Page 1

MS-1 ELECTRONIC

SPEED CONTROL

Special Features

CNC Machined Aluminum Case

•

Gold-plated solder posts

•

Handles down to 2.5T

•

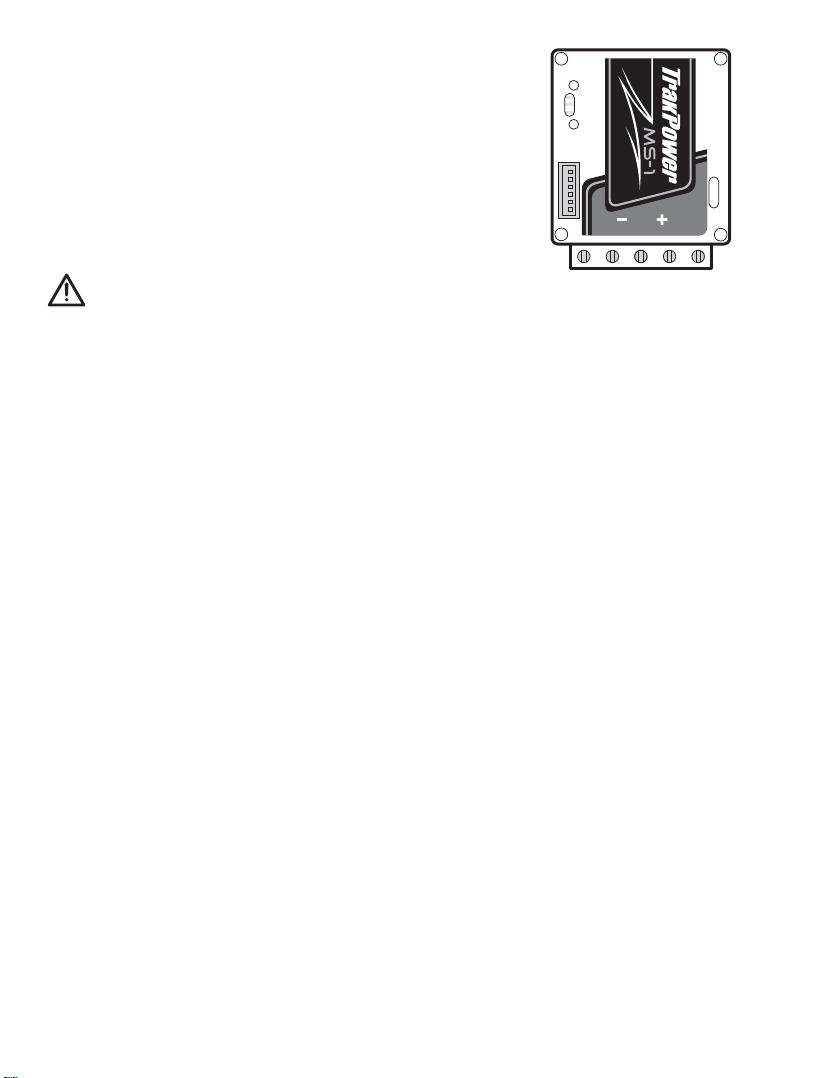

Thank you for choosing TrakPower as your

™

source for brushless electronics. The MS-1

ESC was specifi cally developed for 1/10th

competition. The MS-1 ESC features an

aluminum CNC machined case which is

designed as a heat sink to reduce operating

temperatures and eliminate the need for a

cooling fan. The switch and receiver lead

exit the top of the case to allow the ESC to

fi t into the smallest areas, and gold-plated

solder posts provide the best option for

solder connections. Pre-installed power

capacitors ensure power is available

for when it is demanded. The MS-1 also

features “blinky” mode, a popular race

mode for stock class racing.

It is strongly recommended to

completely read this manual before

use! Damage resulting from misuse or

modification will void your warranty.

