Storage Carrier

User Manual

The information contained herein is subject to change without notice. The only warranties for TradedDX products

and services are set forth in the express warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. TradeDX shall not be liable for technical

or editorial errors or omissions contained herein.

The information contained herein is subject to change without notice. The only warranties for TradeDX products

and services are set forth in the express warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. TradeDX shall not be liable for technical

or editorial errors or omissions contained herein.

Contents

Component identification .................................................. 5

Front panel components ............................................................ 6

Front panel LEDs and buttons ...................................................... 6

Rear panel components ............................................................. 7

EEB module ........................................................................ 7

System LEDs ....................................................................... 8

Power supply LEDs ................................................................. 9

Operations ............................................................... 10

Powering on ...................................................................... 10

Powering down .................................................................... 10

Verifying the power status .................................................. 10

Installation ............................................................. 11

Safety measures .................................................................. 11

Identifying the contents of the Storage Carrier shipping carton ................. 11

Hard disk drives ................................................................. 12

Removing the Hard Disk Drive ................................................ 12

Installing the Hard Disk Drive.............................................. 13

HDD matrix ....................................................................... 14

Power supply units ............................................................... 14

Removing the power supply unit.............................................. 14

Installing the Redundant Power Supply Unit ................................. 15

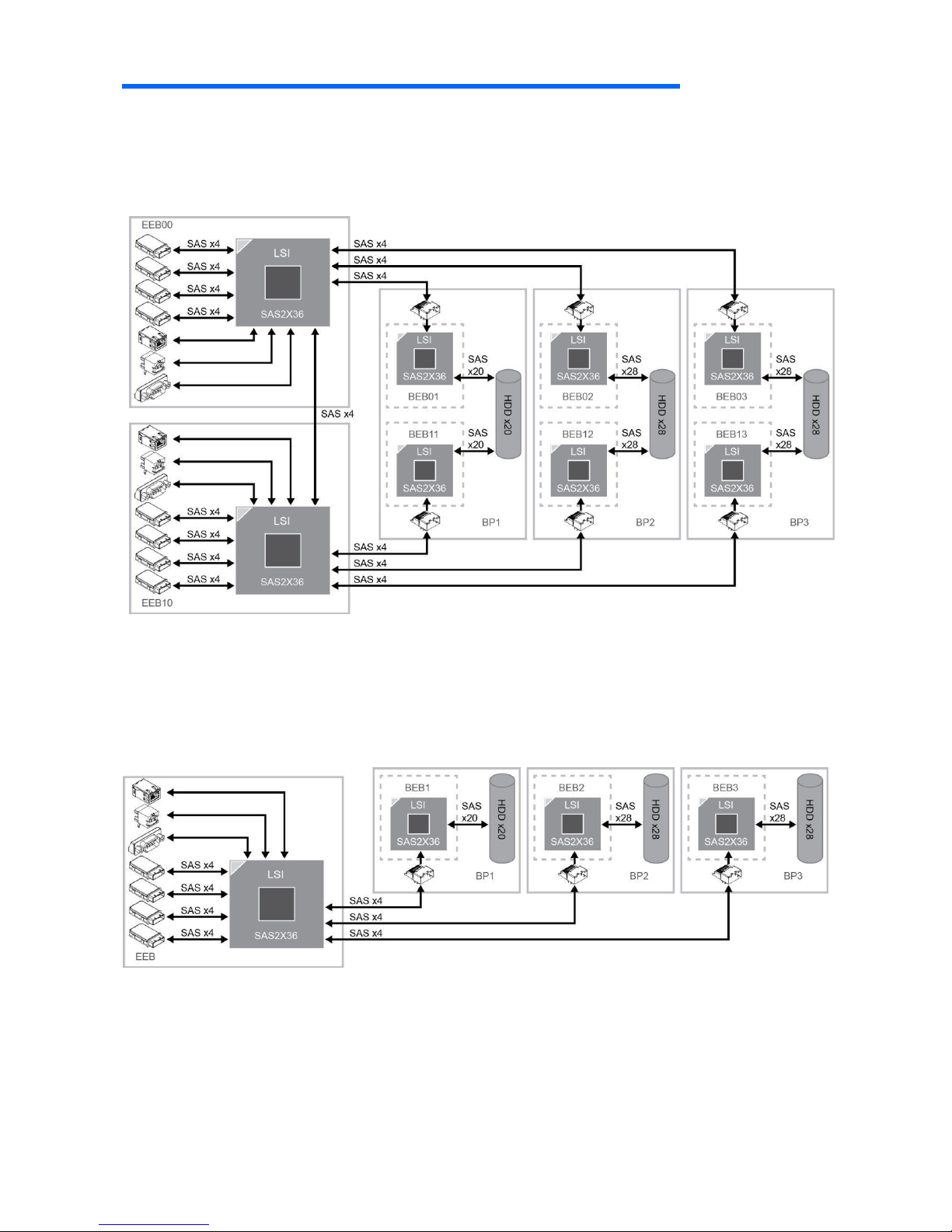

System Architecture ...................................................... 16

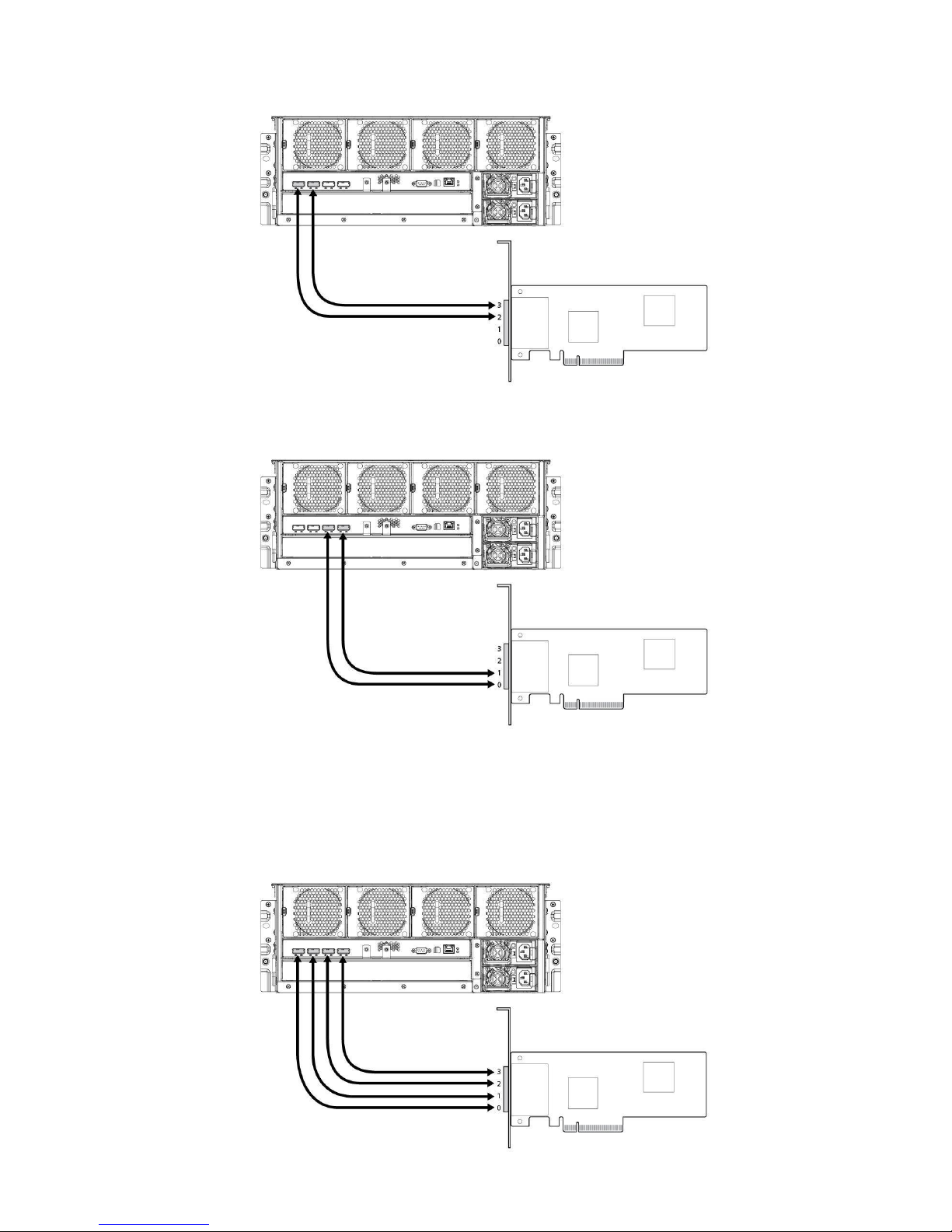

Storage Carrier SAS dual path .................................................... 16

................................................................................. 16

Storage Carrier SATA single path ................................................. 16

Backplane Expander Board (BEB) ................................................... 17

Installing a Backplane Expander Board (BEB) ..................................... 18

Front Control Module ............................................................. 19

Removing the Front Control Module ................................................ 19

Installing the Front Control Module .............................................. 21

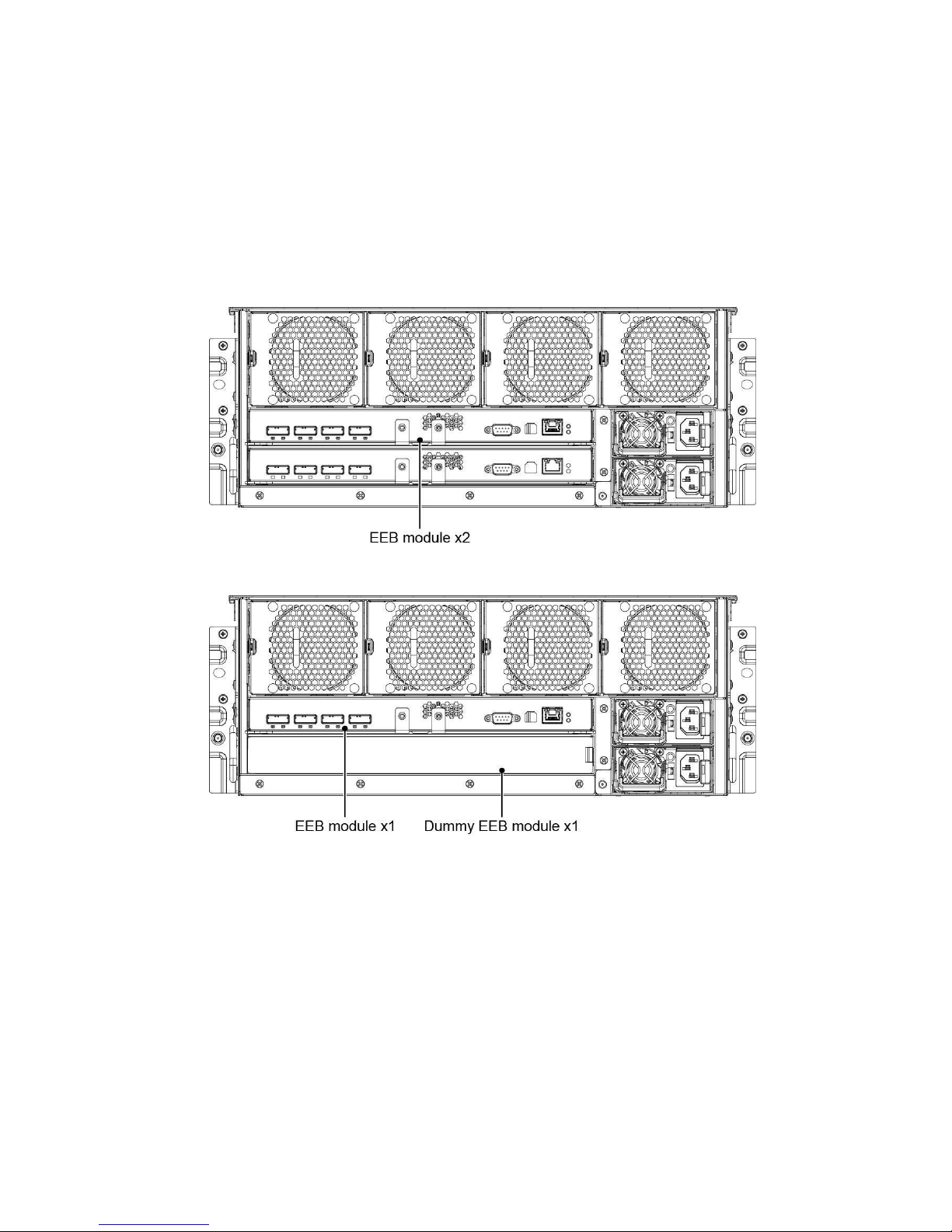

External Expander Board (EEB) .................................................... 23

Supported External Expander Boards ............................................... 23

Removing the External Expander Board (EEB) ...................................... 25

Installing the External Expander Board (EEB) .................................... 26

Fans ............................................................................. 28

Removing the System Fan .......................................................... 28

Installing the System Fan ........................................................ 28

Removing the System Fan (for PSU Cooling)........................................ 29

Installing the System Fan (for PSU Cooling) ..................................... 29

Power Distribution Board (PDB) ................................................... 30

Removing the Power Distribution Board (PDB) ..................................... 30

Installing the Power Distribution Board (PDB) ................................... 32

Mid-plane ........................................................................ 34

Removing the Mid-plane ........................................................... 34

Installing the Mid-plane ......................................................... 35

Power Interface Board (PIB) ...................................................... 36

Removing the Power Interface Board (PIB):........................................ 36

Regulatory information ................................................... 74

Class A .......................................................................... 74

European Union regulatory notice ................................................. 74

Safety ........................................................................... 74

3

Warnings & Safety/ ....................................................... 75

Important safety and compliance information .............................. 75

Safety precautions .......................................................... 75

Safety Instructions ......................................................... 75

Symbols .......................................................................... 76

Safety statements ................................................................ 77

Warnings and cautions ............................................................ 79

Electrostatic discharge .......................................................... 80

Specifications ........................................................... 81

Environmental specifications ..................................................... 81

Mechanical specifications ........................................................ 81

Support information ...................................................... 81

Customer support ................................................................. 81

Before you contact TradeDX ....................................................... 82

