Installation, Operation,

and Maintenance

Voyager™ Commercial

27.5 to 50 Ton 60 Hz

22.9 to 41.7 Ton 50 Hz

CV, VAV, or SZ VA V Rooftop Air Conditioners

with ReliaTel™ Controls, R-410A Refrigerant

Model Numbers

“B” and later design sequence

TC*, TE*, YC*330B, 360B, 420B, 480B, 600B (60 Hz/3 phase)

TC*, TE*, YC*275B, 305B, 350B, 400B , 500B (50 Hz/3 phase)

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all pr ecautions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

June 2014

RT-SVX34H-EN

Proprietary and Confidential

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provided to alert

installing contractors to potential hazards that could result

in personal injury or death. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situatio n that could

result in equipment or property-damage-only accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. R ead these

carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all Personal Protective Equipment (PPE)

recommended for the work being undertaken.

AL W A Y S ref er to appropr iate MSDS sheets and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of ar c or flash, tec hnicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements fo r arc flash protection, PRIOR to

servicing the unit.

Failure to follow instructions could result in death or

serious injury.

WARNING

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and Carbon

(HCFCs). Not all refrigerants containing these compounds

have the same potential impact to the environment. T rane

advocates the responsible handling of all refrigerantsincluding industry replacements for CFCs such as HCFCs

and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain refrigerants

and the equipment that is used in these service procedures.

In addition, some states or municipalities may have

additional requirements that must also be adhered to for

responsible management of refrigerants. Know the

applicable laws and follow them.

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, y ou MUST follow requirements f or

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Overview of Manual

One copy of the appropriate service literature ships inside

the control panel of each unit. The procedures discussed in

this manual should only be performed by qualified,

experienced HVAC technicians.

Note: Do not release refrigerant to the atmosphere! If

adding or removing refrigerant is required, the

service technician must comply with all federal,

state, and local laws.

This booklet describes the proper installation, startup,

operation, and maintenance procedures for TC_, TE_, and

YC_22.9 to 50 Ton CV (Constant Volume), V AV (Variable Air

V o lu me), and SZ VAV (Single Zone Variable Air Volu me)

applications. Refer to the table of contents for a listing of

specific topics. Refer to “Diagnostics,” p. 117 for

troubleshooting information.

© 2014 Trane All rights reserved RT-SVX34H-EN

By carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component dama ge will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual. Should

equipment failure occur, contact a qualified service

organization with qualified, experienced HVAC technicians

to properly diagnose and repair this equipment.

Revision History

RT-SVX34G-EN (3 June 2014)

• Added features: Low Leak Damper option, eStage,

Ultra Low Leak Power Exhaust, Touchscreen Human

Interface.

• Updated Model Number Description, Startup,

Sequence of Operation, Diagnostics, Unit Wiring

Diagrams.

Warnings, Cautions and Notices

60 Hz units with standard options are certified by

Underwriters Laboratory.

RT-SVX34H-EN 3

Table of Contents

Model Number Description . . . . . . . . . . . . . . . 8

60 Hz Description . . . . . . . . . . . . . . . . . . . . . . 8

50 Hz Description . . . . . . . . . . . . . . . . . . . . . 10

General Information . . . . . . . . . . . . . . . . . . . . 12

Commonly Used Acronyms and Abbrevia-

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

About the Unit . . . . . . . . . . . . . . . . . . . . . 12

Precautionary Measures . . . . . . . . . . . . . 13

Unit Inspection . . . . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unit Dimensions and Weights . . . . . . . . . . . 14

Recommended Clearances . . . . . . . . . . . . . 14

Roof Curb and Ductwork . . . . . . . . . . . . . . . 14

Horizontal Ductwork . . . . . . . . . . . . . . . . . 14

Unit Rigging and Placement . . . . . . . . . . . 20

Installation General Requirements . . . . . . . 23

Condensate Drain Connection . . . . . . . . . . 23

Condensate Overflow Switch . . . . . . . . . . . 23

O/A Sensor & Tubing Installation . . . . . . . 23

Units with Statitrac™ . . . . . . . . . . . . . . . . . 23

Installation Electrical . . . . . . . . . . . . . . . . . . . . 25

Disconnect Switch External Handle (Factory

Mounted Option)

. . . . . . . . . . . . . . . . . . . . . 25

Main Power Wiring . . . . . . . . . . . . . . . . . . . 25

Through-the-Base Electrical (Optional Acces-

sory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical Wire Sizing and Protection Device

Equations

Low Voltage Wiring . . . . . . . . . . . . . . . . . 30

Control Power Transformer . . . . . . . . . . . 30

Field Installed AC Control Wiring . . . . . . 30

Field Installed DC Control Wiring . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remote Panels and Sensors . . . . . . . . . . . 34

Constant Volume and Single Zone VAV Con-

trol Options . . . . . . . . . . . . . . . . . . . . . . . . 34

Variable Air Volume (non-SZ VAV) Control

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation Piping . . . . . . . . . . . . . . . . . . . . . . 38

General Requirements . . . . . . . . . . . . . . . . 38

Connecting the Gas Supply Line to the Fur-

nace Gas Train . . . . . . . . . . . . . . . . . . . . . .38

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Unit Control Modules . . . . . . . . . . . . . . . . . .40

RTRM - ReliaTel™ Refrigeration Module .40

ECA/RTEM - Economizer Actuator/ReliaTel

Economizer Module (Optional) . . . . . . . . .40

EBA - Exhaust Blade Actuator (Optional) .40

RTAM - ReliaTel Air Handler Module (Stan-

dard with Traditional VAV) . . . . . . . . . . . .40

ReliaTel Ventilation Module (RTVM) . . . .41

ReliaTel Dehumidification Module

(RTDM) . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Conventional Thermostat Connections

(Available Only with CV) . . . . . . . . . . . . . .42

TCI - Trane Communication Interface (Option-

al) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

LCI - LonTalk® Communication Interface (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

BCI - BACnet® Communication Interface (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Trane Wireless Comm Interface (WCI) . . . 4 2

TD5 Display - 5" Touchscreen Display . . .42

System Operation . . . . . . . . . . . . . . . . . . . . .43

Economizer Operation with a Conventional

Thermostat (CV Only) . . . . . . . . . . . . . . . .43

Microelectronic Control Features . . . . . . .43

Economizer Operation with CV Controls .44

Modulating Power Exhaust . . . . . . . . . . . .44

Mechanical Cooling without an Economizer

(CV and SZ VAV) . . . . . . . . . . . . . . . . . . . .44

Zone Temperature - Occupied Cooling (CV

and SZ VAV) . . . . . . . . . . . . . . . . . . . . . . . .45

Zone Temperature - Occupied Heating (CV

and SZ VAV) . . . . . . . . . . . . . . . . . . . . . . . .45

Supply Fan (CV and SZ VAV) . . . . . . . . . .45

Supply Air Tempering (CV and SZ VAV) .45

Variable Air Volume Applications (Single

Zone VAV)

Supply Fan Output Control . . . . . . . . . . . .46

Minimum Supply Fan Output . . . . . . . . . .46

Supply Fan Mode Operation . . . . . . . . . . .47

. . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4 RT-SVX34H-EN

Table of Contents

Setpoint Arbitration . . . . . . . . . . . . . . . . . 47

Ventilation Control . . . . . . . . . . . . . . . . . . 50

Space Pressure Control . . . . . . . . . . . . . . 52

Traq Overrides and Special

Considerations . . . . . . . . . . . . . . . . . . . . . 53

Supply Air Temperature Control - Heating

and Cooling . . . . . . . . . . . . . . . . . . . . . . . . 53

Variable Air Volume Applications (Traditional

VAV)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Supply Air Temperature Control - Occupied

Cooling and Heating . . . . . . . . . . . . . . . . 53

Supply Air Temperature Control with an

Economizer . . . . . . . . . . . . . . . . . . . . . . . . 54

VHR Relay Output . . . . . . . . . . . . . . . . . . . 54

Zone Temperature Control without a

Night Setback Panel or ICS - Unoccupied

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Zone Temperature Control without a

Night Setback Panel or ICS - Unoccupied

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Morning Warm-up (MWU) Control . . . . . 54

Daytime Warm-up (DWU) Control . . . . . 54

Supply Duct Static Pressure Control . . . 54

Supply Air Temperature Reset . . . . . . . . 55

VAV Supply Air Tempering (Only Available

with Modulating Gas Heat) . . . . . . . . . . . 55

Constant Volume or Variable Air Volume Applications (Single Zone or Traditional)

Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Zone Temperature - Unoccupied Cooling (CV

or SZ VAV Only) . . . . . . . . . . . . . . . . . . . . 55

Zone Temperature - Unoccupied Heating 55

Mechanical Cooling with an Economizer 56

Gas Heat Control . . . . . . . . . . . . . . . . . . . 56

Electric Heat Control . . . . . . . . . . . . . . . . 56

Clogged Filter Option . . . . . . . . . . . . . . . . 56

Ventilation Override . . . . . . . . . . . . . . . . . 57

Emergency Stop . . . . . . . . . . . . . . . . . . . . 57

Phase Monitor . . . . . . . . . . . . . . . . . . . . . 57

Low Pressure Control . . . . . . . . . . . . . . . . 57

Dehumidification Low Pressure Control . 57

High Pressure Cutout and Temperature Dis-

charge Limit . . . . . . . . . . . . . . . . . . . . . . . 57

Power Exhaust Control (Standard) . . . . . 58

. . . 55

Space Pressure Control - Statitrac . . . . . .58

Power Exhaust Control (Tracking) . . . . . .58

Lead/Lag Control . . . . . . . . . . . . . . . . . . . .58

Coil Frost Protection . . . . . . . . . . . . . . . . .59

Dehumidification Frost Protection . . . . . .59

Drain Pan Condensate Overflow Switch (Op-

tional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

VFD Programming Parameters . . . . . . . . .59

Condenser Fan Sequencing Control . . . . .59

Preparing the Unit for Operation . . . . . . . .62

Electrical Phasing . . . . . . . . . . . . . . . . . . . .62

Voltage Supply and Voltage Imbalance . .63

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . .63

Test Modes . . . . . . . . . . . . . . . . . . . . . . . . .63

Verifying Proper Fan Rotation . . . . . . . . . .68

Verifying Proper Air Flow (CFM) -

CV or VFD's . . . . . . . . . . . . . . . . . . . . . . . . .68

Exhaust Fan Operation . . . . . . . . . . . . . . .75

Economizer Damper Adjustment . . . . . . . .77

Economizer (O/A) Dampers . . . . . . . . . . . .77

For Models with Ultra-Low

Leak Economizers . . . . . . . . . . . . . . . . . . .79

Manual Outside Air Damper . . . . . . . . . . .81

Starting the Compressor . . . . . . . . . . . . . . .82

Starting 27.5 to 35 Ton Standard Efficiency

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Starting 40 to 50 Ton Standard Efficiency

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Starting 27.5-50 Ton High Efficiency Units 82

Line Weights . . . . . . . . . . . . . . . . . . . . . . . .82

Compressor Oil . . . . . . . . . . . . . . . . . . . . .84

Scroll Compressor Operational Noises . .97

Compressor Crankcase Heaters . . . . . . . .97

Charging by Subcooling . . . . . . . . . . . . . .97

Measuring Subcooling . . . . . . . . . . . . . . .97

Gas Heat Units . . . . . . . . . . . . . . . . . . . . . . . .97

Electric Heat Units . . . . . . . . . . . . . . . . . . . . .98

Final Unit Checkout . . . . . . . . . . . . . . . . . . . .98

For Constant Volume Units . . . . . . . . . . . .98

For Variable Air Volume Units . . . . . . . . .98

For Single Zone Variable Air Volume

RT-SVX34H-EN 5

Table of Contents

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . 100

General Unit Requirements . . . . . . . . . . . 100

Downflow/Upflow Models: . . . . . . . . . . 100

All Units: . . . . . . . . . . . . . . . . . . . . . . . . . 100

Electrical Requirements . . . . . . . . . . . . . . 100

Field Installed Control Wiring . . . . . . . . 100

Gas Heat Requirements . . . . . . . . . . . . . . 100

Sequence of Operation . . . . . . . . . . . . . . . . . 101

Mechanical Cooling Sequence

Of Operation

Units Without an Economizer . . . . . . . . 101

Economizer Operation Based on

Dry Bulb . . . . . . . . . . . . . . . . . . . . . . . . . 101

Economizer Operation Based on Reference

Enthalpy . . . . . . . . . . . . . . . . . . . . . . . . . 102

Economizer Operation Based on Compara-

tive Enthalpy . . . . . . . . . . . . . . . . . . . . . . 102

Economizers with Traq . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . 101

Dehumidification (Modulating Hot Gas Reheat) Sequence of Operation

Sensible cooling or heating control overrides

dehumidification control. . . . . . . . . . . . 103

. . . . . . . . . . 103

Gas Heat Sequence Of Operation . . . . . . 103

Constant Volume (CV) Unit Fan

Operation . . . . . . . . . . . . . . . . . . . . . . . . 104

Variable Air Volume (VAV) Unit Fan Operation (2 Stage and Modulating Gas Heat) 104

Variable Air Volume (VAV) Unit Fan Opera-

tion (Modulating Gas Heat Only) . . . . . 104

Ignition Control Module . . . . . . . . . . . . . 104

High Temperature Limit Operation and Loca-

tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Electric Heat Sequence Of Operation . . . 104

Constant Volume (CV) . . . . . . . . . . . . . . 104

Variable Air Volume (VAV) . . . . . . . . . . 105

Variable Air Volume Applications (Single

Zone VAV) Sequence of Operation

Occupied Cooling Operation . . . . . . . . . 105

Occupied Heating Operation . . . . . . . . . 106

Unoccupied Cooling and

Heating Operation . . . . . . . . . . . . . . . . . 106

Dehumidification Operation . . . . . . . . . 106

. . . . . 105

Failure and Overriding Conditions . . . . .107

Low Pressure Control (LPC) Sequence of Operation (ReliaTel Control)

. . . . . . . . . . . . . .108

High Pressure Control and Temperature Discharge Limit (ReliaTel Control)

. . . . . . . . .108

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Fan Belt Adjustment . . . . . . . . . . . . . . . . . .109

Monthly Maintenance . . . . . . . . . . . . . . . . .111

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Condensate Overflow Switch . . . . . . . . .111

Cooling Season . . . . . . . . . . . . . . . . . . . .111

Heating Season . . . . . . . . . . . . . . . . . . . .112

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . .113

Fall Restraint . . . . . . . . . . . . . . . . . . . . . . . . .113

Refrigeration System . . . . . . . . . . . . . . . . .114

Refrigerant Evacuation and Charging . .114

Charge Storage . . . . . . . . . . . . . . . . . . . .114

Compressor Oil . . . . . . . . . . . . . . . . . . . .114

Compressor Replacements . . . . . . . . . . . .115

Electrical Phasing . . . . . . . . . . . . . . . . . . .115

Precision Suction Restrictor . . . . . . . . . .115

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

System Status/Diagnostics . . . . . . . . . . . .117

Terminal locations . . . . . . . . . . . . . . . . . .117

System Status / Diagnostics checkout proce-

dure (DC volt meter required) . . . . . . . . .117

Diagnostics (CV and SZ VAV Units Only) 118

Diagnostics (VAV only) . . . . . . . . . . . . . .118

Resetting Cooling and Ignition Lockouts 119

Zone Temperature Sensor (ZSM) Service In-

dicator . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

RTRM Zone Sensor Module (ZSM) Tests 120

Programmable & Digital Zone Sensor

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

ReliaTel Refrigeration Module (RTRM) .121

Economizer Actuator (ECA/RTEM)

