FluidSecure

Installation

Instructions

Installation, Operation and Safety Manual

Trak Engineering, Inc. ▲ Tallahassee, Florida 32301

850-878-4585 ▲ support@trakeng.com

www.fluidsecure.com ▲www.trakeng.com

1 | P a g e

Safety Information

Warning! All wiring should be installed in accordance with local, state and national

electrical code requirements under NEC/ANSI/NFPA 70. IMC threaded conduit, sealed

fittings and proper electrical wiring practices should be adhered to. Improper installation

can result in fire, serious bodily injury or death.

Warning! Pay attention to the following safety practices.

1) Never smoke or use an open flame anywhere near the tanks or dispensers.

2) All mechanical joints containing fuel products must be sealed with sealant tape

appropriate for the product dispensed.

3) Never use any tools near the dispenser or tanks that can create unexpected sparks

4) Always have a fire extinguisher available in case of fire

5) Always turn off all electrical power when working on any pumps or dispensers.

6) It is highly recommended that someone who is capable of rendering first aid be

present during the installation process

7) Follow OSHA lockout/tagout procedures during installation, service and

maintenance.

8) Know where the emergency shutoff is located. Do not use emergency stops to

disconnect electrical power. Always disconnect at the breakers.

9) Always cordon off all work areas from vehicle traffic.

10) The State of California cautions that fuel and fuel handling systems contain

chemicals that are known to cause cancer or reproductive harm.

