Page 1

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

S7-USB user manual

Art.Nr. 9352-S7-USB

documentation of version XXX

1 Description

The MPI-USB cable connects the computer via USB with a MPI interface (9 pin interface of the PLC).

2 System requirements

2.1 Operating system (s)

Windows 98 + SE Windows ME/NT/2000 Windows XP Windows Vista Windows 7

2.2 Software

PLC - programming software (eg PG2000, Step © 7, S7 for Windows, Microwin) Direct driver for SimaticManager for USB PLC - VCOM Software A video description of the installation of direct-driver and how to

configure it can be found on the page support!

2.3 Hardware

USB 1.1 - Type A

2.4 Provided PLCs

S7-200 S7-300 (provides baudrates up to 12M (when the PLC is able to support this) S7-400 (provides

baudrates up to 12M) FM-devices Sinamix (Step7-direct-driver up V1.20 or PLCVCom up V2.71)

MicroMaster and other electrical drives and inverter-feds (Step7-direct-driver up V1.20 or PLCVCom up

S7-USB user manual 1 / 85 2019/10/05 05:07

Page 2

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

V2.71) Sinumerik (only PLC-side) SEW-EURODRIVE power inverter and at last routing of S7-PLCs

3 Connecting options

S7-USB directly connected to the PC.

S7-USB is connected to the PC via a USB hub.

S7-USB Connection options with control terminal

4 Installation

4.1 Hardware

The S7/MPI-USB is plugged directly into the PLC. Via the USB cable of the module can be connected to the

PLC as follows:

Normal installation (for programming)

The MPI cable will be connected to the S7 PLC via the 9 pin connector (short side of the cable). The USB

connector on the long side of the cable will be connected with the computer.

S7/MPI-USB as HMI (Human Machine Interface) – adapter

The HMI – function provides the possibility to connect a operator panel (which has instead of a MPI

interface a USB device and understands the HMI protocol) with a S7 PLC (300/400). Connect the cable

between the terminal and the PLC. The HMI – protocol must be part of the operator panel.

There must be a serial communication with the operator panel if this op is new/used at the first time.

Therefore connect your operator panel with the serial COM interface of your computer. After the

communication has been running successfully the panel is ready to be connected to the PLC.

4.2 Software

To communicate with the PLC, please install following products for MPI-USB, S7-USB, MPI-II[only USB], MPILAN and S7-LAN:

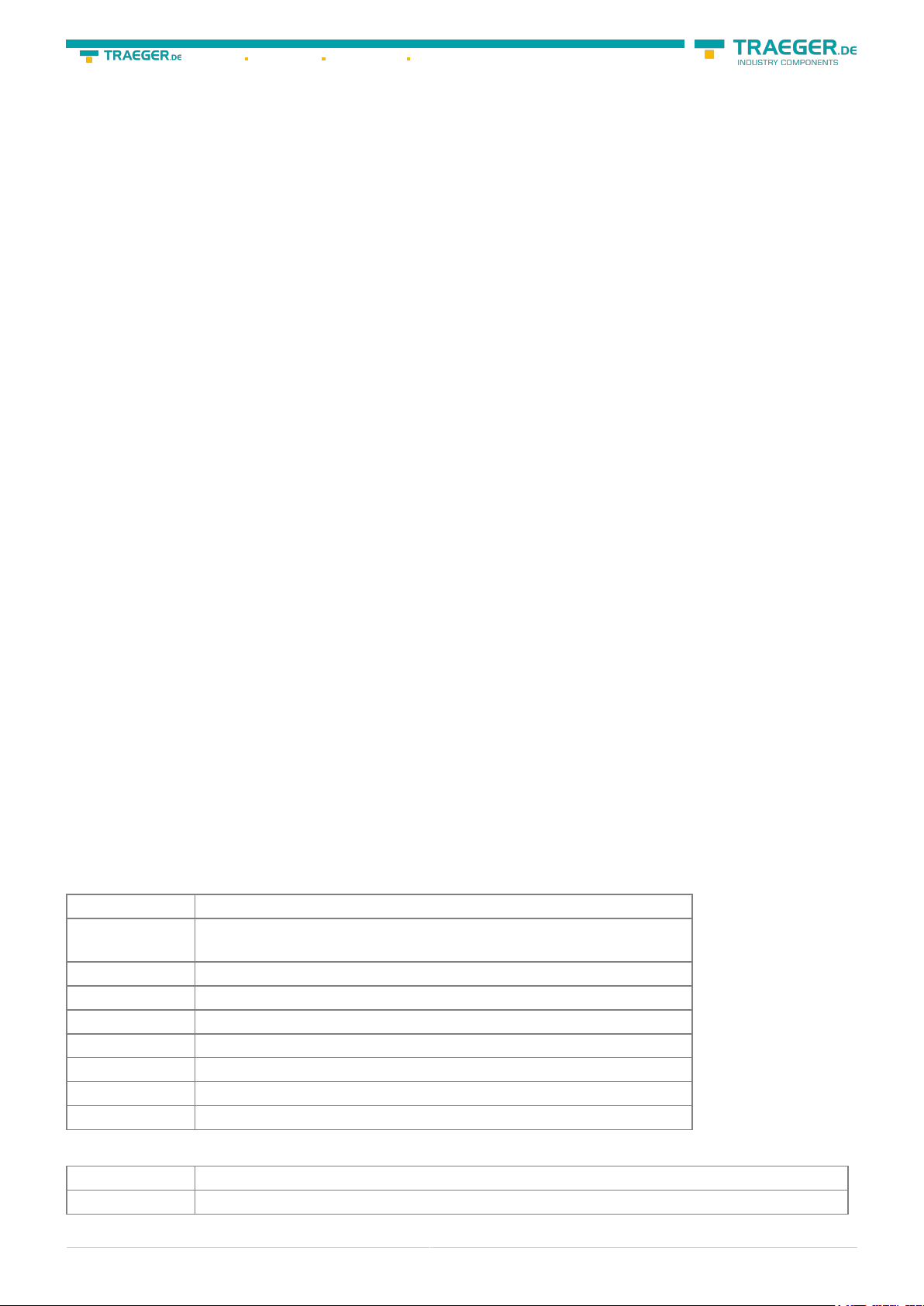

Product Driver

TIA-Portal

Simatic-Manager TIC ⇒ “TIC ETH/USB” for MPI, PPI or PROFIBUS

Starter-Software TIC ⇒ “TIC ETH/USB” for MPI or PROFIBUS

MicroWin TIC ⇒ “TIC ETH/USB” for PPI and S7-22x-PLC

MicroWin PLCVCom for S7-21x-PLC (no MultiMaster-protocol)

PG-2000 PLCVCom or for S7-LAN/MPI-LAN direct in interface-settings

S7 for Windows TIC ⇒ “TIC ETH/USB” for MPI or PROFIBUS over PD/PC-interface

S7 for Windows PLCVCom

To communicate with the PLC, please install following products for MPI/PPI and MPI-II[only serial]:

TIC ⇒ “TIC ETH/USB” for MPI, PPI or PROFIBUS

configuration of driver with control-panel ⇒ setting PD/PC-interface

Product Driver

TIA-Portal no support because Siemens has taken out the serial support in the driver “PC-Adapter”

S7-USB user manual 2 / 85 2019/10/05 05:07

Page 3

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Product Driver

Simatic-Manager included driver “PC-Adapter” for MPI and PROFIBUS

Starter-Software included driver “PC-Adapter” for MPI and PROFIBUS

MicroWin included driver “PC/PPI-cable”

PG-2000 Standard-function, configuration in the interface-settings

S7 for Windows Standard-function, configuration in the interface-settings

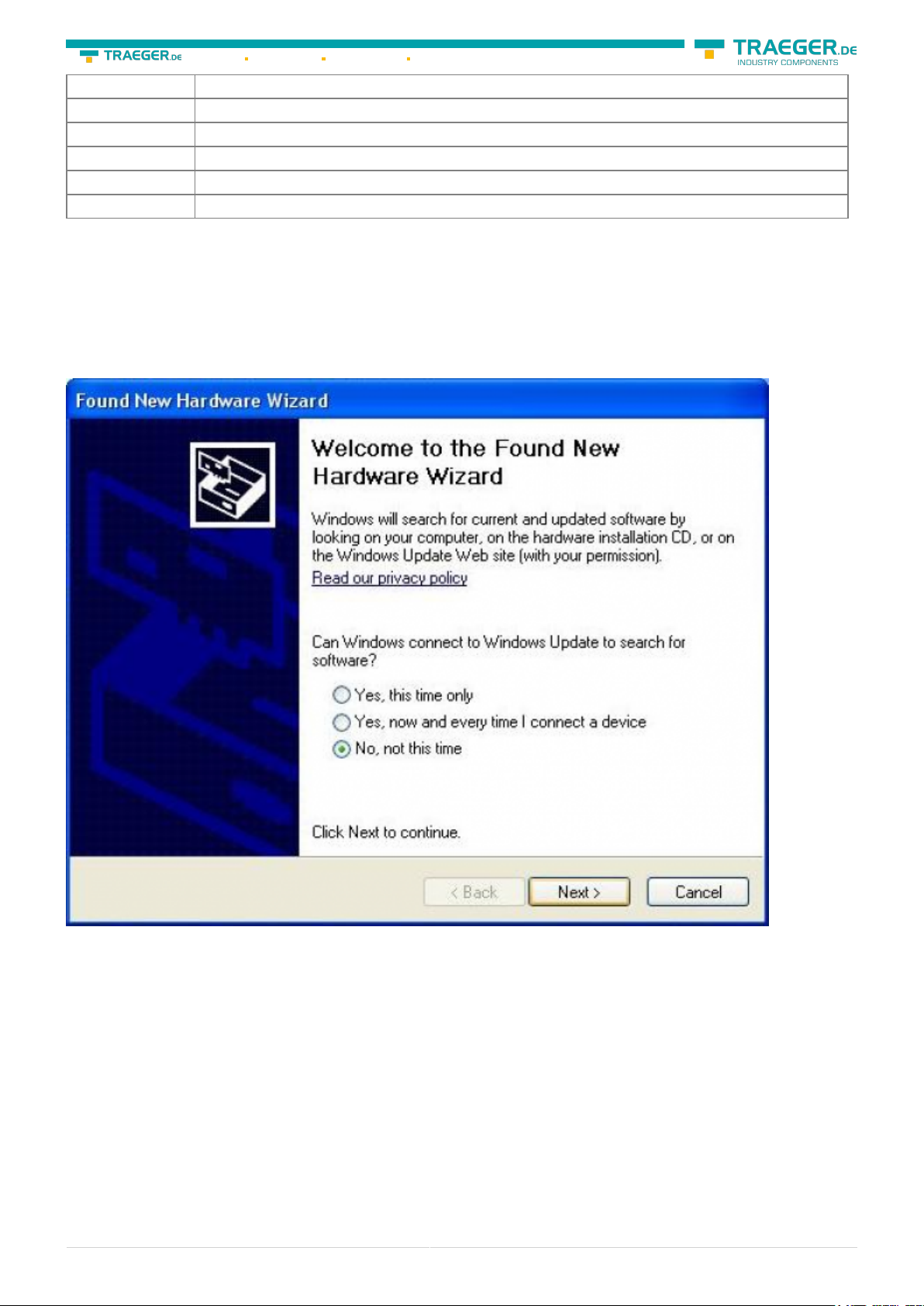

4.3 USB-driver-installation for 32-bit-systems

The S7-Interface S7-USB, MPI-USB or MPI-II-Cabel over USB as well as the devices of TeleService-family will

be connected to USB 1.1-compatible port of the PC.

This opens the Hardware-Installation-Wizard:

We don´t need a connection to Windows update.

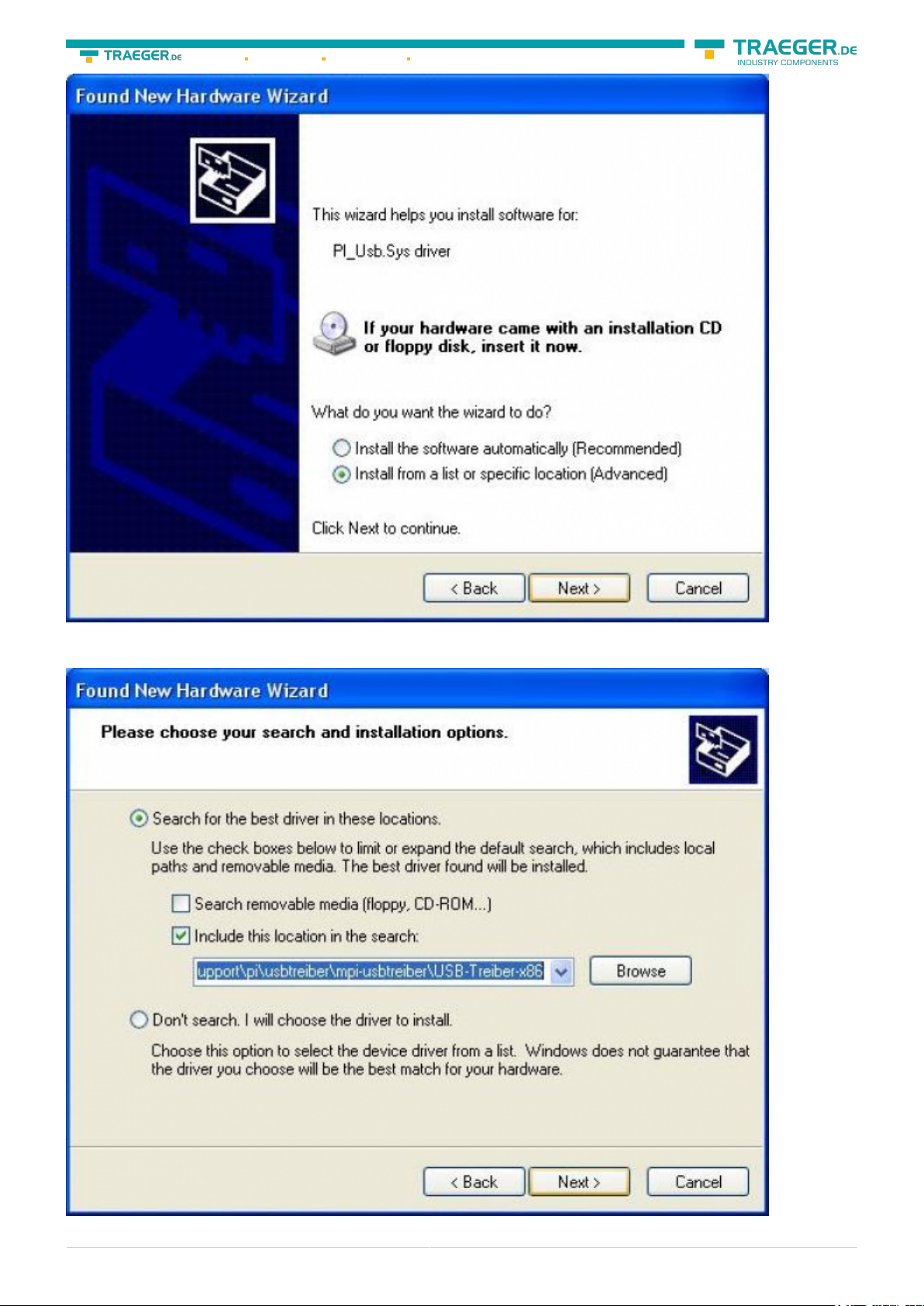

Select now “Install from a list or specific location”:

S7-USB user manual 3 / 85 2019/10/05 05:07

Page 4

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Enter as source the folder “..\USB-Treiber-x86”. Either in the folder where the downloaded drivers were

extracted or the directory on the product CD:

S7-USB user manual 4 / 85 2019/10/05 05:07

Page 5

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

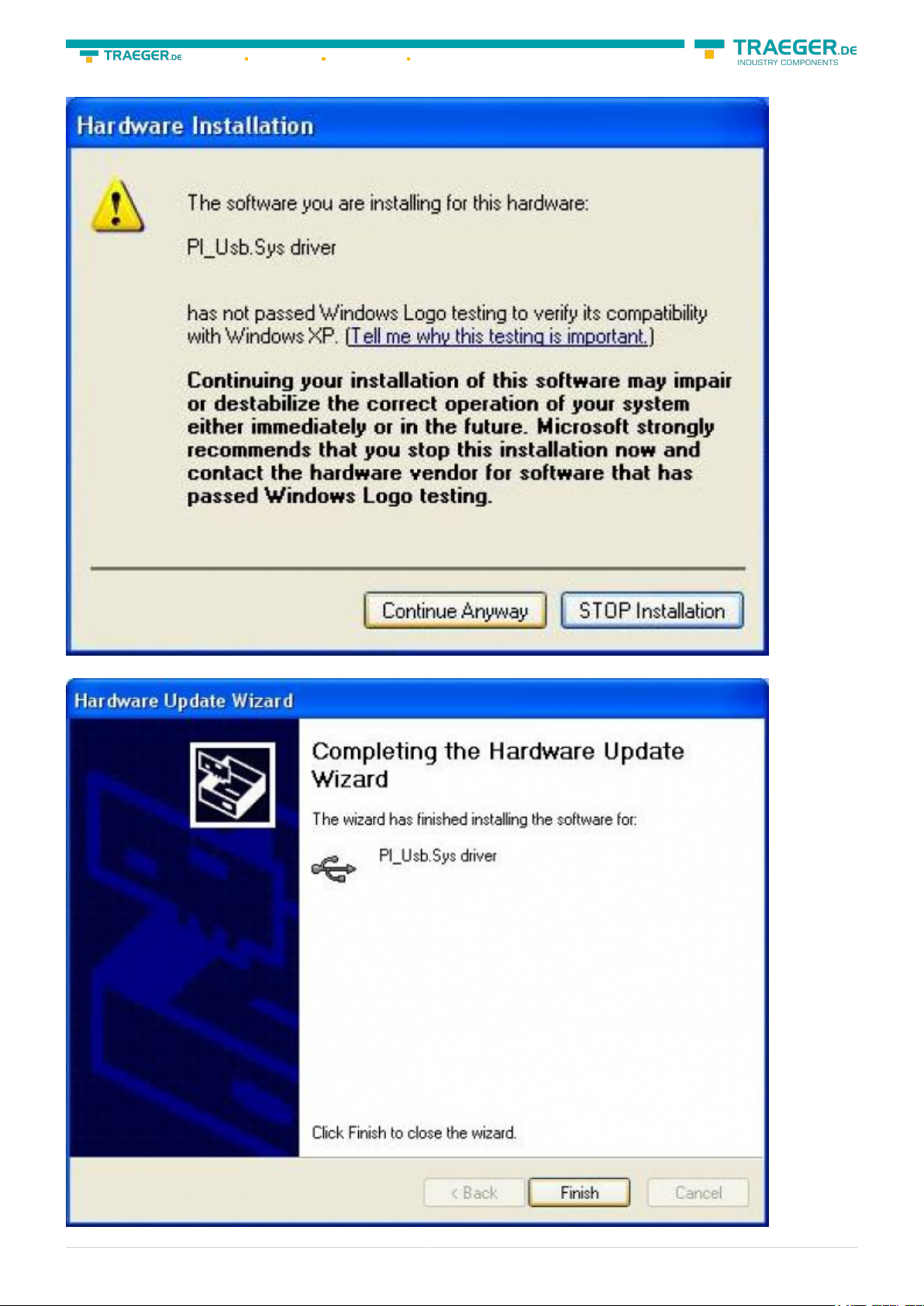

The message of windows logo test skip with “Continue Anyway”:

After copying the data appears a little moment later the success message:

S7-USB user manual 5 / 85 2019/10/05 05:07

Page 6

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

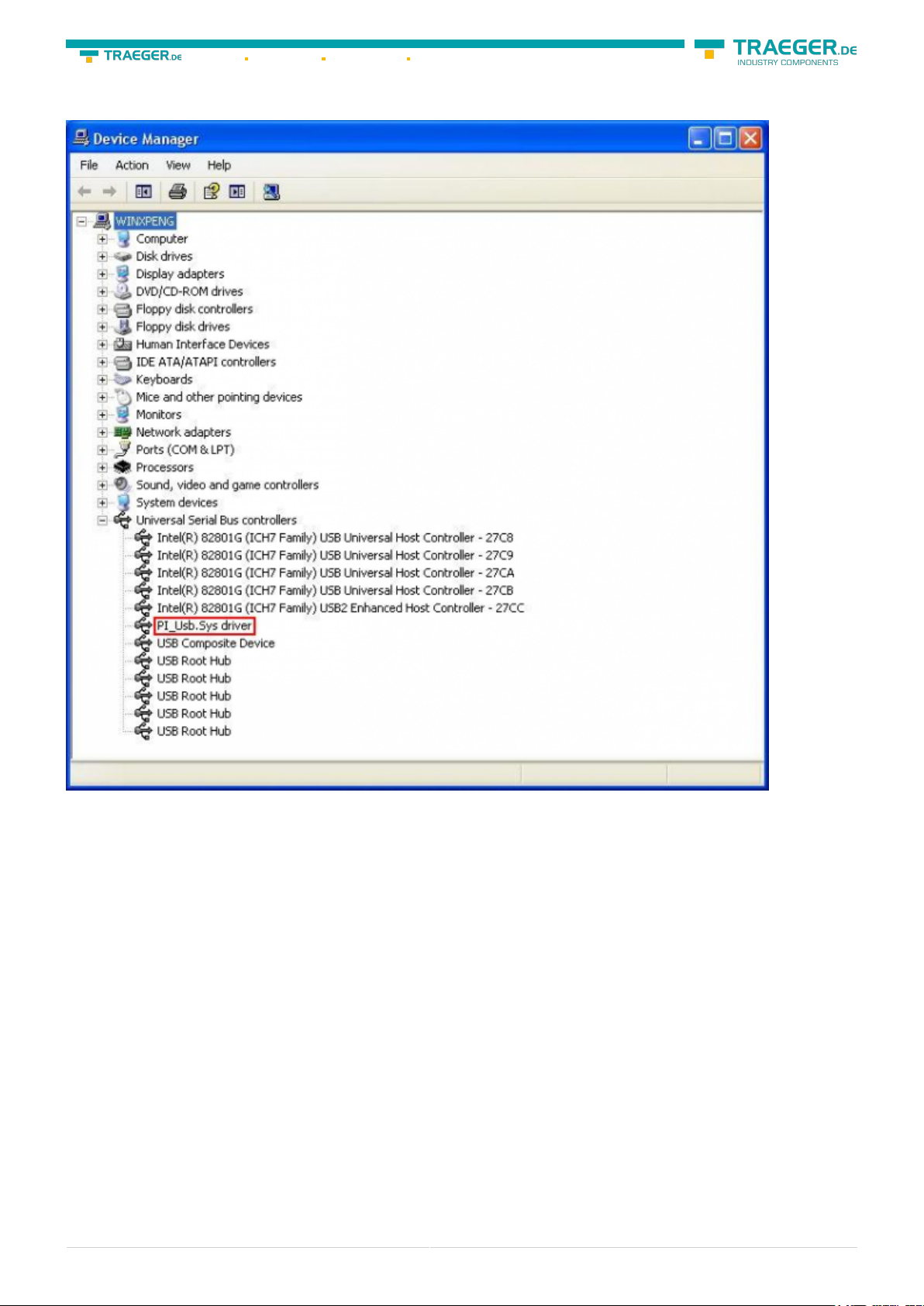

Upon a successful installation the “PI_Usb.Sys driver” will be displayed without any warnings in the device

manager:

Will this entry in the device manager shown with a “yellow exclamation mark”, then please install the

driver again or look in the driver properties about the reason.

If the driver has to be updated, please use the function “Update …” in the driver properties:

S7-USB user manual 6 / 85 2019/10/05 05:07

Page 7

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

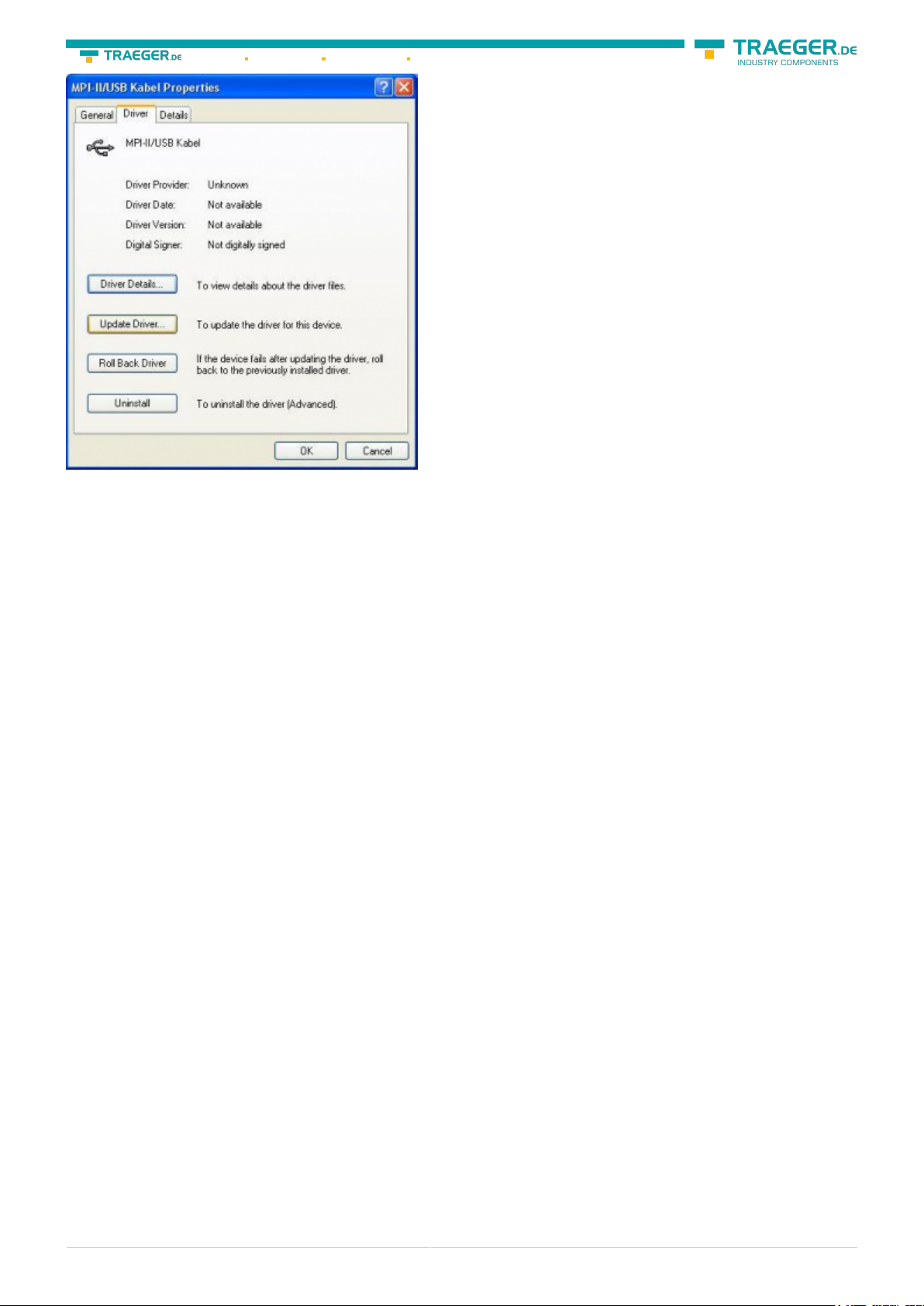

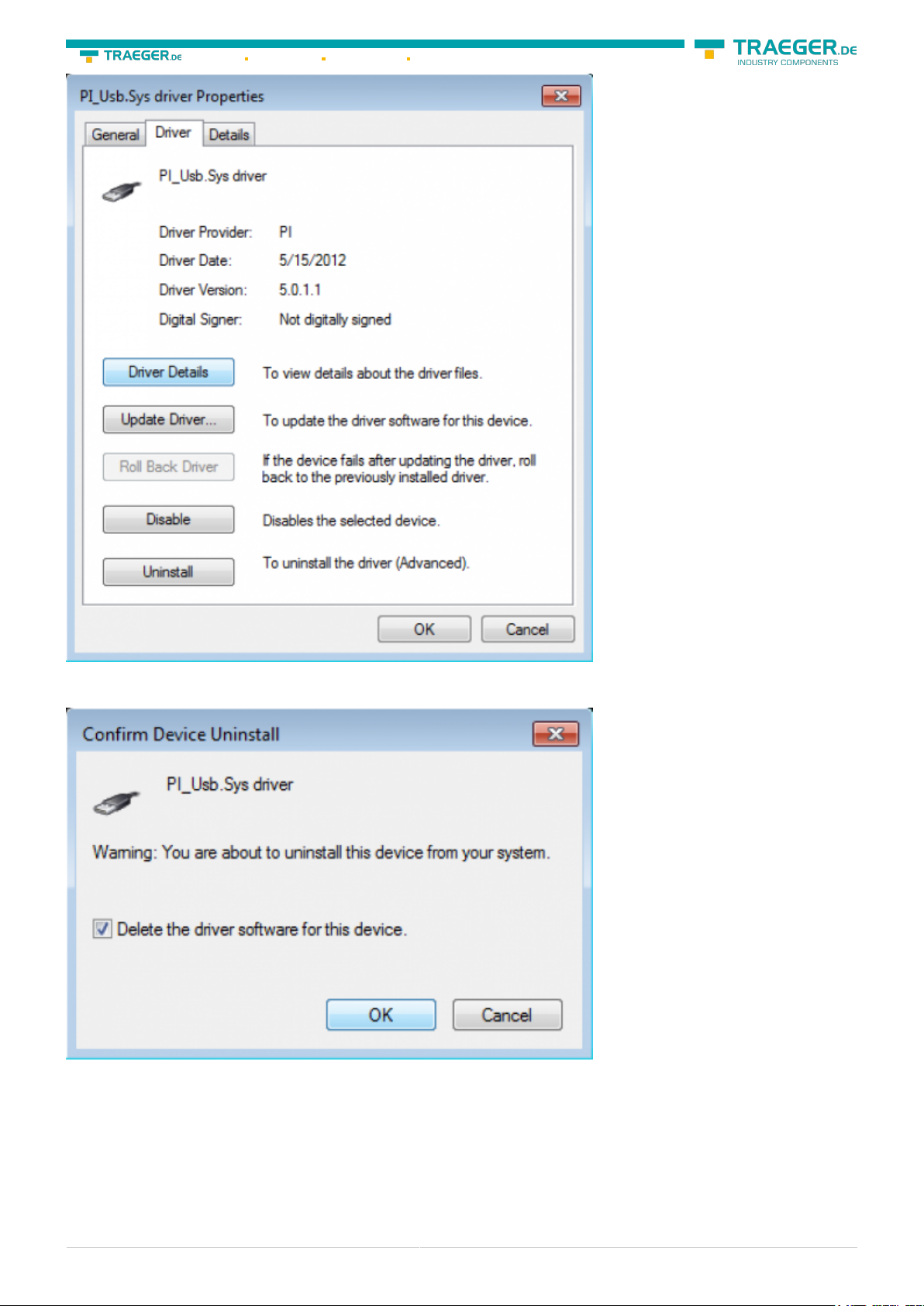

If the driver has to be deleted, please use the function “Uninstall” in the driver properties:

If you install older versions of PLCVCom, Step7-direct-driver or S7IFC, the actual usb-driver will be possible

overwritten by previous versions because it was included until 01/11/2012 in their install-shields!

4.4 USB-driver-installation for Win7 64-bit

The S7-Interface S7-USB, MPI-USB or MPI-II-Cabel over USB as well as the devices of TeleService-family will

be connected to USB 1.1-compatible port of the PC.

After the first plug of the device Win7 displays the message „Installing device driver software“ and after

some time „Device driver software was not installed“. This messages could be closed.

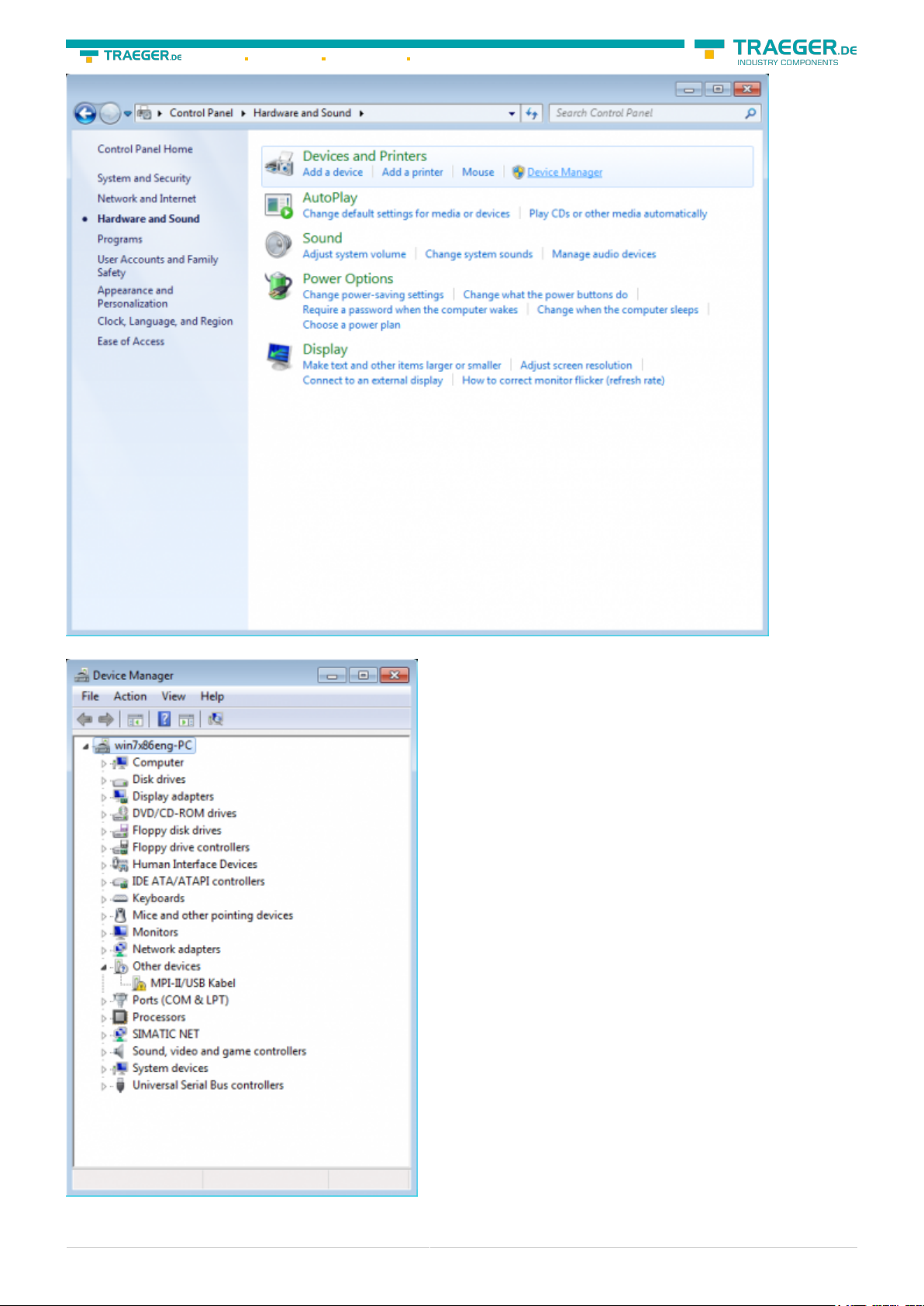

Please start the windows device manager in the control panel.

