Page 1

COMPREHENSIVE CATALOGUE FREE ON REQUEST

Tools etc

Train Tech overview - ask for free catalogue

Signal kits - OO/HO low cost easy to make signals for DC

Sensor Signals - easy automatic block signalling - DCC or DC

Smart Lights - small effects built in - DC/DCC - just 2 wires:

Arc welding • Emergency vehicle • TV • Fire effect •!Party disco

Automatic Coach Lights - motion - no pickups or wiring:

Older Warm White • Modern Cool White • Tail Light • Spark Arc

Automatic Tail Lights - motion - easy, no wires - lantern LED:

Flickering flame oil lamp • Modern Flashing • Constant light

Track Tester - quickly tests DC polarity or DCC - N-TT-HO-OO

SFX+ Sound capsules - no wires! - real trains - DC or DCC

Steam •!Diesel • DMU • Passenger coach • Shunted stock

Buffer Light - clip in lights for buffer stops - N or OO - DC/DCC

LFX Lighting effects - DC/DCC - screw terminals - with LEDs:

Home & Shop lighting • Welding •!Flashing Effects •!Fire

Traffic Lights - fully assembled - just connect to DC or DCC

Level Crossings - assembled - N & OO versions - DC / DCC

DCC fitted signals - slide in the track - easy one touch setup:

2 aspect • 3 aspect • 4 aspect • Dual head • Feathers • Theatre

Smart Screen animated sign - for Trains, Stations etc

DCC Signal & Point Controllers

LEDs

www.train-tech.com

SC100 - Auto Controller

©DCP Microdevelopments Limited 2018 V1.0 151118

DCP Microdevelopments, Bryon Court, Bow Street, Great Ellingham, NR17 1JB, UK

Telephone 01953 457800 • email sales@dcpmicro.com • www.dcpexpress.com

See our website, your local model shop or contact us for a free colour brochure

www.Train-Tech.com

•

Works with DCC or 12-16v smooth DC

Slides into OO track slots on DCC

Or 2 power wires for DCC or DC

Control 2, 3 or 4 aspect colour signals

Links to others for block signalling

Built in sensor to detect train

SC100 Automatic Signal Controller

Enables standard LED colour light

signals to change automatically

•

•

•

•

•

Page 2

SC100 Auto Signal Controller

Please read carefully and always connect up with the power switched OFF!

