Page 1

18-EB24D1-19

WARNING:

HAZARDOUS VOLTAGE - DISCONNECT POWER and DISCHARGE

CAPACITORS BEFORE SERVICING

Installer's Guide

WCC-IG-19

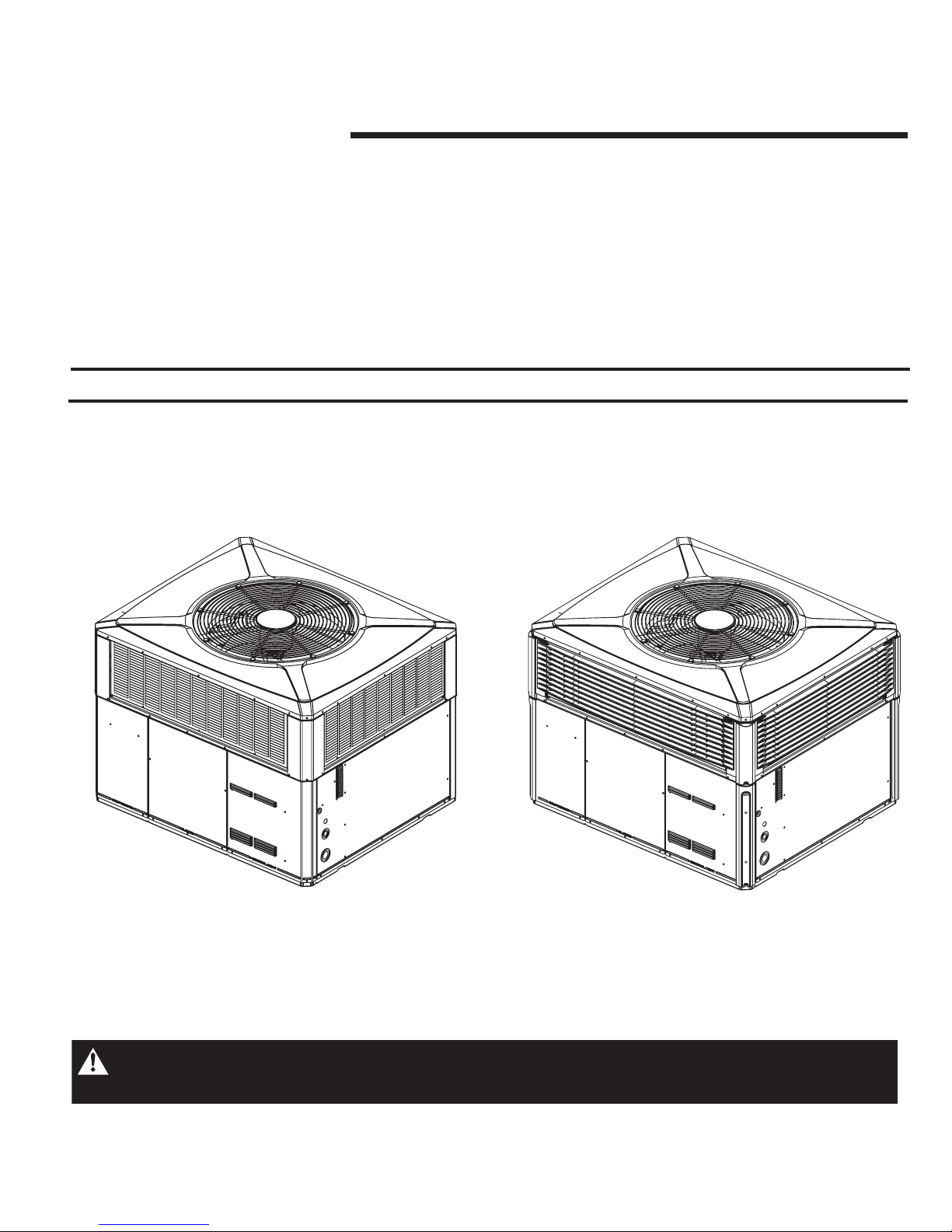

Single Packaged Heat Pump, 13 SEER

Convertible, 1½ - 5 Ton, R-410A

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

Important — This Document is customer property. Please return to service information pack and give this Installer's Guide to the homeowner

upon completion of work.

4WCC3018 through 4WCC3060

4WCX3018 through 4WCX3060

Page 2

Installer’s Guide

▲

WARNING

!

▲

WARNING

!

▲

WARNING

!

▲

CAUTION

!

▲

CAUTION

!

▲

CAUTION

!

▲

CAUTION

!

▲

CAUTION

!

Safety Considerations

IMPORTANT: Read this entire manual before beginning installation procedures.

Read this manual carefully before attempting to install, operate,

or perform maintenance on this unit. Installation and maintenance

should be performed by qualified service technicians only.

NOTE: "Warnings" and "Cautions" appear at appropr iate places

in this manual. Your personal safety and the proper operation of

this air conditioning product require that you follow them carefully. The manufacturer assumes no liability for installations or

servicing performed by unqualified personnel.

NOTICE

Warning and Cautions appear at appropriate

locations throughout this guide. Read these

carefully.

WARNING: INDICATES A POTENTIALLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR

SERIOUS INJURY.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices and where propertydamage-only accidents could occur.

CONTAINS REFRIGERANT!

SYSTEM CONTAINS OIL AND REFRIGERANT UNDER

HIGH PRESSURE. RECOVER REFRIGERANT TO RELIEVE

PRESSURE BEFORE OPENING SYSTEM. Failure to follow

proper procedures can result in personal illness or injury

or severe equipment damage.

RECONNECT ALL GROUNDING DEVICES.

All parts of this product that are capable of conducting

electrical current are grounded. If grounding wires, screws,

straps, clips, nuts, or washers used to complete a path to

ground are removed for service, they must be returned to

their original position and properly fastened.

Unit contains R-410A Refrigerant!

R-410A operating pressure exceeds the limit of R-22. Proper

service equipment is required. Failure to use proper service

tools may result in equipment damage or personal injury.

SERVICE

Use only R-410A Refrigerant and approved POE compres-

sor oil.

SAFETY HAZARD!

This information is for use by individuals having adequate

backgrounds of electrical and mechanical experience. Any

attempt to repair a central air conditioning product may result

in personal injury and/or property damage. The manufacturer

or seller cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection

with its use.

SAFETY HAZARD!

Bodily injury can result from high voltage electrical components, fast moving fans, and combustible gas. For protection

from these inherent hazards during installation and service,

the electrical supply must be disconnected and the main

gas valve must be turned off. If operating checks must be

performed with the unit operating, it is the technicians responsibility to recognize these hazards and proceed safely.

SAFETY HAZARD!

Do not operate the unit without the evaporator fan or coil

access panels in place. Reinstall the access panels after

performing maintenance procedures on the fan. Operating

the unit without the access panels properly installed may

result in severe personal injury or death.

Hot Surface!

Do Not touch top of compressor. May cause minor to severe

burning.

Caution must be taken at all times to avoid personal injuries

and/or damage to equipment.

IMPORTANT: Wear appropriate gloves, arm sleeve protectors,

and eye protection when servicing or maintaining this equipment.

Page 2

Page 3

Installer’s Guide

Contents

Safety Considerations 2

Introduction 3

Step 1-Inspect Shipment 3

Step 2-Determine Unit Clearances 4

Step 3-Review Location & Recommendation

Information 16

Step 4-Unit Installation 17

Ground Level Installation 17

Rooftop Installation -- Curb Mounting 17

Covert Horizontal Airflow to Down Airflow 17

Install Full Perimeter Roof Mounting Curb 17

Lifting and Rigging 18

Placing the Unit on the Mounting Curb 18

Rooftop Installation -- Frame Mounting 19

Rooftop Installation -- No Curb/Frame 19

Ductwork Installation 22

Attaching Downflow Ductwork to Roof Curb 22

Attaching Horizontal Ductwork to Unit 22

Condensate Drain Piping 22

Air Filter Installation 22

Electrical Wiring 23

Electrical Connections 23

Electrical Power 23

Disconnect Switch 23

Overcurrent Protection 23

Power Wiring 23

Field Wiring Diagram 24

Control Wiring (Class II) 25

Step 5-Unit Startup 25

Pre-start Quick Checklist 25

Starting the Unit in the Cooling Mode 25

Operating Pressures 25

Voltage Check 25

Cooling Shut Down 25

Starting the Unit in Heating Mode 26

Heating Shutdown 26

Sequence of Operation 26

Demand Defrost Operation 26

Defrost Control 26

Final Installation Checklist 27

Maintenance 27

Owner Maintenance 27

Service Maintenance 27

Cooling Season 27

Heating Season 27

Indoor Fan Motor Speed Tap Setting 27

Introduction

Read this manual carefully before attempting to install, operate, or perform maintenance on this unit. Installation and

maintenance should be performed by qualified service technicians only. This unit is listed by Underwriters Laboratory.

Model 2/4WC*3 heat pump units are designed for outdoor

mounting with a vertical condenser discharge. They can be

located either at ground level or on a roof in accordance with

local codes. Each unit contains an operating charge of refrigerant as shipped.

Extreme mounting kits are available for slab (BAYEXMK003A), utility curb (BAYEXMK002B) and perimeter curb

(BAYEXMK001A) mountings.

This guide is organized as follows:

Step 1 - Inspect Shipment

Step 2 - Determine Unit Clearances

Step 3 - Review Location & Recommendation Information

Step 4 - Unit Installation

Step 5 - Unit Startup

Sequence of Operation

Maintenance

Step 1—Inspect Shipment

1. Check for damage after the unit is unloaded. Report promptly

to the carrier any damage found to the unit. Do not drop the

unit.

IMPORTANT: To prevent damage to the sides and top of the

unit when hoisting, retain the top shipping skid on the unit or

use “spreader bars” as shown on page 20.

