Trademaster BM16 Operator's Manual

INDUSTRIAL TOOLS

OPERATOR’S MANUAL

B

B

M

M--1166

BEVELLING MACHINE

BM16

BEVELLING MACHINE

OPERATOR’S MANUAL

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

Serial #............................................ Date of Purchase............................

TRADEMASTER BM16 BEVELLING MACHINE

LIMITED WARRANTY

Industrial Tool & Machinery Sales (hereinafter referred to as ITMS) will, within twelve (12)

months from the original date of purchase, repair or replace any goods found to be defective

in materials or workmanship.

This warranty is void if the item has been damaged by accident, neglect, improper service or

other causes not arising out of defects in materials or workmanship. This warranty does not

apply to machines and/or components which have been altered, changed, or modified in any

way, or subjected to overloading or use beyond recommended capacities and specifications.

Worn componentry due to normal wear and tear is not a warranty claim. Goods returned

defective shall be returned prepaid freight to ITMS or agreed repair agent, which shall be the

buyer’s sole and exclusive remedy for defective goods. ITMS accepts no additional liability

pursuant to this guarantee for the costs of travelling or transportation of the product or parts to

and from ITMS or the service agent or dealer, such costs are not included in this warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

THE MANUFACTURER RESERVES THE RIGHT TO MAKE IMPROVEMENTS AND

MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

PRODUCTS IMPORTED AND DISTRIBUTED NATIONALLY BY:

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST, YATALA QLD 4207

T: 07 3287 1114 E: sales@industrialtool.com.au

F: 07 3287 1115 W: www.industrialtool.com.au

TABLE OF CONTENTS

1.GENERAL INFORMATION ............................................................................................3

1.1.Application ...................................................................................................................3

1.2.Technical data .............................................................................................................3

1.3.Equipment included .....................................................................................................4

1.4.Dimensions ..................................................................................................................4

1.5.Design .........................................................................................................................5

2.SAFETY PRECAUTIONS...............................................................................................6

3.STARTUP AND OPERATION ........................................................................................8

3.1.Installing and removing the milling head .....................................................................8

3.2.Adjusting the bevel parameters .................................................................................10

3.3.Adjusting the guide for bevelling with radius .............................................................11

3.4.Preparing

3.5.Operating

3.6.Replacing the cutting inserts .....................................................................................13

3.7.Replacing the roller....................................................................................................14

3.8.Replacing the brushes ...............................................................................................15

4.ACCESSORIES............................................................................................................16

4.1.Guide for bevelling pipes

4.2.Anti-scratch guide sticker

4.3.Worktable fixture........................................................................................................18

4.4.Radius insert positioner .............................................................................................22

4.5.Milling tools ................................................................................................................23

5.SPARE AND WEARING PARTS..................................................................................23

6.WIRING DIAGRAM ......................................................................................................24

2

7.PARTS LIST

...................................................................................................................11

...................................................................................................................12

...........................................................................................16

..........................................................................................18

.................................................................................................................25

GENERAL INFORMATION

BM-16

1~ 220–240 V, 50–60 Hz

1~ 110–120 V, 50–60 Hz

Power

2200 W

Rotational speed (without load)

