OPERATION MANUAL / SPARE PARTS LIST

PNEUMATIC SEALER

MODEL A461.0002

13.4510.01 - 13.4511.01

CE Declaration of conformity

We declare that the machine A461

is in conformity with the following standard or

13451001.en/MAS/© 02.04

13451101.en

standardised documents:

98/37/EEC

FROMM Holding AG

Hinterbergstrasse 26

CH - 6330 Cham

25.02 2004

R.Fromm

Director

Sales and Service 877-862-6699

INDEX PAGE

1 SAFETY INSTRUCTIONS 3

2 WARRANTY CONDITIONS AND LIABILITY 4

3APPROPRIATE USE 4

4 CHART OF TYPES A461.0002 4

5 TECNICAL DATA 5

5.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.2 Compressed air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.3 Steel strap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.4 Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.5 Joint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.6 Sound information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.7 Vibration information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 INSTALLATION 6

6.1 Compressed air connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2 Suspension of tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7 MAINTENANCE 6

7.1 Air-unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7.2 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8USE 7

8.1 Feeding the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8.2 Tensioning the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8.3 Sealing the strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9 SPARE PARTS LIST 13. 4510.01/13.4511.01 9

10 JOINT CONTROL 10

11 EXCHANGE OF WEARING PARTS 10

11.1 Exchange of cutting jaws and notching knives . . . . . . . . . . . . . . . . . . . . 10

12 ACCESSORIES 11

WWW.TRADITIONALTOOL.COM

2

Sales and Service 877-862-6699

1 SAFETY INSTRUCTIONS

Read these instructions carefully. Failure to follow these instructions can result in severe personal injury.

Eye injury hazard

Failure to wear safety glasses with side shields can result in

severe eye injury or blindness. Always wear sa fety glasses with

side shields which conform to ANSI Standard Z87.1.

Operation

Tool must not be used by persons not properly trained in their use.

Before tensioning strap, read and understand the tool oper ating

instructions. Failure to follow the operating instructions or improper

load positioning could result in strap breakage.

Become familiar with your tool and keep fingers away from areas

that can pinch or cut.

Joints

You are fully responsible to review the joints made by your tool.

Become familiar with the seal control and seal adjustment

described in this operation manual. Misformed joints may not

secure the load and could cause serious injury. Never handle or

ship any load with improperly formed joints.

Strap breakage hazard

Improper operation of the tool, excessive tensioning, using strap

not recommended for this tool or sharp corners on the load can

result in a sudden loss of strap tension or in strap breakage during

tensioning, which could result in the following:

• A sudden loss of balance causing you to fall.

• Both tool and strap flying violently towards your face.

Note as follows:

• If the load corners are sharp, use edge protectors.

• Place the strap correctly around a properly positioned

load.

• Positioning yourself in-line with the strap, during

tensioning and sealing, can result in severe personal

injury from flying strap or tool. When tensioning or sealing,

position yourself to one side of the strap and keep all

bystanders away.

• Use the correct strap quality, strap width, strap gauge and

strap tensile strength recommended in this manual for

your tool. Using strap not recommended for this tool can

result in strap breakage during tensioning.

•

Cutting tensioned strap

When cutting strapping, use the proper strapping cutter and keep

other personnel and yourself at a safe distance from the strap.

Always stand to side of the strap, away from the direction the

loosened strap end will fly. Use only cutters designed for strap and

never hammers, pliers, hacksaws, axes, etc.

Dispensing strap

Only dispense strap from a dispenser specifically designed for

strap.

Tuck strap end back into dispenser when not in use.

Protective gloves

When handling strap, always wear protective gloves.

Fall hazard

Keep your working area tidy. Untidiness of your working area may

cause a risk of injury. Maintaining improper footing and/or balance

when operating the tool can cause you to fall. Before tensioning

and especially in elevated areas, always establish good balance.

Both feet should be securely placed on a flat, solid surface,

especially when working in elevated areas. Do not use the tool

when you are in an awkward position.

Pay attention to the rules and regulations for preventions of

accident which are valid for the work place.

Tool hazards

A well maintained tool is a safe tool!

Check tool regularly for broken or worn parts. Do not operate a

tool with broken or worn parts.

Never modify any tool. Modification can result in severe bodily

injury.

Strap warnings

Never use strap as a means of pulling or lifting loads. Failure to

follow these warnings can result in severe personal injury.

WWW.TRADITIONALTOOL.COM

Sales and Service 877-862-6699

3

2 WARRANTY CONDITIONS AND LIABILITY

FROMM Holding AG warrants all its strapping tools and machine heads during a period of 90 days from the

date of

Damage claims as a result of production shutdowns and claims for damage to persons and to property resulting

from warranty deficiencies cannot be asserted by the customer.