2 | P a g e

FluidSecure Link Performance Specifications

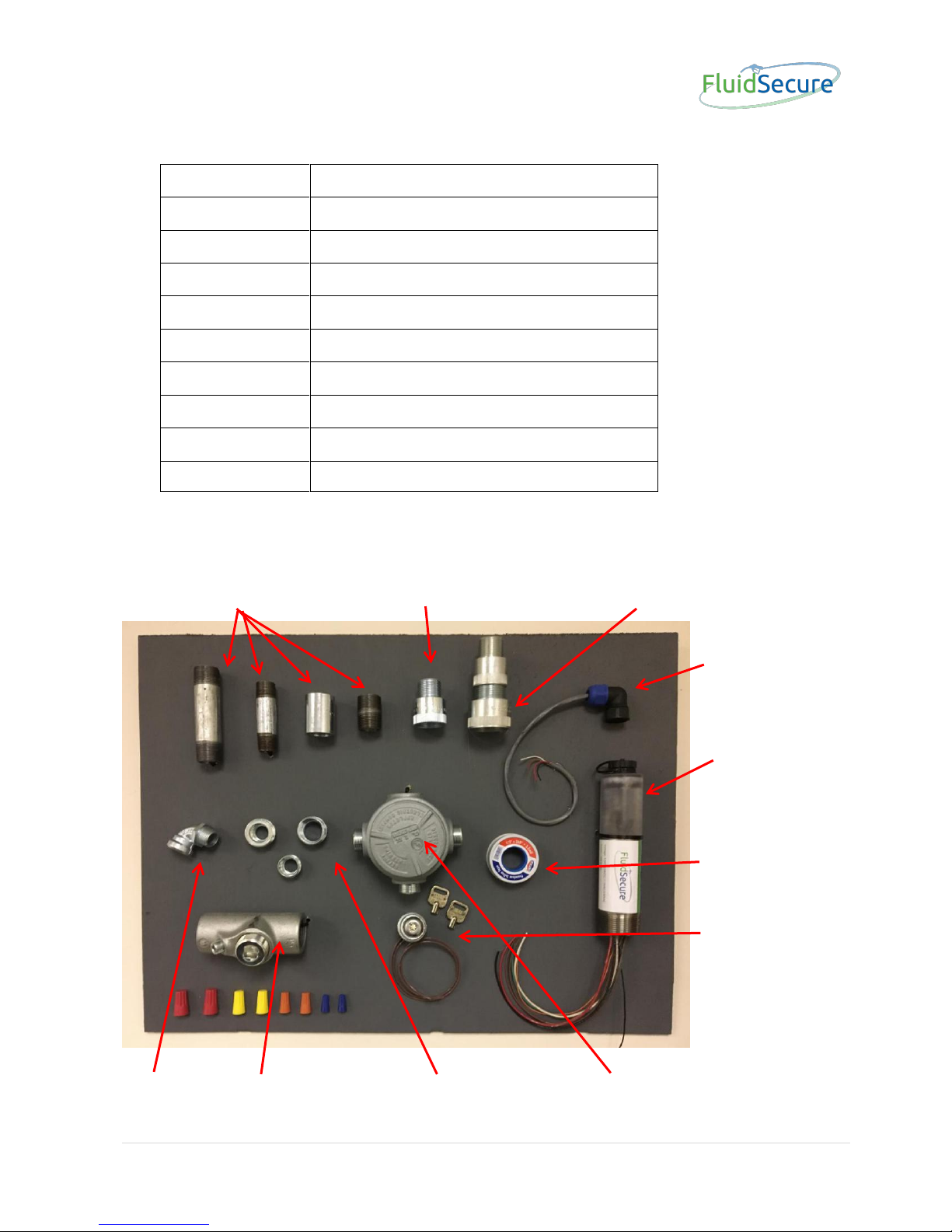

The picture below shows the parts that are included with a FluidSecure kit.

Conduit Nipples 1” to 3/4” Reducing Adapter 11/4” to 1” Reducing Adapter

Pulser Cable

(External)

LINK

Pipe Tape

Manual Override

Switch and Keys

90 Elbow 1” Sealoff Various Reducing Bushings 3/4” 5 way Junction Box

Voltage

115VAC, 230VAC, 12VDC, 24VDC

Power (Link)

1.5 watts

Control

Maximum 3/4hp motor

Pulser Input

Dry reed switch or Open Collector

Link Comm

WiFi 802.11

Temp

-40 to +80 C (-40 to 176 F)

Class

Class 1, Div. 1

Listing

Pending

Flow Pulser

+/- 2%

External Pulser

Pulser dependent

3 | P a g e

A: Installation - Above Ground Tank

FluidSecure LINK is designed to work with virtually any electrically operated

dispenser, pump or solenoid. There are a large variety of dispensing systems and

electrical connections and methods of connecting such devices together. It is not the

intention of this manual to cover all possible combinations of connections. This manual

will cover a “typical” installation however the installer should be sufficiently proficient in

all aspects of dispensing systems to be able to understand how a FluidSecure should be

installed and to make sound judgments on how to modify a typical installation to suit the

needs for any configuration that may and will be different from a typical one explained

here.

1) Conduit Connections between Pump and LINK

The FluidSecure kit contains the conduit fittings, bodies and connectors to install the

FluidSecure LINK into a typical dispenser/pump. A typical installation for an above

ground tank will look similar to the picture below.

Trak supplied pulser (optional) FluidSecure LINK

4 | P a g e

FluidSecure LINK

Manual Override Switch

Wiring Junction Box

Pulser Cable

Conduit Sealoff

5 | P a g e

2) Wiring Connections

The installation typically involves disconnecting the AC power supply wring (generally

that comes from a nearby building or power source) from the dispenser and re-routing it

through the supplied conduit parts that are supplied as part of the LINK kit and reconnecting the wires to the FluidSecure LINK and dispenser. Under no condition

should a FluidSecure LINK control a pump motor larger than 3/4hp. Larger loads

can be controlled with an external contactor or power relay.

DISPENSER

Solenoid/

Motor

MANUAL

OVERRIDE

SWITCH

FLUIDSECURE LINK

POWER

FROM

BUILDING

or Dispenser

WIRENUTS

BROWN

BROWN

BROWN

BROWN

BLACK

120VAC/

240VAC

BLACK

BLACK

WHITE

WHITE

WHITE

(Neutral)

RED

(+12VDC)

GREEN

(DC Gnd)

ORANGE

GRAY

INTERNAL

PULSER

CONNECTIONS

NOTE:

Two brown wires coming

from the FluidSecure

unit are dry contacts of

a 16 amp mechanical

relay and are not electrically

connected internally in the

FluidSecure Link

FluidSecure Link Wiring Diagram

Alternate power input to run Link from a 12VDC source

External

Link

Pulser

Connector

6 | P a g e

3) Pulser Installation

Two Options:

#1 - Trak Supplied Optional Flow Pulser Use the optional Trak supplied flow

pulser installed between the pump and the hose as seen in prior pictures.. This will

involve removing the hose. This guide shows one of several pulser types that may be

used with the system. Regardless of the configuration, each flow pulser is marked with

an arrow showing the direction of fluid flow. Please note that the optional pulsers are

shipped with pre-installed adapters that convert the 1” straight G type thread into a 1”

NPT female opening. The adapters are O-ring protected into the pulser. Please ensure

that the adapters are secure but do not over tighten.