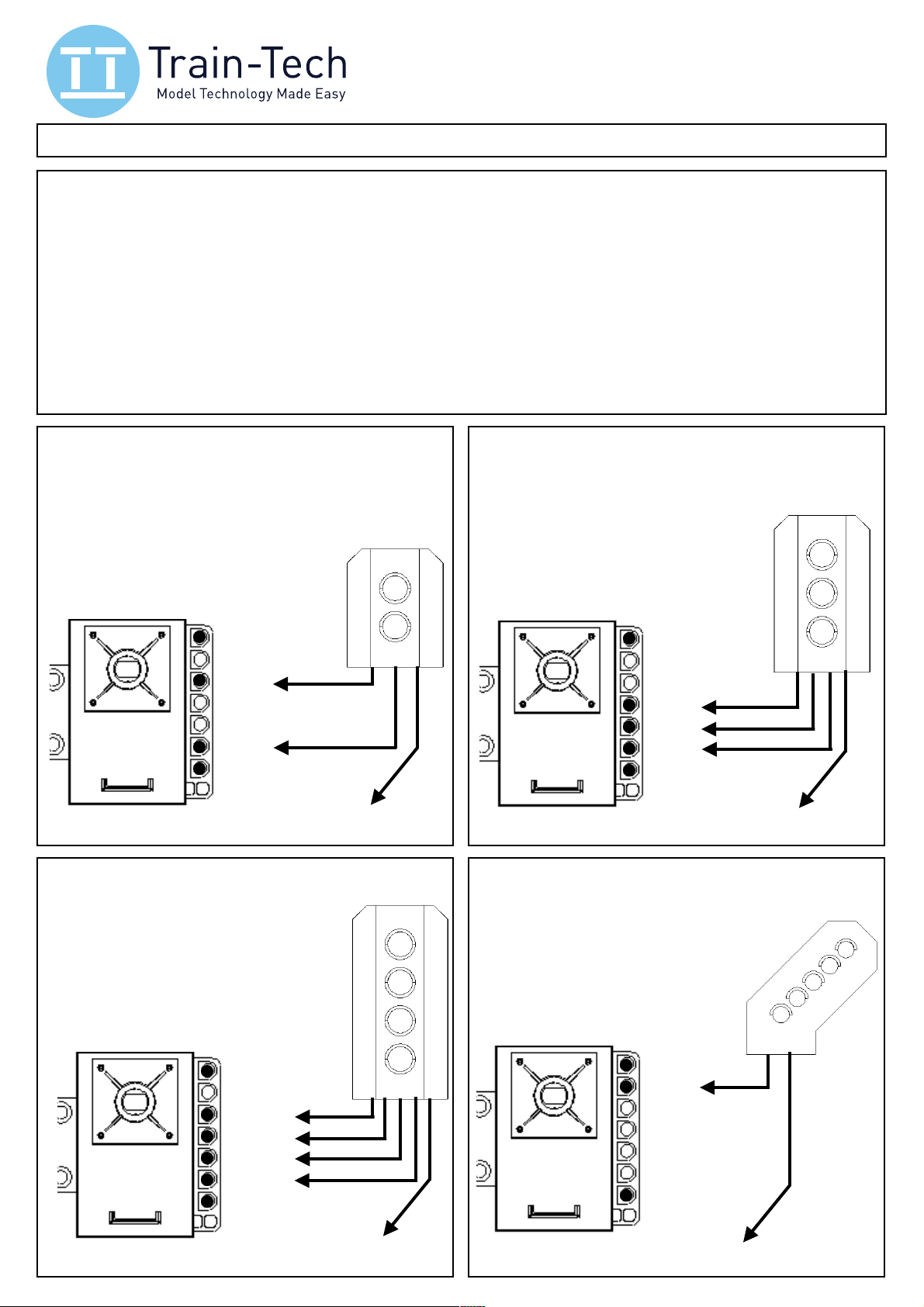

Connecting LED colour light signals to the signal controller

The SC100 has a built-in train sensor and can directly control LED colour light signals automatically.

Although originally designed for OO gauge it can also be used on N, TT and HO gauge layouts.

It is part of the Train-Tech Sensor Signal system and can interconnect with Sensor Signals, but instead of a

built-in signal you can wire to almost any type of LED colour light signal or signal heads on gantries etc.

The drawings below show the wiring for each type of signal and this requires careful soldering using fine

wires to the connection pads (optionally you can fit CON8 SIL sockets - contact Train-Tech for details).

Signals have a common - negative (eg Train-Tech signal kits) or common + positive but the SC100 detects

the polarity as it is switched on and also senses whether there are 2, 3 or 4 aspect LEDs connected.

Note that resistors are built in so you do not need to use additional resistors in series with your LEDs signals.

2 aspect Red-Green Signal

G

R

Common +

Green

Red

Common -

Connect to Common - or + depending on signal

4 aspect Red-Yellow-Green-Yellow

Y

G

3 aspect Red-Yellow-Green Signal

G

Y

Common +

Green

Yello w

Red

Common -

Connect to Common - or + depending on signal

R

Connecting a Feather or Theatre

Signals can also have a Feather or Theatre

route indicator and this can be controlled

by the SC100 using DCC - see

page 6 for details.

Y

R

Common +

Yello w 2

Green

Yello w 1

Red

Common -

Connect to Common - or + depending on signal

Common +

Route

Common -

Use the same - or + common as the main signal

1"