Test Procedures . . . . . . . . . . . . . . . . . . . .121

ReliaTel Air Module (RTAM) Tests . . . . .122

ReliaTel Air Module (RTOM) Tests . . . . .123

Compressor—Blink Codes . . . . . . . . . . . .124

Troubleshooting . . . . . . . . . . . . . . . . . . . . . .124

6 RT-SVX34H-EN

TR-200 VFD Programming Parameters . 130

Unit Wiring Diagram Numbers . . . . . . . . . . 132

Warranty and Liability Clause . . . . . . . . . . . 138

COMMERCIAL EQUIPMENT - 20 TONS AND

LARGER AND RELATED ACCESSORIES

138

Table of Contents

RT-SVX34H-EN 7

Model Number Description

YCD 330 B E L A 0 A1

123 456 7 8 9 10 11 1213

60 Hz Description

Digit 1, 2 — Unit Function

TC = DX Cooling, No Heat

TE = DX Cooling, Electric Heat

YC = DX Cooling, Natural Gas Heat

Digit 3 — Unit Airflow Design

D = Downflow Supply and Return

H = Horizontal Supply and Return

F = Horizontal Supply and Upflow

Return

R = Downflow Supply and Horizontal

Return

Digit 4, 5, 6 — Nominal Cooling

Capacity

330 = 27½ Tons

360 = 30 Tons

420 = 35 Tons

480 = 40 Tons

600 = 50 Tons

Digit 7 — Major Development

Sequence

B = R-410A Refrigerant

Digit 8 — Power Supply

E = 208/60/3

F = 230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 9 — Heating Capacity

0 = No Heat (TC only)

L = Low Heat (YC only)

H = High Heat (YC only)

J = Low Heat-Stainless Steel Gas

Heat Exchanger (YC only)

K = High Heat-Stainless Steel Gas

Heat Exchangers (YC only)

M = Low Heat-Stainless Steel Gas

Heat Exchanger w/

Modulating control

(27.5-35 ton YC only)

P = High Heat-Stainless Steel Gas

Heat Exchangers w/

Modulating control

(27.5-35 ton YC only)

R = Low Heat-Stainless Steel Gas

Heat Exchanger w/

Modulating control

(40-50 ton YC only)

T = High Heat-Stainless Steel Gas

Heat Exchangers w/

Modulating control

(40-50 ton YC only)

1

4

Note: When second digit is “E” for

A = 36 kW (27 kW for 208v)

B = 54 kW (41 kW for 208v)

C = 72 kW

D = 90 kW

E = 108 kW

Electric Heat, the following values

apply in the ninth digit.

Digit 10 — Design Sequence

A = First

Digit 11 — Exhaust

0= None

1 = Barometric Relief (Available

w/ Economizer only)

2 = 100% Power Exhaust Fan

(Available w/ Economizer only)

3 = 50% Power Exhaust Fan

(Available w/ Economizer only)

4 = 100% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

5 = 50% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

6 = 100% Power Exhaust w/

Statitrac™

7 = 100% Fresh Air Tracking Power

Exhaust Fan w/ Ultra Low Leak

Exhaust Damper (Available w/

Economizer only)

8 = 50% Fresh Air Tracking Power

Exhaust Fan w/ Ultra Low Leak

Exhaust Damper (Available w/

Economizer only)

9 = 100% Power Exhaust w/ Ultra L ow

Leak Exhaust Damper w/

Statitrac™

6

Digit 12 — Filter

A = 2” MERV 4, Std Eff, Throwaway

B = 2” MERV 8, High Eff, Throwaway

C = 4” MERV 8, High Eff, Throwaway

D = 4” MERV 14, High Eff, Throwaway

Filters

Filters

Filters

Filters

Digit 13 — Supply F an Motor, HP

1= 7.5 Hp

2=10 Hp

3= 15 Hp

4 = 20 Hp

Digit 14 — Supply Air Fan Drive

Selections3

A = 550 RPM H = 500 RPM

B = 600 RPM J = 525 RPM

C = 650 RPM K = 575 RPM

D = 700 RPM L = 625 RPM

E = 750 RPM M = 675 RPM

F = 790 RPM N = 725 RPM

G = 800 RPM

Digit 15 — Fresh Air Selection

A=No Fresh Air

B = 0-25% Manual Damper

C = 0-100% Economizer, Dry Bulb

Control

D = 0-100% Economizer,

Reference Enthalpy Control

E = 0-100% Economizer,

Differential Enthalpy Control

F = “C” Option and Low Leak

Fresh Air Damper

G = “D” Option and Low Leak

Fresh Air Damper

H = “E” Option and Low Leak

Fresh Air Damper

J = “C” Option and Ultra Low Leak

Outside Air Damper

K = “D” Option and Ultra Low Leak

Outside Air Damper

L = E Option and Ultra Low Leak

Outside Air Damper

1 = Option “C” with Traq

2 = Option “D” with Traq

3 = Option “E” with Traq

4 = Option “F” with Traq

5 = Option “G” with Traq

6 = Option “H” with Traq

7 = Option “C” with Traq w/ Ultra

Low Leak Outside Air Damper

8 = Option “D” with Traq w/ Ultra

Low Leak Outside Air Damper

9 = Option “E” with Traq w/ Ultra Low

Leak Outside Air Damper

Digit 16 — System Control

1 = Constant Volume w/Zone

Temperature Control

2 = Constant Volume w/ Discharge Air

Control

4 = VAV Supply Air Temperature

Control w/Variable Frequency

Drive w/o Bypass

5 = VAV Supply Air Temperature

Control w/Variable Frequency

Drive and Bypass

6 = Single Zone VAV w/VFD w/o

Bypass

7 = Single Zone VAV w/VFD w/

Bypass

8 RT-SVX34H-EN

Model Number Description

A = VAV Supply Air Temperature

Control w/VFD w/o Bypass w/

Motor Shaft Grounding Ring

B = VAV Supply Air Temperature

Control w/VFD w/Bypass w/Motor

Shaft Grounding Ring

C = Single Zone VAV w/VFD w/o

Bypass w/ Motor Shaft Grounding

Ring

D = Single Zone VAV w/VFD w/

Bypass w/Motor Shaft Grounding

Ring

Note: Zone sensors are not included

with option and must be ordered

as a separate accessory.

Miscellaneous Options

Digit 17

A = Service Valves

Note: Service valves cannot be selected

with High Efficiency units

(Digit 29 = K or L). Liquid and

discharge service valves are

included with High Efficiency

units.

2

Digit 18

B = Through the Base Electrical

Provision

Digit 19

C = Non-Fused Disconnect Switch

w/External Handle

Digit 20

D = Factory-Powered 15A GFI

Convenience Outlet and

Non-Fused Disconnect Switch

w/External Handle

Digit 21

E = Field-Powered 15A GFI

Convenience Outlet

Note: If convenience outlet needed w/

High Fault SCCR, option must be

ordered under digit 27.

Digit 22

F = Trane Communication

Interface (TCI)

Digit 23

G = Ventilation Override

Digit 24

H = Hinged Service Access

Digit 25

H = Tool-less Condenser Hail Guards

J = Condenser Coil Guards

Digit 26

K = LCI (LonTalk)

B = BACnet Communications

Interface (BCI)

Digit 27

0 = 5kA SCCR

D = High Fault SCCR w/ Disconnect

E = High Fault SCCR w/ Disconnect w/

Powered Convenience Outlet

7

7

Digit 28

0 = Pre-Painted Steel Drain Pan

M = Stainless Steel Drain Pan

1 = Pre-Painted Steel Drain Pan w/

2 = Stainless Steel Drain Pan w/

Condensate Overflow Switch

Condensate Overflow Switch

Digit 29 — Condenser Coil

Options

0 = Standard Efficiency

J = Corrosion Protected Condenser

K = High efficiency unit (eStage)

L = High efficiency unit (eStage) w/

Condenser Coil

Coil

Corrosion Protected Condenser

Coil

Digit 30-31 — Miscellaneous

Options

P = Discharge Temperature

R = Clogged Filter Switch

Sensor

Digit 32 — Dehumidification

Option

T = Modulating Hot Gas Reheat

Digit 33 — Human Interface

5 = Touchscreen Human Interface, 5"

Model Number Notes

1. All voltages are across the line

starting only.

2. Option includes Liquid, Discharge,

Suction Valves.

3. Supply air fan drives A thru G are

used with 27½-35 ton units only and

drives H thru N are used with 40 & 50

ton units only.

4. Electric Heat KW ratings are based

upon voltage ratings of 208/240/480/

600 V. For a 240 V heater derated to

208 V, the resulting kW rating

decreases from 36 kW to 27 kW, and

from 54 kW to 41 kW. Voltage

offerings are as follows:

Electric

Heater

Rated

Tons

Voltage

27½

to 35

40

and

50

5. The service digit for each model

number contains 32 digits; all 32

digits must be referenced.

6. Ventilation override exhaust mode is

not available for the exhaust fan with

fresh air tracking power exhaust. V OM

is available for the exhaust fan

without fresh air tracking power

exhaust.

7. High fault is 65kA on 208/230/460V

and 25kA on 575V.

27/3641/

208 x x

240 x x

480 xxxx

600 x x x

208 x

240 x

480 x x x x

600 x x x x

KW

54 72 90 108

RT-SVX34H-EN 9

Model Number Description

YCD 275 B C L A 0 A1

123 456 7 8 9 10 11 1213

50 Hz Description

Digits 1, 2 – Unit Function

TC = DX Cooling, No Heat

TE = DX Cooling, Electric Heat

YC = DX Cooling, Natural Gas Heat

Digit 3 – Unit Airflow Design

D = Downflow Supply and Return

H = Horizontal Supply and Return

F = Horizontal Supply and Upflow

Return

R = Downflow Supply and Horizontal

Return

Digits 4, 5, 6 – Nominal Cooling

Capacity

275 = 22.9 Tons (82 kW)

305 = 25.4 Tons (89 kW)

350 = 29.2 Tons (105 kW)

400 = 33.3 Tons (120 kW)

500 = 41.7 Tons (148 kW)

Digit 7 – Major Development

Sequence

B = R-410A Refrigerant

Digit 8 – Power Supply

C = 380/50/3

D = 415/50/3

Digit 9 – Heating Capacity

0 = No Heat (TC only)

L = Low Heat (YC only)

H = High Heat (YC only)

Note: When second digit is “E” for

Electric Heat, the following values

apply in the ninth digit.

380V / 415V

A = 23 kW / 27 kW

B = 34 kW / 40 kW

C = 45 kW / 54 kW

D = 56 kW / 67 kW

E = 68 kW / 81 kW

Digit 10 – Design Sequence

A=First

Digit 11 – Exhaust6

0= None

1 = Barometric Relief (Available

w/Economizer only)

2 = 100% Power Exhaust Fan

(Available w/ Economizer only)

3 = 50% Power Exhaust Fan

(Available w/ Economizer only)

4 = 100% Fresh Air Tracking Power

Exhaust Fan (Available

w/Economizer only)

5 = 50% Fresh Air Tracking Power

Exhaust Fan (Available

w/ Economizer only)

6 = 100% Power Exhaust w/

Statitrac™

1

4

7 = 100% Fresh Air Tracking Power

8 = 50% Fresh Air Tracking Power

9 = 100% Power Exhaust w/ Ult ra Low

Exhaust Fan w/ Ultra Low Leak

Exhaust Damper (Available w/

Economizer only)

Exhaust Fan w/ Ultra Low Leak

Exhaust Damper (Available w/

Economizer only)

Leak Exhaust Damper w/

Statitrac™

Digit 12 – Filter

A = 2” (51 MM) MERV 4, Std Eff,

B = 2” (51 MM) MERV 8, High Eff,

C = 4” (102 MM) MERV 8, High Eff,

D = 4” (102 MM) MERV 14, High Eff,

Throwaway Filters

Throwaway Filters

Throwaway Filters

Throwaway Filters

Digit 13 – Supply Fan Motor, HP

1 = 7.5 Hp (5.6 kW)

2 = 10 Hp (7.5 kW)

3=15 Hp (10 kW)

4 = 20 Hp (15 kW)

Digit 14 – Supply Air Fan Drive

Selections

A = 458 RPM H = 417 RPM

B = 500 RPM J = 437 RPM

C = 541 RPM K = 479 RPM

D = 583 RPM L = 521 RPM

E = 625 RPM M = 562 RPM

F = 658 RPM N = 604 RPM

G = 664 RPM

3

Digit 15 – Fresh Air Selection

A=No Fresh Air

B = 0-25% Manual Damper

C = 0-100% Economizer, Dry Bulb

D = 0-100% Economizer,

E = 0-100% Economizer,

F = “C” Option and Low Leak

G = “D” Option and Low Leak

H = “E” Option and Low Leak

J = “C” Option and Ultra Low Leak

K = “D” Option and Ultra Low Leak

L = “E” Option and Ultra Low Leak

1 = Option “C” with Traq

2 = Option “D” with Traq

3 = Option “E” with Traq

4 = Option “F” with Traq

Control

Reference Enthalpy Control

Differential Enthalpy Control

Fresh Air Damper

Fresh Air Damper

Fresh Air Damper

Outside Air Damper

Outside Air Damper

Outside Air Damper

5 = Option “G” with Traq

6 = Option “H” with Traq

7 = Option “C” with Traq w/ Ultra

8 = Option “D” with Traq w/ Ultra

9 = Option “E” with Traq w/ Ultra L ow

Low Leak Outside Air Damper

Low Leak Outside Air Damper

Leak Outside Air Damper

Digit 16 – System Control

1 = Constant Volume w/ Zone

2 = Constant V olume w/ Di scharge Air

4 = VAV Supply Air Temperature

5 = VAV Supply Air Temperature

6 = Single Zone VAV w/VFD w/o

7 = Single Zone VAV w/VFD w/

A = VAV Supply Air Temperature

B = VAV Supply Air Temperature

C = Single Zone VAV w/VFD w/o

D = Single Zone VAV w/VFD w/

Note: Zone sensors are not included

Temperature Control

Control

Control w/Variable Frequency

Drive w/o Bypass

Control w/Variable Frequency

Drive and Bypass

Bypass

Bypass

Control w/VFD w/o Bypass w/

Motor Shaft Grounding Ring

Control w/VFD w/Bypass w/Motor

Shaft Grounding Ring

Bypass w/ Motor Shaft Grounding

Ring

Bypass w/Motor Shaft Grounding

Ring

with option and must be ordered

as a separate accessory.

Miscellaneous Options

Digit 17

A = Service Valves

Note: Service valves cannot be selected

with High Efficiency units

(Digit 29 = K or L). Liquid and

discharge service valves are

included with High Efficiency

units.

2

Digit 18

B = Through the Base Electrical

Provision

Digit 19

C = Non-Fused Disconnect Switch

with External Handle

Digit 20

* = Unused Digit

Digit 21

* = Unused Digit

10 RT-SVX34H-EN

Model Number Description

Digit 22

F = Trane Communication Interface

(TCI)

Digit 23

G = Ventilation Override

Digit 24

H = Hinged Service Access

Digit 25

H = Tool-less Condenser Hail Guards

J = Condenser Coil Guards

Digit 26

K = LCI (LonTalk)

B = BACnet Communications

Interface (BCI)

Digit 27

0 = 5kA SCCR

D = High Fault SCCR w/ Disconnect

Digit 28

0 = Pre-Painted Steel Drain Pan

M = Stainless Steel Drain Pan

1 = Pre-Painted Steel Drain Pan w/

Condensate Overflow Switch

2 = Stainless Steel Drain Pan w/

Condensate Overflow Switch

Digit 29 — Condenser Coil

Options

0 = Standard Efficiency

Condenser Coil

J = Corrosion Protected Condenser

Coil

K = High efficiency unit (eStage)

L = High efficiency unit (eStage) w/

Corrosion Protected Condenser

Coil

Digit 30-31 — Miscellaneous

Options

P = Discharge Temperature Sensor

R = Clogged Filter Switch

Digit 32 — Dehumidification

Option

T = Modulating Hot Gas Reheat

Digit 33 — Human Interface

5 = Touchscreen Human Interface, 5"

29.2 ton (82-105 kW) units only and

heaters B, C, D, E are used with 33.3-

41.7 ton (120-148 kW) units only.