2. Check the unit’s nameplate to determine if the unit is correct for the intended application. The power supply must be

adequate for both the unit and all accessories.

3. Check to be sure the refrigerant charge has been retained

during shipment. Remove the Compressor access panel to

access the 1/4" flare pressure taps.

Page 3

4. If this unit is being installed on a curb, verify that the correct

curb is provided with the unit.

• 4WC*3018-036 use model BAYCURB050A.

• 4WC*3042-060 use model BAYCURB051A.

5. If the unit is being hoisted, accessory kit BAYLIFT002A is

recommended. It includes a kit of four (4) lifting lugs and

instructions.

NOTE: If practical, install any internal accessories to the

unit at the shop.

Page 4

Installer’s Guide

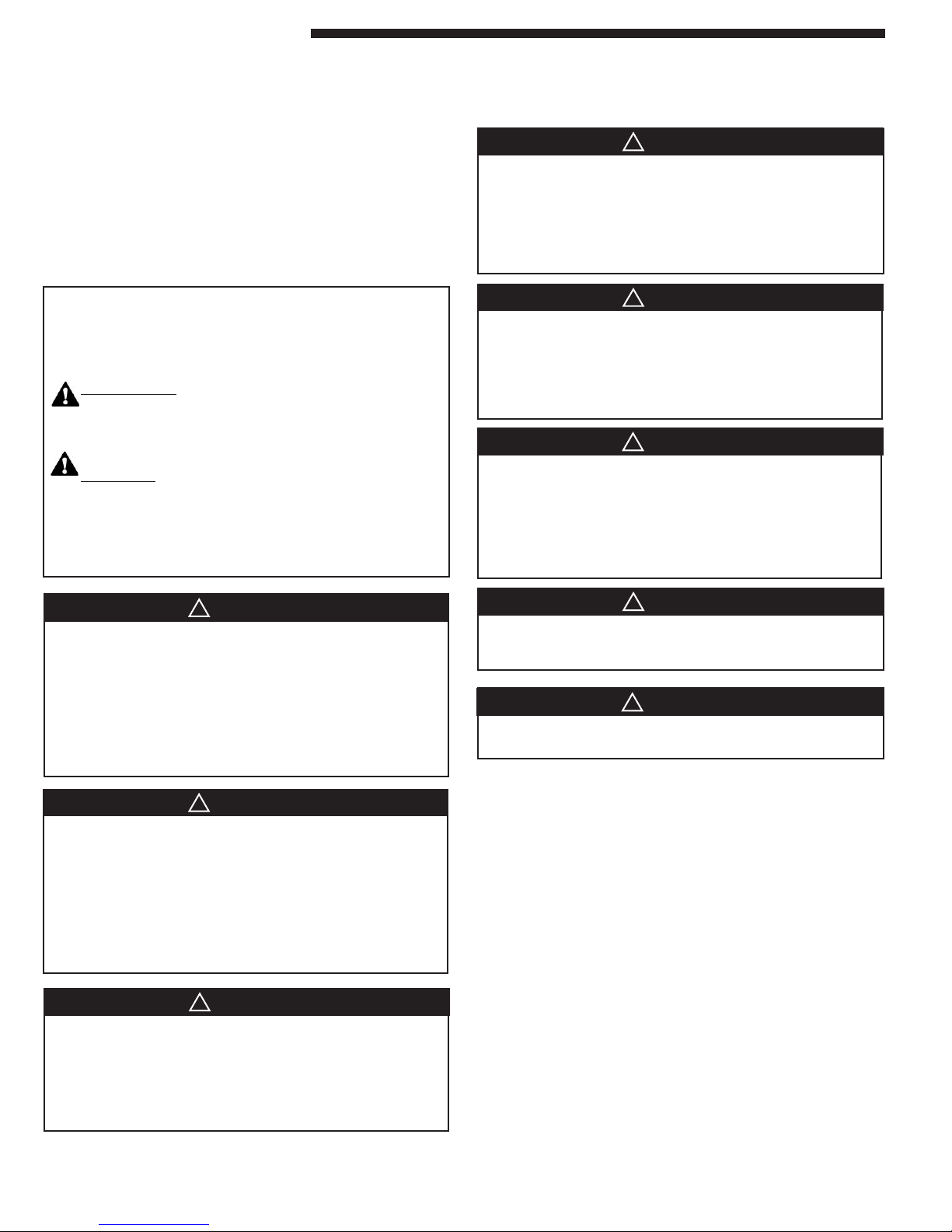

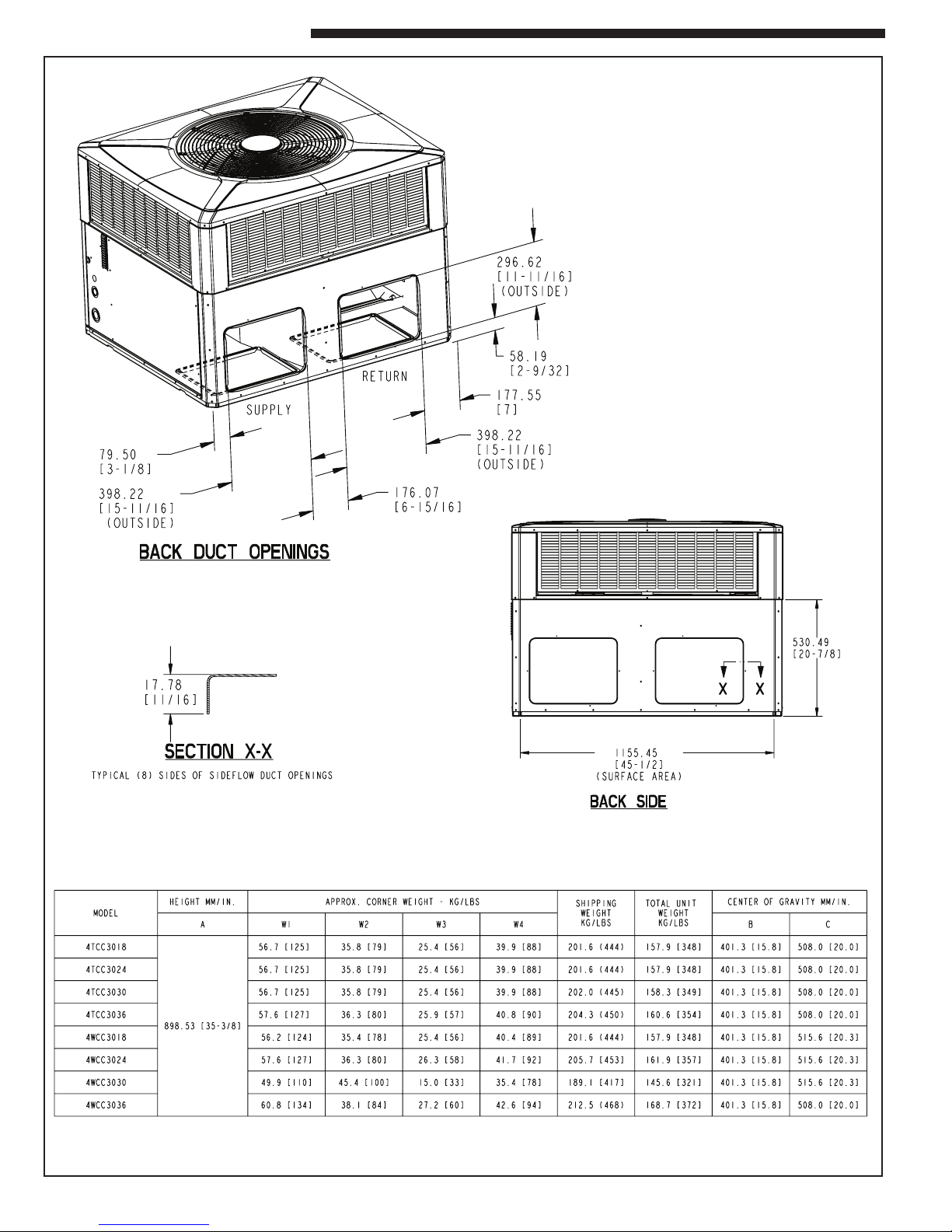

Step 2—Determine Unit Clearances

Figures 1 through 12 show the unit critical dimensions. Figures 1 through 6 show the 4WCC3 clearances and Figures 7

through 12 show the 4WCX3 clearances.

NOTE: The view

labeled “Bottom

Side” represents

the Base as viewed

looking up from

underneath the unit.