100A continuous current

•

Compact design

•

“Blinky” Mode

•

Specifi cations

Motor Types: Sensored

Motor Limit: 2.5T (on 2S)

Input Voltage: 2-3S LiPo

Direction: Forward, Brake, Reverse

BEC: 6.0V/3A

Protection: low voltage, thermal

Rated Current: 100A Continuous

Battery Connections:

Gold-plated solder posts

Motor Connections:

Dimensions: 24 x 33 x 36mm

Weight: 55g

Programming: Manual

Indicators: LEDs (Green, Blue, Red)

Includes: Sensor cable, (x5)12AWG

Gold-plated solder posts

silicon wires, heat shrink

and mounting tape

Page 2

Important Precautions

MS

ABC

MS

ABC

Disconnect the battery from the ESC immediately if the ESC or battery becomes hot!! Allow

•

the ESC or battery to cool down before reconnecting.

NEVER use more than the specifi ed voltage on the ESC’s input.

•

ALWAYS mount the ESC in a position where free air can fl ow across it during operation.

•

ALWAYS monitor ESC temperatures.

•

Always turn on the transmitter before connecting the battery to the ESC.

•

Always disconnect the battery from the ESC when not in use.

•

Make sure the input battery is fully charged before connecting to the ESC, so the low voltage

•

cutoff feature can function properly.

Do not attempt to use with brushed motors.

•

Use heat shrink tubing to insulate any bare wires between the motor battery and ESC, and

•

from the ESC to the motor, to prevent a short circuit.

Allow the ESC to cool before touching.

•

Do not run the car near water! Never allow water, moisture or any foreign material onto the

•

ESC’s PC board.

Do not allow metal/conductive materials to accidentally make contact across all motor/

•

battery posts.

Never turn on the ESC before plugging it into the receiver and switching on the transmitter.

•

Keep out of reach of children.

•

TrakPower is not responsible for incidental damage or personal injury as a result of misuse

•

of this product.

Installation

Refer to your vehicle’s manual for the best mounting location and position on your chassis.

Always mount in a location where it will receive maximum airfl ow over and around the unit.

The MS-1 ESC features a CNC machined aluminum case that functions as a heat sink and helps

reduce operating temperatures. Once the mounting location has been determined, use the

included mounting tape to secure the ESC to the chassis.

Included are fi ve 200mm pieces of 12AWG silicon wire for the motor and battery connections.

You will need to supply the battery connector of your choice. It is highly recommended to make

one solder connection at a time so that there is no possibility of making an incorrect connection

which could result in permanent damage to the ESC and/or motor.