Page 3

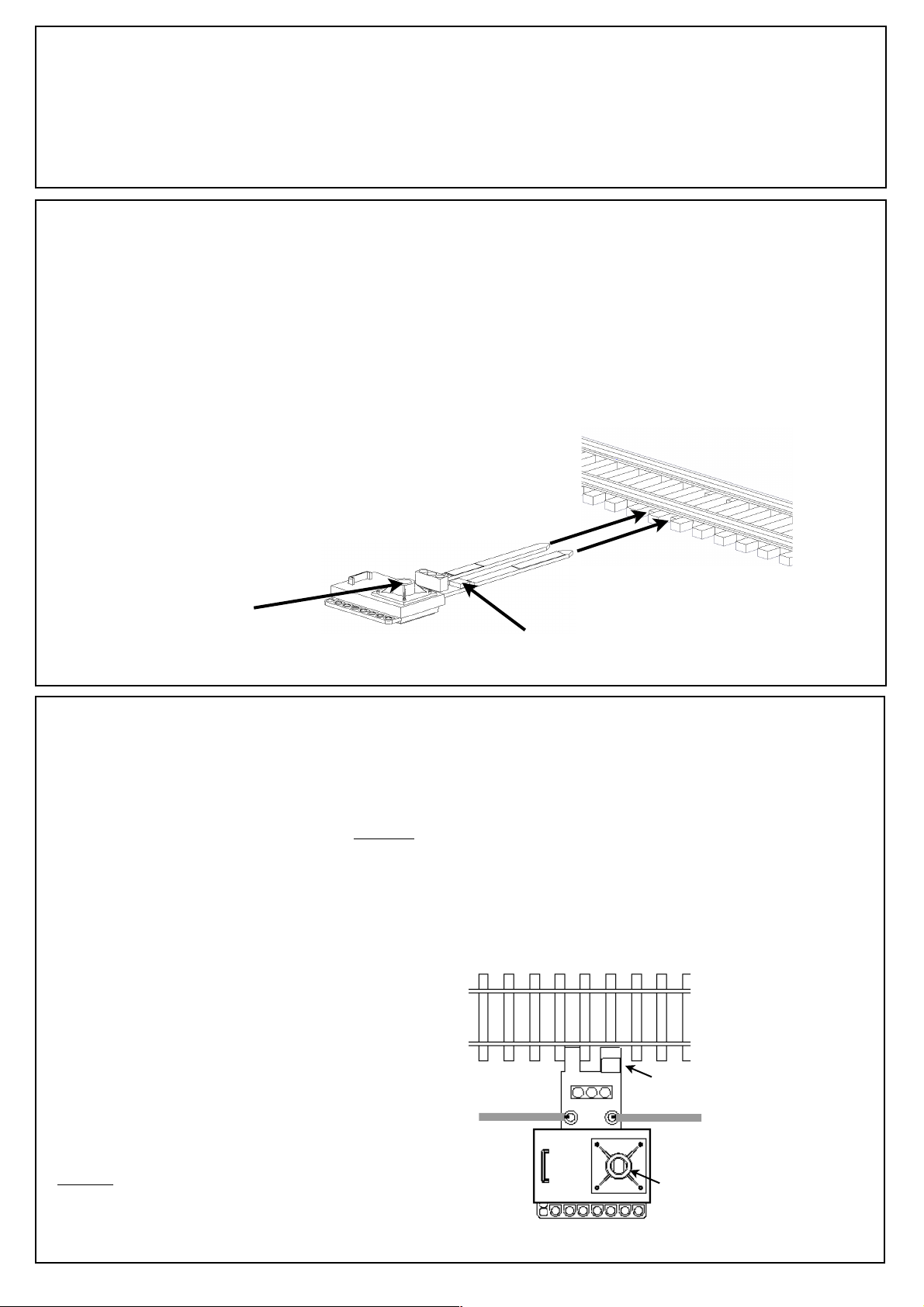

•!Locating the SC100 & signal " " Switch off power first!

Choose an appropriate location for your SC100 and signal. The SC100 and signal is usually

located at the same position on the track because the signal should change just after the train has

passed it, ideally not on a sharp bend because the optical sensor needs to ‘see’ the train above it.

Then you are ready to connect power to the SC100:

• Sliding SC100 into OO track suitable for DCC layouts only

DCC layouts have power on the tracks all of the time and so the SC100 and Sensor Signals can

take their power straight from the track by sliding contact fingers into the slots which some track

has for power clips. Note this is only suitable for some OO track such as Hornby and Bachmann

fixed track and a very good connection must be made at all times for reliable operation. Some

Peco track also has slots but they are wider and will need a little packing to make a solid reliable

connection. If in any doubt we recommend wiring power directly to the SC100 - see below.

