Page 1

OPERATORS MANUAL

TRAK-IT TOOL MODEL W3-21FRH / W3-34CDH

Page 2

2

INDEX

INHALTSVERZEICHNIS

INDEX

INHOUDSOPGAVE

INDICE

ENGLISH Page 3 to 24 Page

DEUTSCH Page 25 to 46 Page

FRANÇAIS Page 47 to 68 Page

NEDERLANDS

Page 69 to 90 Page

ESPAÑOL Page 91 to 112 Page

DEFINITIONS OF SIGNAL WORDS

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTE: Emphasizes essential information.

DEFINITIONEN DER HINWEISBEZEICHNUNGEN

ACHTUNG! Zeigt eine eventuell gefährliche Situation an, die den Tod oder schwere Verletzungen zur Folge haben

könnte, wenn sie nicht vermieden wird.

VORSICHT! Zeigt eine eventuell gefährliche Situation an, die leichte oder mittelschwere Verletzungen zur Folge

haben könnte, wenn sie nicht vermieden wird.

HINWEIS: Hebt wichtige Informationen hervor.

DÉFINITIONS DES DIFFÉRENTS DEGRÉS D’ AVERTISSEMENTS

AVERTISSEMENT Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée, pourrait provoquer la

mort ou des blessure sérieuses.

ATTENTION Indique une situation éventuellement dangereuse qui, si elle n’est pas contournée, pourrait provoquer

des blessures légères à moyennement sérieuses.

REMARQUE Souligne des informations importantes.

BETEKENIS VAN GEBRUIKTE WOORDEN

!WAARSCHUWING: Betekent dat er een potentiële gevaarlijke situatie is indien de gegeven informatie niet wordt opgevolgd,

met mogelijk ernstig letsel met dodelijke afloop als gevolg.

!LET OP: Betekent dat er een potentiële gevaarlijke situatie is indien de gegeven informatie niet wordt opgevolgd,

met mogelijk persoonlijk letsel als gevolg.

OPMERKING: Betekent dat er belangrijke informatie is.

DEFINICIÓN DE LAS INDICACIONES DE ADVERTENCIA

¡

ATENCIÓN! Indica una situación potencialmente peligrosa que podría causar la muerte o graves lesiones si no se

evita.

¡

PRECAUCIÓN! Indica una situación potencialmente peligrosa que podría causar lesiones menos graves o leves si no

se evita.

NOTA: Resalta informaciones importantes.

Page 3

3

ENGLISH

W3-21FRH / W3-34CDH

GAS POWERED FASTENING SYSTEM

INDEX

1. SAFETY INSTRUCTIONS

……………

4

2. SPECIFICATIONS &

TECHNICAL DATA

…………………

11

3. SAFETY DEVICE

……………………

12

4. HOW TO USE THE BATTERY AND

THE CHARGER

……………………

13

5. HANDLING OF FUEL CELL

………

17

6.

INSTRUCTIONS FOR OPERATION

…

20

7. MAINTAIN FOR PERFORMANCE

…

23

8. STORING

……………………………

23

9. TROUBLESHOOTING/REPAIRS

……

24

OPERATING and MAINTENANCE MANUAL

BEFORE USING THIS TOOL, STUDY THIS MANUAL TO ENSURE SAFETY WARNING

AND INSTRUCTIONS.

KEEP THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE.

WARNING:

Page 4

4

1. SAFETY INSTRUCTIONS

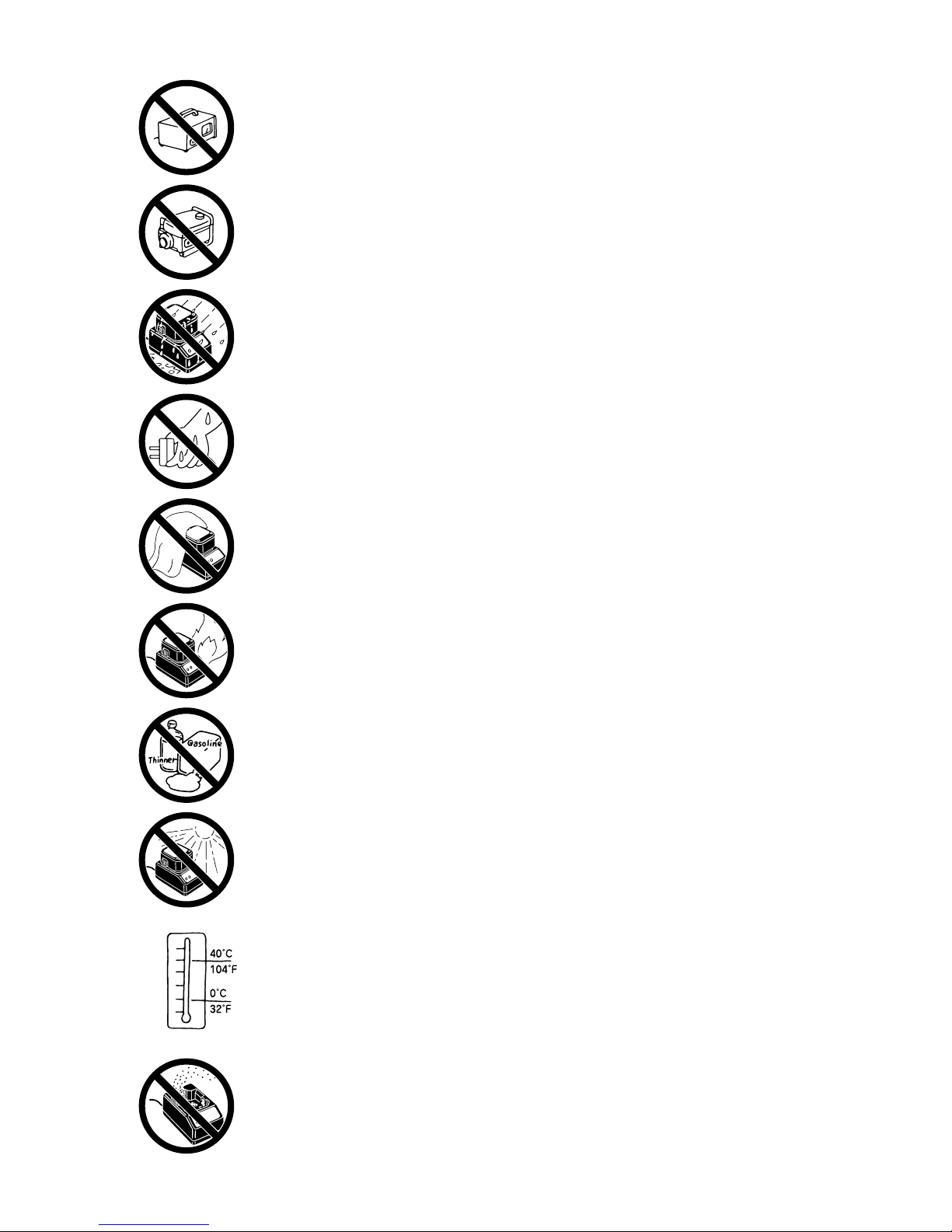

PRECAUTIONS ON USING THE TOOL

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists due to the possibility of dust being blown up by the exhausted air

or of a fastener flying up due to the improper handling of the tool. For these reasons, safety glasses

or goggles shall always be worn when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment

must conform to the requirements of the American National Standards Institute, ANSI Z87.1 (Council

Directive 89/686/EEC of 21 DEC. 1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator

and all other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

2. EAR PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

As the working condition may include exposure to high noise levels which can lead to hearing

damage, the employer and user should ensure that any necessary hearing protection is provided

and used by the operator and others in the work area.

3. WEAR THE CLOTHINGS AND A PROTECTIVE GEAR SUITABLE FOR THE WORKING

ENVIRONMENT

Depending on the working environment, wear a long-sleeve work uniform and a protective gear

such as a helmet, safety shoes.

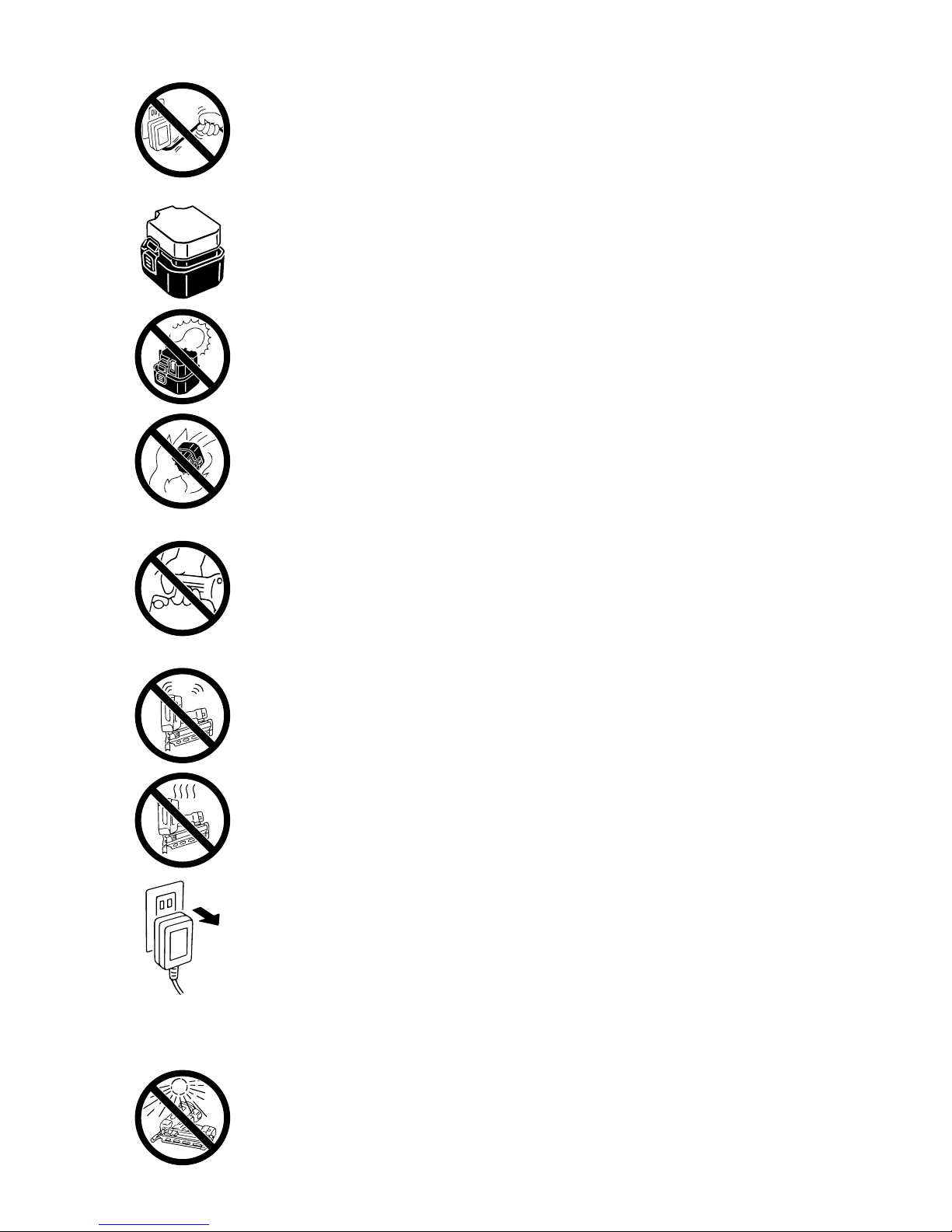

4. CAUTIONS FOR FUEL CELL

q

Be sure to set Fuel Cell.

w

Store Fuel Cell in well ventilated area.

e

Do not expose the Fuel Cell to the direct sunshine.

Do not place the Fuel Cell in a vehicle or a trunk where the temperature could rise. It could

explode. A used empty Fuel Cell still contains a combustible jet gas, which could swell and

explode a container into pieces.

r

Store the Fuel Cell at ambient temperature of 49°C (120°F) or lower.

The Fuel Cell contains the pressurized combustible gas. If it is exposed to the temperature

higher than 49°C (120°F), the gas could leak from it or burst, resulting in a fire.

WARNING:

TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE

BEFORE USING THE TOOL, READ CAREFULLY AND UNDERSTAND THE FOLLOWING

“SAFETY INSTRUCTIONS”. FAILURE TO FOLLOW WARNINGS COULD RESULT IN DEATH OR

SERIOUS INJURY.