S7-USB user manual 7 / 85 2019/10/05 05:07

Page 8

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

In the device manager would be the new device shown with a exclamation mark:

With a right mouse-button-click you will open the properties of the new device:

S7-USB user manual 8 / 85 2019/10/05 05:07

Page 9

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Now select “Update Driver…”:

S7-USB user manual 9 / 85 2019/10/05 05:07

Page 10

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

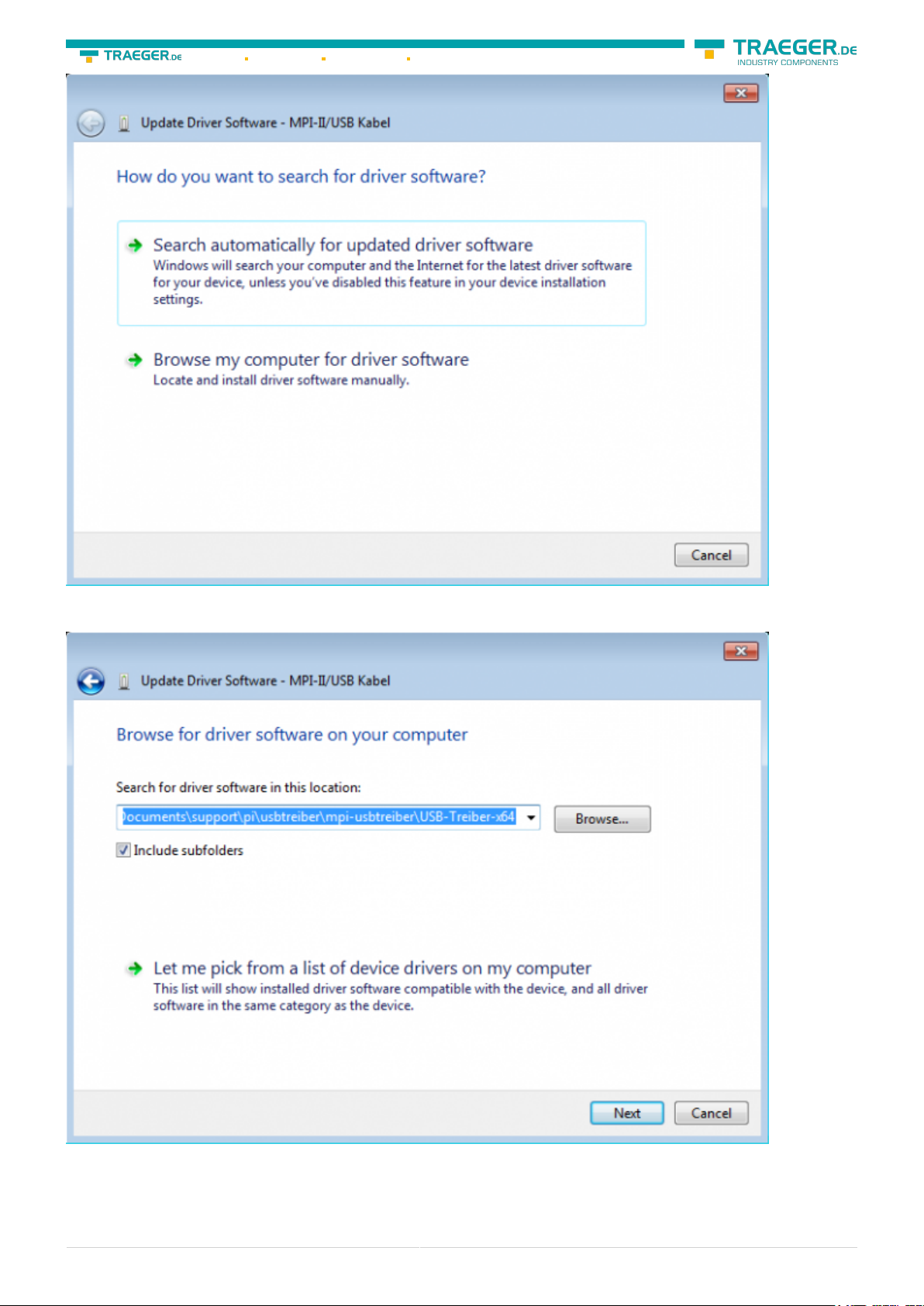

Please select “Browse my computer for driver software” and define as source the folder “..\USB-Treiberx64”. Either in the folder where the downloaded drivers were extracted or the directory on the product CD:

After pressing “Next” the message appears of windows UAC

S7-USB user manual 10 / 85 2019/10/05 05:07

Page 11

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Please press install and a little moment later appears the success message

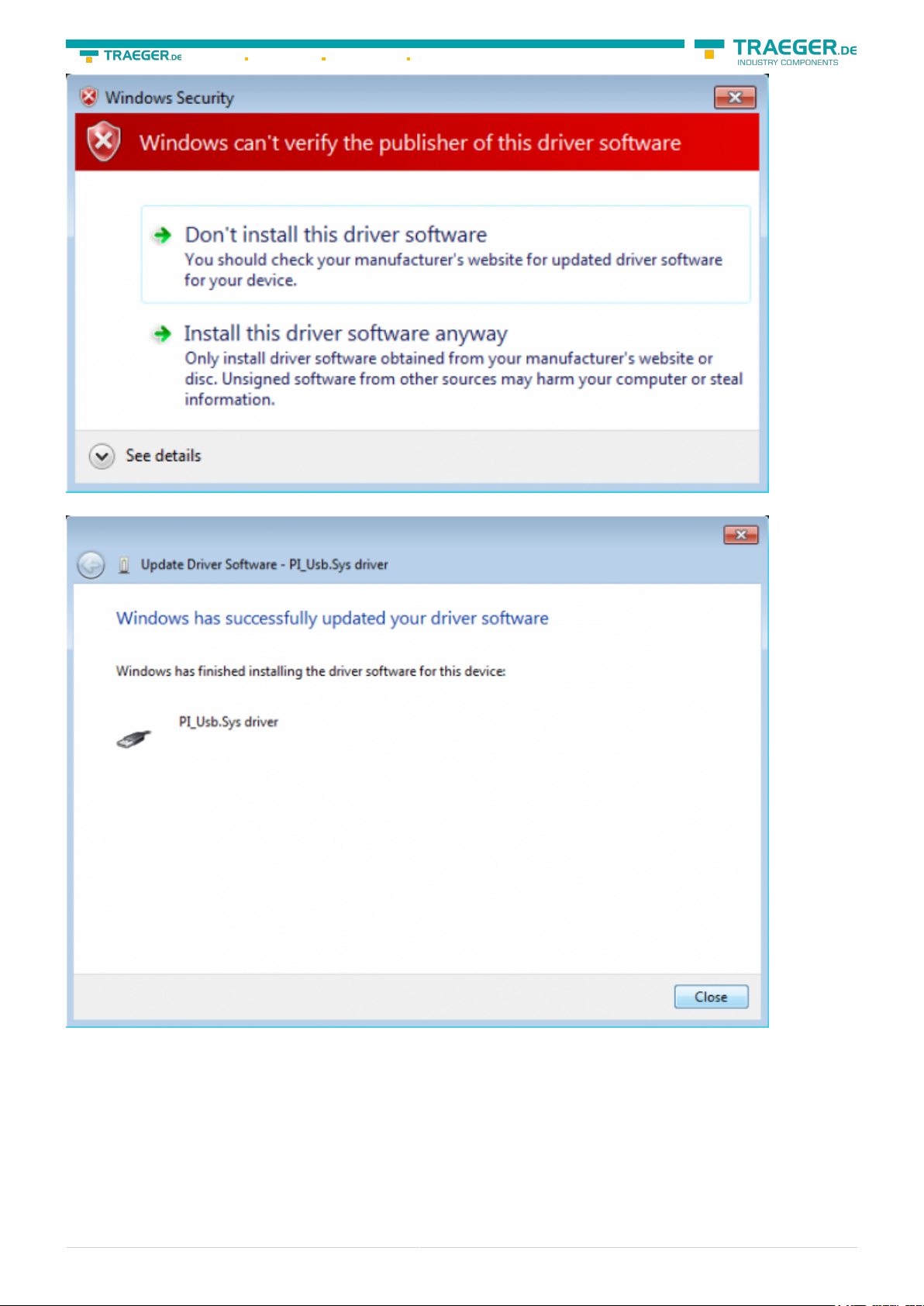

To verify the successful installation, you can look again in the device manager:

S7-USB user manual 11 / 85 2019/10/05 05:07

Page 12

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Here may appear no exclamation mark!

If the driver has to be updated, please use the function “Update driver …” in the driver properties:

S7-USB user manual 12 / 85 2019/10/05 05:07

Page 13

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

If the driver has to be deleted, please use the function “Uninstall” and set the check-box in “Delete the

driver software for this device”:

If you install older versions of PLCVCom, Step7-direct-driver or S7IFC, the actual usb-driver will be possible

overwritten by previous versions because it was included until 01/11/2012 in their install-shields!

S7-USB user manual 13 / 85 2019/10/05 05:07

Page 14

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

5 Control elements

5.1 Lateral LEDs

Green LED OFF Power OFF (S7-USB is not supplied with voltage)

Green LED is blinking BUS Communication

Green LED is on Power ON (S7-USB is supplied with voltage)

Yellow LED is OFF no error in the communication

1x Module does not come into bus

2x Participants provided with the same MPI address

Yellow LED is blinking

3x Wrong MPI baud rate is used

4x Detected parity error on the bus

5x Buffer overflow condition in module

6 Implementing

Connect your module as described in the chapter “ Hardware installation ” to the PLC and to the

programming device or to your computer.

If you want to respond to a PLC via the module you have to comply the requirements as described in the

chapter “system requirements” . In addition,please make sure that the module is properly connected

6.1 Using the PLC-VCOM

(The PLC-VCOM is only needed if your module is not connected via the 9 pin COM port to the computer. For

products with USB, Ethernet connection, etc., the PLC-VCOM is required)

1. Start the PLC - VCOM application (If it has not already started yet).

2. Click in the main window of the PLC-VCOM, in the status area “configure”. The configuration wizard will

start.

3. It lists all the found modules / cables and the additional information’s such as IP address and MAC

address of the module.

4. Choose the desired MPI cable and click „OK“ to go on.

5. If the connection is established the chosen cable is shown in the section state and on the left side you

can see the status connected.

6. It also displays, the PLC-VCOM the IP address for the module and the IP address of the computer which

is connected to the module.

If you have any problems with the use of PLC-VCOM software, go to the chapter PLC – VCOM and look there

for operating instructions.

S7-USB user manual 14 / 85 2019/10/05 05:07

Page 15

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

6.2 Programming software to use with direct access

After you have adjusted and connected the PLC-VCOM or the programming adapter to the COM-port on

your computer, you will be able to connect with your programming software

to the PLC and work with it.

How you have to adjust your programming software is described in the following points:

6.2.1 PG2000 für S7 (V5.10)

1. Start the PG 2000 software by using the desktop link or by using the application entry in the start menu.

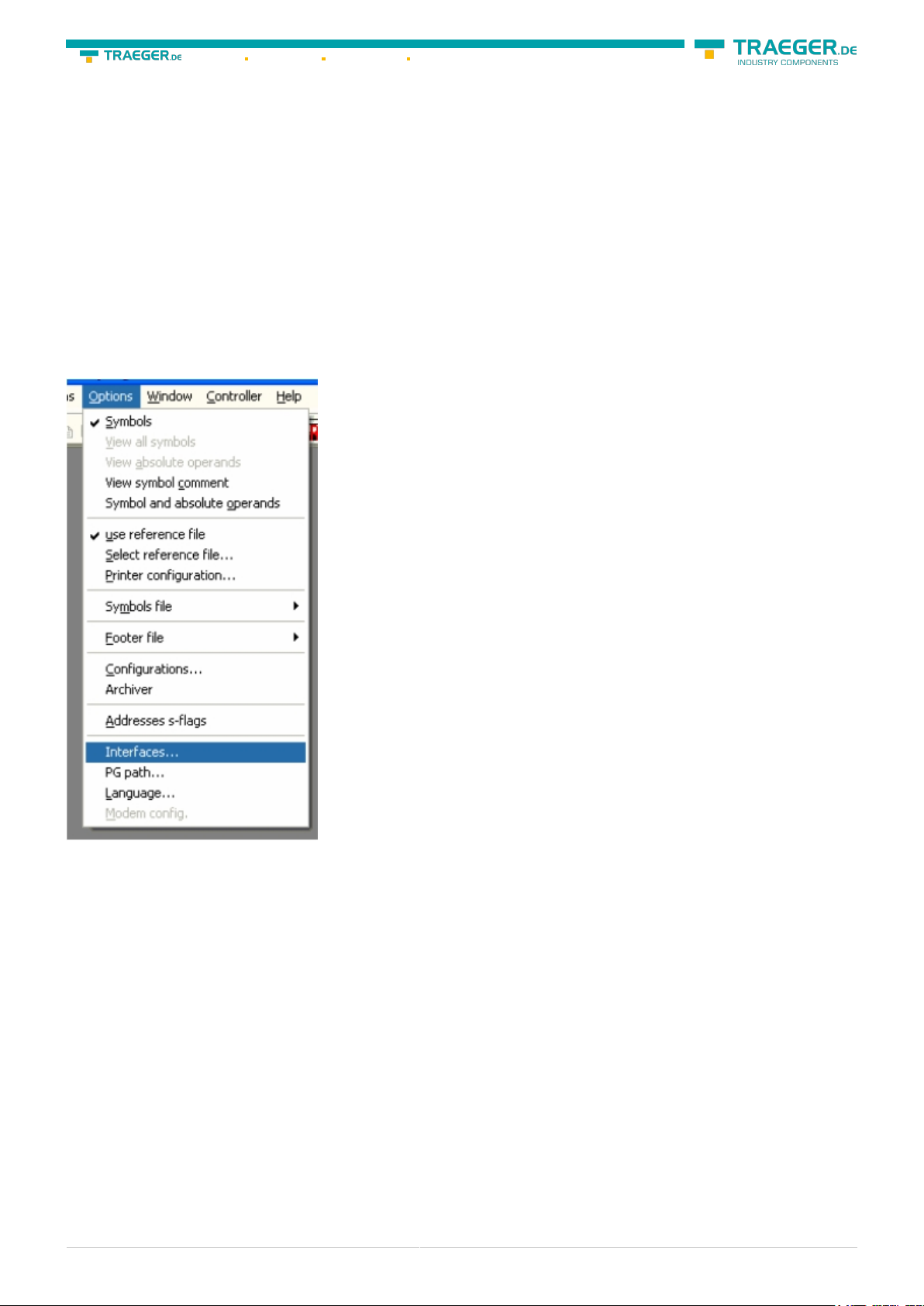

2. Choose from “View” ⇒ “S7-300/400” In the menu “Options“ click “Interfaces“..

S7-USB user manual 15 / 85 2019/10/05 05:07

Page 16

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

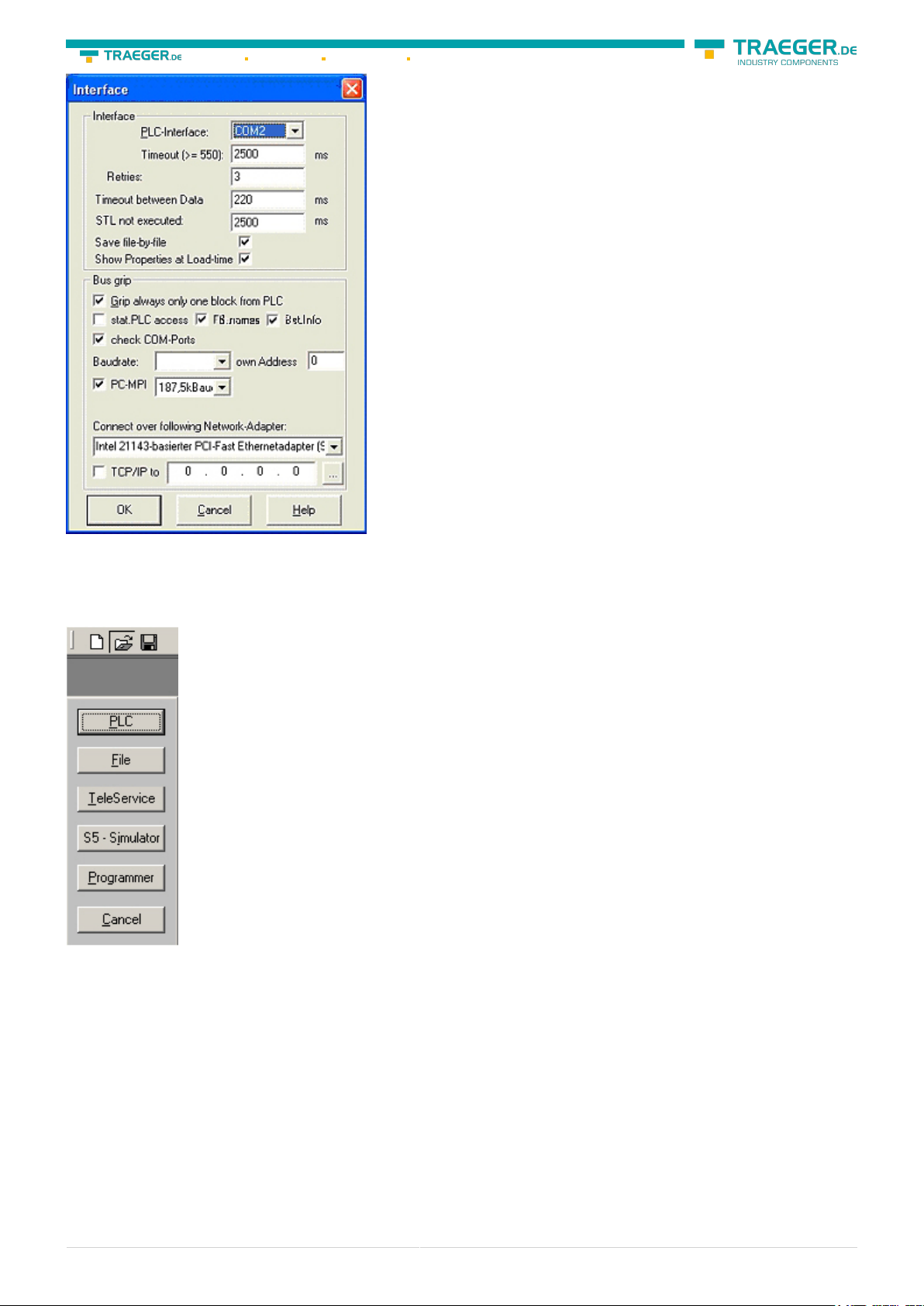

3. A dialog appears, in which you are able to set the “AG-Interface” (COM-port) in the section “Interfaces”.

4. Configure the baud rate in the section “Bus access“ to “19,2k“. Below change the value for PC - MPI to

“187,5kBaud“.