5. The service digit for each model

number contains 32 digits; all 32

digits must be referenced.

6. Ventilation override exhaust mode is

not available for the exhaust fan with

fresh air tracking power exhaust. VOM

is available for the exhaust fan

without fresh air tracking power

exhaust.

Model Number Notes

1. All voltages are across-the-line

starting only.

2. Option includes Liquid, Discharge,

Suction Valves.

3. Supply air fan drives A thru G are

used with 22.9-29.2 ton (82-105 kW)

units only and drives H through N are

used with 33.3 and 41.7 ton (120-148

kW) units only.

4. Electric Heat kW ratings are based

upon voltage ratings of 380/415 V.

Heaters A, B, C, D are used with 22.9-

RT-SVX34H-EN 11

General Information

Commonly Used Acronyms and Abbreviations

BAS = Building Automation System PSIG = Pounds Per Square Inch Gauge pressure

CFM = Cubic Feet per Minute PHM = Phase monitor

CLV = Cooling Valve (Reheat only) R/A = Return Air

COMM = Module Designation for TCI/LCI RAH = Return Air Humidity

CV = Constant Volume RAT = Return Air Temperature sensor

CW = Clockwise RH = Right Hand

CCW = Counterclockwise RHP = Reheat Pumpout Solenoid

DSP = Direct Space Pressure control RHV = Reheat Valve

DTS = Discharge Air Sensor RLP = Reheat Low Pressure Cutout

DWU = Daytime Warm-up RPM = Revolutions Per Minute

E/A = Exhaust Air RTAM = ReliaTel Air Handler Module

ECA = Economizer Actuator RTDM = ReliaTel Dehumidification Module

EET = Entering Evaporator Temperature Sensor RTVM = ReliaTel Ventilation Module

F/A = Fresh Air RTOM = ReliaTel Options Module

FDD = Fault Detection & Diagnostics RTRM = ReliaTel Refrigeration Module

FFS = Fan Failure Switch S/A = Supply Air

HI = Human Interface SCCR = Short Circuit Current Rating

ICS = Integrated Comfort System (See BAS) SPC = Space Pressure Calibration Solenoid

IDM = Indoor Fan Motor SPP = Space Pressure Transducer

I/O = Input/Output SPT = Static Pressure Transducer

IOM =

LCI = LonTalk® Communication Interface TCI = Trane Communication Interface

LCI-R = LonTalk Communication Interface with ReliaTel TCO = Temperature Cutout

LH = Left Hand TD5 = 5" Touchscreen Display

MAS = Mixed Air Sensor TDL = Temperature Discharge Limit

MAT = Mixed Air Temperature VAV = Variable Air Volume

MCHE = Microchannel VFD = Variable Frequency Drive

MWU = Morning Warm Up VHR = Ventilation Heat Relay (VAV box relay)

NSB = Night Setback (programmable ZSM BAYSENS119*) W.C. = Water Column

O/A = Outside Air WCI = Wireless Comm Interface

OAH = Outside Air Humidity XFSP = Exhaust Fan Setpoint

OAT = Outside Air Temperature ZSM = Sensor, Zone Sensor, Zone Sensor Module, Zone Panel

PGA = Power Exhaust Actuator

Installation, Operation and Maintenance manual (Ships

with each unit)

SZVAV = Single Zone Variable Air Volume

About the Unit

Overall unit dimensional data is illustrated in Figure 1,

p. 14 to Figure 9, p. 18. Each package rooftop unit ships

fully assembled and charged with the proper refrigerant

quantity from the factory. They are controlled by a

microelectronic unit control processor . Several solid state

modules are grouped to form the “Control System”. The

number of modules within any given control system will

be dependent upon the options and accessories ordered

Basic unit components include:

• Scroll compressors

• One (1) Intertwined Evaporator Coil

• One (1) Supply Fan

• Three (3) to Four (4) Condenser Fans

• Microchannel Condenser Coils

• Filters (type is dependent on opti on selection)

with the unit. Acronyms are used extensively throughout

this manual when referring to the “Control System”.

12 RT-SVX34H-EN

Precautionary Measur es

WARNING

Fiberglass Wool!

Product contains fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or rep air will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. You MUST wear all necessary Personal

Protective Equipment (PPE) including gloves, eye

protection, mask, long sleev es and pants when w orking

with products containing fiberglass wool. Exposition to

glass wool fibers without all necessary PPE equipment

could result in cancer, respiratory, skin or eye irritation,

which could result in death or serious injury.

- Avoid breathing fiberglass dust.

- Use a NIOSH approved dust/mist respirator.

- Avoid contact with the skin or eyes. Wear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

- Wash clothes separately from other clothing: rinse

washer thoroughly.

- Operations such as sawing, blowi ng , tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact - Flush eyes with water to remove dust. If

symptoms persist, seek medical attention.

Skin Contact - Wash af fected areas gently with soap and

warm water after handling.

An optional roof curb, specifically designed for the V oyager

commercial rooftop units is available from T rane. The roof

curb kit must be field assembled and installed according to

the latest edition of the curb installation guide.

Unit Inspection

As soon as the unit arrives at the job site:

• V erify that the nameplate data corresponds to the sales

order and bill of lading (including electrical data).

• Visually inspect the exterior of the unit, including the

roof, for physical signs of shipping damage.

• Check for material shor tages. Figure 11, p. 19 illustrates

where “ship with” items are placed inside the unit.

If the job site inspection reveals damage or material

shortages, file a claim with the carrier immediately . Specify

the type and extent of the damage on the “bill of lading”

before signing. Do not install a damaged unit without the

Appropriate Trane sales representative's approval!

• Visually check the internal components for shipping

damage as soon as possible after delivery and before it

is stored. Do not walk on the sheet metal base pans.

General Information

WARNING

No Step Surface!

Do not walk on the sheet metal drain pan. Walking on

the drain pan could cause the supporting metal to

collapse, resulting in the operator/technician to fall.

Failure to follow this recommendation could result in

death or serious injury.

Bridging between the unit's main supports may consist of

multiple 2 by 12 boards or sheet metal grating.

• If concealed damage is discovered, notify the carrier's

terminal office immediately by phone and by mail.

Concealed damage must be reported within 15 days.

• Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove the

damaged material from the receiving location. Take

photos of the damage, if possible. The owner must

provide reasonable evidence that the damage did not

occur after delivery.

Storage

Take precautions to prevent condensate formation inside

the unit electrical components and motors when:

a. The unit is stored before it is installed; or,

b. The unit is set on the roof curb and temporary

auxiliary heat is provided in the building.

Isolate all side panel service entrances and base pan

openings (e.g., conduit holes, S/A and R/A openings, and

flue openings) to minimize ambient air from entering the

unit until it is ready for startup.

Do not use the unit heater as temporary heat without

completing the startup procedures detailed under

“Startup,” p. 40.

Trane will not assume responsibility for equipment

damage resulting from accumulation of condensate on the

unit electrical components.

RT-SVX34H-EN 13

Unit Dimensions and Weights

Recommended Clearances

Adequate clearance around and above each Voyager

Commercial unit is required to ensure proper operation

and to allow sufficient access for servicing.

If the unit installation is higher than the typical curb

elevation, a field constructed catwalk around the unit is

recommended to provide safe, easy access for

maintenance and servicing. Table 1, p. 20 lists the

recommended clearances for single and multiple unit

installation. These clearances are necessary to assure

adequate serviceability, cataloged capacities, and peak

operating efficiency.

If the clearances available on the job site appear to be

inadequate, review them with your Trane sales

representative.

Roof Curb and Ductwork

The curbs for the 27.5 to 50 Ton commercial rooftop units

enclose the entire unit base area. They are referred to as

“full perimeter” type curbs.

Step-by-step instructions for the curb assembly and

installation with curb dimensions and curb configuration

for “A”, “B”, and “C” cabinets ship with each Trane

accessory roof curb kit. (See the latest edition of the curb

installation guide) Follow the instructions carefully to

assure proper fit when the unit is set into place.

The S/A and R/A ductwork adjoining the roof curb must be

fabricated and installed by the installing contractor b efore

the unit is set into place. Trane curbs include flanges

around the openings to accommodate duct attachment.

Ductwork installation recommendations are included in

the instruction booklet that ships with each Trane

accessory roof curb kit.

Note: For sound consideration, cut on ly the holes in the

roof deck for the supply and return duct

penetration. Do Not remove the roof decking from

the inside perimeter of the curb.

the unit into the ductwork. Refer to figures beginning on

page 14 for the S/A and R/A opening dimensions.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

If optional power exhaust is selected, an access door must

be field-installed on the horizontal return ductwork to

provide access to exhaust fan motors.

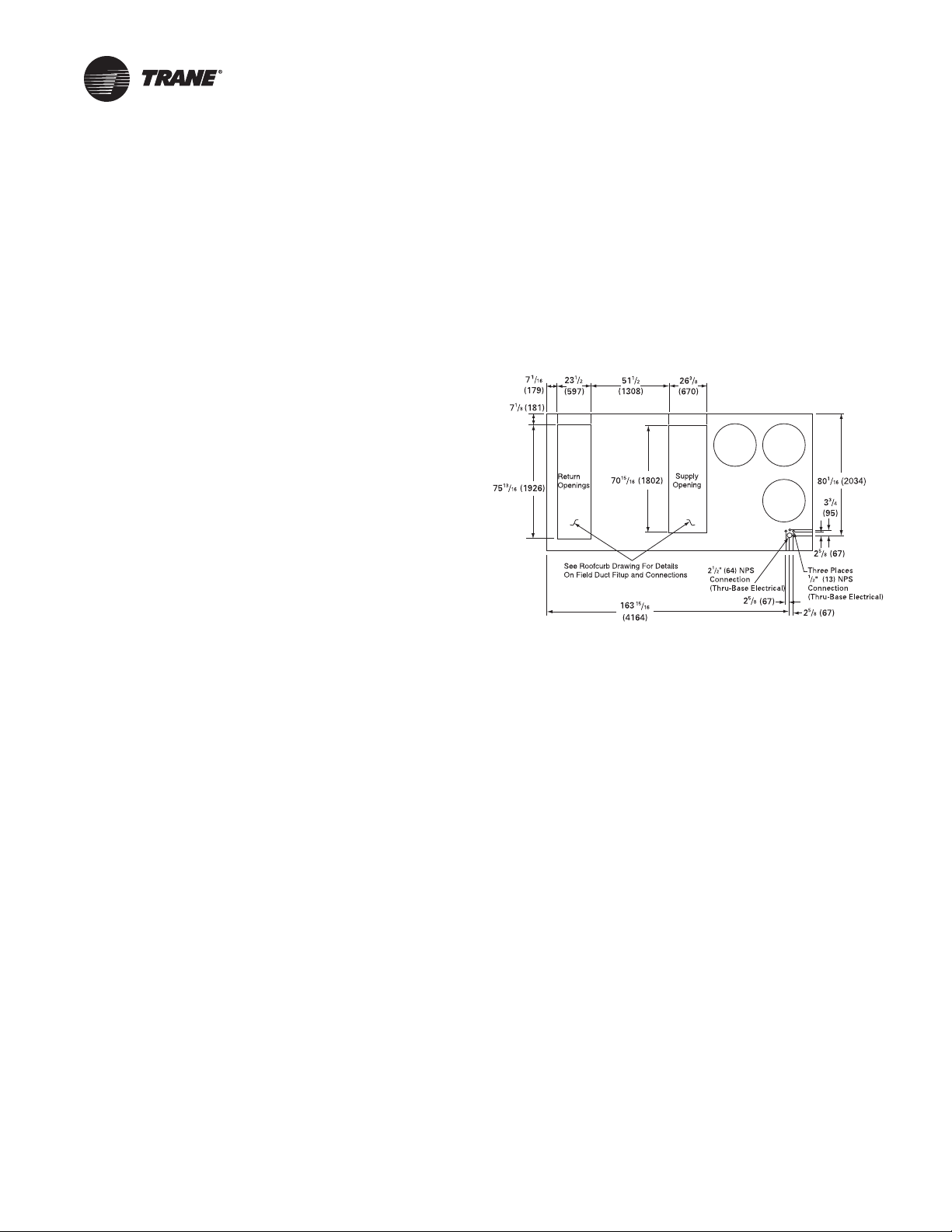

Figure 1. 60 Hz 27½-35, 50 Hz 23-29 Tons (TCD, TED,

YCD low heat)

If a Trane curb accessory kit is not used:

a. The ductwork can be attached directly to the S/A

and R/A openings. Be sure to use a flexible duct

connector at the unit.

b. For “built-up” curbs supplied by others, gask ets

must be installed around the curb perimeter flange,

Supply Air opening, and Return Air openings.

c. Insulation must be installed on the bottom of the

condenser section of the unit.

Horizontal Ductwork

When attaching the ductwork to a horizontal supply or

horizontal return unit, provide a water tight flexible

connector at the unit to prevent noise transmission from

14 RT-SVX34H-EN

Unit Dimensions and Weights

1 1/4

(32)

3 1/4

(81)

NOTES:

1. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

179 3/4"

4565.65mm

42"

1066.8mm

83 13/16"

2128.8mm

90 1/16"

2287.5mm

180 5/16"

4579.9mm

90 3/8"

2295.5mm

5 3/8"

136.5mm

7 9/16"

192.1mm

3.25 [82.55mm] TO TOP OF FAN GRILLE

70 7/16"

1789.1mm

31.39"

797.3mm

6.91"

175.6mm

1 1/4" [31.7mm]