Figure 1. 4WCC3018 through 4WCC3036 (1 of 3)

Page 4

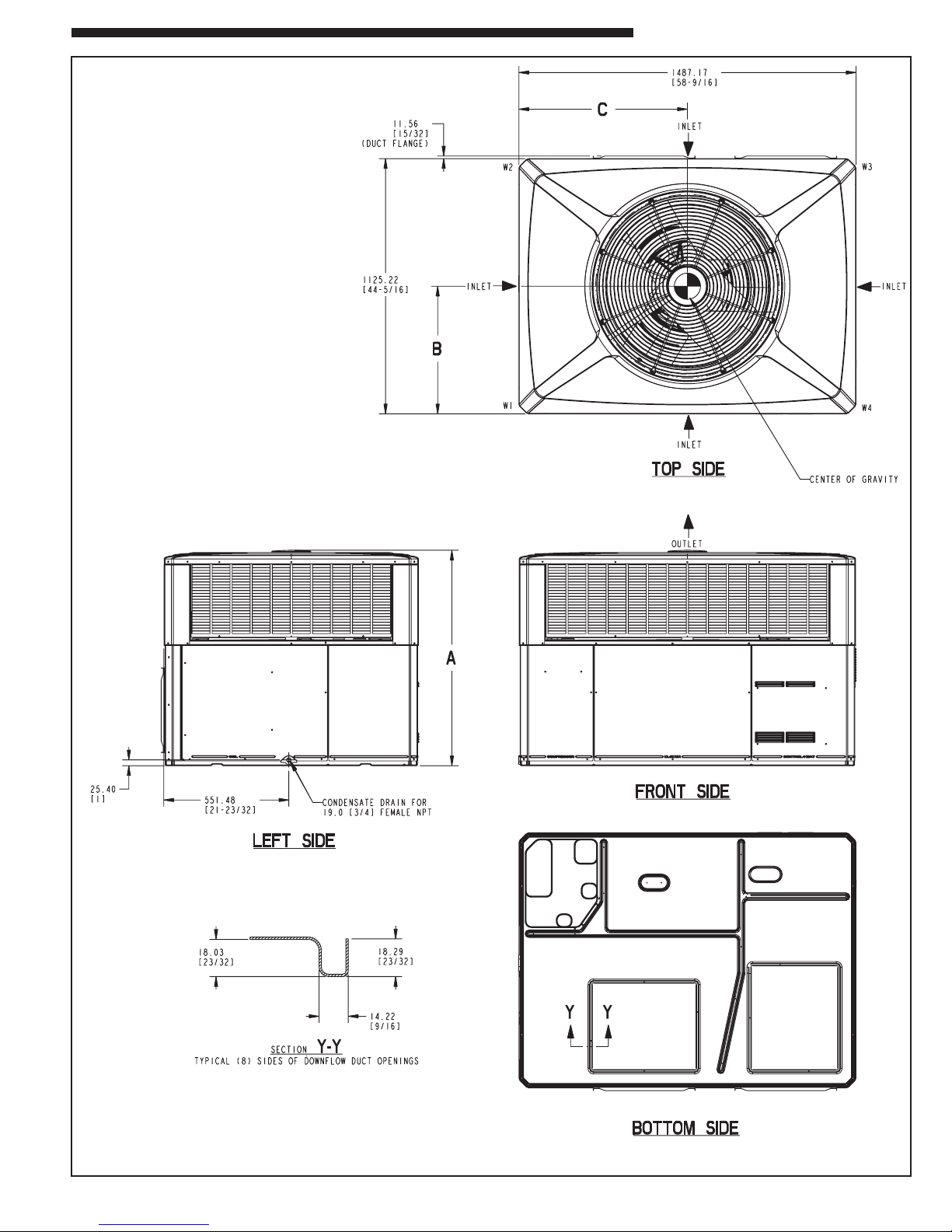

Page 5

Installer’s Guide

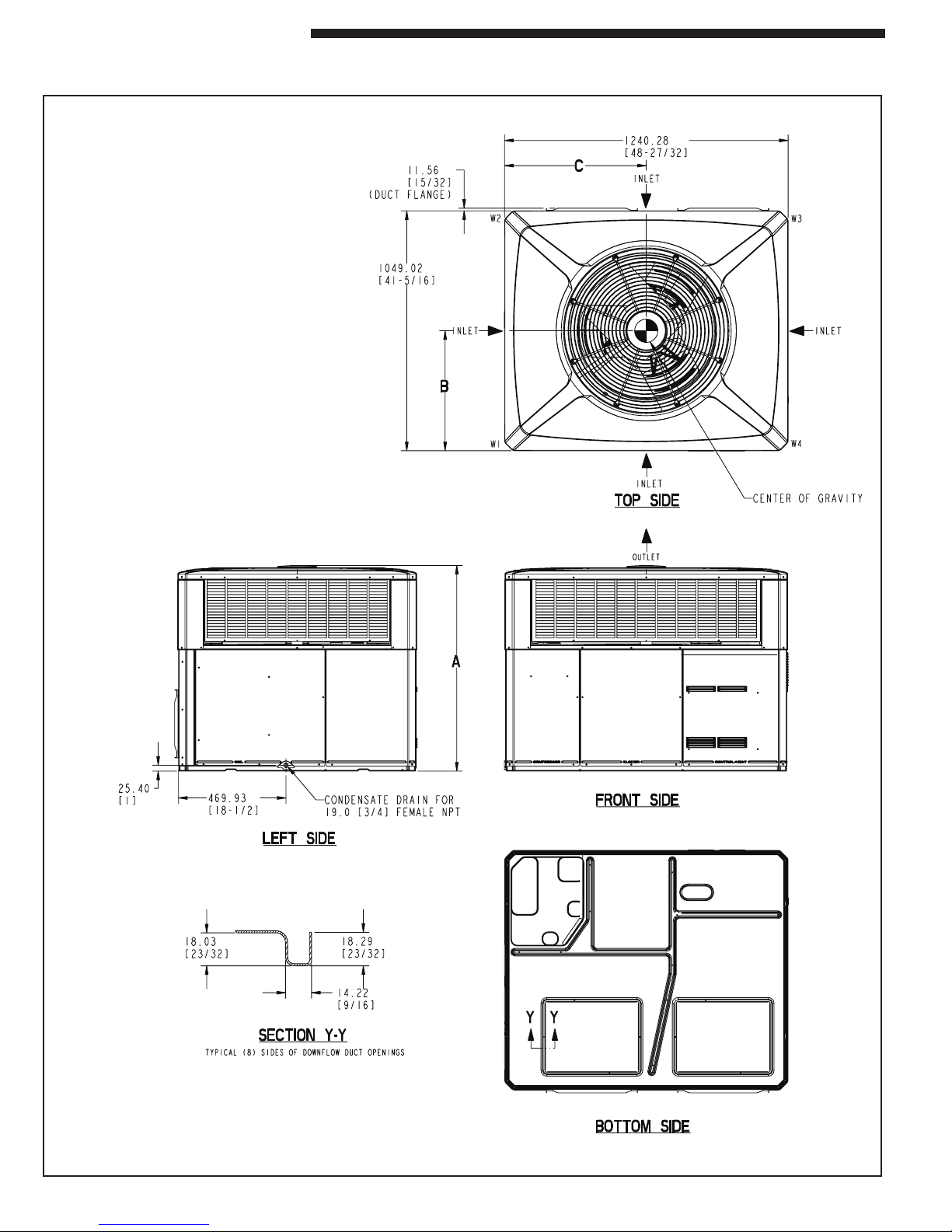

Figure 2. 4WCC3018 through 4WCC3036 (2 of 3)

