TRAMEX RWS User Manual

RWS

Roof & Wall

Moisture Scanner

NON-DESTRUCTIVE

MOISTURE DETECTION

FOR

BUILT-UP &

SINGLE PLY ROOFS

AND

EXTERIOR

INSULATION

FINISHING SYSTEMS

(EIFS)

User

Guide

RWSUG01/05

TRAMEX MOISTURE/HUMIDITY

INSTRUMENTS

DEC SCANNER.

Mobile non-destructive moisture surveying instrument

for inspecting flat roofs.

LEAK SEEKER.

Leak tracing in flat and built-up roofing

SURVEY ENCOUNTER.

“State of the art” non-destructive moisture meter for

measuring and recording moisture in building

materials.

MOISTURE ENCOUNTER PLUS.

Non-destructive moisture meter employing advanced

analog and digital technology with automatic timed cutout and HOLD facility.

PROFESSIONAL MOISTURE METER.

Digital resistance meter with probes, tests deep into

wood.

COMPACT MOISTURE METER.

Economical pin-type resistance meter for wood.

WOOD MOISTURE ENCOUNTER.

Non-destructive testing of wood and wood products.

CONCRETE ENCOUNTER CME 4.

Non-destructive moisture meter for concrete floors.

CRH FLOORING METER.

“State of the art” non-destructive testing and recording

of moisture content and relative humidity in concrete,

gypsum screeds and sub-floors.

SKIPPER PLUS

Checks wooden boats for decay and finds osmosis in

GRP.

MOISTURE & HUMIDITY KITS ARE

AVAILABLE FOR THE FOLLOWING

INDUSTRIES:

EIFS and Wall Inspection, Roof inspection, Floor

inspection, Indoor Air Quality and Building

Maintenance

R.W.S.

User Guide

R.W.S.