4

5

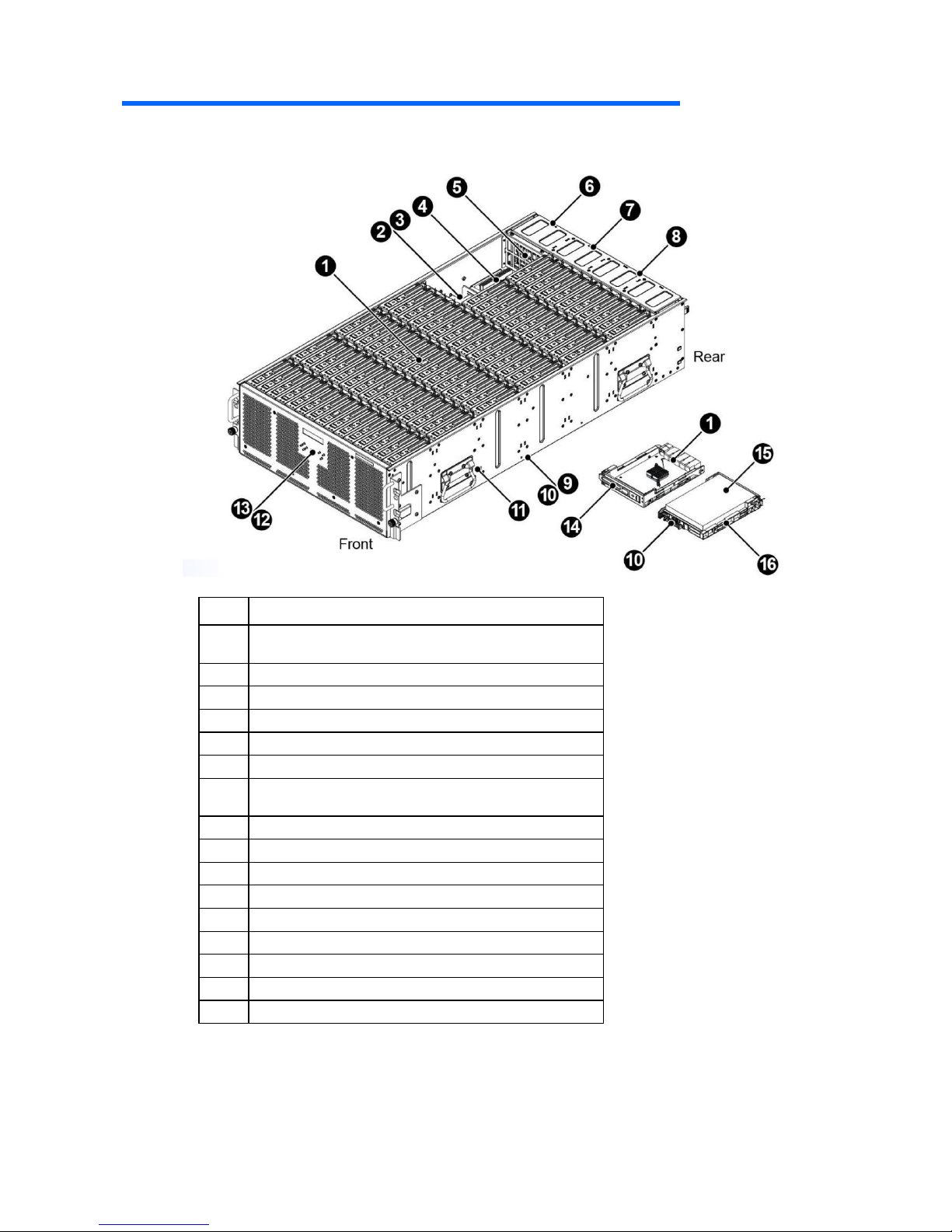

Component identification

Item

Description

1

BEB module x3 (SATA single path)

BEB module x6 (SAS dual path)

2

Power interface board

3

PSU Fan

4

Power distribution boards

5

Mid- plane

6

Power supply unit

7

EEB module x1 (SATA single path)

EEB module x2 (SAS dual path)

8

System Fans

9

HDD backplane

10

SAS interposer board

11

4U chassis

12

Fron panel board

13

LCD module

14

BEB carrier

15

SAS/ SATA HDD

16

SAS/ SATA HDD Carrier

6

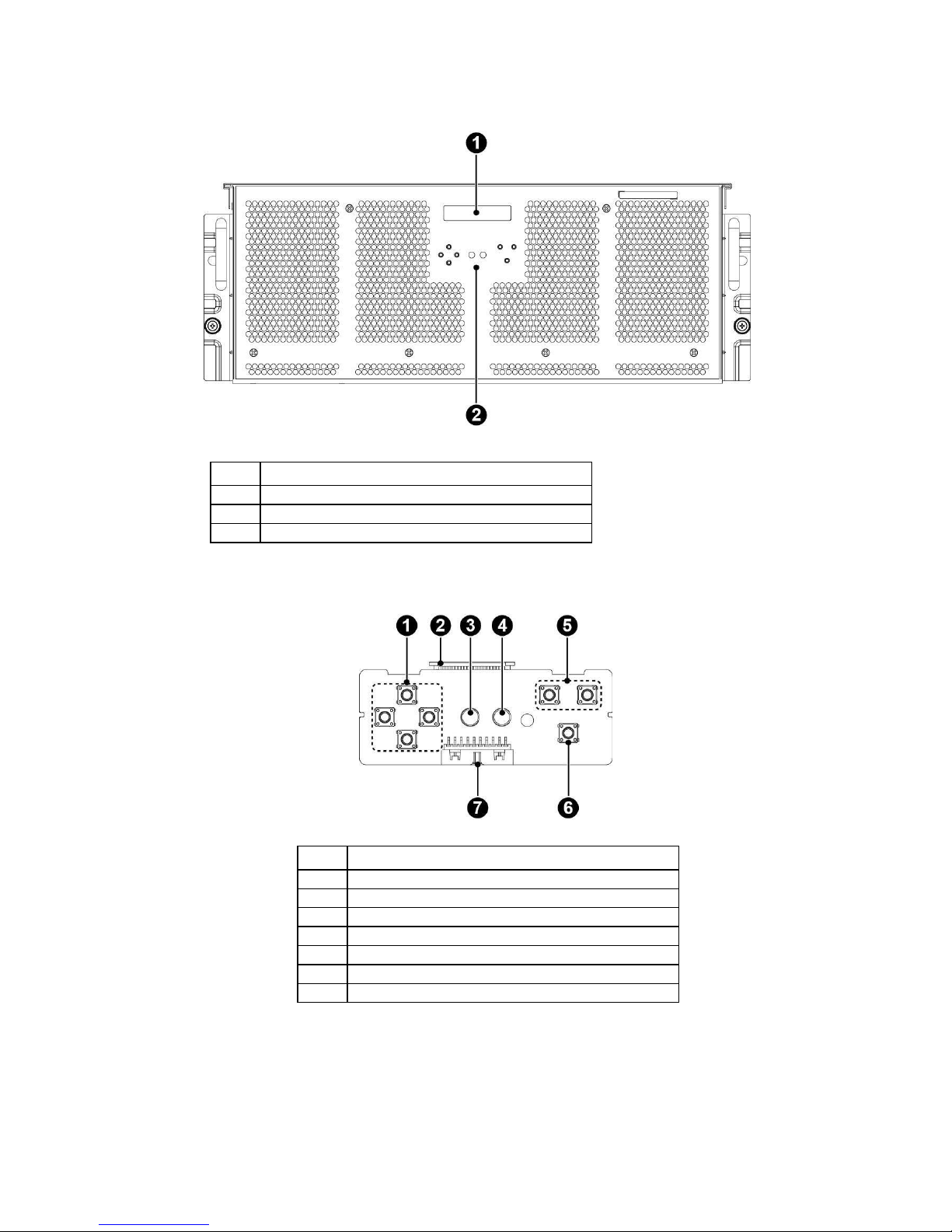

Front panel components

Front panel LEDs and buttons

Item

Description

1

LCD control buttons

2

LCD connector

3

UID LED

4

System Status LED

5

LCD control buttons

6

Power button

7

Fron panel board connector

Item

Description

1

LCD Module

2

Front panel board

3

Front control board

7

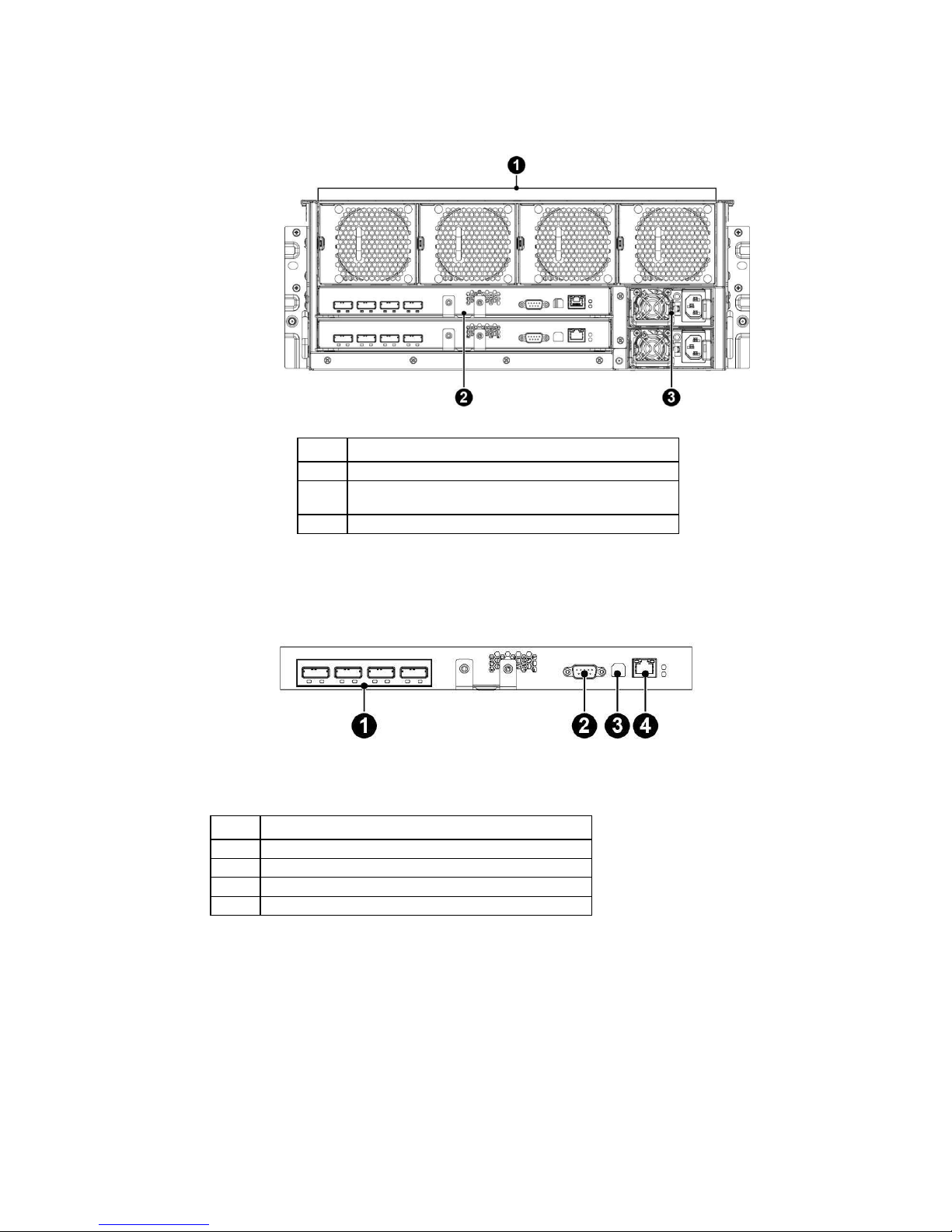

Rear panel components

Item

Description

1

System fans

2

EEB module x1 (SATA single path)

EEB module x2 (SAS dual path)

3

Power supply units

EEB module

Item

Description

1

External SAS ports

2

COM port

3

USB port

4

LAN port

8

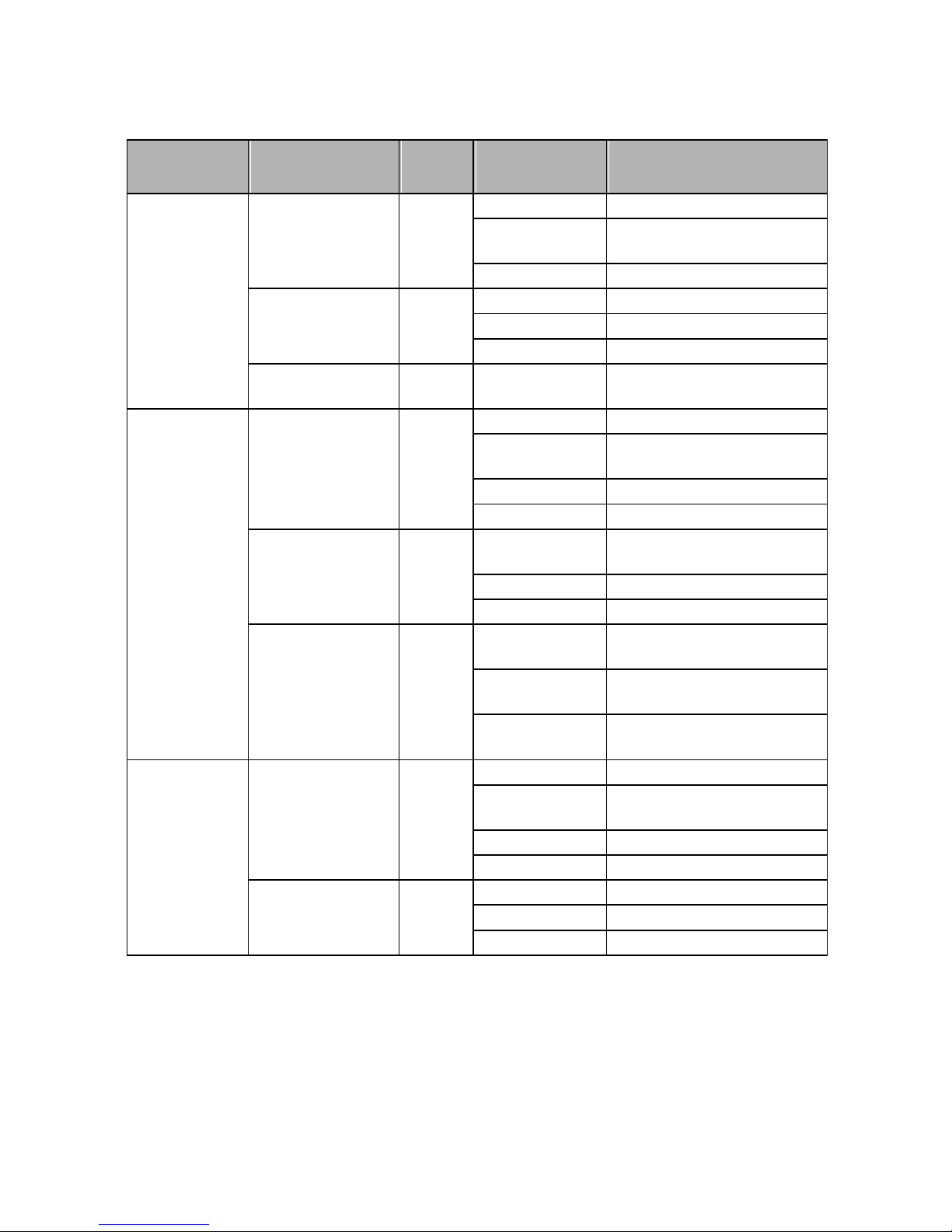

System LEDs

Module

LED

Color

Condition

Description

Name

Front Panel

UID LED

Blue

Blinking

Enclosure identification

Blink on and off

System stand-by

rapidly

On

System power on

System Status

Red

On

System fault

LED

Blinking

System warning

Off

System good

UID LED/System

Red/

Intermittent

Firmware updating

Status LED

Blue

blinking

EEB

Status LED

Amber

On

EEB fault

Intermittent

FW Updating

blinking

Rapid blinking

System warning

Off

Normal

Identify LED

Blue

On

EEB firmware ready

Master EEB identification

Blinking

EEB identification

Off

Normal

SAS Link/Status

Green/

On (Green)

SAS link on

LED

Amber

Off (Amber)

Off (Green)

SAS link down

Off (Amber)

On (Green)

SAS link with activity

Blink (Amber)

BEB

Status LED

Amber

On

BEB fault

Intermitent

FW Updating

blinking

Rapid blinking

System warning

Off

Normal

Identify LED

Blue

On

BEB firmware ready

Blinking

BEB identify

Off

Normal

9

Module

LED

Color

Condition

Description

Name

HDD

Activity LED

Blue

On

HDD present, no activity

Blinking

HDD activity

Off

HDD not present

Locate/Fault LED

Amber

On

HDD fail

Intermittent

HDD rebuild

blinking

Off

Normal

Green

On

HDD hot sparing

Rapid blinking

HDD identify

Off

Normal

Power supply LEDs

The 1600W power supply comes with one LED and the LED is

visible from the rear of the power supply.