To fit SC100 into the track, find the power

clip slots in the track between the rails and

the sleepers and, holding the base,

carefully align and slide the contact fingers

into the slots all the way until they stop the sensor should be close to but not

touching the rail!

This may be a tight fit so take great care!

Power indicator LED

Lights red to indicate the SC100 is

powered. Light hole may be blocked

off with blue tack or similar if desired.

Sensor - careful never to let the sensor pins

to touch the rail or SC100 will be damaged!

Power clip slots

provided at regular

intervals on some track types

• Wiring the SC100 suitable for both DC and DCC layouts

If your layout is conventional DC or you have DCC but do not like the slide in fingers or do not

have suitable OO gauge track with power clip slots as above, you can wire your SC100 to the

layout power by cutting off the track fingers and soldering two wires - see below.

Signals can be powered by DCC or smooth DC and require a voltage of 12-16 Volts max and

current of approx 0.05A each (they should not be powered by an AC or unsmoothed DC supply).

Recommended supply for DC use is Gaugemaster Model GMC-WM4 12 V 1.25A Power Supply

Using a sharp pair of wire side cutters or modelling

cutters, carefully trim off the fingers exactly along the

dotted lines marked - - - - - - on the signal circuit

base, taking great care not to touch or damage the

small black sensor or any of its wires as this will

cause permanent damage!

Carefully solder 2 thin pretinned wires into the holes

marked P P on the drawing, making sure that any

loose strands or whiskers of wire do not touch

any other contacts or component!

On DC layouts connect these wires to a 12-16V

smooth DC supply, on DCC layouts connect them to

the nearest rails, DCC Bus bar or direct to the DCC

controller output.

Locating SC100 with N, TT or OO/HO track

Locate SC100 with the

sensor close to but

not actually touching

the rail. If using with N

or TT gauge track you

may need to cut away

some of the sleeper.

(This picture shows it

with N gauge track)

Power

Signal Connections

P P

Sensor

Power

Power indicator LED

2

Page 4

• Using a SC100 signal on its own

Train detect LED

As soon as the power is switched on the signal connected to the SC100 should light green. If it

does not light at all check the power connections thoroughly - see previous page.

To test push a wagon or coach past the SC100. The sensor should detect it and the signal should

change from green to red.

Several seconds after the train has passed the signal it will change back to green (via yellow if it is

a home-distant type signal). Note that the signal will only change back to green after it has not

seen any train over it for several seconds, so if you have a long train it will stay at danger for as

long as a train is moving over it. A signal used on its own can only ever work in this way because it

does not know how far ahead the train is, but if multiple SC100 and Sensor Signals are linked

together the first signal will stay at danger until a train has cleared the following block and so on

through the block sections protected by other sensor signals - see page 4.

The sensor uses infrared and is quite tolerant

of varied lighting conditions, but for reliable

operation avoid strong lights (such as the sun,

bright or flickering lights) or shadows directly

onto the sensor.

The sensor should detect most locomotives

and rolling stock, but if a particularly tall or

dark train passes undetected a small label or

dab of white paint underneath will help reflect

the infrared more consistently.

Train

Sensor

Avoid bright light or the sun

shining directly at sensor

• Manual override of a single SC100 Signal

Although SC100 / Sensor Signals will work completely autonomously, you can manually override

them to force a signal to stop/caution using either a Mimic Switch or a DCC command. On the real

railway these are called semi-automatic signals & exist so that a central signal box can stop trains

in the event of an emergency, like a tree which has fallen on the line or other operational reasons.

