Trademaster BM-21 Operator's Manual

OPERATOR’S MANUAL

BM-21

BEVELLING MACHINE

IMPORTED & DISTRIBUTED BY

18 BUSINESS ST

YATALA QLD 4207 AUSTRALIA

07 3287 1114

T

07 3287 1115

F

sales@industrialtool.com.au

E

www.industrialtool.com.au

W

INDUSTRIAL TOOL & MACHINERY SALES

WARRANTY TERMS

In addition to any warranties or conditions implied by applicable Statute or Regulations,

Industrial Tool & Machinery Sales warrants all of it’s products against defective workmanship

and faulty materials for a period of twelve (12) months from the date of purchase, unless otherwise stated. At our option we will repair or replace, free of charge, any item on the condition that:

- The complete machine or tool is returned, freight prepaid to ITM or one of it’s authorised

service agents as directed by ITM, and is found to have a material or constructional defect.

- The machine or tool has not been subject to misuse, neglect or damage by accident.

- The fault is not a result of normal “wear and tear”.

- Written permission has been received from ITM prior to commencement of repair.

- Repairs, tampering or modification carried out by unauthorised personnel will void all warranty.

- Consumable items such as cutting tools, pilot pins, saw blades, grinding wheels etc. are

NOT covered by warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

Read Operator’s Manual

before you start to work with the machine

Operator’s Manual – BM-21 Bevelling Machine

2

CONTENTS

1. GENERAL INFORMATION.................................................................4

1.1. Application....................................................................................4

1.2. Technical data..............................................................................4

1.3. Equipment included ....................................................................5

2. SAFETY

3. STARTUP AND OPERATION.............................................................8

3.1. Preparing to operation..................................................................8

3.2. Adjusting bevel width and angle...................................................9

3.3. Bevelling metal plates.................................................................10

3.4.Bevelling pipes............................................................................10

3.5.Bevelling larger pipes (only for optional equipment)...................13

3.6.Replacing cutting inserts.............................................................14

3.7.Replacing milling head................................................................15

4. WIRING DIAGRAM...........................................................................16

PRECAUTIONS....................................................................6

Operator’s Manual – BM-21 Bevelling Machine

3

1. GENERAL INFORMATION

GENERAL INFORMATION

1.