LED Staate

LED

Color

Description

AC Power

Green

On: Normal work

Off: No AC power to all power supplies

Blink (1Hz): AC present / Only 12VSB on (PS off) or

PS in CR state

Red

On:

o AC cord unplugged; with a second power

supply in parallel still with AC input power

o Power supply critical event causing a

shutdown; failure, OCP, OVP, Fan Fail

Blink (1Hz): Power supply warning events where the

power supply continues to operate; high temp, high

power, high current, slow fan, input voltage lower

than 90Vac (not warning above 90V condition, must

be warning state below 85V condition)

10

Operations

Powering on

Please follow these steps to turn on the system

1. Connect the power cord to the power socket at the rear

of the Storage Carrier and plug the other end into a

power outlet

2. Press the power button onc to turn on the Storage Carrier

Powering down

Please follow these steps to power down the system

1. Press and hold the power button and to turn off the

Storage Carrier

2. Disconnect the power cord from the power outlet

Verifying the power status

Verify all power LED indicators of the server and make sure

the power LED light is off before replacing and removing

the server components from the rack.

11

Installation

Safety measures

Static electricity discharges can damage computer

components and electronic circuit boards. Working on

computers that are still connected to a power supply can

be extremely dangerous. Follow these guidelines to avoid

self-injury and damage to the computer:

Always disconnect the Storage Carrier from the power

outlet when working inside of the computer case.

If possible, wear a grounded wrist strap when working

inside the computer case. Alternatively, discharge any

static electricity by touching the bare metal chassis

of the computer case, or the bare metal body of any other

grounded appliance.

Hold electronic circuit boards only by the edges. Do not

touch the components on the board unless it is necessary

to do so. Do not flex or stress the circuit board.

Leave all components inside the static-proof packaging

until ready to use the component for the installation.

Identifying the contents of

the Storage Carrier shipping

carton

Unpack the server shipping carton and locate the materials

for installing the server.

The contents of the server shipping carton include:

Storage carrier

Power cord

Rack-mounting hardware

In addition to the supplied items, you might need:

Hardware options

12

Hard disk drives

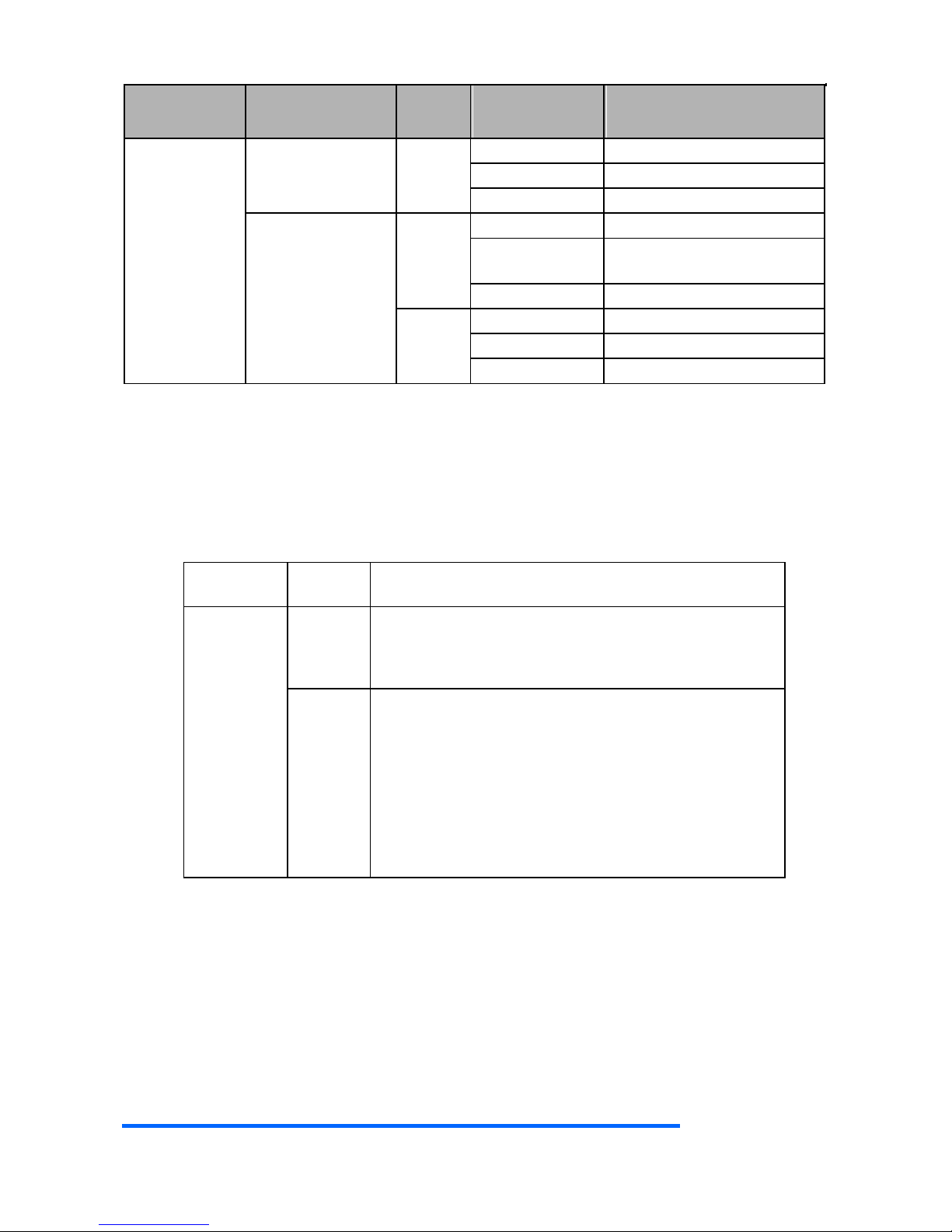

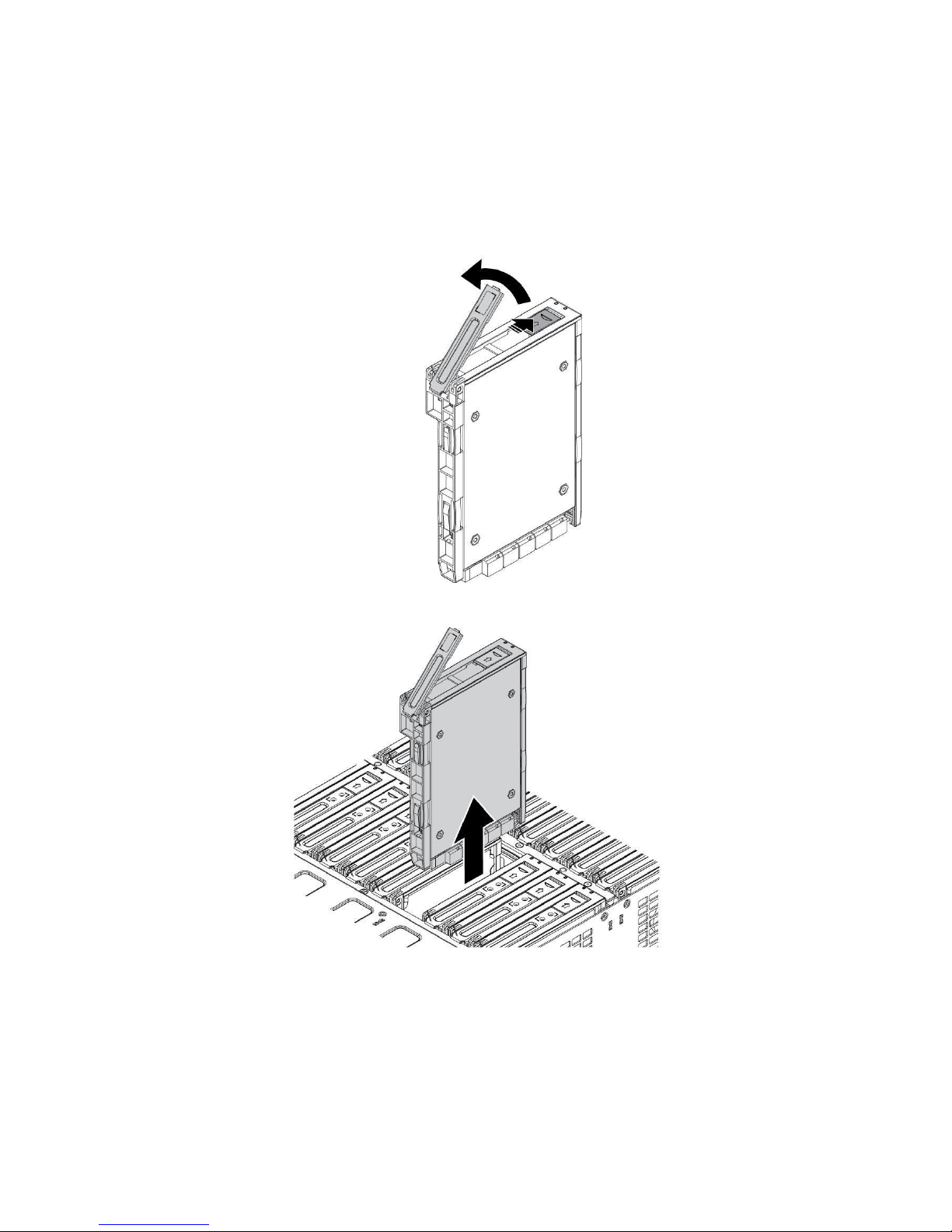

Removing the Hard Disk Drive

CAUTION!

Hard disks that require maintenance can be removed while the

server is operating normally. However, do not simultaneously remove

multiple hard disks. You can only remove one hard drive at a time

and for no longer than 10 minutes.

Please follow these steps to remove a HDD:

1. Press and slide the release button. The latch pops up.

2. Lift up the HDD tray handle to open.

3. Lift up the HDD tray handle to open.

13

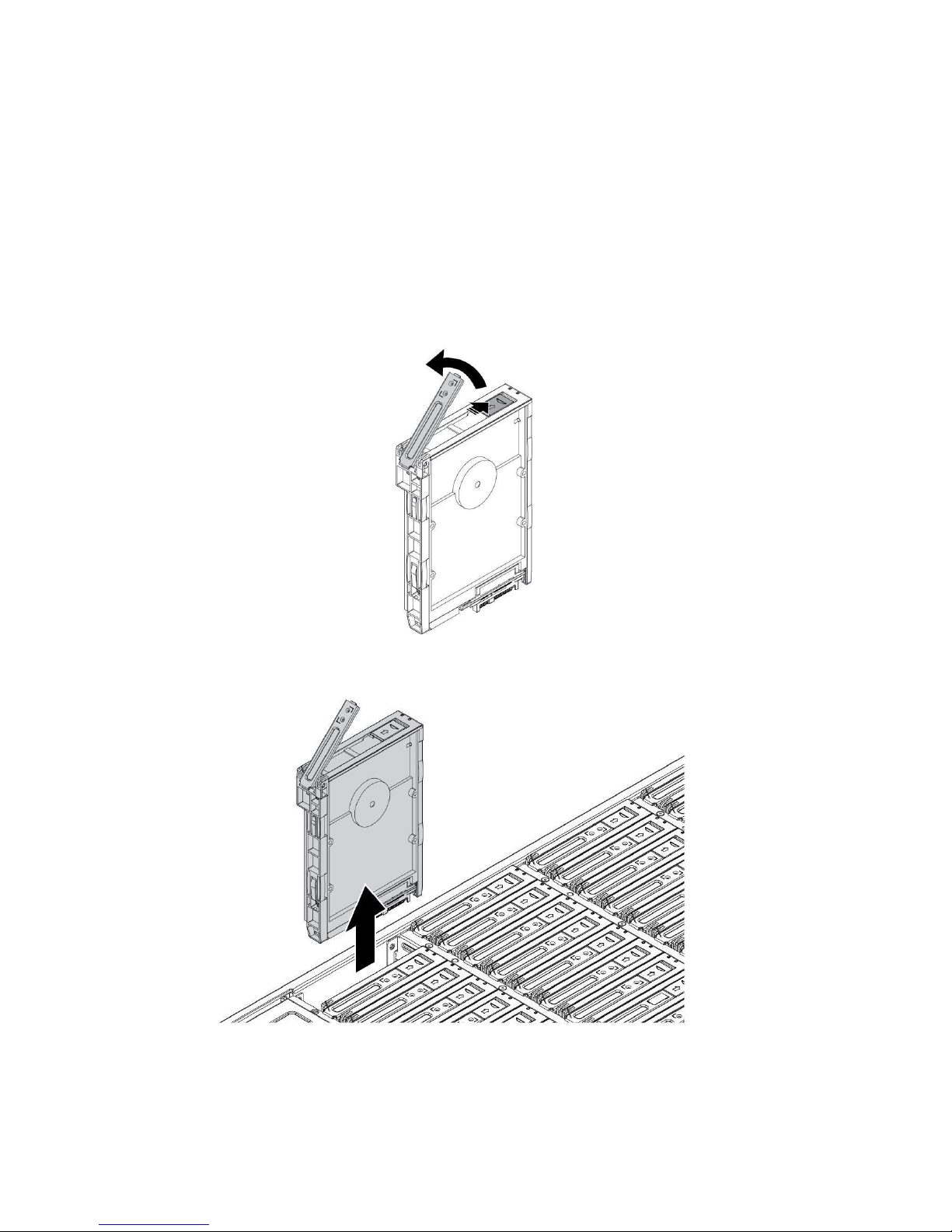

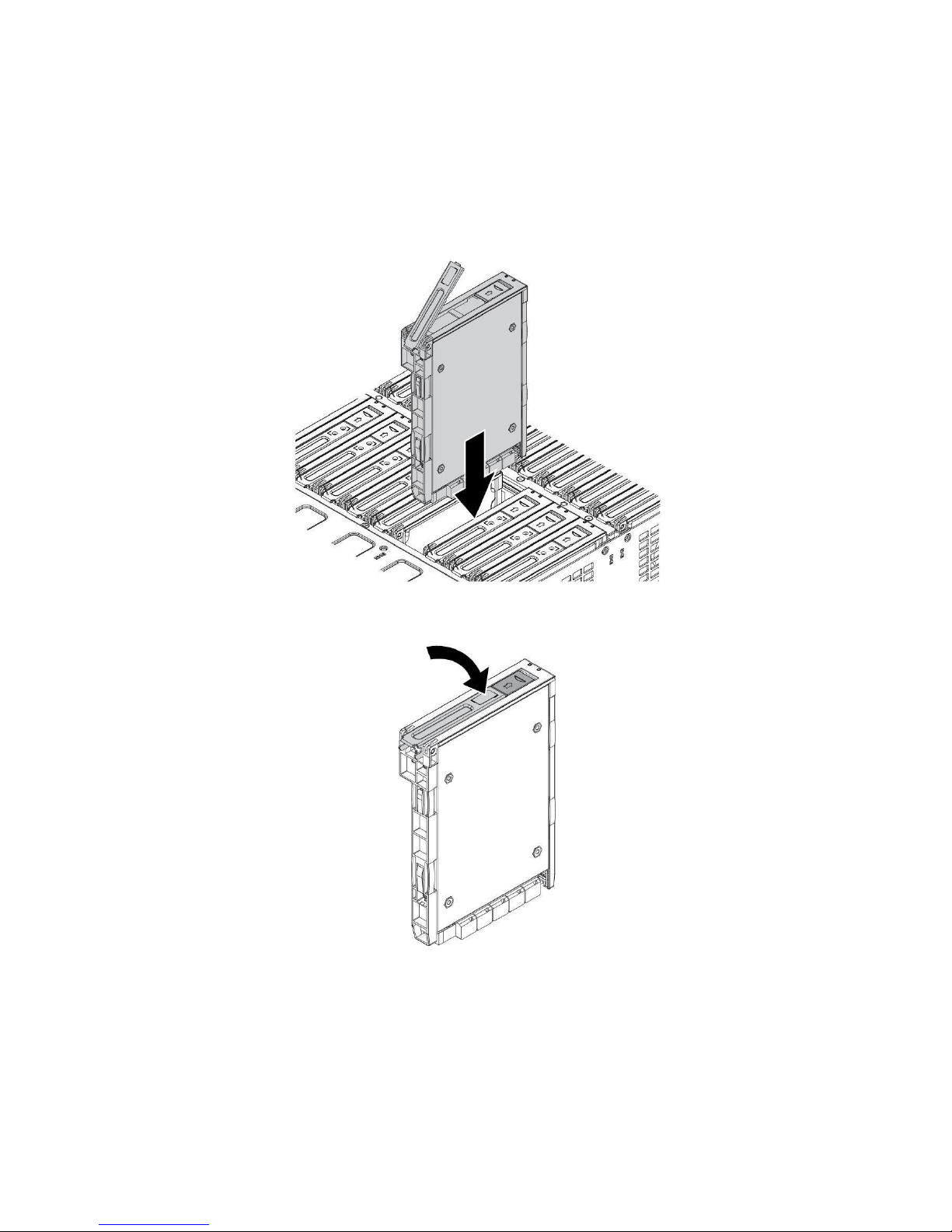

Installing the Hard Disk Drive

CAUTION!