49°C

120°F

Page 5

5

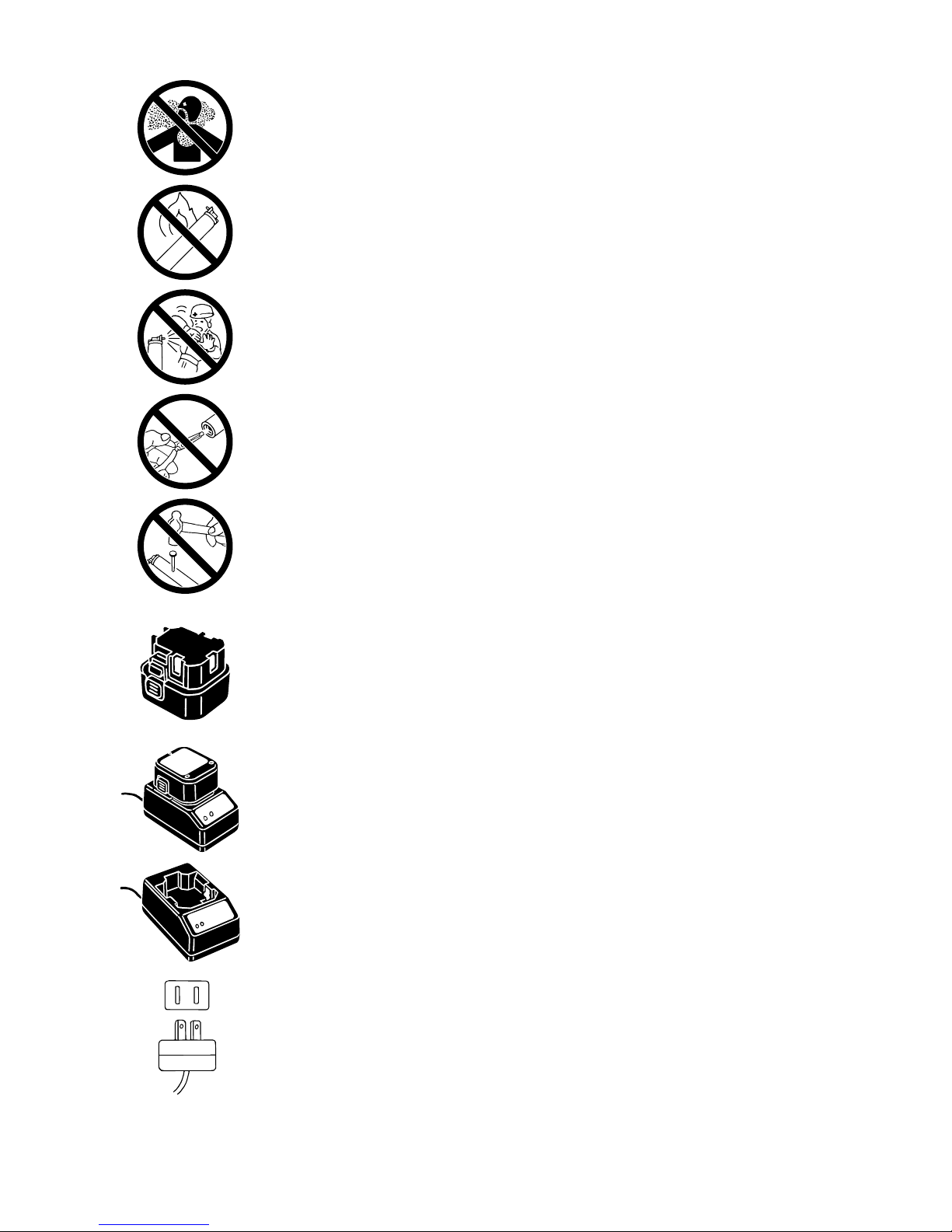

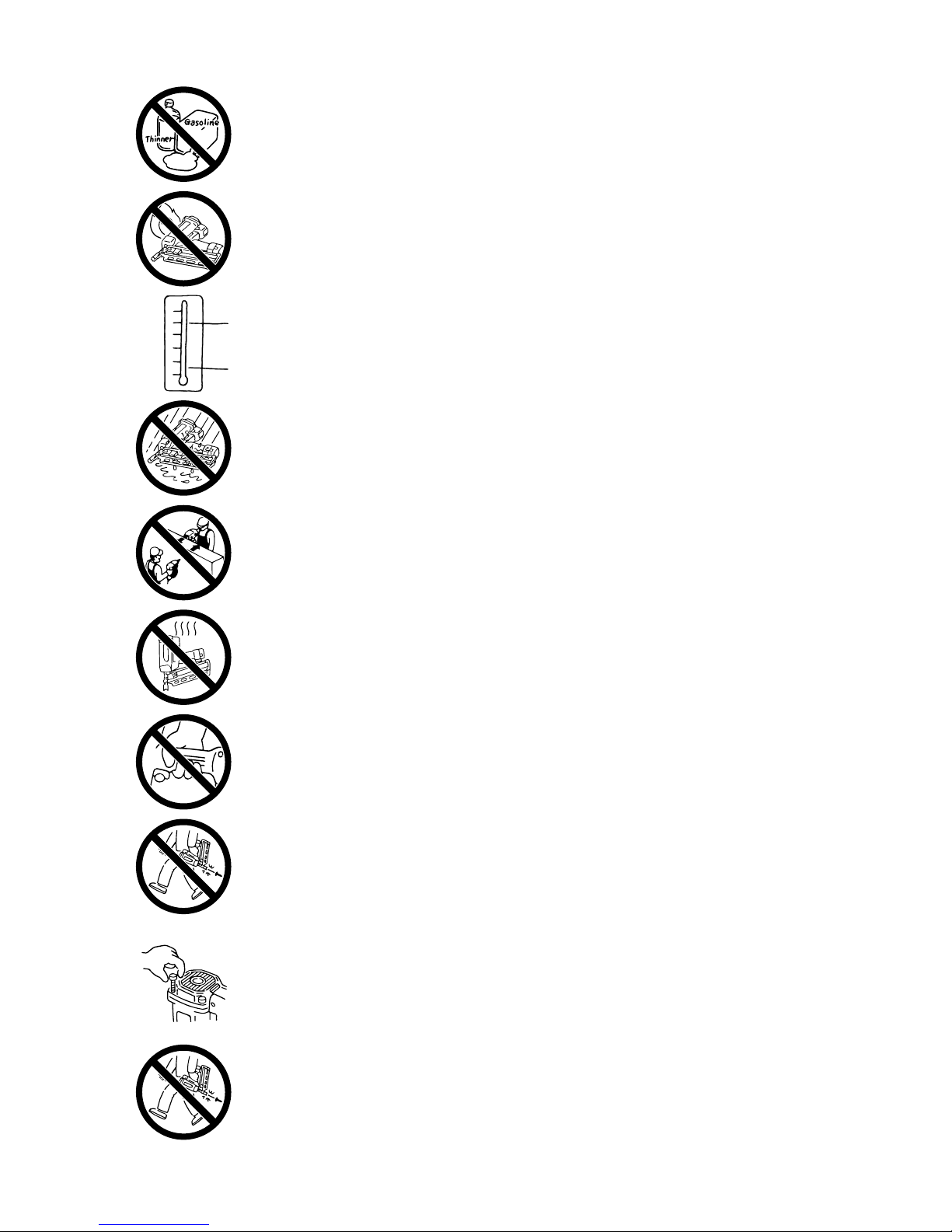

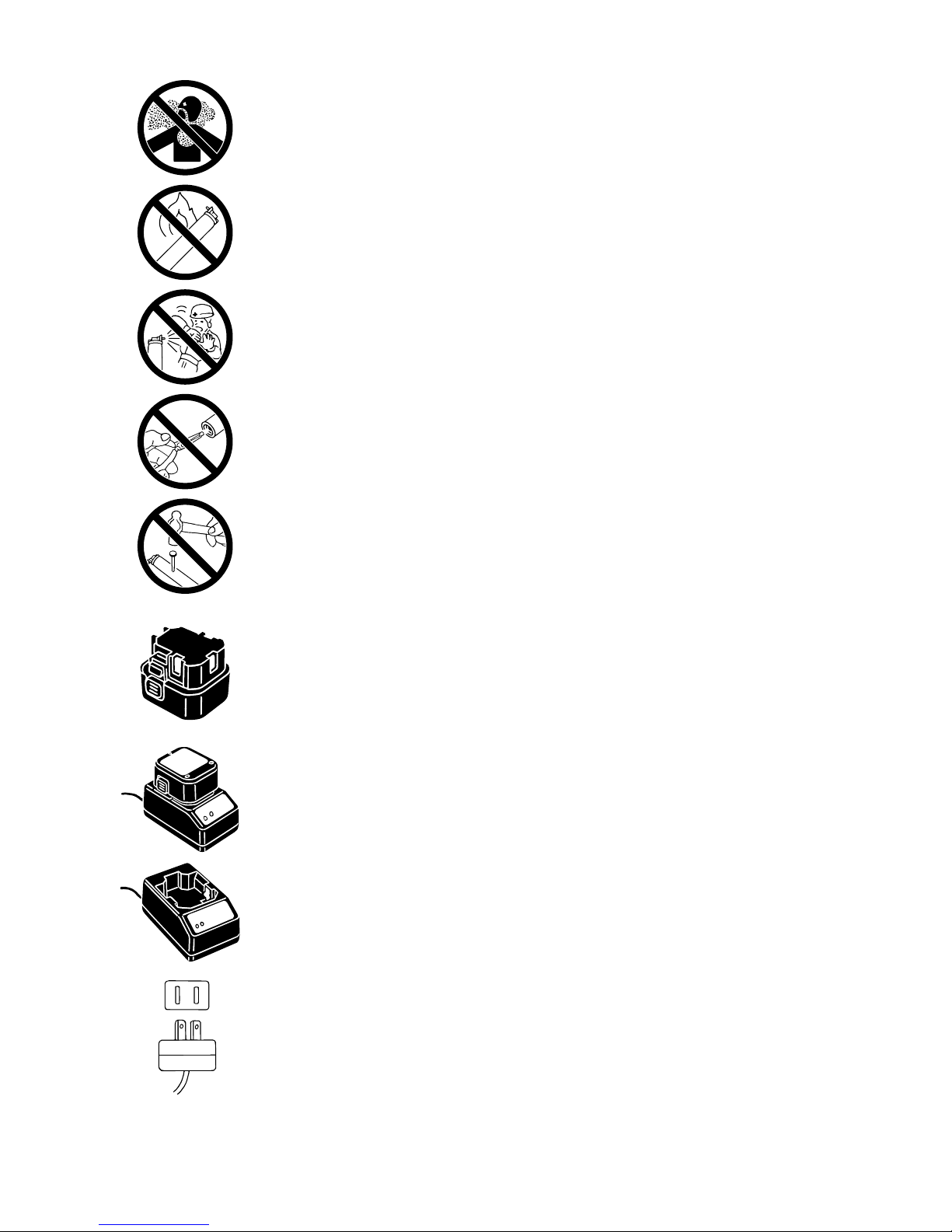

t

Do not breathe in the gas.

y

Do not incinerate or recycle the empty Fuel Cell.

u

Never jet the gas to the human body.

i

Do not remove the rubber plug from the bottom of the Fuel Cell except at disposal.

o

Do not make a hole in the Fuel Cell.

5. CAUTIONS FOR CHARGING METHOD, THE CHARGER AND THE BATTERY

q

Be sure to use Battery (Cat.#55583).

Be sure to use Battery (Cat.#55583) for the tool. Never connect the tool to a power source or

other rechargeable battery, dry cells or storage battery for automobiles.

Neglect of this could cause breakage, trouble, heat generation or combustion.

(See Page 11 for Battery (Cat.#55583))

w

Be sure to charge with Charger Base (Cat.#55618).

Be sure to charge the Battery with Charger Base (Cat.#55618).

If charged with other charger, it could fail to be properly charged as well as get broken, ignited or

generate the heat. (See Page 11 for Charger Base (Cat.#55618))

e

Charge the Battery prior to use.

The new Battery or the one which has not been used for a long period may not be fully charged

due to self-discharge. Be sure to charge it with Charger Base (Cat.#55618).

r

Charge the Battery at the specified voltage.

Be sure to charge, using a 100-240 V AC plug socket (for household use). Never charge at other

than the specified voltage. Neglect of this could cause combustion or heat generation.

Page 6

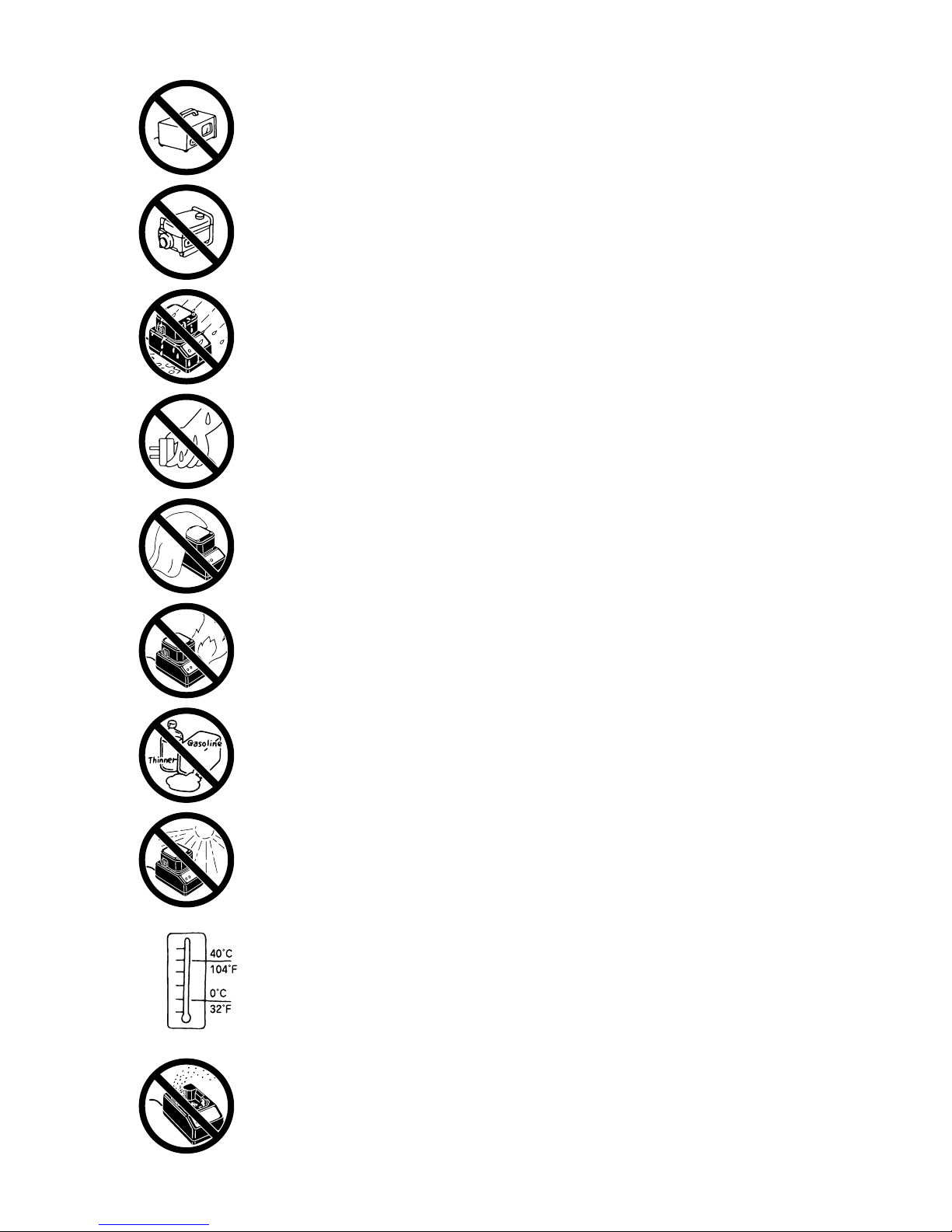

6

t

Never use a transformer such as a booster for the power source of the charger.

Neglect of this causes a trouble or burnout of the charger.

y

Never use an engine generator or DC power source to charge the Battery.

Neglect of this causes a trouble or burnout of the charger.

u

Never charge the Battery in the rain or in the place exposed to water splash or moisture.

If it is charged in the wet condition, it could cause an electric shock or short-circuiting, resulting

in a fire due to burnout or combustion.

i

Never touch a power plug with a wet hand.

Holding it with a wet hand could cause an electric shock.

o

Never cover the charger in use with a cloth, and so on.

Putting a cover could generate the heat, resulting in a burnout or fire.

!0

Do not put the charger close to a fire.

!1

Do not charge the Battery near any combustible substance.

!2

Charge the Battery in a well-ventilated area, protected against the direct sunshine.

Charging in the direct sunshine could overheat the charger, resulting in a burnout or fire.

!3

Charge the Battery at ambient temperature of 0°C (32°F) to 40°C (104°F).

If the ambient temperature is less than 0°C (32°F) to 40°C (104°F), charging may not be

allowed, could result in a fire.

!4

Do not allow foreign objects into a ventilation hole or Battery plug socket in the charger.

They cause an electric shock or trouble. Use in the place free of dust.

Page 7

7

!56

Handle a power cord with care.

If you hold the power cord of the AC adapter to carry or pull it to disconnect from a plug socket, it

will be damaged, resulting in snapping or short-circuiting. Also, take care that it will not come into

contact with cutters, high-temperature substances, oil or grease. Replace the damaged power

cord with a new one.

!6

Once the Battery is disconnected from the tool body, be sure to cover it with a pack cap,

unless it is used.

In order to prevent short-circuiting, cover the terminal block (metal section) of the unused Battery

with the pack cap.

!7

Never short-circuit the terminal block (metal section) of the Battery.

If it is short-circuited, a large current will run to overheat the Battery, causing you a burn or

damage on it.

!8

Never throw the Battery into a fire.

Neglect of this could cause an explosion.

6. CARE SHOULD BE TAKEN WHEN CONNECTING THE BATTERY TO THE TOOL

When connecting the Battery to the tool, be sure to observe the following in order to prevent

malfunctioning.

1. Do not put your finger on the trigger.

2. Do not press the contact arm against the object.

3. Never put your finger or hand near the muzzle.

7. BE SURE TO CHECK WHEN THE BATTERY IS CONNECTED

Prior to using the tool, connect the Battery to it without pressing the contact arm against the object

and loading the nails and Fuel Cell, and be sure to check the following:

1. Check whether or not operating sound is heard, by only connecting the Battery.

※ If you connect the Battery and press the contact arm against the floor, and so on, the fan of the

tool will run, but this is not abnormal.

2. Check for heat generation or abnormal smell or sound.

If the tool is activated, generates the heat or emits abnormal smell or sound, it is an indication of

trouble. Using the tool in that condition results in an accident. If any abnormality is found, contact

your nearest authorized distributor.

8. UNPLUG THE CHARGER WHEN IT IS NOT USED

9. ONLY USE TOOL IN WELL VENTILATED AREA

If used in an ill-ventilated place, you could suffer from oxygen starvation.

10. AVOID THE DIRECT SUNSHINE

Do not place the tool in a vehicle or a trunk where the temperature could rise, because it could

explode. A used empty Fuel Cell still contains a combustible jet gas, which could swell and explode

a container into pieces.

Page 8

8

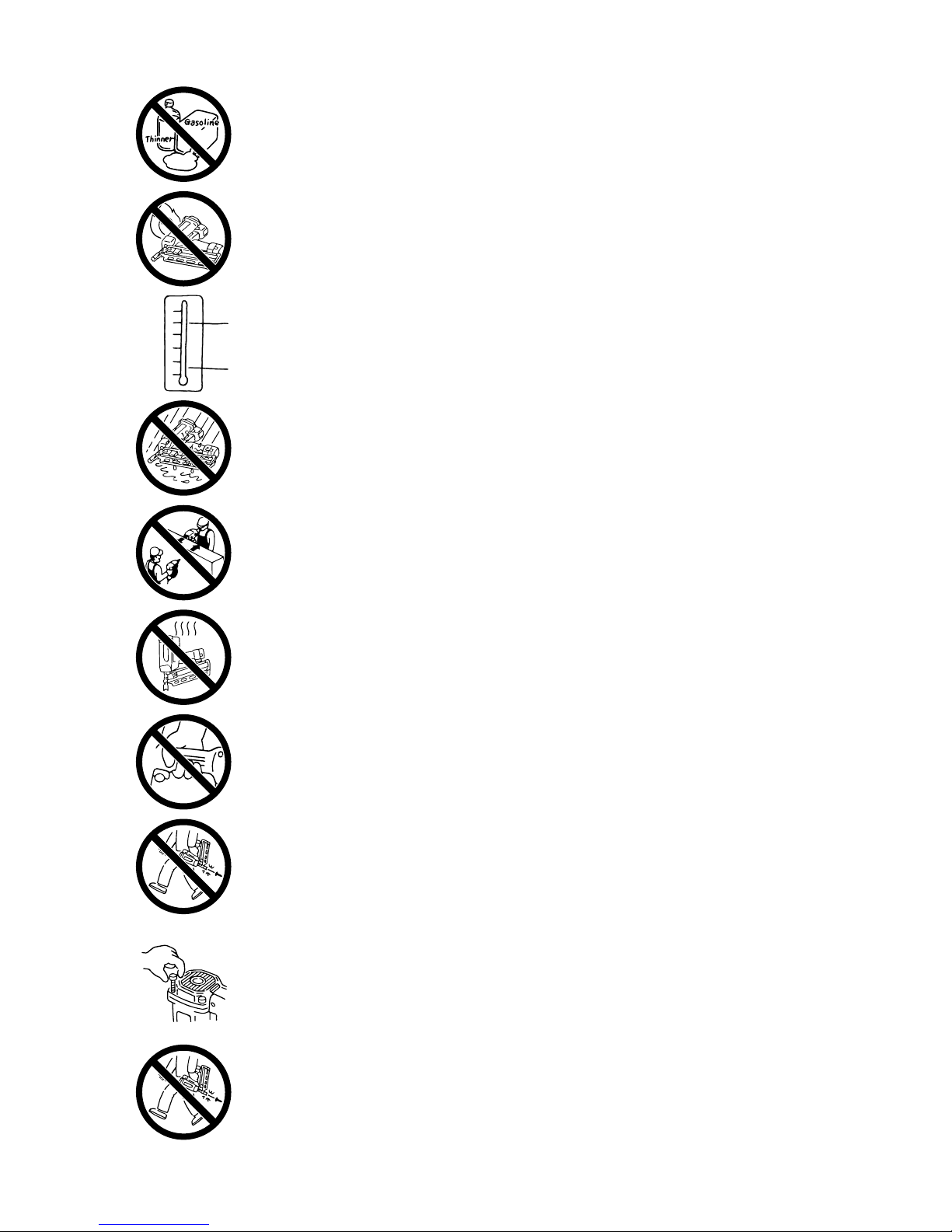

11. NEVER USE THE TOOL NEAR THE VOLATILE COMBUSTIBLE SUBSTANCES

Never use the tool near gasoline, thinner, gas, paint or adhesive agent, because it could ignite or

explode.

