Trademaster TGMD400 User Manual

www.industrialtool.com.au

®

GEARED HEAD DRILL / MILL MACHINE

INSTRUCTION MANUAL

READ CAREFULLY AND UNDERSTAND THESE INSTRUCTIONS BEFORE USE.

LIMITED WARRANTY

PRIOR TO OPERATION

Industrial Tool & Machinery Sales (hereinafter

refered to as ITMS) will, within twelve (12)

months from the original date of purchase,

repair or replace any goods found to be

defective in materials or workmanship.

This warranty is void if the item has been

damaged by accident, neglect, improper

service or other causes not arising out of

defects in materials or workmanship. This

warranty does not apply to machines and/or

components which have been altered,

changed, or modified in any way, or

subjected to overloading or use beyond

recommended capacities and specifications.

Worn componentry due to normal wear and

tear is not a warranty claim. Goods returned

defective shall be returned prepaid freight to

ITMS or agreed repair agent, which shall be

the buyer’s sole and exclusive remedy for

defective goods. ITMS accepts no additional

liability pursuant to this guarantee for the

costs of travelling or transportation of the

product or parts to and from ITMS or the

service agent or dealer, such costs are not

included in this warranty.

The manufacturer reserves the right to make

improvements and modifications to design

without prior notice.

Imported & Distributed By

Industrial Tool & Machinery Sales

18 Business St, Yatala, QLD 4207

PH: 07 3287 1114 FX: 07 3287 1115

sales@industrialtool.com.au

www.industrialtool.com.au

1. Power source; ensure that the power

source to be used conforms to the power

requirements specified on the name plate.

2. Power switch; ensure that the power switch

is in the OFF position before any power is

supplied to the machine.

3. Extension cord; when an extension cord

must be used, ensure it is of sufficient

thickness and rated capacity, and kept in the

shortest length possible while remaining

practical.

SAFETY PRECAUTIONS

Warning! When using electric tools basic

safety precautions should always be followed

to reduce the risk of fire , electric shock and

personal injury, including but not limited to

the following.

Safety - Environment

1. Keep work area clean. Cluttered areas and

benches invite injury.

2. Keep children & unauthorised persons

away from the tool. Keep tool in work area

with authorised trained personnel to use

machine.

3. Power tools must be used in dry areas only.

When using power tools outdoors, use

suitable extension cord.

1

Safety - Peronal

1. Dress properly, do not wear loose clothing

or jewellery, they can invite personal injury.

Always cover long hair.

2. When operating power tools suitable

personal protective equipment must be worn

where necessary, including, but not restricted

to eye, ear, respiratory and foot protection.

3. Stay alert, do not use power tools when

tired or under the influence of alcohol, drugs

or medicine as injury may occur.

Safety - Operation

1. Secure the work in the vice. Do not hold

material by hand.

2. Keep proper footing and balance at all

times when using tool.

