TRAMEX CMEX II User Manual

04/2015

user guide

CMEX II

concrete moisture

meter (Digital)

USER GUIDE

TABLE OF CONTENTS

Introduction.......................................................................4

How it works...................................................................5-6

Instrument Features........................................................7-8

Operating Instructions.......................................................9

Non-Destructive Measurement Mode .......................10-15

Concrete Scale.............................................................10

CM (Carbide Method) Equivalent Scale......................11

Gypsum Scale..............................................................11

REF (Reference) Scale..................................................11

Calibration .................................................................12

CMEX II Displays.......................................................13

Drying time for concrete oors and screeds............13-14

Testing moisture content in a oor slab.......................14

Pre-testing guidelines..................................................14

Guideline test procedures as per ASTM F2659...........15

Humidity Measurement Mode ..................................16-25

Relative Humidity Measurement................................17

Moisture Testing Guidelines...................................17-23

Hole Liner Instructions ASTM F2170 / BS8201,

8203, 5325...........................................................20-21

Calibration Check Salts..........................................24-25

Wood Pin Meter Mode...............................................26-43

Factors Affecting Moisture Readings..........................27

Wood Flooring ......................................................28-29

Temperature Adjustment Chart..................................30

Humidity and Moisture Content Relationship.............31

Species Correction Charts......................................32-43

Limitations .......................................................................44

Calibration ......................................................................44

Warranty ............................................................................45

Product Development......................................................46

Safety...............................................................................46

3

USER GUIDE

INTRODUCTION

Thank you for selecting the new CMEXpert II instrument,

from Tramex. It has 3 measurement modes.

1. Non-invasive, Non-destructive test (NDT) mode

The CMEXpert II utilises “state of the art”

electronic technology to provide you with an

accurate and easy to use non-invasive instrument

for non-destructive testing (NDT) of Moisture

Content (MC%) in concrete and comparative

readings in gypsum and other oor screeds.

2. Hygro-i probe mode

This enables the CMEXpert II to measure

relative humidity (RH), temperature, dew point

temperature and mixing ratio of the environment

or in a structural material. A structural material

such as a concrete slab can be tested using the insitu method (ASTM F2170) or RH Hood methods

(British Standards BS 8201, 8203, 5325).

3. PIN Probe mode

This enables the CMEXpert II to measure the

percentage moisture content (MC%) of wood. The

CMEXpert II can also be used for wood-based

products.

4

USER GUIDE

HOW IT WORKS

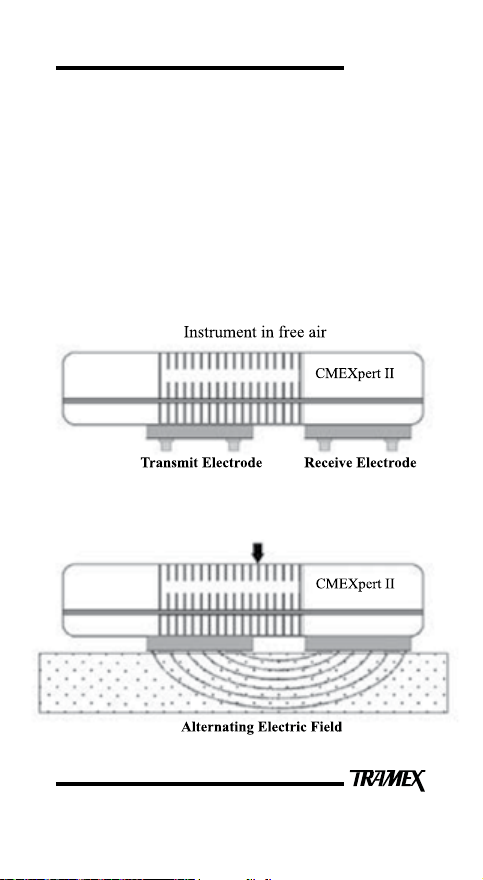

In concrete moisture measurement NDT mode, the

instrument operates on the principle that the electrical

impedance of a material varies with its moisture content.

The electrical impedance is measured by creating a

low frequency alternating electric eld between the

electrodes as illustrated in Figure 1.