12. KEEP TOOL AWAY FROM FIRE

13. BE SURE TO USE THE TOOL IN THE WORKING ENVIRONMENT OF -7°C (19°F) TO 49°C

(120°F), BECAUSE THE TOOL BODY COULD BE DAMAGED, IGNITE OR EXPLODE

-7°C (19°F) or lower: The tool body could be damaged.

49°C (120°F) or higher: The Fuel Cell could be damaged, resulting in ignition or explosion.

14. DO NOT USE THE TOOL IN THE RAIN OR IN A VERY HUMID PLACE

Neglect of this causes a trouble.

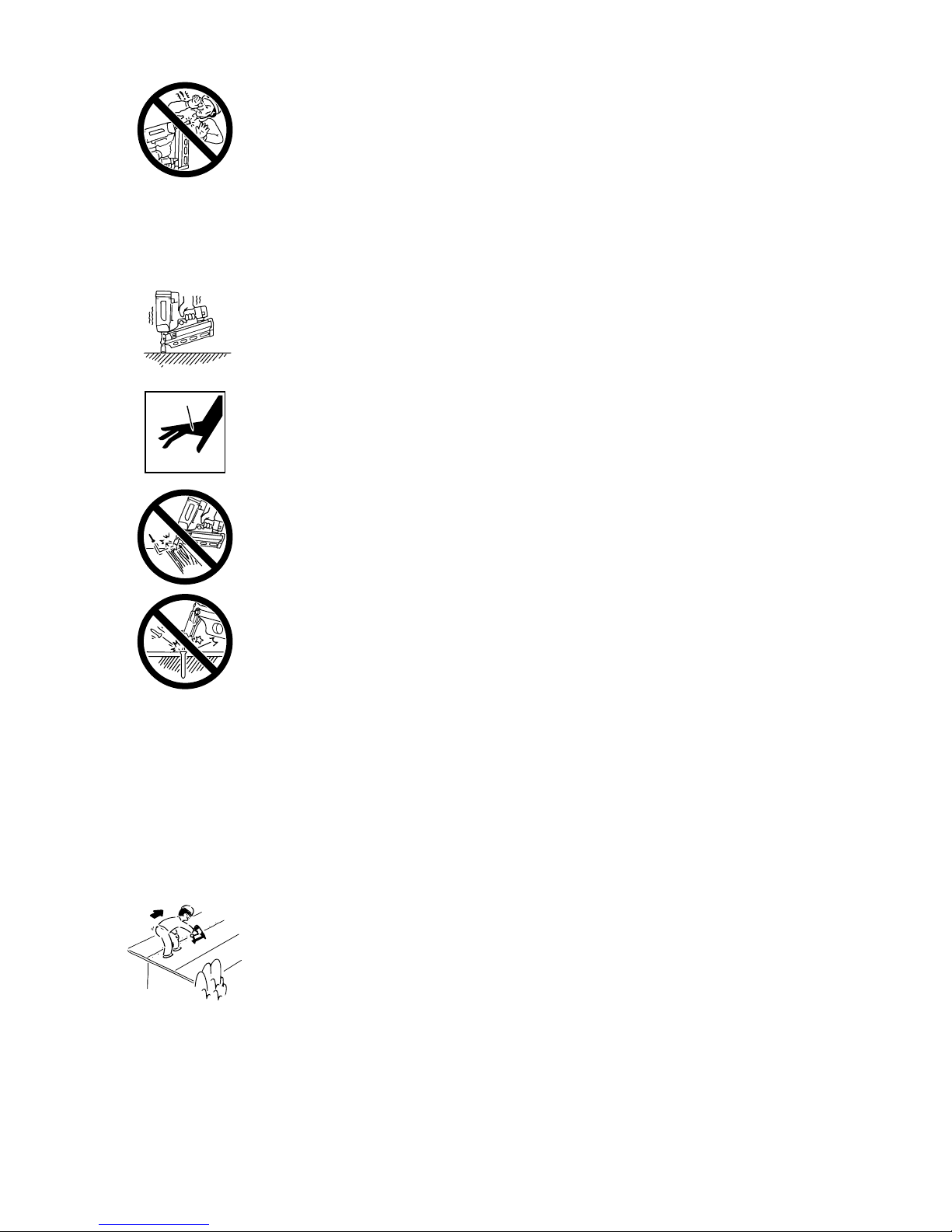

15. NEVER DRIVE THE NAILS, FACING EACH OTHER

If you drive the nails, facing each other, an improperly driven nail may hit and injure the worker

facing you.

16. BEWARE OF THE HIGH TEMPERATURE OF THE TOOL

If the tool is used for a long period of time, the nose and contact arm will become hot. Be careful not

to get a burn.

17. WHEN USING THE HOOK, BE SURE TO RELEASE YOUR FINGER FROM THE TRIGGER

18. REMOVE THE FUEL CELL AND THE BATTERY AND EMPTY THE MAGAZINE WHEN THE

TOOL IS NOT IN USE

Always remove the Fuel Cell and the Battery from the tool and empty the magazine when operation

has been completed or suspended, when unattended, moving to a different work area, adjusting,

disassembling, or repairing the tool, and when clearing a jammed fastener.

19. INSPECT SCREW TIGHTNESS

Loose or improperly installed screws or bolts cause accidents and tool damage when the tool is put

into operation. Inspect to confirm that all screws and bolts are tight and properly installed prior to

operating the tool.

20. DO NOT TOUCH THE TRIGGER UNLESS YOU INTEND TO DRIVE A FASTENER

Never touch the trigger unless you intend to drive a fastener into the work. It is dangerous to walk

around carrying the tool with the trigger pulled, and this and similar actions should be avoided.

49°C

120°F

−7°C

19°F

Page 9

9

21. NEVER POINT THE DISCHARGE OUTLET TOWARD YOURSELF AND OTHER PERSONNEL

If the discharge outlet is pointed toward people, serious accidents may be caused when misfiring.

Be sure the discharge outlet is not pointed toward people when the Fuel Cell and the Battery are

inserted or not, loading and unloading the fasteners or similar operations.

22. USE SPECIFIED FASTENERS

The use of fasteners other than specified fasteners will cause the tool malfunction. Be sure to use

only specified fasteners when operating the tool.

23. PLACE THE DISCHARGE OUTLET ON THE WORK SURFACE PROPERLY

Failure to place the discharge outlet of the nose in a improper manner can result in a fastener flying

up and is extremely dangerous.

24. KEEP HANDS AND BODY AWAY FROM THE DISCHARGE OUTLET

When loading and using the tool, never place a hand or any part of body in fastener discharge area

of the tool. It is very dangerous to hit the hands or body by mistake.

25. DO NOT DRIVE FASTENERS CLOSE TO THE EDGE AND CORNER OF THE WORK AND THIN

MATE RIAL

The workpiece is likely to split and the fastener could fly free and hit someone.

26. DO NOT DRIVE FASTENERS ON TOP OF OTHER FASTENERS

Driving fasteners of the top of other fasteners may cause deflection fasteners which could cause

injury.

27. REMOVING THE FASTENERS AFTER COMPLETING OPERATION

If fasteners are left in the magazine after the completion of operation, there is the danger of a serious

accident occurring prior to the resumption of operation, should the tool be handled carelessly, or

when inserting the Fuel Cell and the Battery. For this reason, always remove all fasteners remaining

in the magazine after completion of the operation.

28. CHECK OPERATION OF THE CONTACT TRIP MECHANISM FREQUENTLY IN CASE OF

USING A CONTACT TRIP TYPE TOOL

Do not use the tool if the trip is not working correctly as accidental driving of a fastener may result.

Do not interfere with the proper operation of the contact trip mechanism.

29. WHEN USING THE TOOL OUTSIDE OR ELEVATED PLACE

When fastening roofs or similar slanted surface, start fastening at the lower part and gradually work

your way up. Fastening backward is dangerous as you may loose your foot place.

30. NEVER USE THE TOOL IF ANY PORTION OF THE TOOL CONTROLS (e.g., TRIGGER, CONTACT

ARM) IS INOPERABLE, DISCONNECTED, ALTERED OR NOT WOKING PROPERLY

31. NEVER ACTUATE THE TOOL INTO FREE SPACE

This will avoid any hazard caused by free flying fasteners and excessive strain of the tool.

32. ALWAYS ASSUME THAT THE TOOL CONTAINS FASTENERS

Page 10

10

33. RESPECT THE TOOL AS A WORKING IMPLEMENT

34. NO HORSEPLAY

35. NEVER LOAD THE TOOL WITH FASTENERS WHEN ANY ONE OF THE OPERATING CONTROLS

(e.g., TRIGGER, CONTACT ARM) IS ACTIVATED

36. TAKE GOOD CARE OF THE TOOL

Clean the tool with dry soft cloth. Never use wet cloth or volatile solutions such as thinner, benzine.

37. AVOID THE DIRECT SUNSHINE

Do not leave the tool or Charger in the direct sunshine for a long time.

OBSERVE THE FOLLOWING GENERAL CAUTION IN ADDITION TO

THE OTHER WARNINGS CONTAINED IN THIS MANUAL

•

Do not use the tool as a hammer.

•

The tool must be used only for the purpose it was designed.

•

Never remove, tamper with the operating controls (e.g., TRIGGER, CONTACT ARM)

•

Keep the tool, the Fuel Cell and the Battery in a dry place out of reach of children when not in

use.

•

Do not use the tool without Safety Warning label.

•

Do not modify the tool from original design or function without approval by CO., LTD.

Page 11

11

2. SPECIFICATIONS AND TECHNICAL DATA

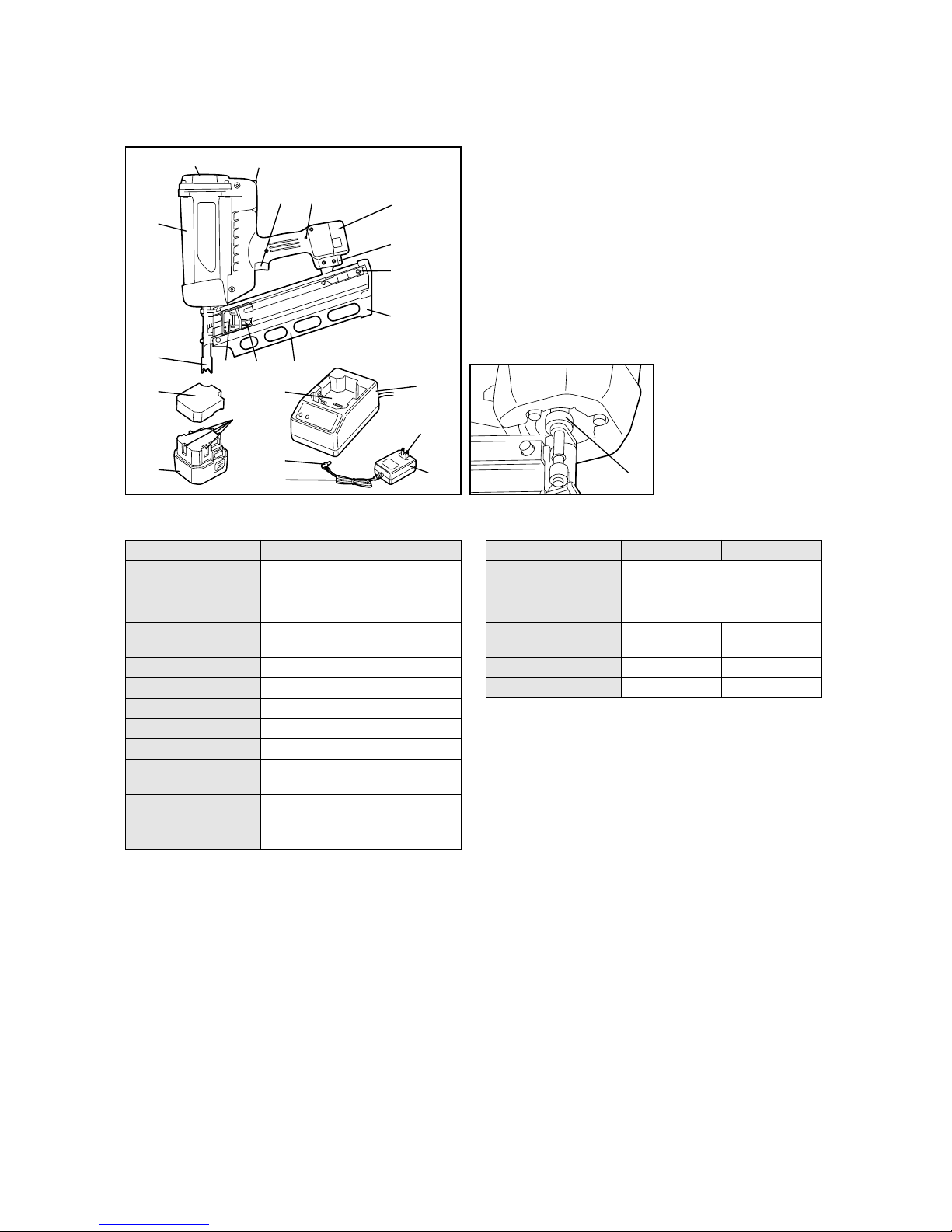

1. NAME OF PARTS

2. TOOL SPECIFICATIONS

q

e

w

rt

y

u

i

!1 !2 !3

!8

!9

@0

!0

!5

!6

!7

!4

@1

@2

@3

o

q

Air Filter Cover

w

Actuator

e

Housing

r

LED

t

Trigger

y

Battery

u

Hook

i

Nail Stopper

o

Depth Adjustment Dial

!0

Contact Arm

!1

Follower Holder

!2

Follower

!3

Magazine

!4

Magazine Foot

!5

Pack Cap

!6

Terminal Block

!7

Battery (Cat.#55583)

!8

Battery Setting Hollow

!9

Jack

@0

Power Cord

@1

Charger Base(Cat.#55618)

@2

Power Plug

@3

AC Adapter

3. FASTENER SPECIFICATIONS

4. TECHNICAL DATA

q

NOISE

A-weighted single-event ------ LWA, 1s, d 105.4 dB

sound power level

A-weighted single-event ------ Lp A , 1s, d 98.8 dB

emission sound pressure

level at work station

These values are determined and documented in accordance to EN12549 : 1999.

w

VIBRATION

Vibration characteristic value

= 4.46 m/s

2

These values are determined and documented in accordance to ISO 8662-11.

This value is a tool-related characteristic value and does not represent the influence to the hand-arm-system when using the tool.

An influence to the hand-arm-system when using the tool will for example depend on the gripping force, the contact pressure

force, the working direction, the workpiece, the workpiece support.

