Page 1

Satellite Television

KVHTracVision

®

G4

technical

manual

•

Installation

•

Configuration

•

Maintenance

A Guide to TracVision G4

Page 2

TracVision G4T/M Cover 54-0147 Rev. G

12 1110987612543 13 14 232221201918 24171615 25 26 353433323130 36292827

48 47 383940414243 3744454660 59 505152535455 49565758

Green/White

White/Green

Blue/White

White/Blue

Brown/White

White/Brown

Gray/White

White/Orange

Orange/White

White/Gray

Data Cable

#32-0619-100*

#32-0619-50

†

* European

Systems

†

N. American

Systems

Black

Red

TracVision

Power

#32-0510-50

Ground

+12 VDC

Ship’s

Power

(11-16 Vdc)

Not

Used

Not Used

Green/White

White/Green

White/Blue

Blue/White

White/Orange

Orange/White

GyroTrac Sensor

Module Cable

#32-0623-30

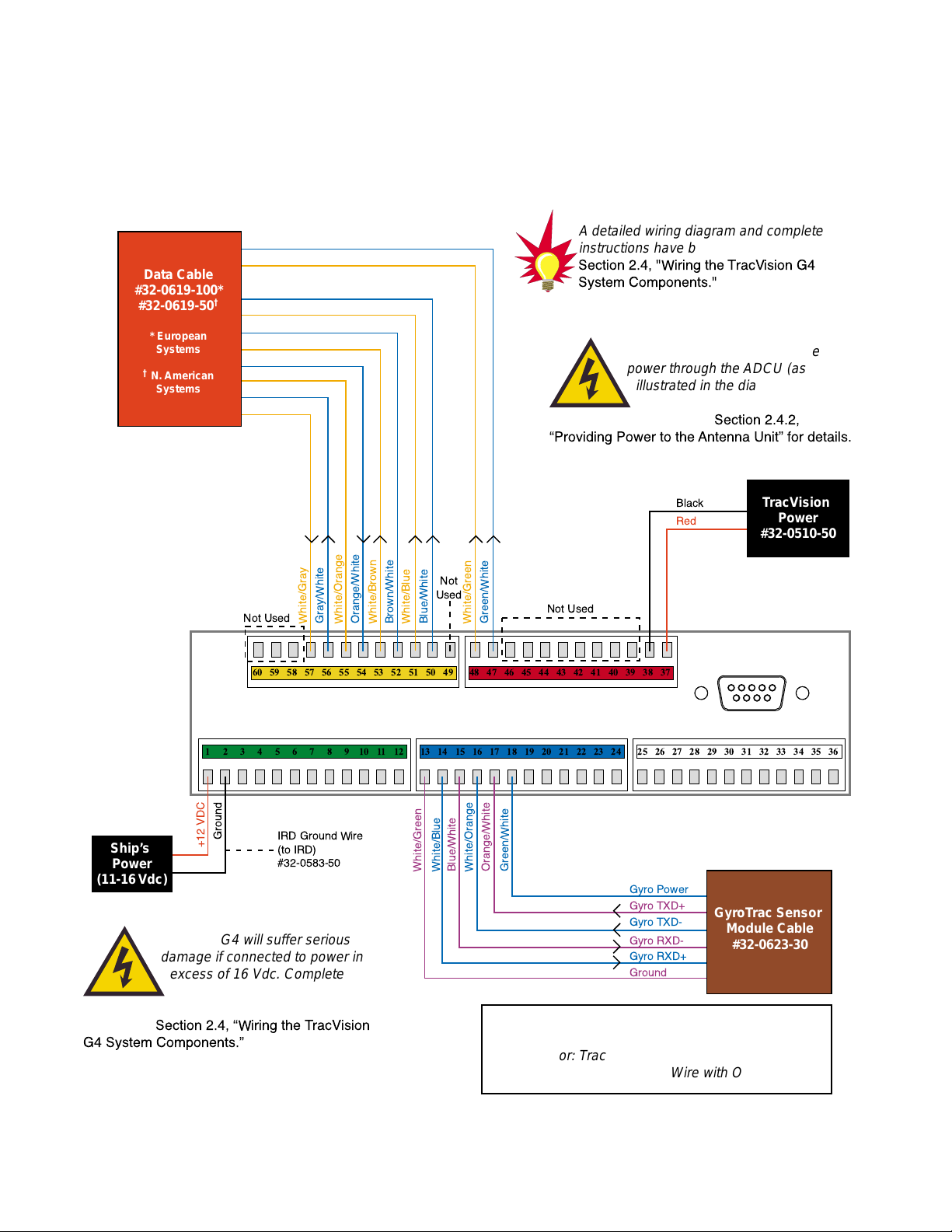

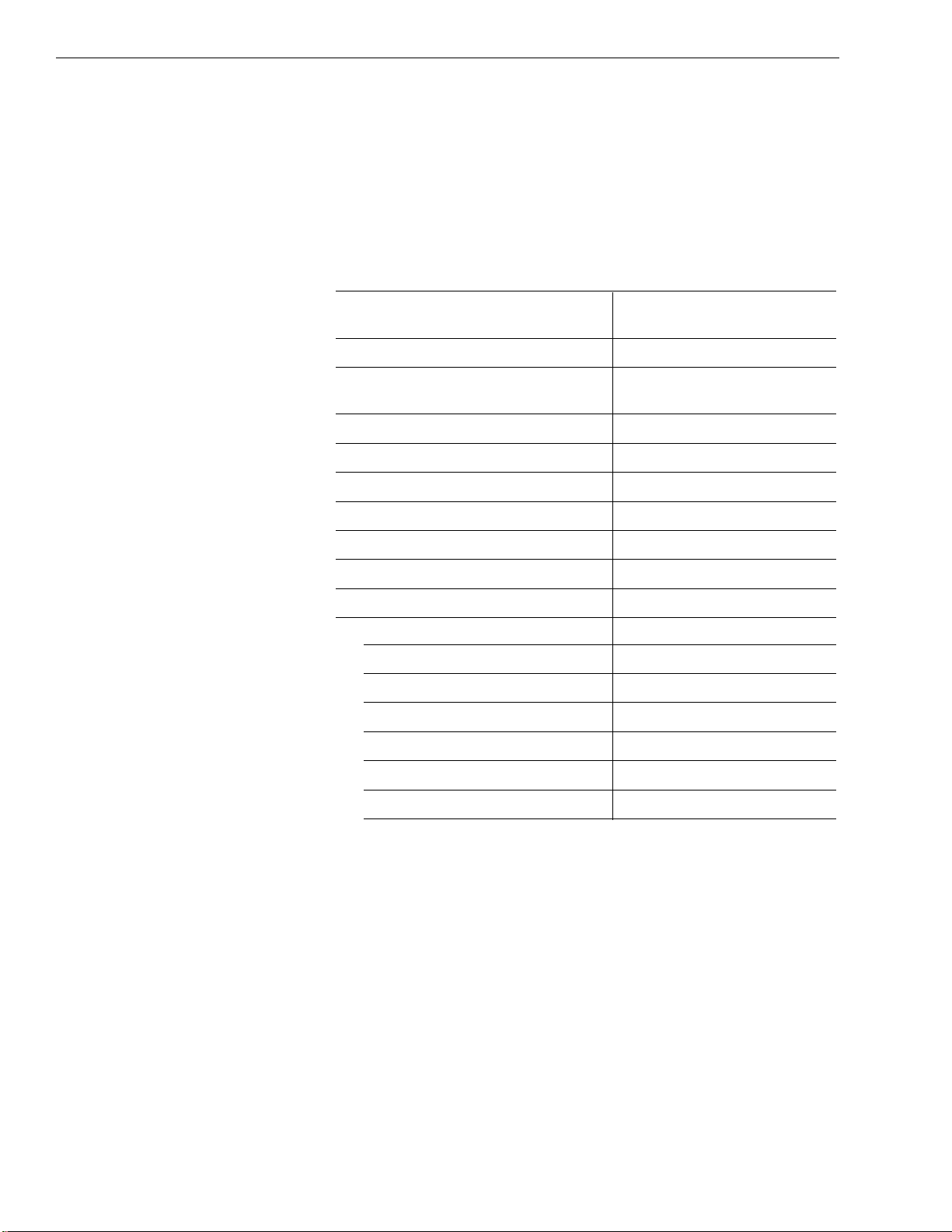

A detailed wiring diagram and complete

instructions have been provided in

Section 2.4, "Wiring the TracVision G4

System Components."

Wiring Color Code Definitions

First Color: Wire

Second Color: Tracer

Example: Red/Orange = Red Wire with Orange Tracer

TracVision G4 will suffer serious

damage if connected to power in

excess of 16 Vdc. Complete

details regarding connecting

TracVision G4 to ship's power have been

provided in

Section 2.4, ÒWiring the TracVision

G4 System Components.Ó

Gyro Power

Ground

Gyro RXD+

Gyro RXD-

Gyro TXD-

Gyro TXD+

Not Used

IRD Ground Wire

(to IRD)

#32-0583-50

TracVision G4 can either receive

power through the ADCU (as

illustrated in the diagram) or

directly from ship’s power if that is

more convenient. Refer to

Section 2.4.2,

ÒProviding Power to the Antenna UnitÓ for details.