Page 5

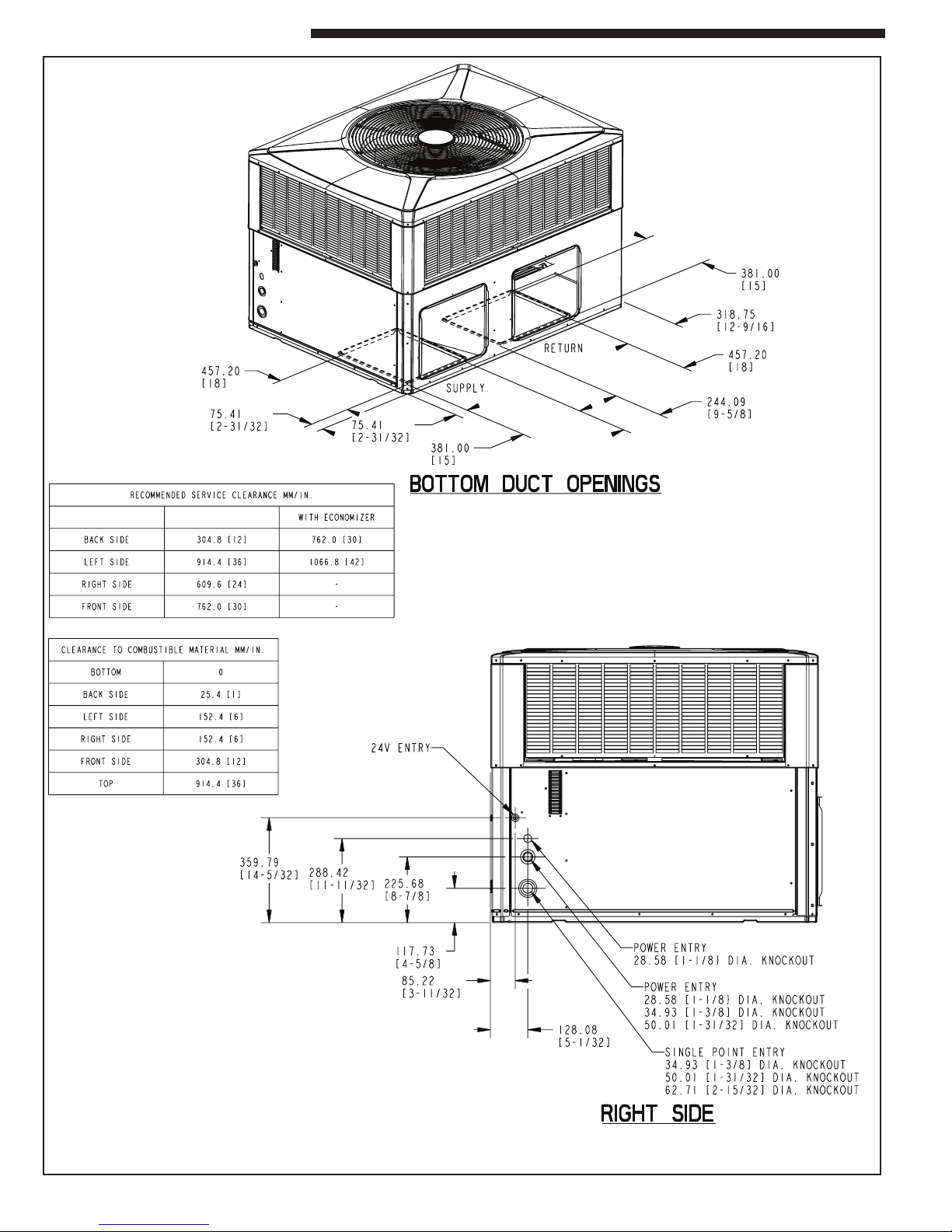

Page 6

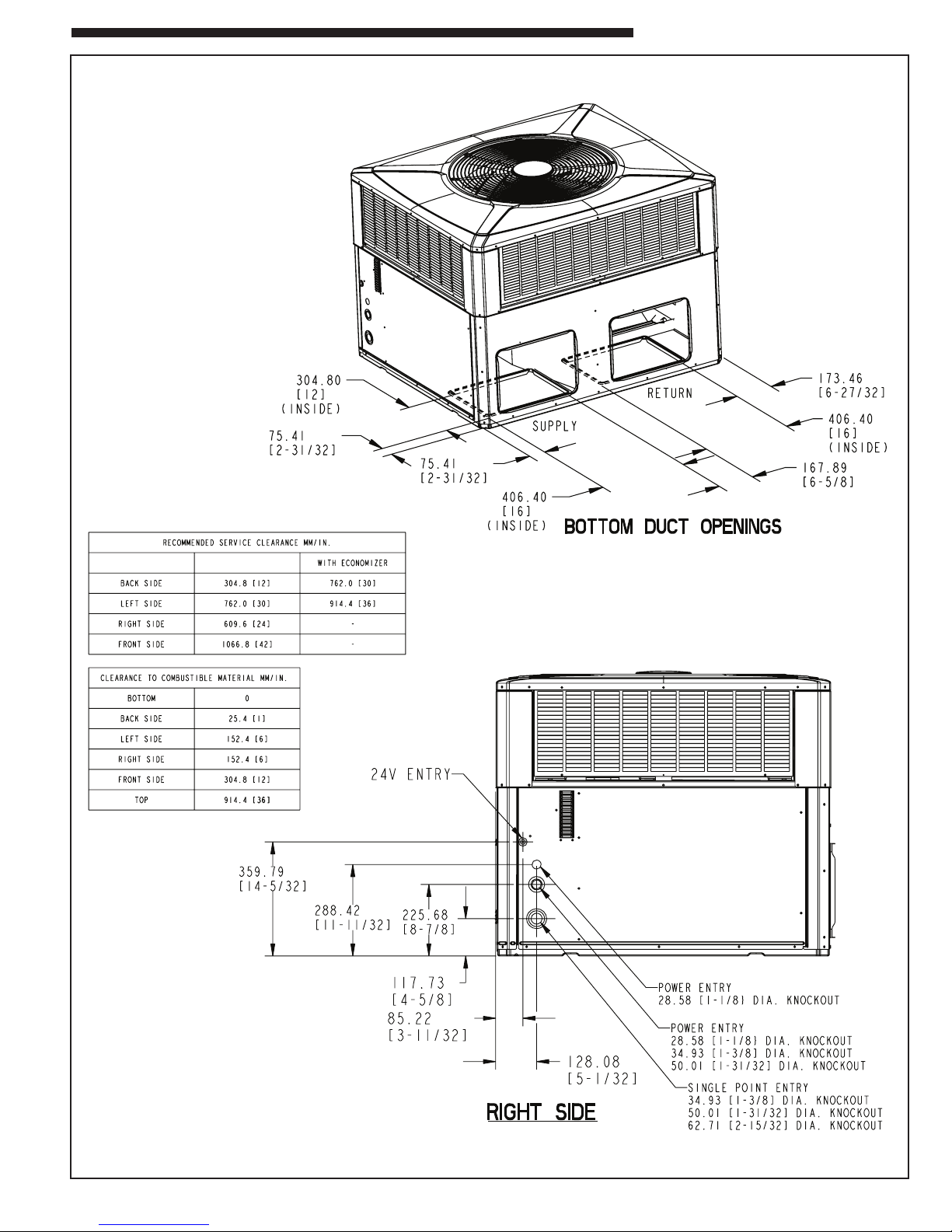

Installer’s Guide

Figure 3. 4WCC3018 through 4WCC3036 (3 of 3)

Page 6

Page 7

Installer’s Guide

NOTE: The view

labeled “Bottom

Side” represents

the Base as viewed

looking up from

underneath the unit.

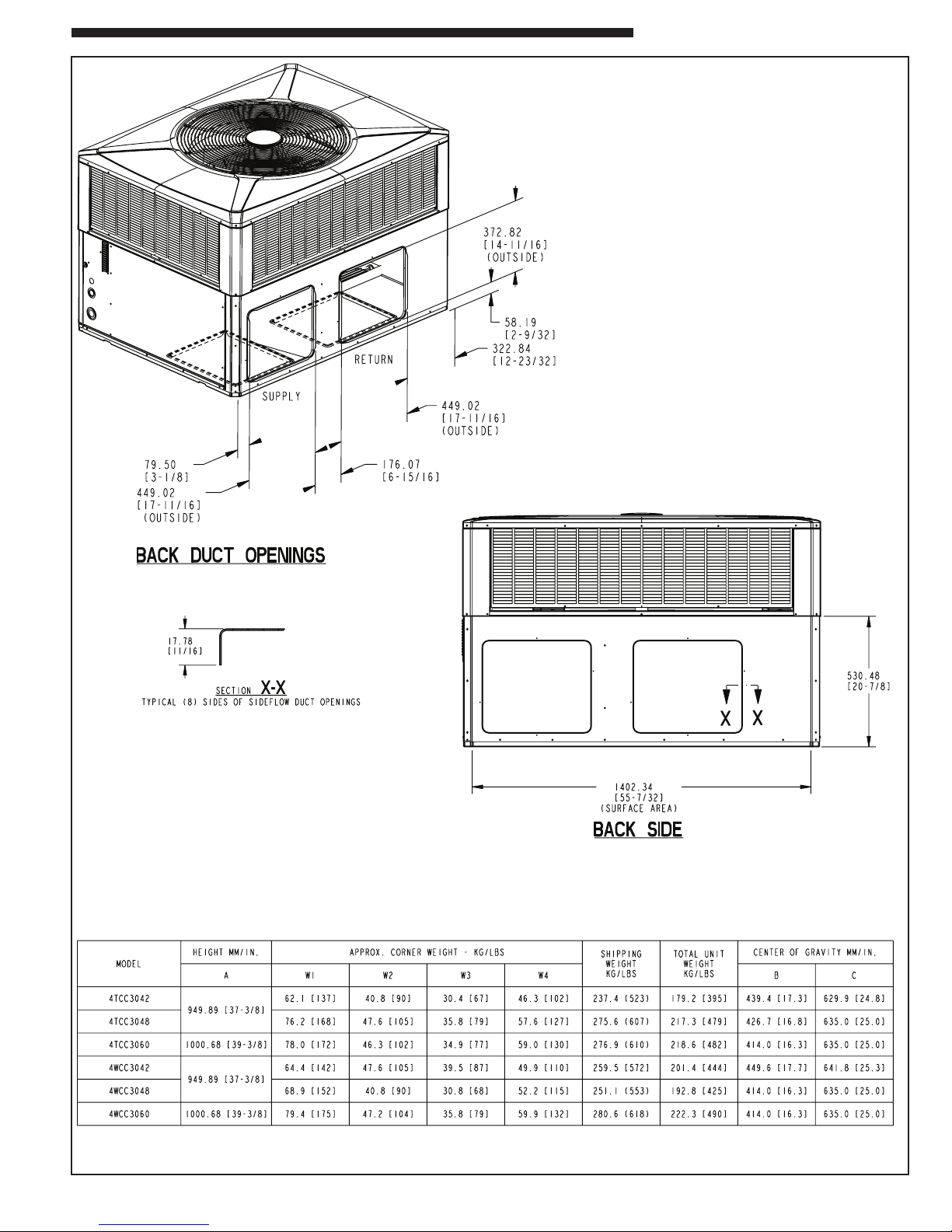

Figure 4. 4WCC3042 through 4WCC3060 (1 of 3)

Page 7

Page 8

Installer’s Guide

Figure 5. 4WCC3042 through 4WCC3060 (2 of 3)

Page 8

Page 9

Installer’s Guide

Figure 6. 4WCC3042 through 4WCC3060 (3 of 3)

Page 9

Page 10

Installer’s Guide

NOTE: The view

labeled “Bottom

Side” represents

the Base as viewed

looking up from

underneath the unit.

Figure 7. 4WCX3018 through 4WCX3036 (1 of 3)

Page 10

Page 11

Installer’s Guide

Figure 8. 4WCX3018 through 2/4WCX3036 (2 of 3)

Page 11

Page 12

Installer’s Guide

Figure 9. 4WCX3018 through 4WCX3036 (3 of 3)

Page 12

Page 13

NOTE: The view

labeled “Bottom

Side” represents

the Base as viewed

looking up from

underneath the unit.

Installer’s Guide

Figure 10. 4WCX3042 through 4WCX3060 (1 of 3)

Page 13

Page 14

Installer’s Guide

Figure 11. 4WCX3042 through 4WCX3060 (2 of 3)

Page 14

Page 15

Installer’s Guide

Figure 12. 4WCX3042 through 4WCX3060 (3 of 3)

Page 15

Page 16

Installer’s Guide

▲

CAUTION

!

Step 3—Review Location and Recommendation Information

Down Airflow Units

Caution must be taken at all times to avoid personal injuries

and/or damage to equipment.

NOTE: The unit is shipped for horizontal installation.

Horizontal Airflow Units

1. Location of the unit must allow service clearance around it

to ensure adequate serviceability, maximum capacity, and

peak operating efficiency.

2. These units are design certified for outdoor installation. They

may be installed directly on a slab, wood flooring, or on

Class A, B, or C roof covering material. The discharge air

from the condenser fans must be unrestricted for a minimum

of 3 feet above the unit.