1800–5850 rpm

Protection level

IP 20

Protection class

II

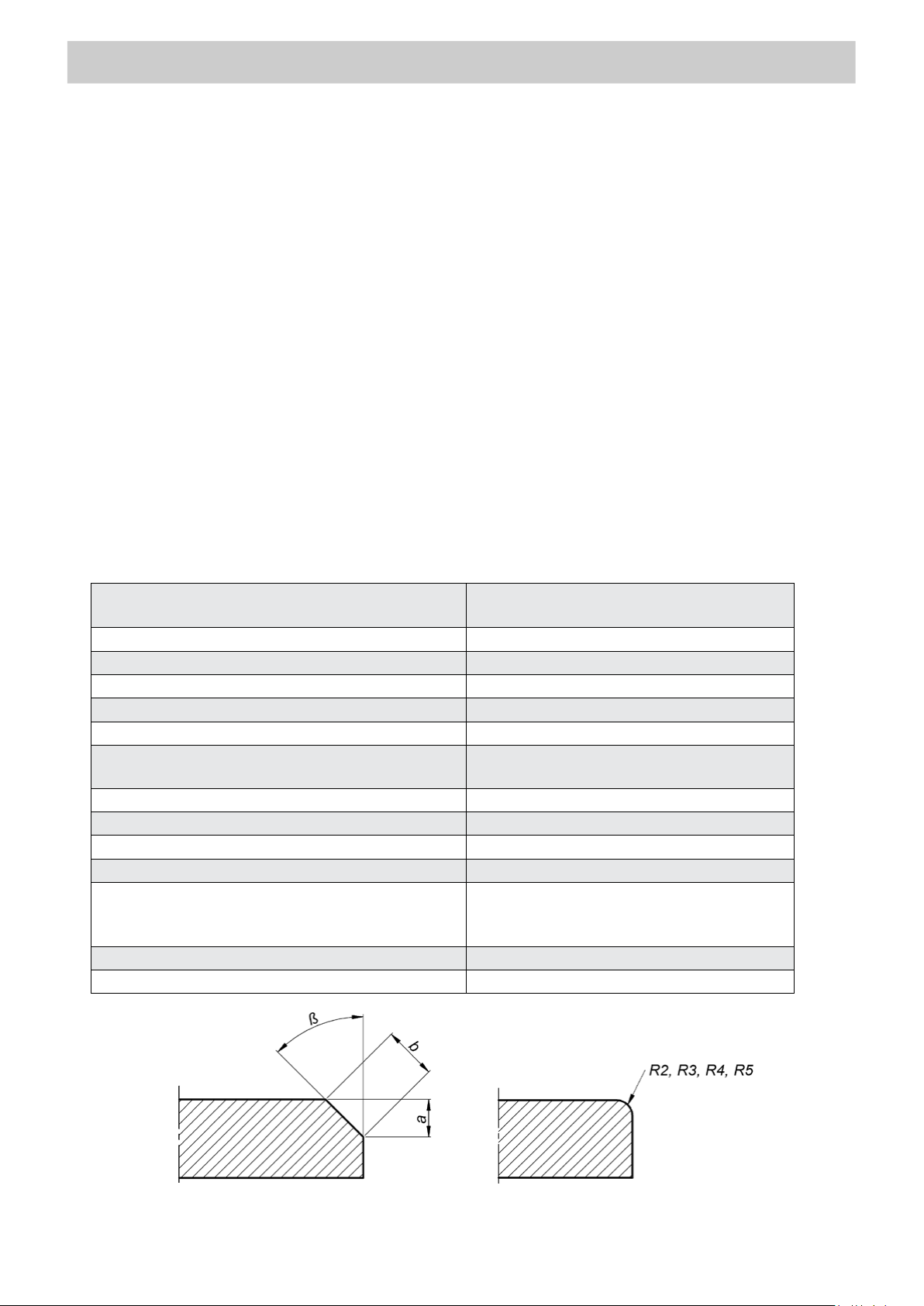

Maximum bevel width (b)

16 mm (0.63’’, Fig. 1)

Bevel angle (ß, depends on the

milling head used)

22.5°, 30°, 37.5°, 45°, 50°, 55°, 60°, 65°

(Fig. 1)

Minimum workpiece thickness for bevelling

1.5 mm (0.06’’)

Minimum hole diameter

40 mm (1.57’’)

Edge radius

2 mm, 3 mm, 4 mm, 5 mm (Fig. 1)

Noise level

More than 70 dB

2.3 m/s2 (7.5 ft/s2)

break s during work.

Required ambient temperature

0–40°C (34–104°F)

Weight (without milling head)

10 kg (22 lbs)

1. GENERAL INFORMATION

1.1. Application

The BM-16 is a bevelling machine designed to mill edges of plates and pipes made

of steel, aluminum alloys, brass, or plastics.

Depending on the milling head used the machine allows bevelling workpieces

with a thickness of at least 1.5 mm (0.06’’) at the angle of 22.5°, 30°, 37.5°, 45°, 50°,

55°, 60°, or 65° to the maximum bevel width of 16 mm (0.63’’). A radius m illing h ead

allows bevelling with a radi us of 2, 3, 4, or 5 mm. The minimum diameter of a hole to

be machined is 40 mm (1.57’’).