The warranty excludes:

• wearing parts

• deficiencies resulting from improper installing, incorrect handling and maintaining the tool

• deficiencies resulting from using the tool without or with defective security- and safety devices

• disregard of directions in the operation manual

• arbitrary modifications of the tool

• deficient control of wearing parts

• deficient repair works of the tool

• Use of consumable products not recommended by FROMM Holding AG

We reserve the right to modify the product at any time in order to improve its quality.

sale. The warranty includes all deficiencies clearly resulting from poor manufacturing or faulty materials.

3 APPROPRIATE USE

The tool model A461 has been designed to strap packages with steel strapping exclusively.

The warranty / liability excludes:

• non appropriate use of the tool,

• disregard of directions in the operation manual,

• disregard of control- and mainten anc e ins truc tions.

4 CHART OF TYPES A461.0002

Item No. Model Strap width Strap thickness

Uniflex Ultraflex

13.4310 A461/19/0.63-0.70/N 19mm / 3/4" 0.63-0.70mm / .025"-.028" 0.63-0.70mm / .025"-.028"

13.4311 A461/19/0.63-0.70/P 19mm / 3/4" 0.63-0.70mm / .025"-.028" 0.63-0.70mm / .025"-.028"

13.4312 A461/19/0.8-1.00/N 19mm / 3/4" 0.80-1.00mm / .031"-.040" 0.80-1.0mm / .031"-.040"

13.4313 A461/19/0.80-1.00/P 19mm / 3/4" 0.80-1.00mm / .031"-.040" 0.80-1.0mm / .031"-.040"

13.4410 A461/25/0.80-1.00UNI/

0.80-0.90ULT/N

13.4411 A461/25/0.80-1.00UNI/

0.80-0.90ULT/P

13.4510 A461/32/0.80-0.90/N 32mm / 1 1/4" 0.80-0.90mm / .031"-.035" 0.80-0.90mm / .031"-.035"

13.4511 A461/32/0.80-0.90/P 32mm / 1 1/4" 0.80-0.90mm / .031"-.035" 0.80-0.90mm / .031"-.035"

13.4512 A461/32/1.00UNI/N 32mm / 1 1/4" 1.00m m / .040" --

13.4513 A461/32/1.00UNI/P 32mm / 1 1/4" 1.00mm / .040" --

UNI = Uniflex (Regular Duty max. 850 N/mm2 / 123‘000 psi)

ULT = Ultraflex (High Tensile max. 1100 N/mm

25mm / 1" 0.80-1.00mm / .031"-.040" 0.80-0.90mm / .031"-.035"

25mm / 1" 0.80-1.00mm / .031"-.040" 0.80-0.90mm / .031"-.035"

2

/ 160‘000 psi)

WWW.TRADITIONALTOOL.COM

4

Sales and Service 877-862-6699

A4610002en.teil1

5 TECNICAL DATA

5.1 Dimensions

Assembling "N"

Assembling "P"

Weight net: 4.2 kg / 9.3 lbs

5.2 Compressed air

Joining thread: G 1/4" or G 3/8"

Tube: Min. inside diam. = 8 mm / 5/16"

Max. air pressure: 6 bar / 87 psi

Air consumption: 7.25 Nl / 0.26 cu.ft./seal

5.3 Steel strap

Width: 19 - 32 mm / 3/4" - 1 1/4"

Thickness: 0.63 - 1.0 mm / .025" - .040" maximal

Tensile strength:

Finish: Waxed, smooth edges

600 - 1100 N/mm

2

/ 87 000 - 160 000 psi

5.4 Seals

Strap width: Seal dimensions:

19mm 19 x 45 x 0.9 mm / 3/4" x 1/ 3/4" x .035", with overlapping flanges

25mm 25 x 45 x 0.9 mm / 1" x 1/ 3/4" x .035", with overlapping flanges

32mm 32 x 45 x 0.9 mm / 1 1/4" x 1/ 3/4" x .035", with overlapping flanges

5.5 Joint

Joint strength: approx. 75% of the strap’s tensile strength

WWW.TRADITIONALTOOL.COM

A double notch (two pairs of cut notches) is made per cycle.

A4610002en.teil1

Sales and Service 877-862-6699

5

5.6 Sound information

The A-weighted equivalent continuous sound level at the work place of the machine operator is

typical 84 dB (A).

This value was determined according to DIN 45 635 T3 (11.85).