FEMALE

PVC PIPE

3/4" [19.0mm] NPT

GAS INLET

SEE NOTE 2

CUSTOMER

CONNECTION POINT

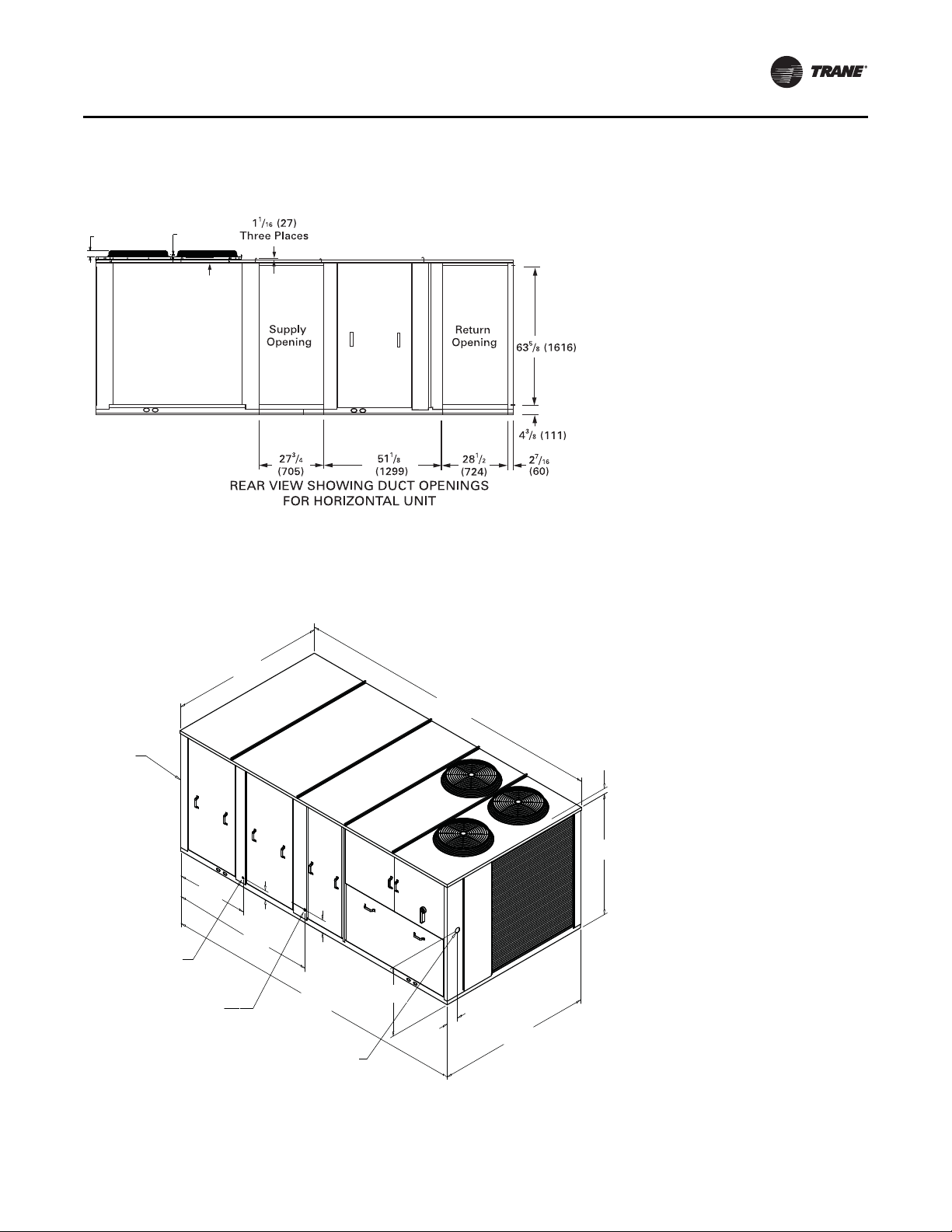

Figure 2. Rear view showing duct openings for horizontal supply and return, 60 Hz 27½-35, 50 Hz 23-29 Tons (TCH,

TEH, YCH low heat)

Notes:

• For combination of horizontal and downflow openings

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

Figure 3. 60 Hz 27½-35 , 50 Hz 23-29 T o ns (TC, TE, YC low heat)

(digit 3 = F or R) see Figure 1, p. 14 for appropriate

downflow/upflow dimensions and Figure 2, p. 15 for

appropriate horizontal dimensions.

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

RT-SVX34H-EN 15

Unit Dimensions and Weights

1 1/4

(32)

3 1/4

(81)

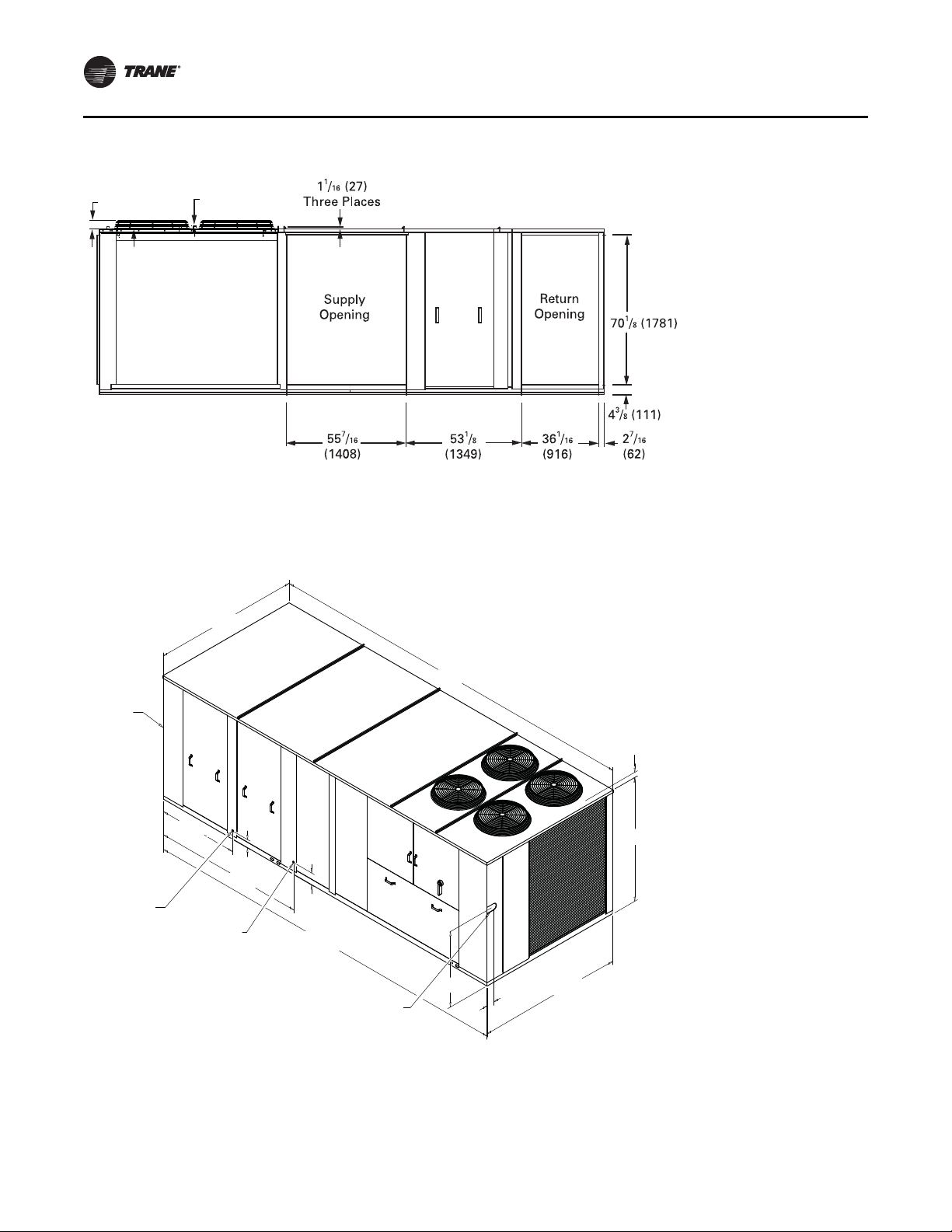

Figure 4. 60 Hz 27½-35, 50 Hz 23-29 Tons (YD high heat)

191

Figure 5. Duct openings, 60 Hz 27½-35, 50 Hz 23-29 Tons (YH high heat)

Notes:

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

• For combination of horizont al and downflow openings

(digit 3 = F or R) see Figure 4, p. 16 for appropriate

downflow/upflow dimensions and Figure 5, p. 16 for

appropriate horizontal dimensions.

16 RT-SVX34H-EN

Figure 6. 60 Hz 27½-35 , 50 Hz 23-29 Tons (YC high heat)

5270.5mm

207 1/2"

42"

5 3/8"

83 13/16"

2128.8mm

7 9/16"

208 1/16"

5284.7mm

90 5/8"

2301.8mm

90 1/16"

70 7/16"

31.39"

6.89"

PVC PIPE FEMALE

1" [25.4MM] NPT

GAS INLET

NOTES:

1. SEE ROOFCURB DRAWING FOR DETAILS

ON FIELD DUCT FITUP AND CONNECTIONS

2. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

SEE NOTE 2

CUSTOMER

CONNECTION POINT

1066.8mm

2287.5mm

136.5m

192.1m

3.25 [82.55mm] TO

TOP OF FAN GRILLE

1789.1mm

797.3mm

175mm

1 1/4" [31.7mm]

Unit Dimensions and Weights

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

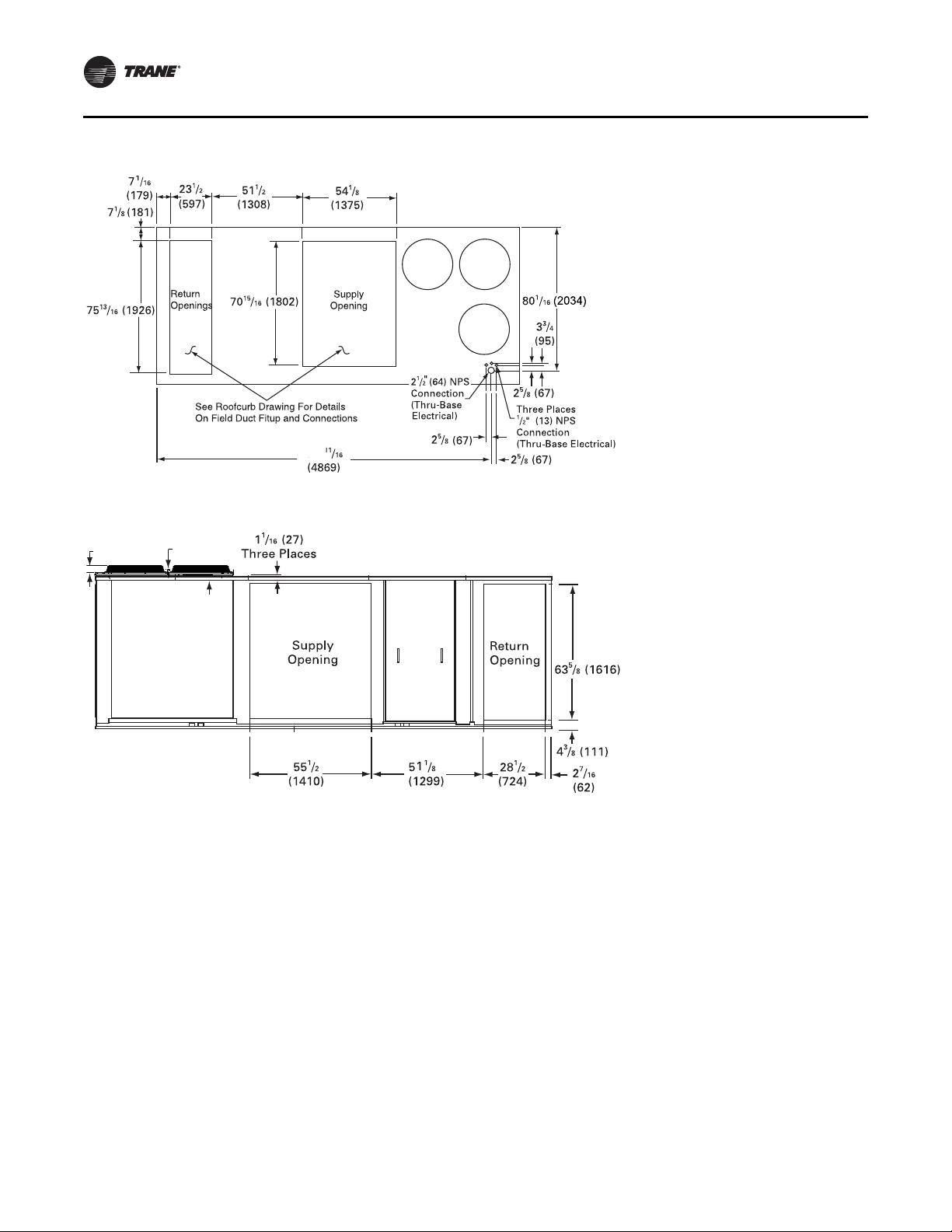

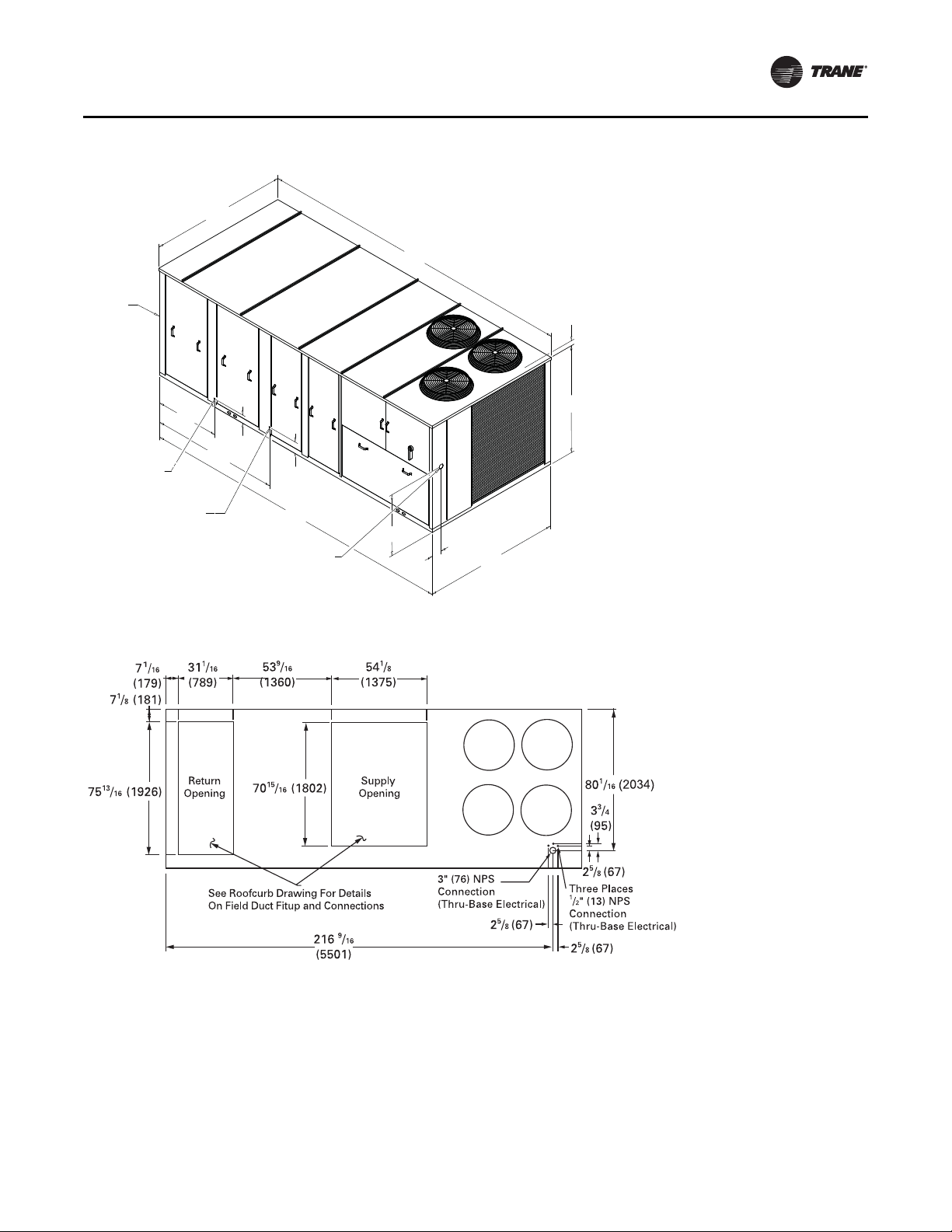

Figure 7. 60 Hz 40-50, 50 Hz 33-42 Tons (TD, TD, YD low and high heat)

RT-SVX34H-EN 17

Unit Dimensions and Weights

1 1/4

(32)

3 1/4

(81)

7 9/16"

232 3/8"

5902.3mm

232 3/4"

5911.8mm

90 5/8"

49 9/16"

1258.8mm

93 3/8"

2371.7mm

5 5/16"

90 1/16"

77"

1955.8mm

32.84"

834.2mm

4.66"

118.4mm

NOTES:

1. SEE ROOFCURB DRAWING FOR DETAILS

ON FIELD DUCT FITUP AND CONNECTIONS

2. SEE DETAIL HOOD DRAWING FOR HORIZONTAL /

DOWNFLOW UNITS FOR ADDITIONAL DIMENSION

AND LOCATION.