3. Check the handling facilities to ensure the safety of personnel and the unit(s).

4. The unit must be mounted level for proper drainage of water

through the drain holes in the base pan.

5. The unit should not be exposed to direct roof water runoff.

6. Flexible duct connectors must be of a flame retardant

material. All duct work outside of the structure must be

insulated and weatherproofed in accordance with local

codes.

7. Holes through exterior walls or roof must be sealed in

accordance with local codes.

8. All fabricated outdoor ducts should be as short as possible.

Clearances

1. The recommended clearances for single-unit installations

are illustrated in Figures 1 to 12, pages 4-15.

2. Any reduction of the unit clearances indicated in these

figures may result in condenser coil starvation or the recirculation of warm condenser air. Actual clearances, which

appear to be inadequate should be reviewed with a local

engineer.

3. See the unit’s nameplate for the absolute minimum clearance between the unit and any combustible surfaces.

1. Location of the unit must allow service clearance around it to

ensure adequate serviceability, maximum capacity, and peak

operating efficiency.

2. Refer to the Installation section for instruction on converting

the supply and return airflow covers to down airflow.

3. The field assembled Roof Mounting Curb (BAYCURB050A or

BAYCURB051A) or a field fabricated curb should be in place

before the unit is hoisted to the roof top.

The Roof Mounting Curb (frame) must be installed on a flat,

level section of the roof (maximum of 1/4" per foot pitch) and

provide a level mounting surface for the unit. Also, be sure to

provide sufficient height above the roof to prevent water from

entering the unit.

4. Be sure the mounting curb spans structural members (trusses)

of the roof, thereby providing sufficient support for the weight of

the unit, the curb, the duct(s), and any factory or field installed

accessories.

5. The unit must be mounted level for proper drainage of water

through the drain holes in the base pan.

6. Be sure the hole in the structure for the ducts is large enough

to accommodate the fabricated ducts and the insulation surrounding them. Flexible duct connectors must be of a flame

retardant material. All duct work outside of the structure must be

insulated and weatherproofed in accordance with local codes.

7. Holes through exterior walls or roof must be sealed in accordance with local codes.

8. These units are design certified for outdoor installation. They

may be installed directly on a slab, wood flooring, or on Class

A, B, or C roof covering material. The discharge air from the

condenser fans must be unrestricted for a minimum of 3 feet

above the unit.

9. Check the handling facilities to ensure the safety of personnel

and the unit(s).

Clearances

1. The recommended clearances for single-unit installations are

illustrated in Figures 1 to 12, pages 4-15.

2. Any reduction of the unit clearances indicated in these figures may result in condenser coil starvation or the recirculation of warm condenser air. Actual clearances, which appear

to be inadequate should be reviewed with a local engineer.

3. See the unit’s nameplate for the absolute minimum clearance

between the unit and any combustible surfaces.

Page 16

Page 17

Step 4—Unit Installation

NOTE: The factory ships this unit for horizontal installation.

Ground Level Installation

To install the unit at ground level:

1. Place the unit on a pad the size of the unit or larger. The unit

must be mounted level for proper drainage of water through

the holes in the base pan. To attach the unit securely to the

slab, use extreme mounting kit, BAYEXMK003A.

The pad must not come in contact with the structure (see Fig-

ure 13.) Be sure the outdoor portion of the supply and return

air ducts are as short as possible.

Unit requires vibration support as indicated in Figure 13 below

and in Figure 15 on page 19.

2. Location of the unit must allow service clearance around it.

Clearance of the unit must be given careful consideration.

See Figures 1 to 12, pages 4-15.

NOTE: Any reduction of the unit clearances indicated in these

illustrations may result in condenser coil starvation or the

recirculation of warm condenser air. Actual clearances, which

appear to be inadequate should be reviewed with a local engineer.

IMPORTANT: A minimum 0” clearance to combustible mate-

rial shall be maintained on air outlet duct.

3. Attach the supply and return air ducts to the unit as explained

in the following Ductwork Installation section on page 22.

4. Flexible duct connectors must be of a flame retardant material. Insulate any ductwork outside of the structure with at least

two (2) inches of insulation and weatherproof. There must be

a weather proof seal where the duct enters the structure.

5. Do not expose the unit to direct roof water runoff.

6. Seal all holes through exterior walls in accordance with local

codes.

7. Continue with the following installation sections to complete

the installation: Ductwork on page 22, Filter on page 22, and

Electrical Wiring on page 23.

Installer’s Guide

Rooftop Installation -- Curb Mounting

Convert Horizontal Airflow to Down Airflow

The factory ships the unit for horizontal airflow. Perform this

procedure to convert it to down airflow:

1. Remove the three (3) sheet metal screws securing the supply

air cover and the four (4) sheet metal screws securing the return

air cover from the base of the unit. Remove the covers from the

base. See Figure 14, page 18.

2. Place the covers over the horizontal supply and return openings (painted side out). Align the screw holes, and secure using

the same screws removed in step 1.

Install Full Perimeter Roof Mounting Curb

1. Verify that the roof mounting curb is correct for the unit. There

are two Installer's Guides depending on the cabinet sizes:

• 2/4WC*3018 through 2/4WC*3036 use model BAYCURB050A.

• 2/4WC*3042 through 2/4WC*3060 use model BAYCURB051A.

2. Assemble and install the curb following the instructions in the

appropriate Installer's Guide.

SIDING

RETURN

AIR

DUCT

EXTERIOR

WALL

INSULATE WEATHERPROOF OR RAIN

SHIELD

Figure 13. Typical Ground Level Applications

Page 17

SUPPLY AIR

DUCT

FLEXIBLE DUCT

CONNECTORS

OUTDOOR AIR DISCHARGE

Note: Use the extreme mounting kit, BAYEXMK003AA, to

secure the unit to the slab.

SUPPORT PAD FOUNDATION

3/4" VIBRATION ISOLATORS, USE 7 ISOLATORS

AS SHOWN IN FIGURE 15, PAGE 19.

Page 18

Installer’s Guide

Figure 14. Converting Horizontal to Down Airflow

Lifting and Rigging

IMPORTANT: Do not lift the unit without test lifting for balance

and rigging. Do not lift the unit in windy conditions or above

personnel. Do not lift the unit by attaching clevis, hooks, pins,

or bolts to the unit casing, casing hardware, corner lugs, angles,

tabs, or flanges. Failure to observe these warnings may result

in equipment damage.

1. Before preparing the unit for lifting, check the unit dimension

drawings for center of gravity for lifting safety (Figures 1 to 12,

page 4-15). Because of placement of internal components,

the unit’s weight may be unevenly distributed. Approximate unit

weights are also provided in the unit drawings.

NOTE: Unit rigging and hoisting requires accessory kit BAY-

LIFT002A. It includes a kit of four (4) lifting lugs. See Figure 16

inset B, on page 20.

2. Insert the four lifting lugs in the openings provided in the drip lip

on each end of the unit. See Figure 16 inset B on page 20. A

tap or jerk to the lug will overcome the interference that arises

due to the dimple on the lug.

3. When hoisting the unit, be sure that a proper method of rigging

is used. Use either the unit's top shipping skid and straps or

slings and spreader bars for protection during lifting. Always

test-lift the unit to determine the exact unit balance and stability

before hoisting it to the installation location.

4. When the curb and air ducts have been properly installed, the

unit is ready to be hoisted to the roof and set in position.

IMPORTANT: To prevent damage to the sides and top of the

unit when hoisting, retain the top shipping skid on the unit or

use “spreader bars” as shown on page 20.

Placing the Unit on the Mounting Curb

1. The unit is designed with a perimeter drip lip that is lower than

the unit base pan, see Figure 16, inset A, on page 20.

2. Position the unit drip lip down over and in contact with the outside

corner of the curb, as illustrated in Figure 16, inset A, on page

20. Continue to lower the unit on top of the curb, with the unit

drip lip astraddle, and in contact with, both the end and side rail

of the curb. The unit should now rest on top of the curb. Use the

extreme mounting kit, BAYEXMK001A, to add additional hold

down strength to the mounting.

NOTE: The ductwork is installed as part of the curb installation. Do not attach ductwork to the unit and lower the unit with

ductwork onto the curb.

IMPORTANT: The unit must be lowered into position. The P.V.C.

rubber tape on the curb flange permits the unit to be repositioned

if required without destroying the P.V.C. rubber seals affixed to

the mounting curb.

Page 18

Page 19

Installer’s Guide

Small Cabinet

*****018-036

Medium Cabinet

*****042-060

NOTE: These views represent the base as viewed looking up from underneath the unit.

IMPORTANT: Unit requires vibration isolator support in the general areas shown. Locate 3/4" thick vibration isolators on the

bottom of the basepan as illustrated by black dots for ground level pad applications. Modify vibration isolator location as necessary for frame and rail applications. All vibration isolators must be located on basepan, do not locate on drip lip.

Figure 15. Vibration Isolators/Snow Feet Locations

Rooftop Installation -- Frame Mounting

For roof top applications using field fabricated frame and ducts, use

the following procedure:

1. Locate and secure the frame to the roof by bolting or welding.

Frame must provide adequate center suppor t via a cross member

centrally located channel rail. See Figures 18 and 19 on page

21. Vibration isolators should be installed as indicated in Figure 15, adjust as necessary for your frame. The isolators must

be placed on base pan, not drip lip. Add flashing as required.

Flashing must conform to local building codes.

2. Prepare the hole in the roof in advance of installing the unit.

3. Secure the horizontal or down airflow ducts to the roof. Refer

to the previous Convert from Horizontal Airflow to Down Airflow

section on page 17, if conversion is needed.

4. All fabricated outdoor ducts should be as short as possible.

5. Place the unit on the frame. Refer to Figures 18 or 19 on page

21.

6. The unit must be mounted level for proper drainage of water

through the holes in the base pan.