TracVision®G4 Wiring Quick Reference Guide

Page 3

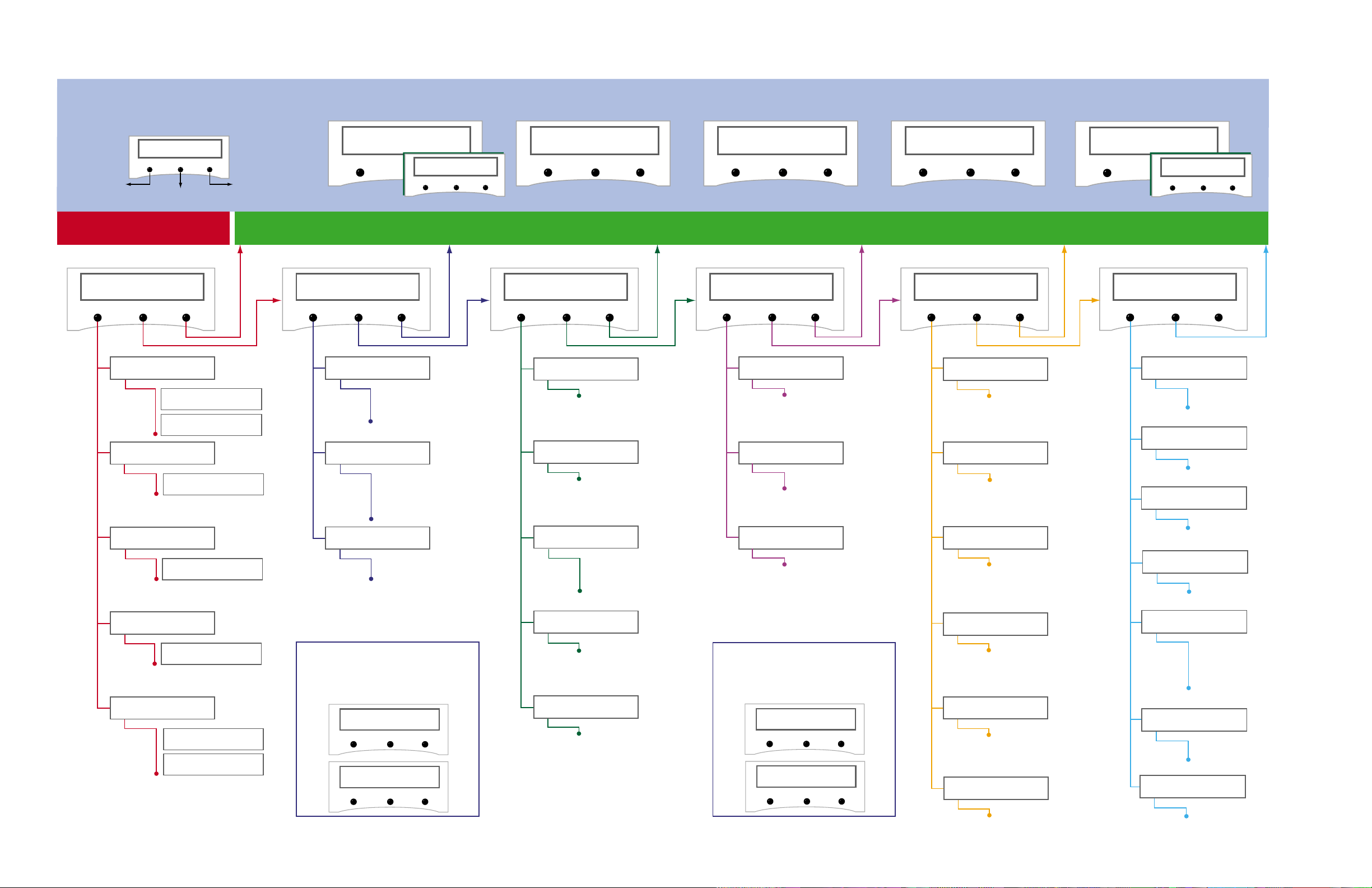

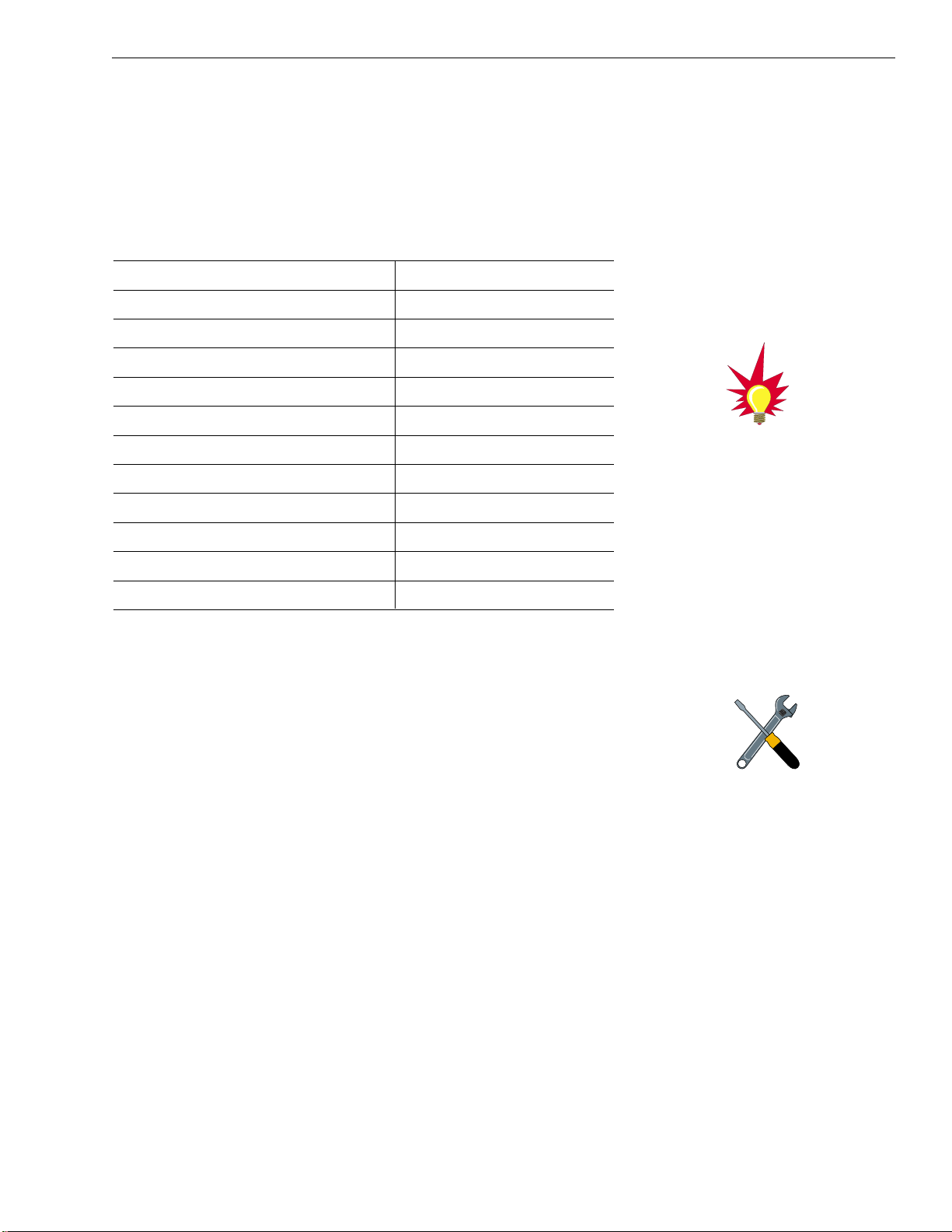

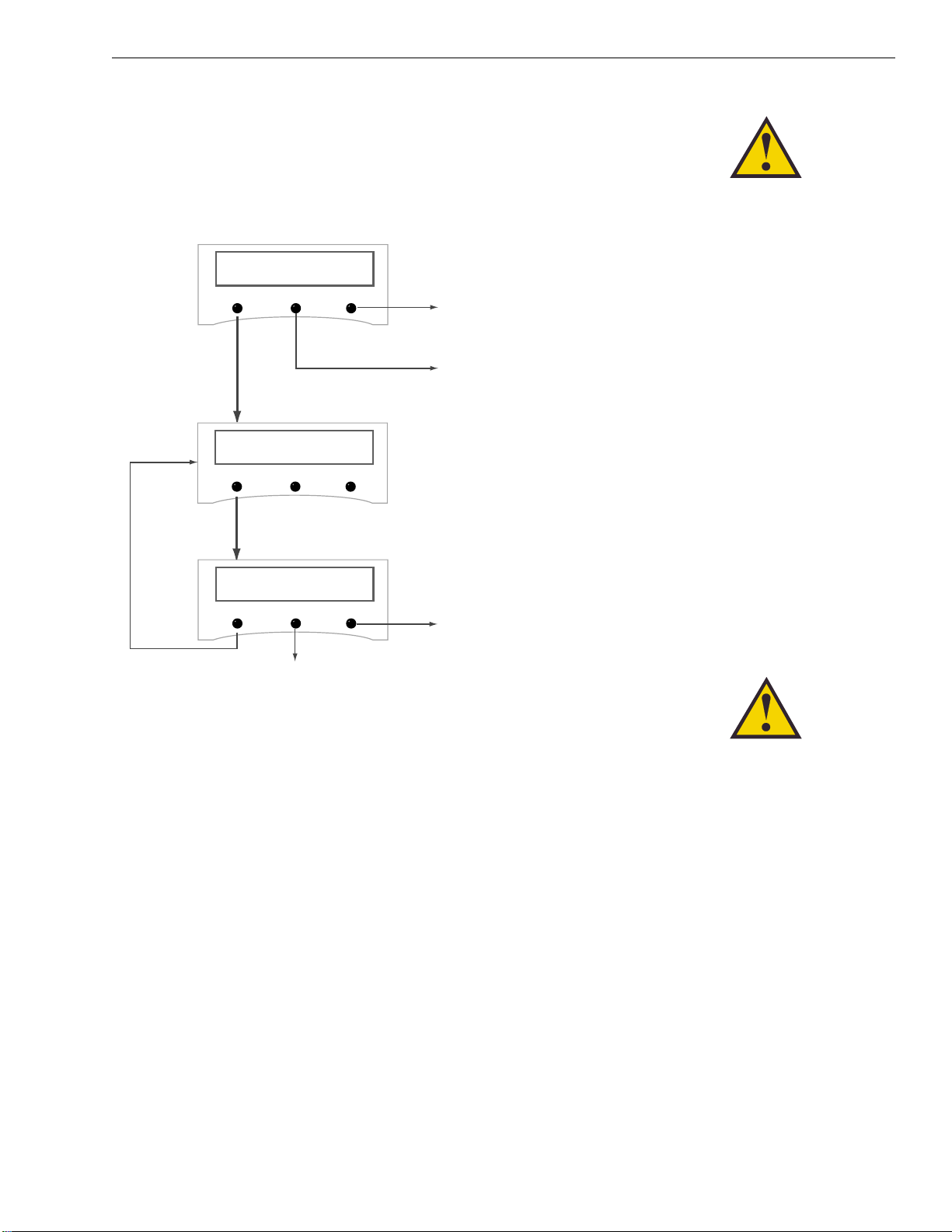

GyroTrac Mode Menus

Setup display type?

Enter Next Return

Setup data outputs?

Yes Next Return

Setup configuration?

Yes Next Return

Get Antenna status?

Enter Next Return

control antenna?

Enter Next Return

Select Mag/True

Select Serial Port 1, 2, or 3

Set NMEA Outputs

Select Mag/True

Control Compass?

Enter Next Return

Autocalibration On or Off

Calibration Accuracy, Magnetic

Environment, and Calibration #

Compass Calibration Reset

Set AutoCal On/Off?

Yes Next Return

Read Cal score?

Yes Next Return

Clear Compass Cal?

Yes Next Return

The Control Compass Menus are only

available if the selected heading

reference source is INTERNAL.

Magnetic Heading

###.#°

Mag/HDG True/HDG

###.#° ###.#°

Pitch Roll Yaw

#.#° #.#° #.#°

Mag/Hdg Rate/Sec

#.#° #.#°

Tracking <Sat Name>

###.#° ##.#° ####

ANTENNA Initializing

No Antenna Information

Lat: ##

