Trajan 125 Instructions For Use And Maintenance / Spare Parts

PORTABLE BAND SAWING

INSTRUCTIONS FOR USE AND MAINTENANCE / SPARE PARTS

MODEL: 125

125-080605-R1

WARNING

!!

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to the State of California to

cause cancer, birth defects or other reprodrctive harm.

Some examples of these chemical are:

‧Lead from lead-based paints.

‧Crystalline silica from bricks, cement and other

masonry products.

‧Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: Work in a well ventilated

area, and word with approved safety equipment, such

as those dust masks that are specially designed to

filter out microscopic particles.

4

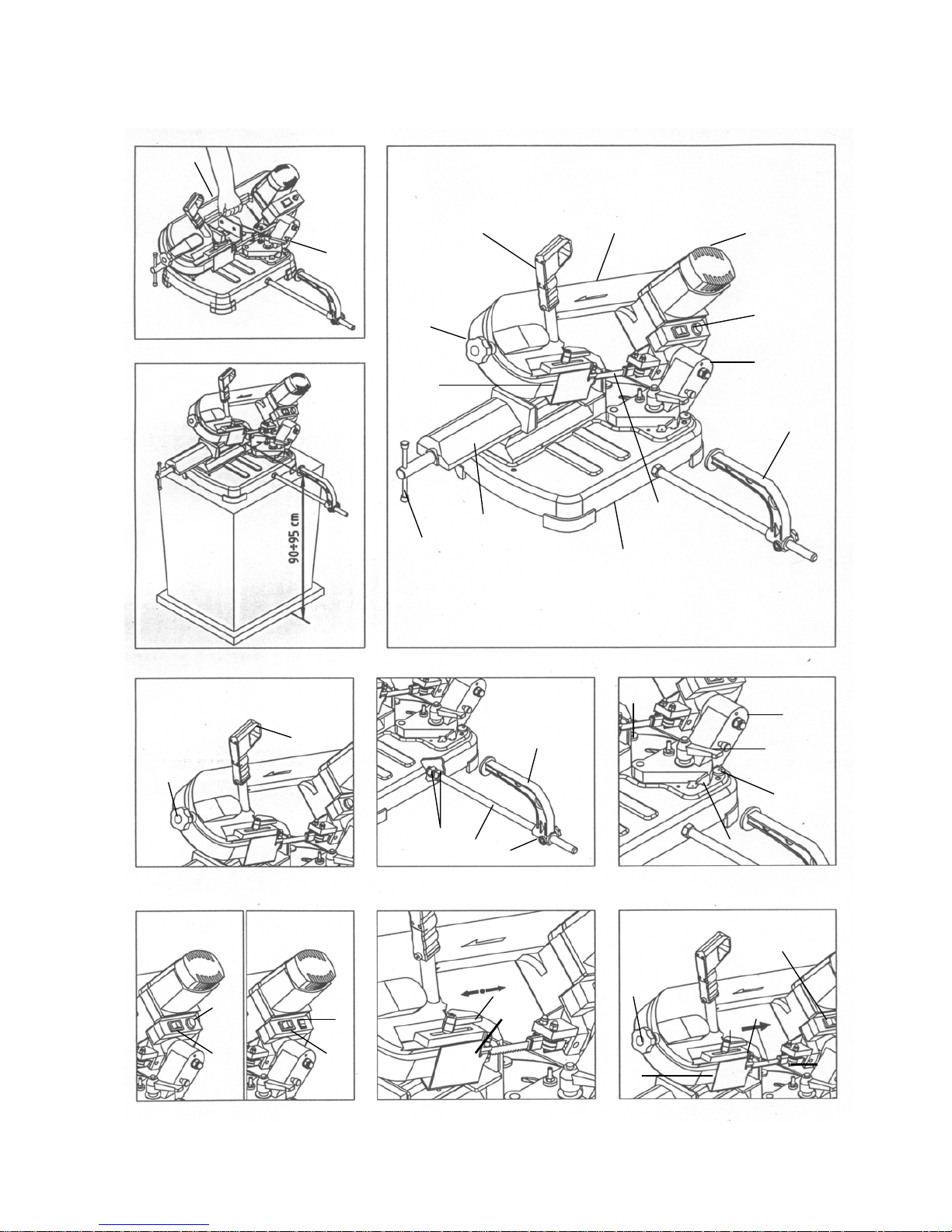

Fig.Abb.6

F

Fig-Abb.8

F

5

5

1

7

2

5

7 U

8

8

Fig.-Abb.2

Fi

9

10

6

4

11

12

13

g

.-Abb.3 Fig.-Abb.1

K

J

I

H

M

L

G

E

Fig-Abb.6Fig-Abb.5

A

B

Fig-Abb.4

B

Q

R

D

P

S

Fig-Abb.9

Q

P

Fig-Abb.7 Fig-Abb.8 Fig-Abb.9

D

N

O

D

F

Fig.-Abb.1 Fig.-Abb.3

Fig.-Abb.6 Fig.-Abb.5 Fig.-Abb.4

Fig.-Abb.9

Fig.-Abb.8 Fig.-Abb.7

1

INDEX

CAUTION

Install saw blade and blade guard

before use. Set proper blade tension

Pag.

1.0 INTRODUCTION TO USE...............................2

1.1 SYMBOLS PLACED IN

CORRESPONDANCE WITH USAGE

POINTS .......................................................2

to prevent any danger caused by

damaged saw blade or work piece.

1.2 SAFETY AND RULES..................................2

1.3 RECOMMENDED AND NOT

RECMMENDED USAGE.............................3

1.0 INTRODUCTION TO USE

1.4 STANDARD SAFETY PROCEDURS...........3

1.5 SAFETY PROCEDURS FOR FURTHER

RISKS..........................................................3

Before starting work with your sawing machine, carefully

read this instructions manual so that you are familiar with

the machine and its uses and where it should not be used.

Keep this manual in a safe place.

1.6 NOISE CONDITION .....................................3

1.7 INFORMATION ABOUT THE

ELECTROMAGNETIC COMPTIBILITY ......3

It is an integral part of the machine and should be used for

reference in operating the machine correctly and in the

proper safety conditions.

1.8 DESCRIPTION OF THE MACHINE.............3

2.0 INSTALLATION...............................................3

2.1 REMOVING THE PACKAGING ...................3

Use the machine only and exclusively for the uses

specified below, as recommended in this manual. The