Before powering on the server, check that each HDD is

installed and ensure empty slots contain an HDD carrier.

1. Align the HDD module with the connector on the HDD

backplane.

2. Install the HDD module.

3. Gently press down on both ends of the HDD to ensure it

is seated in the HDD backplane.

4. Push the HDD tray handle closed.

Verify that the drive is fully seated.

14

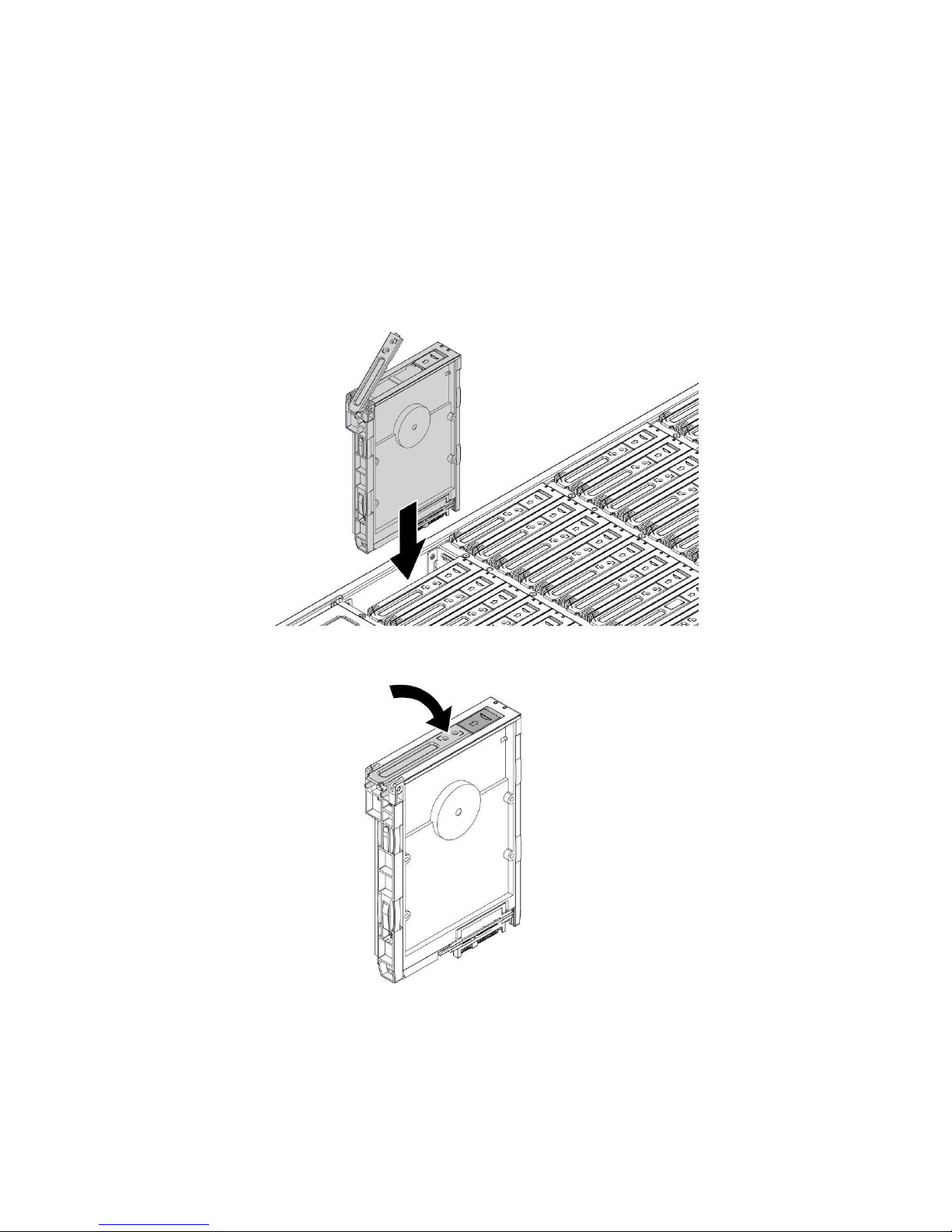

HDD matrix

Power supply units

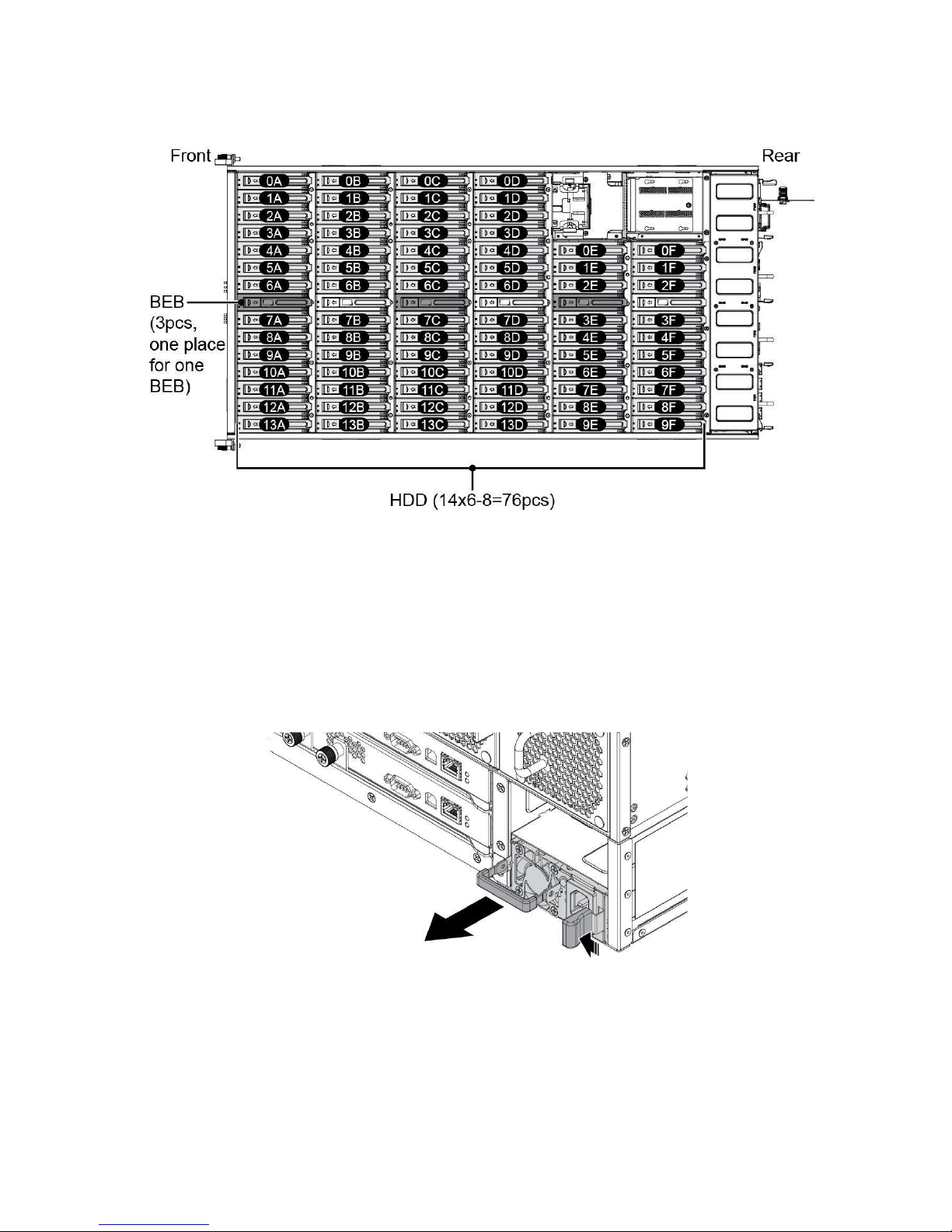

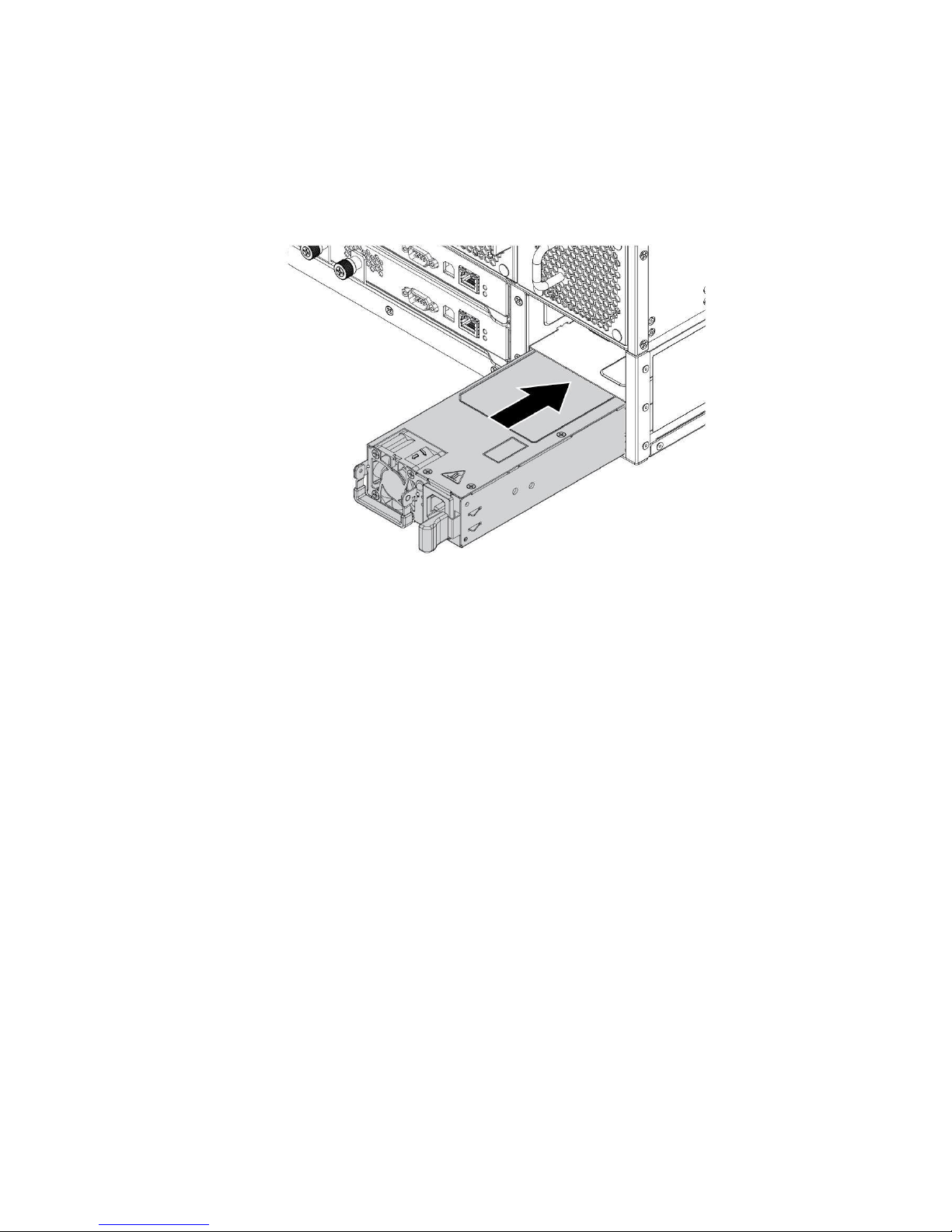

Removing the power supply unit

Please follow these steps to remove the power supply unit.

1. Lift up the handle and hold it.

2. Press the release latch to unlock the PSU.

3. Pull the PSU out to remove.

15

Installing the Redundant Power Supply Unit

Follow these steps to install the power supply unit.

1. Align the PSU in the chassis and make sure the release lever

is positioned on the right side.

2. Slide the PSU into the chassis until the release

latch is secure and the component is locked in

place.

16

System Architecture

Storage Carrier SAS dual path

Storage Carrier SATA single path

17

Backplane Expander Board (BEB)

Removing a Backplane Expander Board (BEB)

Follow these steps to remove a Backplane Expander Board (BEB):

1. Press and slide the release button. The latch pops up.

2. Lift up the BEB tray handle to open.

3. Remove the BEB module from the chassis.

NOTE: Refer to page 17 to differentiate SAS dual path and SATA

single path.

18

Installing a Backplane Expander Board (BEB)

Follow these steps to install a Backplane Expander Board (BEB):

1. Align the BEB with the connector on the HDD backplane.

2. Install the BEB on the HDD backplane.

3. Gently press down on both ends of the BEB to ensure it is seated in the

HDD backplane.