Long: ##

compass?

Yes Next Return

Pitch, Roll & Yaw?

Yes Next Return

Rate of Turn?

Yes Next Return

Latitude Longitude?

Yes Next Return

Antenna display?

Yes Next Return

Set Reference Voltage

Set Swing Voltage

Set Speed

Select Output Type

Set Data Rate

Set sine-cos levels?

Yes Next Return

Set serial outputs?

Yes Next Return

Set Furuno outputs?

Yes Next Return

Select Internal or External

Heading Reference Source

TV Antenna Communication

On or Off

Set Heading int/ext?

Yes Next Return

Set Gyro Offsets?

Yes Next Return

Default Display box?

Yes Next Return

Set TV com on/off?

Yes Next Return

Display Default

Set Offset Roll

Set Offset Yaw

Set Offset Pitch

Errors Detected

Antenna Type and Version

Antenna Serial Number

Threshold and

Signal Levels

LNB Skew Angle

Get System Errors?

Yes Next Return

Get Thres/sig level?

Yes Next Return

Get version?

Yes Next Return

Get serial number?

Yes Next Return

Get skew angle?

Yes Next Return

Bit Error Rate

Get bit error rate?

Yes Next Return

Antenna Restarts

Set Latitude

Set Longitude

Select Active Satellite

Man control antenna?

Yes Next Return

Restart antenna?

Yes Next Return

Install satellite?

Yes Next Return

Set Lat/Long?

Yes Next Return

Select Satellite?

Yes Next Return

Adjust Azimuth

Adjust Elevation

Install Sat Pair

Set Latitude

Set Longitude

Restart Antenna

* ARE YOU SURE? *

Yes No

** WARNING **

Data will be HALTED

Alert Screens

Certain operations temporarily halt data

output. In this event, the ADCU will display a

set of alert screens. Select Yes to proceed,

No to return to the Main Data Display.

System Security - PIN Code Screens

Certain functions require the entry of a

Personal Identification Number (PIN). PIN

entry and selection are done on the screens

below. The default setting is 0000.

Enter pincode = XXXX

- Enter +

New pincode = XXXX

- Enter +

Dim or Brighten

ADCU Display

Set brightness?

Yes Next Return

Return to Selected Primary Display

Sleep Mode On/Off*

Set sleep on/off?

Yes Next Return

Instant On Mode On/Off**

set instant on/off?