PRODUCT NO. W3-21FRH W3-34CDH

HEIGHT

15˝ (382 mm) 15-3/8˝ (391 mm)

WIDTH

4-3/8˝ (111 mm) 4-3/8˝ (110 mm)

LENGTH

15˝ (379 mm) 13-3/8˝ (340mm)

WEIGHT

7.8 lbs. (3.5 kg)

(including Fuel Cell and Battery)

LOADING CAPACITY 32 nails (1 strip) 40 nails (1 strip)

BATTERY Battery (Cat.#55583)

BATTERY CAPACITY

6V DC, 1.5 Ah

CHARGER Charger Base (Cat.#55618)

POWER SOURCE 100-240V AC, 50 or 60 Hz

POWER CONSUMPTION

8VA (10V 800mA)

(Rated output)

CHARGING TIME 150 minutes at maximum

ACCESSORIES

Goggles, carrying case, Battery,

Charger

PRODUCT NO. W3-21FRH W3-34CDH

NAIL LENGTH 2˝ to 3-1/2˝ (50 to 90 mm)

SHANK DIAMETER .113˝ to .131˝ (2.9 to 3.3 mm)

SHANK TYPE Smooth, Ring, Screw

HEAD DIAMETER

.267˝ to .295˝ .256˝ to .303˝

(6.8 to 7.5 mm) (6.5 to 7.7 mm)

COLLATION ANGLE 21 degree 34 degree

HEAD Full round head Clipped head

Page 12

12

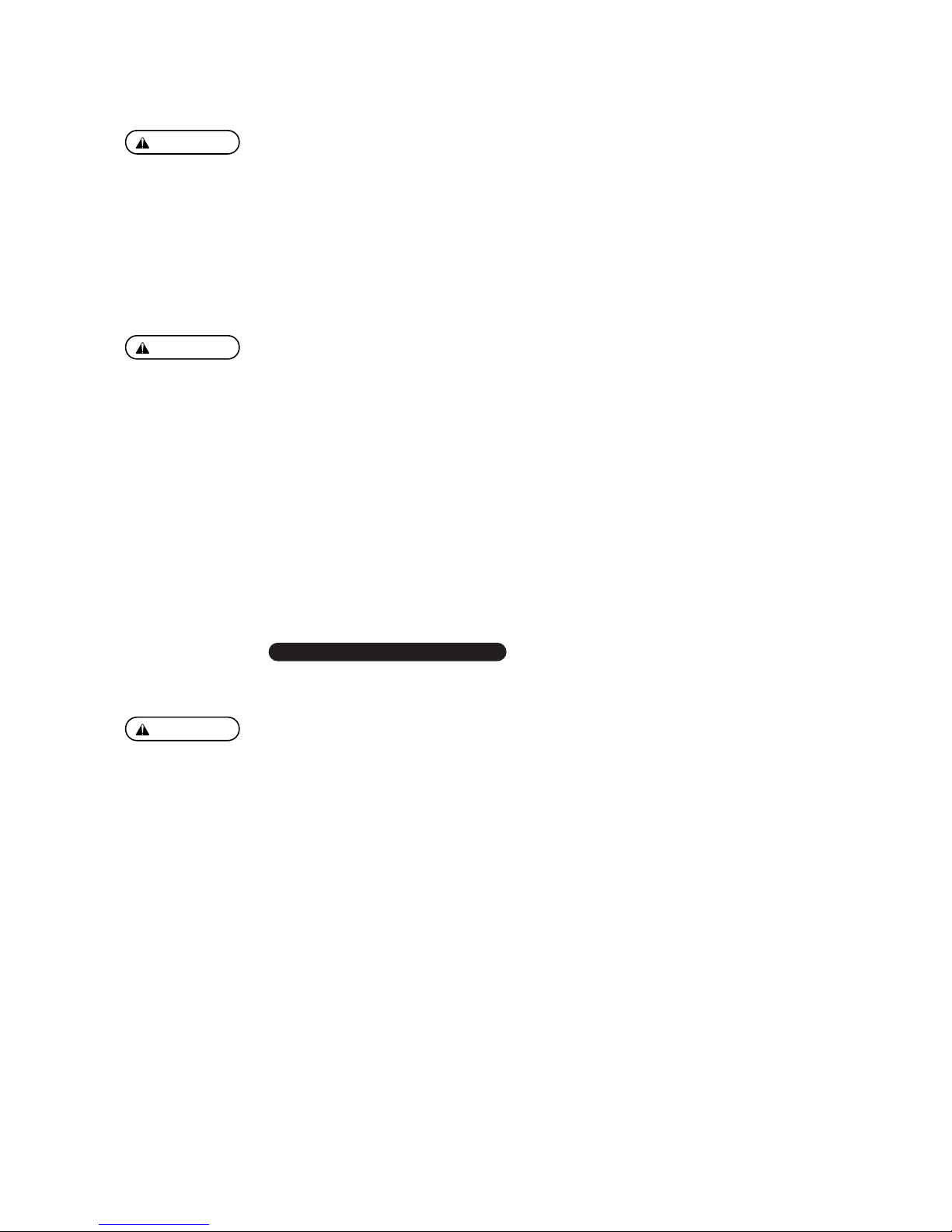

3. SAFETY DEVICES

The tool is provided with the following safety devices in order to secure safety for nail driving work.

Mechanical Safety Device

This tool is to prevent discharge of nails unless the Contact Arm and Trigger have been

activated simultaneously. The nails are not discharged by neither simply pulling the

Trigger nor applying the Contact Arm to the nails driving object. The nails are

discharged only after applying the Contact Arm to the object and pulling the Trigger.

Trigger

Contact Arm

CAUTION:

●

Prior to using the tool, be sure to inspect it to see whether the safety devices function

properly. Do not use it if they do not function properly.

Prior to using the tool, check whether the safety devices function properly. With no nails

loaded, install the Battery and Fuel Cell to check.

※

In the following cases, the safety devices are out of order. Never use the tool.

1. An operating sound is emitted by simply pulling the trigger.

2. The tool starts dry-fire operation by simply applying the contact arm to the object.

※

A fan running sound is heard, this is OK.

If any abnormality is found, contact your nearest authorized distributor for

inspection/repairing.

Page 13

13

4. HOW TO USE THE BATTERY AND THE CHARGER

WARNING:

●

Be sure to charge Battery (Cat.#55583) for the tool with Charger Base (Cat.#55618).

If charged with other charger, the Battery could fail to be properly charged as well as get

broken, ignited or generate the heat.

●

Do not put the Battery close to a fire.

●

Do not leave the Battery in the direct sunshine.

●

Do not charge or use the Battery in the wet condition with a liquid such as water, sea water,

milk, soft drink, soap water.

●

Unplug the charger when it is not used.

●

Be sure to charge at 0 to 40°C to avoid the possibility of fire.

●

Do not give a strong shock such as hitting with a hammer, stamping or dropping.

WARNING:

●

In order to prevent short-circuiting, be sure to cover the terminal block (metal section) of the

Battery with the Pack Cap (wind the insulating tape) for recycling.

<Battery cells in Battery Pack>

・

Nominal voltage: 1.2 V/piece

・

Quantity used in 1 pack: 5 pieces

CAUTION:

●

When the Battery is discharged or is not used for a long period, remove it from the Charger.

●

After setting the Battery in the tool, do not hold it to carry around.

PROPER USE OF BATTERY

q

Fully charge and discharge the Battery.

If you repeat charging the Battery while not fully discharged more than half the capacity, the number

of nails drivable by each charging could decrease dramatically, shortening the life of the Battery. It is

recommended to use it until the LED of the tool has been illuminated in red, running out of electricity.

w

Use two Batterys alternately.

To ensure the longer life of the Battery, it is recommended to use two of them alternately, preparing a

spare one.

The Battery for the tool uses nickel-hydrogen batteries which are a precious recyclable resource. Once

the Battery runs out of life, take it to your nearest distributor without disposing of it.

Recycling the Nickel-Hydrogen Battery

Page 14

14

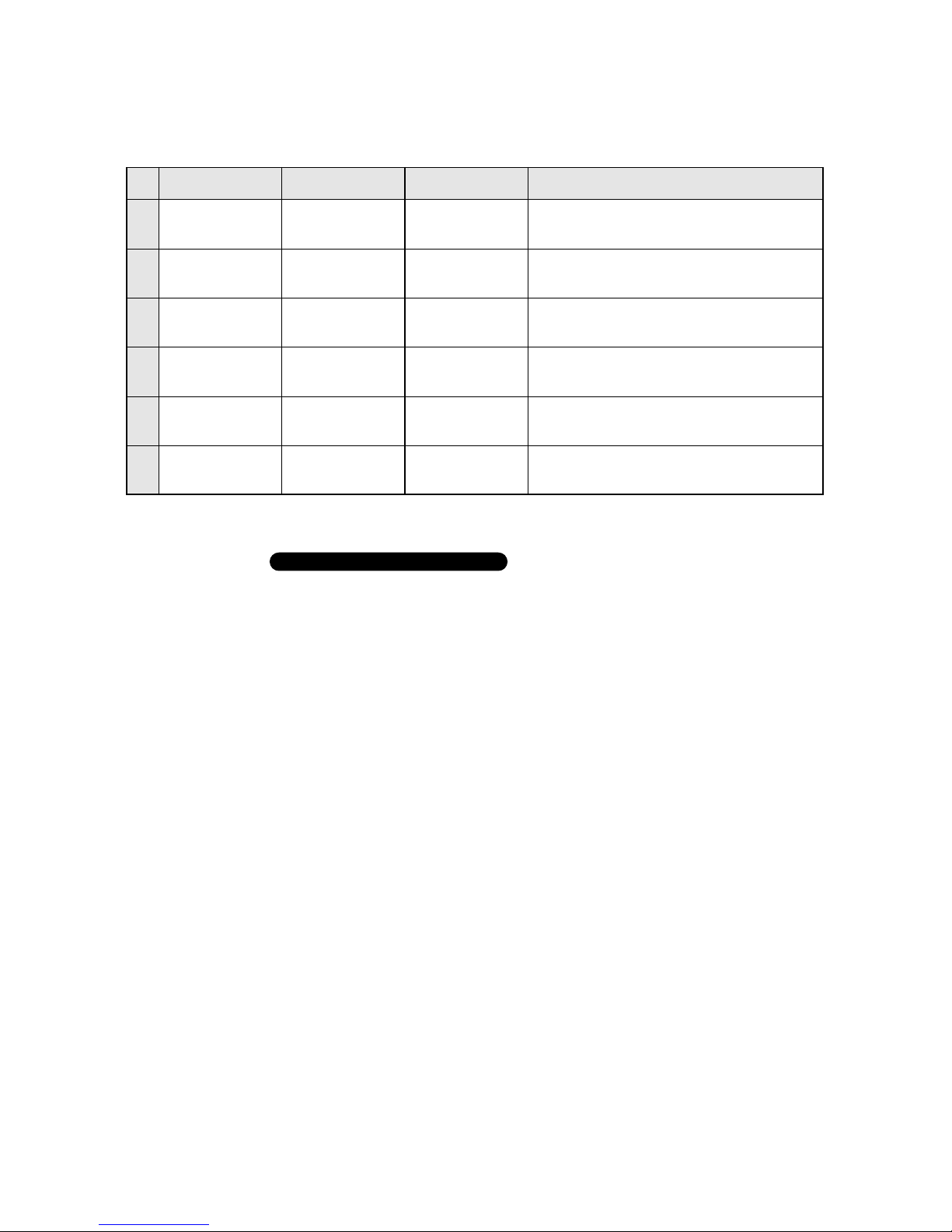

Green LED Red LED Status Description

1.

2.

3.

4.

5.

6.

HOW TO USE THE CHARGER

The special purpose charger Base (Cat.#55618) has the LEDs (green, red) which indicate the status of

the charger and Battery.

The following cases are considered to be the problems. Replace the charger and Battery with new ones.

●

The green LED is not turned on if the power plug of the charger is plugged into a 100-240 V AC (for

household use) plug socket. (With the Battery unset)

※

Check with another electric appliance to see whether electricity is available at the plug socket.

●

Neither green nor red LED is turned on or blinks if the Battery is set in the Charger.

●

The green LED is not turned on 150 minutes after the red one has been turned on.

●

The red LED is not turned on if the Battery is set in the charger.

Battery Charger problems

○

ON

●

OFF

Power-on

The charger has been plugged in. (Power-on status:

Battery unset)

●

OFF

○

ON

Charging The Battery is being charged.

○

ON

●

OFF

Charge Completed The Battery has been completed charged.

Blinking Blinking

High temparature

alarm

The Battery is hot. (Remove it from the Charger and

cool it down for a while before charging.)

○

ON

○

ON

Battery alarm The Battery is defective. (Replace it with a new one)

Blinking

○

ON

Battery high

temparature alarm

The Battery is defective and hot. (Replace it with a

new one.)

Page 15

15

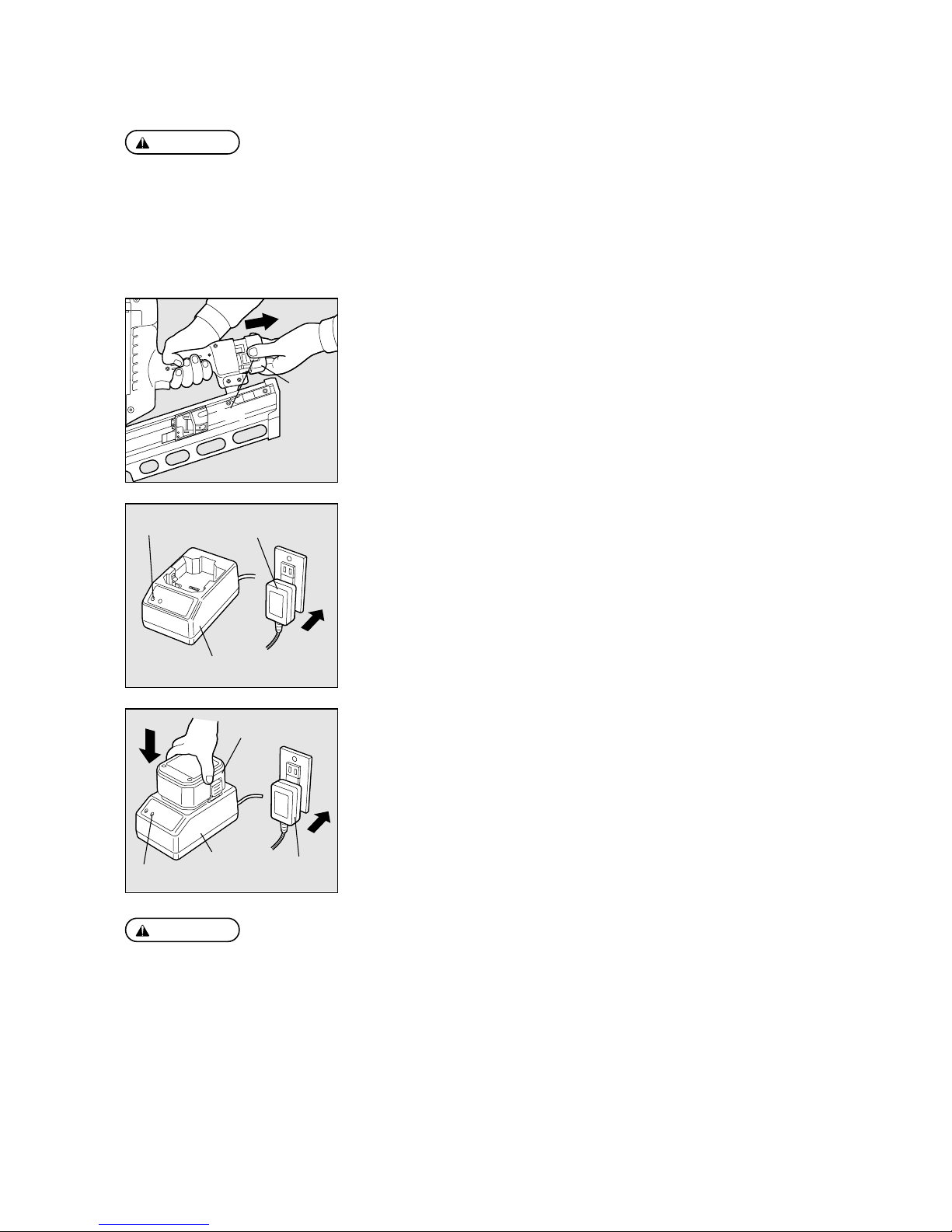

WARNING:

HOW TO CHARGE

●

Charge the Battery at the specified voltage.

Be sure to charge from a 100-240 V AC (for household use) plug socket. Use of the nonspecified voltage not only causes a trouble, but also is dangerous.

●

Handle the power cord with care.

Do not use the Charger whose power cord is damaged.

●

Use a proper plug socket.

Use of the rickety or slack plug socket causes an accident due to overheat. If this is the case,

use another proper one.

q

If the Battery is used up, remove it from the tool.

Firmly holding the tool body, press the latches on both side of the Battery with your

fingers to remove.

Battery

w

Insert the AC adapter’s jack into the Charger and plug the power plug into a

plug socket.

The green LED is turned on to inform you of the power-on status.

Green LED

Charger

100-240 V

AC Power Adapter

Latch

CAUTION:

●

Do not try to charge the Battery which has been fully charged. The life of the Battery could be

shortened.

e

Charge the Battery.

1. Set the Battery firmly in the charger.

2. Once it is set in the charger, charging will start automatically. The red LED is turned

on to inform you that charging is under way.

3. The maximum charging time is approx. 150 minutes. The charging time depends on

the temperature, supply voltage or remaining battery capacity. Once charging is fully

completed, the green LED will be illuminated to inform you that charging has been

completed. If the fully charged Battery is set in the charger again, the red LED will be

turned on again, indicating that it is being charged. This is not an abnormality. After a

while, the green LED will be turned on to indicate completion of charging.

r

The Illuminated Green LED Indicates completion of charging.

1. Holding down the charger, remove the Battery.

2. Disconnect the AC adapter’s power plug from the plug socket.

Now Charging is complete.

Battery

Red LED

Charger

100-240 V

AC Power Plug

Page 16

16

CAUTION:

●

After completing your work or when the tool is not used, be sure to remove the Battery Pack

from the tool to store it. (Remove the Fuel Cell and nails as well)

If it is left connected, the electric power will be consumed in the standby state.

In the following cases the Battery Pack must be charged for 24 HOURS to reach top performance:

・

Upon purchasing the tool.

・

When the tool has not been used for 1 month or longer.

・

When it is clear that you can drive less nails even when fully charged.

After the Charge Complete lamp has been turned on, leave the Battery set in the Charger for about

another 24 hours.

Preventing the Battery Pack from becoming inactive

Page 17

17

5. HANDLING OF FUEL CELL

The Fuel Cell is doubly structured; the inner container has been filled with a liquid fuel gas and the outer

one with a propellant gas (another pressurized gas).

Like squeezing a toothpaste tube, the inner fuel gas is pushed out by the pressure of the propellant gas,

thus being used up to the last without wasting it. Because of this structure, the combustible propellant

gas in the outer container remains even after the fuel gas in the inner container has been used.

Therefore, utmost care should be taken when disposing the empty Fuel Cell.

WARNING:

●

Be sure to use the Fuel Cell exclusively designed for the Gas powered Fastening System.

●

Never smoke a cigarette when attaching or operating a metering valve.

●

Do not remove the rubber plug from the bottom of the Fuel Cell except at disposal.