Page 3

Solder Connections

MS

ABC

MS

ABC

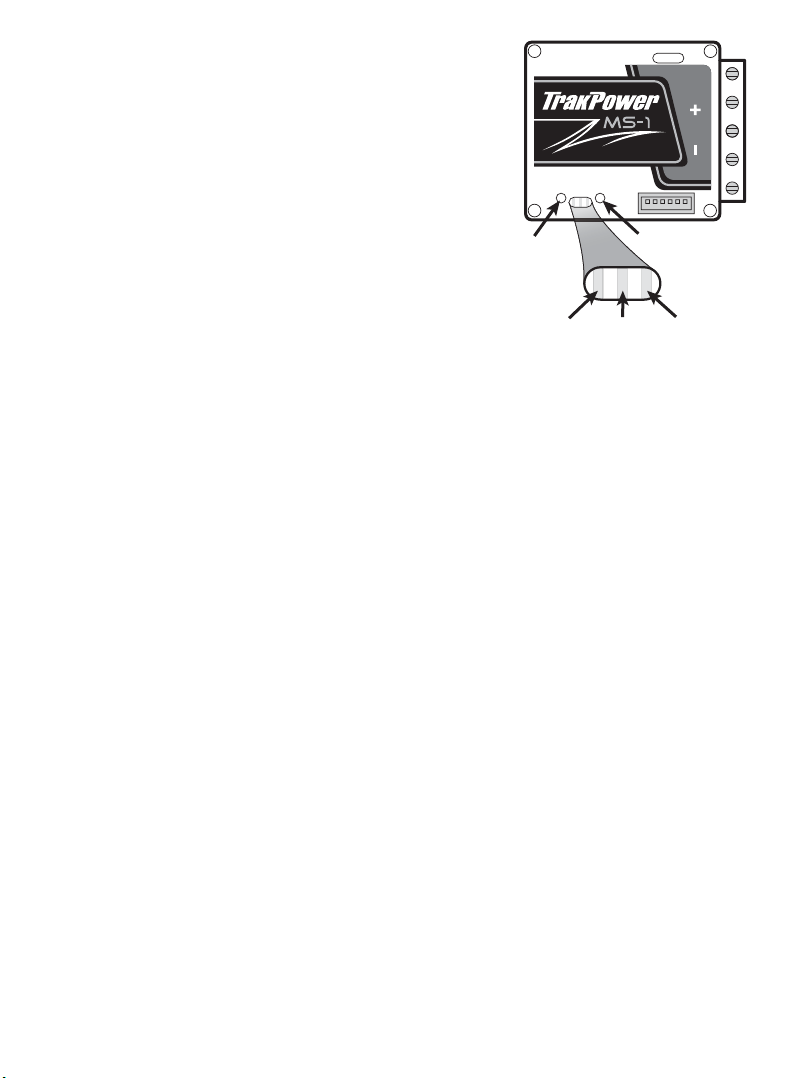

1. Begin with solder post “A”. Heat up the solder post by

positioning the iron tip in the cutout section of the post. Apply

a small amount of solder to the post. Next, heat up the tinned

wire to get the solder fl owing. Apply a small amount of solder

to the iron tip, then set the wire into the solder post cutout

and heat both the wire and post together. Once the solder

begins to fl ow at the joint, apply solder in small amounts until

the wire and post have a solid connection.

IMPORTANT: Only apply the solder in small amounts.

Applying solder in large amounts will cause excessive

solder drip and potentially make connection to the next post.

Once the wire has been connected to the solder post, solder the other end of the wire to the “A”

tab on the motor. Repeat for “B” and “C” connections.

2. Solder the included red wire to the “+” (positive) solder post in the same manner as the motor

wires. The other end of this wire will be soldered to the battery connector of your choice. If

using a dual pin type connector, such as Deans

to the “+” on the connector.

3. Solder the remaining black wire to the “–” (negative) solder post as listed above. The other

end of this wire will be soldered to the negative pin on the selected connector type. Again,

note proper polarity and ensure the black wire from the negative (–) solder post on the ESC is

connected to the negative (–) pin on the connector.

4. Install the included sensor wire by plugging into the ESC fi rst and then the motor. TrakPower

MS Series brushless motors include a clip screw for the sensor wire. See the TrakPower

Brushless Motor manual for installation of the clip screw.

5. Connect the ESC lead into Channel 2 of the receiver and secure the power switch to the

desired location on the chassis by using a small piece of double sided mounting tape.

®

or Traxxas™, be sure that the “+” is connected

AB(–) (+) C

Throttle Calibration

Before the ESC can be used, throttle calibration must be performed to ensure the throttle is

setup properly. Be sure that all trims and sub-trims are set to ZERO before performing calibration

and that throttle and brake end points are set to maximum. Use a small diameter screwdriver

or similar to adjust the ESC. Failure to do so may result in the inability to complete calibration

or possibly case forward or reverse input when the trigger is at neutral.

Note:

If using a Futaba transmitter, the throttle channel will need to be reversed prior to calibration.

1. Turn on transmitter.

2. With the small screwdiver, press and hold the Modify button (“M”) on the ESC. This button is

located on the left side of the LEDs as shown above in the diagram.

Page 4

3. Turn ESC on.

MS

ABC

4. ALL LEDs will illuminate once power is applied.

Release the Modify button (“M”) at this time. After

releasing the Modify button, the green LED will fl ash.

5. Move the trigger to the full throttle position. The

green LED will turn solid. Hold the trigger in position

until the red LED begins to fl ash.

6. Move the trigger to the full brake position. The red

LED will turn solid. Continue to hold the trigger in the

brake position until the blue LED begins to fl ash.

7. Return the trigger to the neutral position. The blue

LED will turn solid. All LEDs will fl ash simultaneously 3

times to complete throttle calibration.