Yes Next Return

See Section 3.2.3 for more detailsSee Section 3.2.2 for more details

GyroTrac™ Menu Quick Reference Guide

ADCU Primary Display Options

Pitch Roll Yaw

#.#° #.#° #.#°

Pitch, Roll, Yaw

Mag/Hdg Rate/Sec

#.#° #.#°

Rate of TurnCompass Displays*

* True North Display requires GPS data

Magnetic Heading

###.#°

Mag/HDG True/HDG

###.#° ###.#°

Antenna Displays

Tracking <Sat Name>

###.#° ##.#° ####

ANTENNA Initializing

No Antenna Information

SELECTED DISPLAY

Select Installed

Satellite A

Select Installed

Satellite B

Enter GyroTrac Mode Menus

Lat: ##

Long: ##

Latitude/Longitude

†

†

Lat/Long Display requires GPS data

* Sleep Mode only available in systems with antenna software version 3.02 or later

** Instant On Mode only available in systems with antenna software version 3.27 or later

See Section 3.3 for details See Section 3.4 for details See Section 3.5 for details See Section 3.6 for details See Section 3.7 for details See Section 3.8 for details

See Section 3.2 for details

Page 4

1

TracVision G4 Installation and Technical Manual – ADDENDUM

54-0147 Addendum to Rev. G

TracVision G4 Technical

Manual Addendum

(ECO #5416)

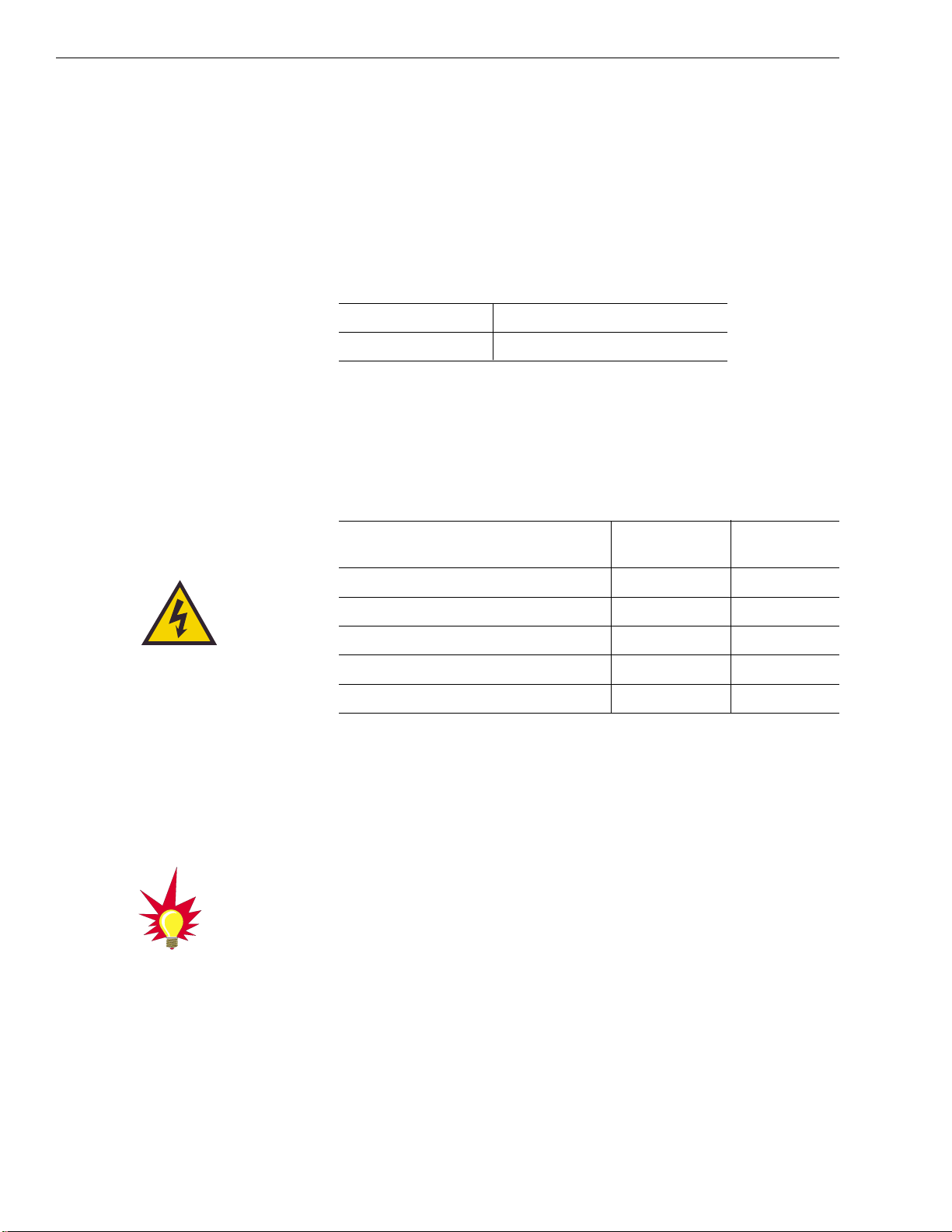

The following information applies to Revision G of the

TracVision G4 Installation and Technical Manual (KVH Part

Number 54-0147).