●

Do not make a hole in the Fuel Cell.

●

Be careful not to breathe in the gas.

Breathing in the gas could cause sleepiness, dizziness or nausea.

●

Never jet the gas to the human body.

●

Do not incinerate or recycle the empty Fuel Cell.

(See Page 19 for disposal of the Fuel Cell)

WARNING:

●

Attach the metering valve properly to the Fuel Cell.

Attach it firmly until it has “clicked.”

Unless it is properly attached, the fuel gas will not be jetted from the metering valve. Also, the

gas could leak, causing danger to you.

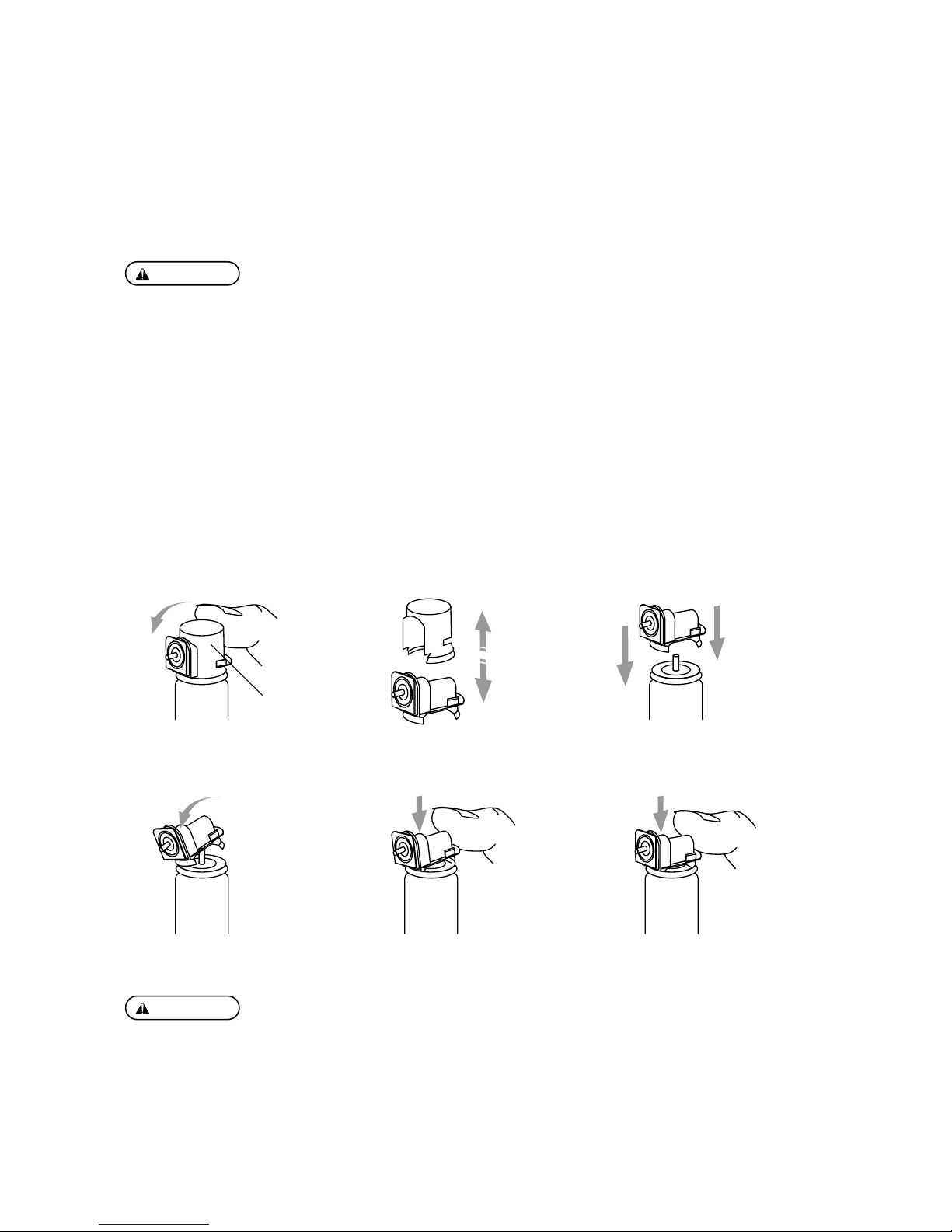

ATTACHING THE METERING VALVE TO THE FUEL CELL

The metering valve is designed to jet a constant amount of fuel gas into the combustion chamber of the

tool.

1. Push to release the valve. 2. Separate valve from cap. 3. Align ridges square.

4. Push in the front ridge first 5. Push in the rear ridge until it 6. Push in horizontally. It clicks again.

5. has clicked.

metering Valve

Page 18

18

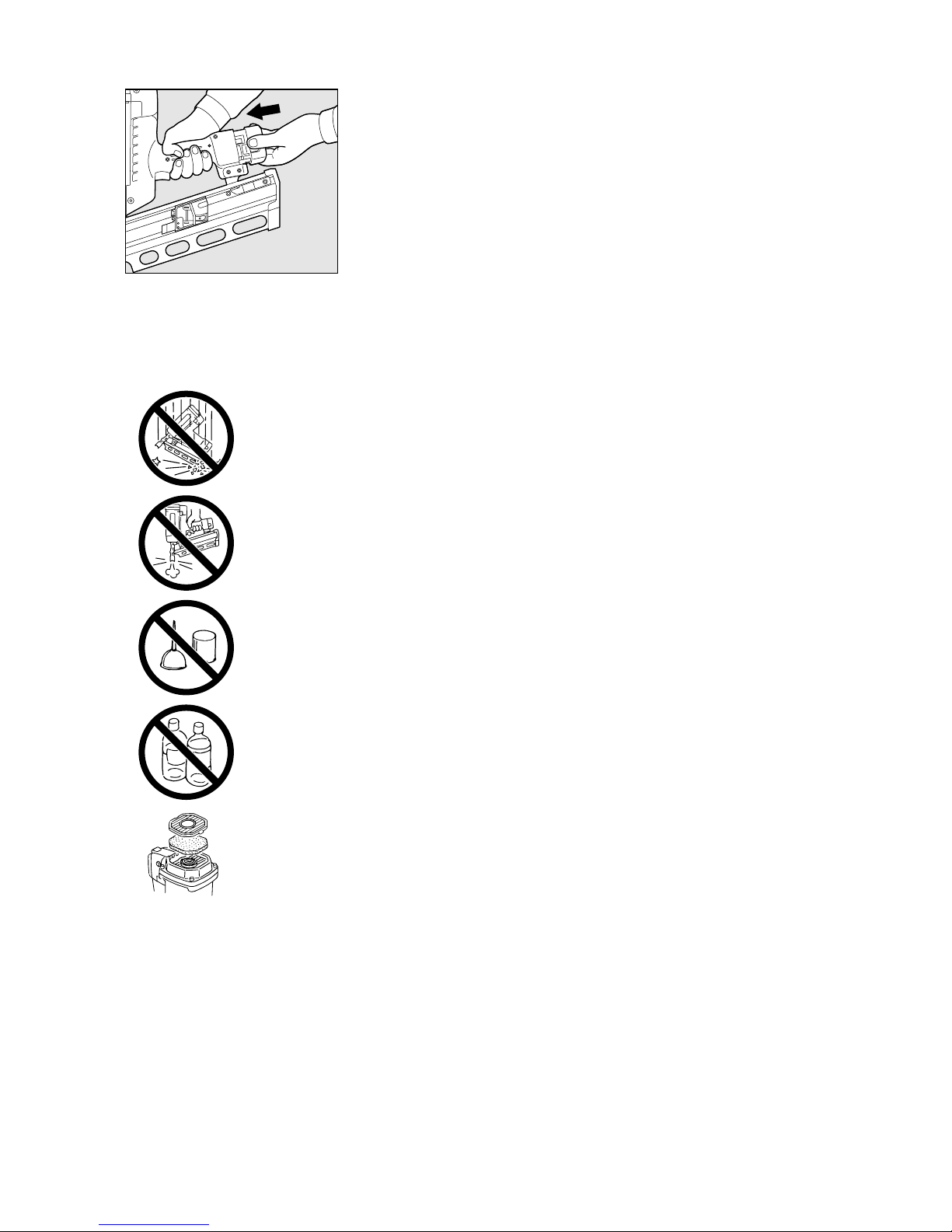

WARNING:

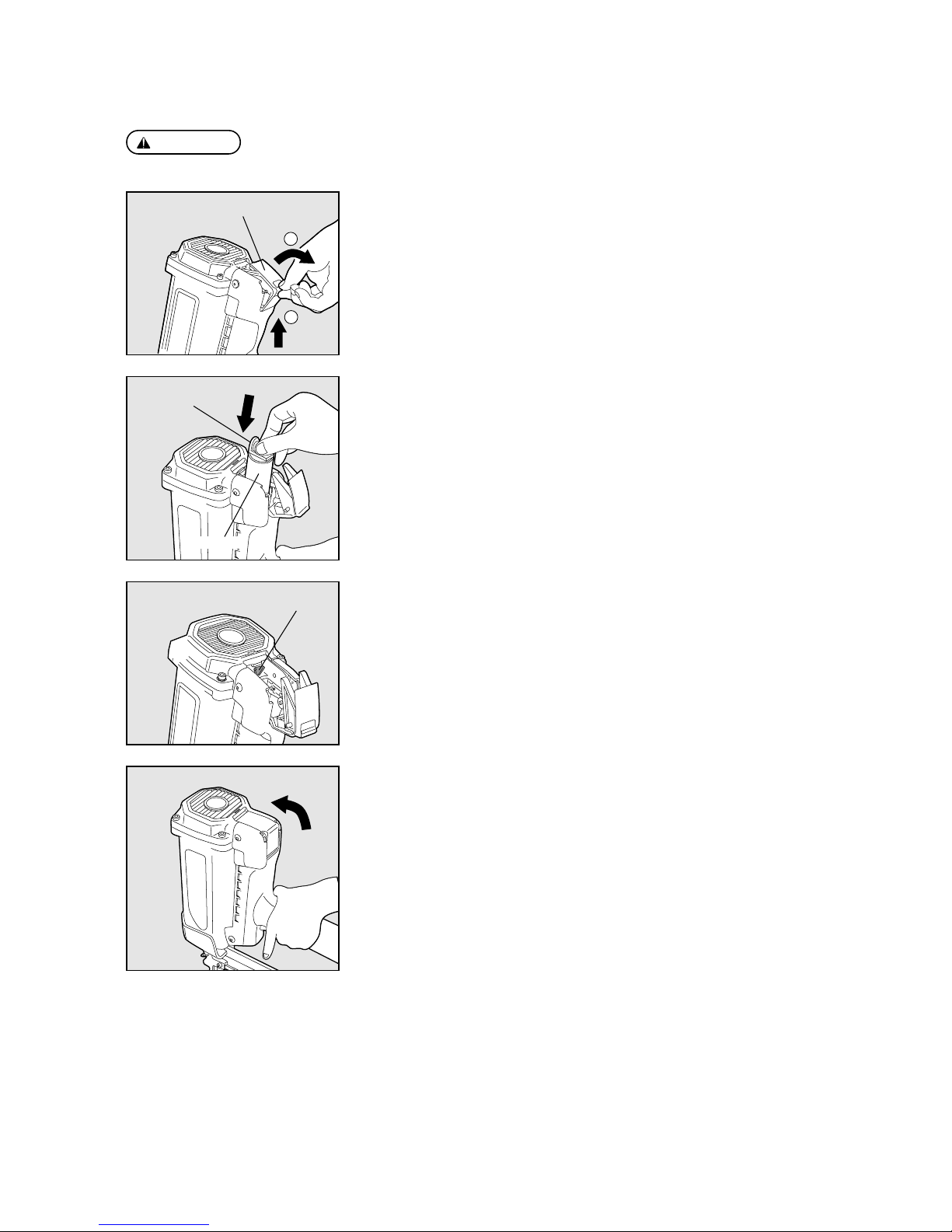

INSERTING THE FUEL CELL IN TO THE TOOL

●

Be sure to release your finger from the Trigger.

●

Do not press the Contact Arm against the object.

2

1

q

Push up and pull the Actuator to this side to open it.

Actuator

w

Directing the Valve Stem of the Metering Valve forward (toward the Air Filter Cover),

set the Fuel Cell.

Metering Valve

e

When you open the Actuator, you can see a Red Adapter.

Fit the Valve Stem into this adapter.

Red Adapter

r

Put the Actuator over the Metering Valve and push it down to latch.

Fuel Cell

Page 19

19

DISPOSING OF THE USED FUEL CELL

Combustible jet gas still remains in the used Fuel Cell.

WARNING:

●

Do not throw the used Fuel Cell into a fire.

●

Never smoke a cigarette.

●

Never breathe in the gas.

Page 20

20

6. INSTRUCTIONS FOR OPERATION

Read section titled “SAFETY INSTRUCTIONS”.

1. BEFORE OPERATION

q

Wear Safety Glasses or Goggles.

w

Do not insert the Fuel Cell and Battery.

e

Inspect screw tightness.

r

Check operation of the Contact Arm & Trigger if moving smoothly.

t

Insert the Fuel Cell and Battery.

y

Hold the tool with finger-off the Trigger, then push the Contact Arm against the work-piece. (The

tool must not operate.)

u

Hold the tool with Contact Arm free from work-piece and pull the Trigger. (The tool must not

operate.)

i

Remove the Fuel Cell and Battery.

WARNING:

WARNING:

2. OPERATION

Wear safety glasses or goggles

Danger to the eyes always exists due to the possibility of dust being blown up by the exhausted air or of

a fastener flying up due to the improper handling of the tool. For these reasons, safety glasses or

goggles shall always be worn when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment

must conform to the requirements of the American National Standards Institute, ANSI Z87.1 (Council

Directive 89/686/EEC of 21 DEC. 1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all

other personnel in the work area.

NOTE: Non-side shielded spectacles and face shields alone do not provide adequate protection.

Keep hands and body away from the discharge outlet

When driving the fasteners because of dangerous of hitting the hands or body by mistake.

Procedure

q

Load the nails into the slit in the rear of the Magazine until they reach in front of the

Nail Stopper.

WARNING:

LOADING THE NAILS

●

When loading the nails, be sure to release the finger from the Trigger.

●

Do not press the Contact Arm against the object.

Nails

●

Abrupt release of the Pusher Holder causes jamming of nails or dry-firing.

CAUTION:

Nail Stopper

Page 21

Follower Holder

21

w

Pull the Follower Holder as far to the rear and of the magazine and release it gently.

●

Never put your face above the tool. Reaction of the tool may cause an

unexpected injury.

●

Never bring your hand or finger close to the discharge outlet.

WARNING:

WARNING:

2

1

q Press the nose of the Contact Arm

against the object.

w Pull the Trigger.

HOW TO DRIVE THE NAILS

Procedure

q

Install the Battery and Fuel Cell.

w

Press the nose of the Contact Arm against where you want to drive the nails.

The fan motor is activated, the fuel gas is jetted, mixing the fuel with the air.

e

Firmly pressing the Contact Arm, pull the Trigger. The nails are driven into the object

by combustion of the fuel.

●

Prior to starting work, be sure to check whether the tool functions as

mentioned above.

●

If the tool is used for a long period of time, it could get hot and burn you.

If any abnormality is found, contact your nearest authorized distributor for

inspection and repairing.

※

The fan keeps running for approx. 10 seconds even after driving the nails.

WARNING:

r

The nails are not shot even if the Contact Arm is applied to the object with the

Trigger pulled. Release the Trigger and repeat Step

w

.

DRIVING DEPTH ADJUSTMENT

●

ALWAYS remove Fuel Cell and Battery before making adjustment.

●

The Depth Adjustment Dial may be hot.

The driving depth adjustment is made by adjusting the Depth Adjustment Dial.

q

With Fuel Cell and Battery install, drive a few nails into a representative material

sample to determine if adjustment is necessary.

w

If adjustment is required, remove Fuel Cell and Battery.

e

Refer to the mark on the Magazin for direction to turn the Adjustment Dial.

r

Reinstall Fuel Cell and Battery.

Adjustment Dial

Deeper Shallow

CAUTION:

Page 22

22

REPLACING THE FUEL CELL

If the Fuel Gas is low, the nails cannot be driven.

●

Be sure to release the Trigger.

●

Do not press the Contact Arm against the object.

q

Push up and pull the Actuator to this side to open it.

WARNING:

REPLACING THE BATTERY

If the Battery is low, the red LED of the tool will be turned on.

●

Be sure to remove the Fuel Cell.

●

Release the Trigger.

●

Do not press the Contact Arm against the object.

WARNING:

w

Grab the Metering Valve and remove the used Fuel Cell.

e

Set the new Fuel Cell.

(See Page 18 for the setting method)

q

Firmly holding the main body, press the latches on both sides of the Battery to

remove it.

2

1

Actuator

Valve Stem

Fuel Cell

●

Remove the Fuel Cell and Battery.

WARNING:

CHANGING THE HOOK DIRECTION

The Hook can be directed in the two directions. Remove the hexagon socket head bolts

with hexagon wrench, change the direction, and then, put back the bolts to reassemble.

Hexagon Socket

Head Bolt

Hook

Battery

Latch

Page 23

23

7. MAINTAIN FOR PERFORMANCE

1. HANDLE THE TOOL WITH CARE

Never drop, collide or hit the tool against a hard material. It may be deformed, cracked or damaged.