7. Secure the unit to the frame.

8. Insulate any ductwork outside of the structure with at least two

(2) inches of insulation and then weatherproof. There must be

a weatherproof seal where the duct enters the structure.

9. The unit should not be exposed to direct roof water runoff.

10. Flexible duct connectors must be of a flame retardant material.

All duct work outside of the structure must be insulated and

weatherproofed in accordance with local codes.

11. Access and service clearances for the unit must be given careful consideration when locating the duct entrance openings.

Figures 1 to 12, on pages 4-15, provide unit dimensions.

12. Continue with the following installation sections to complete

the installation: Ductwork on page 22, Filter on page 22, and

Electrical Wiring on page 23.

Rooftop Installation -- Flat Roof - No Curb/Frame

For roof top applications using field fabricated ducts and sleeper

rails rather than a curb or frame, use the following procedure:

1. Locate and secure the sleeper rails to the roof by bolting. Three

(3) sleeper rails are required. One on each end to support the

edges of the unit and one across the center of the unit. The center rail must run inside both drip lips. Vibration isolators should

be installed as indicated on Figure 15, adjust as necessary for

your sleeper rails. The isolators must be placed on base pan,

not drip lip. Add flashing as required. Flashing must conform to

local building codes.

2. Prepare the hole in the roof in advance of installing the unit.

3. Secure the horizontal or down airflow ducts to the roof. Refer

to the previous Convert from Horizontal Airflow to Down Airflow

section on page 17, if conversion is needed.

4. All fabricated outdoor ducts should be as short as possible.

5. Place the unit on the rails.

6. The unit must be mounted level for proper drainage of water

through the holes in the base pan.

7. Secure the unit to the rails.

8. Insulate any ductwork outside of the structure with at least two

(2) inches of insulation and then weatherproof. There must be

a weatherproof seal where the duct enters the structure.

9. The unit should not be exposed to direct roof water runoff.

10. Flexible duct connectors must be of a flame retardant material.

All duct work outside of the structure must be insulated and

weatherproofed in accordance with local codes.

11. Access and service clearances for the unit must be given careful consideration when locating the duct entrance openings.

Figures 1 to 12, on pages 4-15, provide unit dimensions.

12. Continue with the following installation sections to complete

the installation: Ductwork on page 22, Filter on page 22, and

Electrical Wiring on page 23.

Page 19

Page 20

Installer’s Guide

Base of unit

rest on top of

curb rails

Drip lip on

perimeter of

unit

Spreader Bars

IMPORTANT: To prevent damage

to the sides and top of the unit when

hoisting, retain the top shipping skid

on the unit or use “spreader bars” as

shown in these illustrations.

Top shipping skid attached to unit

Gasket Seal

Figure 16. Lifting and Rigging

Drip Lip

Dimple

BAYLIFT002A

Lifting Lugs

This drawing was prepared by the manufacturer in order to provide detail regarding job layout only. This drawing is not

intended to be used as a basis to construct, build or modify the item depicted in the drawing. The manufacturer is not

responsible for the unauthorized use of this drawing and expressly disclaims any liability for damages resulting from

such unauthorized use.

Page 20

Figure 17. Curb Dimensions

Page 21

Roof Flashing

Installer’s Guide

Supply Air

Return Air

Channel Iron Center

Support (Center Support required on all

Frame Applications.)

Angle Iron Frame

Figure 18. Typical Rooftop Horizontal Airflow Application with Frame

Supply Air

Return Air

Roof Flashing

Figure 19. Typical Rooftop Down Airflow Application with Frame

Page 21

Channel Iron Center Support

(Center Support required on all

Frame Applications.)

Roof Flashing

Angle Iron Frame

Page 22

Installer’s Guide

FIELD DUCT

UNIT DUCT

FLANGE

UNIT BASE

AIR PROOF

THIS SEAM

FIELD DUCT

UNIT DUCT

FLANGE

UNIT BASE

AIR PROOF

THIS SEAM

FIELD

DUCT

UNIT DUCT FLANGE

UNIT BASE

AIR PROOF

THIS SEAM

FIELD DUCT

UNIT DUCT

FLANGE

UNIT BASE

NOT RECOMMENDED

WATERPROOF SEAM

WITH BUTYL OR

SILICONE

FIELD DUCT

UNIT EXTERIOR

WEATHERPROOF

THIS SEAM

FIELD DUCT

UNIT EXTERIOR

WEATHERPROOF

THIS SEAM

3

/4" PVC OR COPPER

TUBING AND FITTINGS

1-1/2"

MIN.

1-1/2"

MIN.

Ductwork Installation

Attaching Downflow Ductwork to Roof Curb

Supply and return air flanges are provided on the roof curb for easy

duct installation. All ductwork must be run and attached to the curb

before the unit is set into place.

Attaching Downflow Ductwork to Roof Frame

Follow these guidelines for ductwork construction:

Connections to the unit should be made with three (3) inch canvas

connectors to minimize noise and vibration transmission.

Elbows with turning vanes or splitters are recommended to minimize

air noise and resistance.

The first elbow in the ductwork leaving the unit should be no closer

than two (2) feet from the unit, to minimize noise and resistance.

To prevent leaking, do not attach the ductwork to the bottom of the

unit base. Refer to the bottom example in Figure 20, below.

Figure 21. Attaching Horizontal Airflow Ductwork

Condensate Drain Piping

A 3/4-inch female NPT condensate drain connection is provided on

the evaporator access panel end of the unit. Provide a trap and fill

it with water before starting the unit to avoid air from being drawn

through. Follow local codes and standard piping practices when

running the drain line. Pitch the line downward away from the unit.

Avoid long horizontal runs. See Figure 22, below.

Figure 20. Attaching Down Airflow Ductwork

Attaching Horizontal Ductwork to Unit

All conditioned air ductwork should be insulated to minimize heating

and cooling duct losses. Use a minimum of two (2) inches of insulation

with a vapor barrier. The outside ductwork must be weatherproofed

between the unit and the building.

When attaching ductwork to a horizontal unit, provide a flexible

watertight connection to prevent noise transmission from the unit

to the ducts. The flexible connection must be indoors and made

out of heavy canvas.

NOTE: Do not draw the canvas taut between the solid ducts.

NOTE: Do not use reducing fittings in the drain lines.

The condensate drain must be:

● Made of 3/4" pipe size.

● Pitched 1/4" per foot to provide free drainage to convenient drain

system.

● Trapped.

● Must not be connected to a closed drain system unless the trap

is properly vented.

Figure 22. Typical Condensate Drain Piping

Air Filter Installation

The packaged unit requires an air filter. The unit does not come

with a factory installed filter rack in it, however, two filter frame accessories are offered that will allow the installation of a filter within

the unit, BAYFLTR101 & BAYFLTR201. Otherwise a field supplied

filter rack must be installed by the installer in the return duct work.

Refer to Table1 to determine filter sizes for field supplied filter racks.

Page 22

Page 23

Table 1. Filter Sizes (field supplied filter rack)

Installer’s Guide

UNIT NOMINAL CFM

WC~3018 600 2.00 0.08

WC~3024 800 2.67 0.08

WC~3030 1000 3.33 0.08

WC~3036 1200 4.00 0.08

WC~3042 1400 4.67 0.08

WC~3048 1600 5.33 0.08

WC~3060 2000 6.67 0.08

*Filters must be installed in the return air system. The above square footages are

based on 300 F.P.M. face velocity. If permanent filters are used, size per manufacturer recommendation with clear resistance of 0.05" W.C.

FILTER SIZE

(Sq Ft)

FILTER RESISTANCE

("W.C.)

Electrical Wiring

Note: This unit is factory wired for 230V. See wiring diagram

for 208V conversion.

Electrical Connections

Electrical wiring and grounding must be installed in accordance

with local codes or, in the absence of local codes, with the National

Electrical Code ANSI/NFPA 70, Latest Revision.

Electrical Power

It is important that proper electrical power be available for the unit.

Voltage variation should remain within the limits stamped on the

unit nameplate.

Disconnect Switch

Provide an approved weatherproof disconnect within close proximity and within sight of the unit. If disconnect must be mounted

to the cabinet, the location shown in Figure 25 should be the only

one considered.

Over Current Protection

The branch circuit feeding the unit must be protected as shown on

the unit's rating plate.

Power Wiring

The power supply lines must be run in weather-tight conduit to the

disconnect and into the side of the unit control box. Provide strain

relief for all conduit with suitable connectors.

Provide flexible conduit supports whenever vibration transmission

may cause a noise problem within the building structure.

1. Remove the Control/Heat access panel. Pass the power

wires through the Power Entry hole in the end of the unit.

See Figure 23.

2. Connect the high voltage wires to the appropriate contactor

terminals. Single phase units use a two (2) pole contactor

and three phase units use three (3) pole contactor. Connect

the ground to the ground lug on the chassis. See Figure 25.

Be sure all connections are tight.

GROUNDING: THE UNIT MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES OR

THE NATIONAL ELECTRIC CODE.