Appendix F

Predefined Satellite

Configurations

Some minor corrections have been made to the table of predefined

satellite configurations for European satellites (corrections are noted in

bold type). The North American satellite data remains unchanged.

As noted previously, your TracVision G4 comes programmed

with the satellite configurations for seven European and seven

North American satellite services. For your reference, those

configurations are listed below. These configurations are current

as of July 1, 2001, and are subject to change by the satellite

service providers.

Page 5

2

European Satellites

Satellite F,S,C,ID,P,B,D

Astra 1 11778,27500,34,0x0020,V,H,3

11742,27500,34,0x0020,V,L,3

12344,27500,34,0x0035,H,H,3

11876,27500,34,0x0020,H,L,3

Astra 2N 11778,27500,23,0x0020,V,H,3

00000,27500,34,0x0000,V,L,3

11914,27500,23,0x0020,H,H,3

00000,27500,34,0x0000,H,L,3

Astra 2S 11817,27500,23,0x0020,V,H,3

00000,27500,34,0x0000,V,L,3

11798,27500,23,0x0020,H,H,3

00000,27500,34,0x0000,H,L,3

Hispasat 12152,27500,34,0x0031,V,H,3

11660,27500,34,0x0031,V,L,3

12154,27500,34,0x0031,H,H,3

11522,27500,34,0x0031,H,L,3

Hotbird 12073,27500,34,0x013E,V,H,3

11958,27500,34,0x013E,V,L,3

11862,27500,34,0x013E,H,H,3

11862,27500,34,0x013E,H,L,3

Sirius 12130,27500,34,0x03E8,V,H,3

00000,27500,34,0x0000,V,L,3

12108,27500,34,0x0001,H,H,3

00000,27500,34,0x0000,H,L,3

Thor 12226,28000,78,0x0046,V,H,3

11309,24500,78,0x0046,V,L,3

12322,27800,34,0x0046,H,H,3

11229,24500,78,0x0046,H,L,3

Configuration Definitions

F = Frequency

S = Transponder symbol rate

C = FEC code

ID = Satellite network ID

P = LNB polarization (vertical or

horizontal)

B = LNB band (high, low, or USA)

D = Decoding type (3 = DVB)

Page 6

1

TracVision G4 Installation and Technical Manual – ADDENDUM

54-0147 Addendum to Rev. G

ECO #5342

TracVision G4 Technical

Manual Addendum

(ECO #5342)

The following changes have been made to Revision G of the

TracVision G4 Installation and Technical Manual (KVH Part

Number 54-0147).

2 Installation

The correct part number for the PC cable is 32-0628-06. The correct

length for the PC cable is 6 ft (1.8 m).

Cable (Function) KVH Part # Length

Data Cable (ADCU to Antenna Unit) 32-0619-100* 100 ft (30 m)

32-0619-50

†

50 ft (15 m)

PC Cable (ADCU to PC) 32-0628-06 6 ft (1.8 m)

RF Cable (Antenna to IRD) 32-0417-50

†

50 ft (15 m)

Power Cable (Power to Antenna Unit) 32-0510-50 50 ft (15 m)

Sensor to ADCU Cable (GyroTrac) 32-0623-30 30 ft (10 m)

IRD Ground to ADCU Ground Cable 32-0583-50 50 ft (15 m)

* European TracVision G4 systems only

†

North American TracVision G4 systems only

2.4.7 Connecting a PC to the ADCU

Locate cable 32-0628-06. For purposes of diagnostics and

maintenance, it is occasionally necessary to hook up a PC to the

system. This may be done using the DB9 maintenance port on the

back of the ADCU. To do so, connect the DB9 (female) to the PC

and the DB9 (male) to the ADCU.

Table 2-3

Lengths of Provided

Below-decks Cables

Page 7

54-0147 Rev. G

TracVision G4 Installation

and Technical Manual

This manual provides detailed instructions on the proper

installation, use, and maintenance of the KVH TracVision G4

automatic satellite tracking system.

Throughout this manual, important information is marked for

your attention by these icons:

Direct questions, comments, or suggestions to:

KVH Industries, Inc. KVH Europe A/S

50 Enterprise Center Ved Klaedebo 12

Middletown, RI 02842 USA 2970 Hoersholm Denmark

tel: +1 401 847-3327 tel: +45 45 16 01 80

fax: +1 401 849-0045 fax: +45 45 86 70 77

e-mail: info@kvh.com e-mail: info@kvh.dk

Internet: www.kvh.com Internet: www.kvh.com

KVH Part # 54-0147 Rev. G

© 2001, KVH Industries, Inc.