An optional guide allows bevelling pipes, sticker protects aluminum workpieces

against scratches, and worktable fixture allows bevel ling flat bars.

1.2. Technical data

Voltage

Vibration level

Machine harmful for health. Take periodic

Fig. 1. Bevel dimensions

3

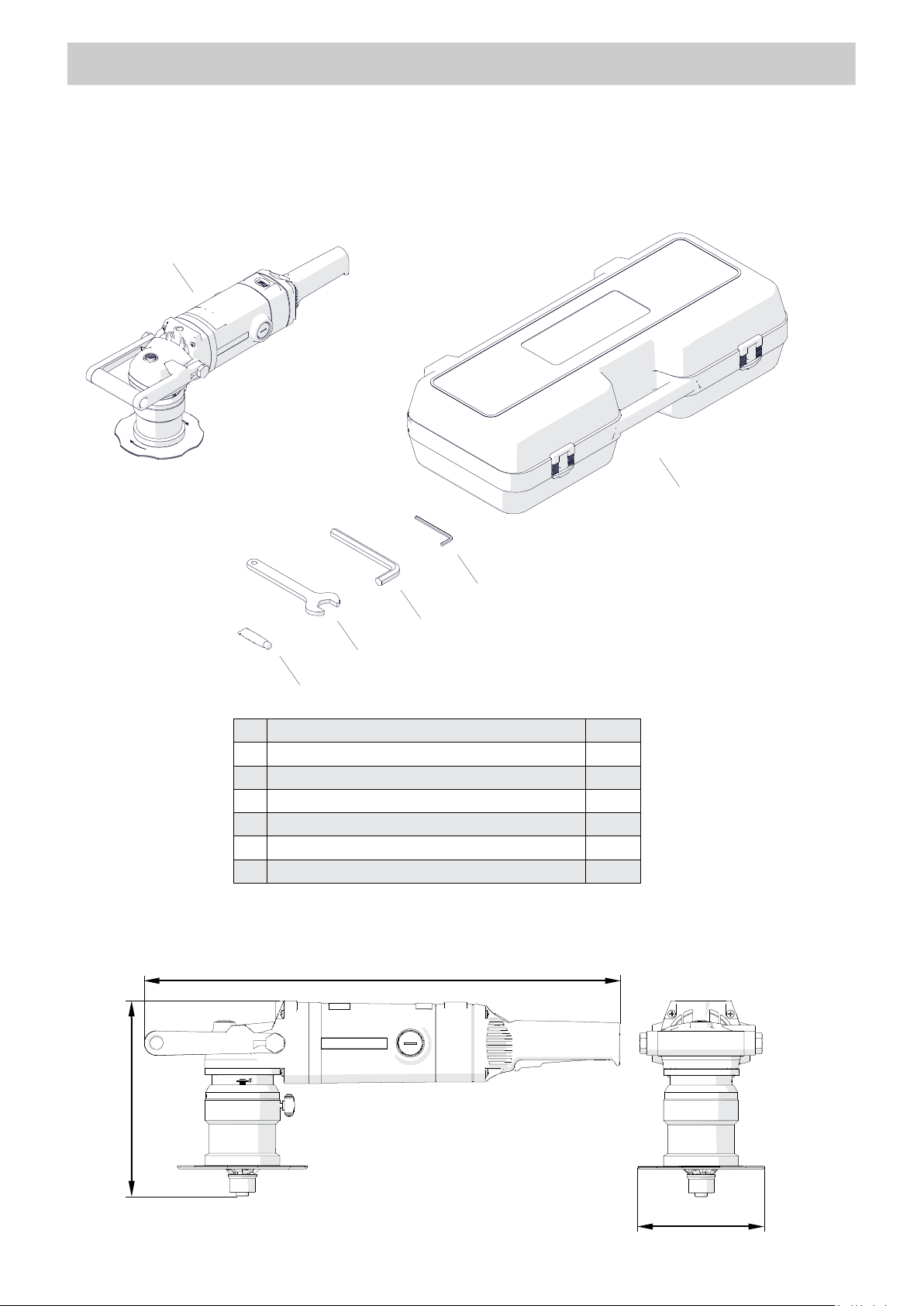

BM-16

1

Bevelling machine (without milling head)