Figure 1

The instrument is pressed onto the material surface

with the pins fully compressed to measure/detect the

moisture content.

5

USER GUIDE

This eld penetrates the material under test. The very

small alternating current owing through the eld is

inversely proportional to the impedance of the material.

The instrument detects this current, determines its

amplitude and thus derives the moisture value.

In Hygro-i probe mode, the CMEXpert II determines

the capacitance of the RH probe sensor which varies

with the relative humidity of the testing environment.

The CMEXpert II displays this capacitance as percentage

relative humidity (%RH). It also measures temperature

and displays dew-point temperature and mixing ratio.

In Pin probe mode the CMEXpert II is a resistance-type

pin-meter for determining the moisture content of wood

and wood-based products.

6

USER GUIDE

INSTRUMENT FEATURES

Your CMEXpert II employs advanced digital technology

to enable the incorporation of the many features listed

below.

● 3 modes of measurement: Non-destructive moisture

measurement, hygrometer and wood pin probe.

● 6 simple membrane keypad controls:

ON/OFF

SCALE

UP

DOWN

HOLD / AUDIO

BACKLIGHT

● Moisture readings and scale are displayed on a

clear easy to read liquid crystal display (LCD).

● 4 NDT Scales: Concrete, CM Equiv (Carbide

Method equivalent for concrete), Gypsum and a

Ref (Reference) scale. These are selected using the

key and the or keys.

● Wood pin probe mode is selected by using the

key.

● Relative Humidity (RH) readings, probe

temperature, dew point temperature and mixing

ratio are automatically displayed when the

Hygro-i Probe is plugged into the CMEXpert II

(Hygrometer Mode).

7

USER GUIDE

● To conserve battery life, the instrument automatically

powers OFF after 10 minutes of inactivity or when

the key is pressed. If a key is pressed the

power off time will be extended for an additional ten

minutes.

● Backlit display allows the display to be easily read

in poor light conditions. This is enabled by pressing

the key. The backlight stays on for a period of

time set.

● Backlight display time. To adjust the backlight

display time, press the and keys together.

Then scroll with the key from 10 – 60 seconds.

(If the key is pressed, you will enter language

choice settings.) When time is chosen select

key to conrm and return to scale mode. (Longer

backlight timeouts will reduce the battery life.)

● Language display adjustment. To adjust the language

display, press the and keys together. Then

scroll with the key through the language library.

(If the key is pressed, you will enter the backlight

time settings.) When language is chosen select

key to conrm and return to scale mode.

● HOLD freezes reading to facilitate ease of

recording readings. When the CMEXpert II is in

HOLD mode, ‘H’ will ash on the display. If HOLD

was selected prior to the CMEXpert II automatically

powering off, the frozen display reading is digitally

memorized and restored next time ON is selected.

● When the battery requires replacement a LOW

BATTERY message is shown on the LCD.

8

USER GUIDE

OPERATING INSTRUCTIONS

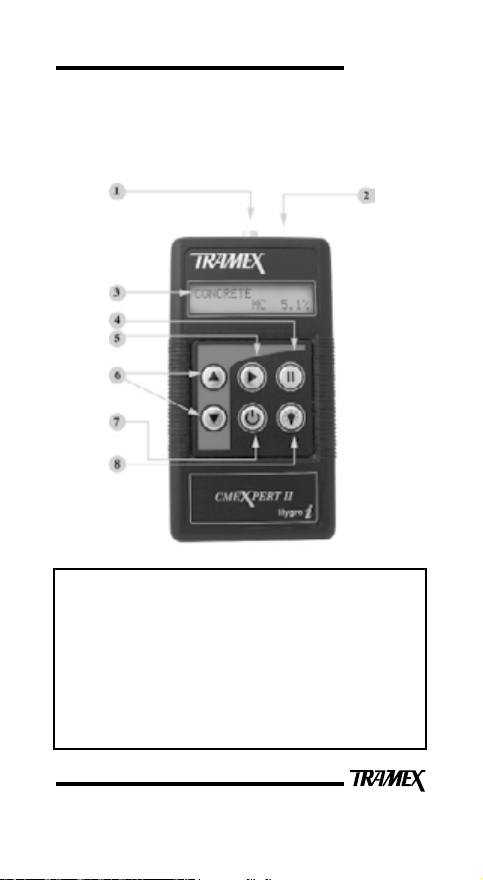

The instrument face with brief notes on the push button

controls and LCD is shown below.