Modify

Green Blue Red

Setting

LEDs

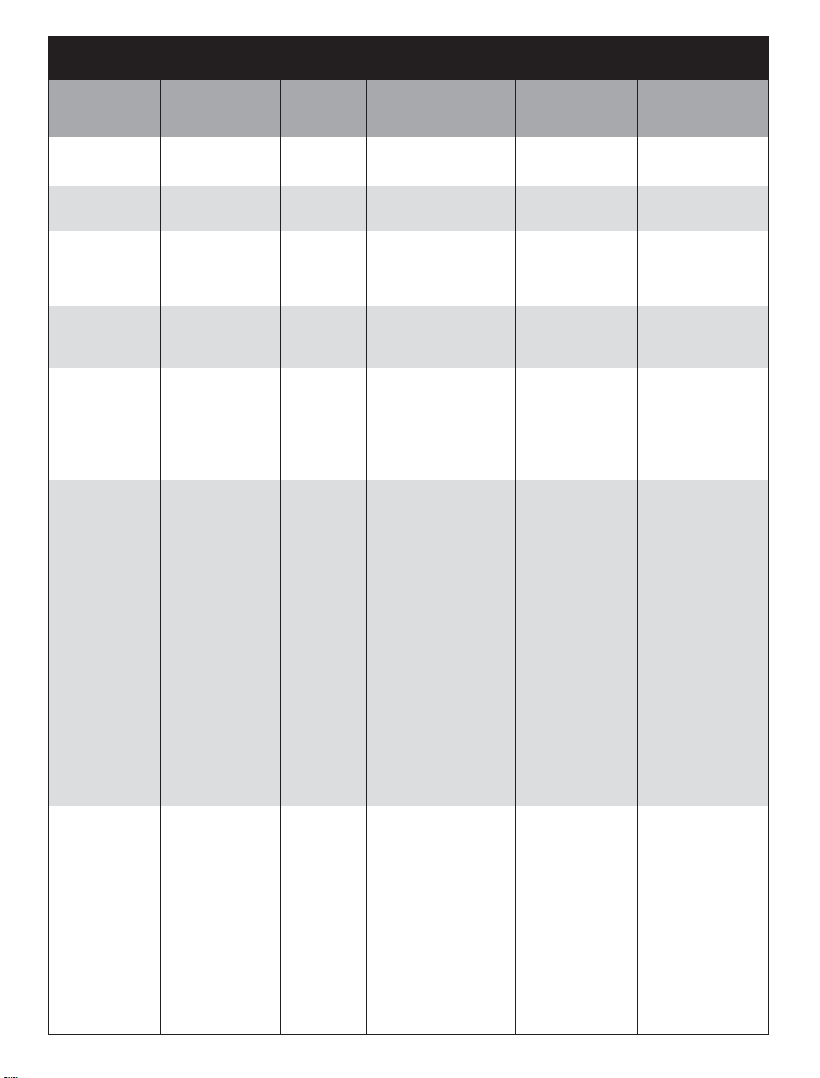

Programming

1. Turn on transmitter.

2. Plug in battery and turn the ESC on. The blue LED will illuminate. Note: If 0° of advanced

timing is currently selected, the blue LED will fl ash indicating the ESC is in “blinky” mode.

Otherwise the LED will be solid.

3. Press and hold the Setting (S) button on the ESC and release once all LEDs have illuminated.

The green LED will remain lit after releasing. This signals that the fi rst programmable feature

(Voltage Cutoff) is ready to be adjusted. Pressing the S button will advance through the features.

Each LED or LED combination will correspond to a particular feature. Use the below chart as a

reference.

4. To modify or change the setting within a feature, press the Modify (M) button. The M button

will need to be pressed a certain amount of times to match the desired setting. Example:

Pressing the M button twice while the Red LED is illuminated will change the drive mode to

“Forward/Reverse”. Use the below chart as a reference.

To determine which setting a particular feature is currently on, use the S button to locate the

correct feature. Press and hold the M button. The LEDs will then turn off and begin fl ashing. The

current setting is displayed by the number of times the LEDs are OFF (not on).

5. After choosing a particular setting for a feature, the LEDs will then repeat the selection by

fl ashing the corresponding amount of times. This is displayed by the number of times the LEDs

are OFF (not on).

When programming is completed, press and hold the S button until all LEDs illuminate and then

release. Once the ESC returns to the blue LED, the ESC is ready for use.