A Mimic Switch is an easy way to override a SC100 Signal and also offers other benefits such as

an LED showing the colour of the signal and another LED which lights when the train passes the

signal, as well as controlling a route indicator etc. Wiring is simple too with just one wire from the

signal to the mimic switch and it works on both DC and DCC layouts. (details on a following page)

This picture shows a

Sensor Signal, but the

same principles apply

to SC100 signals

Signal colour LED

Mimic

Switch

A Mimic switch

connects to a

Sensor Signal using

just one wire and

allows manual

override of the

signal as well as

LEDs which show

signal state and

train detection, etc

DCC override

If you are using the SC100 Signal on a DCC layout you can override the signal to stop/caution

using a single command to an address you set up using One-Touch DCC - see page 5. (Make

sure that you choose an address not used on anything else on your layout!)

3

Page 5

• Using multiple SC100 and Sensor Signals

Sensor Signals and SC100 really come into their own when you link several together because

they all sequence as a complete block section system automatically! Mixed 2, 3 and 4 aspect

SC100 and Sensor Signals will all work together, including distant only signals which show yellow

when the next signal is red. The example below shows 4 x 4 aspect signals linked, although in

practice you can run virtually any number of signals connected in this way as long as you have

sufficient power to supply them all (each signal needs approximately 0.05A).

Wiring is easy because you just need one

Use solid core

wire to link signals

Train

Sensor

Link first signal to the last on complete circuits for automatic operation

This picture shows

Sensor Signals, but the

same principles apply

to SC100 signals

If the SC100 / Sensor signals are located in a

continuous circuit of track then you can link every

signal to each other front to back in a loop for fully automatic

block signalling around the track.

Tip - careful not to obstruct the sensor ‘view’ with the link wires

wire between each signal, the output of one

to the input of the next one as shown.

Always use Single core wire (1/0.6mm

type is best) stripped 3-4mm at each end

which just plugs into the signal sockets you can either hide wires under your

baseboard or run them on the top alongside

the track - just like the real thing!

If you are using SC100/Sensor Signals on a

complete circuit, you can link every signal to

each other to make each section automatic.

If it is an ‘end to end’ type layout the last

signal will turn green a short while after the

end of the train has passed the signal.

If the signals are used on a single line which

has trains running in both directions you can

signal both sides, but only link together

signals running in the same direction.

If a train runs backwards the signals will

turn red (or yellow on a distant signal), then

after a short time cycle back to green.

• Manual override of multiple SC100 and Sensor Signals

Multiple Sensor Signal and SC100 Signals can be overridden to show stop / caution in the same

way as a single signal can, and because they are linked they also control any distant signals

located in front of them to correctly display yellow or double yellow etc.

This picture shows

Sensor Signals, but the

same principles apply

to SC100 signals

Signal colour LED

Mimic switches can be wired to one

or more linked SC100 / Sensor

Signals using just a single wire.

The top LED lights the same colour

as the signal. The bottom LED

flashes as a train goes past a signal

and lights continuously while a train

is still in the following section to show

block occupancy - ideal for a control

panel to show where trains are on

your layout.

If your layout is digital you can also

manually override any signal to red

using a DCC command - see page 6

Mimic Switches

Occupancy LED

4

Page 6

• Using Mimic Switches with the SC100 and Sensor Signals

•

Sensor signals may be used on their own but Train-Tech Mimic Switches and Mimic Lights are a

great way of both controlling and monitoring your signals and trains on a control panel.

Mimic switches can override an SC100/Sensor Signal to show stop/caution or switch on a route

indicator and they come supplied with 2 plug-in LEDs to show the red, green or yellow state of the

signal they are connected to, as well as train presence and occupancy of the following block. It is

easy to mount using a single mounting hole and easy to connect having just a single wire to the

signal and 2 wires to the same DC or DCC supply that you are supplying the signals from.

Mimic Switches come in two versions fitted with either a 3 way toggle switch or push button and

there is also a Mimic Light version which has just the indicator lights and no control. Mimic switches

can also be used to control and monitor other Layout Link compatible products such as points and

level crossings - full instructions supplied with each Mimic product or see Train-Tech.com

Mimic Switch Wiring and Functions

LIGHT FUNCTIONS:

LED A mimics the signal status:

Red, Yellow or Green

Pulsing red if on Manual override

LED B Train passing & occupancy:

Pulses as train goes past signal

Constant while train is in following block

C

•

• ••

A

D

SWITCH FUNCTIONS:

1: Route indicator (if fitted on signal)