Figure 2

1 = Phono socket for Wood Probes.

2 = Hygro-i Probe Socket (automatic hygrometer mode when

plugged in).

3 = Backlit display.

4 = Hold Key

5 = Scale Key.

6 = UP / DOWN Keys

7 = ON / OFF Key 10 minute switch off

8 = Light Key.

9

USER GUIDE

NON-DESTRUCTIVE MEASUREMENT MODE

1. Press the key to power up. With no Hygro-i

probe or pin probe connected the last used scale

will be displayed on the LCD. Press key again

to power off.

2. To change mode, press key to select the Concrete,

Pin Probe or the comparative material scales. The

comparative material scales consist of CM Equiv.,

Gypsum and Ref. Select the CM Equiv., Gypsum or

Ref. scale using the key or key.

3. Press your CMEXpert II directly onto the surface

of the material being tested ensuring that all the

electrode spring-loaded pins are fully compressed.

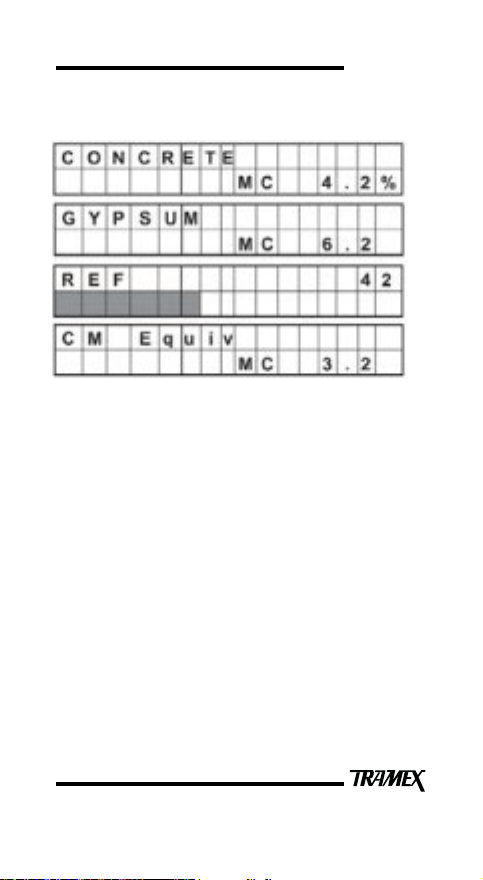

Concrete Scale

When the Concrete scale is selected the moisture content

(MC) is shown on the right-hand side of the bottom line of

the display. The moisture content (MC) is displayed 0 to

6.9% on the CMEXpert II display. Readings on a concrete

oor slab obtained on this scale indicate moisture content

and should not be confused with Pounds (lbs) emission or

any other unit of measurement obtained by other moisture

testing methods or meters. It should also be noted that

there seems to be no linear correlation between moisture

content measurements and lbs emission measurements as

obtained using calcium chloride testing methods.

10

USER GUIDE

CM Equivalent Scale (for concrete)

The CMEXpert II gives readings of 0 to 4.3 on the CM

Equivalent Scale. These are approximated equivalent

readings to the carbide test method for concrete.

Gypsum Scale

The CMEXpert II gives moisture content readings from 0

to 12 (comparative) on Gypsum and Anhydrite screeds.

REF Scale

For the Reference scale the readings are comparative

from 0 to 99. A visual indication is also given by the bar

display on the bottom line of the LCD.

The readings on the reference scale are not to be interpreted

as a measurement of percentage moisture content (%MC)

or relative humidity (RH). It is not a relative humidity

reading and it does not have any linear correlation with

Relative Humidity measurements. This scale should

be regarded as a comparative or qualitative scale only.

This reference scale is included to facilitate comparative

testing of different areas where direct contact with the bare

concrete surfaces may not be possible due to some form of

very thin coating or covering on the concrete, or additive

in the concrete that could inuence the readings. This scale

is not suitable for reading through thicker oor coverings

such as wood laminates etc. Readings from the reference

scale are comparative only and of help in identifying areas

with moisture problems.