SEE NOTE 2

CUSTOMER

CONNECTION POINT

2301.8mm

PVC PIPE FEMALE

1" [25.4MM] NPT

HIGH HEAT GAS INLET

2287.5mm

136.5m

192.1m

3.25 [82.55mm] TO

TOP OF FAN GRILLE

1 1/4" [31.7mm]

3/4" [19MM] NPT

LOW HEAT GAS INLET

Figure 8. Duct openings, 60 Hz 40-50, 50 Hz 33-42 Tons (TH, TH, YH low and high heat)

Notes:

• On horizontal units, the VFD is located between the

supply and return ductwork, which makes access

limited.

• For combination of horizontal and downflow openings

(digit 3 = F or R) see Figure 7, p. 17 for appropriate

downflow/upflow dimensions and Figure 8, p. 18 for

appropriate horizontal dimensions.

Figure 9. 60 Hz 40-50, 50 Hz 33-42 Tons (TC, TE, Y C low and high heat)

Note: Dimensions in ( ) are mm, 1”= 25.4 mm.

18 RT-SVX34H-EN

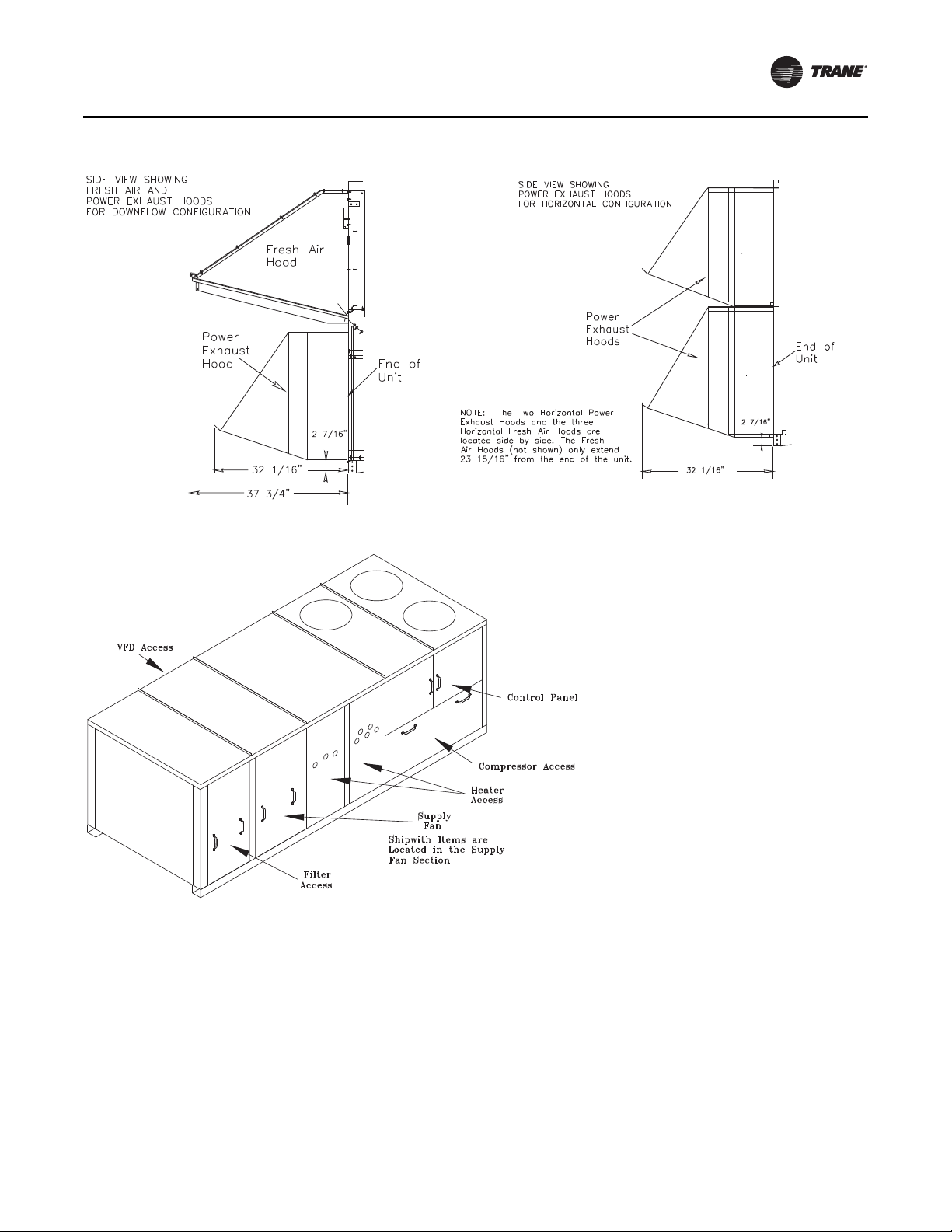

Figure 10. Fresh air and power exhaust dimensions for TC*, TE*, and YC* units

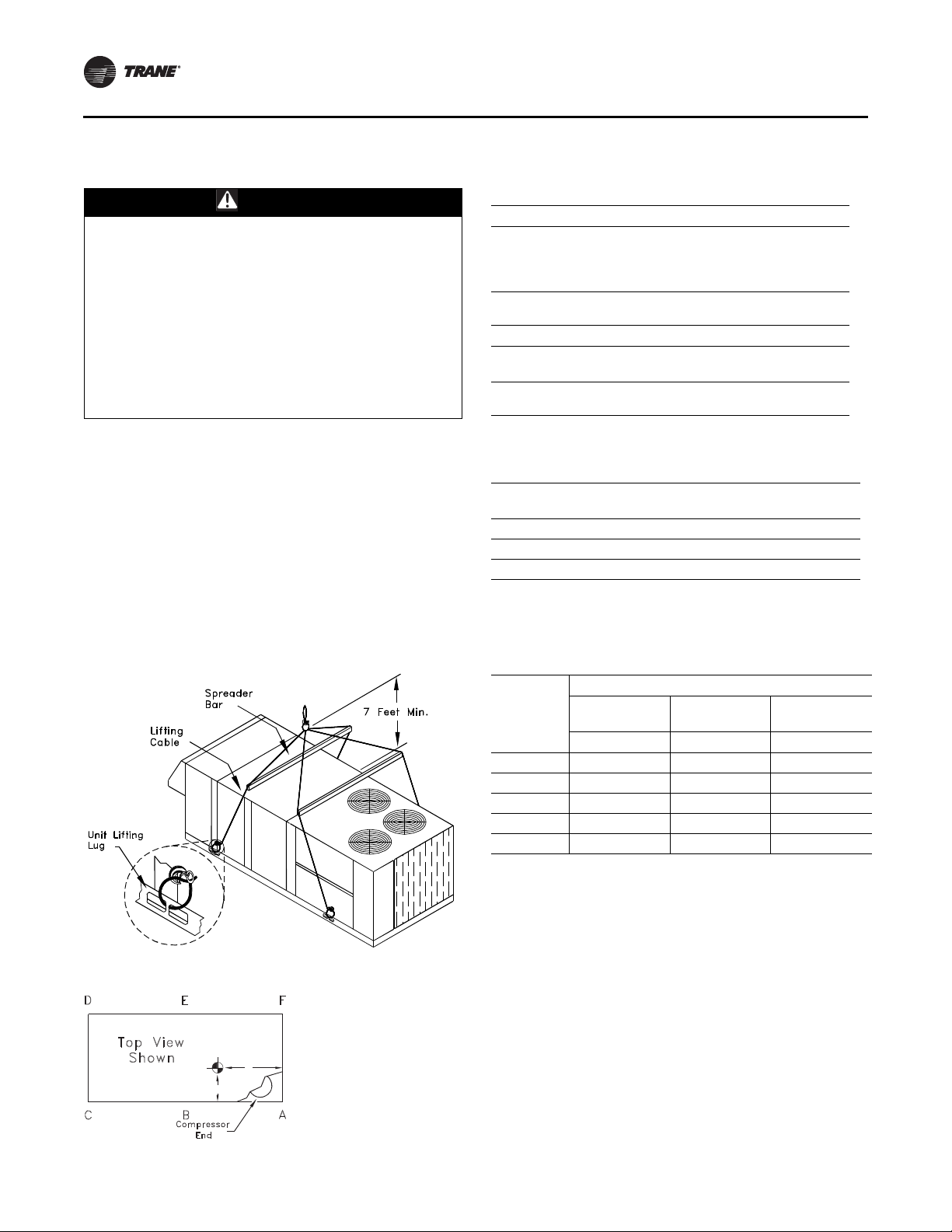

Figure 11. Location of “Ship With” items for TC*, TE*, and YC* units

Unit Dimensions and Weights

RT-SVX34H-EN 19

Unit Dimensions and Weights

Unit Rigging and Placement

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

Use spreader bars as shown in the diagram. Refer to the

Installation manual or nameplate for un it weight. Refer to

the Installation instructions located inside the control

panel for further rigging information.

1. Verify that the roof curb has the proper gaskets

installed and is level and square to assure an adequate

curb-to-unit seal.

The units must be as level as possible in order to

assure proper condensate flow out of the unit. The

maximum side-to-side and end-to-end slope allowable

in any application is listed in Table 2, p. 20.

Table 1. Minimum operating clearances installation

(horizontal, downflow, and mixed airflow

configurations)

Recommended Clearances

Condenser

(a)

Coil

Single Unit

TC*, TE*, YC*

27.5 to 50 Tons

Multiple Unit

TC*, TE*, YC*

27.5 to 50 Tons

(a) Condenser coil is located at the end and side of the unit.

Economizer/

Exhaust End

6 Feet 8 Feet 4 Feet

Distance Between Units

Economizer/

Exhaust End End/Side

12 Feet 16 Feet 8 Feet

Orientation

End/Side

Service Side

Access

Service Side

Access

Table 2. Maximum slope

Cabinet

“A” (27.5 - 35 Ton Low Heat) 3 1/2 1 5/8

“B” (27.5 - 35 Ton High Heat) 4 1 5/8

“C” (All 40 and 50 Ton Units) 4 1/2 1 5/8

Note: Do not exceed these allowances. Correct the improper slope by

building up the curb base. The material used to raise the base must

be adequate to support both the curb and the unit weight.

End to End

(inches)

Side to Side

(inches)

Figure 12. Unit rigging

Figure 13. Center of gravity

Y

Z (see note 2)

X

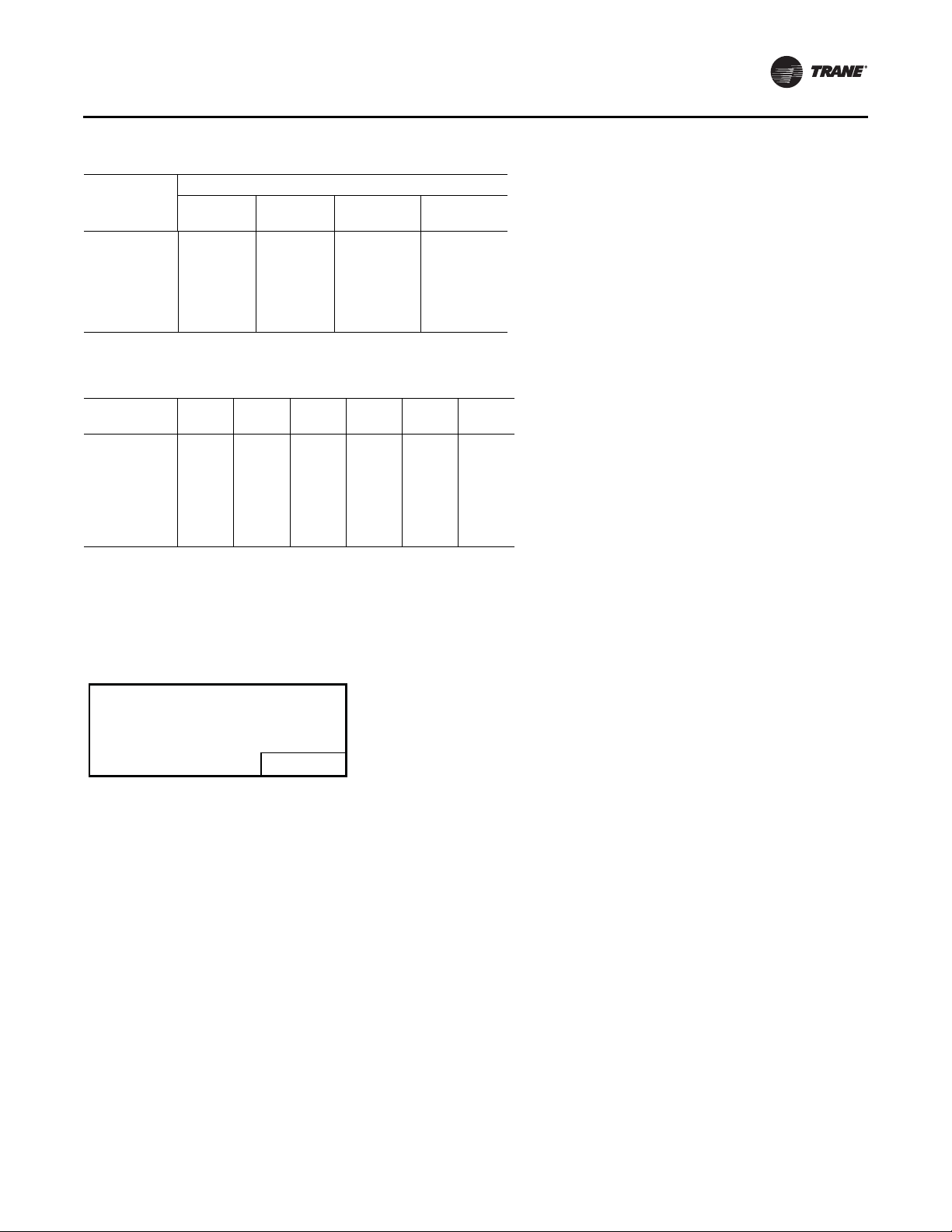

Table 3. Center of gravity

Center-of-Gravity (inches)

YC Low Heat

Dimension

Unit Model

***330/275* 41 76 33 41 84 33 42 76 33

***360/305* 43 77 33 43 85 33 44 77 33

***420/350* 42 78 33 42 86 33 43 78 33

***480/400* 42 111 35 42 111 35 42 111 35

***600/500* 43 108 35 43 108 35 43 108 35

Note: Center-of-gravity dimensions are approximate, and are based on the

unit equipped with: standard efficiency coils, standard efficiency

motors, economizer, and throwaway filters.

Note: Z dimension is upward from the base of the unit.

Example:

Locating the center-of-gravity for a YC-360 MBH High Heat unit with 100%

exhaust.