2: Automatic

3: Manual override - signal stop/caution

CONNECTIONS:

E

LED C (optional - no LED socket fitted)

Mimics signal’s route indicator

(if a feather or theatre version)

LED D (optional - no LED socket fitted)

Lights as train passes the sensor

LED E (optional - no LED socket fitted)

Mimics the 2nd yellow (if fitted on signal)

•

B

Fit long wire of LEDs to top marked socket •

DC / DCC power (same supply as signal)

To centre socket of SC100/Signal

DC / DCC power (same supply as signal)

• Using DCC to control an SC100 Signal

In addition to using a mimic switch you can use DCC to override a signal and/or control a route

indicator. Train-Tech products use a unique system called One-Touch DCC to easily set up any

DCC accessory - note you must set controller to DCC Accessory control mode, not loco mode.

Two ‘Learn’ Contacts

Briefly touch together the

two contacts at the end to

set signal DCC addresses

wiring to signal

To Setup an SC100 for DCC manual override control

To setup your signal for DCC manual override, turn the power on and use a short

link of insulated wire to briefly short together the 2 ‘Learn’ contacts (see picture)

until the signal lights flash, then send a Direction ▹ / " or a 1 / 2 (depending on

the make of your controller) on the accessory address you want to use to

manually override your SC100 Signal. The signal will stop flashing and your

Automatic signal can now be overridden at any time using the command and

address you chose - change it between override / automatic using ▹ / " or 1 / 2

command on your address. Other SC100/Sensor Signals linked to this signal will

react correctly too, so for example a distant will display yellow when the following

signal is red. Make sure you choose an address not used by anything else!

To set up DCC control of a Feather or Theatre connected to an SC100

To setup a signal Route Indicator, use a short link of insulated wire to briefly short

together the two ‘Learn’ contacts (see picture) until the signal lights flash, then

touch them again and the Route indicator should flash.

Send a Direction ▹ / " or a 1 / 2 (depending on your controller) on the

accessory address you want to use to use to turn the Route on. The Route will

stop flashing and will now light using the command and address you chose. You

can use the same address as a DCC controlled point so that it changes with the

point - note that the route indicator always lights with the same ▹ / " or 1 / 2 you

used to set up, so use the same as the point to make them work together.

5

Page 7

• Route Indicator Signals

Train-Tech Signals are available with ‘Feather’ and ‘Theatre’ type route indicators which can be

wired to the SC100 and switched on and off using DCC or a Mimic Switch as shown previously.

Route indicators advise the train driver which route or platform etc they are going and are often

dictated by point position. Feather and Theatres are also available on their own from Train-Tech.

The Train-Tech Theatre route indicator

can easily be set to display almost any

single character or symbol of your

choice. This is called a ‘dot matrix

display’ and is how many theatre & other

signs are created on the real railway.

DCC Control of a Signal Route Indicator

Feather or Theatre route indicators can either be on or off and are all controlled in the same way,

much like the main signal control. If you are controlling your points using DCC you can give the

route the same address so that it lights automatically when the point(s) are set to the selected

route. To set the route address, set your chosen accessory address on your controller and then

touch the Learn contacts together twice until the feather or theatre flashes. Then send a ▹ / "

Direction or 1 / 2 command from your controller to set the address for your route indicator to be

on. (NB: if you want the route to synchronise to a point operation, ensure the same command

used also sets the point to that route). More information on the DCC control page 5.

Note that like the real thing, the SC100 automatically turns off route indicator if signal is at Red.

Using Signal Heads and Gantries

•

Train-Tech now offer OO gauge Signal heads only (SH2-SH6) which are available in 2, 3 and 4

aspect versions and all include preassembled LED panels and fine connecting wire. LK1/RK1

Feathers and TK1 Theatres can also be fitted to these signal heads with just two soldered joints.

The signal heads are ideal for making your own signals, or they can be mounted on a gantry such

as this Dapol CO17 which shows how signal heads could replace the dummy signals from the kit.