1 unit

2

Plastic box

1 unit

3

5 mm hex wrench

1 unit

4

14 mm hex wrench

1 unit

5

32 mm flat wrench

1 unit

6

Grease for screws (5 g, 0.17 oz)

1 unit

–

Operator’s Manual

1 unit

1

3 4 5

2

6

585 mm (23’’)

241 mm (9.4’’)

156 mm (6.1’’)

1.3. Equipment included

GENERAL INFORMATION

1.4. Dimensions

4

GENERAL INFORMATION

BM-16

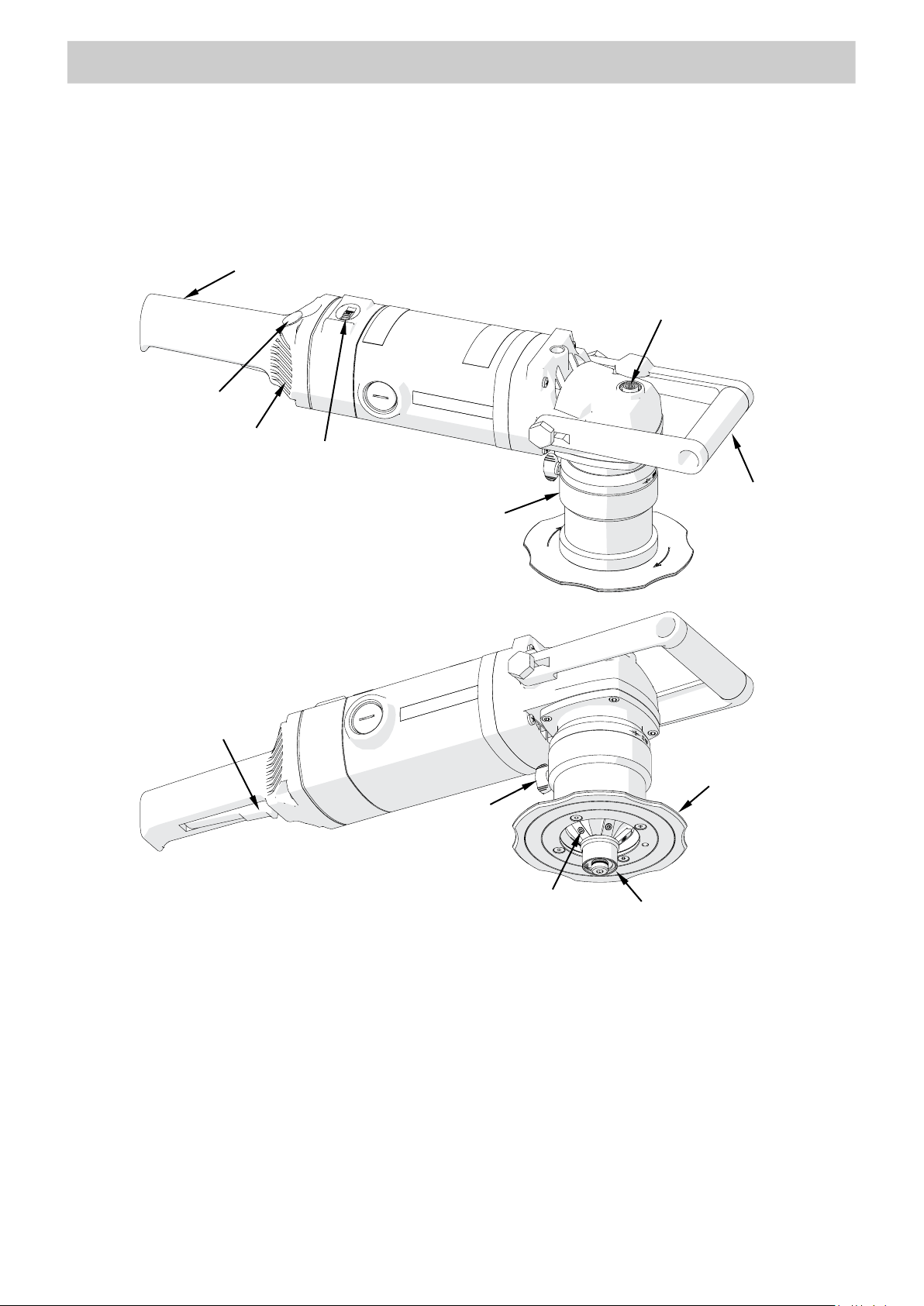

Speed adjustment dial

Handle

Handle

Spindle lock button

Switch lock

ON/OFF switch

Guide

Clamping

Milling head

Guiding roller

Sleeve

Air vents

1.5. Design

screw

5

SAFETY PRECAUTIONS

BM-16

2. SAFETY PRECAUTIONS

1. Before starting, read this Operator’s Manual and complete proper occupational

safety and health training.

2. Use the machine only in applications specified in this Operator’s Manual.

3. The

4. The specifications of the power source must conform to those specified on the

5. Never carry the machine by the cord and never pull the cord because this may

6. Untrained bystanders must not be present near the machine.

7. Before starting, ensure the correct condition of the machine, power source, power

8. Keep the machine dry, and never expose it to rain, snow, or frost.

9. Keep the work area well lit, clean, and free of obstacles.

machine must be complete and all parts must be genuine and ful l y functional.

rating plate.

damage it and result in electric shock.

cord, plug, control components, and milling tools.

10. Never use near flammable liquids or gases, or in explosive environments.

11. Use only tools specified in this Operator ’ s Manual.

12. Never use tools that are dull or damaged.

13. Install the cutting inserts and milling head securely. Remove adjusting keys and

wrenches