1.1. Application

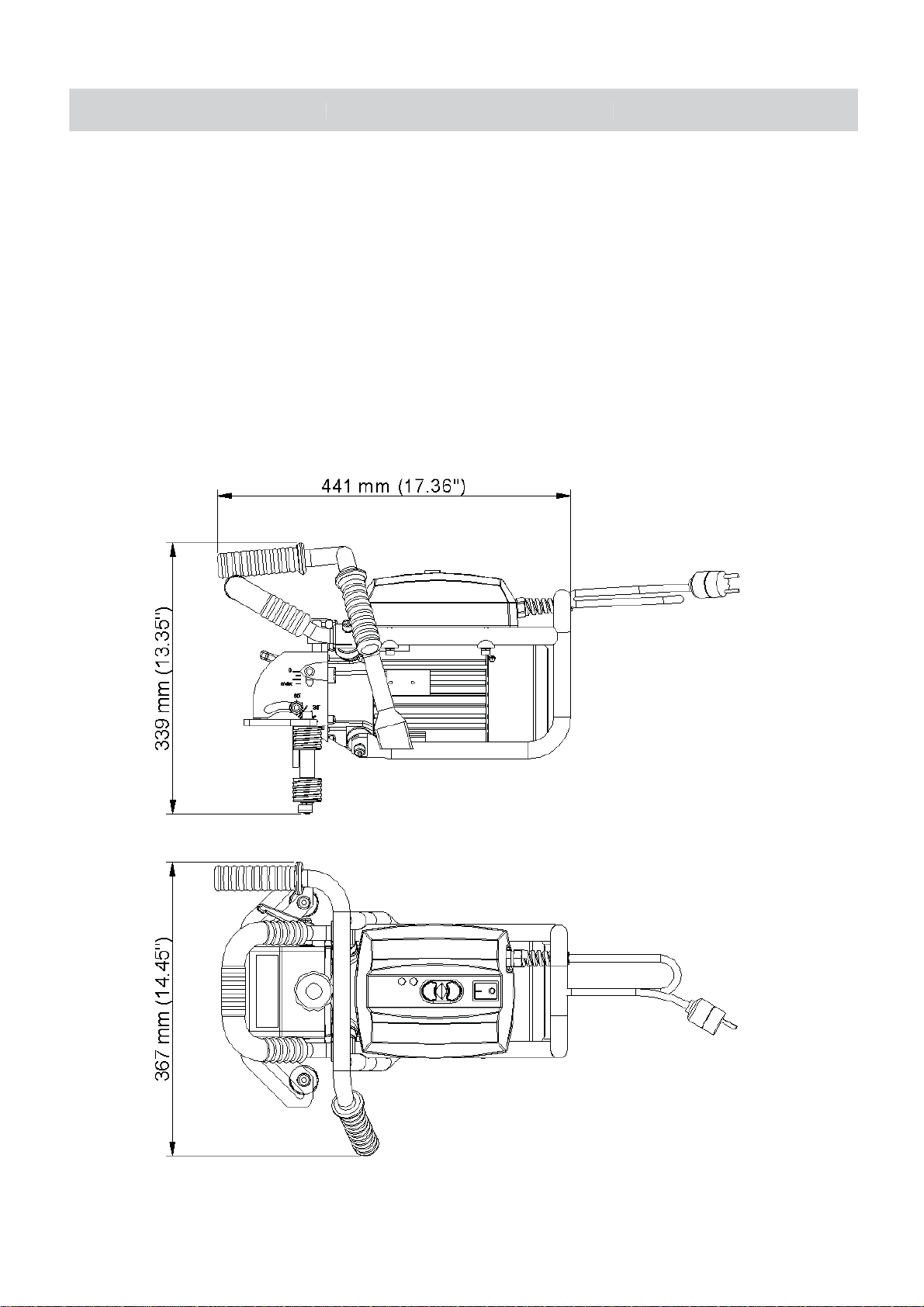

The BM-21 Bevelling Machine is designed for milling edges of plates and pipes

made of carbon steel. The machine enables the bevelling of sheet steel edges and

pipe edges with diameters from 150 mm (6’’) to 300 mm (12’’) in 0–60° angular range

with maximum bevel width of 21 mm (13/16’’). When equipped with the optional

guide available on request, it can also work on pipes with diameters above 300 mm

(12’’). The machine contains dampers that enable more comfortable operation, reducing unwanted vibrations.