5. Save your configuration by pressing “OK“.

6. Now the software is ready to establish a connection to the PLC Click the symbol “Open“ and afterwards

press “PLC”. Alternative you can click:

„File“ ⇒ „Open“ ⇒ „PLC“

S7-USB user manual 16 / 85 2019/10/05 05:07

Page 17

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

The connection between PG 2000 and the PLC is now established. A new window appears. Now you can

edit the blocks in the PLC.

6.2.2 PSet PG/PC interface

This step is required for the following software:

⇒ SIMATIC Step© 7 Manager (v5.2 + SP1)

⇒ Windows Control Center (WinCC) (v6.0)

⇒ Windows Control Center flexible 2004 (WinCC flexible) (v5.2.0.0)

⇒ ProTool/Pro (v6.0 + SP2)

⇒ Microwin 3.2

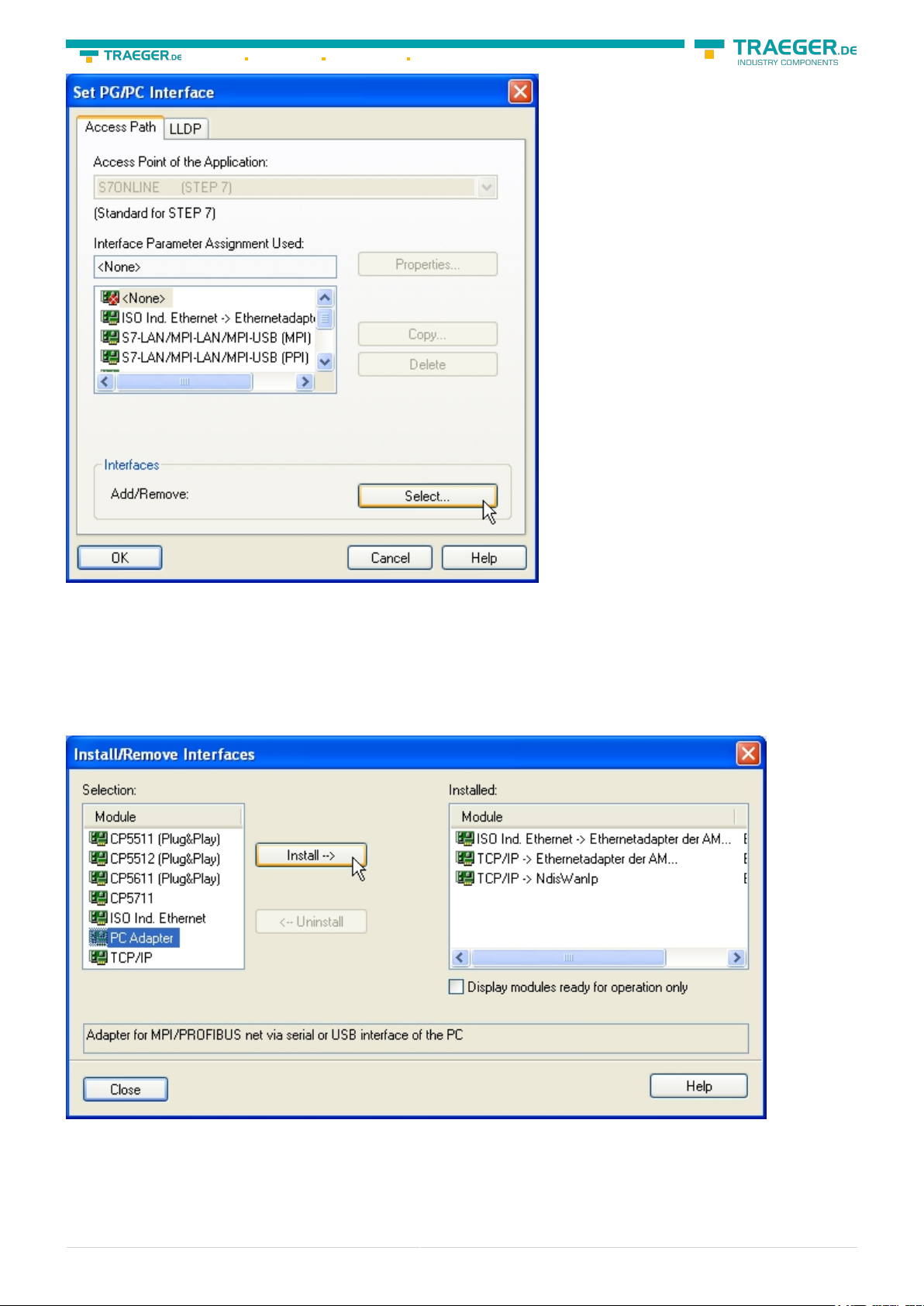

1. Open the system configuration by using the start menu. 2. Click on „Set PG/PC interface“.

S7-USB user manual 17 / 85 2019/10/05 05:07

Page 18

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

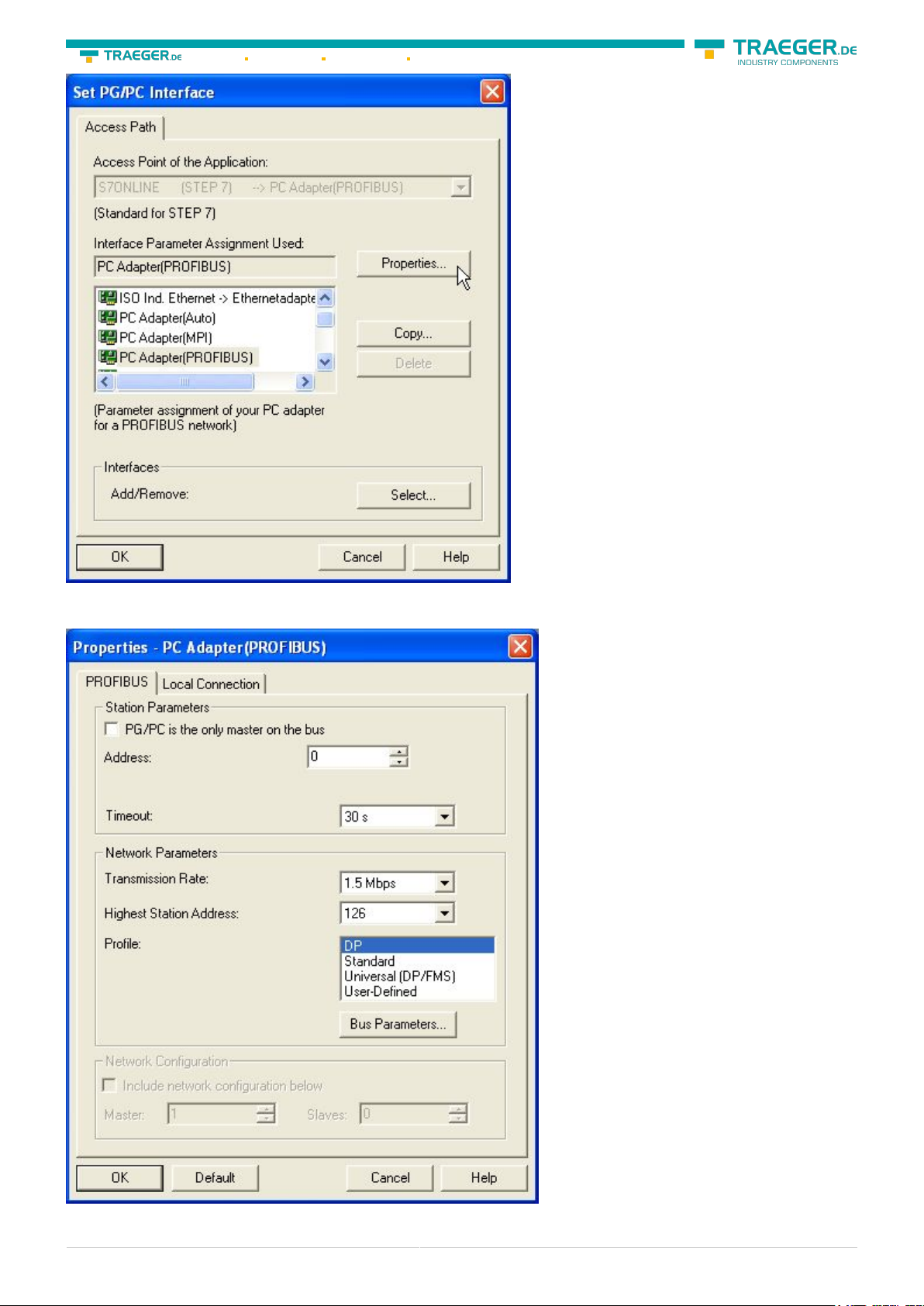

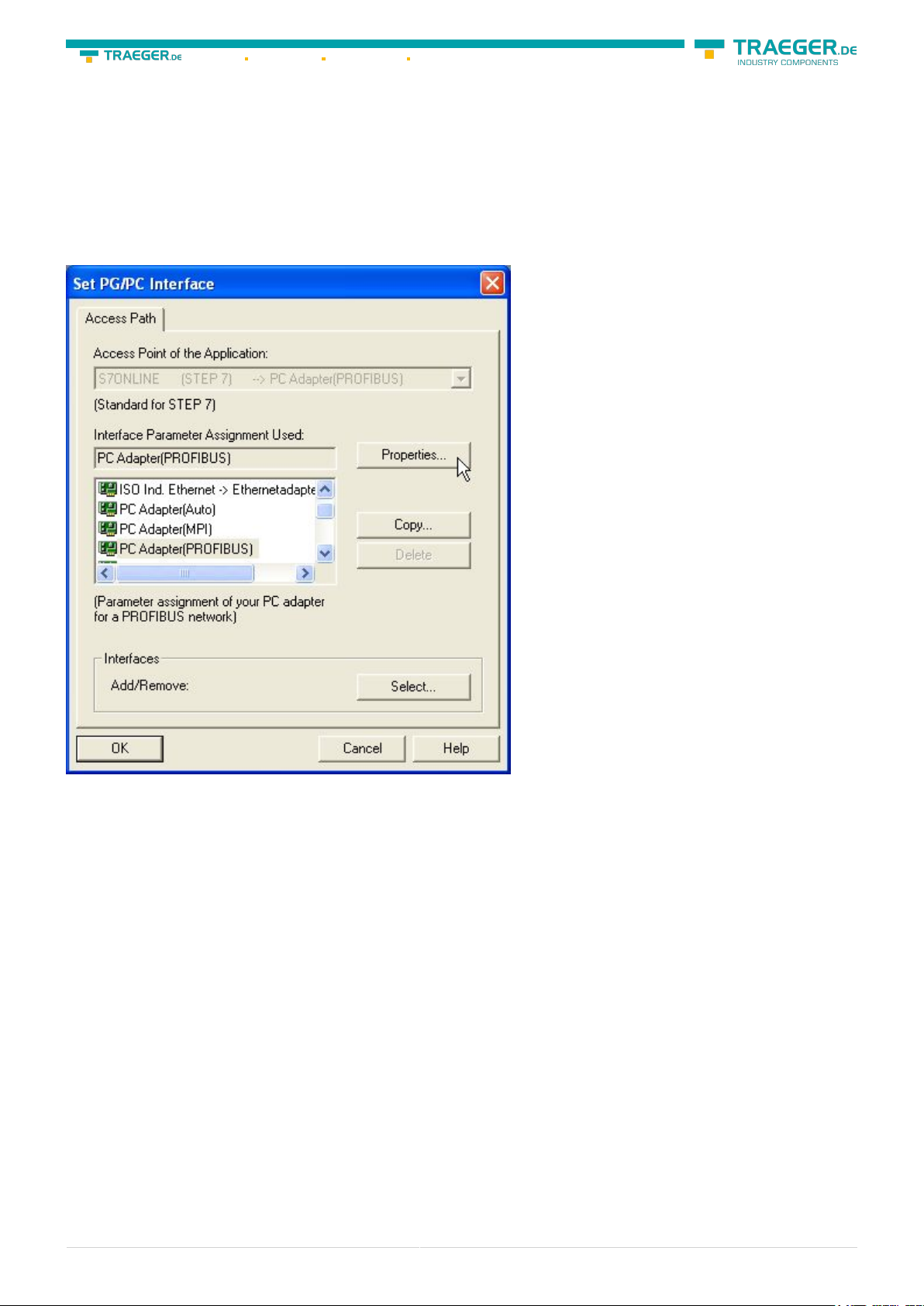

3. A Dialog with a list box named “Interface Parameter Assignment Used:” appears. This box should offer

some “PC - Adapter” entries If this is the case, please continue with the step MPI settings or Profibus

settings. If you can't find these entries go ahead with step PC-Adapter orTCP/IP installation.

6.2.2.1 PC-Adapter(Auto, MPI, PROFIBUS)

4. Click on „Choose“ to add these entries to the PG/PC interface configuration

\

5. In this dialog you can deinstall every installed construction set Furthermore you can add various

modules (see “Selection”) Choose „PC - Adapter“ from the „Selection“ box on the left side and click on

„Install“.

6. The chosen construction set will be installed and a question appears which asks you to use the “MPI“

S7-USB user manual 18 / 85 2019/10/05 05:07

Page 19

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

access for the PLC used. Click “Yes“ if you want to use the „MPI“communication type. Otherwise click

“No“(e.g. if you want to use the “PROFIBUS“ communication type).