Warning! Removal of the hose will result in a minor amount of fuel spillage. This

can result in a fire hazard and must be handled with extreme care.

⚫ Power to the dispenser must be turned off before attempting.

⚫ Steps must be taken to recover as much of the fuel contained in the hose for return

back to the tank.

⚫ A fire extinguisher should be available in case of emergency.

⚫ Use non-sparking tools for this operation.

Empty as much fuel from the hose as possible before removing. Hold the end of the

hose high once removed until it can be placed in the recycle container for removal of the

remainder of the fuel. Once the hose is removed, screw the input end of the pulser into

the dispenser using the supplied teflon tape wrapped around the hose nipple adapter.

Note that the pulser has an arrow pointing towards the hose end of the pulser. Next, re-

attach the hose to the output end of the pulser. In general, a 1” hose will screw directly

into the pulser and a 3/4” will require a 1” to 3/4” adapter. Connect the included external

LINK pulser cable to the top of the FluidSecure LINK.

Pulser

PulserAdapter

7 | P a g e

The diagram below shows the wiring connections that are utilized in the external pulser

cable. If using the Trak supplied pulser, the cable is already attached to the pulser and

the installer simply needs to plug the cable into the top of the LINK. If using alternate

third party pulsers, the cable is not terminated at the pulser end. The diagram below

shows the the electrical connections that form the LINK pulser cable. The cable will

have to be connected to the third party pulser by using the appropriate wires suitable for

the pulser.

1 2 3 4 5 6 7

1 2 3 4 5 6 7

SD20TA-ZM Jelen Connector

Male

SD20TA-ZM Jelen Connector

Female

Red

White

Yellow

Black

Brown

Orange

Blue

Pulser Switch

Note: All wires except white, yellow

and black are capped off in pulser

Red

White

Yellow

Black

Brown

WiFi Board

R W B Y BL

Pulser

Security

Red - +3.3

White - Pulser disconnect sense

Yellow - Pulser input

Brown - +5

Black - Ground

10k

+5

+3.3

Pulser Wiring

accessible to user

470

INTERNAL - Not accessible by user

8 | P a g e

#2: Utilizing Exiting Pulsers on Dispensers/Meters Many dispensers and

metering systems come already equipped with pulser units or can be equipped with

third party pulsers. The LINK will interface with most of them. The LINK is equipped

with 2 separate pulser inputs.

a) The first pulser input is a two wire combination that exits from the bottom of the

LINK with all the other wires and is referred to as the LINK internal pulser wires.

Please see wiring diagram on page 5. This input is used when the existing pulser

wires are already internal in the conduit system. These two wires, orange and gray,

are part of an optically isolated circuit. Connecting them together causes the optical

circuit to flash. This in turn will pulse a single pulse each time the wires are

connected. An external pulser will have to connect the two wires for each pulse.The

gray wire is ground and the orange wire is positive.

b) The second alternate pulser input enters into the LINK at the top of the LINK

through the 7-pin circular connector as shown on page 8. This is the same cable

that is supplied with the Trak flow pulser but has no pulser on the end. The wires

can be connected to any pulser output by tying the wires together using wire nuts.

The wiring from the FluidSecure LINK is designed intrinsically safe and can be safely

run without conduit in a Class 1, Division 1 location or any lesser classification. Do

NOT allow it to enter into a junction box, conduit or other device that could connect

these pulser wires to external high voltage wiring.

The black and yellow wires form a pulled up circuit that the external pulser must

connect together to pulse the circuit. External 5VDC is also supplied via the red wire to

power an external pulser circuit.