4. Push the BEB tray handle closed.

19

Front Control Module

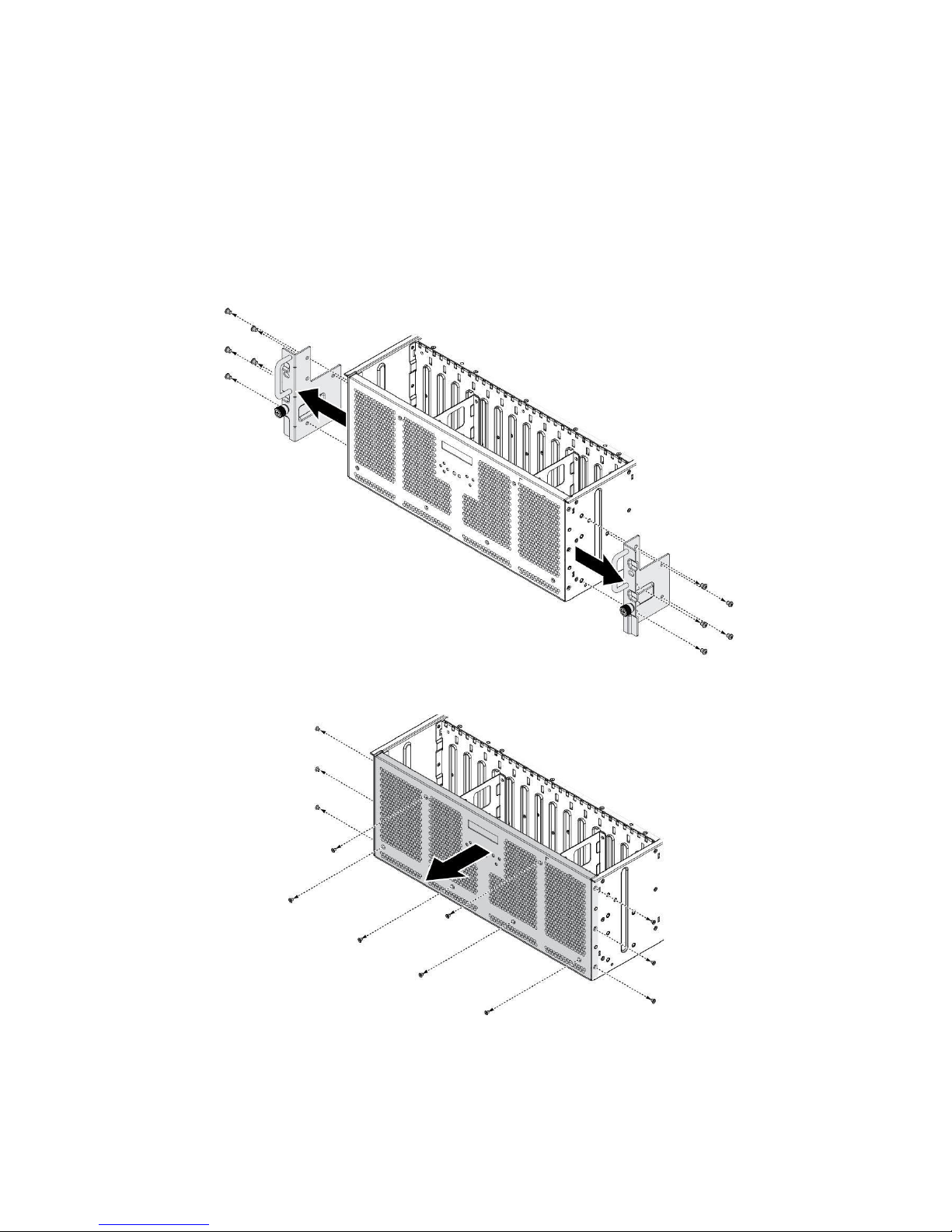

Removing the Front Control Module

Follow these steps to remove the front control module:

1. Power down the system by disconnecting the power cables.

2. Remove the securing screws and remove the mounting ears.

3. Remove the securing screws and remove the rear bracket.

20

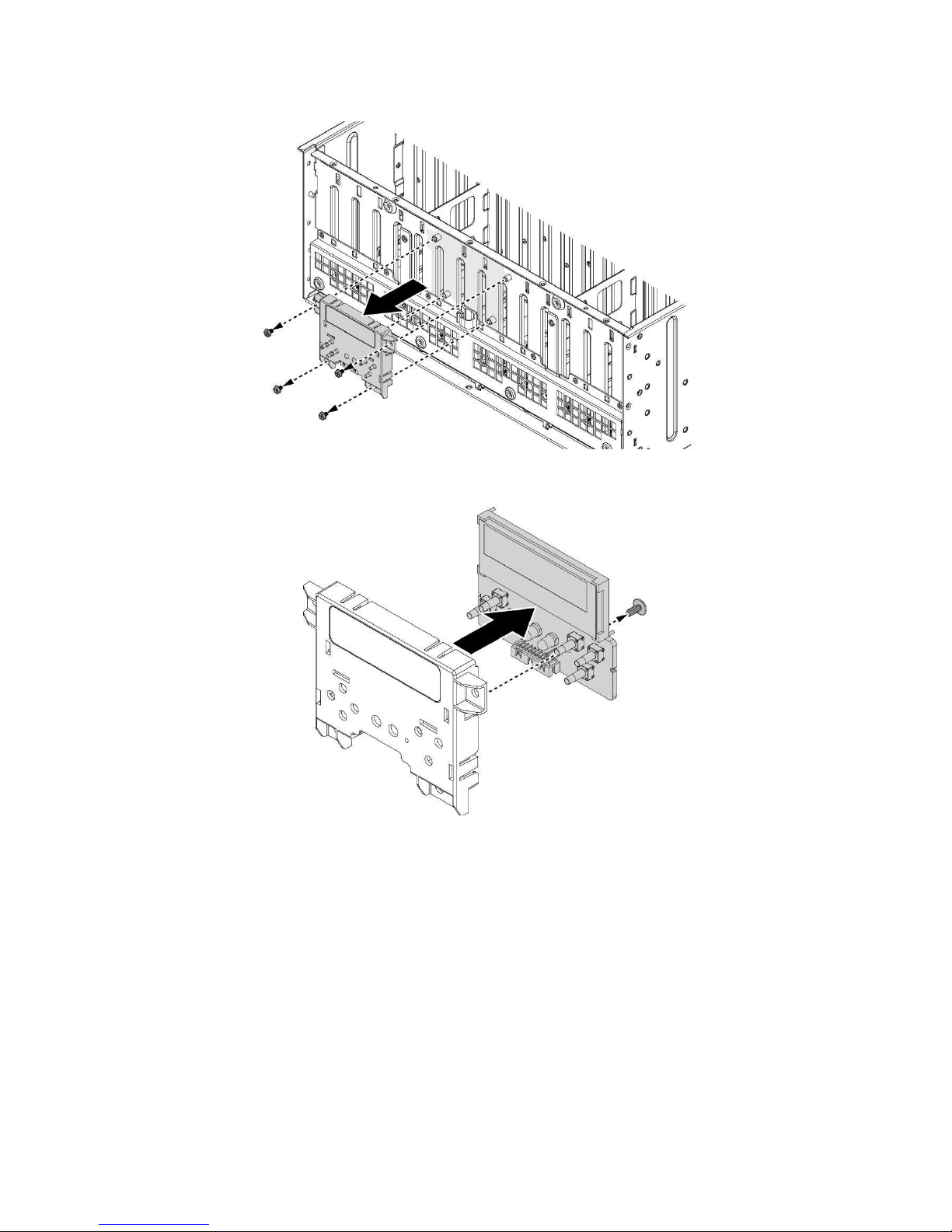

4. Remove the securing screws to remove the front control module assembly.

5. Remove the securing screw to remove the front control module.

21

Installing the Front Control Module

Follow these steps to replace the front control module:

1. Align the front control panel with the cover.

2. Install the front control panel and secure with a screw.

3. Align the front control panel assembly on the chassis as illustrated

in the following image.

4. Install the front control panel assembly.

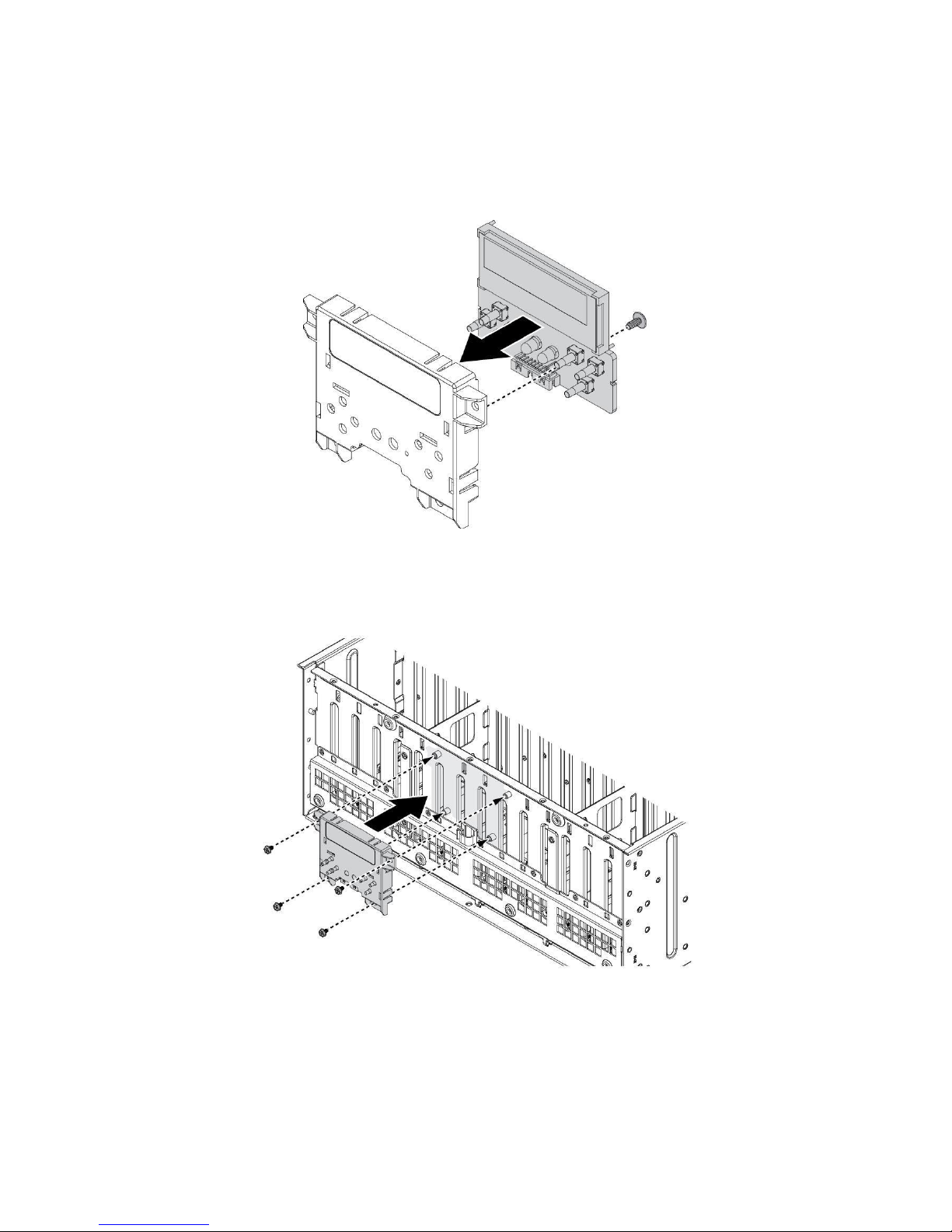

5. Secure the front control panel assembly to the chassis with screws.

22

6. Align the front bracket on the chassis.

7. Secure the front bracket to the chassis with the

screws.

8. Secure the mounting ears to the chassis with the

screws.

23

External Expander Board (EEB)

The system supports two External Expander Boards (EEB). For purposes

of this demonstration EEB is used.

Supported External Expander Boards

Carrier JBOD SAS Dual Path

Carrier JBOD SATA Single Path

Refer to the following examples to connect single path SATA drive cables.

24

Correct SATA drive connection 1:

Correct SATA drive connection 2:

Incorrect SATA drive connection 1:

25

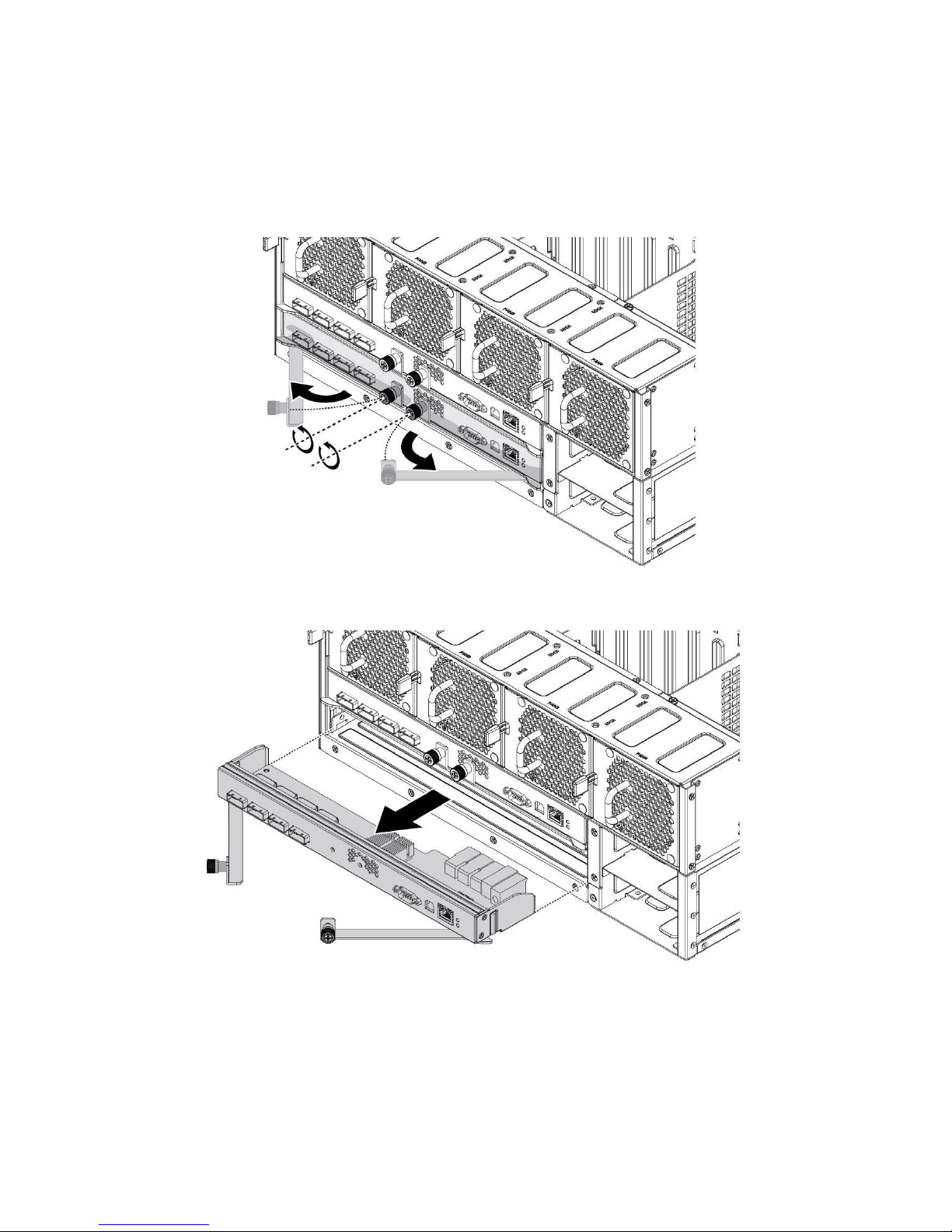

Removing the External Expander Board (EEB)

Follow these steps to remove the External Expander Board (EEB):

