Traditional Tool Repair Inc. DTP-100UL Operating Instructions Manual

DTP-100UL MANUAL TENSIONER

Part No. 306185

GENERAL SAFETY CONSIDERATIONS

1. EYE INJURY HAZARD.

Failure to wear safety glasses with side shields can result

in severe eye injury or blindness. Always wear safety

glasses with side shields which conform to ANSI

Standard Z87.1.

2. STRAP BREAKAGE HAZARD.

Improper operation of the tool or sharp corners on the

load can result in strap breakage during tensioning,

which could result in the following:

P A sudden loss of balance causing you to fall.

P Both tool and strap flying violently towards your face.

Failure to place the strap properly around the load or on

an unstable or shifted load could result in a sudden loss

of strap tension during tensioning. This could result in a

sudden loss of balance causing you to fall.

Read the tools operating instructions. If the load corners

are sharp use edge protectors. Place the strap correctly

around a properly positioned load.

Positioning yourself in-line with the strap, during

tensioning and sealing, can result in severe personal

injury from flying strap or tool. When tensioning or

sealing, position yourself to one side of the strap and

keep all bystanders away.

3. FALL HAZARD.

Maintaining improper footing and/or balance when

operating the tool can cause you to fall. Do not use the

tool when you are in an awkward position.

STRAP SPECIFICATIONS

Width: 3/8" to 3/4" Steel

Gauge: .015 to .023" Thick

OPERATING INSTRUCTIONS

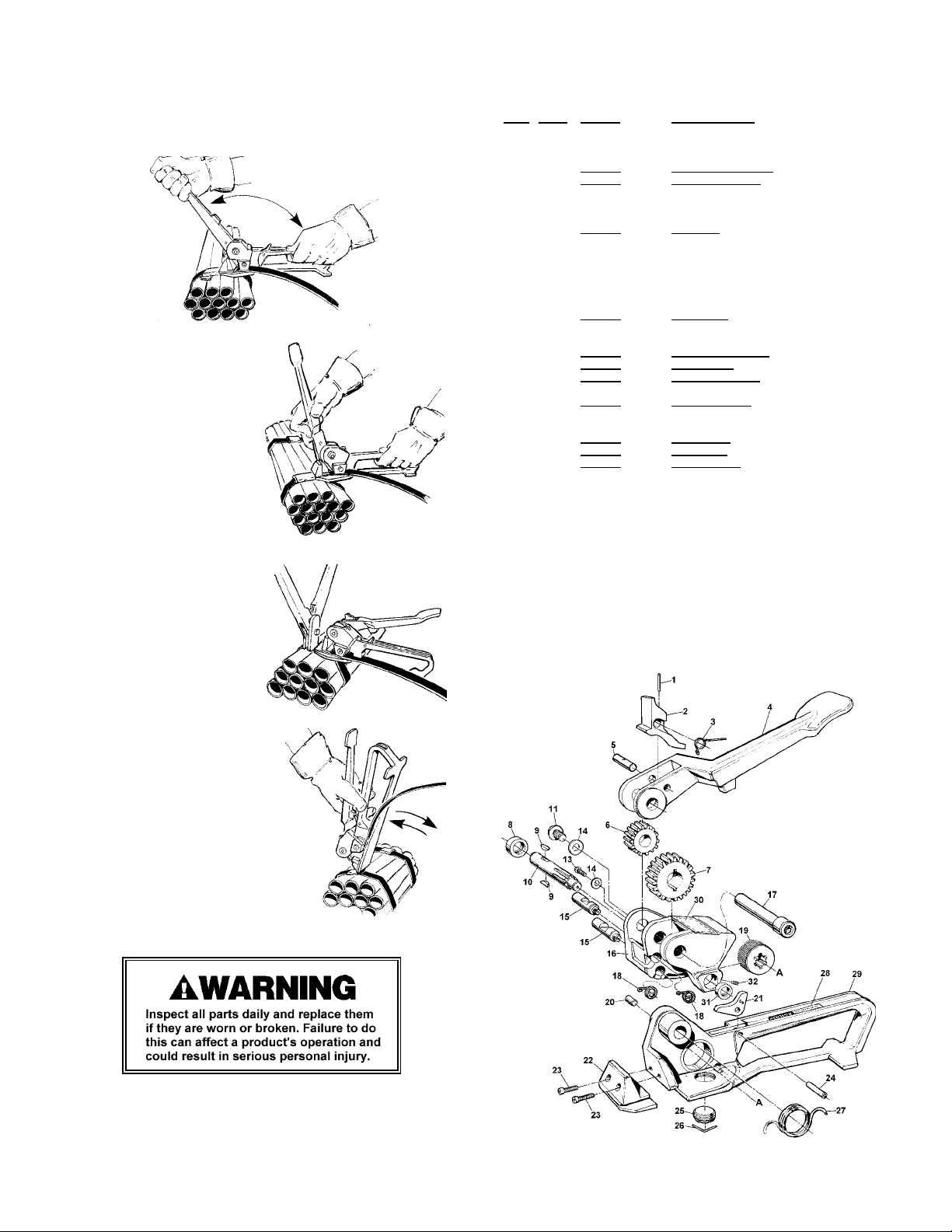

1. Thread the strap through the seal. Encircle the bundle

and thread the strap through the seal again. Bend the

lower strap back sharply beneath the seal and pull out all

slack strap.

4. CUT HAZARD.

Handling strap or sharp parts could result in cut hands or

fingers. Wear protective gloves.

5. TRAINING.

This tool must not be used by persons not properly

trained in their use. Be certain that you receive proper

training from your employer. If you have any questions

contact your Acme Representative.

6. TOOL CARE.

Take good care of the tool. Inspect and clean it daily,