See the quick reference chart on other side for programming:

Page 5

PROGRAMMING CHART

Adjustable

Feature

Voltage

Cutoff

Motor

Direction

Drive

Mode

Neutral

Width

Start

Power

Drag

Brake

Timing

Press Modify

Button

Press Setting

Button

Greenx1

Bluex2

Redx3

Grn & Blx4

Grn &Rdx5

Bl & Rdx6

G, B & Rx7

2S

3S

Forward

Reverse

Forward Only

Forward/Reverse

For/Rev Delay

6us

9us

15us

Lowest

Low

Normal

High

Highest

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

65%

70%

75%

0°

5°

10°

15°

20°

25°

30°

35°

40°

45°

50°

x1

x2

x1

x2

x1

x2

x3

x1

x2

x3

x1

x2

x3

x4

x5

x1

x2

x3

x4

x5

x6

x7

x8

x9

x10

x11

x12

x13

x14

x15

x16

x1

x2

x3

x4

x5

x6

x7

x8

x9

x10

x11

LED

FlashesSettingLED

Green x1

Green x2

Blue x1

Blue x2

Red x1

Red x2

Red x3

Grn & Bl x1

Grn & Bl x2

Grn & Bl x3

Grn & Rd x1

Grn & Rd x2

Grn & Rd x3

Grn & Rd x4

Grn & Rd x5

Bl & Rd x1

Bl & Rd x2

Bl & Rd x3

Bl & Rd x4

Bl & Rd x5

Bl & Rd x6

Bl & Rd x7

Bl & Rd x8

Bl & Rd x9

Bl & Rd x10

Bl & Rd x11

Bl & Rd x12

Bl & Rd x13

Bl & Rd x14

Bl & Rd x15

Bl & Rd x16

G, B &R x1

G, B &R x2

G, B &R x3

G, B &R x4

G, B &R x5

G, B &R x6

G, B &R x7

G, B &R x8

G, B &R x9

G, B &R x10

G, B &R x11

Page 6

Troubleshooting

Below is a reference for troubleshooting. These are common problems with easy solutions. If a

problem other than what is listed below exists, contact Hobby Services for assistance.

Green and Red fl ashing LED: No signal. Check to see if transmitter is turned on. Also be sure

that the ESC lead is plugged into Channel 2 of the receiver.

Turning the steering wheel causes motor to spin: ESC lead is plugged into Channel 1 of

receiver. Reinstall into Channel 2.

Blue LED illuminates normally but nothing happens when throttle is applied:

Check that

the sensor wire is plugged in securely to both the ESC and motor. Also check that the A, B and C

wires are soldered correctly to the motor tabs and there is not a solder bridge between the tabs.

LEDs illuminate normally but motor does not spin every time throttle is applied: Ensure

that the wires that connect the ESC and motors are connected and soldered well. Also, be sure

that the battery is charged.

Solid Blue and Red LEDs: Low voltage cut-off. The LiPo battery is equal to or less than the

programmed low voltage cut-off point. Turn off ESC and re-charge battery.

Solid Red and Green LEDs: Thermal protection. The ESC has reached an unsafe temperature

for operation and has shut down to protect itself. Allow the ESC to cool to room temperature

before attempting another run. If the ESC continues to enter thermal protection mode, a

different gearing option might need to be considered.

Warranty

TrakPower warrants this product to be free from defects in materials and workmanship for a period of 120 days

from the date of purchase. During that period, we will repair or replace, at our option, any product that does not

meet these standards. You will be required to provide proof of purchase date (receipt or invoice). If, during the

warranty period, your motor shows defects caused by abuse, misuse or accident, it will be repaired or replaced

at our option, at a service charge not greater than 50% of the current retail list price. Be sure to include your

daytime telephone number in case we need to contact you about your repair. This warranty does not cover

components worn by use, application or reverse voltage, cross connections, poor installation, subjection of

components to foreign materials, or tampering. In no case shall our liability exceed the original cost of the

product. Your warranty is voided if:

You apply an input voltage that exceeds the maximum specifi cations of the ESC.

•

You allow water or moisture to enter the ESC.

•

You attempt to modify or tamper this ESC.

•

Under no circumstances will the purchaser be entitled to consequential or incidental damages. This warranty

gives you specifi c legal rights, and you have other rights which vary from state to state.

For service to your TrakPower ESC, either in or out of warranty, send it post-paid and insured to

Hobby Services

3002 N. Apollo Dr. Suite 1 (217) 398-0007

Champaign, IL 61822

Email: hobbyservices@hobbico.com

trakpowerusa.com

© 2012 Hobbico, Inc. All rights reserved.

TKPM0010

Loading...

Loading...