600 0.12 0.21 0.08 0.08 0.14 - .44 .31

5

7½

10

15

20 TWE240B/TWE240E 8000 0.17 0.66 0.10 0.10 0.20 0.30 .70 .58

(i)

Return air filter ESP included in Fan Performance Table data.

(ii)

At louver opening angle of 42 degrees. For ESP at other angle openings, see accessory Installer’s Guide.

TWE060A 2000 0.18 0.33 0.13 0.13 0.19 - .62 .44

TWE060B 2400 0.28 0.47 0.19 0.19 0.37 - . 80 .59

2400 0.08 0.27 0.03 0.06 0.08 0.12 .38 .23

TWE090A 3000 0.13 0.4 0.06 0.12 0.17 0.23 .50 .33

TWE090B 3600 0.18 0.58 0.08 0.16 0.24 0.32 .66 .44

3200 0.07 0.43 0.06 0.13 0.19 0.26 .42 .40

TWE120A 4000 0.11 0.66 0.10 0.20 0.30 0.40 .59 .56

TWE120B 4800 0.15 0.95 0.14 0.28 0.42 0.57 .76 .75

4800 0.09 0.23 0.03 0.03 0.06 0.08 .46 .38

TWE180B 6000 0.15 0.34 0.06 0.06 0.12 0.17 .64 .54

7200 0.2 0.49 0.08 0.08 0.16 0.24 .82 .72

6400 0.11 0.43 0.06 0.06 0.13 0.19 .50 .41

9600 0.23 0.95 0.14 0.14 0.28 0.42 .89 .78

Return

Grille

Discharge

Plenum and

(ii)

Grille

Electric Heaters (kW) Hydronic Coils

5-10 15-20 25-30 35-50 Steam Hot Water

(i)

- Air Handlers

Table 32. Auxiliary Electric Heat Capacity - Air Handler

Stage 1 Stage 2 Total

Unit Model No.

TWE060A3, A4, AW 9.96 1 9.96 33,993 - - 9.96 33,993

TWE060B3, B4 14.96 1 14.96 51,058 - - 14.96 51,058

TWE090,120A3,AW 9.96 1 9.96 33,993 - - 9.96 33,993

TWE090B3 14.96 1 14.96 51,058 - - 14.96 51,058

TWE120B3, BW 24.92 2 14.96 51,058 9.96 33,993 24.92 85,051

TWE060,090,120A1 5.76 1 5.76 19,659 - - 5.76 19,659

TWE060B1 11.52 1 11.52 39,318 - - 11.52 39,318

TWE090B1 17.28 1 17.28 58,977 - - 17.28 58,977

TWE120B1 23.04 2 11.52 39,318 11.52 39,318 23.04 78,636

TWE090,120A1 28.8 2 17.28 58,977 11.52 39,318 28.8 98,295

TWE120B1

TWE090,120A3, AW 34.88 2 19.92 67,987 14.96 51,058 34.88 119,045

TWE120B3, BW 10.00 1 10.00 34,130 - - 10.00 34,130

TWE180, 240B, 240E 29.92 2 19.92 67,987 10.00 34,130 29.92 102,117

Notes: Heaters are rated at 240V, 480V and 600V. For other than rated voltage capacity = (Voltage/Related Voltage)2 x Rated Capacity.

Total kWNo. of

5.00 1 5.00 17,065 - - 5.00 17,065

24.92 2 14.96 51,058 9.96 33,993 24.92 85,051

5.00 1 5.00 17,065 - - 5.00 17,065

19.92 1 19.92 67,987 - - 19.92 67,987

49.84 2 29.92 102,117 19.92 67,987 49.84 170,104

Stages kW Input

BTUH

Output kW Input

BTUH

Output kW Input

BTUH

Output

30 SSP-PRC001-EN

Page 31

Controls

Thermostats

Two stage heating/cooling or one

stage heating/cooling thermostats

are available in either manual or

automatic changeover.

Programmable Electronic Night

Setback Thermostat

Heating setback and cooling setup

with 7-day, 5-1-1 programming

capability. Available in 2 heating/

cooling or 1 heating/cooling versions

with automatic changeover.