X = 43 inches inward from the control panel side

Y = 85 inches inward from the compressor end

Z = 33 inches upward from the base

XY ZXY ZXY Z

YC High Heat

Dimension

TC/TE

Dimension

20 RT-SVX34H-EN

Unit Dimensions and Weights

DE F

TOP VIEW

OF UNIT

COMPRS

CBA

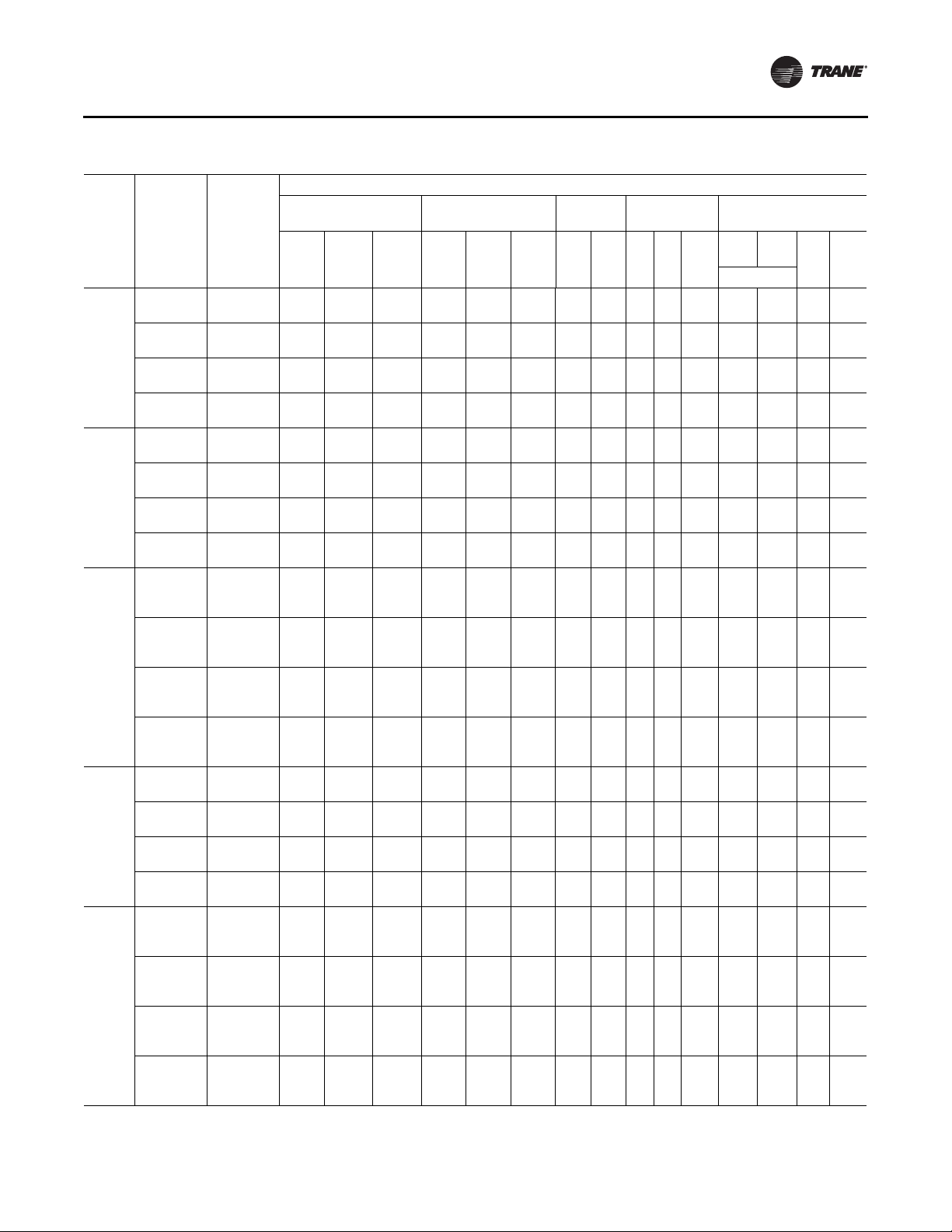

Table 4. Approximate units operating weights — lbs./kg

Basic Unit Weights

Unit Models

(60Hz/50Hz)

330/275 3720 / 1687 4150 / 1882 3590 / 1628 3610 / 1637.5

360/305 3795 / 1721 4225 / 1916 3665 / 1662 3685 / 1671.5

420/350 3876 / 1758 4306 / 1953 3746 / 1699 3766 / 1708

480/400 4825 / 2189 4950 / 2245 4565 / 2071 4600 / 2086.5

600/500 5077 / 2303 5202 / 2360 4827 / 2189.5 4852 / 2201

1. Basic unit weight includes minimum horsepo wer supply fan motor.

Table 5. Point loading average weight

Unit Models

(60Hz/50Hz) A B C D E F

330/275 852 / 386 695 / 315 754 / 342 740 / 335 602 / 273 504 / 228

360/305 878 / 398 681 / 309 750 / 340 713 / 323 577 / 262 622 / 282

420/350 841 / 381 842 / 382 669 / 303 735 / 333 582 / 264 634 / 287

480/400 835 / 378 869 / 394 950 / 431 748 / 339 769 / 349 776 / 352

600/500 882 / 400 931 / 422 954 / 433 740 / 336 844 / 382 847 / 384

Notes:

1. Point loading is identified with corner A being the corner with the compressors.

As you move clockwise around the unit as viewed from the top, mid-point B,

corner C, corner D, mid-point E and corner F.

2. Point load calculations provided are based on the unit weight for YC high heat

gas models.

YC

Low HeatYCHigh Heat TC TE

1,2

1

— lbs./kg

1

RT-SVX34H-EN 21

Unit Dimensions and Weights

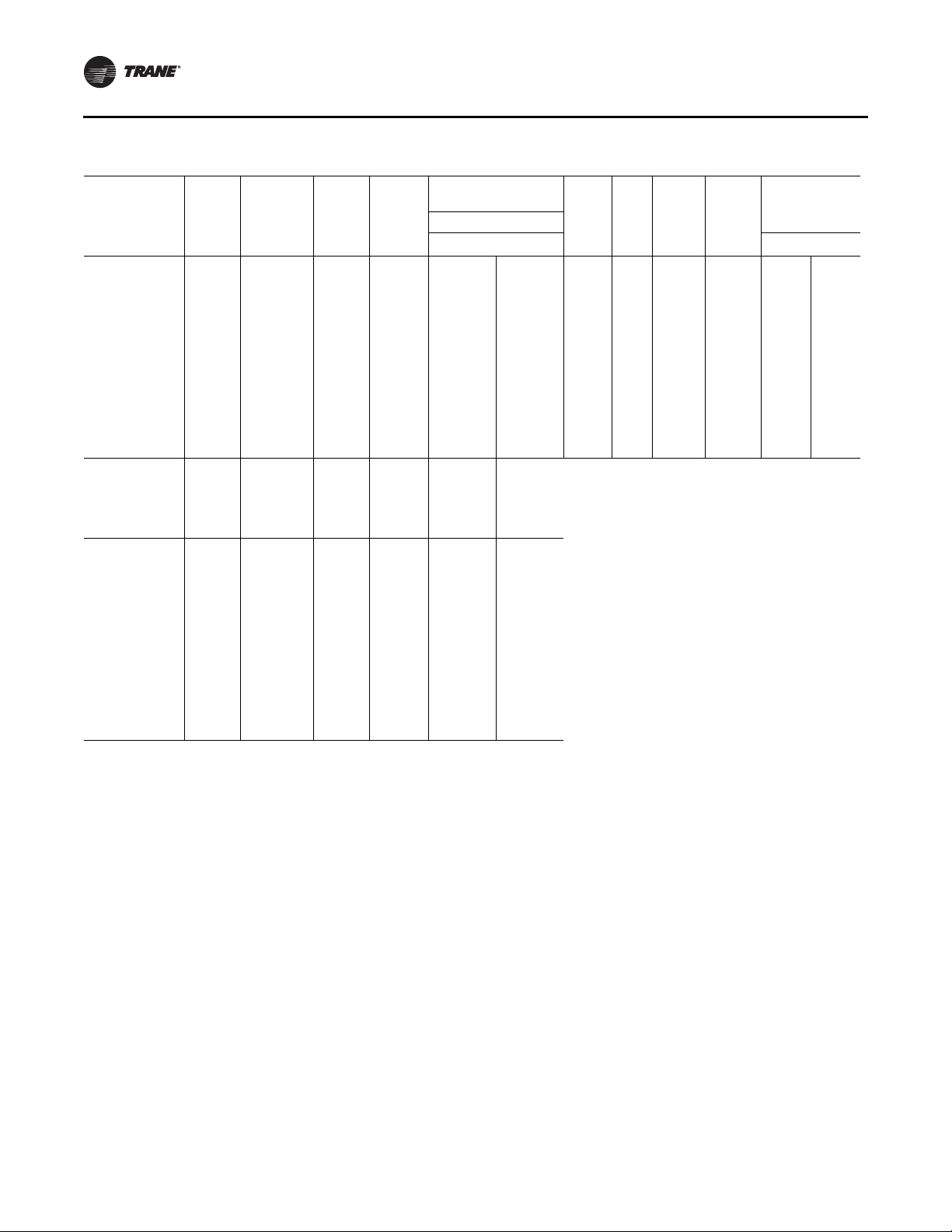

Table 6. Approximate operating weights— optional components — lbs./kg

Var. Freq. Drives

0-25%

(VFD’s)

Unit Model

(60Hz/50Hz)

**(D,F)330/275 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(H,R)330/275 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(D,F)360/305 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(H,R)360/305 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(D,F)420/350 110/50 165/74 50/23 260/117 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(H,R)420/350 145/65 200/90 50/23 285/128 85/39 115/52 18/8 6/3 30/14 85/38 310/141 330/150

**(D,F)480/400 110/50 165/74 50/23 290/131 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**(H,R)480/400 145/65 200/90 50/23 300/135 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**(D,F)600/500 110/50 165/74 50/23 290/131 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

**(H,R)600/500 145/65 200/90 50/23 300/135 115/52 150/68 18/8 6/3 30/14 85/38 365/169 365/169

Baro.

Relief

Power

Exhaust

Man

Damper Econ.

Bypass Lo Hi

Valves

Serv

Thru-

the

base

Elec.

Fused

Discon.

Switch

Ultra

Tool-Less

Condenser

Unit Model

(60Hz/50Hz)

**(D,F)330/275 107/49 105/48 112/51 34 / 15 7 4 / 34 326/148

**(H,R)330/275 107/49 105/48 78/35 34 / 15 77 / 35 326/148

**(D,F)360/305 107/49 105/48 112/51 34 / 15 7 4 / 34 255/116

**(H,R)360/305 107/49 105/48 78 /35 34 / 15 77 / 35 255/116

**(D,F)420/350 107/49 105/48 112/51 34 / 15 7 4 / 34 173/78

**(H,R)420/350 107/49 105/48 78/35 34 / 15 77 / 35 173/78

**(D,F)480/400 112/51 130/59 114/52 34 / 15 7 4 / 34 241/109

**(H,R)480/400 112/51 130/59 100/45 34 / 15 84 / 38 241/109

**(D,F)600/500 112/51 130/59 114/52 34 / 15 74 / 34 -25/-11

**(H,R)600/500 112/51 130/59 100/45 34 / 15 84 / 38 -25/-11

Note: Basic unit weight includes minimum horsepower supply fan motor.

HGRH

Coil

Hail

Guards

Ultra

Low

Leak

Econ

Low

Leak

50%

Exhaust

Ultra Low

Leak

100%

Exhaust

High

Efficiency

(eStage)

Non-

Factory

GFI

with

Discon.

Switch

Roof CurbW/O With

22 RT-SVX34H-EN

Installation General Requirements

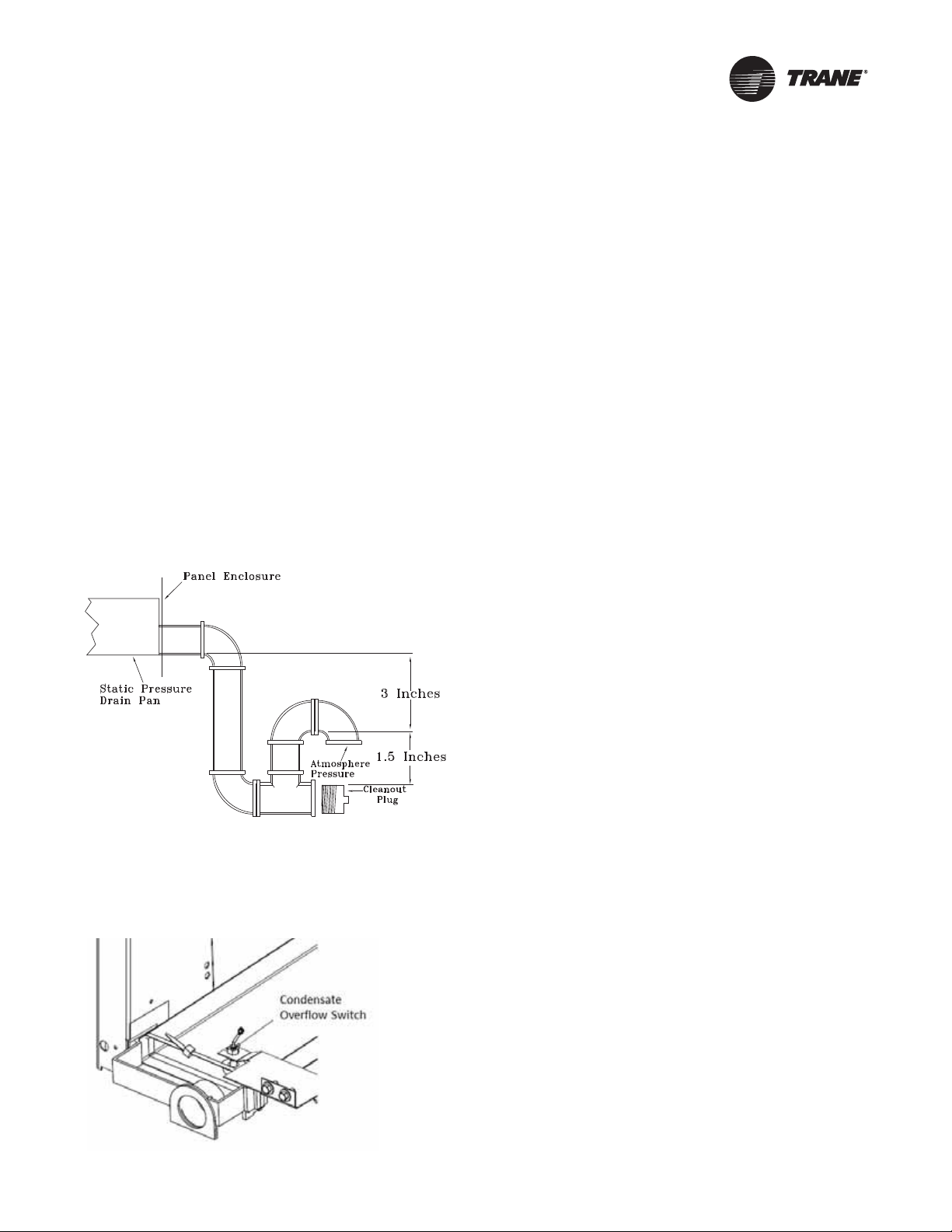

Condensate Drain Connection

Each commercial rooftop unit is equipped with one (1) 11/4 inch Female PVC condensate drain connection.

Refer to Figure 11, p. 19 for the location of the connector. A

condensate trap must be installed due to the drain

connection being on the “negative pressure” side of the

fan. Install a P-Trap at the unit using the guidelines in

Figure 14, p. 23.

Pitch the drain line at least 1/2 inch for every 10 feet of

horizontal run to assure proper condensate flow.

Ensure that all condensate drain line installations comply

with applicable building and waste disposal codes.

Notes:

• For units with optional Condensate Overflow Switch

(COF), the switch will not work properly if unit is not

level or slightly sloped toward switch.

• To ensure proper condensate flow during operation

the unit and the curb must be level.