machine should not in any way be tampered with, or

forced, or used for unsuitable purposes.

2.2 HANDLING...................................................4

2.3 TRANSPORTATION.....................................4

2.4 POSITION/WORK STATION........................4

2.5 ELECTRICAL CONNECTION......................4

3.0 ADJUSTMENT.................................................4

1.1 SYMBOLS PLACED IN CORRESPONDANCE

3.1 TENSION OF THE BLADE...........................4

WITH USAGE POINTS

3.2 BAR STOP....................................................4

Never underestimate the warnings “ ATTENTION –

CAUTION ” given in this manual.

3.3 CUTTING ANGLE.........................................4

3.4 CUTTING SPEED.........................................4

In order to draw the user’s attention and to preserve safety,

hazardous operation are preceded by symbols and notes

that point out the danger and explain how to behave to

avoid any risk.

3.5 SLIDING BLADE GUIDE..............................4

3.6 BEARINGS BLADE GUIDE..........................5

4.0 USE..................................................................5

4.1 RUNNING-IN THE BLADE...........................5

These symbols and notes are divided in three categories,

identified by the following words:

4.2 WORKING....................................................5

4.3 REPLACING THE BLADE............................5

4.4 CUTTING CAPACITY...................................6

Attention: dangerous-behaviours that could cause serious

injuries.

4.5 POSITIONING OF THE PIECE IN THE

CLAMP ........................................................6

4.6 CUTTING TABLE .........................................6

CAUTION: behaviours that could cause slight injuries or

damages to things.

5.0 ACCESSORIES...............................................6

5.1 CHOISING THE BLADE...............................6

6.0MAINTENANCE................................................6

NOTE: the notes preceded by this symbols are technical

and are aimed at making operations easier.

6.1 REGULAR MAINTENANCE.........................6

6.2 ASSISTENCE...............................................6

6.3 DISPOSAL OF THE MACHINE....................7

1.2 SAFETY AND RULES

7.0 TROUBLESHOOTING.....................................7

The machine was designed and built according to the

Community Directives in force: EEC 98/37 –EEC

91/368 – EEC 93/68 – EEC 73/23 – EEC 89/336.