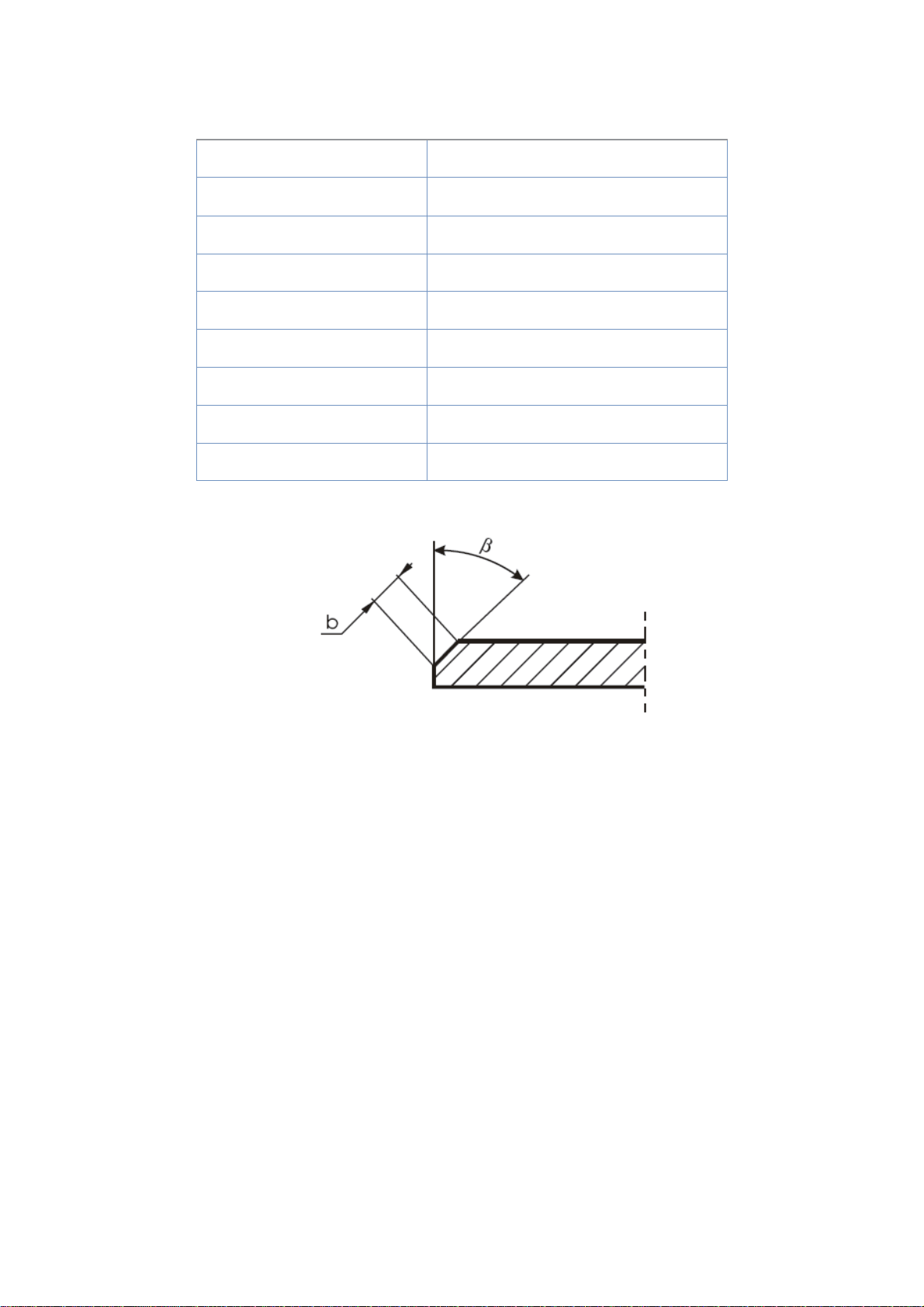

1.2. Technical data

Operator’s Manual – BM-21 Bevelling Machine

4

Voltage ~ 220–240 V, 50–60 Hz

Electric motor

Single-phase induction motor with run

capacitor; 1100 W

Power 1600–1800 W

Rotational speed 2780–3340 rpm

Protection level IP 20

Milling speed 550–650 m/min (1800–2200 ft/min)

Maximum bevel width b 21 mm (13/16’’, Figure 1)

Bevel angle range 0° ß 60° (Figure 1)

Weight Approx. 23 kg (51 lbs)

Milling tool is equipped with 10 removable multi-edge cutting inserts made of carbide.

Figure 1. Bevel dimensions

1.3. Equipment included

BM-21 Bevelling Machine is supplied in metal box with complete standard equipment.

The included equipment consists of:

• bevelling machine with a set of cutting inserts – 1 unit

• metal box – 1 unit

• size 8 Allen key – 1 unit

• size 6 Allen key – 1 unit

• size 4 Allen key – 1 unit

• size 12 flat key – 1 unit

• torx T15 screwdriver – 1 unit

• Operator’s Manual – 1 unit

Operator’s Manual – BM-21 Bevelling Machine

5

2. SAFETY PRECAUTIONS

Using the machine is not allowed if:

1. Operator has not read Operator’s Manual or has not completed proper occupational safety and

health training.

2. Machine is to be used in applications not stated in Operator’s Manual.

3. Machine is not complete or parts used for repair are not genuine.

4. Power supply specifications do not conform to those stated on rating plate.

5. Operator has not checked condition of machine, including power cord, control panel components

and milling tools.

6. Power supply socket is not equipped with earthing pin.

7. Bystanders are present in immediate vicinity of machine.

Detailed safety rules:

1) Before you start to work with machine, check condition of electrical installation, including power

cord and plug.

2) Connect machine only to power sockets equipped with a safety circuit (earthing) protected with

16A fuse for 230 V supply. When used on building sites, supply power to machine through

a separation transformer with a class 2 power supply.

3) Never carry machine by cord or pull it to disconnect plug from socket. It may cause power cord

to break and result in electric shock.

4) Keep machine dry. Exposing it to rain or snow is prohibited.

5) Ensure proper lighting on your worksite.

6) Never use machine in vicinity of combustible fluids or gases or in explosive environments.

7) Always use safety goggles, hearing protection, gloves and protective clothing during operation.

Do not wear loose clothing!

8) Never use blunt or damaged tools.

9) Never remove hot and sharp metal chips with bare hands.

10) Securely fasten cutting inserts in milling head using fastening screws.

WARNING! Do not hold rotating parts

of the machine or metal chips formed during milling!

Operator’s Manual – BM-21 Bevelling Machine

6

Loading...

Loading...