lubricate it weekly and adjust when necessary. Replace

any worn or broken parts.

7. WORK AREA.

Keep work areas uncluttered and well lighted.

Sales and Service 877-862-6699

2. Squeeze the handles together to lift the feedwheel. Insert

the strap into the slot of the breaker nose and push the

tool up against the seal.

© Copyright 2008, Acme 286160 Revised 11/2008

OPERATING INSTRUCTIONS, Continued

3. Stand to one side of the strap line and tension the strap

with forward and backward motions of the tension

handle.

4. When desired tension is

reached, push the drive

pawl forward and rotate

the tension handle back

to contact the lift arm.

5. Notch the seal with a

Delta sealer to complete

the joint.

PARTS LIST

KEY QTY. PART# DESCRIPTION

1 1 014809 Roll pin, .093 x 1.000

2 1 017910 Drive pawl

3 1 017920 Drive pawl spring

4 1 422017 Tension handle

5 1 017919 Pawl pin

6 1 017912 Pinion gear

7 1 017911 Tension gear

8 1 017918 Bushing

9 2 023093 Woodruff key, #403

10 1 017922 Feedwheel shaft

11* 1 003359 BHCS, 5/16-24 x 3/8

12 1 004959 Washer, 5/16 SAE

13 1 041912 BHCS, #10-24 x 3/8

14 1 023089 Washer, 3/16 SAE

15 2 017915 Hold pawl

16 1 422018 Gear housing

17 1 017921 Pivot pin

18 2 017916 Hold pawl spring

19 1 017923 Feedwheel

20* 1 001656 Strap guide pin

21 1 017913 Lift arm

22 1 017908 Breaker nose

23* 2 004618 SHCS, #10-24 x 5/8

24 1 005756 Roll pin, 3/16 x 3/4

25 1 008777 Wear plug

26 1 001644 Lock wire

27 1 017914 Base spring

28 1 003133 Caution sign

29 1 422016 Base

30 1 422022 Nameplate

31 1 424036 Bushing

32 1 020694 Set screw

When ordering parts, please show tool model, part number

and name. All recommended spare parts a underlined and

should be stocked. Standard hardware parts may be obtained

from local hardware suppliers.

For Parts Support Call 1-800-541-5736

* Apply one drop of Loctite #271 (Red) or equivalent.

6. Break off the strap at the

seal by raising the tool

perpendicular to the seal,

then lowering it.

501 W. Lake Street • Suite 105 • Elmhurst, IL 60126

Acme Sales

1-630-589-5100

Sales and Service 877-862-6699

Loading...

Loading...