14. Never use the machine in upside down position with the milling head facing up.

15. If the cutting edge of the insert is worn, rotate the insert in the socket by 90° or

180° or, if all possible to use edges are worn, replace with a new insert specified in

this Operator’s Manual.

16. Before every use, inspect the machine to ensure it is not damaged. Check whether

any part is cracked or improperly fitted. Make sure to maintain proper conditions

that may affect the operation of the machi ne.

17. Always use eye and hearing protection, non-skid footwear, and protective clothing

during work. Do not wear loose clothing.

18. Never use the spindle lock button when operating the machine or removing the

from the work area before connecting the machine to the power sourc e.

milling head because this may damage the machine.

19. Do not touch moving parts or metal chips formed during milling. Prevent objects

from being caught in movi ng parts .

6

SAFETY PRECAUTIONS

BM-16

20. After every use, remove metal chips from the machine, especially from the milling

head. Never remove chips with bare hands. Clean

the machine with a c otton cloth

without using any agents.

21. Cover steel parts with a thin anti-corrosion coating to protect them from rust when

not in use for any extended period.

22. Maintain the machine and install/remove parts and tools only when the machine

is unplugged from the power source.

23. Repair only in a service center appointed by the seller.

24. If the machine falls from any height, is wet, or has any other damage that could

affect the technical state of the machine, stop the work and promptly

send the

machine to the service center for inspection and repair.

25. Remove

from the worksite and store in a secure and dry place when not in use.