MACHINE OPERATION

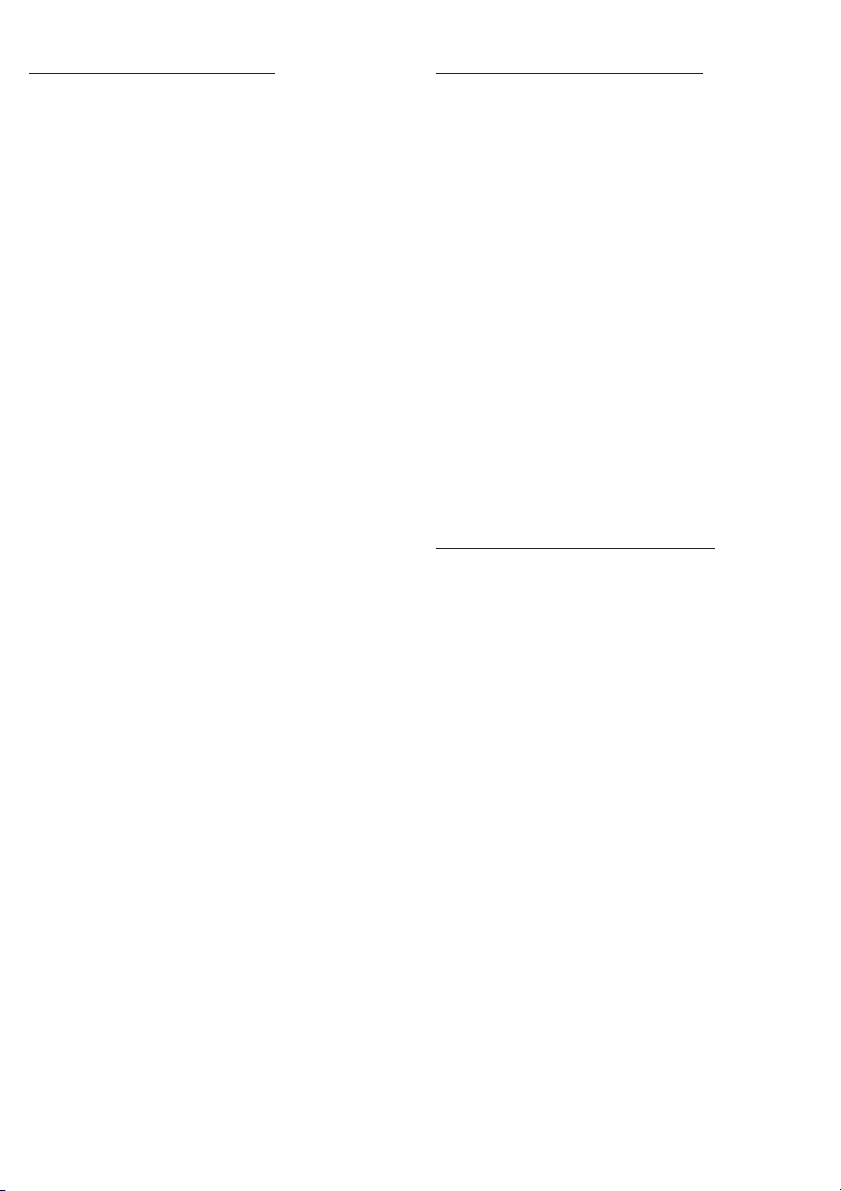

FIGURE 1

3. Keep hands away from cutting area while

machine is in operation.

4. Guards should be in place and in working

order. Remove adjusting keys and wrenches

before turning on.

4. Ensure cutting tool is correctly secured

into machine before operation.

Safety - After Use

1. Disconnect machine from power when not

in use.

2. Store machine in a dry place, well out of

reach of children.

2

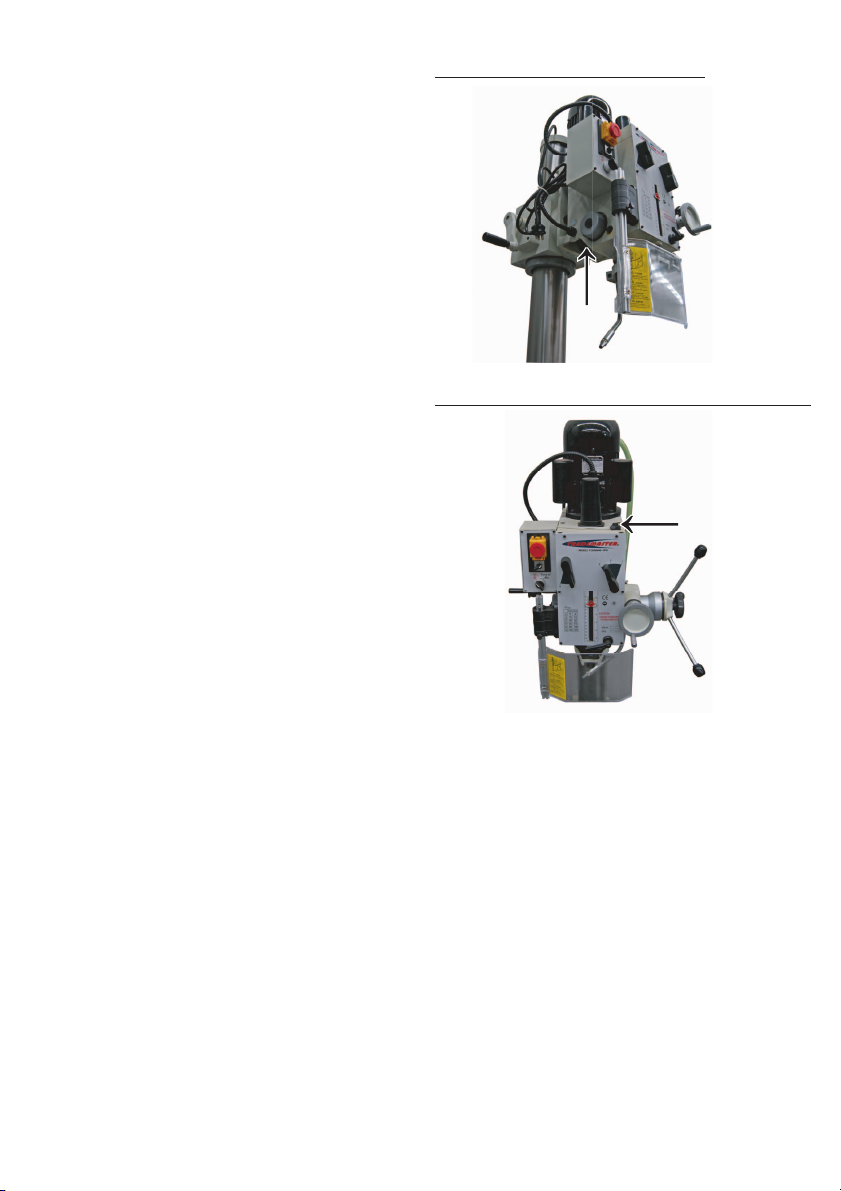

FIGURE 2

CHANGING THE GEAR BOX OIL

Place a bucket to catch the oil onto the work

table, then remove the oil drain socket head

bolt located within the drill head as shown in

Figure 1, and allow the oil to drain from the

opening completely. Then replace & tighten

the oil drain socket head bolt into it’s original

position. Remove the oil filler bolt shown in

figure 2, fill the oil in the gear box with

standard 80weight gear oil until the oil level

reaches the middle of oil fluid level indicator

glass. Then replace and tighten the bolt.

Loading...

Loading...