6.2.2.2 TCP/IP RFC1006 Communication

7. Press “Select” to add the RFC1006 required elements to the PG / PC - interface configuration.

8. In the dialog “Select”, choose“ TCP / IP” and click on “Install”.

9. After successful installation, click “Close”.

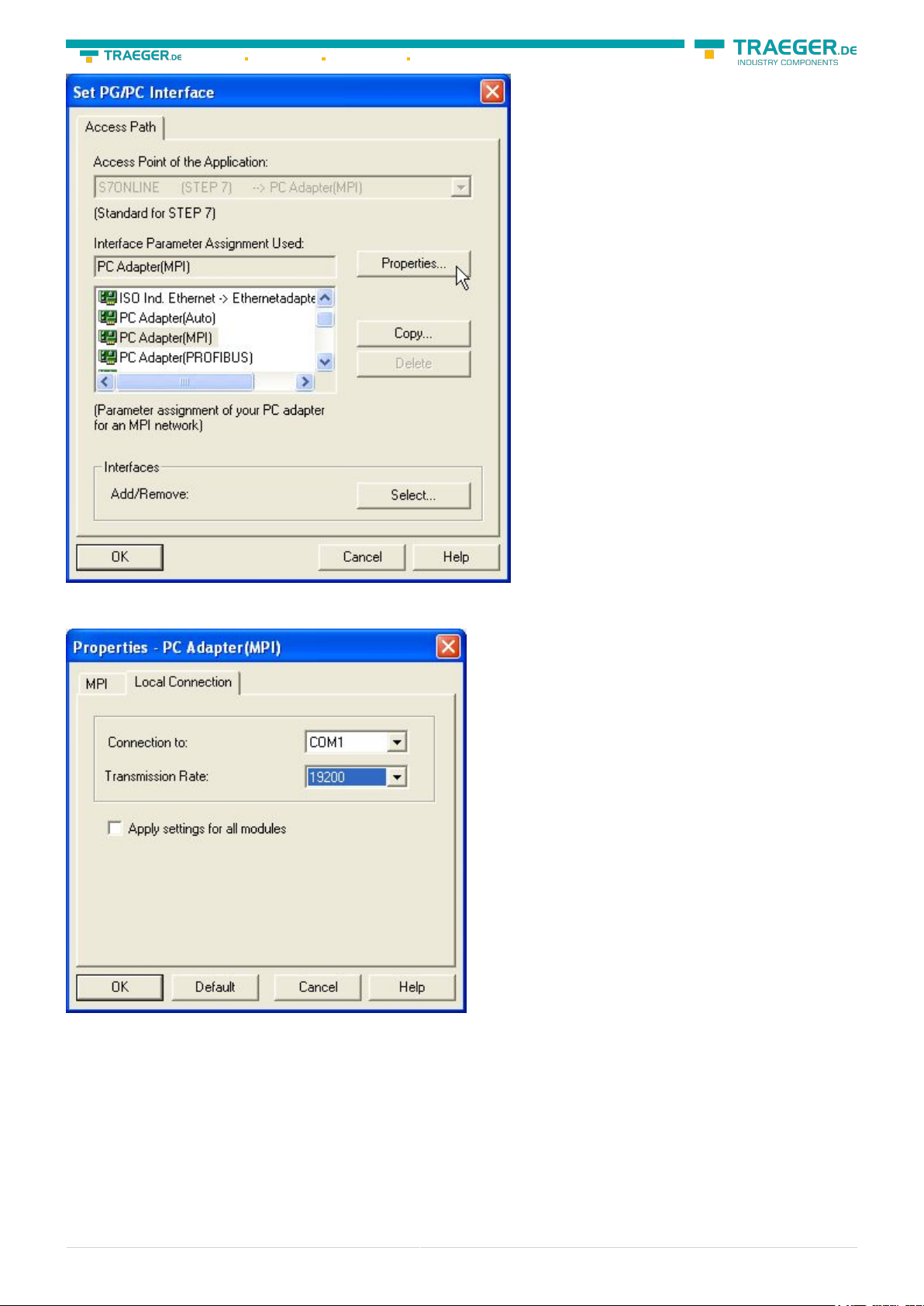

10. Back to the “Set PG/PC interface“ dialog you will now find the desired entries called “PC Adapter(Auto)“ (not supported), “PC - Adapter(MPI)“ and “PC - Adapter(PROFIBUS)“. Now you are able to

configure the bus. If you want to use the “MPI“communication type go ahead with step MPI setting . The

settings for “PROFIBUS” is explained in Profibus setting .

6.2.2.3 MPI setting

S7-USB user manual 19 / 85 2019/10/05 05:07

Page 20

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

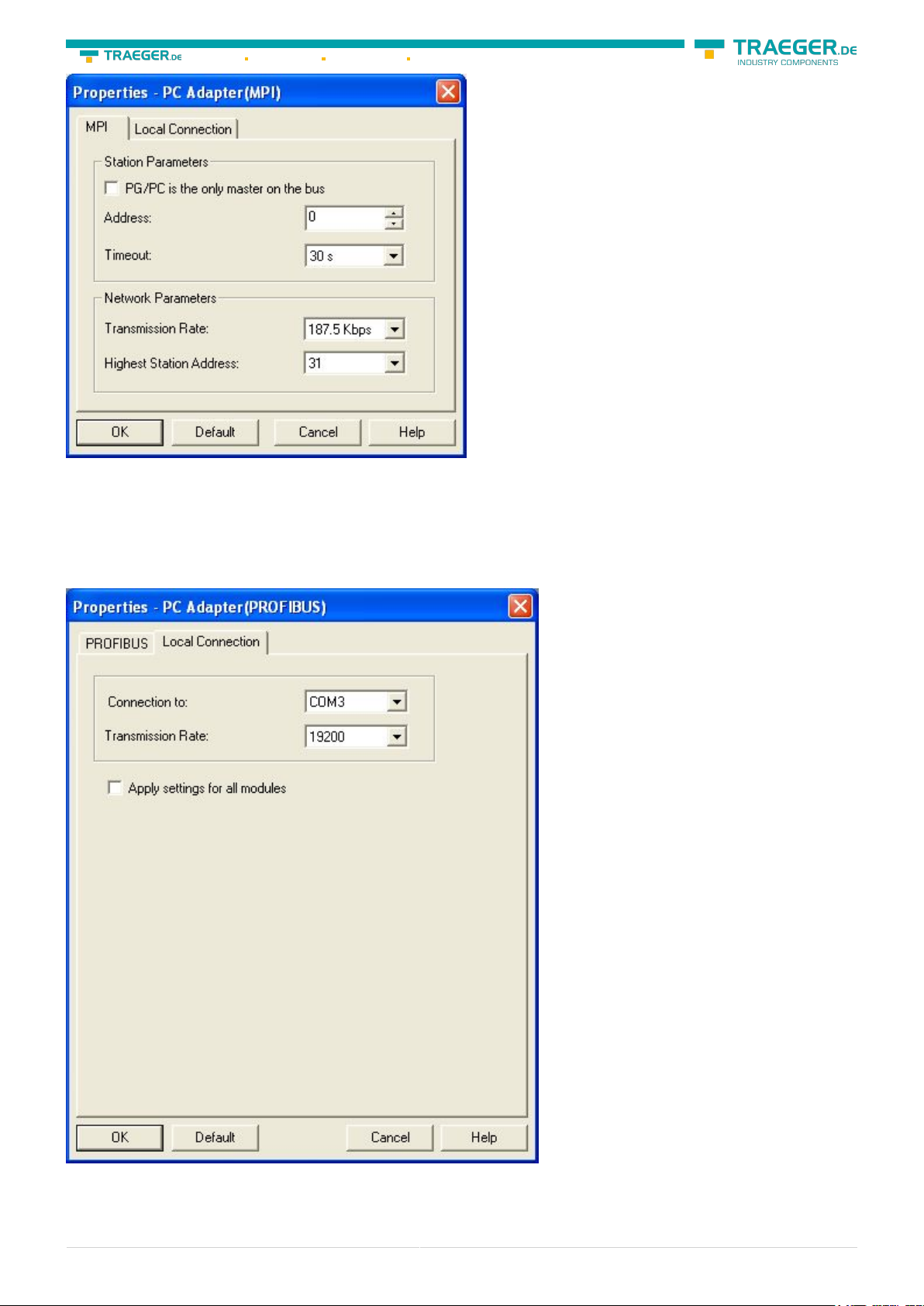

11. Select “PC Adapter (MPI)” and click “Properties”.

12. Open the properties dialog Choose the register “Local Connection”

13. Set here the COM port.

14. You also change the “transfer rate” to “19200”.

S7-USB user manual 20 / 85 2019/10/05 05:07

Page 21

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

15. In the register card “MPI“choose the “Transmission Rate” to “187,5 kbit/s“. Change the “Highest

Station Address” (HSA) to “126”.

16. Accept your settings with “OK” and exit the “PG / PC interface setting” dialog with “OK”.

6.2.2.4 Profibus setting

17. Mark the entry „PC - Adapter(PROFIBUS)“ and click on „Properties“.

S7-USB user manual 21 / 85 2019/10/05 05:07

Page 22

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

18. In the registry card “Locale connection” you have to set the COM Port. 19. Set the “Transmission Rate”

to “19200”

20. Choose the registry card “PROFIBUS” and set the “Transmission Rate” to “187,5kbit/s”.

S7-USB user manual 22 / 85 2019/10/05 05:07

Page 23

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

21. Set the “Profile“ to “DP“ (“decentralized Peripherals “).

22. Save your settings by clicking the “OK“button and close the opened “Set PG/PC - interface“dialog

6.2.2.5 TCP/IP RFC1006 setting

23. For this kind of communication you only have to install the corresponding software.

6.2.2.6 ProTool/Pro RunTime (RT) Configuration

24. If you want to use ProTool/Pro RunTime you can set the “PG/PC Interface” by selecting the entry

“DPSONLINE”. Therefore you have to select “Access Point of Application” and configure it as described

above. The easiest way is to use the S7-LAN/MPI-LAN/MPI-USB- driver which supports USB and LAN

products.

The interface configuration for these programs is finished.

Continue with the software which you want to use:

⇒ SIMATIC Step© 7 Manager (v5.2 + SP1)

⇒ Windows Control Center (WinCC) (v6.0)

⇒ Windows Control Center flexible 2004 (WinCC flexible) (v5.2.0.0)

⇒ ProTool/Pro (v6.0 + SP2)

⇒ Microwin 3.2

6.2.3 SIMATIC Step© 7 Manager (v5.2 + SP1)

Configure the interface as described in Set PD/PC-Interface.

S7-USB user manual 23 / 85 2019/10/05 05:07

Page 24

To use one of the other options please go ahead and read in the manual of WinCC software.

5. Please wait until the project is created. The project content will be shown in the left part of the main

window.

1. Click in the drop - down menu “target system” on “Display Accessible Nodes”.

2. If you can see the list with possible Bus-devices, a communication over the cable has taken place.

“Direct” connected devices will be shown, also the conditions if it is an “active” or “passive” assembly.

3. In this window you can edit each assembly with his blocks.

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

6.2.4 Windows Control Center (WinCC) (v6.0)

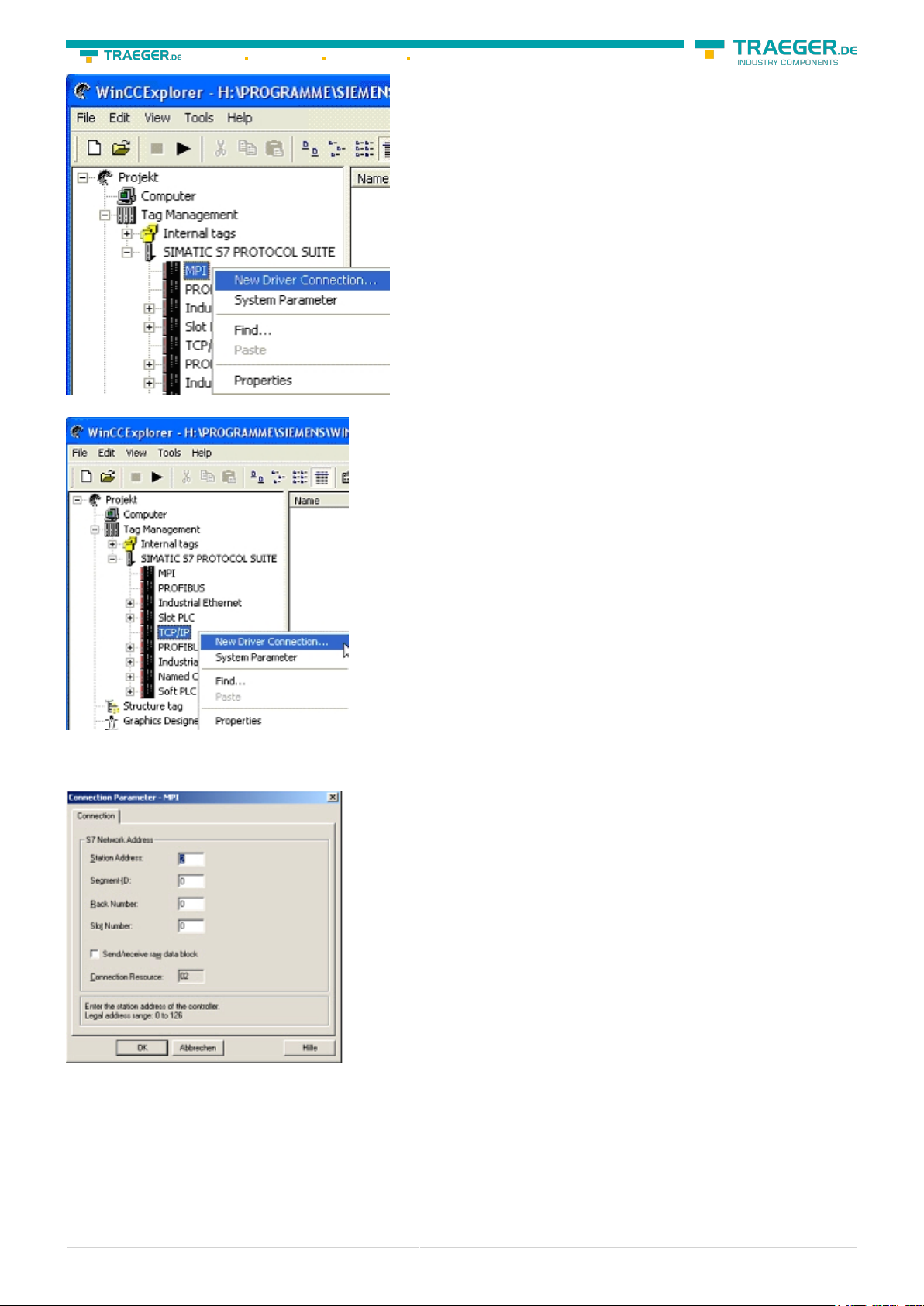

6. For a proper working communication with the PLC there must be defined how the software has to

Configure the interface as described in Set PD/PC-Interface.

communicate with the PLC Therefore you have to right-click on “Tag Management” it opens the context

1. Start WinCC by using the desktop link or the program entry in the start menu.

menu. Choose “New Driver Connection … “.

2. Choose „New” in the menu „File” or click on the white („letter”) symbol to start a new project.

7. In the „Add new driver“ dialog select the driver which fits to your PLC For a S7 PLC choose „SIMATIC S7

Protocol Suite.chn“. If you want to use an other PLC please inform yourself first, which driver fits with your

PLC.

It is very important that the selected driver fits with the PLC otherwise the connection cannot be

3. The next dialog offers you several project types “Single-User Project”, “Multi-User Project” and “Client

established..

Project”. The next steps are the describing for the “Single- User Project”.

8. You should see now in the Explorer under the branch “Tag Management” the branch “SIMATIC S7

PROTOCOL SUITE”. Expand the branch and many protocols for various compounds will appear. The General

way of proceeding a new connection is to: Right-click on the desired connection (MPI - > Picture: “MPI“,

TCP/IP - > Picture: “TCP/IP“). A context menu opens. Click on „New Driver Connection…”. This manual

describes the connection configurations for MPI and TCP/IP

MPI

4. “OK” leads you to a new dialog. Type in the “Project Name” and the “Subfolder” of the project path. The

chosen configuration is confirmed with “Create”.

S7-USB user manual 24 / 85 2019/10/05 05:07

Page 25

TCP/IP

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

6.2.4.1 MPI Configuration

9. Now you are able to type in the name of the connection. With a click on “Configuration“ a new dialog

will appear. Now you are able to set the properties of the connection. Set up the station address of the PLC

(in this example “2“). Confirm with “OK” until you are back to the main window. Read further

”Communication and fault diagnosis “ .

S7-USB user manual 25 / 85 2019/10/05 05:07

Page 26

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

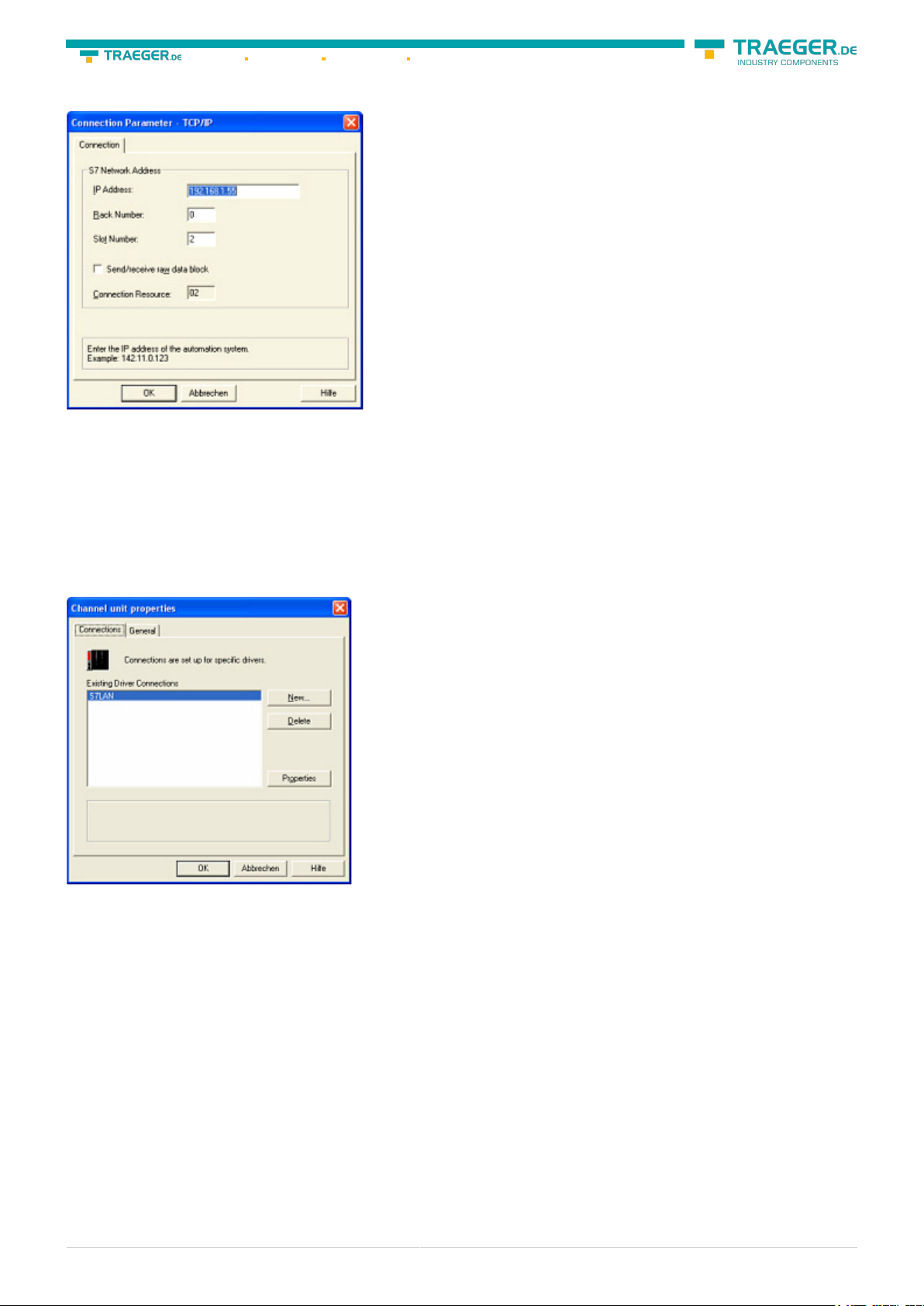

6.2.4.2 TCP/IP Configuration

10. A dialog appears where you can configure the connection parameters. Set up the IP - Address of the

module and configure the rack number as well as the slot number. Confirm this configuration by clicking

“OK”. Example configuration:

IP - address 192.168.1.55

Rack - Number: 0

Slot - Nr.: 2

11. With a right-click on the new connection you can start the properties dialog. In this dialog please click

on properties.