Gantry Image ©Dapol

6

Page 8

• Automatic Signals

Like Sensor Signals, the SC100 incorporates an infrared sensor which automatically changes the

signal when a train passes to signal danger to following trains. When used on their own they

gradually change back to green a short time after the last part of the train has crossed over the

signal, but when linked to other SC100 or Sensor Signals (using just a single wire) they all work

together to provide fully automatic block working, each signal protecting the following block by

staying at danger until the train has left the block. We developed the Sensor Signal system after

recognising that most modellers run their layouts on their own most of the time and so do not have

time to be signalmen as well as train drivers! However much of the ‘real’ railways main lines use

automatic signalling and Sensor Signals work in a very similar way.

Signalling basics

The most basic signals are 2 aspect Home (red & green) and Distant (yellow & green). A Distant

signal is installed ahead of a home signal to give early warning to the driver of what the next signal

is, so if the Distant signal is green he knows the next signal is also green, but if it is showing yellow

he knows the next signal will be red. There are also 3 aspect Home-Distant signals with yellow

lights as well as the Red & Green which are called Home-Distant, and on high speed main lines

there are 4 aspect Outer-Distant signals with red, green and 2 yellow distant lights which give an

even earlier indication of the next 2 signals to the train driver. Much of the ‘real’ railways main lines

actually use automatic signalling and Sensor Signals work in a very similar way. We cannot cover

any real detail of signal planning and operation here, but there are many good books and websites

(eg www.signalbox.org) dedicated to the subject. The illustrations in this guide mainly show 4

aspect Sensor Signals, but the same principles apply to all variations of Train-Tech signals.

• Troubleshooting….

When powered one of the signal lights should always be lit and not flickering. If not and locos run correctly track check

•

signal power connections - if using signal contact fingers for connection check they are clean and tightly fitted between

the track sleeper and rail - clean if necessary or consider wiring the signal instead of using slide in fingers. The power

connections to every Sensor Signal linked together must be very good and consistent to ensure reliable operation.

If powering your Sensor Signal from DC it must be a Smooth DC supply between 12 and 16 volts DC maximum - we

•

can recommend the Gaugemaster GMC-WM4 power pack as ideal, being 12 volt Smooth & Regulated DC @1.25A.

If the signal stays on one colour, not changing as the train passes, check that signal is pushed in around the sleepers

•

and the sensor is close to the rail (but NOT touching!) so that it can ‘see’ the train moving over it and that there is no

bright light or sun shining directly onto the sensor to prevent it from working. We do not recommend mounting Sensor

Signals on curves because long stock can miss the sensor on outside curves or crash into the signal on inside curves.

• If signal stays on red (or yellow on a distant signal) check you have not sent an override command inadvertently - note

that Sensor Signals are set to a Test DCC address at the factory and this might be the same address as something else

on your layout, so if in doubt give it your own unique address even if you do not intend using DCC override - see page 6

If sensing is unreliable on some trains you can add a white label or white paint under the train to improve reflectivity,

•

but it should work with most stock. Do not get the signal wet or cover the sensor with paint or any other scenic material.

If your signal does not respond to DCC, double check that your controller is in accessory addressing mode (not regular

•

locomotive addressing) to set up & operate (this will be explained in your controllers instructions).

• If these steps fail please contact your supplier or us direct: www.train-tech.com sales@dcpmicro.com 01953 457800

Computer and advanced control systems

Some DCC controllers can be connected to a PC or tablet to enable computer control of locomotives and accessories for full details on compatibility consult your controller supplier. Some controllers have Railcom® or Railcom Plus® and

although our Sensor Signals will work with this system on if you are not using Railcom it is best to turn it off.

Signal design

Our signals are based on colour light signals in Norfolk which we photographed, CAD, tooled and make in the UK.

As well as Sensor signals we also make DCC fitted and switch controlled signals with Feathers & Theatres, plus a wide

range of easy to use signal and point controllers, lighting and sound effect products. Ask for our latest free brochure.

Caution

This product is not a toy but a precision model kit and as such contains small parts which may choke or harm a child.

Always take special care when using tools, electricity, adhesives and paints, especially if children or pets are nearby.

7

Publication reference D779643/4A ©DCP 2017 David Palmer

Loading...

Loading...