CIRCUIT DIAGRAM ...........................................8

PARTS LISTS…………………………………….10

The enclosed CE declaration of conformity, togheter

with the CE mark on product, essentially comprise and are

an integral part of the machine : both guarantee product

conformity with the aforesaid safety Directives.

2

1.3 RECOMMENDED

AND NOT RECOMMENDED USAGE

This belt sawing machine was designed and constructed

according to the most advanced technologies and may be

used for all cutting requirements for metals commonly

used in industry and artisanship.

It can cut:

.COMMON STEELS (FE 37…)

.SPECLAL STEELS (C 40, 18NiCrMo5…)

.ALUMINIUM AND ITS ALLOYS

.BRASS

.BRONZE

.STEEL TUBING (FE 35, FE 52…)

.PROFILED SECTIONS IN SHEET METAL AND

ALUMINIUM

It is not suitable for cutting:

-WOOD AND SIMILAR MATERALS

-BONE AND SIMILAR MATERIALS

ATTENTION:The band saw has been developed and

manufactured to cut in dry condition; the use of any

cooler by lubricating oil makes the machine unusable.

Consult the relative sections for cutting capacities, the

speeds to use and the type of tools for use according to

the material to be cut and its section.(See list of contents).

1.4 STANDARD SAFEY PROCEDURS

-Do not use the machine in very damp places or in the

presence of inflammable liquids or gases.

-Do not use it in the open air when general weather and

environmental conditions are unfavourable (eg.

Explosive atmospheres, during a storm or rain).

-Wear suitable clothes, without wide sleeves or articles

such as scarves, chains and bracelets which could get

caught in the moving parts.

-Always use personal protection devices: protective

goggles as recommended by safety standards, gloves of

the right size, headphones or earplugs, and hairnets if

necessary.

-Use the tools recommended in this manual if you want to

achieve the best performance from your sawing

machine.

-Any power cable extensions must be type approved and

comply with safety standards.

-Avoid using the machine if your psycho-physical condition

are precarious or upset.

1.5 SAFETY PROCEDURS FOR FURTHER RISK

-Always keep processing residues away from the cutting

area.

-Always use the clamp. The parts to be cut must always

be held firmly in the clamp.

-Always keep hands away from the working areas while

the machine is moving: before loading or unlading the

part, release the run button on the hand grip.

-Do not force the machine unnecessarily : excessive

cutting pressure could cause rapid wear to the blade

and negatively influence the performance of the

machine in terms of finishes and cutting precision.

1.6 NOISE CONDITIONS

In normal conditions of use as described in this manual,

this belt sawing machine determines an equivalent level of

acoustic pressure:

Leq= 82dB(A) when operating unloaded;

Leq= 84.3 dB(A) during processing (eg. cutting of a steel

tube D.80mm thickness 5mm), at cutting speed of

80m/min., with a weighted operating cycle of 1 minute.

Measurement were obtained in compliance with UNI

7712, ISO 3740,ISO 3746 and CEE 89/392 regulation.

NOTE : Personal hearing protection should be used,

such as headphones or earplugs.

1.7 INFORMATION ABOUT THE ELECTROMAGNETIC

COMPATIBILITY

The European regulations on safety and , in particular, the

EEC Directive 89/336 contemplate that all the equipment

be equipped with shielding devices against radio

interferences both from and towards the outside.

This machine is equipped with filters both on the motor

and on the power supply through which the machine is

safe and in compliance with above regulations.

Tests were carried out according to EN 55011, EN 55014,

EN50082-1, IEC 1000-4-2, IEC 1000-4-4 regulations.

1.8 DESCRIPTION OF THE MACHINE (Fig.1)

The belt sawing machine consists of two basic parts: the

machine body (5) complete with motor and drive (7) which

is integrated into lower part, consisting of the clamp (11)

and the base (13), by means of the swivel support (9).

Here is a list of the main parts with the number indicating it

in the drawing.

Legend Fig. 1

1 - Command grip

2 - Blade tension handwheel

4 - Sliding blade guide

5 - Machine body

6 - Blade

7 - Motor

8 - Control box

9 - Bar stop

10 - Clamp (vice)

11 - Morsa

12 - Clamp drive

13 - Base

2.0 INSTALLAZIONE

2.1 REMOVING THE PACKING

Remove the wooden frame which protects the

machine during transit.