5.7 Vibration information

The weighted effective value of the acceleration typically amounts to less than 2,5m/s2.

This value was determined according to DIN EN 28 662 T1 (01.93).

6 INSTALLATION

6.1 Compressed air connection

The compressed air is connected to the reducing coupling N6.5133 using a coupling. An air-unit consisting of

a separator for water and dirt, a pressure regulator with a manometer and a lubricator should be installed

within a distance of 15 ft/5 meters. The compressed air must be free from dirt, rust and moisture.

6.2 Suspension of tool

It is possible to suspend the tool on a spring loaded balancer using various suspension brackets.

They have to be ordered separately (see paragraph "ACCESSORIES").

7 MAINTENANCE

Depending on the working conditions and the use of the tool the following maintenance has to be made

periodically:

7.1 Air-unit

• Checking the air-pressure daily (never exceed 87 psi / 6,0 bar).

• Checking oil-level dail y.

• Checking the water separator daily (unless automatic), draining when necessary.

• Cleaning the filter following the instructions of the manufacturer of the air-unit.

Oil for the air unit

HL or CL ISO-VG 10

7.2 Lubrication

When being exchanged, all valve parts and other movable parts have to be greased with grease of type

ESSO BEACON 2 or with some equivalent product.

WWW.TRADITIONALTOOL.COM

6

Sales and Service 877-862-6699

A4610002en.teil1

8USE

8.1 Feeding the strap

The strap is fed through the seal, around the package

to be strapped and pushed again through the seal.

Then the strap end is bent.

Afterwards the operator tensions the loose hoop

manually making sure that the bent strap end is

adjacent to the object to be strapped.

Always wear safety

glasses with side shields

which confor m to ANSI

Standard Z87.1.

When handling strap,

always wear protective

gloves.

8.2 Tensioning the strap

The strap is tensioned with a suitable tensioner

(e. g. Fromm model A451).

8.3 Sealing the strap

Place the sealer on top centre of the seal.

Notch the seal with the strap by pushing the valve

lever until it stops.

It is possible to release the valve lever immediately

after pushing because of the tools automatic sealing

cycle.

Remove the sealer after finishing sealing cycle.