2. DO NOT TRIGGER THE TOOL WITH NO NAILS LOADED

If you repeatedly operate the tool with no nails loaded, the durability of each section will be

reduced.

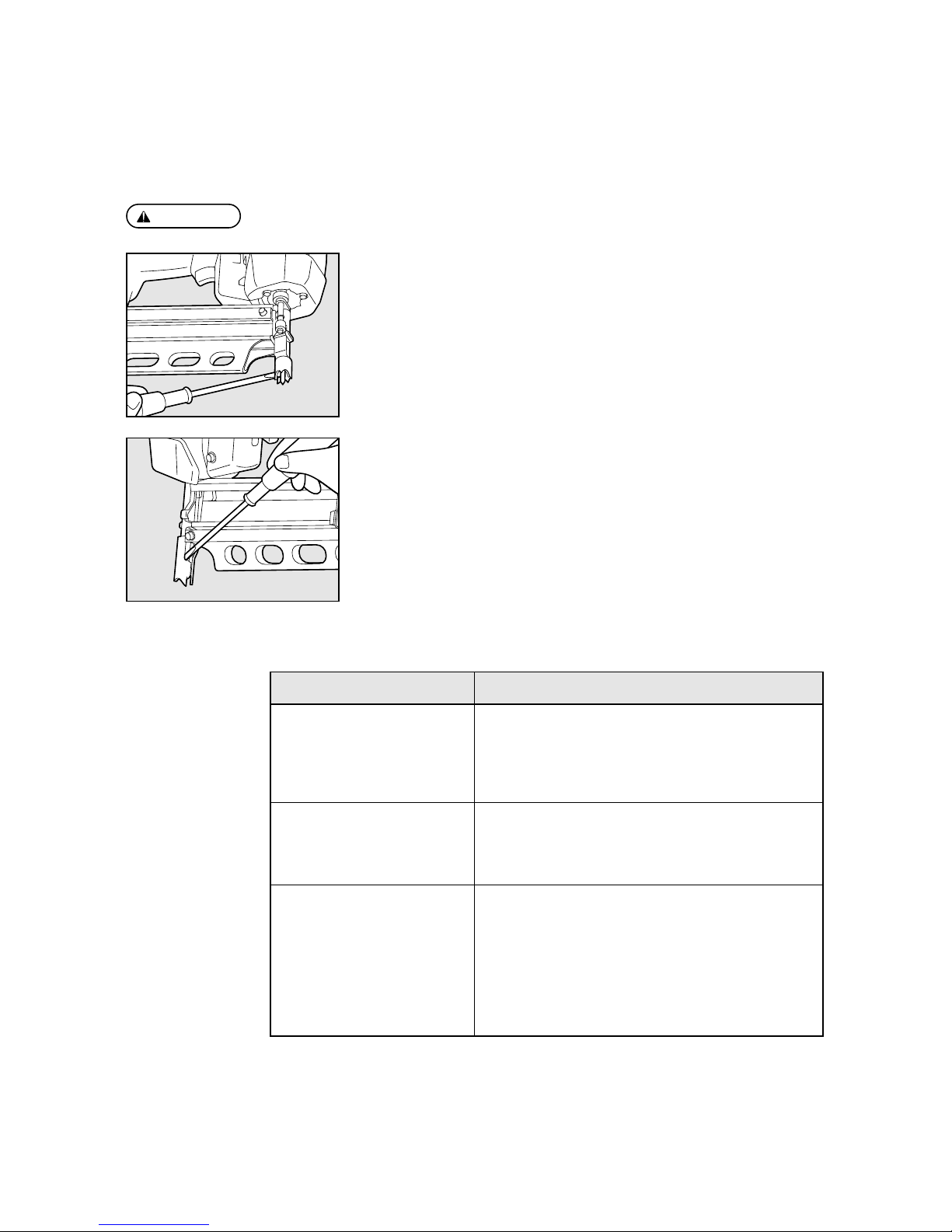

3. DO NOT LUBRICATE THE TOOL

Never lubricate the Tool because it will cause problems.

4. INSPECT THE TOOL PERIODICALLY

In order to maintain the performance of the tool, clean and inspect the tool periodically. To have it

inspected, contact your nearest distributor.

5. CLEAN THE AIR FILTER

Clean the Air Filter every other day. Open the Air Filter Cover with a regular screwdriver, remove

the Air Filter from the inside and clean it with Compressed air.

8. STORING

q

When not in use for an extended period, apply a thin coat of the lubricant to the steel parts to avoid

rust.

w

Do not store the tool in a cold weather environment. Keep the tool in a warm area.

e

When not in use, the tool should be stored in a warm and dry place. Keep out of reach of children.

r

All quality tools will eventually require servicing or replacement of parts because of wear from

normal use.

w

Install the newly charged Battery into the Housing until it has clicked.

(See Page 15 for the charging method)

e

Install the Fuel Cell.

(See Page 18 for the Installation method)

Page 24

24

e

Phenomenon Check Item

The Battery cannot be charged.

・

The AC adapter’s power plug is firmly connected to the

plug socket.

・

The AC adapter’s jack is firmly inserted into the charger.

・

The Battery is properly set in the charger.

・

The charger’s LED is turned on.

While charging, the charger, AC

adapter and power cord are

heated, emit abnormal sound or

generate heat.

・

Stop using them immediately and consult your nearest

distributor.

The pins cannot be driven.

・

The tool body is properly loaded with the pins, Battery and

Fuel Cell.

・

Check the LEDs of the tool body.

・

The gas still remains in the Fuel Cell.

・

The Fuel Cell is not out of life.

・

The battery capacity is still remaining.

・

The nails are not jamming.

・

The Contact Arm is properly pressed against the object.

9. TROUBLE SHOOTING/REPAIRS

q

The repairs shall be carried out only by the Powers authorised distributer.

w

Removing Jammed Nail

WARNING:

●

Remove the Fuel Cell and Battery.

Procedure

q

Take out the nails from the inside of the Magazine.

w

Remove nails that are jammed inside the Nose by using a punch or slotted screw

driver.

Page 25

25

DEUTSCH

W3-21FRH / W3-34CDH

GASBETRIEBENES BEFESTIGUNGSSYSTEM

VERZEICHNIS

1. SICHERHEITSVORSCHRIFTEN

……

26

2. SPEZIFIKATIONEN UND

TECHNISCHE DATEN

………………

33

3. SICHERHEITSVORRICHTUNGEN

…

34

4. VERWENDUNG VON AKKU UND

LADEGERÄT

………………………

35

5.

HANDHABUNG DER BRENNSTOFFZELLE…39

6.

BETRIEBSANWEISUNGEN

…………

42

7.

WICHTIGE PUNKTE ZUR AUFRECHTERHALTUNG

DER LEISTUNGSFÄHIGKEIT

…………………

45

8. LAGERUNG

…………………………

45

9.

STÖRUNGSBESEITIGUNG/INSTANDSETZUNG

…

46

BETRIEBSANLEITUNG

LESEN SIE VOR INBETRIEBNAHME DES GERÄTES DIE GEBRAUCHS- UND SICHERHEITS-

HINWEISE. BITTE BEWAHREN SIE DIE GEBRAUCHS- UND SICHERHEITSHINWEISE AUF,

DAMIT SIE AUCH SPÄTER EINGESEHEN WERDEN KÖNNEN.

ACHTUNG:

Page 26

26

1. SICHERHEITSVORSCHRIFTEN

VORSICHTSHINWEISE ZUM GEBRAUCH DES WERKZEUGS

1. SCHUTZBRILLE TRAGEN

Durch das austretende Gas aufgewirbelter Staub und Nageldübel, die durch unsachgemäße

Handhabung des Werkzeugs aus diesem geschleudert werden oder von einem Gegenstand

abprallen, stellen eine stetige Gefahr für die Augen dar. Daher ist beim Einsatz des Werkzeugs

stets eine Schutzbrille zu tragen.

Der Arbeitgeber und/oder Benutzer ist für einen ausreichenden Augenschutz verantwortlich. Die

Augenschutzausrüstung muss dem Standard ANSI Z87.1 (Council Directive 89/688/EEC vom 21.

Dez. 1989) entsprechen und sowohl Frontal- als auch Seitenschutz bieten.

Der Arbeitgeber ist für die Durchsetzung des Augenschutzgebrauchs durch den Werkzeugbenutzer

und alle anderen Mitarbeiter im Arbeitsbereich verantwortlich.

HINWEIS: Eine Brille ohne Seitenschutz oder ein Gesichtsschutz allein bietet keine ausreichende

Schutzwirkung.

2. IN GEWISSEN UMGEBUNGEN KANN EIN GEHÖRSCHUTZ ERFORDERLICH SEIN

Da die Arbeitsbedingungen eine Aussetzung hoher Geräuschpegel einschließen können, die dem

Gehör schaden, sind der Arbeitgeber und der Benutzer für die Bereitstellung eines ggf.

erforderlichen Gehörschutzes und die Verwendung durch den Werkzeugbenutzer und alle anderen

Personen im Arbeitsbereich verantwortlich.

3. ZUR ARBEITSUMGEBUNG PASSENDE KLEIDUNG UND SCHUTZAUSRÜSTUNG TRAGEN

Je nach Arbeitsumgebung einen langärmeligen Arbeitsanzug sowie Schutzausrüstung wie

Schutzhelm, Sicherheitsschuhe u. dgl. tragen.

4. VORSICHTSHINWEISE ZU BRENNSTOFFZELLEN

q

Unbedingt -Brennstoffzellen verwenden.

w

Brennstoffzellen nicht an einem schlecht belüfteten Platz aufbewahren.

e

Brennstoffzellen nicht direkt dem Sonnenlicht aussetzen.

Brennstoffzellen nicht in einem Fahrzeug oder einem anderen geschlossenen Behälter

aufbewahren, in dem hohe Temperaturen herrschen können, da sie explodieren kann. Auch

verbrauchte, leere Brennstoffzellen enthalten noch Gasreste, die sich ausdehnen und den

Behälter zum Explodieren bringen können.

r

Brennstoffzellen bei Umgebungstemperaturen von maximal 49°C (120°F) lagern.

Brennstoffzellen enthalten brennbares Gas, das unter Druck steht. Bei Temperaturen oberhalb

49°C (120°F) kann Gas austreten oder die Zelle bersten und einen Brand verursachen.

WARNUNG:

ZUR VERMEIDUNG VON SCHWEREN KÖRPERVERLETZUNGEN UND SACHSCHÄDEN

VOR GEBRAUCH UNBEDINGT DIE FOLGENDEN “SICHERHEITSVORSCHRIFTEN” LESEN

UND VERSTEHEN. NICHTBEACHTUNG VON WARNHINWEISEN KANN DEN TOD ODER

SCHWERE KÖRPERVERLETZUNGEN ZUR FOLGE HABEN.

49°C

120°F

Page 27

27

t

Das Gas nicht einatmen.

y

Leere Brennstoffzellen nicht verbrennen oder recyceln.

u

Das Gas nicht auf den menschlichen Körper sprühen.

i

Den Gummistopfen an der Unterseite der Brennstoffzelle nicht entfernen. Der Stopfen

darf erst bei der Entsorgung der Zelle entfernt werden.

o

Brennstoffzellen nicht punktieren.

5. VORSICHTSHINWEISE ZU AKKU, LADEGERÄT UND LADEVERFAHREN

q

Unbedingt den Battery (Cat.#55583) verwenden.

Das Werkzeug darf nur mit dem Battery (Cat.#55583) betrieben werden. Eine

Spannungsversorgung über ein Stromnetz oder mit einem Akku unterschiedlichen Typs,

Trockenzellen oder einer Fahrzeugbatterie ist nicht zulässig.

Nichtbeachtung kann einen Defekt, eine Funktionsstörung, Wärmeentwicklung oder einen Brand

verursachen. (Weitere Informationen zum Battery (Cat.#55583) siehe Seite 33.)

w

Unbedingt mit Charger Base (Cat.#55618) laden.

Der Akku muss mit dem Charger Base (Cat.#55618) geladen werden.

Bei Verwendung eines anderen Ladegeräts wird der Akku unter Umständen nicht

vorschriftsmäßig geladen oder kann beschädigt werden, sich stark erwärmen oder sich

entzünden. (Weitere Informationen zum Charger Base (Cat.#55618) siehe Seite 33.)

e

Den Akku vor Gebrauch laden.

Ein Akku, der neu erworben oder längere Zeit nicht benutzt wurde, ist aufgrund seiner

kontinuierlichen Selbstentladung nicht voll aufgeladen. Daher unbedingt mit dem Charger Base

(Cat.#55618) laden.

r

Den Akku von einem Netz mit der vorgeschriebenen Spannung laden.

Das Ladegerät an eine Steckdose mit 100-240 V Wechselstrom (Haushaltsnetz) anschließen.

Nur an Stromnetze mit der vorgeschriebenen Spannung anschließen. Nichtbeachtung kann

starke Wärmeentwicklung oder ein Entzünden zur Folge haben.

Page 28

28

t

Niemals Transformatoren wie z. B. einen Spannungsverstärker als Stromquelle für das

Ladegerät verwenden.

Nichtbeachtung dieses Punkts kann eine Störung oder ein Durchbrennen des Ladegeräts zur

Folge haben.

y

Zum Laden des Akkus keinen motorgetriebenen Generator und auch keine

Gleichstromquelle verwenden.

Nichtbeachtung dieses Punkts kann eine Störung oder ein Durchbrennen des Ladegeräts zur

Folge haben.

u

Den Akku niemals im Regen oder an anderen Orten aufladen, wo er Spritzwasser oder

Feuchtigkeit ausgesetzt ist.

Aufladen in feuchter Umgebung kann einen elektrischen Schlag oder Kurzschluss und im

Extremfall ein Brand durch Durchbrennen oder Entzündung zur Folge haben.

i

Den Netzstecker niemals mit nassen oder feuchten Händen anfassen.

Berührung mit nassen oder feuchten Händen kann einen elektrischen Schlag zur Folge haben.

o

Das Ladegerät bei Gebrauch nicht mit einem Lappen o. dgl. zudecken.

Es kann sich bei Zudeckung stark erwärmen und ein Durchbrennen oder einen Brand

verursachen.

!0

Das Ladegerät von offenen Flammen fernhalten.

!1

Den Akku nicht in der Nähe brennbarer Stoffe aufladen.

!2

Den Akku an einem gut belüfteten Ort und vor Sonnenlicht geschützt aufladen.

Beim Laden in direkt einfallendem Sonnenlicht kann sich das Ladegerät überhitzen, was ein

Durchbrennen oder einen Brand verursachen kann.

!3

Den Akku bei Umgebungstemperaturen zwischen 0°C (32°F) und 40°C (104°F) aufladen.

Bei einer Umgebungstemperatur unter 0°C (32°F) oder über 40°C (104°F) wird der Akku nicht

ordnungsgemäß geladen und es kann ein Brand entstehen.

!4

Darauf achten, dass keine Fremdkörper in die Belüftungsöffnung oder die Akkuaufnahme

des Ladegeräts gerät.

Dies kann einen elektrischen Schlag oder eine Störung verursachen. Das Ladegerät an einem

staubfreien Ort verwenden.

Page 29

29

!56

Das Netzteilkabel vorsichtig handhaben.

Das Netzteil nicht am Kabel tragen und auch nicht durch Ziehen am Kabel von der Steckdose

trennen, da dies eine Beschädigung des Kabels (Kabelbruch oder Kurzschluss) verursachen

kann. Außerdem darauf achten, dass das Netzteilkabel nicht mit Schneidwerkzeugen, heißen

Substanzen, Öl und Fett in Berührung kommt. Im Falle einer Beschädigung das Netzteil(kabel)

durch ein neues ersetzen.

!6

Die Akkukappe stets aufsetzen, wenn der Akku nicht im Werkzeug sitzt und nicht

verwendet wird.

Diese Kappe, die über dem Klemmenblock (Metallteil) angebracht wird, verhindert einen

Kurzschluss, während der Akku nicht in Gebrauch ist.

!7

Den Klemmenblock (Metallteil) am Akku nicht kurzschließen.

Bei kurzgeschlossenen Klemmen fließt ein starker Strom, der ein Erwärmen des Akkus und

Verbrennungen oder eine Beschädigung verursachen kann.

!8

Den Akku nicht ins Feuer werfen.

Nichtbeachtung dieses Hinweises kann eine Explosion zur Folge haben.

6. VORSICHT BEIM EINSETZEN DES AKKUS IN DAS WERKZEUG

Beim Einsetzen des Akkus in das Werkzeug folgende Punkte beachten, um eine Funktionsstörung

zu vermeiden.

1. Den Finger nicht auf den Auslöser legen.

2. Den Kontaktarm nicht gegen einen Gegenstand drücken.

3. Finger und Hände nicht in den Bereich der Mündung bringen.

7. BEI DER ANBRINGUNG DES AKKUS STETS EINE FUNKTIONSPRÜFUNG DURCHFÜHREN

Vor Gebrauch des Werkzeugs zunächst nur den Akku anbringen (weder Nageldübel noch

Brennstoffzelle laden), ohne den Kontaktarm gegen einen Gegenstand zu drücken, und folgende

Funktionsprüfung durchführen:

1. Prüfen, ob das Betriebsgeräusch zu hören ist, wenn lediglich der Akku eingesetzt ist.

※ Wenn der Kontaktarm bei eingesetztem Akku auf den Boden o. dgl. gedrückt wird, läuft der

Lüfter des Werkzeugs, was jedoch normal ist.

