Trademaster TPF24, TPF30, TWF30 Quick Start Manual

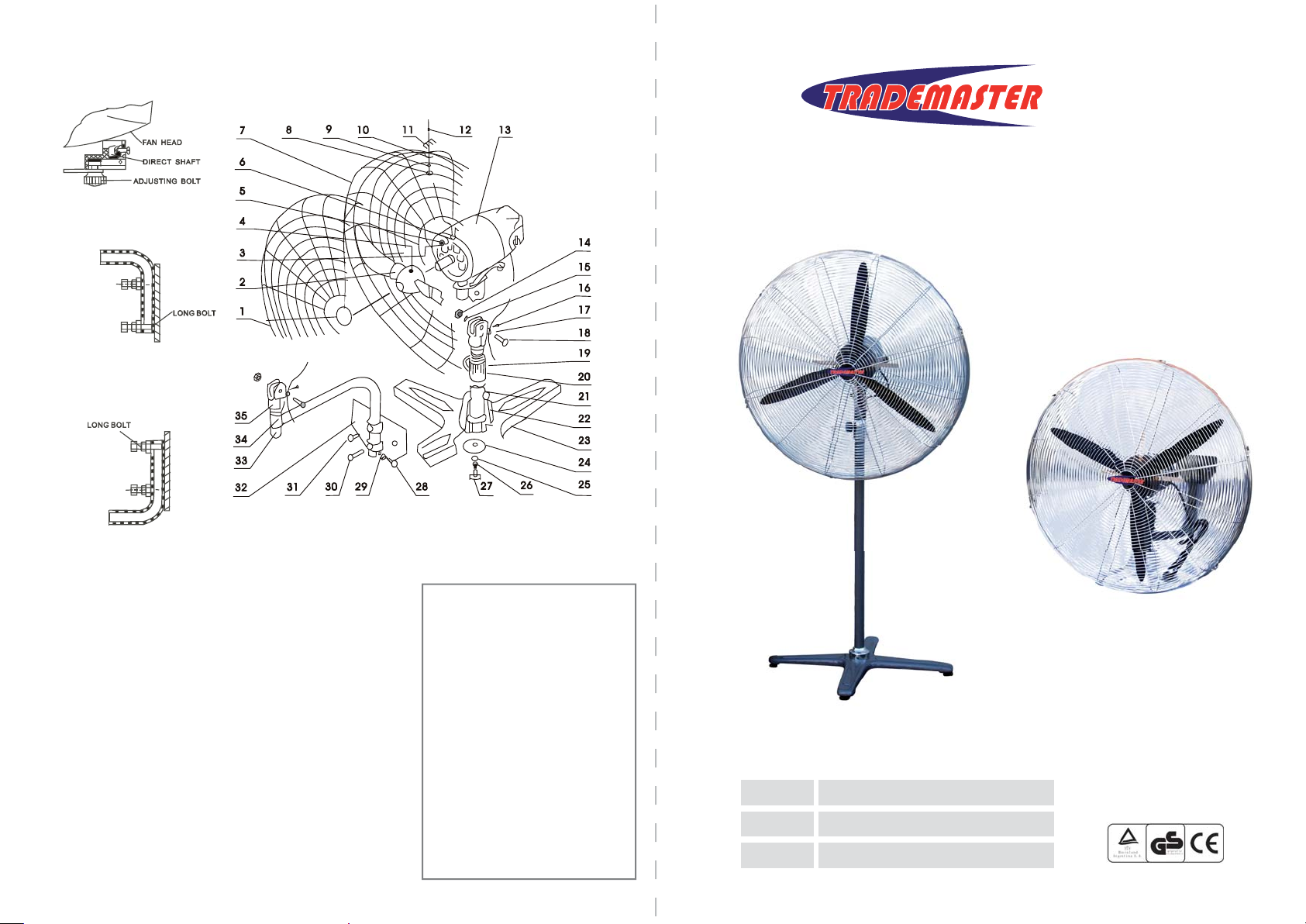

ASSEMBLING DIAGRAM

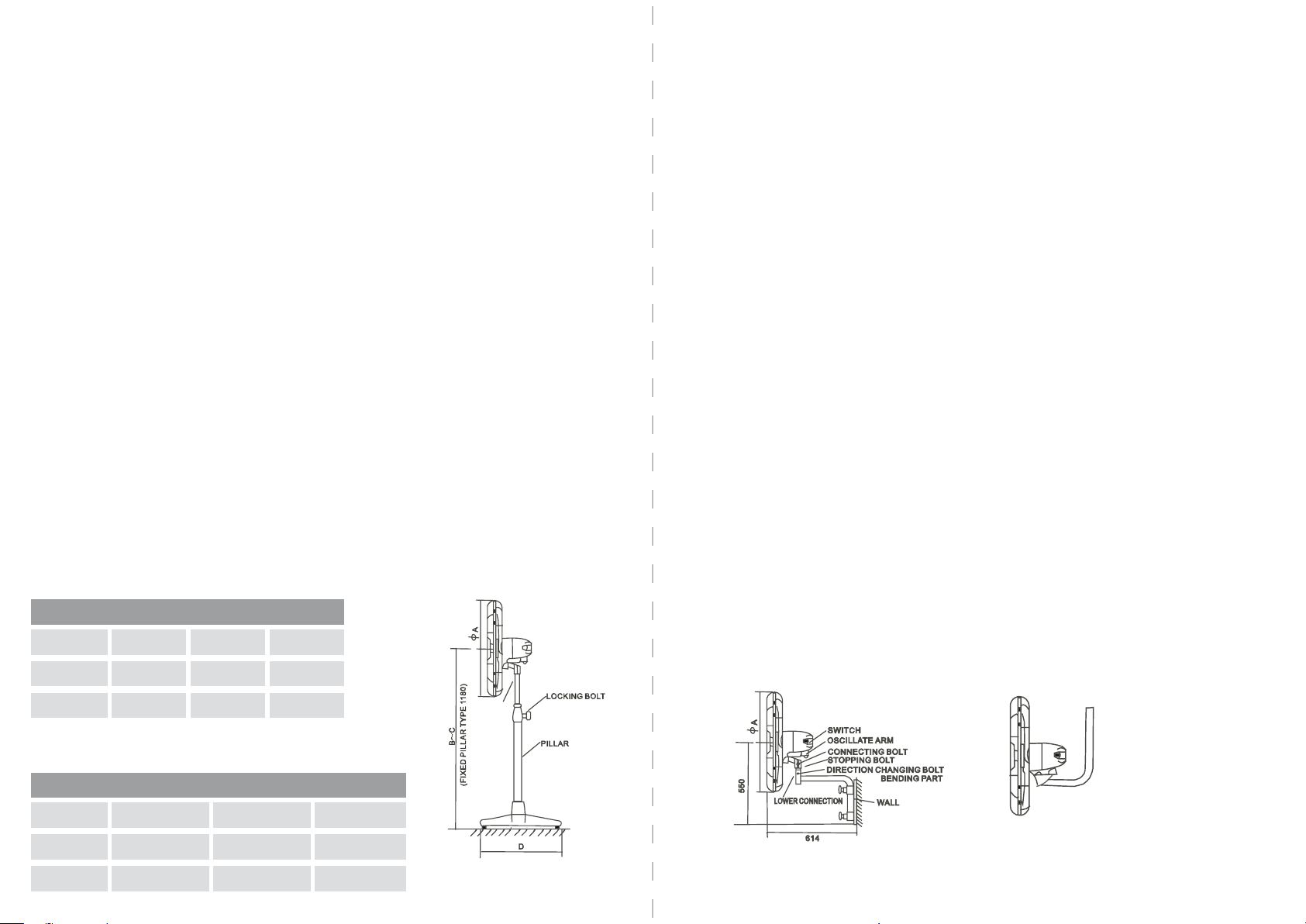

OSCILLATING CONTROL

UPWARD INSTALLATION

OF ANGLE ARM

DOWNWARD INSTALLATION

OF ANGLE ARM

®

INDUSTRIAL WORKSHOP FANS

1. FRONT GUARD

2. BLADE

3. SCREW

4. BOLT

5. SPRING WASHER

6. WASHER

7. BACK GUARD

8. NUT

9. SPRING WASHER

10. GUARD CLIP

11. GUARD CLIP

12. SCREW

13. MOTOR

14. NUT

15. WASHER

16. SCREW

17. WIRING CLIP

18. BOLT

19. FIXING COVER

20. FIXING SCREW

21. SUPPORT

22. DECORATING COVER

23. PEDESTAL

24. WASHER

25. WASHER

26. SPRING WASHER

27. BOLT

28. BOLT

29. NUT

30. BOLT

31. BOLT

32. WALL PLATE

33. SUPPORT ARM

34. FIXING SCREW

35. LOWER CONNECTION

PEDESTAL FAN

ASSEMBLING ORDER

21→23→24→25→26→27→22

→19→20→13→18→15→14→7

→6→5→4→2→3→1→10→11

→12→9→8→17→16

WALL MOUNT FAN

ASSEMBLING ORDER

35→33→34→32→30→31→29

→28→13→18→15→14→7→6

→5→4→2→3→1→10→11→12

→9→8→17→16

TPF24

TPF30

TWF30

24” / 600mm PEDESTAL FAN

30” / 750mm PEDESTAL FAN

30” / 750mm WALL MOUNT FAN

READ CAREFULLY AND UNDERSTAND THESE INSTRUCTIONS BEFORE USE.