WWW.TRADITIONALTOOL.COM

A4610002en.teil1

Sales and Service 877-862-6699

7

B

C

A46.2125

N6.6123

1 2 3 4A

A46.0108

A46.2128

N6.6204

N2.5180

A46.2150

A46.2151

N6.6208

A46.2146

N1.1815

N2.4902

N41.9128 N4.9159

N41.9129

N2.4902

N1.1815

N1.2114

A46.2152

N2.5198

N4.9136

D

E

F

N6.6213

A46.2130

N6.5133

A46.2127

N6.6235

A46.2129

A48.1237

N1.2108

A46.2154

A46.2126

N1.5305

A46.2143

N6.6204

N6.6232

N1.1808

A46.2147

A46.2149

N2.2164

A46.2116

A46.2148

A46.2121

A46.2118

A46.2145

A46.2109

A46.2145

A46.2113

A46.2132

N2.2118

A46.2134

A46.2153

A46.2118

N2.2124

A46.2145

A46.2116

A46.2117

A46.2154

A46.2143

N1.1118

N1.2108

Loctite 222

Loctite 603

Talcum

ESSO Beacon 2

8

A46.0105

WWW.TRADITIONALTOOL.COM

13451001.z

Sales and Service 877-862-6699

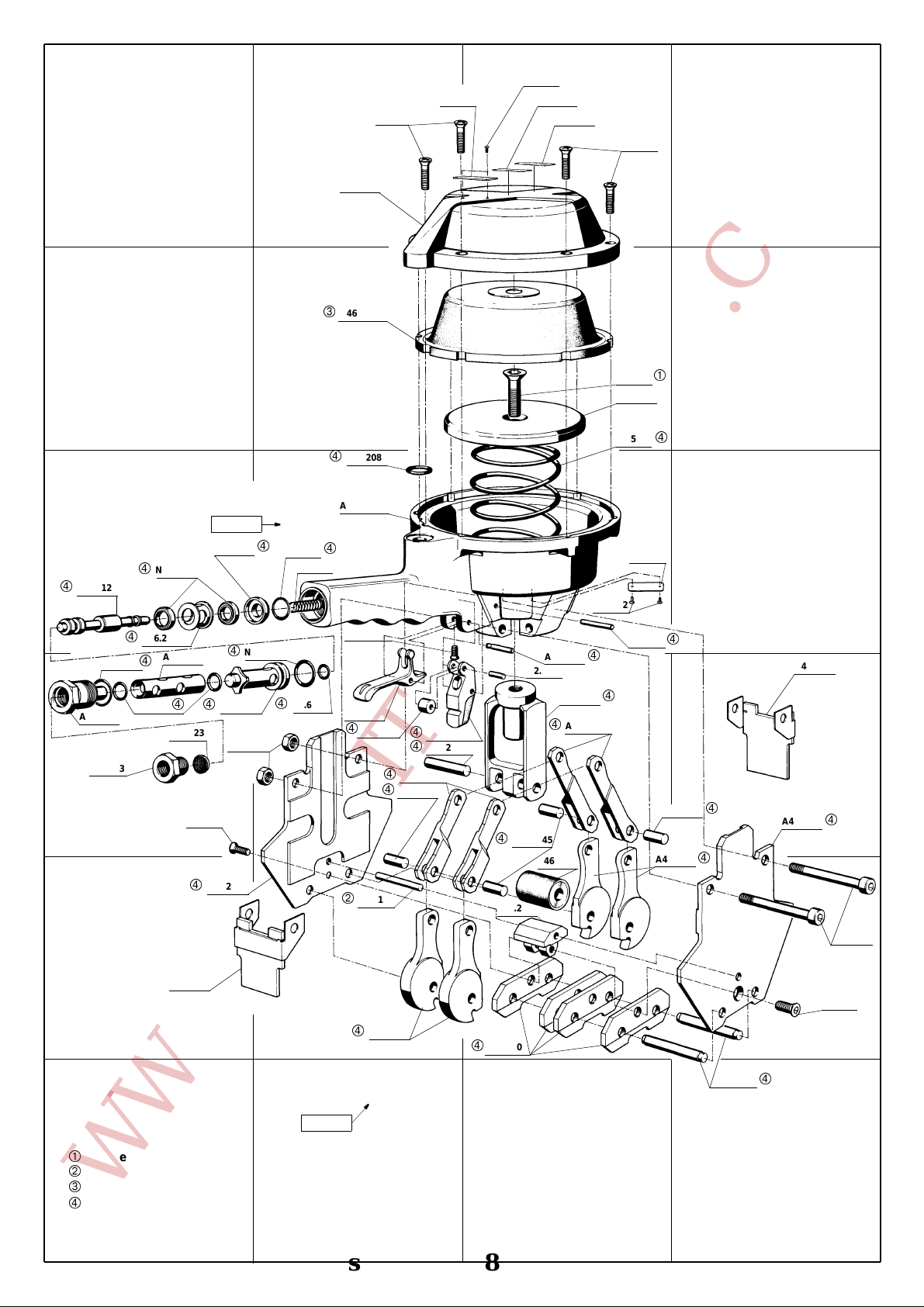

9 SPARE PARTS LIST 13.4510.01/13.4511.01

13.4510.01

13.4511.01 Item-No. Pcs. Description Dimension Field

[A46.0105] 1 JAW ASSEMBLY F2

[A46.0108] 1 CYLINDER BOTTOM C1

A46.2109

A46.2113 ->[A46.0105] 1 DISTANCE SUPPORT E3

A46.2116

A46.2117 ->[A46.0105] 2 JAW PIN F4

A46.2118 ->[A46.0105] 4 FRONT TOGGLE LINK D2+

A46.2121 ->[A46.0105] 1 ROD BAR BOLT D2

A46.2125 ->[A46.0108] 1 VALVE STEM C1

A46.2126 ->[A46.0108] 1 VAL VE SHELL D1

A46.2127 ->[A46.0108] 1 EXHAUST RING C1

A46.2128 ->[A46.0108] 1 SUSTAINING RING C1

A46.2129 ->[A46.0108] 1 SUPPORTING TUBE D1

A46.2130 ->[A46.0108] 1 CONNECTING SCREW D1

A46.2132 ->[A46.0108] 1 LEVER SHAFT D3

A46.2134 ->[A46.0105] 1 BUFFER E3

A46.2143 ->[A46.0105] 2 SIDE PLATE D4+

A46.2145 ->[A46.0105] 4 LEVER BOLT D2+

A46.2146 ->[A46.0108] 1 CYLINDER BOTTOM C2

A46.2147 ->[A46.0108] 1 VAL VE LEVER D2

A46.2148 ->[A46.0108] 1 PIVOTED LEVER D2

A46.2149 ->[A46.0108] 1 SLIDING ROLLER D2

A46.2150 1 CYLINDER COVER A2

A46.2151 1 DIAPHRAGM B2

A46.2152 1 PISTON PLATE B3

A46.2153 ->[A46.0105] 1 PISTON ROD D3

[A46.2154] 2 SAFETY GUARD D4+

A48.1237 ->[A46.0108] 1 SIEVE D1

N1.1118 2 SCREW M8 X 50 E4

N1.1808 ->[A46.0108] 1 SCREW M4 X 10 C2

N1.1815 7 SCREW M6 X 25 A2+

N1.2108 ->[A46.0105] 2 SOCKET COUNTERSUNK HEAD SCREW M6 X 16 D1+

N1.2114 1 SOCKET COUNTERSUNK HEAD SCREW M10 X 40 B3

N1.5305 2 RETAINING NUT M8 D1

N2.2118 ->[A46.0108] 1 PARALLEL PIN 4 M6 X 14 D3

N2.2124 ->[A46.0108] 1 PARALLEL PIN 4 M6 X 40 C3

N2.2164 ->[A46.0105] 1 PARALLEL PIN 6 M6 X 40 E2

N2.4902 4 HAMMER HEAD BOLT 1,85 X 4,76 A3+

N2.5180 ->[A46.0108] 1 PRESSURE SPRING 0.8X7.8X30/8.5 C2

N2.5198 1 PRESSURE SPRING 4,5X67,5X180/7,5 B3

N4.9136 1 LABEL <<A461>> C3

N4.9159 1 LABEL <<CE>> A2

N41.9128 1 ADHESIVE LABEL A3