1. Loosen the thumb screws to unlock the EEB.

2. Pull the thumb screws to open the latches.

3. Using the latches, pull the expander out to remove.

26

4. Remove the screws.

5. Lift the expander board from the bracket.

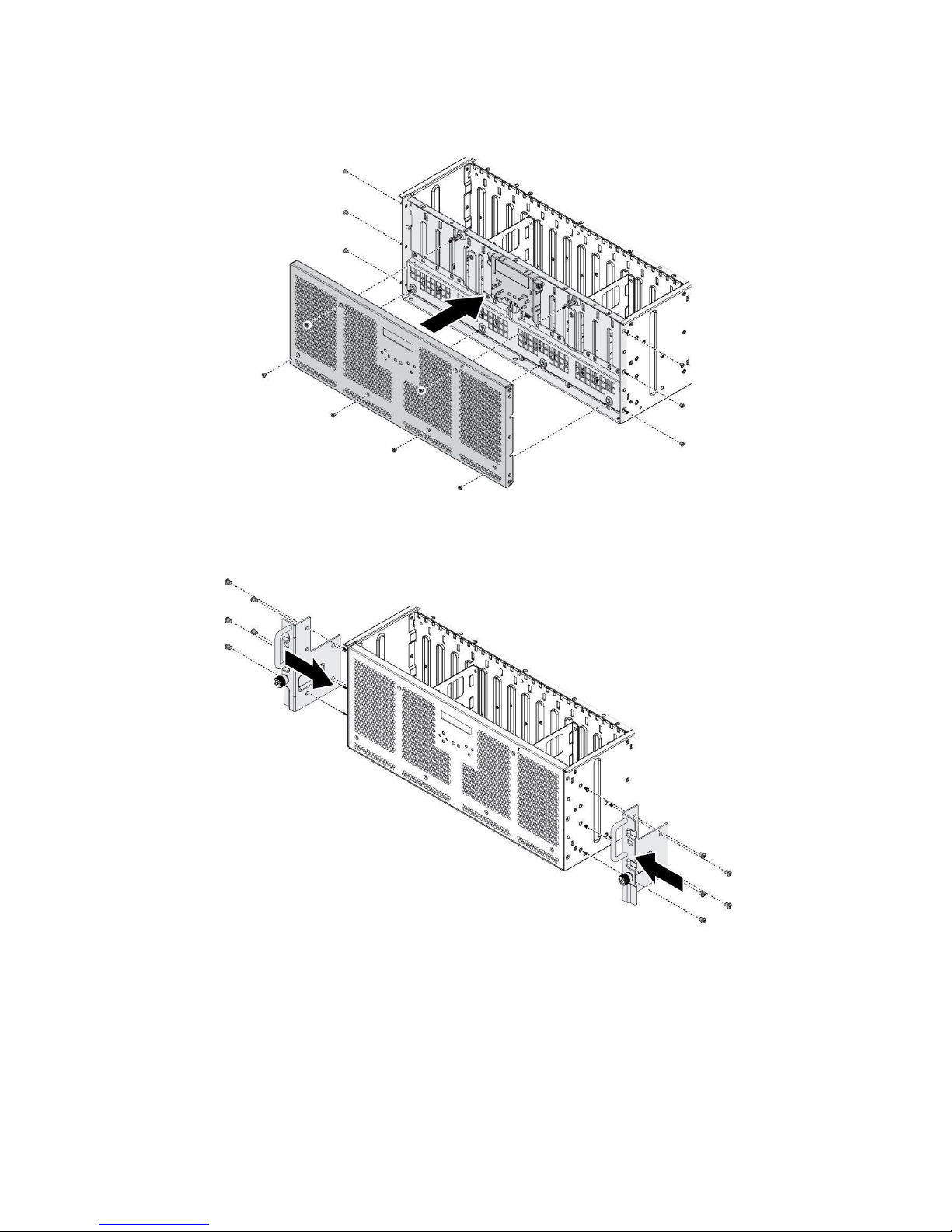

Installing the External Expander Board

(EEB)

Follow these steps to install the External Expander Board (EEB):

1. Align the I/O ports on the EEB with the bracket.

2. Install the EEB.

3. Secure the EEB to the bracket with screws.

27

4. Align the EEB with the bay in the chassis and slide in.

5. Press the EEB in to seat correctly in place.

6. Close the latches and tighten the thumb screws to secure.

28

Fans

Removing the System Fan

Use the following steps to remove the system fan:

1. Press the release latch and pull the fan out of the fan/expander bracket.

Installing the System Fan

Use the following steps to install the system fan:

1. Align the fan assembly in the fan/expander bracket making sure the release lever is

positioned on the right side.

2. Slide the fan into the fan/expander bracket until the release latch is secured and the fan

is locked in place.

29

Removing the System Fan (for PSU Cooling)

Use the following steps to remove the system fan:

1. Press the locking lever in to unlock the system fan.

2. Remove the system fan from the chassis.

Installing the System Fan (for PSU Cooling)

Use the following steps to install the system fan:

1. Align the fan with the connector on the HDD backplane.

2. Install the system fan into the chassis.

3. Firmly press down on the system fan to activate the locking lever.

30

Power Distribution Board (PDB)

Removing the Power Distribution Board (PDB)

Follow these steps to remove the Power Distribution Board (PDB):

1. Power down the system by disconnecting the power cables.

2. Remove the screw from PDB2.

3. Slide PDB2 away from PDB1 and pull off to remove.

31

4. Loosen the thumb screw on

PDB1.

5. Lift the PDB1 up and out to

remove.

32

Installing the Power Distribution Board

(PDB)

Follow these steps to replace the Power Distribution Board (PDB):

1. Align the PDB1 with the PSU cage.

2. Slide the PDB1 over the PSU cage and install.

NOTE: PDB1 connectors are facing the inside of the PSU cage.

3. Tighten the thumb screw to secure.

33

4. Align the PDB2 over the standoffs on the PSU cage making sure the power

connectors are facing up.

5. Slide PDB2 into PDB1 to connect.

6. Secure the PDB2 to the PSU cage with a screw.

34

Mid-plane

Removing the Mid-plane

Use the following steps to remove the mid-plane:

1. Power down the system by disconnecting the power cables.

2. Remove the EEBs and system fans.

3. Remove the securing screws from the fan/expander bracket.

4. Remove the fan/expander bracket.

5. Remove the securing screws from the mid-plane.

6. Remove the mid-plane.

35

Installing the Mid-plane

Use the following steps to install the mid-plane:

1. Orient the mid-plane so that the connectors are facing the top of the

fan/expander bracket. See the following illustration.

2. Install the mid-plane. Make sure all screw holes are aligned with the bracket.

3. Install the mid-plane assembly in the chassis.

4. Secure the mid-plane assembly to the chassis with screws.

5. Install the system fans and EEBs.

36

Power Interface Board (PIB)

Removing the Power Interface Board (PIB):

Use the following steps to remove the Power Interface Board (PIB):

1. Power down the system by disconnecting the power cables.

2. Remove all the hot-swappable hard disk drive assemblies.

3. Remove all components from the system.

4. Flip the chassis and remove the securing screws.

5. Remove the PIB from the HDD backplane 3.

Installing the Power Interface Board (PIB):

Use the following steps to install the Power Interface Board (PIB):

1. Connectl the PIB to the HDD backplane 3.

NOTE: PIB connectors are facing the inside of the chassis.

2. Secure the PIB to the HDD backplane 3.

37

HDD Backplane

Removing the HDD Backplane

Use the following steps to remove the HDD Backplane:

1. Power down the system by disconnecting the power cables.

2. Remove all the hot-swappable hard disk drive assemblies.

3. Remove all components from the system.

4. Remove the securing screws.

5. Remove the HDD backplanes.

38

Installing the HDD Backplane

Use the following steps to install the HDD Backplane:

1. Align each HDD backplane in the chassis. Make sure the connectors are facing up, see

the following illustration.

2. Secure with screws.

3. Install all components.

4. Install the hot-swap hard drives.

5. Connect the power cabling and power on the system.

39

Rail

Installing the Slide Rail

Follow these steps to install the slide rail:

1. Release and detach the inner member from the slide.

2. Attach inner member to the system.

40

3. Install the nuts on the rack. See the following illustration for the

specific nut type.

A. CAGE-NUT: Support for square hole posts.

B. U-NUT: Support for round hole posts.

4. Attach outer member to the rack.

5. Pull the intermediate member outward fully from the outer member. (A)

Ensure ball bearing retainer is locked forward on the intermediate member.

(B) Horizontally install system half way into slide rail. (C)

41

6. Slide release tab and push system into rack.

7. Insert the extension bracket to the outer

member.

42

8. Fasten the chassis by shipping screw. Use screw driver to install M5x13

screw.

(A)

Install the transportation accessory (B):

A. Fasten the manual screw to lock the outer member extension bracket.

B. Fasten the shipping brackets and the M5x13 shipping screws.

Remove the transportation accessory after the system arrives the

final destination. (C)

Removing the CMA (Cable Management Arm)

Follow these steps to remove the CMA:

1. Press the "PUSH" button on the CMA plug-in part to draw it out.

43

2. Turn CMA 90 degree to the right hand side to maintain the chassis or resume

the removal.

3. Press the "PUSH" button on the CMA plug-in part to draw it out.

4. Press the "PUSH" button on the CMA plug-in part to draw it out.

44

Installing the CMA (Cable Management Arm)

Follow these steps to install the CMA:

1. Install the CMA connector to the inner member. Install CMA connector (A)

onto CMA connector base on inner member (B).

2. Install the CMA connector to the outer member. Install CMA connector (C)

onto CMA connector base on outer member (D).

3. Install the CMA connector beside the center CMA body (E) to the outer member

CMA connector base (F).

45

Switch Left/Right Side

1. Press "PUSH" button.

2. Spin 180 degree to change the direction.

Loop strap must be tied to the CMA crossbar. This is a

transportation accessory; remove the Loop strap after the system

arrives the final destination.

CAUTION

46

LCM

LCM Overview

This section includes information about the Liquid Crystal Module (LCM) display and

the features available through the menu set.

No.

Button

Description

1. LCD screen

The LCD screen offers four display states:

Home, Information, Setting and Events.

2. Left button

3. Up button

4. Right button

Press to display information pages.

5. Down button

6. Del button

If HDD backplane is off, press 0.5 seconds to power on

the

7. Power button

HDD backplane.

If HDD backplane is on; press 5 seconds to power off the

HDD backplane.

8. Set button

Press to display information pages.

Panel Lock

The Panel Lock and Unlock function is only available through CLI. You can use the

commands panel lock or panel unlock to initiate a function.

47

Home Page

The Home page is the default state of the LCD panel and displays the product name,

time and date.

Information Page

The Information pages displays information for available settings. In the Home page,

press any button to view the Information pages.

Button Function

Button

Description

Up / Down

Go through the displayed information.

Left / Right

Go to previous or next information page.

Del

No function.

Set

Enter corresponding setting page.

Information Pages

The following is a list of the available pages found in the Information menu setting.

Page

Description

TIME&DATE

Display JBOD time and date. (Time: hh:mm; Date: yyyy/mm/dd)

Use command time to validate the displayed information.

Display JBOD IP address, subnet mask, gateway and DHCP

IP CONFIG

setting.

Use command ip to validate the displayed information.

ZONE TYPE

Display JBOD current zone type and detail information.

Use command zone to validate the displayed information.

TEMP.

Display JBOD temperature sensors information.

Use command temp to validate the displayed information.

VOLTAGE

Display JBOD voltage sensors information.

Use command volt to validate the displayed information.

FAIL DISK

List JBOD failed disks.

Use command diskinfo to validate the displayed information.

FAN RPM

Display JBOD fan module information.

Use command fan to validate the displayed information.

48

FAIL LIST

List JBOD failed devices.

Use command jbodstat to validate the displayed information.

SUB-ENCL.

Display JBOD sub-enclosure mode.

Use command subenclosure to validate the displayed

information.

JBOD ID

Display JBOD ID.

Use command jbodid to validate the displayed information.

FW VER.

Display JBOD firmware version.

Use command fwinfo to validate the displayed information.

FAIL LIST

Event

Description

FAN_FAIL

Read RPM through I2C failed.

FAN_SPEED_ABNORMAL

Fan speed abnormal.

TEMP_FAIL

Read temperature through I2C failed.

TEMP_WARNING

Temperature is higher than warning temperature.

TEMP_CRITICAL

Temperature is higher than critical temperature.

VOLTAGE_FAIL

Read voltage through I2C.

VOLTAGE_WARNING

Voltage is higher than warning voltage.

VOLTAGE_CRITICAL

Voltage is higher than critical voltage.

RTC_FAIL

Read RTC through I2C.

FW_FAIL

Firmware failed.

PS_FAIL

Read power supply information through I2C.

PS_AC_FAIL

Power supply AC abnormal.

DISK_FAULT

Disk failed.

DISK_TEMP_WARNING

Disk temperature is higher than warning temperature.

DISK_TEMP_CRITICAL

Disk temperature is higher than critical temperature.

Setting Page

In an Information page, press Set to enter the corresponding setting page—only

available for TIME&DATE, IP CONFIG, ZONE TYPE, SUB-ENCL. and JBOD ID.

Button Function

49

Button

Description

Up / Down

Select value.

Left / Right

Move cursor.

Del

Exit without saving.

Set

Select the displayed menu setting.

Event Page

Three types of event displays are available; see the following for a short

description.

Interactive message: A pop-up menu that displays “Message[Y] + Event details”

Setting: A pop-up menu that displays “Event[Y/N] + Event details”

Non-interactive message: A pop-up menu that displays “Event details”. This Event page

cannot be closed.

Button Function

Button

Description

Up / Down

Go through the displayed information.

Left / Right

Move cursor.

50

Button

Del

Set

Description

Exit Event page (In a non-interactive message, the

function is not available).

No function

No.

Command

Description

Advanced

Standard

1 addr

Display all expander addresses

● ● 2 dhcp

Enable or disable DHCP function

● 3 disable

Disable specific disk, or port

● ● 4

disk

Display all disks information

● ● 5

diskcnt

Display disks error counter

● ● Information

6

enable

Enable specific disk, or port

● ●

7 fan

Get fan module status

● ● 8

fdl

Download file to specify flash

region.

● ● 9 fwfdl

Download firmware to all expanders

●

10

fwinfo

Display all expanders firmware

● ● Information

11

fwsync

Sync firmware with HA Master.

● 12

ha Display HA status and information

●

13

ident

Identify device with LED

● ●

14

ip Configure IP address

●

15

jbodid

Configure JBOD ID

● ●

CLI Commands

Overview

The firmware provides sample CLI command for user upgrading firmware and diagnostic

system status. The base implementation of the CLI supports the following command set.

The following section has complete information about every CLI command.

51

16

jbodstat

Display JBOD information.

● ● 17

log

Display or clear the system log.

4096

512

18

panel

Front LCD panel configuration

●

lock/unlock

19

passwd

Change Login password

● ● 20

phy

Display all PHYs information

● ● 21

phycnt

Display PHYs error counter

● ● Information

22

port

Display all ports information

● ●

No.

Command

Description

Advanced

Standard

23

portcnt

Display ports error counter

● ● Information

24

post

Display POST test information

● ● 25

power

Manage backplane power supply

● ◎ 26

ps Set/get power supply status

● ● 27

reset

Reset all expanders or specify

● ● expander.

28

smart

Display S.M.A.R.T info.

●

29

subenclosure

Enable or disable subenclosure

●

30

temp

Display temperature sensor

● ● Information

31

time

Set/get the system time

● ● 32

volt

Display voltage sensor

information

● ● 33

zone

Specify the zone configuration.

● ●

34

ful

File Upload from Flash

● ●

52

35

sasaddr

Display expander SAS address

● ● 36

exit

Exit CLI and telnet session

● ● 37

rev

Display board‟s revision

information

● ● 38

help

Display all CLI commands

● ●

◎ Support partial function.

CLI Commands

addr

Syntax

addr

Parameters

None.

Description

The addr command used to display all expander SAS addresses in the same enclosure.

Examples

EEB00 >addr

Enclosure Expander SAS Addresses -

0. EEB00: 50060000 000272BF

BEB01: 50060001 000272BF

BEB02: 50060002 000272BF

BEB03: 50060003 000272BF

EEB10: 50060004 000272BF

BEB11: 50060005 000272BF

BEB12: 50060006 000272BF

BEB13: 50060007 000272BF

dhcp

Syntax

dhcp enable dhcp

disable

Parameters

None.

Description

53

The dhcp command used to enable or disable DHCP function.

Examples

EEB00 >dhcp disable

DHCP function enable/disable -

DHCP function is disabled.

disable

Syntax

disable Device Name(S) FRU-ID(D)

Parameters

Device Name: „port‟ or „disk‟.

FRU-ID: ID of the port or disk. Use „all‟ parameter to disable all ports or disks.

Description

The disable command used to disable specific PHYs on disk or port.

Examples

EEB00 >disable port 0

EEB00 >disable disk 13

disk

Syntax

disk Option(S)

Parameters

Option: Function name for the disk command. All supported function names are listed below.

info: List all disk informationtemp: Show all disks temperature. The unit is Celsius.

speed: Show all disks PHY link speed. (1.5G, 3.0G, or 6.0G)

type: Show the disk interface type is SATA or SAS.

zone: Show the disk zone number.

ident: Show if disk is in identify status.

fault: Show if disk is in fault status.

hotspare: Show if disk is in hot-spare status.

conschk: Show if disk is in consistency check status.

ok: Show if disk is in OK status.

rebuild: Show if disk is in rebuild status.