Run power supply Lines through weather-tight

conduit and secure to unit with strain relief

Figure 23. Power Wiring

Contactor

Unit Ground Lug

Figure 24. Power Connections

Page 23

Figure 25. Mounted Disconnect Location

Page 24

Installer’s Guide

COMMON

FAN

COMPRSSOR

1ST STAGE ELECTRIC HEAT

2ND STAGE ELECTRIC HEAT

SWITCHOVER VALVE

DEFROST CONTROL 'T' SIGNAL

24 VOLTS

B

G

Y

W1

W2

O

T

R

UNIT LOW VOLTAGE AREA

TYPICAL THERMOSTAT

UNIT HEATER AREA

ELECTRIC

HEATER

CONTROL

BOX

POLARIZED

PLUG

UNIT CONTROL BOX

3 PH

POWER

UNIT

NOTE 1,8

3 PH

POWER

HEATER

1 PH

POWER

1 PH

POWER

UNIT CONTROL

BOX

UNIT HEATER AREA

FACTORY PROVIDED

FIELD CONNECTED

WIRES

(BL)

(YL)

(GR)

(PR)

(OR)

(OR)

B

G

Y

W1

W2

O

T

R

(BR)

(RD)

(GR)

(BL)

(WH)

(WH)

(YL)

(OR)

1 PH

POWER

3 PH

POWER

GROUND

WIRE

SINGLE POWR ENTRY

W1

W2

(WH)

(WH)

W1

W2

(WH)

(WH)

HEATER SECOND STAGE AMBIENT

TEMPERATURE LOCKOUT

NOTE 7,8

UNIT LOW

VOLTAGE

AREA

OUTDOOR

THERMOSTAT

ACCESSORY

BAYSTAT033A

NOTE 10

HEATER AMBIENT

TEMPERATURE LOCKOUT

NOTE 7,8

UNIT LOW

VOLTAGE

AREA

OUTDOOR

THERMOSTAT

ACCESSORY

BAYSTAT033A

NOTE 10

TYPICAL THERMOSTAT

TYPICAL THERMOSTAT

TYPICAL 2-STAGE

THERMOSTAT

UNIT LOW

VOLTAGE AREA

UNIT LOW

VOLTAGE AREA

TO COMPR.

CONTACTOR

ELECTRIC

HEATER

CONTROL

BOX

HEATER

FUSES

UNIT

FUSES

SPE

ACCESSORY

KIT

TO ECONOMIZER

FACTORY PROVIDED

FIELD INSTALLED WIRES

NOTE 9

(NOT APPLICABLE TO THE

WCM---F MODELS)

FIG. 3 OUTDOOR THERMOSTAT ACCESSORY CONNECTIONS

FIG. 1

SINGLE POWER ENTRY ACCESSORY CONNECTIONS FIG. 2 ECONOMIZER ACCESSORY

CONNECTIONS

GROUND

WIRE

SEE SPEK INSTALLER'S GUIDE

FOR ALL OTHER EXAMPLES

NOTES:

1. FUSED DISCONNECT SIZE, POWER WIRING AND

GROUNDING OF EQUIPMENT MUST COMPLY WITH

CODES.

2. BE SURE POWER SUPPLY AGREES WITH EQUIPMENT AND HEATER NAMEPLATE.

3. LOW VOLTAGE WIRING TO BE 18 AWG MINIMUM

CONDUCTOR.

4. SEE HEATER NAMEPLATE FOR CURRENT RATING

OF HEATER USED.

5. SEE UNIT AND HEATER DIAGRAM FOR ELECTRICAL

CONNECTION DETAILS.

6. IF ELECTRIC HEATER ACCESSORY IS NOT

INSTALLED OMIT THE ELECTRIC HEATER, ASSOCIATED POWER WIRES AND THE ‘W’ AND ‘X2’

THERMOSTAT WIRES.

7. FIG. 3 DEMONSTRATES CONNECTION OF THE

OUTDOOR THERMOSTAT ACCESSORY ONLY. FOR

FURTHER UNIT CONNECTION DETAILS REFER TO

THE OTHER FIGURES.

8. THE W1 WIRE IS FIRST STAGE ELECTRIC HEAT. IF

THE ELECTRIC HEATER ACCESSORY HAS TWO

HEATING STAGES THE W2 WIRE IS SECOND STAGE

ELECTRIC HEAT.

9. WHEN THE BAYECON101A/102A or

BAYECON200A/201A ECONOMIZER IS INSTALLED,

THE BAYRLAY004A RELAY ACCESSORY KIT IS REQUIRED TO INTERFACE THE ECONOMIZER TO THE

HEAT PUMP FOR PROPER SYSTEM OPERATION.

10. THE BAYSTAT033A OUTDOOR THERMOSTAT ACCESSORY KIT CONTAINS A THERMOSTAT AND A

RELAY. THE RELAY IS NOT REQUIRED TO BE USED

IN THIS APPLICATION.

Page 24

Figure 26. 4WC*3 Field Wiring Diagram

Page 25

Installer’s Guide

▲

CAUTION

!

▲

WARNING

!

Control Wiring (Class II)

Low voltage control wiring should not be run in conduit with power

wiring unless Class 1 wire of proper voltage rating is used. Route

the thermostat cable or equivalent single leads of No. 18 AWG

colored wire from the thermostat subbase terminals through the

rubber grommet on the unit. See Figures 1-12 (pages 4-15) for the

control entry (24V Entry) location. Make connections as shown on

the field wiring diagram Figure 26, page 24.

Do not short thermostat wires since this will damage the control

transformer.

Refer to Table 2 for recommended wire sizes and lengths for installing the unit thermostat. The total resistance of these low voltage

wires must not exceed one (1) ohm. Any resistance in excess of 1

ohm may cause the control to malfunction because of the excessive voltage drop.

Table 2. Thermostat Wire Size and Maximum Length

WIRE SIZE MAXIMUM LENGTH (Ft)

18 75

16 125

14 200

IMPORTANT: Upon completion of wiring, check all electrical connections, including factory wiring within the unit, and make sure all

connections are tight. Replace and secure all electrical box covers

and access panels before leaving the unit or turning on the power

to the unit.

Step 5—Unit Startup

Pre-Start Quick Checklist

Is the unit properly located and level with the proper

clearance? See Figures 1-12, pages 4-15. See Step 2-Review

Location and Clearances on page 4.

Is the duct work correctly sized, run, taped, insulated, and

weatherproofed with proper unit arrangement? See

Ductwork Installation section on page 22.

Is the condensate line properly sized, run, trapped, and

pitched? See Condensate Drain Piping section on page

22.

Is the filter of the correct size and quantity? Is it clean and in

place? See Air Filter Installation section on page 22.

Is the wiring properly sized and run according to the unit

wiring diagram? See Electrical Wiring section on page 23.

Are all the wiring connections, including those in the unit,

tight? See Electrical Wiring section on page 23.

Has the unit been properly grounded and fused with the

recommended fuse size? See Electrical Wiring section on

page 23.

Is the thermostat well located, level, and correctly wired?

See Electrical Wiring section on page 23.

Have the air conditioning systems been checked at the service

ports for charge and leak tested if necessary?

Do the condenser fan and indoor blower turn free without

rubbing, and are they tight on the shafts?

Has all work been done in accordance with applicable local

and national codes?

Are all covers and access panels in place to prevent air loss and

safety hazards?

Starting the Unit in Cooling Mode

Safety Hazard. Do not operate the unit without the evaporator fan access panel or evaporator coil access panel in place.

Reinstall the access panels after performing maintenance

procedures on the fan. Operating the unit without the access

panels properly installed may result in severe personal injury

or death.

Before starting the system on the cooling cycle, turn the thermostat switch to OFF and close the unit disconnect switch. This

is a precaution against foaming at startup which could damage

the compressor bearings.

NOTE: See the section on Sequence of Operation , page 26

for a description of the cooling operating sequence.

To start the unit in the cooling mode, set the comfort control to

COOL and to a setting below room temperature. The condenser

fan motor, compressor and evaporator fan motor will operate automatically. Continuous fan mode during Cooling operation may

not be appropriate in humid climates. If the indoor air exceeds

60% relative humidity or simply feels uncomfortably humid, it is

recommended that the fan only be used in the AUTO mode.

Operating Pressure Checks

After the unit has operated in the cooling mode for a short period of

time, install pressure gauges on the gauge ports of the discharge

and suction line valves (behind the Compressor access panel).

Check the suction and discharge pressures and compare them to the

normal operating pressures provided in the unit’s SERVICE FACTS.

NOTE: Do not use the pressures from the unit's SERVICE

FACTS to determine the unit refrigerant charge. The correct

charge is shown on the unit nameplate. To charge the system

accurately, weigh in the charge according to the unit nameplate.

Voltage Check

With the compressor operating, check the line voltage at the unit

(contactor is located behind the Control access panel). The voltage

should be within the range shown on the unit nameplate. If low

voltage is encountered, check the size and length of the supply line

from the main disconnect to the unit. The line may be undersized

for the length of the run.

Cooling Shut Down

Set the comfort control to OFF or to a setting above room temperature.

IMPORTANT: De-energize the main power disconnect ONLY when

servicing the unit. Power may be required to keep the heat pump

compressor warm and to boil off refrigerant in the compressor.

Page 25

Page 26

Installer’s Guide

Starting the Unit in Heating Mode

NOTE: See the section on Sequence of Operation for a description of the heat pump heating operating sequence.

Check that all grills and registers are open and all unit access panels

are closed before start-up.

Set the comfort control above room temperature until achieving a

first stage call for heat and set the fan to AUTO or ON.

Heating Shut Down

Set the comfort control to OFF or at a setting below room temperature.

Sequence of Operation

General

Operation of the unit heating and cooling cycles is automatic when

the system is in the HEAT or COOL functions (the optional automatic

changeover thermostat, when in the AUTO position, automatically

changes to heat or cool with an appropriate room temperature

change). The fan can be set to ON, causing continuous evaporator (indoor) fan operation or set to AUTO causing fan operation to

coincide with heating or cooling run cycles. Continuous fan mode

during Cooling operation may not be appropriate in humid climates.

If the indoor air exceeds 60% relative humidity or simply feels uncomfortably humid, it is recommended that the fan only be used in

the AUTO mode.

Cooling Mode

Note that the TSH and TSC are contacts that are internal to the

indoor comfort control.

With the disconnect switch in the ON position, current is supplied

to the compressor crankcase heater and control transformer (the

outdoor fan relay (ODF) relay is energized through normally closed

contacts on the defrost timer control (DFC) on the 460V units only.).

The cooling cycle is enabled through the low voltage side of the

control transformer to the “R” terminal on the indoor thermostat.