3

Try not to damage the frame as you may have to move

the machine long distances or store it for long

periods.

2.2 HANDLING (Fig.2)

As the machine is not heavy (Kg 16), it can be

lifted and moved by a single person by gripping it

from the machine body (5), duly clamped (see pint 2.3)

2.3 TRANSPORT (Fig.2)

It is necessary to low the saw body till the lower position

and fix it to the base : it is sufficient to insert the pin U in

the hole in the body , then lift the machine, gripping it as

showed in Fig.2.

For transport the machine, it is better to place it in the box

it was when purchased.

Ensure it is placed in the correct position indicated by the

arrows on the packaging.

Pay careful attention to the ideogram printed on the box as

they provide all necessary information for palletization and

stacking of boxes.

Tying the load down with ropes or safety belts is

raccomended during transportation to prevent the load

from sliding or falling.

2.4 POSITION/WORK STATION (Fig.3)

Place the machine on a sufficiently flat workbench so that

the machine has the better possible stability.

In respect of ergonomic criteria during cutting operations,

the workbench must be positioned at such a height that

the clamp level is between 90 and 95 cm from the ground

(see fig.3)

ATTENTION: Make sure that the machine is placed in a

working area with suitable environmental conditions

and lighting. The general conditions of the working

environment are of fundamental importance for

accident prevention.

2.5 ELECTRICAL CONNECTIONS

Check that the mains to which the machine is connected is

earthed in accordance with current safety regulations and

that the power point is in good condition.

Remember that there should be a magnetothermic

protective device fitted upstream of the mains to protect all

the conductors from short circuits and overloads.

This protective device should be selected according to the

electrical features of the machine listed below:

Nominal voltage.................................1~,115 / 230V

Nominal frequency.............................50/60Hertz

Max programmed absorbed value .....3.8Ampere

Nominal input power..........................1250Watt

Power factor.......................................0.93

Nominal speed .................................14.000-19.000rpm

Insulation ...........................................Class B

Type of service...................................intermittent S4-60 %

In case of power failure in mains, while you wait for power

to be restored there is no danger hazard may arise: in face,

the electronic governor O or main switch D is also

equipped with a reset function which prevents the machine

from restarting automatically. ..............................................

The motor of your sawing machine (electronic version)is

equipped with a protective heat circuit breaker which

interrupts the power supply when the temperature of the

coils rises too high.

When the power supply is interrupted, wait for normal

reset.

3.0 ADJUSTING (Fig. 4-5-6-7-8)

3.1 TENSION OF THE BLADE (Fig.4)

Turn the handwheel B in a clockwise direction until it

locks.

If the tension is too high, the blade tends to escape

from the guide. In this case, slacken the blade tension

by turning of one/two turns the handwheel B in a anti

clockwise direction.

3.2 BAR STOP (Fig.5)

Use the bar stop supplied if you have to do several cuts on

pieces of the same length.

In this way you do not have to repeat the same

measurement each time.

Screw rod E into the hole of the base and fasten it with

nuts F. Slacken the handwheel G and place the stop L at

the correct distance from the blade. Tighten handwheel G

again.

3.3 Cutting angle (Fig.6)

The band saw can cut at an angle varying from 0 to 45

degrees : it is sufficient to slacken the handle I and turn

the swiwel support J towards the respective limit stops H

and K.

For all intermediate angles, turn the swiwel support J until

the mark M on the support matches the corresponding

position on the plate.

Then lock the rotating support J again.

3.4 CUTTING SPEED (Fig.7)

Two speed version

Depending on the type of material and its section (see

CUTTINGTABLE) you can choose two different cutting

speed 60 or 80 m/min. by means of the switch N.

Electronic version

Your sawing machine is equipped with CESC (Constant

Electronic Speed Control), which allows gradual and

continuous variation of the cutting speed , adapting it to

the type and dimension of the material to be cut (see

cutting table).

To select the most suitable speed, use the speed control

knob O to increase or decrease the speed as you require.

Example:

Stainless Steel: 30m/min. position 1

Common Steel: 40-60m/min. position 2-3-4

Allum.Alloy: 80m/min. position 6

Pipes/sections: 70-80m/min position 5-6

4

Loading...

Loading...