4) Low Voltage Wiring Connections

The LINK is capable of running from 12 to 24 VDC instead of AC power. The

electrical diagram in A.2. shows a red and green wire labeled as gnd and +12VDC. The

LINK can actually run from 24VDC as well. These two wires can be utilized for power

hookup. The two brown wires also shown are still used to control the power to the

solenoid or pump. Since the brown wires are not electrically connected internally in the

LINK, they can be used with any external control voltage from 5VDC to 240VAC

regardless of the power used to operate the LINK. The same safety warnings apply to

low voltage installation as the high voltage ones.

B. Installation - Standard Dispenser

Wiring connections are the same as the above ground tanks. However, there are

many different dispensers and each one will have differences from one manufacturer to

another. It is not within the scope of this document to address all possible combinations.

9 | P a g e

In general, the FluidSecure LINK should control a solenoid valve, dispenser authorization

signal or a small pump motor. Under no condition should a FluidSecure LINK control

a pump motor larger than 3/4hp. Larger loads can be controlled with an external

contactor or power relay.

1) Conduit Connections between Pump and LINK

Installation for standard dispensers is quite simple. Most have an explosion proof

junction box located in the bottom section of the dispenser. This junction box generally

will have two or more conduits that feed into it. Normally there are additional available

conduit openings in the junction box. Simply unscrew the cap from one of the unused

ports and screw in the FluidSecure LINK. If there are no available openings you will have

to use a rated Class 1, Division 1, T box (or purchase the optional hardware kit) to attach

to the junction box and re-route an existing conduit to the box and then attach the

FluidSecure LINK. The manual override switch can be removed from the wiring

enclosure and inserted into an additional conduit opening in the junction box.

Manual Override Junction Box LINK

10 | P a g e

2) Wiring Connections

Once the LINK is installed, the control wires will be available inside the junction box the LINK

is connected to. The wiring diagram in section A.2 is also applicable here. You can control the

dispenser solenoid valve, dispenser motor, dispenser control signal input or other such device.

The installation typically involves disconnecting the AC power source, making the appropriate

electrical connections and re-connecting the wires to the FluidSecure LINK and dispenser.

Under no condition should a FluidSecure LINK control a pump motor larger than

3/4hp. Larger loads can be controlled with an external contactor or power relay.

3) Pulser Installation

Many dispensers have included pulsers which can be attached to the FluidSecure

LINK. To connect to an existing pulser wire that is located outside the conduit system,

you must utilize the cable and connector that is supplied with the FluidSecure LINK. The

external pulser wiring from the FluidSecure LINK is designed intrinsically safe and can

be safely run without conduit in a Class 1, Division 1 location or any lesser classification.

Do NOT allow it to enter into a junction box, conduit or other device that could connect

these pulser wires to external high voltage wiring

Other pulsers often have their pulser wires within the conduit system and can

connect to the internal LINK pulser wires. Those pulser wires are shown in the drawing

in section A.2 and are labeled orange and gray. The gray wire is ground and the orange

wire is positive DC.

It is not within the scope of this document to cover all possible pulser combinations

that exist on standard dispensers. However, there are generally two common types that

are often used.

1. Reed Switch or microswitch - This is a non- powered switch that opens and closes

for every tenth of a gallon. Some will count more often and others less but a 1/10-gallon

pulse rate is extremely common in the commercial environment. Connect either wire from

this type pulser to the red and green wire in the pulser cable.

2. Open Collector - This is a powered pulser and generally requires 5 to 12 volts to

operate. In general, you will have to determine which of the pulsers wires is ground and

which are the pulse output. Additionally, if the pulser requires external excitation, you

may have to connect a 5 or 12-volt line to the pulser. The FluidSecure LINK produces a

5 VDC output that can be used to power an open collector circuit. The diagram in section

A.2 shows those connections.

11 | P a g e

C. Operating Instructions

Your physical installation should be complete. Power the dispenser on, which in turn

will power the FluidSecure LINK. You will notice a faint blue light in the top half of the

FluidSecure LINK when power is applied. If there is no light, reconfirm that power is

present. If no light is observed, recheck your electrical connections and try again. If no

light is still not observed, refer to the troubleshooting section using the manual.