With the comfort control set to AUTO and TSC-1 contacts closed,

power is supplied to the “O” terminal on the indoor thermostat to

the switchover valve coil (SOV). This ener gizes the switch-over

valve (SOV) and places it in the cooling posi tion (it is in the heating

position when de-energized).

When the indoor temperature rises 1-1/2 degrees, TSC-2 contacts

close, supplying power to the “Y” terminal on the indoor thermo stat,

and to the compressor contactor (CC). This starts the outdoor fan

motor and compressor. The TSC-2 contacts also provide power to

the “G” terminal which provides power to the fan relay (F) starting

the indoor fan motor.

Heating Mode

With the comfort control set to ON, current is sup plied to the compressor crankcase heater and control trans former. (The outdoor

fan relay (ODF) is energized through normally closed contacts on

the defrost timer control (DFC) on the 460V units). Starting at the

“R” terminal on the indoor comfort control, current goes through

the system switch (which is in “AUTO” position) to the TSH-1 con-

tacts. When closed, these con tacts supply power to terminal ”Y”

on the indoor thermostat as well as to the heating anticipator. The

switch-over valve will not ener gize because of the high resistance

of the heating anticipator in the thermostat. Power is provided from

“Y” to the compressor contac tor (CC) which starts the compressor

and outdoor fan motor. The indoor thermostat contact TSH-1 also

provides power to “G” ter minal on the indoor thermostat energizing

the fan relay (F), which starts the indoor fan motor.

Supplementary Heat

The supplementary electric heat is brought on when the indoor

temperature drops 1-1/2 degrees below the thermostat setting.

TSH-2 contacts close providing power to the “W” terminal on the

indoor thermostat and to the supplementary heater control circuit.

Note that the fan relay (F) must have been energized. An outdoor

thermostat may have been added to disallow the second stage (if

provided) of electric heat above a selected outdoor temperature.

If the outdoor temperature falls below the setting on the outdoor

thermostat, this additional heater stage will come on. When the

outdoor air temperature rises, and the outdoor T-stat setpoint is

reached, the system will revert back to first stage electric heating.

When the indoor ambient is satisfied, TSH-2 contacts will open and

the unit will revert back to the compressor only heating mode and

then off. For emergency heat (use of supplementary electric heat

only), an emergency (EMERG) heat switch is provided within the

comfort control. When placed in the emergency heat position, it will

dis able the compressor, bypass the outdoor thermostats, if provided,

and engage the supplementary electric heaters and indoor fan.

Demand Defrost Operation

During the heating cycle, the outdoor coil may require a defrost

cycle which is determined by the demand defrost control (DFC). This

control continuously measures the outdoor coil temperature (CBS)

and the outdoor ambient temperature (ODS-B) and calculates the

difference or delta-T measurement. When the calculated delta-T is

met, the demand defrost control (DFC) opens the circuit to the outdoor fan motor (ODM) and energizes the switch-over valve (SOV),

placing the unit in the cooling mode to defrost the outdoor coil (on

SCROLL bearing units only, the control will stop the compressor

for a minimum of thirty (30) seconds). The outdoor coil temperature

sensor (CBS) terminates the defrost cycle, or times off after twelve

minutes in defrost, the (DFC) energizes the outdoor fan motor (ODM)

and twelve seconds later de-ener gizes the (SOV), which returns the

unit to the heating mode. Supple mentary electric heat, if provided,

is brought on to control indoor temperature during the defrost cycle.

Defrost Control

The demand defrost control measures heat pump outdoor

ambient temperature with a sensor located outside the outdoor

coil. A second sensor located on the outdoor coil is used to

measure the coil temperature. The difference between the

ambient and the colder coil temperature is the difference

or delta-T measurement. This delta-T measurement is

representative of the operating state and relative capacity of the

heat pump system. Measuring the change in delta-T determines

the need for defrost. The coil sensor also senses outdoor coil

temperature for termination of the defrost cycle.

NOTE: Refer to the SERVICE FACTS for fault detecting, test sensor, and checkout procedures.

Page 26

Page 27

Installer’s Guide

Final Installation Checklist

Does the unit run and operate as described in the section on

Sequence of Operation, page 26, in response to the room

thermostat?

Are the condenser fan and indoor blower operating correctly

with proper rotation and without undue noise?

Is the compressor operating correctly and has the system

been checked with a charging chart?

Has the voltage and running current been checked to deter

mine if it is within limits?

Has the thermostat been checked for calibration and the air

discharge grills adjusted to balance the system?

Has the ductwork been checked for air leaks and

condensation?

Has the furnace manifold pressure been checked and

adjusted if necessary?

Has the heating air temperature rise been checked?

Has the unit been checked for tubing and sheet metal

rattles? Are there any other unusual noises to be checked?

Are all covers and panels in place and properly fastened?

Has the owner been instructed on the proper operation and

maintenance of the unit? Be sure to leave this manual with

the owner.

Service Maintenance

Cooling Season

To keep the unit operating safely and efficiently, the manufacturer

recommends that a qualified service technician check the entire

system at least once each year or sooner if needed. The service

technician should examine these areas of the unit:

● filters (for cleaning or replacement)

● motors and drive system components

● economizer gaskets (for possible replacement)

● safety controls (for mechanical cleaning)

● electrical components and wiring (for possible replacement

and connection tightness)

● condensate drain (for proper sealing and cleaning)

● unit duct connections (to see that they are physically sound

and sealed to the unit casing)

● unit mounting support (for structural integrity)

● the unit (for obvious unit deterioration)

Heating Season

Complete the following unit inspections and service routines at

the beginning of each heating season.

● Visually inspect the unit to ensure that the airflow required

for combustion and condenser coil is not obstructed from the

unit.

● Inspect the control panel wiring to verify that all electrical

connections are tight and that the wire insulation is intact.

Maintenance

Owner Maintenance

Some of the periodic maintenance functions of the unit can be

performed by the owner; this includes replacing the disposable

or cleaning the permanent air filters, cleaning the unit cabinet,

cleaning the condenser coil, and conducting a general unit

inspection on a regular basis.

Filters

When the system is in constant operation, inspect the filters

at least once each month.

If the unit has disposable-type filters, replace them with new

filters of the same type and size. Do not attempt to clean

disposable filters.

Permanent-type filters can be cleaned by washing them with a

mild detergent and water. Make sure that the filters are thoroughly

dry before reinstalling them in the unit (or duct system).

NOTE: It may be necessary to replace permanent filters

annually if washing fails to clean the filter or if the filter shows

signs of deterioration. Be sure to use the same type and

size as was originally installed.

Condenser Coil

Be sure to keep all vegetation and debris away from the condenser coil area.

Indoor Fan Motor Speed Tap Setting

The 208/230 and 460 Volt units are factory set to high speed

with one exception. The 4WC*3030 is factory set to low

speed.

208/230 Volt Motor Tap Settings (Figure 25, page 28)

High speed setting: On the IGN board:

1. Connect the "RD" wire to the "PARK" terminal.

2. Connect the (IDM) PR wire to the "BLOWER LOAD" terminal.

Low speed setting: On the IGN board:

1. Connect the "RD" wire to the "BLOWER LOAD" terminal.

2. Connect the (IDM) PR wire to the "PARK" terminal.

460 Volt Motor Tap Settings (Figure 26, page 28)

High speed setting (460V):

1. At the "FTBA", connect the "PR" wire from the IGN board to

the "HI" (B) terminal.

2. Connect the "PR" wire from the "HI" (B) terminal on the

"FTBA" to the "H" terminal on the IDM.

3. Connect the Orange wire on the IDM to the "P" terminal on

thE IDM.

Low speed setting (460V):

1. At the "FTBA", connect the "PR" wire from the IGN board to

the "LOW" (D) terminal.

2. Connect the "PR" wire from the "HI" (B) terminal on the

"FTBA" to the "P" terminal on the IDM.

3. Connect the Orange wire on the IDM to the "H" terminal on

the IDM.

Page 27

Page 28

Installer’s Guide

LOAD

BLOWER

LOAD

INDUCER

YL

(CC1) RD

RD

(IDM) PR

PARK

IN

IN

( CC1) RD

LOAD

BLOWER

LOAD

INDUCER

YL

(CC1) RD

RD

(IDM) PR

PARK

IN

IN

( CC1) RD

(IGN) PR

P

H

L

IDM

BK

HI

LOW

RD

PR

ORANGE

YELLOW

BLACK

(IGN) PR

P

H

L

IDM

BK

HI

LOW

RD

PR

ORANGE

YELLOW

BLACK

B

B

D

D

C

C

Hi Speed Tap

Setting

Low Speed Tap

Setting

Hi Speed Tap Setting

Low Speed Tap Setting

Figure 26. 460 Volt Speed Taps

Figure 25. 208/230 Volt Speed Taps

Important Product Information

Registering your products helps provide you with one of the strongest manufacturer limited warranties available. To register, go to the

manufacturer’s website or contact your dealer. You will need the serial number, model number, and installation date for each product

being registered. Your dealer may have included these on your invoice or can provide a list for you to use. Please take a few moments to

record the following information to ensure your product registration process is quick and easy:

Packaged Unit Serial Number_____________________________________________________

Packaged Unit Model Number_____________________________________________________

Date of Installation______________________________________________________________

Dealer________________________________________________________________________

Service Information

Call your installing dealer if the unit is inoperative. Before you call, always check the following to be sure service is required:

Service Phone_________________________________________________________________

a. Be sure the main switch that supplies power to the unit is in the ON position.

b. Replace any burned-out fuses or reset circuit breakers.

c. Be sure the thermostat is properly set.

Trane

6200 Troup Highway

Tyler, TX 75707-9010

© 2014 Trane

Page 28

The manufacturer has a policy of continuous product and product data improvement.

It reserves the right to change design and specification without notice.

04/14

Loading...

Loading...