12. In this “Channel unit properties” you are able to see all “available connections”. Choose the latest

created connection and click again on „Properties”. Now you can see all the variables which has been

created for this connection. In fact this connection is a new connection so there should not be any variable

in the list. To add a new variable click on „New”.

13. Now you are able to set up the name of the variable and different more properties. In our example, we

assign the following values: Name: „S7LAN_MW0“

Data type : „unsigned 16 - Bit value“

Length: „2“

Address: „MW0“

Format adaptation: „WordToUnsignedWord“ Click on „Choose” beside the Address to define the address

from the variable.

Example configuration: The data area from the variable is set to „Mark“ and the address is set to „Word”.

The edit box „MW“ is set to „0”.

14. Confirm all open dialogs with „OK“ until you reach the main window.

15. The connection needs to know which network interface card it should be used to send data via the

S7-USB user manual 26 / 85 2019/10/05 05:07

Page 27

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Ethernet. Open the “System parameters“dialog from the context menu (right-click on TCP/IP).

16. Choose from the registry card „Unit“ and set the “logical device name“ to your network interface card

(usually the name of the NIC begins with a „TCP/IP - > „).

17. Confirm with „OK“.

18. Now you are able to start the communication. Stop it by clicking on .

6.2.4.3 Communication and fault diagnosis

To clean up errors faster the WinCC Software offers a tool named “Channel Diagnosis”. This tool analyses

all connections from your WinCC software. For demonstration purposes please stop the last started

connection from your WinCC explorer.

19. Start the software “Channel Diagnosis“ by using your link in the start menu.

20. The tool could not detect a running connection so it marked the connection/s with a red ‘X’ (registry

card “Channels/Connections“). Click on the last created, not active connection (with the red ‘X’) and some

informations from the connection will appear in the right part of the dialog. One of these counters is called

“Last Error Code“.

S7-USB user manual 27 / 85 2019/10/05 05:07

Page 28

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

21. If you take a right-click on the error value a window opens with “Help”. Click on the “Help” window and

a yellow window appears (tooltip) with detailed error descriptions.

22. Lets see what happens if the connection runs properly. Start the connection from your WinCC Explorer.

The “Channel Diagnosis“dialog marks the connection with a green hook if everything worked out.

6.2.5 Windows Control Center flexible 2004 (WinCC

flexible) (v5.2.0.0)

Please make sure that the interface configuration is correct as described in PD/PC-Set interface

1. Start the WinCC flexible 2004 software by using the desktop link or the program entry in the start menu.

2. First you need to select “Create an empty project” on your first page.

S7-USB user manual 28 / 85 2019/10/05 05:07

Page 29

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

3. In the “Device selection“mark the used operator panel (example: “TP 170A“) confirm with “OK“.

4. After the project has been created right-click in the project window on “Connections“of the sub menu

“Communication“. In the context menu click on “Add Connection“.

5. A new configuration window “Connections” opens in the right part of the main window. This offers you

different setting options. Important for the connection is:

⇒ the communication driver (set up which PLC you are using (example: “SIMATIC S7 300/400“))

⇒ the Baud rate (Set this on “187 500”)

⇒ the address of the terminal (HMI) (in this example “1“)

⇒ the Profile (“MPI“ for example)

⇒ the Highest Station Address (HSA) (e.g. “126“)

⇒ the address of the PLC (e.g. “2“)

S7-USB user manual 29 / 85 2019/10/05 05:07

Page 30

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

6. Now you can start with your work. If you have finished work you can transfer this project to the panel by

reading the next steps.

7. Choose „Transfer Settings“ from the sub menu „Transfer”.

8. In the new dialog change the „Mode“ to „MPI/DP“ and set the „Station address“ of the operator panel

(e.g. „1“). If desired you can switch the „Delta transfer“ to „On” (in this example we set it „Off”).

9. Press the button „Transfer“ to start communication with the terminal. Your project is about to be

transferred. The WinCC flexible software is now able to communicate with your operator panel.

6.2.6 ProTool/Pro v6.0 SP2

Please be sure that the interface configuration is correct as described in PD/PC-set interface

1. Start ProTool/Pro by using the desktop link or program entry in the start menu.

2. Choose from the menu „File“ the sub menu „New“ or click on the right symbol.

3. The next dialog let you select which operator panel you are using. Mark the used panel (e.g. „TP 170A“)

S7-USB user manual 30 / 85 2019/10/05 05:07

Page 31

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

4. „Next“ leads you to a new dialog. Type in the specific fields the name of the PLC device and choose the

used PLC in the driver selection (e.g. „SIMATIC S7 – 300/400 V6.0“).

5. Via „Parameter…“ you are calling an configuration dialog from the chosen PLC driver Set up the station

address of the panel (example „1“) and of the PLC (example „2“). Leave the point “Interface” in the

standard configuration. In the sector „Net parameter“ choose the interface which uses your module on the

PLC (e.g. „MPI“). Configure the baud rate to „187.5“.

6. The button „More …“ leads you to a small dialog where the „Highest Station Address“ should be

configured to „126“. Set up the „Number of masters“ (e.g. „1“)

7. confirm with „OK“ until you got back to the „Control Selection“.Go on with „Next“. 8. In the main window

start the Transfer Settings dialog by clicking on „File“ „Transfer“ „Settings…“. Choose „MPI / PROFIBUS DP“

from the listbox and type in the station address of the operator panel (e.g. „1“). Confirm with „OK“. and

start with your work If you have finished working on this project you can go on with the next steps.

S7-USB user manual 31 / 85 2019/10/05 05:07

Page 32

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

9. If you want to transfer you project to the panel you have to generate the project first. This can be done

with a click on „File“ -„Compile“.

10. To transfer the project just click on „File“ „Download“ „Start Project Download“ or click on the right

symbol .

Please wait while the project is transferred. The communication between the operator panel is now

established.

6.2.7 Microwin v3.2 (only for S7 200)

Please be sure that the interface configuration is correct as described in PD/PC-set interface

1. Start Microwin using the desktop link or program entry in the Start menu.

2. Click on „Type“ in the menu „PLC

S7-USB user manual 32 / 85 2019/10/05 05:07

Page 33

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Configure the „PLC Type“ (e.g. „CPU 224“) as well as the „CPU Version“ (e.g. „01.22”) to the dialog.

3. Click on „Communications…” to start the next dialog. In the sector „Address” set up the „Remote”

listbox with the station address of the PLC (e.g. „2”).

If you skipped the point b („ PD/PC-set interface“) you can configure the PG/PC interface with a click on

„Set PG/PC interface“.

4. In the right part of the dialog double click on the blue arrow symbol to test the communication with

S7-USB user manual 33 / 85 2019/10/05 05:07

Page 34

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

the PLC.

5. The sector „Address“ should be updated and displays the „PLC Type”. Also the CPU of the PLC is

displayed in the right part of the dialog.

6. Confirm with „OK“ until you get back to the main window. The communication with the PLC ist now

established.

6.2.8 Microwin v4.0 in PPI-Multimaster-Mode

1. The PPI-Multimaster-Mode was developed that more devices can communicate parallel with one PLC.

The following steps describe how to configure this mode in hardware and software.

2. The module or cable has to switched in the PPIMulti-Mode. This mode can be switched in the menu-tree

under „Generally“ and „Bootconfiguration“

3. There you have to select „PPIMMaster“ and confirmed with „Saving“.

For LAN-devices you can do this in the integrated WebServer, also.

4. Now, you have to configure the PG/PC - Interface. This could you also do within the Microwin-Software.

5. Start your Microwin-Software.

6. Click on the button „Set PG/PC-Interface“ under „View“ in the left down part of the window.

7. Select the entry „PC/PPI cable(PPI)“ and click on the button „Properties“.

S7-USB user manual 34 / 85 2019/10/05 05:07

Page 35

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

8. In the menu „PPI“ you are able to configure diverse settings like for e.g. “HSA“.

S7-USB user manual 35 / 85 2019/10/05 05:07

Page 36

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

9. In the menu “Local Connection“ you select the com-port “Interface to“ to the port which is served from

the tool PLCVCom. 10. Click on the button “OK“ and click in the left down area in your windows on

„Communikations“.

11. Click double on “Double-Click to refresh“. The PLCs would be searched.

S7-USB user manual 36 / 85 2019/10/05 05:07

Page 37

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

12. When the PLC was found, the picture changes it like this:

13. Prove the dialog with „OK“ until you would be in the main window. The communication to the PLC is

now ready.

6.2.9 S7 for Windows v5.02

1. Start the „S7 for Windows” software by using the link on your desktop or use the link in your start menu

(standard is „Programs\S7 for Windows\S7 for Windows“)

S7-USB user manual 37 / 85 2019/10/05 05:07

Page 38

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

2. Choose File - >Preferences… to configure the communication configuration between the computer and

the PLC. A new dialog appears which provides to set up a lot of configuration data about the

communication with your PLC.

3. Choose the first registry card „Interface“ (standard) and set up the configuration data as described

below:

⇒ Area: „Preferences from:“ ⇒PC

⇒ Area: „PLC Type:“ ⇒ S7

⇒ Area: „Protocol:“ ⇒ MPI - Umsetzer

⇒ Area: „Serial Port:“

⇒ Choose the virtual COM port which has been created by PLC - VCom (e.g. „COM 4”).

⇒ Area: „Baud Rate“ ⇒ Choose the speed you want to use at the bus (e.g. „115200“)

⇒ Area: „MPI Converter:“ - Activate the checkbox „Only Master at the Bus“ if you have only one PLC in the

bus.

- Leave the fields „ S7W MPI Address“ and „MPI Address PLC“ as it is.

S7-USB user manual 38 / 85 2019/10/05 05:07

Page 39

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

- The number in the listbox „Max MPI Address“ must be higher than the PLC with the highest station

address in your MPI bus. Otherwise every PLC which is higher than this number will not been seen (e.g. if

there is only one PLC in your bus „15“ is more than enough).

4. After the software is configured , please click „Select PLC” in the area „MPI Converter“. A new dialog

appears where you can select the desired PLC

5. The dialog displays all the PLCs that can be found in your MPI bus. Select the desired one and confirm

with „OK”.

6. Close the preferences dialog by pressing the „OK“ button.

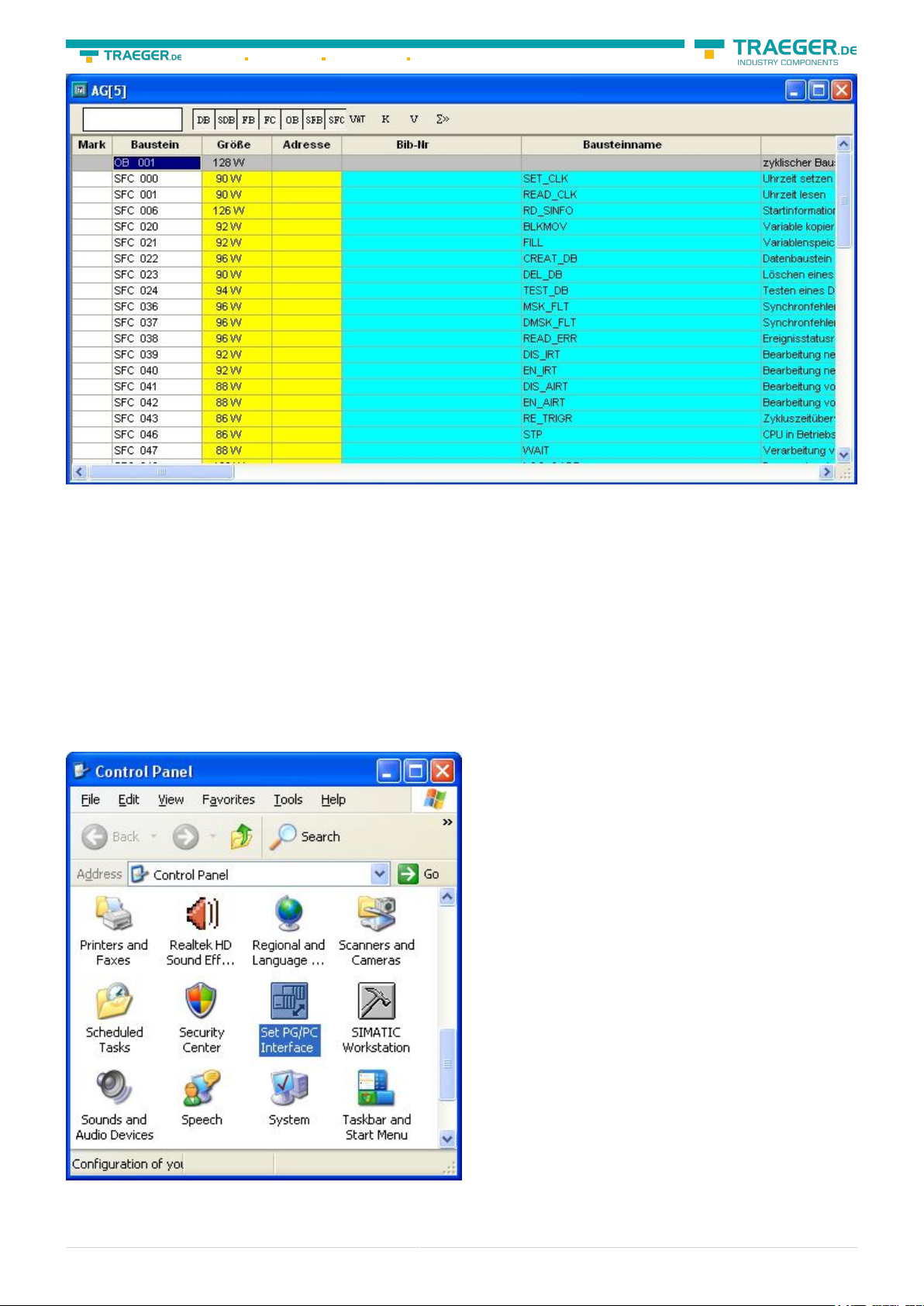

7. Back in the main window press the „PC Block List“ button for testing the new established

communication configuration.

8. Please wait a moment for the software to read the desired blocks from the PLC. The blocks will be

displayed in the listbox below the menu bar (see picture to the right).

S7-USB user manual 39 / 85 2019/10/05 05:07

Page 40

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

The communication between the software and your PLC is established.

6.2.10 Direct setting of a slave address to a passive

Profibus-Slave

With the S7-LAN-module or MPI-LAN-cable and Step7-direct-driver V1.21 (or later) and the MPI-II-cable

(only with USB) or S7-USB and Step7-direct-driver V1.22 (or later) is it possible to give a directly connected

Profibus-Slave a bus-address.

Important here is that the subscriber is connected directly to the S7-interface and the external supply of

24V DC is also connected. In the Step7-direct-driver must then in the properties set that “PD/PC is only

master”. There is no another note in this case, you will use this function as if you are connected with your

PD to the module.

7 S7-Interface Configurator Help

Language selection

User interface

Bus configuration

Network settings

Parameterize TELEService

Index "Network"

Index "Modem"

Index "Serial Parameter"

Index "Access Protection"

Index "GSM/ISDN/SMS"

Index "Internet/Mail"

S7-USB user manual 40 / 85 2019/10/05 05:07

Page 41

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Tuning

Factory defaults

PPI Boot off

Emergency-Loader

7.1 Language selection:

Select the menu Configuration to change the language permanently:

7.2 User interface:

Select near Search which interfaces are searched permanently for devices.

You could choose:

• Serial All existing COM-Ports are scanned for devices

• USB Search devices which are connected by USB

• LAN Search devices on all network-cards

The button Search starts a parallel search on all selected interfaces.

After selecting a updateable device the button Update gets available.

Below the buttons is a list of the found devices. In each line an image, the type of the device, name (if

existing), interface, serial number (if possible) and the OS-version of the device is displayed. On the

rightmost position the actual OS-version on the harddisk is displayed.

The background of the lines could use the following colours:

• White The OS of the device is up-to-date

S7-USB user manual 41 / 85 2019/10/05 05:07

Page 42

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

• Light blue The OS of the device is not up-to-date, the device could be updated

• Red An error occured by accessing the device

• Yellow Update is in progress for this device

• Dark blue Selected device

Double click onto a device which could be updated shows the version-documentation of the device (only

available in German):

The button Update with FD updates the OS of the device and sets the factory default.