User Guide

Roof and Wall Moisture Scanner R.W.S. ......................4

Introduction..............................................................4

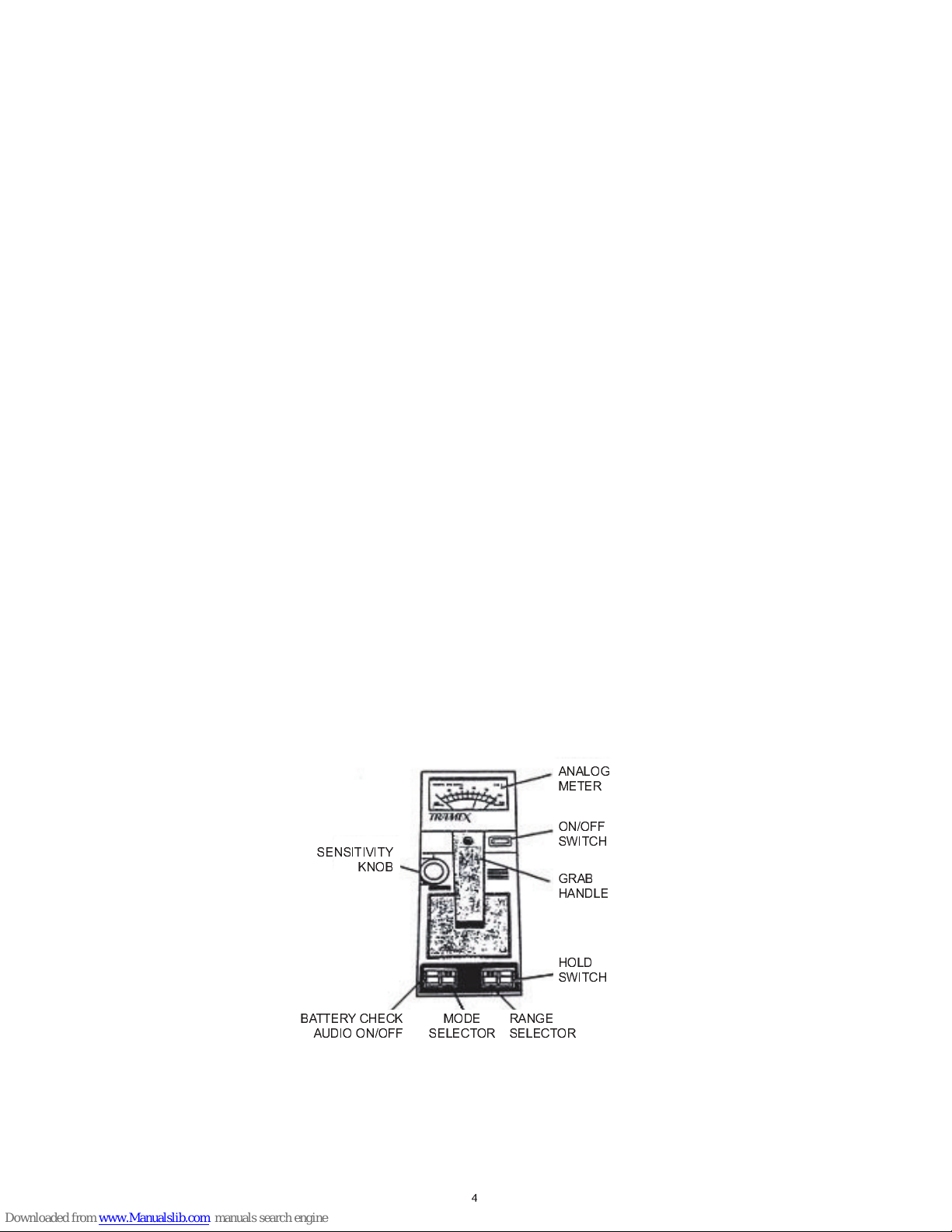

Fig. 1. The RWS......................................................4

Modes Of Operation ................................................5

How It Works ..........................................................5

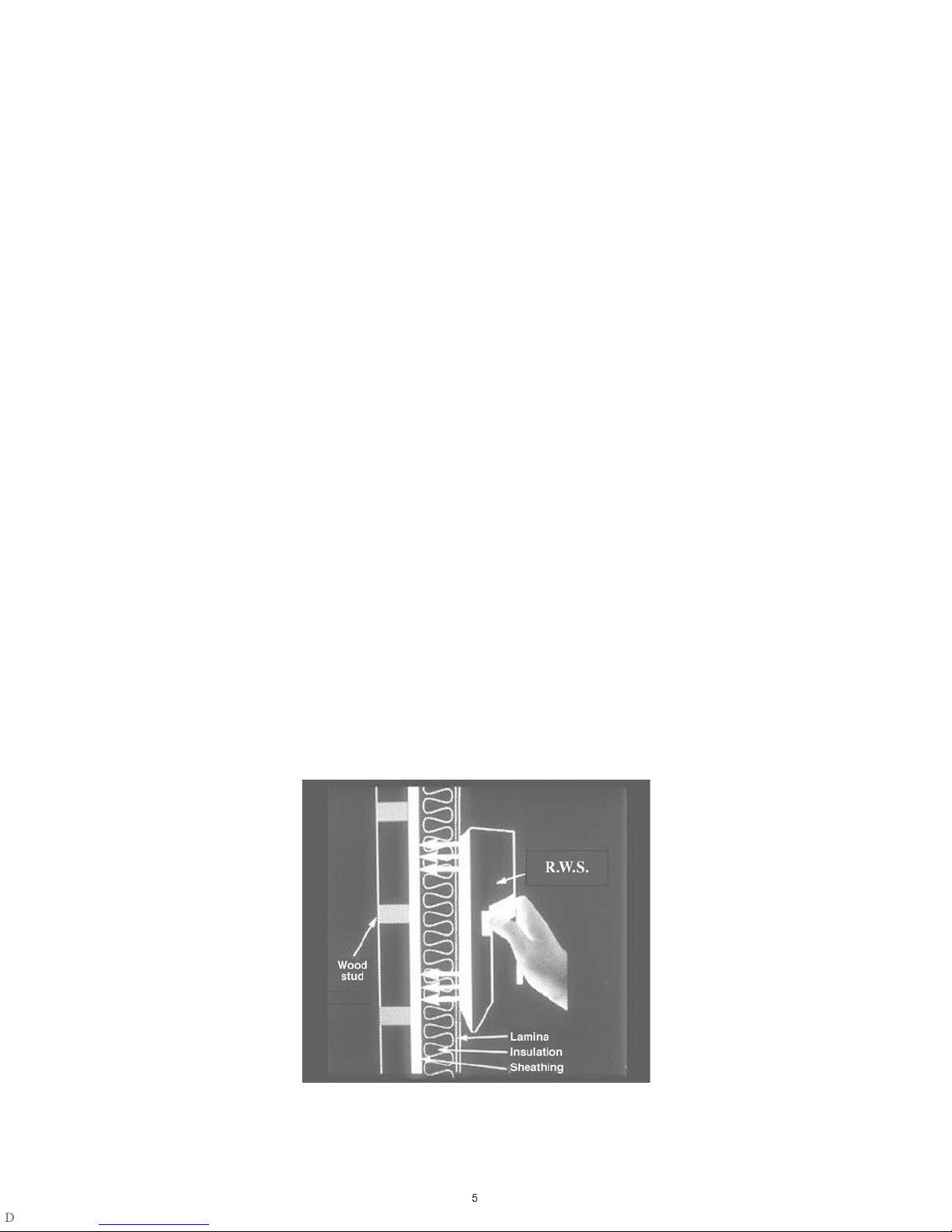

Fig. 2. RWS Low Frequency Signals on EIFS........5

Principles Of Operation ..........................................6

Prior To Use.............................................................6

Conducting A Moisture Survey ..............................6

OPERATION MODES ..................................................7

EIFS MODE ............................................................7

ROOF MODE..........................................................7

Conducting A Moisture Survey: ....................................8

IN EIFS Mode ........................................................8

Fig. 3. Laboratory Mock-Up ..................................9

Interpretation of Readings ......................................9

Table 1. Comparison of RWS and Professional

Pin Type Resistance Meter Readings ......................10

Tracing Moisture Back To Source In EIFS Or

Similar Construction................................................11

Fig. 4. Professional Pin Meter With

Deep Wall Probe......................................................11

Conducting A Moisture Survey: ....................................12

In Roof Mode ..........................................................12

Conducting A Roof Survey............................................12

Procedure ................................................................12

Fig. 5. Roof Grid Sketch ........................................13

Tracing A Leak And Checking Suspected

Trouble Areas ..........................................................13

Fig. 6. Tracing and Marking a Leak

on your Roof ............................................................14

Types Of Roofing Structures And Their More

Common Problems ..................................................14

Possible Problems Leading To Moisture Intrusion

Of The Roof System ................................................15

Moisture Survey Checklist ......................................15

Useful Items Required When Conducting

A Survey...................................................................15

Correct Use Of RWS. ..............................................16

Maintenance of RWS...............................................16

Warranty ........................................................................17

Warranty Claims ......................................................17

Product Development ..............................................17

Safety ......................................................................17

Additional Notes ............................................................18

R.W.S.

User Guide

Roof and Wall Moisture Scanner R.W.S.

Introduction

The RWS is a hand held, non-destructive, electronic

moisture meter specially developed for non-destructive

moisture evaluation and surveying of built-up or single

ply roofing and EIFS (Exterior Insulation Finishing

Systems).

The Tramex RWS is an effective Moisture Scanner with

2 operating modes, EIFS (Walls) and Roofing, each

mode has 2 ranges of sensitivity, affording you the

opportunity to scan roofing, walls and the building

envelope for excess moisture. In the EIFS mode, the

RWS can also be used on foamed-over roofing systems.

For those familiar with Tramex moisture meters, the

RWS incorporates two of Tramex’s well-known moisture scanners, with additional features and benefits, in

one instrument. These are the Leak Seeker, for Roofing

moisture detection and Wet Wall Detector for Wall