7

STARTUP AND OPERATION

BM-16

2 1 3 6 7 5 8

CORRECT

INCORRECT

INCORRECT

Washers

Distance

4

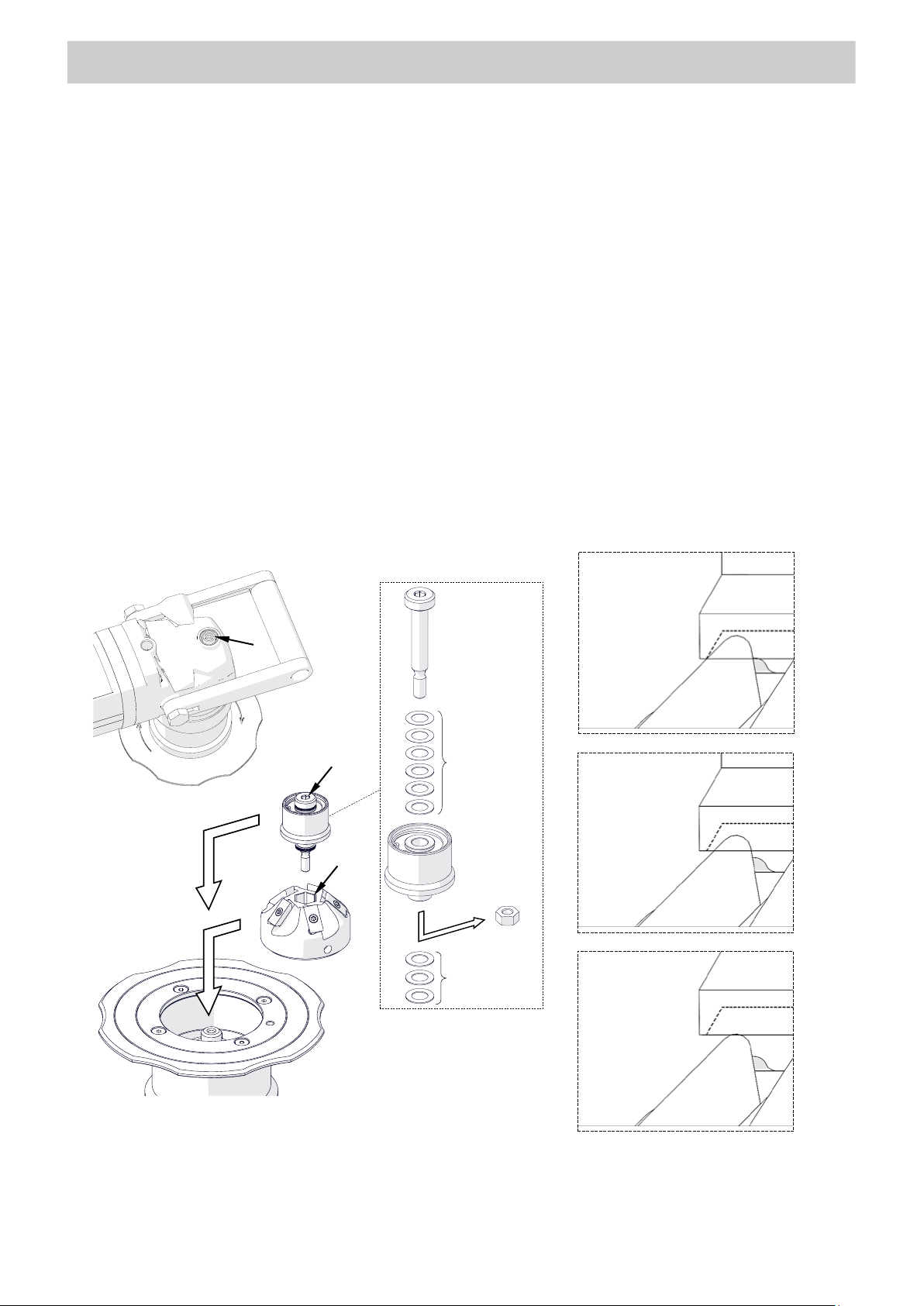

3. STARTUP AND OPERATION

3.1. Installing and removing the milling head

Unplug the machine from the power source. To install the milling head, place it on the

spindle (1, Fig. 2), and then press and hold the spindle lock button (2) and tighten the

head with the 14 mm hex wrench (3). Next, remove the nut (4) and assemble the roller

with

the pivot pin by using washers (5), and then place the roll er on the milli ng head ( 6),

press and hold the button (2), and tighten the roller with the 5 mm hex wrench (7).

Use such a number of 0.5-mm and 0.1-mm washers to keep a little gap between the

roller and cutting inserts (8). The number of washers needed depends on the milling

head used.

unused

washers

(collision

between

roller and

cutting insert)

✓

(too large gap

between roller

and cutting

insert)