N41.9129 1 ADHESIVE LABEL A3

N6.5133 ->[A46.0108] 1 REDUCING COUPLING D1

N6.6123 ->[A46.0108] 2 SEAL 12 X 19 X 2.3 C1

N6.6204 ->[A46.0108] 2 O-RING 18 X 2 C2+

N6.6208 1 O-RING 14 X 2 C2

N6.6213 ->[A46.0108] 1 O-RING 20 X 2 D1

N6.6232 ->[A46.0108] 1 O-RING 8 X 2 D2

WWW.TRADITIONALTOOL.COM

N6.6235 ->[A46.0108] 2 O-RING 12 X 2 D1

A461/32/0.80-0.90/N

A461/32/0.80-0.90/P

*

->[A46.0105] 4 NOTCHING KNIFE E3

*

->[A46.0105] 4 CUTTING JAW E2+

A461.0002.01 15/06/98

[ ] = Group * = Wearing Parts

Sales and Service 877-862-6699

913451001.een

10 JOINT CONTROL

A regular control of the joint is necessary. The joint can be checked visually and the person controlling can

easily judge the quality of the joint. Following illustration shows a proper joint:

Sharp edged or misformed joints which do not appear as shown have to be taken away from the load

immediately. The tensile strength of these joints is insufficient and they could cause serious injury.

Having faulty joints proceed as follows:

• Checking the sealing cycle for improper use.(see 8. USE)

• Havin g faulty joints in spit e of proper use inspect th e tool for worn or damaged parts. In case of

wearing out or damaging replace tool parts as needed.

1 1 EXCHANGE OF WEARING PARTS

1 1.1 Exchange of cutting jaws and notching knives

Procedure:

• Unscrew cylinder cover A46.2150 (7 recessed countersunk head screws).

• Remove diaphragm A46.2151.

• Unsc rew pisto n plate A46 .2152 (scr ew N1.2114), push piston plate a gainst the pr essure sp ring at

the same time.

• Remove pressure spring.

• Disas s emb le sc rews N1.1118 and remove jaw assembly.

• In order to be able to exchange notching knives and cutting jaws the side plates have to be

removed from the jaw assembly. For this remove screws N1.2108.

• Assembling in opposite order.

Important!

WWW.TRADITIONALTOOL.COM

10

Safe screw N1.2114 with Loctite 222.

A4610002en.teil2

Sales and Service 877-862-6699

12 ACCESSORIES

Following suspension brackets can be mounted on the tool and have to be ordered separately:

Suspensions for tool assembling „N“

Universal suspension

A46.2201

for normal, vertical and

horizontal working position

Suspensions for tool assembling „P“

Universal suspension

A46.2207

for normal, vertical and

horizontal working position

Suspension

A46.2210

left side

Suspension

A46.2213

left side

Suspension

A46.2216

right side

Suspension

A46.2218

right side

WWW.TRADITIONALTOOL.COM

A4610002en.teil2

Sales and Service 877-862-6699

11

WWW.TRADITIONALTOOL.COM

12

Sales and Service 877-862-6699

A4610002en.teil2

Loading...

Loading...