The button Bootstrap sets the firmware/configuration to factory default.

The button Factory defaults sets the configuration to factory default.

The button Parametrize activates a dialog regarding to the device:

Overview:

Device Dialog

TELEService

MPI / PPI - Profibusmodem

Parametrize TELEService

MPI/PPI Parametrize TELEService

MPI-II

MPI-USB

Choices:

Bus configuration

Parametrize TELEService

S7-USB Bus configuration

S7-LAN

MPI-LAN

Choices:

Bus configuration

Network settings

The button PPI Boot off disables the PPI boot option of a serial connected device.

The button Emergency-Loader tries to repair LAN products which are in emergency-loader mode.

The button Tuning activates a dialog for special parameters.

The button Exit leaves the application.

S7-USB user manual 42 / 85 2019/10/05 05:07

Page 43

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

7.3 Bus configuration

To Parametrize the connection to the device, select a device and click “Parametrize”.

Regarding to the device you maybe have to click on the button Bus configuration (see Parametrize

table).

Here you can Parametrize the following:

Use bus config for PC Tooks the bus configuration from the PC

Baud rate chooses the Baudrate for the cable to bus communication

The highest station-address in the bus

Highest station address

PD/PC is the only master on

the bus

Profile Bustype of the connection

Local client address

Protocol type Protocol type of the connection

Boot settings Boot setting of the connection

(the less you use, the more performance on the MPI-bus,

must be corresponding with the configuration in the CPU’s)

The TS-Adapter is the one and only master in the MPI-bus

(adapter hast to speak to all passive clients)

Which local station-address is used for the TS-Adapter.

Please consider that a programming device has normally the number 0,

operator panel have 1, CPU’s use 2, FM/CP’s 3 etc.

Please: Never use the same station-number for 2 different stations!

7.4 Network settings

Here you can set the network configuration of the selected device:

S7-USB user manual 43 / 85 2019/10/05 05:07

Page 44

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

• Factory default This button sets all over the network reachable devices to factory default.

• DHCP-client active When set the device acts as DHCP-client.

• IP address

• Subnetmask Here you could enter the Subnetmask of your network.

• Gateway address Here you could enter the IP address of your Gateway. Usual a router address.

• Device name Here you could change the device name.

Factory default:

• DHCP-client active not set

• IP Address 192.168.1.56

• Subnetmask 255.255.255.0

• Gateway address 0.0.0.0

• Device name empty

Here you could enter the IP Address over which the device is accessed in the

network.

7.5 Parametrize TELEService

To Parametrize the device, first click on the device, after that on “Parametrize”.

S7-USB user manual 44 / 85 2019/10/05 05:07

Page 45

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Regarding to the device, you maybe have to click on the TELEService button.

After clicking on “TELEService” a message will show up:

Depending on the version of your TELEService software choose Yes or No.

The regular parameters can be changed manually in the following categories:

7.5.1 Index "Network":

Here you can configure following:

S7-USB user manual 45 / 85 2019/10/05 05:07

Page 46

Station related:

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

PD/PC is the only master on

the bus

Address

Network related:

Network type The network type MPI or PROFIBUS

Transmission rate The transmission speed on the MPI bus

Current transfer rate Shows the current transfer rate of the device

The highest station address in the bus

Highest station address

(the less you use, the more performance on the MPI bus, must be

corresponding with the configuration in the PLC’s)

The TS-Adapter is the only master on the MPI-bus

(adapter must speak to all passive clients)

Which local station-address is used for the TS-Adapter.

Please consider that a programming device has normally the number 0,

operator panel have 1, CPU’s use 2, FM/CP’s 3 etc.

Remind: Never use the same station-number for 2 different stations!

7.5.2 Index "Modem":

In this dialog you could configure the modem related setup.

Modem Settings:

The initialization string consists of several commands to the modem:

AT ⇒ start command

&F ⇒ use factory settings

E0 ⇒ echo off

Initialization

Hang up

Location:

S7-USB user manual 46 / 85 2019/10/05 05:07

L1 ⇒ volume of speaker is low

M1 ⇒ speaker is on at connection

Q0 ⇒ output of the return values

V1 ⇒ return values plain text

&C1 ⇒ DCD shows status of the carrier sound

S0=1 ⇒ automatic connection after 1 ring

The deselection text is made up of 2 parts:

+++ ⇒ Switch to command mode

AT ⇒ start command

H ⇒ Hang up connection

Page 47

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Dialing method

Official number

To access an outside

line, first dial

Call Preferences:

There are two possible call techniques:

MFV tone, the telephone number is transferred by several frequencies

IWV pulse, the telephone number is transferred with the amount of several

pulses on the line

If you need a prefix before your number to establish a call outside, you must

enter the prefix here e.g. 0.

Wait for dial tone before

dialing

Number of redial

attempts

Redial after

In case the modem should wait for a free line, you should set the

corresponding checkbox.

At number of retries you could configure the number of retries for a

connection before the call is stopped.

Using a retry you could enter the seconds the application should wait

between calls.

7.5.3 Index "Serial parameter":

In this dialog the transfer rate between modem and TS-Adapter is selected.

Connection Preferences:

Transfer rate

Parity

The transfer-rate could be selected between the following values:

2400, 4800, 9600, 19.2k, 38.4k, 57.6k and 115.2kBaud

The parity could be selected, but this is modem depended because some modems could

not handle the parity bit:

None: (There is no parity testing)

Odd: (The amount of bits set to 1 is odd)

Even: (The amount of bits set to 1 is even)

7.5.4 Index "Access Protection":

The access over a telephone line could be configured in this dialog.

Access Protection:

The administrator can change the configuration over a telephone line. The two user accounts can not

change the configuration.

S7-USB user manual 47 / 85 2019/10/05 05:07

Page 48

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

The username is maximal 8 characters long. Every user and the administrator should use a password

which is used to login in the TELEService over a telephone-line.

After three failed retries the connection is hanged up, so you must call again (not like the original TSadapter).

After changing the password for a user/administrator you must re-type it again correctly.

You can enter a callback number which is used for a callback from the TS-adapter. After you dialed the

number of the TS-adapter, you are asked for username and password. In case the username and password

is valid, the connection is hang up and the TS-adapter calls back the configured callback number.

7.5.5 Index "GSM/ISDN/SMS":

Information about the three different devices:

Analog Modem:

Type You could choose the location of the modem.

ISDN Modem:

Type Choose the type of the ISDN network:

AT&T 5ESS Nothern Telecom DMS-100 EuroISDN NET3 (Standard) INS64 US NI-1 VN4 Protocol Choose the

transfer protocol type:

Modem like V.120 X.75 (Standard) ML-PPP SoftBonding HDLC CLEAR MSN Multiple Subscriber Number is

used for all ISDN channels. If empty no MSN is used.

GSM Modem:

S7-USB user manual 48 / 85 2019/10/05 05:07

Page 49

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

PIN PIN number of the SIM card, up to eight numeric characters (only for TELE-SERVICE GSM).

With the button „Provider“ the provider could be chosen. Read the list of providers could be

elapse more than a minute. In the end the possible provider are listed for selection.

With „Automatic“ the GSM-Modem tries to connect automatically to a provider. On the right side

of the button, the actual used selection is displayed.

Display Description:

Provider

Automatic: The provider is automatically searched and selected from the GSM-modem.

Manual: The Provider is selected manually from the GSM-Modem

no network registered: No connection to the GSM-network, the receive-quality is too bad set

format: The format of the provider is set

Manual/automatic: The modem tries to select manually the provider, if this fails an automatic

search is done

unknown: Unknown response from GSM-Modem

The button „Refresh“ reads the signal strength from the modem, the quality is displayed.

Display Description:

Unknown: Unknown state of the GSM-network

no registration: The modem is not registered in the GSM network, no provider found

registration denied: Registration in the GSM-network is denied

Search network: In Search for a GSM-Provider

GSM: Attached to GSM

GSM(ROAMING): Attached to GSM, but with a Roaming-Partner. This could lead to high costs!

Refresh

The radio quality is displayed, together with the bit-error-rate.

Value Description:

99 No network, no receive

00 Very, very bad receive-quality

01 Very bad receive-quality

02 to 09 Bad receive-quality

10 to 17 Medium receive-quality

18 to 25 Normal receive-quality

26 to 30 Good receive-quality

31 Best receive-quality

Information about the rest of the Index GSM/ISDN/SMS:

S7-USB user manual 49 / 85 2019/10/05 05:07

Page 50

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

SMS:

Switches:

NO SEND SMS RECEIVE SMS SEND+RECEIVE SMS DMTF CONFIRMATION SEND

SMS+DTMF CONFIRMATION RECEIVE SMS+DTMF CONFIRMATION

SEND+RECEIVE+DTMF CONFIRMATION SEND MAIL SEND MAIL+SEND SMS SEND

MAIL+RECEIVE SMS SEND MAIL+SEND+RECEIVE SMS SEND MAIL+DTMF

SMS

CONFIRMATION SEND MAIL+SEND SMS+DTMF CONFIRMATION SEND

MAIL+RECEIVE SMS+DTMF QUITTUNG SEND MAIL+SEND+RECEIVE+DTMF

CONFIRMATION

Attention: before setting ON check configuration, after activating the device

will go on the MPI bus and tries to connect to the defined PLC.

Receive of SMS only with TELEService-GSM Receive of DTMF only with

TELEService GSM

Bus address TS local station address (should not be used twice in the MPI/Profibus!)

Bus address CPU

Communication flag

word

Communication data

block

from this station address the flag word and data block is accessed for

communication

communication-flagword (the first byte is the command, the second is the

state). Use even operand-addresses.

Address of the CPU in the Bus

Configure the SMS-Provider to use, including type, phone-number and charcode.

Provider 0/1/2/3

First Input: Choose a type of the transmission.

Second Input: Telephone number or email address.

Third Input: Choose a character encoding.

NTP-Server Input for an Network Time Protocol - Server

Error analysis:

The possible error conditions for the modem, mpi bus problems or other problems are displayed in this

text-field.

First the modem-related information is shown:

Message

S7-USB user manual 50 / 85 2019/10/05 05:07

Page 51

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Modem ready

Modem error

No answer from modem

Modem detects ring

End of connection

connected via modem line

No dialtone detected

Phone-line or telephone busy

Phone-number is blacklisted in modem

Phone-number delayed

Access denied for 1 minute

Fax-call detected

Data-call detected

unknown error

The selected direct-access-number not configured

The configured PIN-Number is wrong for the inserted SIM-Card

The SIM-Card is not or wrong inserted or the SIM-Card is a 5V Type

Possible MPI-Bus error-messages

MPI/Profibus-Configuration erroneous

Timeout at MPI/Profibus detach from device

The local station-address is used twice in the MPI/Profibus

A20/M20/TC35 Modem operation

The MPI/Profibus is not correctly configured

The HSA is not configured optimal

The MPI/Profibus-Baudrate is not detectable

Overflow in the internal MPI-Readbuffer

Overflow in the internal LAN-Readbuffer

Overflow in the serial Buffer

The selected MPI/Profibus-Baudrate is wrong

Overflow in internal LAN-Writebuffer

LAN-Receive-Error

LAN-Send-Error

The PD-Number is wrong

The transferred SAP is wrong/unknown

ErrCode 01: The Destination address (XXX) of a State protocol > 127 detected. In the MPI/ProfibusBus there are no stations possible which station number is greater than 127. (FC=YYh)

ErrCode 02: At state-protocol the Source-Address is detected as 127. This is the Broadcast-address

which is not possible.

ErrCode 03: The received State protocols destination address (XXX respectively YYY) does not exist

in the MPI-Bus. (FC=ZZh)

ErrCode 04: The function-code (YYh) of the received State protocol from XXX is incorrect. The 7th Bit

is High, but according to the specification the Bit has to be low.

ErrCode 05: A State protocol has been received. But the function-code (YYh) means that the

participant is not ready to enter the bus.

ErrCode 06: The function-code in the State-protocol received from XXX is unknown (FC=YYh)

ErrCode 11: The sender (XXX) of the received data-protocol is unknown. To send data the participant

must get the Token. (SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 12: Data-protocol with Source-address 255 (Broadcast) is useless. (CPU=XXX, SSAP=YYh,

S7-USB user manual 51 / 85 2019/10/05 05:07

Page 52

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

FC=ZZh, length=UUU)

ErrCode 13: The sender (XXX) of the received data-protocol is unknown. To send data the participant

must get the Token. (SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 14: The 7th Bit of the function-code is High, but according to the specification the Bit has to

be low. (CPU=XXX, SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 15: The upper 4 Bit of the Function-code are wrong/unknown) (CPU=XXX, SSAP=YYh,

FC=ZZh, length=UUU)

ErrCode 16: Unknown function-code has been transmitted to the cable. (CPU=XXX, SSAP=YYh,

FC=ZZh, length=UUU)

ErrCode 17: Destination-SAP are defined till 3Fh in data-protocols. (CPU=XXX, SSAP=YYh, FC=ZZh,

length=UUU)

ErrCode 18: Source-SAP are defined till 3Fh in data-protocols. (CPU=XXX, SSAP=YYh, FC=ZZh,

length=UUU)

ErrCode 19: Received a data-protocol with destination-SAP=0, Connection request from another busparticipant with our cable. (CPU=XXX,SSAP=YYh,FC=ZZh,DSAP=UUh)

ErrCode 1A: Participants are sending data to our cable with source-SAP = 0, which means that the

participant has not made a connection establishment or has lost the negotiated SAP.

(CPU=XXX,SSAP=YYh,FC=ZZh,DSAP=UUh)

ErrCode 1B: Data-protocol with unknown data-function-code received.

(CPU=XXX,SSAP=YYh,FC=ZZh,DFC=UUh)

ErrCode 1C: Data-protocol with unknown data-function-code received.

(CPU=XXX,SSAP=YYh,FC=ZZh,DFC=UUh)

ErrCode 1D: Received a state-protocol with error-code. (CPU=XXX,FPGA=YYh,RAM=ZZh)

ErrCode 1E: FPGA has caused an interrupt although no data present.

(SD1=XXh,SD1=YYh,CPU=ZZZ,FC=UUh)

ErrCode 20: Unknown protocol at PPIMultimaster-Mode. (FC=XXh,Length=YYY)

ErrCode 21: Unknown baud-rate at PPIMultimaster-Mode. (Baudrate=XXh)

After that additional hints are displayed.

7.5.6 Index "Internet/Mail":

The internet connection is configured by PPP, often a username and password is needed. Define them in

“Internet access over PPP”.

Attention: This is NOT the username and password of your E-Mail-account!

In the next section “Mail” the E-Mail-account is defined:

Internet access over PPP:

Username Username for the Internet access

Password Userpassword for the Internet access

S7-USB user manual 52 / 85 2019/10/05 05:07

Page 53

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Mail:

Server

Mail from

Username

Password Password for the E-Mail-Account

Source-E-Mail-Address

(should be from the same Free-mailer, instead a delivery is often not possible)

Name of the User-account

(often the E-Mail-address or Customer-number)

7.6 Tuning

This menu is only used in some special cases.

Select the device and click the button “Tuning” and after that the following dialog is displayed:

The following configuration is possible, it will be transferred to the Cable by pressing the button „OK“.

The configuration is saved permanently in the Flash-ROM:

At ProTool RT the communication could break down, because the MPI-Cable is

Delay before send

S7-USB user manual 53 / 85 2019/10/05 05:07

transferring the answer-protocol to fast. In this case you could insert a time in

0.1ms ticks. Insert at first 300, to great values are preventing the

communication.

Page 54

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Some Touch-panels has the problem, that when they get a wrong version-

HMI-Cable version

A20-Terminal

Show ErrCode

messages in display

Boot settings:

Normally the MPI-Cable automatically selects the correct bus type, no changes are needed. In specialcases the MPI-Bus could be selected as PPI.

For example: This application and the PLC are powered on at the same time. The application is

communicating immediately with the cable, the PLC is booting, in this case the MPI-Bus is not running. The

MPI-Bus is erroneous, so no communication is starting. If this occurs you could choose, that the cable is

working as MPI-Adapter only.

Language:

You could select the language which is used on the cable (German or English).

S5 on MPI mode off:

Deactivates temporary the “S5 on MPI” function, the cable doesn't poll the bus anymore.

information they never retry to connect (and then the correct version is

transferred). In this case the HMI-version-information could be transferred

immediately.

Shows error messages on the display of the connected device

send reset to cable:

Send reset to cable.

Console:

Shows some information about the status of the connection.

7.7 Factory defaults

This button sets the configuration of the selected device to factory defaults.

7.8 PPI Boot off

In PPI boot mode S7IFC cannot communicate with the cable. To disable the PPI boot mode, click on the

button PPI Boot off. In the following dialog you must select the serial port where the cable is connected:

S7-USB user manual 54 / 85 2019/10/05 05:07

Page 55

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

7.9 Emergency-Loader

LAN products running in emergency-loader are automatically found by S7IFC:

After a click on Emergency-

Loader the following dialog appears:

S7-USB user manual 55 / 85 2019/10/05 05:07

Page 56

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

On a click on Yes the emergencyloader tries to run the main program of the firmware.

On a click on No the emergency-loader tries to rewrite the complete firmware.

8 MPI cable manager

8.1 Description

The MPI cable manager allows you to install an update in your cables and modules and configure them.