(EIFS) moisture detection.

To get maximum benefit from your TRAMEX RWS, it

is suggested before undertaking a moisture survey, that

you read this manual to familiarise yourself with the

operation, features and capabilities of this multi-mode

non-destructive moisture detection and scanning instrument.

Fig. 1. The R.W.S.

R.W.S.

User Guide

Modes Of Operation

The RWS (Roof and Wall Moisture Scanner) has two

operating modes, each with two ranges of sensitivity.

EIFS Mode (Yellow LED selected on MODE switch.)

is for moisture scanning of exterior insulation and finish system (EIFS) and similar type of construction

cladding as well as polyurethane and polystyrene foam

insulation and other types of low-density insulation systems applied to the building envelope.

Roof Mode (Red LED selected on MODE switch) is for

moisture scanning and leak tracing of built-up and single ply roofing systems.

Each of these measurement modes incorporates two

sensitivities, which are activated by pressing the

RANGE switch:

Yellow LED for lower sensitivity and lower penetration. Red LED for higher sensitivity and deeper penetration.

How It Works

The R.W.S. is an electronic instrument powered by one

9volt PP3 or similar battery. It operates on the principal of electrical impedance measurement. This means

that a harmless, low frequency, non-destructive signal

is sent from the two rubber coated electrodes at the base

of the instrument through the surface of the material

being tested, deep into this material. See Figure 2.

Fig. 2. RWS Low Frequency Signals On EIFS

Principles Of Operation

To measure / detect moisture, the rubber coated base of

the instrument is pressed onto the material being tested.

The detection signals from the instrument penetrate the

material under test to a depth of up to approximately 75

mm. (3 inches) depending on the mode, the range of

sensitivity selected and the material being tested. The

small current flowing through the field is inversely proportional to the impedance of the material. This current

is a measure of the change in the electrical impedance

caused by a change in the moisture content. This

change is translated by the RWS and instantly and continuously displayed on the large clear analog dial which

gives comparative readings of 0 to 100.

Prior To Use.

Although the RWS is checked on manufacture and at

quality control to ensure it is in working order before

leaving the factory, a few minor checks should be carried out following transit. These are as follows :

Depress ON/OFF switch (located on facia right side of

grab handle) to power on the RWS. Check battery

strength by depressing BATTERY check switch. The

needle on the analog dial should go past the BATTERY

line on the dial. If not, change the battery. Set the sensitivity dial to 10, place your hand on the base of the

instrument, making contact with both electrodes, a fullscale reading of 100 should be obtained, irrespective of

which mode or range is selected. See Figure 1. for

graphic illustration of switches and controls.

Ensure that your new RWS is received in pristine condition, just as it left our factory. Complete and return

warranty registration card to Tramex or the supplier of

your RWS.

Conducting A Moisture Survey

1. Before commencing moisture testing, it is advisable

to familiarise yourself with the RWS, its functions

and principles of operation.

2. It is also advisable, prior to commencing your moisture survey, to familiarise yourself with construction

details and specification, in particular, thickness of

exterior insulation, type and thickness of lamina,

number of layers of lamina and its reinforcing, coating and covering materials. The composition and

specification of the substrate material is also worth

knowing. This familiarisation will help you to make

the best use and interpretation of the RWS.

R.W.S.

User Guide

Loading...

Loading...