54

rrabort: Show if disk is in rebuild array abort status.

remove: Show if disk is in remove status.

incrit: Show if disk is in critical array status.

Infail: Show if disk is in fail array status.

Description

The disk command used to get disk information.

Examples

EEB00 >disk info

EEB00 >disk temp

EEB00 >disk fault

diskcnt

Syntax

diskcnt

Parameters

None.

Description

The diskcnt command display all disk error counters.

Examples

EEB00 >diskcnt

enable

Syntax

enable Device Name(S) FRU-ID(D)

Parameters

Device Name: port or disk.

FRU-ID: ID of the port or disk. Use „all‟ parameter to disable all ports or disks.

Description

The enable command used to enable specific PHYs on disk or port

Examples

EEB00 >enable port 2

EEB00 >enable disk 37

55

fan

Syntax

fan

Parameters

None.

Description

The fan command used to display Fan module information.

Examples

EEB00 >fan

Enclosure FAN module management FAN01: 4420 RPM ( 15%) (OK)

FAN02: 4350 RPM ( 15%) (OK)

FAN03: 3110 RPM ( 15%) (OK)

FAN04: 3130 RPM ( 15%) (OK)

FAN05: 3790 RPM 4050 RPM ( 15%) (OK)

Auto Fan enabled

fdl

Syntax

fdl Buffer-ID(H) Buffer-Offset(H) Erase Flag(S) Expander-ID(D)

Parameters

Buffer-ID: ID of the Read/Write buffer from which the file will be downloaded.

Buffer-Offset: Starting buffer offset within the specified buffer ID to which the file

will be downloaded.

Erase Flag: y or n to specify whether to erase the buffer before downloading the file.

The default erase flag is y.

Expander-ID: Expander ID 0-7. Specify the ID to identify which expander board in JBOD

Enclosure.

Description

The fdl command downloads a file to the specified Read/Write buffer ID at the specified

buffer offset. This command uses the XMODEM protocol to transfer the file. The Erase

option allows the buffer to be erased before the file is downloaded. Erasing is enabled

by default. To abort the fdl command before starting the XMODEM protocol, press Q or

q.

Examples

EEB00 >fdl 2 0 y

56

Download File -

Please Use XModem Protocol for File Transmission.

Prepare to download, please wait a moment...

Use Q Or q to quit Download before starting XModem.

Received 492672Bytes

Buffer Download Complete

fwfdl

Syntax

fwfdl Option(S)

Parameters

Option: Specify which expander boards will be downloaded by firmware file. If the

parameter is empty, only download to self side expander boards.

all: Whole expander boards of JBOD Enclosure.

peer: Whole expander boards in opposite side of JBOD Enclosure.

Description

The fwfdl command downloads a firmware file to the specified expander boards of JBOD

Enclosure.

Examples

EEB00 >fwfdl

Download Expander Firmware -

Please Use XModem Protocol for File Transmission.

Prepare to download, please wait a moment...

Use Q Or q to quit Download before starting XModem.

Received 496640Bytes

Buffer Download Complete

Updating EEB00 Firmware ... OK

Updating BEB01 Firmware ... OK

Updating BEB02 Firmware ... OK

Updating BEB03 Firmware ... OK

fwinfo

Syntax

fwinfo

Parameters

None.

57

Description

The fwinfo command is used to display firmware versions for all expander boards in JBOD

Enclosure.

Examples

EEB10 >fwinfo

fwsync

Syntax

fwsync Board-SRC-ID(D) Board-DEST-ID(D)

Parameters

Board-SRC-ID: Specify which expander board to be source firmware. Support only one

expander ID.

Board-DEST-ID: Specify which expander boards to be downloaded. Support one or more

expander IDs.

Description

The fwsync command is used to synchronize firmware with Master. If no any parameters,

the firmware in other expander boards which are not same as HA Master will be downloaded

and synchronized as HA Master automatically.

Examples

EEB00 >fwsync

Master (EEB00) firmware: 0023/0023 (Active/Backup)

Press 'y' to sync firmware for all expanders.

Updating BEB01 Firmware ... ######################################### OK (reset)

Updating BEB02 Firmware ... ######################################### OK (reset)

Updating BEB03 Firmware ... ######################################### OK (reset)

Updating BEB11 Firmware ... ######################################### OK (reset)

Updating BEB12 Firmware ... ######################################### OK (reset)

Updating BEB13 Firmware ... ######################################### OK (reset)

Updating EEB10 Firmware ... ######################################### OK (reset)

ha

Syntax

ha Option(S)

Parameters

Option: Run High Available (HA) functionality with assigned option.

status: Display HA status and information. (default)

loop: Display HA status and information every one second.

58

HA

Status and

Information

-

[HW:ADV]

ID

Name Role

FW ZT SEID

EID

PL

RG

VDP

PHYs COMMTO

*0

EEB00

M

0023

FF

4C

FF FF 00~00(78) 50~BF(76)

On 1 BEB01

0023

FF

4C

FF

00~00(78) 50~BF(76)

On 2 BEB02

0023

FF

4C

FF

00~00(78) 50~BF(76)

On 3 BEB03

0023

FF

4C

FF

00~00(78) 50~BF(76)

On 4 EEB10

S

0023

FF

4C

FF FF 04~00(74) 50~BF(76)

On 5 BEB11

0023

FF

4C

FF

04~00(74) 50~BF(76)

On 6 BEB12

0023

FF

4C

FF

04~00(74) 50~BF(76)

On 7 BEB13

0023

FF

4C

FF

04~00(74) 50~BF(76)

On

info: Display latest HA runtime information.

enable: Enable local HA functionality.

disable: Disable local HA functionality.

state: Get enable state of HA functionality.

Description

The ha command runs operations related with High Available (HA) functionality.

Examples

EEB00 >ha

--------------------------------------------------------------------

ident

Syntax

ident Module Name(S) Stop(S)

Parameters

Module Name: The supported module names are listed below.

JBOD: jbod, JBOD.

BEB: BEB01 - BEB03, BEB05 - BEB07.

EEB: EEB00, EEB04.

Temperature: TEMP00 - TEMP12.

Voltage: VOLT00 - VOLT10.

Disk: DISK00 - DISK76.

stop: Stop identifying the UID LED on the specific module.

Description

The ident command used to identify the location of the specific module device.

Examples

EEB00 >ident jbod

59

EEB00 >ident jbod stop

EEB00 >ident BEB03

EEB00 >ident BEB03 stop

EEB00 >ident DISK55

EEB00 >ident DISK55 stop

ip

Syntax

ip IP Address(S) Sub-Mask Address(S) Gateway Address(S)

Parameters

IP Address: Specify network IP Address.

Sub-Mask Address: Specify network sub-mask address.

Gateway Address: Specify network gateway address.

Description

The ip command is used to configure the network interfaces.

Examples

EEB10 >ip 192.168.1.5 255.255.255.0 192.168.1.254

Saved IP Configuration -

DHCP Enabled. . . . . . . . . . . : No

IP Address. . . . . . . . . . . . : 192.168.1.5

Subnet Mask . . . . . . . . . . . : 255.255.255.0

Default Gateway . . . . . . . . . : 192.168.1.254

jbodid

Syntax

jbodid ID(D)

Parameters

ID: JBOD ID which will be configured into the system. The range of the ID is 0 to 9.

Description

The jbodid command used to configure JBOD ID or display the currently JBOD ID.

Examples

EEB00 >jbodid

Configure JBOD ID -

Active JBOD ID:

JBOD ID is 8.

Saved JBOD ID:

60

JBOD ID is 8.

EEB00 >jbodid 1

Configure JBOD ID -

Active JBOD ID:

JBOD ID is 8.

Saved JBOD ID:

JBOD ID is 1.

Do you want to reset for changes to take effect? (y/n)

jbodstat

Syntax

jbodstat

Parameters

None.

Description

The jbodstat command display system health status. Any system detected error will be

listed by this command. If there is no error exists in the system, the command shows

nothing.

Examples

EEB00 >jbodstat

Display JBOD Status -

JBOD Status

==========================-- - FAN module removed

EEB00

==========================-- - FAN module removed (ID:0)

log

Syntax

log show Count(D) log show Option1(S) log get Count(D) log get Option2(S) log clear

Parameters

show: Display Event Log records (default count is100) and will not clear logs displayed.

get: Display Event Log records (default count is100) and clear logs displayed.

clear: Clear whole Event Log records.

Count: 1 - 4096.

61

Option1: Function name for the command. All supported function names are listed below.

all: All event log.

count: Get total event log count.

type=string: Specify Event Log type to be filtered. Supported string are „power‟, „sas‟,

„hdd‟, „sys‟, „fw‟, „exp‟, „fan‟, „ipc‟, „vol‟, „temp‟, „rtc‟, „ha‟, and „unknow‟.

level=number: Specify Event Log level to be filtered. Supported number from 0 to 5.

hex: Display hexadecimal format of Event Log.

Option2: Description same as Option1, only support all, count, and hex.

Description

The log command is used to display and control Event Log.

Examples

EEB00 >log show count

Manage event logs -

Total log count is : 4096

EEB00 >log show 1

Manage event logs -

The count is 1.

#0001 Information 2014/03/26 15:53:06

-----------------------------------------------------------------Type : Expander

Event: Expander reset. BEB01

------------------------------------------------------------------

panel

Syntax

panel lock

panel unlock

Parameters

None.

Description

The panel command used to lock or unlock front panel. When the panel was locked, all

system information still can be display in LCD module but any system configuration can

NOT be set via front panel.

Examples

62

EEB00 >panel lock

EEB00 >panel unlock

passwd

Syntax

passwd

Parameters

None.

Description

The passwd command used to change password for system log-in.

Examples

EEB00 >passwd

Change Management Password -

OLD password: ***

NEW password: ***

CONFIRM password: ***

Password has been changed!

phy

Syntax

phy Expander-ID(D)

Parameters

Expander-ID: Specify the ID to identify which expander board in JBOD Enclosure. None

of this option means whole expander boards in JBOD Enclosure.

Description

The phy command is used to display detail information of phy in expander board.

Examples

EEB00 >phy

phycnt

Syntax

phycnt reset(S) Expander-ID(D)

Parameters

reset: Reset Phy Error counters. (optional)

63

Expander-ID: Specify the ID to identify which expander board in JBOD Enclosure. None

of this option means whole expander boards in JBOD Enclosure.

Description

This phycnt displays PHY error counters, PHY event counters and generic broadcast counter

for all Phys.

Examples

EEB00 >phycnt reset

Phys Layer Counters -

Phy counters successfully reset.

port

Syntax

port

Parameters

None.

Description

The port command is used to display detail information of port in JBOD Enclosure.

Examples

EEB00 >port

portcnt

Syntax

portcnt

Parameters

None.escription

This portcnt displays phy error counters, phy event counters and generic broadcast

counter for all ports.

Examples

EEB00 >portcnt

post

Syntax

post Expander-ID(D)

Parameters

64

Expander-ID: 0-7. If the parameter is empty, the command display all post information.

Description

The post command displays the ECC information. Instead of displaying all the contents

of the ECC information, the success/failure of the internal memory test and forced ECC

error tests and also the reason for the tests to fail are displayed. Using this command,

you can view the POST information of the following peripherals and ECC error information.

Internal Memory

External Memory

Smart Serial

Watchdog timer

Timer1

Timer2

Interrupt

Phy loopback

ISTWI Channel 0

ISTWI Channel 1

ISTWI Channel 2

ISTWI Channel SEP

Examples

EEB00 >post 2

Check POST status of Bobcat On-Chip Devices -

BEB02 POST Information:

================================================================================

On-Chip Device POST Status

================================================================================

Smart Serial :PASS

Watchdog Timer :PASS

Timer 1 :PASS

Timer 2 :PASS

Interrupt :PASS

Phy Loopback :PASS

ISTWI Channel 0 :PASS

ISTWI Channel 1 :PASS

ISTWI Channel 2 :PASS

ISTWI Channel SEP :PASS

Internal RAM Test :PASS

Forced ECC Error Test :PASS

power

65

0.

PS00:

ID

: Server Power Supply

MODEL

: PS-2112-5L3-LF

REVISION

: X1

LOCATION

: 01

DATE

: Week 10, 2013

BAR CODE

: 6XXXX01X1D1001W

FAN SPEED

: 5440 RPM

TEMPERATURE

: 43 C

VOLTAGE

: 12.9 V

Syntax

power Option(S)

Parameters

Option: Function name for the power command. All supported function names are listed

below.

on: Set on to power on Back Plane boards.

off: Set off to power off Back Plane boards.

auto: Set auto to power on Back Plane boards automatically after AC plug-in PSU

manual: Set manual to power on Back Plane boards manually after AC plug-in PSU.

lock: Set lock to lock the function of power button.

unlock: Set unlock to unlock the function of power button.

Description

The power command used to manage the power state of Back Plane boards.

Examples

EEB00 >power on

EEB00 >power off

ps

Syntax

ps

Parameters

None.

Description

The ps command used to get information about power supply modules

Examples

EEB00 >ps

Enclosure Power Supply Management -

66

CURRENT

: 19.37 A

INPUT WATT

: 250 W

OUTPUT WATT

: 234 W

1.

PS01:

ID

: Server Power Supply

MODEL

: PS-2112-5L3-LF

REVISION

: X1

LOCATION

: 01

ATE

: Week

10, 2013

BAR CODE

: 6XXXX01X1D1000S

FAN SPEED

: 5536

RPM

TEMPERATURE

: 44 C

VOLTAGE

: 12.6

V

CURRENT

: 18.50 A

INPUT WATT

: 246

W OUTPUT WATT

: 222

W

reset

Syntax

reset watchdog(S) Option(S)

Parameters

watchdog: Issue the watchdog reset. (optional)

Option: All supported function names are listed below.

all: Reset all expanders.

peer: Reset peer side expanders.

0-7: Expander ID.

Description

The reset command used to reset any expanders in JBOD. The default reset is hard or cold

reset. If you issue the reset watchdog command, the watchdog reset is triggered.

Examples

EEB00 >reset all

Reset Enclosure Expanders -

Reseting BEB13 ... OK

Reseting BEB12 ... OK

Reseting BEB11 ... OK

Reseting EEB10 ... OK

Reseting BEB03 ... OK

Reseting BEB02 ... OK

Reseting BEB01 ... OK

Reseting EEB00 ...

smart

Syntax

67

Display S.M.A.R.T InformationDISK25

Information:

Vendor

:SEAGATE

Product

:ST4000NM0023

Revision

:0003

Logical Unit ID

:0x1234567812345678

Serial Number

:Z1Z0ZB2E00009350EE9V

User Capacity

:3726

GB

Max LBA

:7814037168 blocks

Logical block size

:512 bytes

Rotation Rate

:7200

rpm

Form Factor

:3.5 inches

Current Drive Temperature

:32 C

( 89 F)

Drive Trip Temperature

:40 C

(104 F)

Manufactured Date

:in week 26 of year 2014

Cycle count over device lifetime

:10000

Accumulated start-stop cycles

:5988

Load-unload count over device lifetime

:300000

Accumulated load-unload cycles

:5994

smart Disk ID(D)

Parameters

Disk ID: 0-75. The Disk ID in system.

Description

The smart command used to get Disks S.M.A.R.T information. If the parameter is empty,

the command displays all disks information.

Examples

EEB00 >smart 25

Blocks sent to initiator = 14207 Blocks received from initiator = 17817

Blocks read from cache and sent to initiator = 265

Number of read and write commands whose size <= segment size = 16 Number of read and

write commands whose size > segment size = 0 number of hours powered up = 707 hr 15 min

number of minutes until next internal SMART test = 52

subenclosure

Syntax

subenclosure enable subenclosure disable

Parameters

None.

Description

The subenclosure command used to display currently enclosure mode and to switch between

sub-enclosure mode and enclosure mode.