The MPI cable manager can be used for the following products:

• MPI-LAN cable– Art. ID. 9352-LAN

• S7-LAN module– Art. ID. 9352-LANCon

• MPI-USB cable– Art. ID. 9352-USB

• S7-USB module– Art. ID. 9352-S7-USB

• MPI-II cable (USB – operation) – Art. ID. 9352 + 9352.1

• MPI/PPI cable– Art. ID. 9350

• Tele-Service – Art. ID. 9377-(ANALOG/ISDN/GSM)-OP

• MPI/PPI-profibusmodem – Art. ID. 9379-(G)-OP

8.2 Installation

1. Download the MPI-Kabelmanager from the product-page of your MPI-product and start the installation.

S7-USB user manual 56 / 85 2019/10/05 05:07

Page 57

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

2.Following the Language selection the installation starts and a welcome-screen is displayed. Next click

onto the button „Next“. To change the installation path, click on “Browse”. Then click “Continue”.

3. Select in this dialog the program folder for the MPI cable manager startup items. Then click “Continue”.

S7-USB user manual 57 / 85 2019/10/05 05:07

Page 58

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

4. Wait for the installation of the files. 5. End the installation after a successful copy of data with “Finish”.

8.3 Overview

8.3.1 Language

After

starting the application the tab Language is displayed at first:

S7-USB user manual 58 / 85 2019/10/05 05:07

Page 59

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

In this Dialog you could choose the used language in the application.

You could choose between German and English and confirm by clicking on the desired language.

8.3.2 Interface

In „set interface“ you can choose the COM-port you device is connected at. Only the COM-port which was

aktive at starting the MPI-Kabel-Manager are shown.

„Search“ update the COM-port listed in „set interface“ and put the Kabelmanager to the respective COMport.

For access query choose „Direct“ if your product connects via USB-cable or Nullmodem-cable. „Modem“ if

your product connects via telephone line or „TELE-Network“ if your product connects with a TELE-Network

device via telephone line. The bars below shows at which COM-port something was found or not.

8.3.3 Update

S7-USB user manual 59 / 85 2019/10/05 05:07

Page 60

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

The diskette show the current operating system installed on your PC for corresponding product.

The cabel-symbol on the right show the operating system which is installed on your product at the

moment.

With the button „default settings“ you can set your products on default settings. Should the device be out

of order after configurated. This button is selectable after the version check.

With „Update“ you can install the current operating system. This button also is selectable after version

check.

With „version check“ your cable which is connected to the COM-Port reviewed.

The symbol next to version check shows the running update.

While update do not plug out the cable from the PLC or turn off the power supply (The cable

will lost all data)!

If the update is breaking before finished, it could be that the MPI-Cable displays in the first line of the LCD

„Load 1.50“ and in the second line „CheckUpd“. Close the MPI-Cable-Manger and restart it. After “check

version” (which could time about 30 seconds) and following „Update“ the broken update is restarted and

finished.

8.3.4 Teleservice

In this dialog the spezific configuration of the Tele-Service is taken. There are 3 Tabs, where the last one is

activated:

S7-USB user manual 60 / 85 2019/10/05 05:07

Page 61

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

8.3.4.1 Telephone book

At the moment not implemented!

In this dialog you could define new elements or edit/erase existing elements in your telephone-book.

You could edit the following data:

⇒ Name for the connection (these are displayed at connection)

⇒ street

⇒ ZIP-code and country

⇒ Telephone number you can reach the TS-adapter

8.3.4.2 Connect

At the moment not implemented!

In this dialog the connection to another modem with a MPI-cable connected is started. Choose on the right

side the named connection, then press „connect“ to establish it.

With „Hang-Up“ you could stop an existing connection.

With the button „State“ the state of the connection is displayed at the lower side of the dialog.

8.3.4.3 Extra

S7-USB user manual 61 / 85 2019/10/05 05:07

Page 62

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

In this dialog, all configuration to the TS-adapter is done.

The actual state of the MPI-cable is displayed right of the button “TS-function”, where the follwing 4

possible Messages could apear:

„TS-Adapterfunction is NOT activ. To activate press TS-function“

The MPI-cable acts like an PC-Adapter. There will no answer for TS-spezific protocols, the attached modem

will not initialized and the baud-rate to the PG/Modem is not fixed. The baud-rate is detected

automatically.

„TS-Adapterfunktion is ACTIVE. To disable press TS-function“

The MPI-cable acts like an TS-Adapter. There will an answer to TS-spezific protocols, the adapter could now

configured. An attached Modem will be initiliazed and the baud-rate to the modem is fixed.

„SNDERR“ or „RCVERR“

There is a communication error at sending or recieving data from the mpi-cable. Disconnect the MPI-cable

from the power supply (PLC). Change to the tab Connect and after that back to Extra. If the problem

remains, check the connection to the MPI-cable, especially the COM-port in the dialog interface.

With the buttons you could define which modem is used, activate or disable the TS-function or configure

the TS-adapter:

8.3.4.3.1 „Setup“

In the follwing dialog you could choose the used modem.

S7-USB user manual 62 / 85 2019/10/05 05:07

Page 63

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

8.3.4.3.2 „TS-function“

With this button you select the function of the MPI-cable as TS- or PC-adapter. Right of this button the

actual state of the MPI-cable is displayed.

8.3.4.3.3 „configure adapter“

In the following dialog you could, after activating the MPI-cable as TS-adapter, configure the TS-spezific

setup.

Network

S7-USB user manual 63 / 85 2019/10/05 05:07

Page 64

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

station related:

Here you can configure following:

The TS-Adapter is the one and only master in the MPI-bus

Which local station-address is used for the TS-Adapter. Please consider that a programming device has

normally the number 0, operator panel have 1, PLC’s use 2, FM/CP’s 3 etc.

Please: Never use the same station-number for 2 different stations!

network related:

Here you can configure following:

The Nettype MPI or PROFIBUS

The transfer-speed on the MPI-bus

The highest station-address in the bus (the less you use, the more performance on the MPI-bus, must be

corresponding with the configuration in the PLC’s)

Modem

S7-USB user manual 64 / 85 2019/10/05 05:07

Page 65

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

In this dialog you could configure the modem-related setup.

The Init-String is composed out of several commands to the modem:

AT ⇒ start command

&F ⇒ use factory settings

E0 ⇒ Echo off

L1 ⇒ loudness of speaker is low

M1 ⇒ speaker is on at connection

Q0 ⇒ output of the return values

V1 ⇒ return values plain text

&C1 ⇒ DCD shows status of the carriersound

S0=1 ⇒ automatic connection after 1 ring

The Hang-Up-String is composed of 2 elements:

+++ ⇒ Change to command-mode

AT ⇒ start command

H ⇒ Hand-Up connection

There are 2 possible calling technics:

MFV tone, the telphone-number is transfer by several frequencies

IWV pulse, the telephone-number is transferred with the count of several pulses on the line

When you must a pre-call to establish a call outside your company, you could define it at Official number.

When the modem should wait for a free line, so you should set the corresponding checkbox.

At number of retries you could configure the number of retries for a connection before the call is stopped.

When using a retry you could choose the seconds which the application should wait between calls.

Serial parameter

S7-USB user manual 65 / 85 2019/10/05 05:07

Page 66

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

In this dialog the transfer-rate between modem and TS-Adapter is selected.

The transfer-rate could choosen between the follwing values:

2400, 4800, 9600, 19.2k, 38.4k, 57.6k and 115.2kBaud

The Parity could be chosen, but this is modem-dependant because some modems could not transfer the

parity-bit:

None: (There is no parity testing)

Odd: (The number of one-bits are odd)

Even: (The number of one-bits are even)

Password

S7-USB user manual 66 / 85 2019/10/05 05:07

Page 67

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

The Access over a telephone-line on the PLC could be configured in this dialog.

The Administrator could change the configuration over a telephone line, where an 2 User could not change

the configuration.

The User-Name is maximal 8 Chars long.Every user and the administrator could use a password which is

used to log into the PLC over a telephone-line. These have to enter for each new call.

After 3 wrong retries the connection is hanged up, so you must call again (Not so with an original TSadapter).

After changing the password for one user/administrator you must re-type it again correctly before it is

used.

In call-back-number you could define a telephone-number which is used for call-back from the TS-adapter.

After you connect with the TS-adapter, you are asked for your user-name and password. When the correct

password and user-name is transfered, the connection is hanged-up and the TS-adapter is calling back this

configured call-back-number.

GSM/ISDN/SMS

Analog modem:

You could choose the Location of the Modem.

ISDN modem:

S7-USB user manual 67 / 85 2019/10/05 05:07

Page 68

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Type: Choose the type of the ISDN-network switch:

AT&T 5ESS

Nothern Telecom DMS-100

EuroISDN NET3 (Standard)

INS64

US NI-1

VN4

Protocol: Choose the transfer-protocol-type:

Modem like

V.120

X.75 (Standard)

ML-PPP

SoftBonding

HDLC

CLEAR

DN/MSN: Directory Number resp. Multiple Subscriber Number Is used for both ISDN-channels. When using

the number 255 no DN/MSN is used.

GSM modem:

S7-USB user manual 68 / 85 2019/10/05 05:07

Page 69

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

PIN: PIN-Number of the SIM-Card, up to 8 numeric chars, (only for TELE-SERVICE GSM).

Provider: With the button „Provider“ the provider could be choosen. Reading of the list of providers could

be elapse more than a minute. At end the possible provider are listed for selection. With „Automatic“ the

GSM-Modem tries to connect automatically to a provider. On the right side of the button, the actual used

selection is displayed.

Display Description:

Automatic: The provider is automatically searched and selected from the GSM-modem.

Manual: The Provider is selected manually from the GSM-Modem

no network registered: No connection to the GSM-network, the receive-quality is too bad

set format: The format of the provider is set

Manual/automatic: The modem tries to select manually the provider, if this fails an automatic search is

done

unknown: Unknown response from GSM-Modem

Refresh:

The button „Refresh“ reads from the Modem the receive quality, the quality is displayed.

Display Description:

Unknown: Unknown state of the GSM-network

no registration: The modem is not registered in the GSM network, no provider found

registration denied: Registration in the GSM-network is denied

Search network: In Search for a GSM-Provider

GSM: Attached to GSM

GSM(ROAMING): Attached to GSM, but with a Roaming-Partner. This could lead to high costs!

The Receive Quality is displayed, also as value together with the bit-error-rate.

Value Description:

99 No network, no receive

S7-USB user manual 69 / 85 2019/10/05 05:07

Page 70

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

00 Very, very bad receive-quality

01 Very bad receive-quality

02 to 09 Bad receive-quality

10 to 17 Medium receive-quality

18 to 25 Normal receive-quality

26 to 30 Good receive-quality

31 Best receive-quality

Messages:

The possible error conditions for the modem, mpi-bus-problems or other problems are displayed in this

text-field. Firstly, the modem-related information is shown:

Message

Modem ready

Modem error

No answer from modem

Modem detects ring

End of connection

connected via modem line

No dialtone detected

Phone-line or telephone busy

Phone-number is blacklisted in modem

Phone-number delayed. Access denied for 1 minute.

Fax-call detected

Data-call detected

unknown error

The selected direct-access-number not configured

The configured PIN-Number is wrong for the inserted SIM-Card

The SIM-Card is not or wrong inserted or the SIM-Card is a 5V Type

Following the possible MPI-Bus error-messages

Message

MPI/Profibus-Configuration erroneous

Timeout at MPI/Profibus detach from device.

The local station-address is used twice in the MPI/Profibus.

A20/M20/TC35 Modem operation

The MPI/Profibus is not correctly configured

The HSA is not configured optimal

The MPI/Profibus-Baudrate is not detectable

Overflow in the internal MPI-Readbuffer

Overflow in the internal LAN-Readbuffer

Overflow in the serial Buffer

The selected MPI/Profibus-Baudrate is wrong

Overflow in internal LAN-Writebuffer

LAN-Receive-Error

LAN-Send-Error

The PD-Number is wrong

The transferred SAP is wrong/unknown

ErrCode 01: The Destination address (XXX) of a State protocol > 127 detected. In the MPI/Profibus-

S7-USB user manual 70 / 85 2019/10/05 05:07

Page 71

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Bus there are no stations possible which station number is greater than 127. (FC=YYh)

ErrCode 02: At state-protocol the Source-Address is detected as 127. This is the Broadcast-address

which is not possible.

ErrCode 03: The received State protocols destination address (XXX respectively YYY) does not exist

in the MPI-Bus. (FC=ZZh)

ErrCode 04: The function-code (YYh) of the received State protocol from XXX is incorrect. The 7th Bit

is High, but according to the specification the Bit has to be low.

ErrCode 05: A State protocol has been received. But the function-code (YYh) means that the

participant is not ready to enter the bus.

ErrCode 06: The function-code in the State-protocol received from XXX is unknown (FC=YYh)

ErrCode 11: The sender (XXX) of the received data-protocol is unknown. To send data the participant

must get the Token. (SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 12: Data-protocol with Source-address 255 (Broadcast) is useless. (CPU=XXX, SSAP=YYh,

FC=ZZh, length=UUU)

ErrCode 13: The sender (XXX) of the received data-protocol is unknown. To send data the participant

must get the Token. (SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 14: The 7th Bit of the function-code is High, but according to the specification the Bit has to

be low. (CPU=XXX, SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 15: The upper 4 Bit of the Function-code are wrong/unknown)

(CPU=XXX, SSAP=YYh, FC=ZZh, length=UUU)

ErrCode 16: Unknown function-code has been transmitted to the cable. (CPU=XXX, SSAP=YYh,

FC=ZZh, length=UUU)

ErrCode 17: Destination-SAP are defined till 3Fh in data-protocols. (CPU=XXX, SSAP=YYh, FC=ZZh,

length=UUU)

ErrCode 18: Source-SAP are defined till 3Fh in data-protocols. (CPU=XXX, SSAP=YYh, FC=ZZh,

length=UUU)

ErrCode 19: Received a data-protocol with destination-SAP=0, Connection request from another busparticipant with our cable. (CPU=XXX,SSAP=YYh,FC=ZZh,DSAP=UUh)

ErrCode 1A: Participants are sending data to our cable with source-SAP = 0, which means that the

participant has not made a connection establishment or has lost the negotiated SAP.

(CPU=XXX,SSAP=YYh,FC=ZZh,DSAP=UUh)

ErrCode 1B: Data-protocol with unknown data-function-code received.

(CPU=XXX,SSAP=YYh,FC=ZZh,DFC=UUh)

ErrCode 1C Data-protocol with unknown data-function-code received.

(CPU=XXX,SSAP=YYh,FC=ZZh,DFC=UUh)

ErrCode 1D: Received a state-protocol with error-code.

(CPU=XXX,FPGA=YYh,RAM=ZZh)

ErrCode 1E: FPGA has caused an interrupt although no data present.

(SD1=XXh,SD1=YYh,CPU=ZZZ,FC=UUh)

ErrCode 20: Unknown protocol at PPIMultimaster-Mode. (FC=XXh,Länge=YYY)

ErrCode 21: Unknown baud-rate at PPIMultimaster-Mode. (Baudrate=XXh) After that additional hints

are displayed.

SMS:

SMS: Switches Processing OFF / Only Receive / Only Send / Receive and Send.

Attention: before setting ON check configuration, after activating the device will go into the MPI-BUS and

tries to connect to the defined PLC. Receive of SMS only with TELESERVICE-GSM Receive of DTMF only with

with TELESERVICE GSM

TS: local station-address (should not be used twice in the MPI/Profibus!)

S7-USB user manual 71 / 85 2019/10/05 05:07

Page 72

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

PLC: from this station-address the Flagword and Data-block is accessed for communication

MW: communication-flagword (the first byte is the command, the second is the state). Use even operandaddresses.

DB: communication-data-block.

Provider 1/2/3/4: Configure the SMS-Provider to use, including type, phone-number and char-code.

Internet/Mail

8.3.4.3.4 „Import parameter“

With this button you could import the parameter from an ASCII-file. This file is compatible to the original

file-format.

8.3.4.3.5 „Export parameter“

With this button you could export the parameter to an ASCII-file which has the same file-format as the

original.

8.3.5 Tuning

S7-USB user manual 72 / 85 2019/10/05 05:07

Page 73

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

This tab is only used in some special cases. If you press the button „Check Adapter“ the cable is connected

und after that the following dialog is displayed:

There are the following configuration possible, they will be transferred to the MPI-Cable by pressing the

button „Transfer“. The configuration is saved permanently in the Flash-ROM:

S7-USB user manual 73 / 85 2019/10/05 05:07

Page 74

Söllnerstr. 9 92637 Weiden info@traeger.de +49 (0)961 48 23 0 0

Time to send:

At ProTool RT the communication could break down, because the MPI-Cable is transferring the answerprotocol to fast. In this property you could insert a time in 0.1ms ticks. Insert at first 300, to great values

are preventing the communication.

HMI-Cable-Version:

Some Touch-panels have the problem, that when they get a wrong version-information they never retry to

connect (and then the correct version is transferred). In this case the HMI-version-information could be

transferred immediately.

A20-Terminal:

When using the A20 or M20-Terminal, the control-lines on the serial port are not used. In that case the

tele-service-function is not working. With this property the control-lines are no longer used and therefore

the A20/M20 can communicate over tele-service.

Bootconfiguration:

Normally the MPI-Cable automatically selects the correct bus-type, no changes are needed. In specialcases the MPI-Bus could be selected as PPI.

For example: This application and the PLC are powered on at the same time. The application is

communicating immediately with the cable, the PLC is booting, in this case the MPI-Bus is not driven. The

MPI-Bus is erroneous, so no communication is starting.

If this occurs you could choose, that the cable is working as MPI-Adapter only..

Language:

You could select the language which is used from the cable (German or English).

9 PLC-VCOM

9.1 Description

It creates a new, virtual com-port in your system, with which the programming software of your PC (such a.