2. Auf Wärmeentwicklung oder ungewöhnliche Geruchs- bzw. Geräuschentwicklung prüfen.

Wenn das Werkzeug im aktivierten Zustand Wärme entwickelt oder einen ungewöhnlichen Geruch

oder ein komisches Geräusch erzeugt, deutet dies auf eine Störung hin. Eine Verwendung des

Werkzeugs in diesem Zustand kann einen Unfall verursachen. Sollte etwas Ungewöhnliches

gefunden werden, den nächsten autorisierten -Händler benachrichtigen.

8. BEI NICHTGEBRAUCH DES LADEGERÄTS DAS NETZTEIL AUS DER STECKDOSE ZIEHEN

9. DAS WERKZEUG NICHT AN EINEM SCHLECHT BELÜFTETEN ORT VERWENDEN

Bei Einsatz an einem schlecht belüfteten Ort kann Sauerstoffmangel auftreten.

10. DIREKTE SONNENBESTRAHLUNG VERMEIDEN

Das Werkzeug nicht in einem Fahrzeug oder einem anderen geschlossenen Behälter aufbewahren,

in dem hohe Temperaturen herrschen können, da es explodieren kann. Auch verbrauchte, leere

Brennstoffzellen enthalten noch Gasreste, die sich ausdehnen und den Behälter zum Explodieren

bringen können.

Page 30

30

11. DAS WERKZEUG NIEMALS IN DER NÄHE FLÜCHTIGER; BRENNBARER SUBSTANZEN

VERWENDEN

Das Werkzeug niemals in der Nähe von Benzin, Verdünner, Gas, Lack oder Klebemitteln

verwenden, die es diese entzünden und eine Explosion verursachen kann.

12. DAS WERKZEUG VON OFFENEN FLAMMEN FERNHALTEN

13. DAS WERKZEUG BEI UMGEBUNGSTEMPERATUREN VON -7°C (19°F) bis 49°C (120°F)

VERWENDEN, DA ES ANDERNFALLS BESCHÄDIGT WERDEN, SICH ENTZÜNDEN ODER

EXPLODIEREN KANN

-7 °C und darunter: Das Gehäuse des Werkzeugs kann beschädigt werden.

49 °C und darüber: Die Brennstoffzelle kann beschädigt werden und einen Brand oder eine

Explosion verursachen.

14. DAS WERKZEUG NICHT IM REGEN ODER AN SEHR FEUCHTEN ORTEN VERWENDEN

Nichtbeachtung dieses Hinweises kann eine Störung zur Folge haben.

15. BEIM EINTREIBEN VON NAGELDÜBELN DARAUF ACHTEN, DASS SICH PERSONEN NICHT

GEGENÜBER STEHEN

Hierbei könnte ein “Fehlschuss” eine Verletzung des gegenüberstehenden Arbeiters verursachen.

16. DIE HEISSEN TEILE DES WERKZEUGS NICHT BERÜHREN

Nach längerem Betrieb sind das Nasenstück und der Kontaktarm sehr heiß. Bei Berührung besteht

Verbrennungsgefahr.

17. BEI VERWENDUNG DES HAKENS UNBEDINGT DEN FINGER VOM AUSLÖSER NEHMEN

Wenn der Haken verwendet wird, muss der Finger vom Auslöser genommen werden.

18. NACH GEBRAUCH DES WERKZEUGS DIE BRENNSTOFFZELLE SOWIE DEN AKKU

ENTFERNEN UND DAS MAGAZIN LEEREN

Nach der Arbeit sowie vor Arbeitspausen oder Verlassen des Arbeitsplatzes, Wechseln des

Arbeitsplatzes, Einstellen, Zerlegen oder Instandsetzen des Werkzeugs und zum Entfernen eines

gestauten Befestigungsteils immer die Brennstoffzelle sowie den Akku aus dem Werkzeug nehmen

und das Magazin leeren.

19. AUF GELOCKERTE SCHRAUBEN UNTERSUCHEN

Gelockerte oder unzureichend angezogene Schrauben können beim Betrieb Schäden am

Werkzeug hervorrufen. Vor Gebrauch des Werkzeugs daher sicherstellen, dass alle Schrauben

vorschriftsmäßig installiert und fest angezogen sind.

20. DEN AUSLÖSER NUR BERÜHREN, WENN EIN BEFESTIGUNGSTEIL EINGETRIEBEN

WERDEN SOLL

Der Auslöser darf nur betätigt werden, wenn ein Befestigungsteil in die Arbeitsfläche eingetrieben

werden soll. Tragen des Werkzeugs mit betätigtem Auslöser ist gefährlich, und derartige

Handlungen sind daher unbedingt zu vermeiden.

49°C

120°F

−7°C

19°F

Page 31

31

21. DIE MÜNDUNG NIEMALS AUF SICH ODER ANDERE PERSONEN RICHTEN

Wenn die Mündung auf Personen gerichtet wird, können “Fehlschüsse” schwere Unfälle

verursachen. Daher steht darauf achten, dass die Mündung nicht auf andere Personen gerichtet

wird, auch dann nicht, wenn die Brennstoffzelle und der Akku entfernt wurden oder

Befestigungsteile geladen bzw. herausgenommen werden.

22. DIE VORGESCHRIEBENEN BEFESTIGUNGSTEILE VERWENDEN

Die Verwendung unzulässiger Befestigungsteile verursacht eine Funktionsstörung des Werkzeugs.

Daher immer die für dieses Werkzeug vorgeschriebenen Befestigungsteile verwenden.

23. DIE MÜNDUNG ORDNUNGSGEMÄSS AN DER ARBEITSFLÄCHE ANSETZEN

Wenn die Mündung am Nasenstück nicht richtig angesetzt wird, kann das einzutreibende

Befestigungsteil von der Fläche abprallen und nach oben geschleudert werden, was extrem

gefährlich ist.

24. HÄNDE UND KÖRPER VON DER MÜNDUNG FERNHALTEN

Beim Laden von Befestigungsteilen und Arbeiten mit dem Werkzeug Hände und andere Körperteile

nicht in den Bereich der Mündung am Werkzeug bringen, um eine Verletzung durch ein

versehentliches Eintreiben zu vermeiden.

25. BEFESTIGUNGSTEILE NICHT IM RANDBEREICH BZW. IN ECKEN DER ARBEITSFLÄCHE

ODER IN DÜNNES MATERIAL EINTREIBEN

Das Material kann reißen, und das dabei abprallende Befestigungsteil kann eine Person treffen und

verletzen.

26. BEFESTIGUNGSTEILE NICHT ÜBEREINANDER EINTREIBEN

Beim Eintreiben eines Befestigungsteils über einem anderen kann dieses abprallen und eine

Verletzung verursachen.

27. ENTFERNEN DER BEFESTIGUNGSTEILE NACH DER ARBEIT

Nach der Arbeit im Magazin verbleibende Befestigungsteile können beim nächsten Gebrauch des

Werkzeugs, bei der Handhabung des Werkzeugs sowie beim Einlegen der Brennstoffzelle bzw. des

Akkus einen schweren Unfall verursachen. Aus diesem Grunde müssen alle im Magazin

verbleibenden Befestigungsteile bei Beendigung der Arbeit entfernt werden.

28. BEI VERWENDUNG EINES WERKZEUGS MIT KONTAKTAUSLÖSUNG DIE FUNKTION DES

KONTAKTAUSLÖSUNGSMECHANISMUS REGELMÄSSIG PRÜFEN

Das Werkzeug keinesfalls verwenden, wenn die Kontaktauslösung nicht einwandfrei funktioniert, da

dies gefährliche “Fehlschüsse” zur Folge haben kann. Keine eigenmächtigen Eingriffe am

Kontaktauslösungsmechanismus vornehmen.

29. BEIM EINSATZ DES WERKZEUGS IM FREIEN ODER AN EINEM ERHÖHTEN ORT

Beim Befestigen von Dachteilen und auf anderen schrägen Flächen am tiefer liegenden Ende der

Fläche beginnen und nach oben arbeiten. Arbeiten in entgegengesetzter Richtung ist gefährlich, da

man leicht das Gleichgewicht verlieren kann.

30. DAS WERKZEUG NIEMALS VERWENDEN; WENN EINES SEINER BEDIENTEILE (AUSLÖSER,

KONTAKTARM) NICHT BZW. NICHT EINWANDFREI ARBEITET ODER ENTFERNT BZW.

ABGEÄNDERT WURDE

31. BEI WERKZEUGBETÄTIGUNG NICHT IN DIE LUFT SCHIESSEN

Dies könnte eine Verletzung Umstehender zur Folge haben und belastet das Werkzeug unnötig.

32. IMMER DAVON AUSGEHEN, DASS DAS MAGAZIN DES WERKZEUGS BEFESTIGUNGSTEILE

ENTHÄLT

Page 32

32

33. DAS WERKZEUG ALS ARBEITSGERÄT SCHÄTZEN

34. KEINEN UNFUG MIT DEM WERKZEUG TREIBEN

35. KEINE BEFESTIGUNGSTEILE IN DAS WERKZEUG LADEN, WÄHREND EINES DER

BEDIENTEILE (AUSLÖSER, KONTAKTARM) AKTIVIERT IST

36. DAS WERKZEUG VORSCHRIFTSMÄSSIG PFLEGEN

Das Werkzeug mit einem weichen Lappen säubern. Niemals einen nassen Lappen oder flüchtige

Reinigungsmittel wie Verdünner oder Benzin verwenden.

37. VOR DIREKT EINFALLENDEM SONNENLICHT SCHÜTZEN

Werkzeug und Ladegerät nicht längere Zeit in direktem Sonnenlicht ablegen.

NEBEN DEN ANDEREN WARNHINWEISEN IN DIESER ANLEITUNG DIE

FOLGENDEN ALLGEMEINEN VORSICHTSMASSREGELN BEACHTEN

•

Das Werkzeug nicht als Hammer verwenden.

•

Das Werkzeug darf nur für den Zweck verwendet werden, für den es vorgesehen ist.

•

Bedienteile (AUSLÖSER, KONTAKTARM) niemals entfernen oder manipulieren.

•

Das Werkzeug, Brennstoffzellen und Akkus bei Nichtgebrauch an einem trockenen Platz

außerhalb der Reichweite von Kindern aufbewahren.

•

Das Werkzeug nicht ohne Warnschild verwenden.

•

Die ursprüngliche Konstruktion bzw. Funktionsweise des Werkzeugs darf ohne Genehmigung

von CO., LTD. nicht abgeändert werden.

Page 33

33

2. SPEZIFIKATIONEN UND TECHNISCHE DATEN

1. TEILEBEZEICHNUNGEN

2. WERKZEUGSPEZIFIKATIONEN

q

e

w

rt

y

u

i

!1 !2 !3

!8

!9

@0

!0

!5

!6

!7

!4

@1

@2

@3

o

q

Luftfilterabdeckung

w

Brennstoffzellenabdeckung

e

Gehäuse

r

LED-Anzeige

t

Auslöser

y

Akku

u

Haken

i

Nageldübelanschlag

o

Einstellrad

!0

Kontaktarm

!1

Schieberhalter

!2

Schieber

!3

Magazin

!4

Endabdeckung

!5

Akkukappe

!6

Klemmenblock

!7

Akku (Cat.#55583)

!8

Akkuaufnahme

!9

Stecker

@0

Netzteilkabel

@1

Ladegerät (Cat.#55618)

@2

Netzstecker

@3

Netzteil

3. BEFESTIGUNGSTEILSPEZIFIKATIONEN

4. TECHNISCHE DATEN

q

GERÄUSCH

A-bewertet, einzelnes Ereignis ------ LWA, 1s, d 105.4 dB Schallleistungspegel

A-bewertet, einzelnes Ereignis ------ Lp A , 1s, d 98.8 dB Emissionsschalldruckpegel am Arbeitsplatz

Ermittlung und Dokumentierung dieser Werte gemäß EN12549 : 1999.

w

SCHWINGUNGEN

Schwingungsverhalten = 4.46 m/s

2

Ermittlung und Dokumentierung dieses Werts gemäß ISO 8662-11.

Dieser Wert ist ein werkzeugbezogener Eigenschaftswert und gibt keine Auskunft über den Einfluss auf Hand und Arm beim

Einsatz des Werkzeugs. Dieser Einfluss ist unter anderem von der Kraft abhängig, mit der das Werkzeug gehalten wird, sowie

der Andruckkraft, der Ausrichtung des Werkzeugs, dem Versorgungsstrom, dem Werkstück und der Werkstückunterlage.

PRODUKT-NR. W3-21FRH W3-34CDH

HÖHE 382 mm 391 mm

BREITE 111 mm 110 mm

LÄNGE 379 mm 340 mm

GEWICHT

3.5 kg (7.8 lbs.)

(einschließlich Brennstoffzelle und Akku)

MAGAZIN-FASSUNGSVERMÖGEN

32 Nageldübel/ 40 Nageldübel/

1 Streifen 1 Streifen

AKKU Battery (Cat.#55583)

AKKUKAPAZITÄT

6 V Gleichspannung, 1.5 Ah

LADEGERÄT Charger Base (Cat.#55618)

NETZANSCHLUSSWERTE

100-240 V, 50 oder 60 Hz

LEISTUNGSAUFNAHME

8VA (10V 800mA)

(Nennwert)

LADEZEIT max. 150 Minuten

ZUBEHÖR

Schutzbrille, Tragekoffer, Akku,

Ladegerät,

PRODUKT-NR. W3-21FRH W3-34CDH

NAGELDÜBEL-LÄNGE

50 bis 90 mm

SCHAFTDURCHMESSER

2.9 bis 3.3 mm

SCHAFTTYPEN glatt, gerillt, mit Gewinde

KOPFDURCHMESSER

6.8 bis 7.5 mm 6.5 bis 7.7 mm

WINKEL 21 Grad 34 Grad

KOPF Rundkopf Verkürzter Kopf

Page 34

34

3. SICHERHEITSVORRICHTUNGEN

Das Werkzeug ist mit den folgenden Sicherheitsvorrichtungen ausgestattet, um für ausreichende

Sicherheit beim Eintreiben von Nageldübeln zu sorgen.

Mechanische Sicherheitsvorrichtung

Dieses Werkzeug ist so konzipiert, dass ein Nageldübel nur ausgestoßen wird, wenn

sowohl der Kontaktarm als auch der Auslöser gleichzeitig aktiviert sind. Wenn entweder

nur der Betätigungsarm gedrückt oder nur der Kontaktarm auf der Eintriebsfläche

angesetzt wird, stößt das Werkzeug keinen Nageldübel aus. Nageldübel können nur

eingetrieben werden, wenn der Kontaktarm auf der Fläche angesetzt ist und der

Auslöser gedrückt wird.

Auslöser

Kontaktarm

VORSICHT:

●

Vor Gebrauch des Werkzeugs dieses unbedingt auf einwandfreie Funktion der

Sicherheitsvorrichtungen überprüfen. Das Werkzeug erst verwenden, wenn sichergestellt ist,

dass es einwandfrei arbeitet.

Bevor das Werkzeug gebraucht wird, zunächst prüfen, ob die Sicherheitsvorrichtungen

ordnungsgemäß arbeiten. Für diese Prüfung bei leerem Magazin (keine Nageldübel geladen)

die Brennstoffzelle und den Akku einlegen.

※

In den folgenden Fällen arbeiten die Sicherheitsvorrichtung nicht. Das Werkzeug darf in

diesem Zustand nicht verwendet werden.

1. Bei alleinigem Drücken des Auslösers (ohne Ansetzen des Kontaktarms) wird ein

Betriebsgeräusch erzeugt.

2. Das Werkzeug startet Trockenauslösung-Betrieb bei einfachem Andrücken des

Kontaktarms an das Werkstück.

※

Ein Lüftergeräusch wird hörbar, was jedoch normal ist.

Falls etwas Ungewöhnliches entdeckt wird, das Werkzeug beim nächsten von autorisierten

Händler überprüfen/instand setzen lassen.

Page 35

35

4. VERWENDUNG VON AKKU UND LADEGERÄT

WARNUNG:

●

Der Battery (Cat.#55583) für das Werkzeug muss mit dem Charger Base (Cat.#55618) geladen

werden. Bei Verwendung eines anderen Ladegeräts wird der Akku unter Umständen nicht

vorschriftsmäßig geladen oder kann beschädigt werden, sich stark erwärmen oder sich

entzünden.

●

Den Akku nicht in die Nähe offener Flammen bringen.

●

Den Akku nicht in der Sonne liegen lassen.

●

Den Akku nicht laden oder verwenden, wenn er nass oder feucht ist (durch Einwirkung von

Flüssigkeiten wie Wasser, Meerwasser, Milch und andere Getränke, Seifenlauge).

●

Das Ladegerät bei Nichtgebrauch von der Steckdose trennen.

●

Bei Temperaturen von 0˚C bis 40˚C laden, um Brandgefahr auszuschließen.

●

Vor starken Schlägen und Stößen schützen (z. B. Hammerschlag, Fußtritt oder Fall).

WARNUNG:

●

Um die Gefahr eines Kurzschlusses auszuschließen, vor der Recycling-Entsorgung den

Klemmenblock (Metallteil) des Akkus mit der Kappe abdecken (zur sicheren Befestigung mit

Klebeband umwickeln).

