Traditional Tool Repair Inc. A338.0002 Operation Manual & Spare Parts List

OPERATION MANUAL / SPARE PARTS LIST

MANUAL SEALLESS

STEEL STRAPPING TOOL WITH

ADJUSTABLE TENSION LEVER

MODEL A338.0002

13.2946.01

13294601.en/MAS/© 01.03

Sales and Service 877-862-6699

INDEX PAGE

1 SAFETY INSTRUCTIONS 2

2 WARRANTY CONDITIONS AND LIABILITY 4

3 APPROPRIATE USE 4

4 TECNICAL DATA 4

5 CHART OF TYPES A338.0002 5

6 OPERATION LEVERS 6

7 OPERATION 6

8 SPARE PARTS LIST 13.2946.01 10

9 SEAL CONTROL 13

10 SEAL ADJUSTMENT 14

11 TENSION FORCE ADJUSTMENT 14

12 CLEANING 15

13 EXCHANGE OF WEARING PARTS 15

1 SAFETY INSTRUCTIONS

Read these instructions carefully. Failure to follow these instructions can result in severe personal injury.

Eye injury hazard

Failure to wear safety glasses with side shields can result in severe eye injury or blindness. Always wear safety glasses with side shields

which conform to ANSI Standard Z87.1.

Operation

Tool must not be used by persons not properly trained in their use. Before tensioning strap, read and understand the tool operating

instructions. Failure to follow the operating instructions or improper load positioning could result in strap breakage.

Become familiar with your tool and keep fingers away from areas that can pinch or cut.

Joints

You are fully responsible to review the joints made by your tool. Become familiar with the seal control and seal adjustment described in

this operation manual. Misformed joints may not secure the load and could cause serious injury. Never handle or ship any load with

improperly formed joints.

WWW.TRADITIONALTOOL.COM

2

Sales and Service 877-862-6699

Dispensing strap

Only dispense strap from a dispenser specifically designed for strap.

Tuck strap end back into dispenser when not in use.

Protective gloves

When handling strap, always wear protective gloves.

Strap warnings

Never use strap as a means of pulling or lifting loads. Failure to follow these warnings can result in severe personal injury.

Strap breakage hazard

Improper operation of the tool, excessive tensioning, using strap not recommended for this tool or sharp corners on the load can result in

a sudden loss of strap tension or in strap breakage during tensioning, which could result in the following:

• A sudden loss of balance causing you to fall.

• Both tool and strap flying violently towards your face.

Note as follows:

• If the load corners are sharp, use edge protectors.

• Place the strap correctly around a properly positioned load.

• Positioning yourself in-line with the strap, during tensioning and sealing, can result in severe personal injury from flying str ap or

tool. When tensioning or sealing, position yourself to one side of the strap and keep all bystanders away.

• Use the correct strap quality, strap width, strap gauge and strap tensile strength recommended in this manual for your tool. Using

strap not recommended for this tool can result in strap breakage during tensioning.

Cutting tensioned strap

When cutting strapping, use the proper strapping cutt er and keep ot her personnel and yourself at a safe distance from the strap. Alw a ys

stand to side of the strap, away from the direction the loosened strap end will fly. Use only cutters designed for strap and never hammers,

pliers, hacksaws, axes, etc.

Fall hazard

Keep your working area tidy. Untidiness of your working area may cause a risk of injury. Maintaining improper footing and/or balance

when operating the tool can cause you to fall. Before tensioning and especially in elevated areas, always establish good balance. Both

feet should be securely placed on a flat, solid surface, especially when working in elevated areas. Do not use the tool when you are in an

awkward position.

Pay attention to the rules and regulations for preventions of accident which are valid for the work place.

Tool hazards

A well maintained tool is a safe tool!

Check tool regularly for broken or worn parts. Do not operate a tool with broken or worn parts.

Never modify any tool. Modification can result in severe bodily injury.