68

Examples

EEB00 >subenclosure

EEB00 >subenclosure disable

temp

Syntax

temp

Parameters

None.

Description

The temp command used to display temperature sensors information.

82Examples

EEB00 >temp

Enclosure temperature sensor information TEMP00: 52 C (125 F) (OK)

TEMP01: 59 C (138 F) (OK)

TEMP02: 64 C (147 F) (High Warning)

TEMP03: 55 C (131 F) (OK)

TEMP04: 51 C (123 F) (OK)

TEMP05: 53 C (127 F) (OK)

TEMP06: 62 C (143 F) (High Warning)

TEMP07: 62 C (143 F) (High Warning)

TEMP08: 33 C ( 91 F) (OK)

TEMP09: 44 C (111 F) (OK)

TEMP10: 43 C (109 F) (OK)

TEMP11: 0 C ( 32 F) (Disconnected)

TEMP12: 30 C ( 86 F) (OK)

time

Syntax

time Year(D) Month(D) Day(D) Hour(D) Minute(D) Second(D)

Parameters

Year: Set system current time (Year 0~99).

Month: Set system current time (Month 1~12).

Day: Set system current time (Day 1~31).

Hour: Set system current time (Hour 0~23).

Minute: Set system current time (Minute 0~59)

Second: Set system current time (Minute 0~59)

69

Description

The time command used to set or get current system time

Examples

EEB00 >time

System Current Time Management -

Current SYS Time: 2014/03/24 18:39:59

EEB00 >time 14 03 24 18 45 00

volt

Syntax

volt

Parameters

None.

Description

The volt command used to display voltage sensors information.Examples

EEB00 >volt

Enclosure voltage sensor information VOLT00: 5.04 V (OK)

VOLT01: 5.04 V (OK)

VOLT02: 5.04 V (OK)

VOLT03: 5.04 V (OK)

VOLT04: 5.03 V (OK)

VOLT05: 5.03 V (OK)

VOLT06: 5.02 V (OK)

VOLT07: 5.04 V (OK)

VOLT08: 5.05 V (OK)

VOLT09: 5.04 V (OK)

VOLT10: 5.04 V (OK)

zone

Syntax

zone Zone-Type(D)

Parameters

Zone-Type: 0-2.

0: All disks in a cluster

1: Disks are divided into two clusters

2: Disks are divided into four clusters

70

Description

The zone command used to configure JBOD Zone Type. (JBOD needs to be reset for changes

to take effect).

Examples

EEB00 >zone 1

ful

Syntax

ful Buffer-ID(H) Buffer-Offset(H) Size In Bytes(D)

Parameters

Buffer-ID: ID of the Read/Write buffer from which the file will be uploaded.

Buffer-Offset: Starting buffer offset within the specified buffer ID from which the file

will be uploaded.

Size In Bytes: Size of the file, in bytes.

Description

The ful command uploads data to a file from the buffer offset within a specified Read/Write

buffer ID. This command uses XMODEM protocol for file transfer. The size of the uploaded

file is specified as a command line parameter. Due XMODEM protocol nature, the size of

uploaded data will be multiples of 128 bytes. Therefore, if the mentioned size is not

a multiple of 128 bytes, pad bytes will be added with undefined contents. Data beyond

the specified size must be ignored. To exit the ful command before starting the XMODEM

protocol, press Q or q.

Examples

EEB00 >ful 2 0 128

Upload File -

Please Use XModem Protocol to Receive File.

Use Q Or q to quit Download before starting XModem.

Transmitted 128Bytes

Buffer Upload Complete

sasaddr

Syntax

sasaddr

Parameters

None.

71

Expander SAS

Addresses -

EXP Port SAS

Address:

0x50060000000272BF

SXP

Port SAS

Address:

0x50060000000272BD

STP

Port SAS

Address:

0x000000000000003E

Description

The sasaddr command used to display expander SAS address (EXP, SXP, and STP ports).

Examples

EEB00 >sasaddr

exit

Syntax

exit

Parameters

None.

Description

The exit command used to close TCP/IP session.

Examples

EEB00 >exit

rev

Syntax

Rev

Parameters

None.

Description

The rev command used to display the following information:

Hardware revision information: Vendor ID, product ID, product revision level, component

ID, component revision level.

Revision information for the firmware images resident in Flash. It also displays which

firmware image is currently

SDK revision information

Examples

72

EEB00 >rev

help

Syntax

help Command(S)

Parameters

Command: CLI command name.

Description

The help command displays help on all the registered CLI commands, there is no argument

passed to this command. Use the help command for the required help.

Examples

EEB00 >help phy

=================================================================

Test Command

=================================================================

Display all phy info. phy [Expander-ID <0 - 7>]

=================================================================

73

Regulatory information

Class A

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference

at his own expense.

European Union regulatory notice

Products bearing the CE mark comply with one or more of the following EU directives

as may be applicable:

Low Voltage directive 2014/35/EC

EMC directive 2014/30/EU

Ecodesign directive 2009/125/EC

RoHS directive 2011/65/EU

Compliance with these directives is assessed using applicable harmonised European

standards.

The full Declaration of Conformity can be found at the following website:

http://www.tradedx.eu/ certificates.

The point of contact for regulatory matters is TradeDX s.r.o., Karlov 245, 28401

Kutná Hora, Czech Republic.

Safety

Before installing this product, read the Safety Information.

74

Warnings & Safety/

Important safety and compliance

information

Be sure to read all caution and warning statements in this documentation before

performing any procedure in this user and maintenance guide. To avoid potential

problems, ALWAYS read the warnings, cautionary and safety information that comes

with server documentation before removing, replacing, reseating or modifying

system components.

Safety precautions

Observe the following safety precautions when setting up equipment:

Follow all cautions and instructions marked on the equipment.

Ensure that the voltage and frequency of power source match the voltage and

frequency inscribed on the equipment’s electrical rating label.

Never push objects of any kind through openings in the equipment. Dangerous

voltages may be present.

Conductive foreign objects could produce a short circuit that could cause

fire, electric shock, or damage to your equipment.

Safety Instructions

1. Please read these safety instructions carefully.

2. Please keep this Manual for later reference.

3. Please disconnect this equipment from AC outlet before cleaning. Don’t use

liquid or sprayed detergent for cleaning. Use moist sheet or cloth for

cleaning.

4. For pluggable equipment, the socket-outlet must be installed near the

equipment and must be easily accessible.

5. Please keep this equipment from humidity.

6. Place this equipment on a safe reliable surface when installing. A drop or

fall could cause injury.

7. Enclosure openings are for air circulation and protect the equipment from

overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source matches rated voltages.

9. Place the power cord so that it won't be stepped on or tripped over. Do not

place anything on top of the power cord.

10. All cautions and warnings on the equipment should be noted.

75

This symbol indicates the presence of hazardous energy circuits or

electric shock hazards. Refer all servicing to qualified personnel.

WARNING: Do not open this enclosure to reduce the risk of injury from

electric shock hazards. Refer all maintenance, upgrades and servicing

to qualified personnel.

CAUTION: There is a risk of personal injury and equipment damage. Follow

the instructions.

CAUTION: The following label indicates sharp edges, corners or joints

nearby.

CAUTION: The following label indicates a hot surface nearby.

Hot surface. Avoid contact. Surfaces are hot and may cause

personal injury if touched.

WARNING: Allow the surface to cool before touching to reduce the

risk of injury from a hot component.

CAUTION: This symbol indicates the presence of electric shock

hazards. The area contains no user or field serviceable parts. Do

not open for any reason.

WARNING: Do not open this enclosure to reduce the risk of injury

from electric shock hazards.

CAUTION: This symbol indicates hazardous moving parts are nearby.

11. If the equipment is not used for a long time, disconnect the equipment from

outlet to avoid damage to the system by transient voltages.

12. Do not spill liquids onto equipment; this may cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should only be

opened by qualified service personnel.

14. If any of the following situations arises, have the equipment checked by

qualified service:

a. The power cord or plug is damaged.

b. Liquid seeped into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well or operation does not match behavior

described in user's manual.

e. The equipment has been dropped or damaged.

f. The equipment has obvious signs of damage.

15. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT WHERE TEMPERATURES EXCEED 70

°C (158 °F); IT MAY DAMAGE THE EQUIPMENT.

Symbols

The following symbols may be placed on the equipment to indicate the presence

of potential hazardous condition.

76

CAUTION: When replacing the lithium battery, use only the TradeDX spare

battery designated for this product. If your system has a module

containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

Do not:

Throw or immerse into water

Heat to more than 100°C (212°F)

Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

CAUTION: When laser products (such as CD-ROMs, DVD drives, fiber optic

devices, or transmitters) are installed, note the following:

Do not remove the covers. Removing the covers of the laser product could result

in exposure to hazardous laser radiation. There are no serviceable parts inside

the device.

Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

Some laser products contain an embedded Class 3A or Class 3B laser diode.

Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Class 1 Laser Product

CAUTION: Do not place any object on top of rack-mounted devices.

CAUTION:

Laser Drive Equipment

The optical transceiver module in this server is a laser Class 1 product.

Ambient Operation

This equipment cannot be operated above an ambient operation temperature

of 40 degrees centigrade.

Equipment Location

This equipment can only be accessed by SERVICE PERSONNEL or by USERS who

have been instructed about the reasons for the restrictions applied to

the location. Access is through the use of a TOOL or lock and key, or

other means of security, and is controlled by the authority responsible

for the location.

Safety statements

READ THIS IMPORTANT SAFETY INFORMATION SECTION. RETURN TO THIS MANUAL FOR

REFERENCE. READ THIS SECTION BEFORE SERVICING.

77

CAUTION: Do not connect the server to any other type of power

system to reduce the risk of electric shock.

WARNING: This server is suitable for use on an IT power

distribution system whose maximum phase-to-phase voltage is 240

V under any distribution fault condition.

Electrical current from power, telephone, and communication cables

is hazardous. To avoid a shock hazard:

Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

Connect all power cords to a properly wired and grounded electrical

outlet.

Connect to properly wired outlets any equipment that will be attached

to this product.

When possible, use one hand only to connect or disconnect signal cables.

Never turn on any equipment when there is evidence of fire, water, or

structural damage.

Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect:

To Disconnect:

1 Turn everything OFF.

2 First, attach all cables to

devices.

3 Attach signal cables to

connectors.

4 Attach power cords to outlet.

5 Turn device ON.

1 Turn everything OFF.

2 First, remove power cords

from outlet.

3 Remove signal cables from

connectors.

4 Remove all cables from

devices.

CAUTION: The power control button on the device and the power

switch on the power supply do not turn off the electrical current

supplied to the device. The device also might have more than one

power cord. To remove all electrical current from the device,

ensure that all power cords are disconnected from the power source.

CAUTION: Never remove the cover on a power supply or any part that

has the following label attached.

Hazardous voltage, current, and energy levels are present inside

any component that has this label attached. There are no

serviceable parts inside these components. If you suspect a problem

with one of these parts, contact a service technician.

Overloading a branch circuit is potentially a fire hazard and a

shock hazard under certain conditions. To avoid these hazards,

ensure that your system electrical requirements do not exceed

branch circuit protection requirements. Refer to the information

that is provided with your device for electrical specifications.

78

WARNING: Only authorized trained technicians should attempt to repair

this equipment. All troubleshooting and repair procedures are detailed

to allow only subassembly/module-level repair. Because of the complexity

of the individual boards and subassemblies, no one should attempt to make

repairs at the component level or to make modifications to any printed

wiring board. Improper repairs can create a safety hazard.

WARNING: To reduce the risk of personal injury or damage to the

equipment, be sure that:

The leveling feet are extended to the floor.

The full weight of the rack rests on the leveling feet.

The stabilizing feet are attached to the rack if it is a single-rack

installation.

The racks are coupled together in multiple-rack installations.

Only one component is extended at a time. A rack may become unstable

if more than one component is extended for any reason.

WARNING: To reduce the risk of electric shock or damage to the equipment:

Do not disable the power cord grounding plug. The grounding plug is

an important safety feature.

Plug the power cord into a grounded (earthed) electrical outlet that

is easily accessible at all times.

Unplug the power cord from the power supply to disconnect power to the

equipment.

Do not route the power cord where it can be walked on or pinched by

items placed against it. Pat particular attention to the plug,

electrical outlet and the point where the cord extends from the server.

WARNING: To reduce the risk of personal injury or damage to the

equipment:

Observe local occupation health and safety requirements and guidelines

for manual handling.

Obtain adequate assistance to lift and stabilize the chassis during

installation or removal.

The server is unstable when not fastened to the rails.

When mounting the server in a rack, remove the power supplies and any

other removable module to reduce overall weight of the product.

CAUTION: To properly ventilate the system, at least 7.6cm (3.0 in) of

clearance at the front and back of the server should be provided.

CAUTION: The server is designed to be electrically grounded (earthed).

Only plug the AC power cord into a properly grounded AC outlet to ensure

power operation.

Warnings and cautions

79

WARNING: The circuit boards and hard drives contain electronic

components that are extremely sensitive to static electricity. Ordinary

amounts of static electricity from clothing or the work environment can

destroy these components. Wear an antistatic wrist strap when handling

the media drive assemblies, circuit boards, processors, DIMMs and PCIe

cards. When servicing or removing server components, attach an antistatic

strap to your wrist and then to a metal area on the server chassis then

disconnect the power cord from the server and the wall receptacle.

Following this caution equalizes all electrical potentials within the

server.

Electrostatic discharge

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions to follow when setting

up the system or handling parts. A discharge of static electricity from a finger

or other conducer may damage system boards or other static-sensitive devices.

This type of damage may reduce the life expectancy of the device.

To prevent electrostatic damage:

Avoid hand contact by transporting and storing products in static-safe

container.

Keep electrostatic-sensitive parts in their container until they arrive at

static-free workstations.

Place parts on a grounded surface before removing from their containers.

Avoid touching pins, leads or circuitry.

Always be properly grounded when touching a static-sensitive component or

assembly.

Grounding methods to prevent electrostatic discharge

Use one or more of the following methods when handling or installing

electrostatic-sensitive parts:

Use a wrist strap connected by a ground cord to a grounded workstation or

computer chassis. Wrist straps are flexible straps with a minimum of 1

mega-ohm +/-10 percent resistance in the ground cords. Wear the strap snug

against the skin to provide proper ground.

Use heel straps, toe straps or boot straps at standing workstations. Wear

the straps on both feet when standing on conductive floors or dissipating

floor mats.

Use conductive field service tools.

Use a portable field service kit with a folding static-dissipating work mat.

Have an authorized reseller install the part if any of suggested equipment for

proper grounding is not available.

Contact an authorized reseller for more information on static electricity or

assistance with product installation.

80

Specification

Value

Temperature

range*

—

Operating

5~35 degree of Celsius

Non-operating

-40~70 degree of Celsius

Relative humidity

(noncondensing)

50%~80%

Non-operating

50%~90% (Non-condensing)

Specification

Value

Height

174 mm

Depth

863.6 mm

Width

430 mm

Specification

Value

Rated Line Voltage

200-240VAC

Rated Current

9.6A

Rated Frequency

50/60Hz

Specifications

Environmental specifications

* All temperature ratings shown are for sea level. An altitude derating of 1°C per 304.8

m (1.8°F per 1,000 ft) to 3048 m (10,000 ft) is applicable. No direct sunlight allowed.

Mechanical specifications

Input requirements

Support information

Customer support

Address:

Karlov 245

284 01, Kutná Hora

Czech Republic

To contact TradeDX by a phone, call 00420 737264041

For other contact information, please visit TradeDX website: tradedx.eu/contacts

81

Before you contact TradeDX

Be sure to have the following information available before you call TradeDX:

Technical support registration number (if applicable)

Product serial number

Product model name and number

Applicable error messages

Add-on boards or hardware

Third-party hardware or software

82

Loading...

Loading...