<Zellen im Akku>

・

Nennspannung: 1,2 V/Zelle

・

Zellen pro Akku: 5 Stück

VORSICHT:

●

Wenn der Akku verbraucht ist oder voraussichtlich längere Zeit nicht gebraucht wird, diesen

aus dem Ladegerät nehmen.

●

Das Werkzeug beim Tragen nicht am eingesetzten Akku halten.

ORDNUNGSGEMÄSSER GEBRAUCH DES AKKUS

q

Den Akku voll aufladen und dann bis zur völligen Entleerung verwenden.

Wenn der Akku wiederholt bei noch verbleibender Restspannung wieder aufgeladen wird, nimmt die

Zahl der pro Ladevorgang eintreibbaren Nageldübel unter Umständen drastisch ab, und die

Lebensdauer des Akkus verkürzt sich. Es wird empfohlen, den Akku zu verwenden, bis er sich völlig

entleert hat (rote LED-Anzeige am Werkzeug leuchtet).

w

Zwei Akkus abwechselnd verwenden.

Zur Akkuschonung wird empfohlen, mit zwei Akkus zu arbeiten, die abwechselnd verwendet werden.

Der Akku für dieses Werkzeug besteht aus Zellen mit Nickel-Wasserstoff, einem wertvollen RecyclingMaterial. Sobald ein Akku das Ende seiner Lebensdauer erreicht hat, diesen beim nächsten

autorisierten Händler abgeben; nicht auf normale Weise entsorgen.

Recycling des Nickel-Wasserstoff-Akkus

Page 36

36

Grüne LED-Anzeige Rote LED-Anzeige Status Beschreibung

1.

2.

3.

4.

5.

6.

VERWENDUNG DES LADEGERÄTS

Das Spezialladegerät Charger Base (Cat.#55618) weist LED-Anzeigen (grün, rot) auf, die über den

Status von Ladegerät und Akku informieren.

Die folgenden Symptome lassen auf eine Störung schließen. In solchen Fällen Ladegerät und Akku

ersetzen.

●

Die grüne LED-Anzeige leuchtet nicht auf, wenn der Netzstecker des Ladegeräts an eine Steckdose

anschlossen wird (100 - 240 V, Haushaltsnetz), ohne dass ein Akku im Ladegerät eingesetzt ist.

※

Mit einem anderen Elektrogerät prüfen, ob Spannung an der Steckdose anliegt.

●

Weder die grüne noch die rote LED-Anzeige leuchtet auf, wenn der Akkus in das Ladegerät

eingesetzt wird.

●

Die grüne LED-Anzeige leuchtet bei beendetem Ladevorgang nicht auf (150 Minuten nach

Aufleuchten der roten LED-Anzeige).

●

Die rote LED-Anzeige leuchtet nicht auf, wenn der Akkus in das Ladegerät eingesetzt wird.

Störungssymptome an Ladegerät und Akku

○

AN

●

AUS

Wird mit Strom

versorgt

Das Ladegerät ist am Stromnetz angeschlossen.

(Ladegerät wird mit Strom versorgt; kein Akku eingesetzt)

●

AUS

○

AN

Ladevorgang läuft Der Akku wird geladen.

○

AN

●

AUS

Ladevorgang

beendet

Der Akku ist voll aufgeladen.

Blinkt Blinkt

Temperaturalarm

Der Akku ist heiß. (Den Akku aus dem Ladegerät nehmen

und vor dem erneuten Laden eine Weile abkühlen lassen.)

○

AN

○

AN

Akkualarm

Der Akku ist defekt. (Durch einen neuen Akku

ersetzen.)

Blinkt

○

AN

Akkuüberhitzung

Der Akku ist defekt und heiß. (Durch einen neuen

Akku ersetzen.)

Page 37

37

WARNUNG:

LADEN DES AKKUS

●

Den Akku mit der vorgeschrieben Netzspannung laden.

Das Ladegerät muss an eine Steckdose mit 100 - 240 V (Haushaltsnetz) angeschlossen

werden. Der Anschluss an eine Stromversorgung mit abweichender Spannung hat nicht nur

Funktionsstörungen zur Folge, sondern ist darüber hinaus gefährlich.

●

Das Netzteilkabel mit Vorsicht behandeln.

Das Ladegerät nicht mit beschädigtem Netzteilkabel verwenden.

●

An eine geeignete Steckdose anschließen.

Ein wackeliger oder lockerer Sitz in der Steckdose kann einen Unfall durch Überhitzung

verursachen. In solchen Fällen eine andere Steckdose verwenden.

q

Falls der Akku verwendet wurde und im Werkzeug eingesetzt ist, diesen vom

Werkzeug lösen.

Das Werkzeuggehäuse gut festhalten, die Zungen an beiden Seiten des Akkus mit

den Fingern zusammendrücken und den Akku herausziehen.

Akku

w

Das Kabel des Netzteils an das Ladegerät anschließen und den Netzstecker an

eine Steckdose anschließen.

Die grüne LED-Anzeige leuchtet auf und bestätigt, dass das Ladegerät mit Strom

versorgt wird.

Grüne LED-Anzeige

Ladegerät

Netzteil (100-240 V)

Zunge

VORSICHT:

●

Nicht versuchen, einen voll aufgeladenen Akku erneut zu laden. Dies verkürzt die

Lebensdauer des Akkus.

e

Den Akku laden.

1. Den Akku fest in das Ladegerät einsetzen.

2. Der Ladevorgang setzt automatisch ein, sobald der Akku im Ladegerät sitzt.

Aufleuchten der roten LED-Anzeige bestätigt, dass der Ladevorgang läuft.

3. Die Ladezeit beträgt ca. 150 Minuten, hängt jedoch von der Temperatur, der

Versorgungsspannung und der Restspannung des Akkus ab. Nach dem

Ladevorgang macht die grüne LED-Anzeige durch Leuchten darauf aufmerksam,

dass der Akku voll aufgeladen ist. Wenn ein voll geladener Akku erneut in das

Ladegerät eingesetzt wird, leuchtet wieder die rote LED-Anzeige auf und zeigt damit

einen erneuten Ladevorgang an. Dies ist jedoch normal. Nach einer Weile leuchtet

dann die grüne LED-Anzeige auf und bestätigt, dass der Akku voll aufgeladen ist.

r

Leuchten der grünen LED-Anzeige bestätigt, dass der Ladevorgang

abgeschlossen ist.

1. Das Ladegerät festhalten und den Akku herausziehen.

2. Das Netzteil aus der Steckdose ziehen.

Der Akku ist damit voll aufgeladen.

Akku

Rote LED-Anzeige

Ladegerät

Netzsteckdose

(100-240 V)

Page 38

38

VORSICHT:

●

Nach Beendigung der Arbeit oder wenn das Gerät nicht verwendet werden soll, immer den

Akku zur Lagerung aus dem Gerät nehmen. (Auch Gaspatrone und Nägel entnehmen)

Bei fortgesetztem Netzanschluss wird auch im Standby-Zustand weiter Strom aufgenommen.

Führen Sie in den folgenden Fällen Erhaltungsladen aus, um volle Leistung zu erzielen:

・

Nach dem Kauf des Geräts.

・

Wenn das Gerät 1 Monat oder länger nicht verwendet wurde.

・

Wenn es klar ist, dass Sie auch in geladenem Zustand weniger Nägel eintreiben können.

Nachdem das Laden-Fertig-Lämpchen aufleuchtet, den Akku etwa weitere 24 Stunden eingesetzt

lassen.

Über Erhaltungsladen

Page 39

39

5. HANDHABUNG DER BRENNSTOFFZELLE

Die Brennstoffzelle hat eine Doppelkonstruktion: ein innerer Behälter ist mit dem Brennstoffgas gefüllt,

ein äußerer mit Treibgas (ein weiteres, unter Druck stehendes Gas).

Das innere Brennstoffgas wird wie bei einer Zahnpastatube vom umliegenden Treibgas herausgedrückt

und so ohne Verschwendung vollständig aufgebraucht. Durch diese Konstruktion bedingt, verbleibt das

brennbare Treibgas auch nach Aufbrauchen des Brennstoffgases in der Brennstoffzelle.

Daher müssen leere Brennstoffzellen mit der entsprechenden Vorsicht entsorgt werden.

WARNUNG:

●

Ausschließlich Brennstoffzellen verwenden, die speziell für das Gasbetriebene

Befestigungssystem vorgesehen sind.

●

Beim Anbringen oder Betätigen des Strahlventils nicht rauchen.

●

Den Gummistopfen am Boden der Brennstoffzelle erst bei der Entsorgung entfernen.

●

Die Brennstoffzelle nicht punktieren.

●

Das Gas nicht einatmen.

Einatmen des Gases kann Müdigkeit, Benommenheit und Übelkeit hervorrufen.

●

Das Gas nicht auf den menschlichen Körper sprühen.

●

Leere Brennstoffzellen nicht verbrennen oder recyceln.

(Hinweise zur Entsorgung von Brennstoffzellen siehe Seite 41.)

WARNUNG:

●

Das Strahlventil vorschriftsmäßig an der Brennstoffzelle anbringen.

Das Ventil gut befestigen, so dass es mit einem "Klicken" einrastet.

Wenn das Strahlventil nicht ordnungsgemäß angebracht ist, wird kein Brennstoff

eingesprüht. Dies könnte außerdem ein gefährliches Lecken des Gases zur Folge haben.

ANBRINGUNG DES STRAHLVENTILS AN DER BRENNSTOFFZELLE

Das Strahlventil ist so ausgelegt, dass es eine konstante Menge Brennstoffgas in die

Verbrennungskammer des Werkzeugs sprüht.

1. Drücken, um das Ventil zu entfernen. 2. Ventil von Kappe trennen. 3. Kanten gerade ausrichten.

4. Vordere Kante hineindrücken. 5. Hintere Kante bis zum 6. Waagrecht drücken, bis ein weiterer

5. Einrasten hineindrücken. 6. Klickton hörbar wird.

Strahlventil

Page 40

40

WARNUNG:

EINSETZEN DER BRENNSTOFFZELLE

●

Den Finger vom Auslöser nehmen.

●

Der Kontaktarm darf nirgendwo aufliegen.

2

1

q

Die Brennstoffzellenabdeckung nach oben und dann zur Seite drücken, um sie zu

öffnen.

Brennstoffzellenabdeckung

w

Die Strahldüse nach vorn (in Richtung Luftfilterabdeckung) ausrichten und die

Brennstoffzelle einsetzen.

Strahldüse

e

Bei geöffneter Brennstoffzellenabdeckungskappe ist ein roterAdapter sichtbar.

Die Strahlduse in diesen Adapter einpassen.

Roter Adapter

r

Die Brennstoffzellenabdeckung wieder schließen und bis zum Einrasten nach unten

drücken.

Brennstoffzelle

Page 41

41

ENTSORGUNG DER VERBRAUCHTEN KRAFTSTOFFZELLE

Entflammbares Düsengas befindet sich immer noch in der verbrauchten Kraftstoffzelle.

WARNUNG:

●

Nicht die verbrauchte Kraftstoffzelle in ein Feuer werfen.

●

Niemals eine Zigarette rauchen.

●

Niemals das Gas einatmen.

Page 42

42

6. BETRIEBSANWEISUNGEN

Den Abschnitt mit der Überschrift “SICHERHEITSVORSCHRIFTEN” lesen.

1. VOR INBETRIEBNAHME

q

Schutzbrille tragen.

w

Brennstoffzelle und Akku noch nicht einsetzen.

e

Auf gelockerte Schrauben untersuchen.

r

Funktion und Leichtgängigkeit von Kontaktarm und Auslöser prüfen.

t

Brennstoffzelle und Akku einsetzen.

y

Werkzeug halten, ohne den Auslöser zu drücken, und den Kontaktarm gegen das Werkstück

drücken. (Das Werkzeug darf nicht arbeiten.)

u

Werkzeug mit nicht am Werkstück angesetztem Kontaktarm halten und den Auslöser drücken. (Das

Werkzeug darf nicht arbeiten.)

i

Brennstoffzelle und Akku wieder entfernen.

WARNUNG:

WARNUNG:

2. BETRIEB

Schutzbrille tragen

Durch das austretende Gas aufgewirbelter Staub und Nageldübel, die durch unsachgemäße

Handhabung des Werkzeugs aus diesem geschleudert werden oder von einem Gegenstand abprallen,

stellen eine stetige Gefahr für die Augen dar. Daher ist beim Einsatz des Werkzeugs stets eine

Schutzbrille zu tragen.

Der Arbeitgeber und/oder Benutzer ist für einen ausreichenden Augenschutz verantwortlich. Die

Augenschutzausrüstung muss dem Standard ANSI Z87.1 (Council Directive 89/688/EEC vom 21. Dez.

1989) entsprechen und sowohl Frontal- als auch Seitenschutz bieten.

Der Arbeitgeber ist für die Durchsetzung des Augenschutzgebrauchs durch den Werkzeugbenutzer und

alle anderen Mitarbeiter im Arbeitsbereich verantwortlich.

HINWEIS: Eine Brille ohne Seitenschutz oder ein Gesichtsschutz allein bietet keine ausreichende

Schutzwirkung.

Hände und Körper von der Mündung fernhalten

Es besteht jederzeit die Gefahr, dass ein versehentlich ausgestoßener Nageldübel eine Hand oder

einen anderen Körperteil trifft.

Vorgang

q

Die Nageldübel durch den Schlitz am hinteren Ende des Magazins einführen, bis sie

am vorderen Ende den Nageldübelanschlag erreichen.

WARNUNG:

LADEN DER NAGELDÜBEL

●

Zum Laden von Nageldübeln unbedingt den Finger vom Auslöser nehmen.

●

Der Kontaktarm darf nirgendwo aufliegen.

●

Abruptes Loslassen des Drücker-Halters führt zu Nagelstau oder

Fehlauslösungen.

VORSICHT:

Nagel

Nageldübel

Page 43

EINTREIBTIEFENEINSTELLUNG

●

IMMER Kraftstoffzelle und Akku vor Einstellungen aus dem Werkzeug

entfernen.

●

Prüfen, ob die Einstellscheibe erhitzt ist.

Die Eintreibtiefeneinstellung wird mit der Einstellscheibe vorgenommen.

q

Bei angebrachter Kraftstoffzelle und Akku einige Nägel in eine typische

Materialprobe eintreiben, um zu bestimmen, ob Einstellung erforderlich ist.

w

Wenn Einstellung erforderlich ist, Kraftstoffzelle und Akku entfernen.

e

Beim Drehen der Einstellscheibe die Richtungsmarkierung am Magazin beachten.

r

Kraftstoffzelle und Akku entfernen.

r

Es wird kein Nageldübel ausgestoßen, wenn der Kontaktarm bei bereits gedrücktem

Auslöser gegen die Fläche gedrückt wird. Den Auslöser loslassen und Schritt

w

wiederholen.

Schieberhalter

43

w

Den Schieberhalter bis zum hinteren Ende des Magazins ziehen und vorsichtig

loslassen.

●

Das Gesicht niemals über das Werkzeug bringen. Der Rückschlag des

Werkzeugs könnte eine Verletzung verursachen.

●

Hände und Finger nicht in den Bereich der Mündung bringen.

WARNUNG:

WARNUNG:

2

1

q Press the nose of the Contact Arm

against the object.

w Pull the Trigger.

EINTREIBEN VON NAGELDÜBELN

Vorgang

q

Akku und Brennstoffzelle einsetzen.

w

Die Nase des Kontaktarms gegen die Fläche drücken, in die der Nageldübel

eingetrieben werden soll. Der Lüftermotor läuft an, und Brennstoffgas wird zur

Vermischung mit Luft eingesprüht.

e

Kontaktarm und Endabdeckung fest andrücken und den Auslöser drücken. Der

Nageldübel wird durch die Verbrennung des Brennstoffs in die Fläche getrieben.

●

Vor Arbeitsbeginn prüfen, ob das Werkzeug vorschriftsmäßig funktioniert, wie

an früherer Stelle beschrieben.

●

Nach längerem Gebrauch kann das Werkzeug heiß werden und

Verbrennungen verursachen.

Falls etwas Ungewöhnliches entdeckt wird, das Werkzeug beim nächsten von

autorisierten Händler überprüfen/instand setzen lassen.

※

Der Lüfter läuft auch nach dem Eintreiben eines Nageldübels etwa 10

Sekunden lang weiter.

WARNUNG:

Einstellrad

Tiefer Höher

q

Die Nase des Kontaktarms gegen die

Fläche drücken.

w

Den Auslöser drücken.

VORSICHT:

Page 44

44

AUSWECHSELN DER BRENNSTOFFZELLE

Wenn das Brennstoffgas aufgebraucht ist, können keine Nageldübel mehr eingetrieben

werden.

●

Den Finger vom Auslöser nehmen.

●

Der Kontaktarm darf nirgendwo aufliegen.

q

Die Brennstoffzellenabdeckung nach oben und dann zur Seite drücken, um sie zu

öffnen.

WARNUNG:

AUSWECHSELN DES AKKUS

Wenn der Akku leer ist, leuchtet die rote LED-Anzeige am Werkzeug.

●

Unbedingt die Brennstoffzelle aus dem Werkzeug nehmen.

●

Den Finger vom Auslöser nehmen.

●

Der Kontaktarm darf nirgendwo aufliegen.

WARNUNG:

w

Das Strahlventil fassen und die verbrauchte Brennstoffzelle entfernen.

e

Eine neue Brennstoffzelle einsetzen.

(Verfahren zum Einsetzen siehe Seite 40.)

q