WWW.TRADITIONALTOOL.COM

Sales and Service 877-862-6699

3

2 WARRANTY CONDITIONS AND LIABILITY

FROMM Holding AG warrants all its strapping tools and machine heads during a period of 90 days from the

date of

Damage claims as a result of production shutdowns and claims for damage to persons and to property resulting

from warranty deficiencies cannot be asserted by the customer.

The warranty excludes:

• wearing parts

• deficiencies resulting from improper installing, incorrect handling and maintaining the tool

• deficiencies resulting from using the tool without or with defective security- and safety devices

• disregard of directions in the operation manual

• arbitrary modifications of the tool

• deficient control of wearing parts

• deficient repair works of the tool

• Use of consumable products not recommended by FROMM Holding AG

We reserve the right to modify the product at any time in order to improve its quality.

sale. The warranty includes all deficiencies clearly resulting from poor manufacturing or faulty materials.

3 APPROPRIATE USE

The tool model A338 has been designed to strap packages with steel strapping exclusively.

The warranty / liability excludes:

• non appropriate use of the tool,

• disregard of directions in the operation manual,

• disregard of control- and mainten anc e ins truc tions.

4 TECNICAL DATA

Dimensions without suspension bracket

Tool Package

Length: 670 mm / 26.4"

(Lever in horizontal position)

Width: 170 mm / 6.7" 215 mm / 8.5"

Height: 450 mm / 17.7"

(Sealing lever in vertical position)

Weight: 5.9 kg / 13 lbs 0.77 kg / 1.7 lbs

Tensioning force

5.5 KN / 1240 lbs with adjustment at 80 Nm / 710 lbs (240 N / 54 lbs manual force).

Sealing force

The manual force required for sealing is approx. 220 N / 50 lbs.

690 mm / 27.2"

160 mm / 6.3"

Joint strength

Approx. 80% of the strap’s tensile strength.

WWW.TRADITIONALTOOL.COM

4

Sales and Service 877-862-6699

A3380002.en_teil1

Steel strapping

Width: 12.7 - 19 mm / 1/2"-3/4" (see chart of types)

Thickness: 0.50 - 0.70 mm / .020"-.028" (see chart of types)

Quality: Fundamentally the A338 allows the use of all current steel straps with tensile strengths ranging

from 700 to 1100 N/mm

Straps with a low breaking elongation are unsuitable.

2

/ 100 000 - 160 000 psi (see chart of types).