Digital Display Programmable

Thermostat (2H/2C)

Two Heat/Two Cool digital display

thermostat. 7-day programmable

stat with night setback shall be

available.

Figure 12.

Tue

Heat

System & Fan

Hold Until

Fan Auto

Override

More

Touchscreen Programmable

Thermostat (2H/2C)

Two Heat/Two Cool programmable

thermostat with touch screen digital

display. Menu-driven programming.

Effortless set-up. Program each day

separately with no need to copy

multiple days. All programming can

be done on one screen. Easy to read

and use. Large, clear backlit digital

display.

Figure 13.

WED THU FRI

TUE

MON

FAN

ON

AUTO

CIRC

CANCEL

SYSTEM

RESET

PERIOD

EM HEAT

HEAT

OFF

PM

COOL

AUTO

DONE WAKE LEAVE RETURN SLEEP EDIT CANCEL

SAT

DEHUMIDIFIER

SUN

HEAT

COOL

Digital Display Programmable

Thermostat with Built-In Relative

Humidity Sensing (3H/2C)

Three Heat/Two Cool digital display

thermostat with built-in humidity

control and display. This thermostat

combines both humidity and dry

bulb into one. Fully programmable

with night setback.

Figure 14.

Tue

Digital Display Thermostat

(3H/2C)

Three Heat/Two Cool digital display

thermostat. Easy access battery

replacement. Flip-out door for easy

battery replacement without

removing or disassembling the

thermostat.

Figure 15.

RA Remote Sensor

Return Air Remote Sensor which can

be mounted in the return air duct to

report return air temperature.

Room Remote Sensor

Space Remote Sensor which can be

mounted on the wall to report/

control from a remote location in the

space.

Outdoor Thermostat

Outdoor thermostat which can be

mounted outdoors to turn on the

units electric heater at a pre-selected

outdoor temperature.

SSP-PRC001-EN 31

Page 32

Electrical Data

Table 33. Unit Wiring - Heat Pumps

Maximum Fuse Size or

Maximum Circuit

Breaker

Tons Unit Model No.

TWA090A3 187-253 34.5 50

7½

10

15

20

(i)

HACR type circuit breaker per NEC.

TWA090A4 414-506 18.1 25

TWA090AW 518-632 14.5 20

TWA120A3 187-253 48.1 70

TWA120A4 414-506 23.3 35

TWA120AW 518-632 18.8 25

TWA180B3 187-253 62.7 80

TWA180B4 414-506 32.9 45

TWA180BW 518-632 26.3 35

TWA240B3 187-253 87.8 100

TWA240B4 414-506 42.5 50

TWA240BW 518-632 34.2 45

Unit Operating Voltage

Range

Minimum Circuit

Ampacity

Table 34. Electrical Characteristics - Compressor and Condenser Fan Motors - 60 Cycle - Heat Pumps

Compressor Fan Motor Condenser Fan Motor

Amps Amps

Tons Unit Model No.

TWA090A3 1 208-230 3 25.1 182 1 208-230 1 3.1 8.1

7½

10

15

20

TWA090A4 1 460 3 13.2 94.9 1 460 1 1.6 3.7

TWA090AW 1 575 3 10.6 70 1 575 1 1.2 3

TWA120A3 1 208-230 3 33.7 278 1 208-230 1 6 17

TWA120A4 1 460 3 16.5 124 1 460 1 2.7 7

TWA120AW 1 575 3 13.4 92 1 575 1 2 5.7

TWA180B3 2 208-230 3 25.1 182 2 208-230 1 3.1 8.1

TWA180B4 2 460 3 13.2 94.9 2 460 1 1.6 3.7

TWA180BW 2 575 3 10.6 70 2 575 1 1.2 3

TWA240B3 2 208-230 3 33.7 278 2 208-230 1 6 17

TWA240B4 2 460 3 16.5 124 2 460 1 2.7 7

TWA240BW 2 575 3 13.4 92 2 575 1 2 5.7

No. Volts Phase

FLA

(ea.)

LRA

(ea.) No. Volts Phase

(i)

FLA

(ea.)

LRA

(ea.)

32 SSP-PRC001-EN