Figure 14. Condensate trap installation

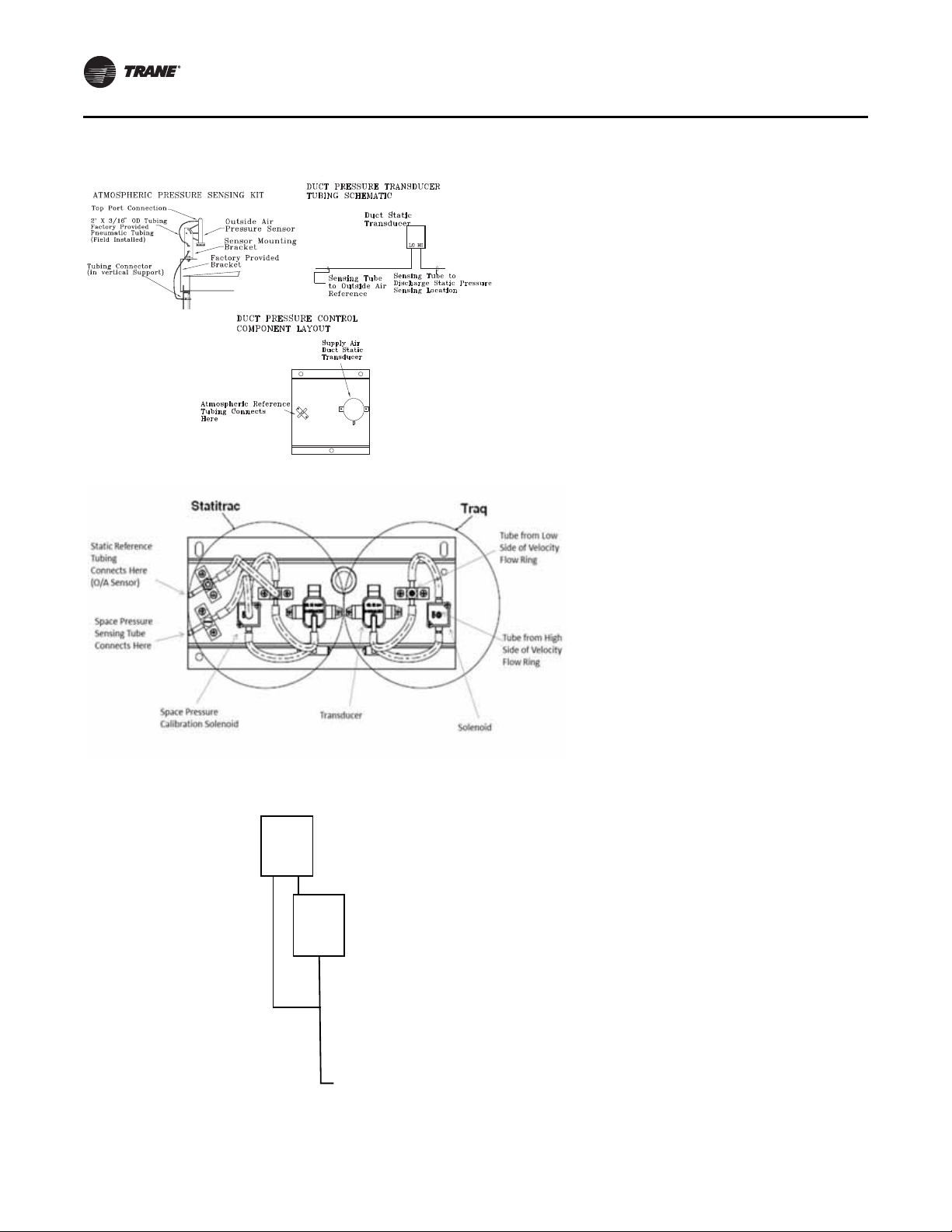

O/A Sensor & Tubing Installation

An Outside Air Pressure Sensor is shipped with all units

designed to operate on traditional variable air volume

applications (non-SZ VAV) and units with Statitrac™.

A duct pressure transducer and the outside air sensor is

used to control the discharge duct static pressure to w ithin

a customer -specified controlband. Refer to the illustration

in Figure 16, p. 24 and the following steps to install the

sensor and the pneumatic tubing.

1 . Remove the O/A pressure sensor kit located inside the

fan section. The kit contains the following items;

• an O/A static pressure sensor

• a sensor mounting bracket

• 50’ of 3/16” O.D. pneumatic tubing

• mounting hardware

2. Using two #10-32 x 1-3/4” screws provided, install the

sensor's mounting bracket to the factory provided

bracket (near the fan section).

3. Using the #10-32 x 1/2” screws provided, install the O/

A static pressure sensor vertically to the sensor

bracket.

4. Remove the dust cap from the tubing connector

located below the sensor in the vertical support.

5. Attach one end of the 50' x 3/16” O.D. factory provided

pneumatic tubing to the sensor's top port, and the

other end of the tubing to the connector in the vertical

support. Discard any excess tubing.

Units with Statitrac™

1. Open the filter access door, and locate the Statitrac

Transducer Assembly illustrated in Figure 17, p. 24.

There are two tube connectors mounted on the left of

the solenoid and transducers. Connect one end of the

Condensate Overflow Switch

This switch protects building from condensate overflow

damage. It is factory-installed and tested.

Figure 15. Condensate overflow switch location

RT-SVX34H-EN 23

field provided 1/4” (length 50-100 ft.) or 3/8” (length

greater than 100 ft.) O.D. pneumatic tubing for the

space pressurization control to the fitting indicated in

the illustration.

2. Route the opposite end of the tubing to a suitable

location inside the building. This location should be

the largest open area that will not be affected by

sudden static pressure changes.

Installation General Requirements

LO

HI

CNO

NC

Sensing Tube

to Traq LO Side

Pressure Port

Airow

Transducer

Sensing Tube

to Traq HI Side

Pressure Port

Figure 16. Pressure tubing

Figure 17. Transducer assembly

Note: Statitrac and Traq transducer assembly shown.

24 RT-SVX34H-EN

Installation Electrical

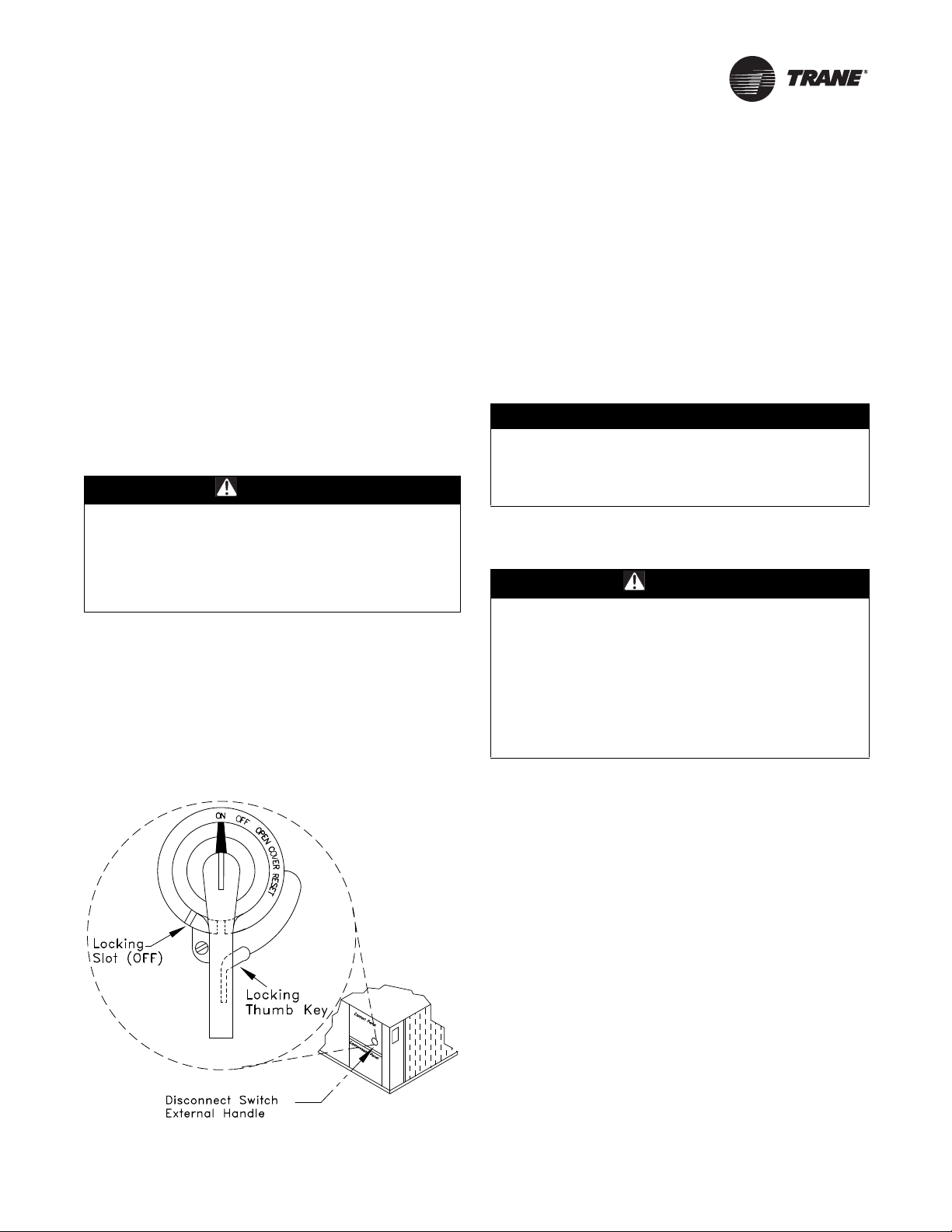

Disconnect Switch External Handle (Factory Mounted Option)

Units ordered with the factory mounted disconnect switch

come equipped with an externally mounted handle. This

allows the operator to disconnect power from the unit

without having to open the control panel door . The handle

location and its three positions are shown below;

ON - Indicates that the disconnect switch is closed,

allowing the main power supply to be applied at the unit.

OFF - Indicates that the disconnect switch is open,

interrupting the main power supply at the unit.

OPEN COVER/RESET - Turning the handle to this position

releases the handle from the disconnect sw itch, allowing

the control panel door to be opened.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing . Follow proper lock out/

tagout procedures to ensure the power can not be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

Once the door has been opened, it can be closed with the

handle in any one of the three positions outlined above,

provided it matches the disconnect switch position. The

handle can be loc ked in the “OFF” position . While holding

the handle in the “OFF” position, push the spring loaded

thumb key, attac hed to the handle, into the base slot. Place

the lock shackle between the handle and the thumb key.

This will prevent it from springing out of position.

Figure 18. Disconnect switch

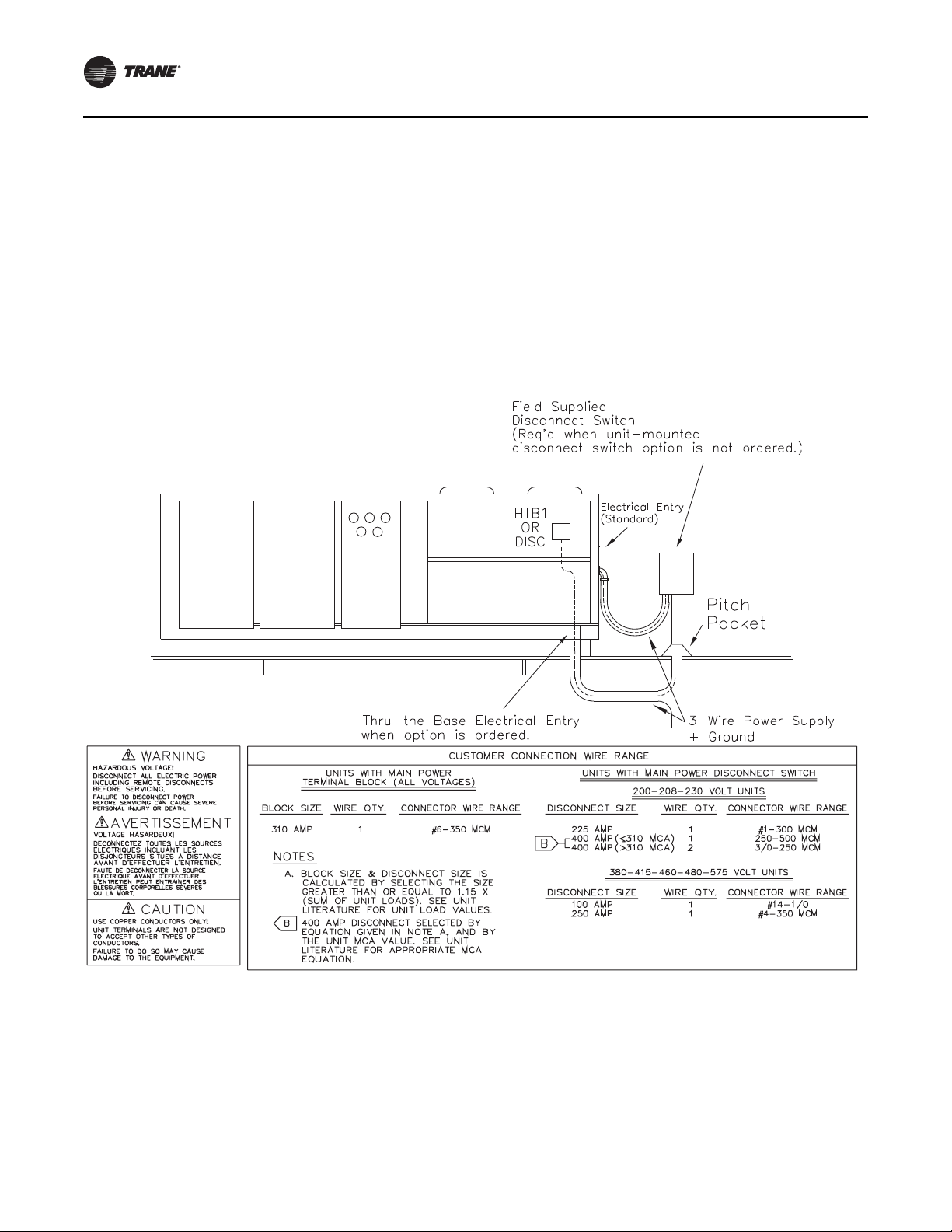

An overall layout of the field required power wiring is

illustrated in Figure 19, p. 26. To insure that the unit supply

power wiring is properly sized and installed, follow the

guidelines outlined below.

Note: All field installed wiring must conform to NEC

guidelines as well as State and Local codes.

Ve rify that the power supply available is compatible with

the unit's name plate ratings for all components. The

available power supply must be within 10% of the rated

voltage stamped on the nameplate. Use only copper

conductors to connect the 3-phase power supply to the

unit.

NOTICE:

Use Copper Conductors Only!

Unit terminals ar e not designed t o accept other types of

conductors. Failure to use copper conductors could

result in equipment damage.

Main Power Wiring

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, y ou MUST follo w requir ements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

1. Table 7, p. 27 to T a bl e 12, p. 29 list the electrical service

sizing data. The electrical service must be protected

from over current and short circuit conditions in

accordance with NEC requirements. Protection

devices must be sized according to the electrical data

on the nameplate. Refer to “Electrical Wire Sizing and

Protection Device Equations” on page 29 for

determining:

a. The appropriate electrical service wire size based

on “Minimum Circuit Ampacity” (MCA),

b. The “Maximum Over current Protection” (MOP)

device.

c. The “Recommended Dual Element fuse size” (RDE).

2. If the unit is not equipped with an optional factory

installed Nonfused disconnect switc h, a field supplied

disconnect switch must be installed at or near the unit

in accordance with the National Electrical Code (NEC

latest edition). Refer to DSS calculations

Wire Sizing and Protection Device Equations” on

page 29 for determining correct size.

“Electrical

RT-SVX34H-EN 25

Installation Electrical

Location for the electrical service entrance is shown in

the unit dimensional drawings beginning with

Figure 1, p. 14. Complete the unit's power wiring

connections onto either the main terminal bloc k HTB1,

or the factory mounted nonfused disconnect switch

inside the unit control panel.