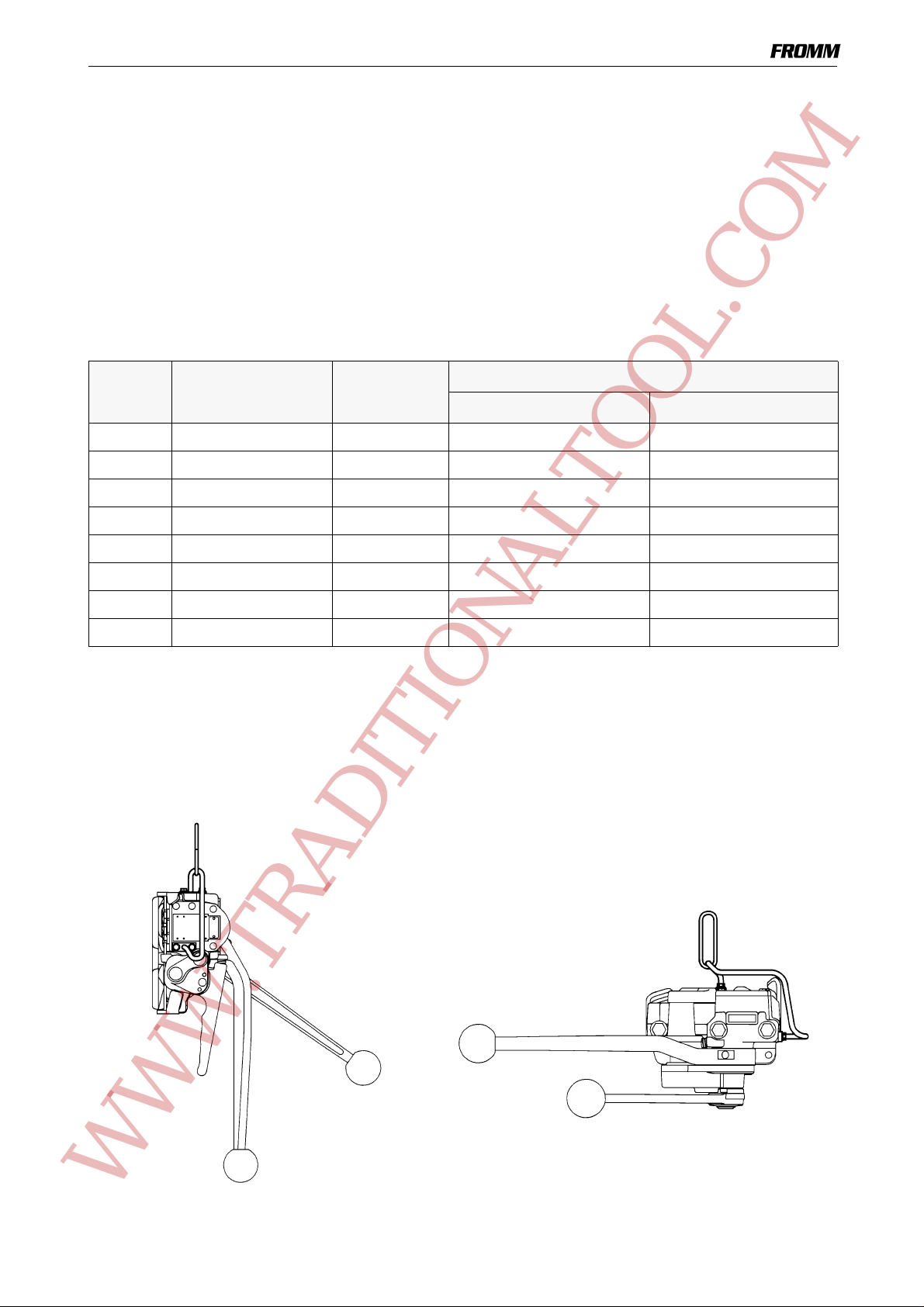

5 CHART OF TYPES A338.0002

Item No. Model Strap width Strap thickness

Uniflex Ultraflex

13.2911 A338/12.7/0.50-0.64/TW 12.7mm / 1/2" 0.50-0.64mm / .020-.025" 0.50-0.64mm / .020-.025"

13.2916 A338/12.7/0.70/UNI/TW 12.7mm / 1/2" 0.70mm / .028" -

13.2921 A338/13/0.50-0.64/TW 13.0mm 0.50-0.64mm / .020-.025" 0.50-0.64mm / .020-.025"

13.2926 A338/13/0.70/UNI/TW 13.0mm 0.70mm / .028" -

13.2931 A338/16/0.50-0.64/TW 16.0 / 5/8" 0.50-0.64mm / .020-.025" 0.50-0.64mm / .020-.025"

13.2936 A338/16/0.70/UNI/TW 16.0 / 5/8" 0.70mm / .028" -

13.2941 A338/19/0.50-0.64/TW 19.0mm / 3/4" 0.50-0.64mm / .020-.025" 0.50-0.64mm / .020-.025"

13.2946 A338/19/0.70/UNI/TW 19.0mm / 3/4" 0.70mm / .028" -

Uniflex = Strapping with max. tensile strength of 850 N/mm2 (123 000 psi)

Ultraflex = Strapping with max. tensile strength of 1100 N/mm

2

(160 000 psi)

Suspension bracket

For vertical and horizontal operation the tool can be suspended on a spring loaded balancer using suspension

bracket A33.5301.

A33.5301

Vertical

A33.5301

Horizontal

WWW.TRADITIONALTOOL.COM

Sales and Service 877-862-6699

5A3380002.en_teil1

Loading...

Loading...