Calibration of the Pulser vs the Meter:

The FluidSecure pulser must be calibrated unless you know 100% the ratio (example

10:1). The FluidSecure LINK along with the optional purchased pulser or if you are using

an already installed pulser, you must read how many pulses are produced per unit of

measure (gallons, liters, quarts, etc.). We will use the word gallon in this explanation, but

it can be any unit of measure. To calibrate the pulser you must have an authorized cell

phone. In the FluidSecure Information page, in the FluidSecure CLOUD, you will need to

enter in the number of gallons pumped during calibration. The pulses field can be any

initial number. You must contact your FluidSecure administrator to obtain authorization

to run a calibration. Once authorized, you will have to either pump fuel into a calibrated

container or use the existing meter on your dispenser to calibrate. If you have just

installed the pulser (and you probably have at this point) you must pump at least 20 to

30 gallons back into the tank to purge the air out of the pulser and hose. For calibration,

It is best to pump at least 5 gallons for high accuracy but a smaller amount can be utilized.

To begin the calibration, refer to your cell phone user guide for the FluidSecure APP.

Start a transaction and begin pumping into your calibrated container. If you are using

your existing meter, then simply pump the fuel back into the tank or into a vehicle. Stop

at a full gallon mark as close as you can. It doesn’t matter how many gallons you pump

but the more the better. (Please note that we refer to gallons, but the label is unimportant.

You can use quarts, liters or anything else.) When you are finished, the cell phone will

display a count. Call the administrator and report to them total gallons you pumped and

the counts. That is all there is to it.

D. Quick CLOUD Startup Guide

Once installation is complete you will need to enter some data into the FluidSecure

CLOUD webpage. Once the system is shipped, a Company page will be setup

automatically allowing you to start using the software.

The CLOUD-based software must be filled out in proper sequence before any testing

can be performed and transactions at the fuel locations can be started. Any users must

12 | P a g e

be authorized and the FluidSecure LINK must be initialized. These steps will guide you

through the process. Please do them in order so you don’t have to repeat steps.

1. Company Information Page

Enter:

Company Name, Contact Name, Contact Address, Contact Phone Number and

Contact Email. These can be modified or updated later if necessary. Press Save.

2. Select Product Type

Enter in a Product Type (Unleaded, Diesel, etc.).

13 | P a g e

3. Edit Department Information

Enter in Department Number (we suggest you start with 1) and Name. Again, these

can be changed later if necessary.

4. Edit FluidSecure LINK Information

Enter in FluidSecure LINK Name - start with 1

Enter in FluidSecure Current

Name - enter in the serial number

that is on the FluidSecure LINK.

The serial number is all alpha

characters.

Enter in FluidSecure New Name The name you would like for it to

be identified by all users, for

example “Unleaded” – this shows

up as the HOSE name on the APP

Enter in a Tank Number - start

with 1

Enter in the product in the tank

from the drop-down menu

Select Authorized Fueling Times

Select Authorized Fueling Days

Check Disable Geo Location

Enter in a Pump On Time - usually 30

Enter in a Pump Off Time - usually 30

Select Company from drop down menu

Enter Original Name of FluidSecure LINK - this is the serial number entered above

14 | P a g e

Enter Units Measured - enter 10

Enter Units Measured - see Calibration above

Select Time Zone from drop down menu

5. Edit Vehicle Information

Enter Vehicle Number Usually how your

vehicles are identified

Enter Vehicle Name Name of vehicle and

what the transaction

reports show

Enter Department from the drop-down

menu

Select Authorized

FluidSecure LINKS the hoses at which this

vehicle will be allowed

to fuel at

6. Enter Personnel information

No fields are required at

this time. All users are

required to download the

FluidSecure APP to their

phones and register on

their own phone. Once

registered you are

required to go back to

this page to:

Enter in their Access

Level – usually “User”

Department - select

from drop down menu

15 | P a g e

Select Vehicles Allowed to Fuel - these are the vehicles this person is allowed to fuel

Select Authorized Fueling Times - these are the times of the day this person is allowed to

fuel this vehicle

Select Authorized Fueling Sites - these are the sites at which this person is authorized to

fuel at

Active? - click this if this person is allowed to fuel, un-click to de-authorize fueling

permission.

Loading...

Loading...