Note: When the factory installed through-the-base

option is not used, the installing contractor is

required to seal any ho les made in the base o f the

unit to prevent water from leaking into the building.

3. Provide proper grounding for the unit in accordance

with local and national codes.

Figure 19. Typical field power wiring

Through-the-Base Electrical (Optional Accessory)

Liquid-tight conduit couplings are secured to the base of

the unit for both power and control wiring. Liquid-tight

conduit must be field installed between the couplings and

the unit control box to prevent water leaks into the

building.

Note: If the unit is set on the roof curb and temporary

auxiliary heat is provided in the building, it is

recommended that the electrical and control wiring

conduit opening in the control box be temporarily

sealed to provide a vapor barrier.

26 RT-SVX34H-EN

Installation Electrical

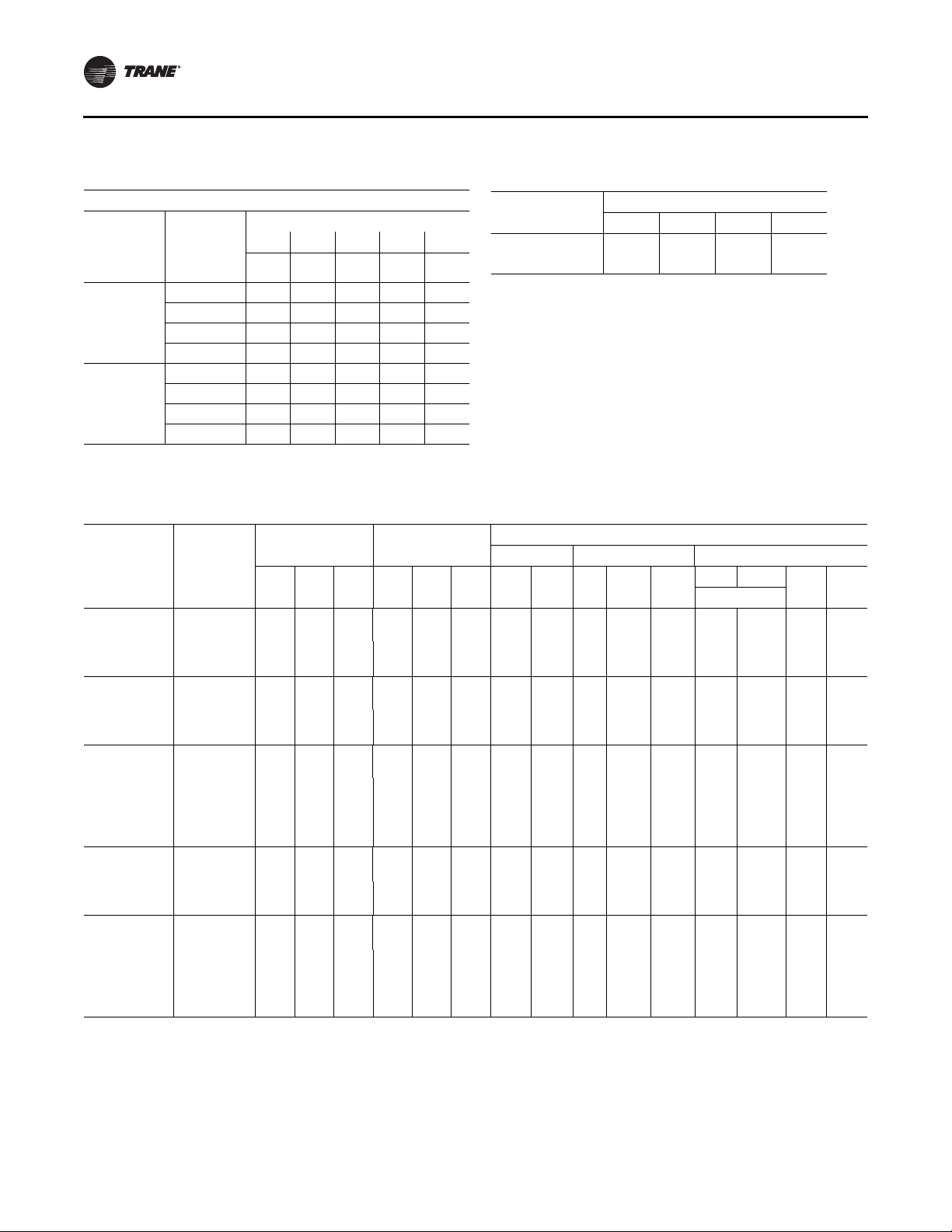

Table 7. 27½-50 ton electrical serv ice sizing data—60Hz

1

Fan Motors

Compressor - Std

Efficiency

Electrical

Characteri

Model

TC/TE/

YC*330

TC/TE/

YC*360

TC/TE/

YC*420

TC/TE/

YC*480

TC/TE/

YC*600

Notes:

1. All customer wiring and devices must be installed in accordance with local and national electrical codes.

2. 100% Power Exhaust is with or without Statitrac™.

stics

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229 2/13 50.5

230/60/3 207-253 2/13 50.5

460/60/3 414-506 2/13 23.0

575/60/3 517-633 2/13 19.0

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

208/60/3 187-229

230/60/3 207-253

460/60/3 414-506

575/60/3 517-633

Allowable

Voltage

Range

No/

Ton

1/12,

1/13

1/12,

1/13

1/12,

1/13

1/12,

1/13

1/13,

1/15

1/13,

1/15

1/13,

1/15

1/13,

1/15

1/13,

1/20

1/13,

1/20

1/13,

1/20

1/13,

1/20

2/13,

1/15

2/13,

1/15

2/13,

1/15

2/13,

1/15

RLA

(Ea.)

44.0/

50.5

44.0/

50.5

21.0/

23.0

17.5/

19.0

50.5/

56.0

50.5/

56.0

23.0/

27.5

19.0/

23.0

50.5/

83.9

50.5/

83.9

23.0/

34.0

19.0/

27.3

50.5/

56.0

50.5/

56.0

23.0/

27.5

19.0/

23.0

(Ea.)

Compressor - High

Efficiency, eStage Supply Condenser Exhaust

LRA

No/

RLA

LRA

(Ea.) H P FLA No HP

203,

267

203,

267

203,

267

203,

267

203,

304

203,

304

98,

147

84,

122

203,

315

203,

315

98,

158

84,

136

267,

345

267,

345

142,

155

103,

126

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

7.5

10.0

15.0

7.5

10.0

15.0

7.5

10.0

15.0

7.5

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

10.0

15.0

20.0

10.0

15.0

20.0

10.0

15.0

20.0

10.0

15.0

20.0

28.0,

37.1

28.0,

37.1

14.1,

16.8

12.2,

14.7

28.0,

40.9

28.0,

40.9

14.1,

18.6

12.2,

15.4

28.0,

44.9

28.0,

44.9

14.1,

19.2

12.2,

16.6

31.1,

50.5

31.1,

50.5

14.1,

23.0

11.5,

19.0

40.9,

56.0

40.9,

56.0

18.6,

27.5

15.4,

23.0

98, 142

84, 103

98, 142

84, 103

22.2

29.5

18.8

25.2

9.4

12.6

7.8

10.1

22.2

29.5

18.8

25.2

9.4

12.6

7.8

10.1

22.2

29.5

40.7

18.8

25.2

35.4

9.4

12.6

17.7

7.8

10.1

15.1

29.5

40.7

25.2

35.4

12.6

17.7

10.1

15.1

29.5

40.7

56.1

25.2

35.4

49.4

12.6

17.7

24.7

10.1

15.1

19.6

304/

315

304/

315

147/

158

122/

136

315/

315

315/

315

158/

158

136/

136

315/

351

315/

351

158/

197

136/

146

315/

485

315/

485

158/

215

136/

175

315/

351

315/

351

158/

197

136/

146

Ton

1/6,

2/9

1/6,

2/9

1/6,

2/9

1/6,

2/9

1/6,

2/10

1/6,

2/10

1/6,

2/10

1/6,

2/10

1/6,

2/11

1/6,

2/11

1/6,

2/11

1/6,

2/11

1/8,

2/13

1/8,

2/13

1/8,

2/13

1/8,

2/13

1/10,

2/15

1/10,

2/15

1/10,

2/15

1/10,

2/15

(Ea.)

50%100

FLA

(Ea.)

31.17.0 1 2 1.0 4.1

31.17.0 1 2 1.0 4.1

31.13.5 1 2 1.0 1.8

31.12.8 1 2 1.0 1.4

31.17.0 1 2 1.0 4.1

31.17.0 1 2 1.0 4.1

31.13.5 1 2 1.0 1.8

31.12.8 1 2 1.0 1.4

31.17.0 1 2 1.0 4.1

31.17.0 1 2 1.0 4.1

31.13.5 1 2 1.0 1.8

31.12.8 1 2 1.0 1.4

41.17.0 1 2 1.5 5.4

41.17.0 1 2 1.5 5.4

41.13.5 1 2 1.5 2.7

41.12.8 1 2 1.5 2.2

41.17.0 1 2 1.5 5.4

41.17.0 1 2 1.5 5.4

41.13.5 1 2 1.5 2.7

41.12.8 1 2 1.5 2.2

%

HP

FLA

(Ea.)No.

RT-SVX34H-EN 27

Installation Electrical

Table 8. Electrical service sizing data — electric heat

module (electric heat only) — 60 Hz

Models: TE(D,H,F,R) 330—600 Electric Heat FLA

KW Heater

Nominal

Unit Size

(Tons)

27½-35

40- 50

Note: All FLA in this table are based on heater operating at 208, 240, 480,

and 600 volts.

Nominal

36 54 72 90 108

Unit

Voltage

208 74.9 112.4 — — —

230 86.6 129.9 — — —

460 43.3 65.0 86.6 108.3 —

575 — 52.0 69.3 86.6 —

208 — 112.4 — — —

230 — 129.9 — — —

460 — 65.0 86.6 108.3 129.9

575 — 52.0 69.3 86.6 103.9

FLA FLA FLA FLA FLA

Table 9. Electrical service sizing data — crankcase

heaters (heating mode only) — 60Hz

Nominal

Unit Size (Tons)

27½ - 35 1111

40, 50 2211

200 230 460 575

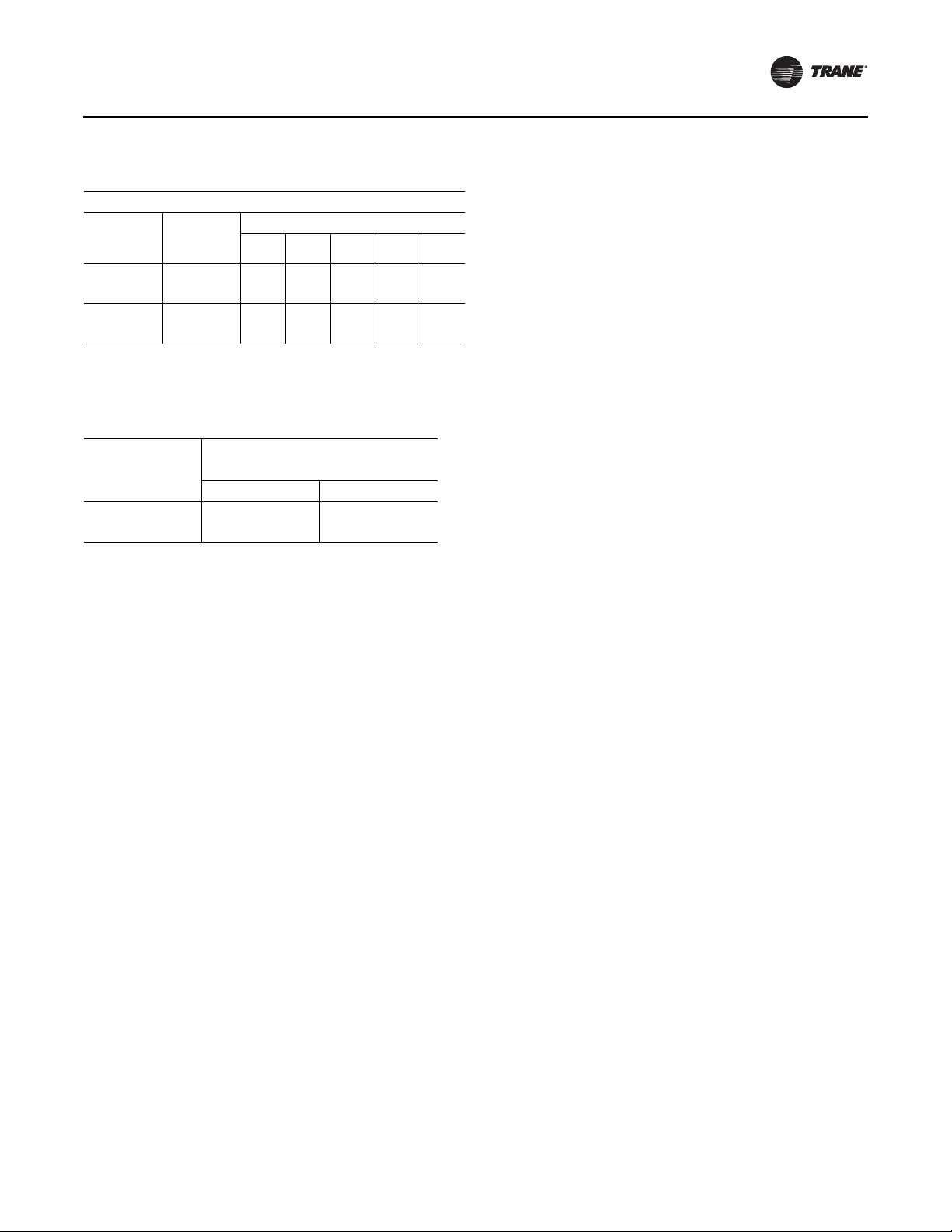

Table 10. Electrical service sizing data — 50Hz

Compressor - Std

Efficiency

Compressor -

High Efficiency

Supply Condenser

Electrical

Model

TC/TE/YC*275 380-415/50/3

TC/TE/YC*305 380-415/50/3 2/11 23.0 158

TC/TE/YC*350 380-415/50/3

TC/TE/YC*400 380-415/50/3

TC/TE/YC*500 380-415/50/3

Notes:

1. All condenser fan motors are single phase.

2. All customer wiring and devices must be installed in accordance with local and national electrical codes.

3. Allowable voltage range for the 380V unit is 342-418V, allowable voltage range for the 415V unit is 373-456.

4. 100% Power Exhaust is with or without Statitrac

tics

Characteris

No/

Ton

1/10,

1/11

1/11,

1/12

1/11,

1/17

2/11,

1/12

RLA

(Ea.)

21.0/

23.0

23.0/

27.5

23.0/

34.0

23.0/

27.5

LRA

(Ea.)

147/

158

158/

197

158/

215

158/

197

No/

Ton

1/6,

2/9

1/6,

2/10

1/6,

2/11

1/8,

2/13

1/10,

2/15

RLA

(Ea.)

14.1,

16.8

14.1,

18.6

14.1,

19.2

14.1,

23.0

18.6,

27.5

LRA

(Ea.)

HP

(kW) FLA No.HP(kW)

98,

7.5

(5.6)

10

(6.8)

7.5

(5.6)

10

(6.8)

7.5

(5.6)

10

(6.8)

15

(10.5)

10

(6.8)

15

(10.5)

10

(6.8)

15

(10.5)

20

(12.8)

13.6/

14.1

16.0/

15.5

13.6/

14.1

16.0/

15.5

13.6/

14.1

16.0/

15.5

24.0/

26.0

16.0/

15.5

24.0/

26.0

16.0/

15.5

24.0/

26.0

29.0/

28.0

142

98,

142

98,

147

98,

158

142,

155

3