Limited Warranty

Industrial Tool & Machinery Sales (hereinafter

refered to as ITMS) will, within twelve (12) months

from the original date of purchase, repair or replace

any goods found to be defective in materials or

workmanship.

This warranty is void if the item has been damaged

by accident, neglect, improper service or other

causes not arising out of defects in materials or

workmanship. This warranty does not apply to

machines and/or components which have been

altered, changed, or modified in any way, or

subjected to overloading or use beyond

recommended capacities and specifications. Worn

componentry due to normal wear and tear is not a

warranty claim. Goods returned defective shall be

returned prepaid freight to ITMS or agreed repair

agent, which shall be the buyer’s sole and exclusive

remedy for defective goods. ITMS accepts no

additional liability pursuant to this guarantee for the

costs of travelling or transportation of the product

or parts to and from ITMS or the service agent or

dealer, such costs are not included in this warranty.

The manufacturer reserves the right to make

improvements and modifications to design without

prior notice.

Technical Specifications

Part #

Phase

Voltage

Power

1. If an electrical fault is detected or the power

supply cord is damaged, the device must sent to a

licenced electrician for repair.

2. Guard against electric shock, avoid body

contact with earthed or grounded surfaces eg.

pipes, air con, refrigerators etc.

Never operate the device in rain or wet conditions,

or if the tool has been exposed to rain or wet

conditions.

3. Power source; ensure that the power source to

be used conforms to the power requirements

specified on the name plate.

Ensure the power supply plug matches the outlet.

Never modify the plug or use adaptors.

4. Do not abuse the power cord. Never use the

cord for carrying, pulling or unplugging the

device. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. Extension cord; when using an extension cord

ensure sufficient thickness and rated capacity.

6. The Trademaster fan is suitable for cooling in

factories, warehouses, workshops and industrial

work areas. It is not designed for domestic use.

Operating Procedures

1. Oscillating control; The oscillating structure is shown in the drawing. When the oscilate arm is

secured to the centre bolt hole, the fan will not oscillate. When oscilate arm is moved to the off-centre

bolt hole, the fan will oscillate 90 degrees. Always ensure the power is turned off before making any

oscillating adjustments

5. Fan Direction; To change the direction of the fan, turn off the power, loosen the direction-changing

bolt, adjust the direction of the fan head and tighten the bolt. It is not necessary to move the base of

the fan.

6. Upward and downward tilt adjustment; Turn off the power, hold the head of the fan, loosen the

connecting bolt and stopping bolt, adjust the fan to satisfactory position and tighten up the two bolts.

19mm Spanner required ( not supplied )

7. Head Height Adjustment(pedestal type only); Turn off the power. Loosen the locking bolt, adjust

the fan head to ideal position and then tighten up the locking bolt. In order to avoid the fan head

falling down suddenly, the fan head must be held when the locking bolt is being loosened.

8. Installation of the wall fan base; The angle arm of the fan can be installed facing upwards or

downwards. In both cases, the longer of the two locking bolts must be inserted through the small hole

at the end of the angle arm in order to avoid falling off.

9. Speed Adjustment; The fan incorporates 3 speed settings which are controlled by the switch on the

back of the fan head. “0” represents stop. “1” is the lowest blade speed setting, “3” is the highest.

Maintenance

1. Grease change; After the fan is operated over 2000 hours (or at least once a year), the grease in the

gearbox and bearing should be changed.

2. Care; If the fan is not used for extended periods, it should be cleaned and put into a dry place.

TPF24

TPF30

TWF30

Installation Dimensions

Spec

TPF24

General Safety Instructions

TPF30

TWF30

1

1

1

Ф

654mm

824mm

824mm

220-240v

220-240v

220-240v

B - C

1235-1760mm

1235-1760mm

160w

280w

280w

D

600mm

700mm

-

-

PEDESTAL TYPE

WALL TYPE

Loading...

Loading...