8

Fig. 2. Installing the milling head

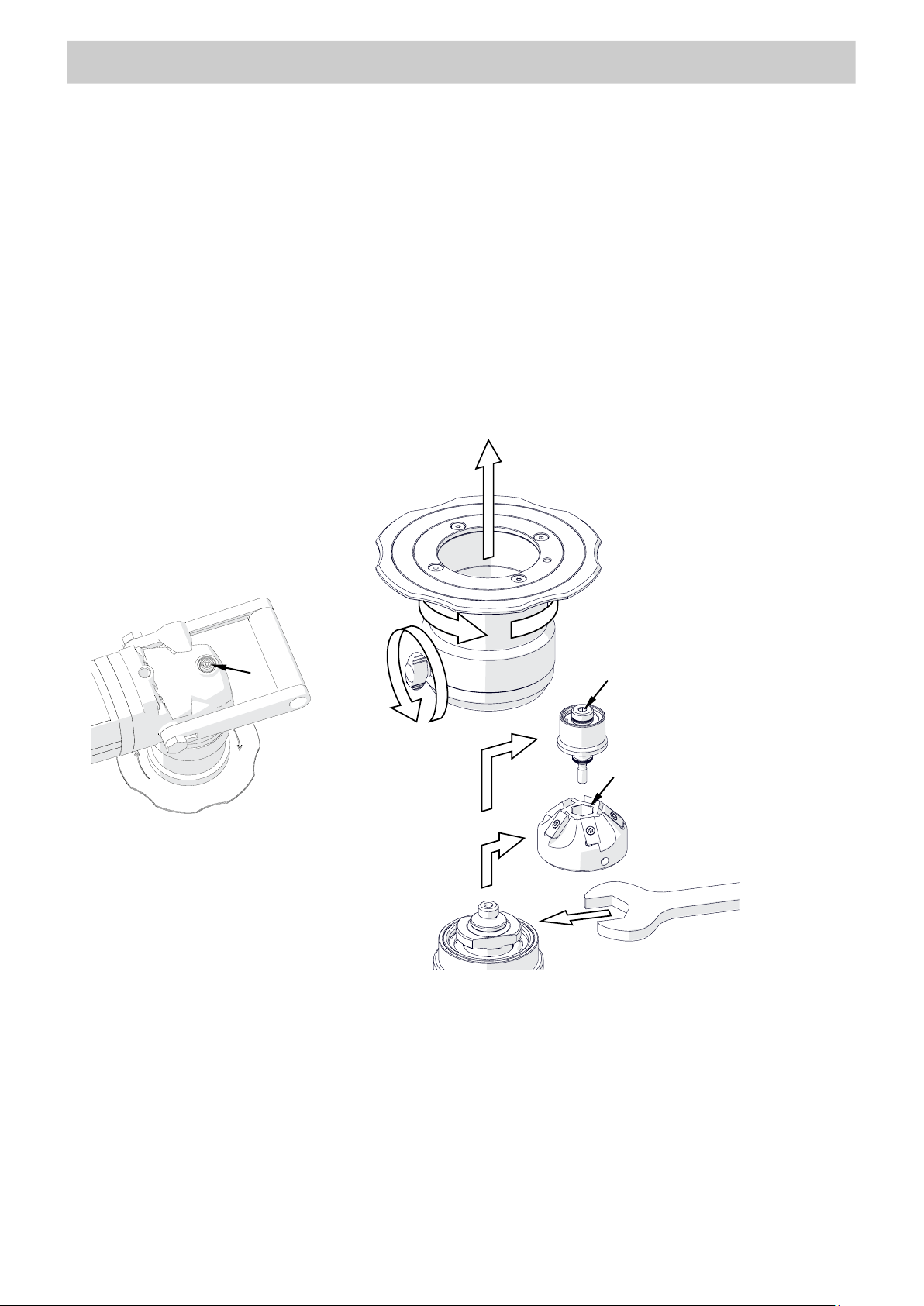

STARTUP AND OPERATION

BM-16

7

2 1 6 9 8

3

5

4

Adjust the gap between the rol l er and t he cutt ing inserts every time you replace the

milling head. Place all unused washers

between the pivot pin and the r ol ler .

To remove the milling head, loosen the clamping screw (1, Fig. 3), and then

unscrew the sleeve (2) and remove it (3). Next, press and hold the button (4), and

then use the 5 mm hex wrench (5) to unscrew the roller, and remove it (6). Lock the

spindle with the 32 mm flat wrench (7, do not use the spindle lock button 4 because

this may damage the machine), and then use the 14 mm hex wrench to unscrew the

head (8), and remove it (9).

Fig. 3. Removing the milling head

9

Loading...

Loading...