11

USER GUIDE

Calibration

For regular on-site assessment of your CMEXpert II in

moisture measurement mode, a calibration-check plate is

available from the suppliers of your CMEXpert II. Should

it be found that readings are outside the set tolerances, it

is recommended that the CMEXpert II be returned for recalibration. Calibration adjustments should not be carried

out by anyone other than Tramex or their authorized

service provider who will issue a calibration certicate on

completion.

Requirements for quality management and validation

procedures, such as ISO 9000 and National Standards,

have increased the need for regulation and verication

of measuring and test instruments. It is therefore

recommended that calibration of the CMEXpert II should

be checked and certied in accordance with the standards

and/or protocols laid down by your industry (usually on

an annual basis) by an authorised test provider. The name

of your nearest test provider and estimate of costs are

available on request.

12

USER GUIDE

Typical CMEXpert II Displays

Drying time for concrete oors and screeds

Concrete oors and screeds must be allowed to dry to an

adequate level before the installation of sheet material,

tile, wood or coating. Manufacturers of such systems

generally require moisture testing to be performed before

installation on a oor slab. Moisture content measurement

is one such method. Excessive moisture in or permeating

from a oor covering or coating can cause failures such

as condensation, blistering, delaminating, movement and

general deterioration of the nished ooring/coating.

There is also a risk of promoting microbial growth. No

exact period can be specied for the drying of such oors

to reach acceptable moisture content, as this is affected by

temperature and humidity within the building as well as

concrete curing times and other factors. Typically a period

of 1 month per inch (25mm) depth of concrete or sand/

cement screed is often quoted. Longer periods may be

required in areas of high humidity or low temperature.

13

USER GUIDE

During the drying period and prior to applying the oor

covering, the oor should be regularly checked to monitor

moisture content.

Testing for moisture content in a oor slab

Pre-test conditioning and preparation

For best and most accurate results, tests should be carried

out after the internal conditions of the building in which

the slab is located have been at normal service temperature

and humidity for at least 48 hours. All articial heating or

drying equipment should be turned off at least 96 hours

before nal readings are attempted, otherwise results may

not accurately reect the amount of moisture present or

moisture movement in the slab during normal operating

conditions. Prior to testing, the actual test area should be

clean and free of foreign substances.

Pre-testing guidelines

Where covered oor slabs are being tested, all covering

materials, adhesive residue, curing compounds, sealers,

paints, etc., shall be removed to expose a test area of clean

bare concrete. For removal of any existing ooring or

adhesives, strictly observe all the appropriate safety and

health practices relevant to cleaning and removal of these

types of materials. Removal of covering materials and

cleaning, if required, should take place a minimum of 48

hours prior to testing. Use of water based cleaning methods

that could lead to elevated surface and/or sub-surface

moisture levels in the oor slab are not recommended, and

the testing after such treatment could result in elevated

readings. No visible water in liquid form should be present

on the concrete at the time of testing. Avoid testing in

locations subject to direct sunlight or sources of heat. Use

of articial aids for accelerated drying of concrete is not

recommended. If they are being used it is recommended

they should be turned off at least four days before taking

nal readings.

14

USER GUIDE

Guideline test procedures as per ASTM F2659

1. Remove any dust or foreign matter from the

CMEXpert II electrodes before commencing tests.

Make sure that the oor slab being tested is clean and

bare and free from dust, dirt or standing water.

2. Push the ON button and press the instrument directly

onto the surface of the material being tested ensuring

that all of the electrode spring loaded pins are fully

compressed. Read the moisture measurement from

the appropriate scale of the display.

3. On a rough surface, take a number of readings in

close proximity to one another such as 3 to 5 readings

within an area of 1 ft

2

(929cm2) at each location. If

the readings vary, always use the one with the highest

value.

4. Perform at least eight tests for the rst 1000ft

2

(100m

) and at least ve additional tests for each

additional 1000ft

2

(100m2). Include test locations in

2

the centre of the oor and within 3ft (1m) of each

exterior wall.

15

Loading...

Loading...