TracVision G4 Serial Number

This serial number will be required

for all troubleshooting or service

calls made regarding this product.

A helpful tip that either directs you to

a related area within the manual or

offers suggestions on getting the

highest quality out of your system.

An alert to important information

regarding procedures, product

specifications, or product use.

Information about installation,

maintenance, troubleshooting, or

other mechanical issues.

An electrical safety warning to help

identify electrical issues that can be a

hazard to either this KVH product or

a user.

Page 8

TracVision®and KVH®are registered trademarks

of KVH Industries, Inc.

GyroTrac

™

is a trademark of KVH Industries, Inc.

DIRECTV

®

is an official trademark of DIRECTV, Inc.,

a unit of GM Hughes Electronics.

DISH Network

™

is an official trademark of

EchoStar Communications Corporation.

ExpressVu is a property of Bell ExpressVu, a wholly owned

subsidiary of Bell Satellite Services.

Cetrek

™

is a trademark of Cetrek USA.

Furuno

®

is a registered trademark of Furuno USA, Inc.

B&G®and Halcyon®are trademarks of Brooks and Gatehouse, Inc.

Page 9

i

54-0147 Rev. G

Table of Contents

1 TracVision G4 System Overview . . . . . . . . . . . . . . . . . .1-1

1.1 Materials Provided With TracVision G4 System . . . . . . . . . . . . .1-2

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 Choosing the Best Location and Getting

the Best Reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Selecting the Best Location for the

TracVision G4 Antenna Unit . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Selecting the Best Location for the

GyroTrac Sensor Components . . . . . . . . . . . . . . . . . . . . . .2-3

2.2 Installing the Antenna Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3 Installing the GyroTrac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.1 GyroTrac Installation Kitpack . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.3.2 Mounting the Sensor Module . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3.3 Mounting the ADCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.4 Wiring the TracVision G4 System Components . . . . . . . . . . . .2-12

2.4.1 Wiring the Antenna Unit to the GyroTrac ADCU . . . . . . . .2-14

2.4.2 Providing Power to the Antenna Unit . . . . . . . . . . . . . . . . .2-14

2.4.3 Connecting External Devices to the GyroTrac ADCU . . . . .2-15

2.4.4 GyroTrac Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.4.5 Wiring the GyroTrac Sine/Cosine Interface . . . . . . . . . . . .2-17

2.4.6 True North Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2.4.7 Connecting a PC to the ADCU . . . . . . . . . . . . . . . . . . . . .2-18

2.4.8 Connecting an Antenna RF Signal Cable to the IRD . . . . .2-18

2.4.8.1 Connecting the IRD Ground Cable . . . . . . . . . . . . . . . .2-19

2.4.8.2 Connecting the Antenna RF Signal Cables

to a Multiswitch (North American

Systems Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2.4.9 Connecting the ADCU to Vessel Power . . . . . . . . . . . . . . .2-21

2.5 Calibrating the Sensor Module . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2.5.1 Compensating the GyroTrac . . . . . . . . . . . . . . . . . . . . . . .2-22

Page 10

2.5.2 The Calibration Score . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2.6 Commissioning the IRD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2.7 Installing Satellites on the ADCU . . . . . . . . . . . . . . . . . . . . . . .2-24

2.7.1 Programming User-defined Satellites . . . . . . . . . . . . . . . .2-26

2.8 Setting the Skew Angle (European Systems Only) . . . . . . . . .2-31

2.9 Checking Out the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

3 Interface Configuration and Operation . . . . . . . . . . . . . .3-1

3.1 Startup and Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 TracVision Startup and Self-test Screens . . . . . . . . . . . . . .3-2

3.2 Data Display and Accessing the Main Menu . . . . . . . . . . . . . . .3-3

3.2.1 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.2 Alert Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.2.3 System Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.2.4 The RETURN and CANCEL Keys . . . . . . . . . . . . . . . . . . . .3-6

3.2.5 Antenna Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.3 Setup Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.4 Set Data Outputs Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.4.1 Setting the Sine/Cosine Data Output . . . . . . . . . . . . . . . . .3-9

3.4.2 Setting the Serial Outputs . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.4.2.1 Setting the NMEA Outputs . . . . . . . . . . . . . . . . . . . . . .3-11

3.4.3 Setting the Furuno Output . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.5 Set Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

3.5.1 Setting Display Brightness . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.5.2 Selecting Heading Reference Source . . . . . . . . . . . . . . . .3-14

3.5.3 Entering Gyro Offset Values . . . . . . . . . . . . . . . . . . . . . . .3-15

3.5.4 Choosing the Default Display . . . . . . . . . . . . . . . . . . . . . .3-16

3.5.5 Selecting TracVision or GyroTrac-only Operations . . . . . . .3-16

3.6 Control Compass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

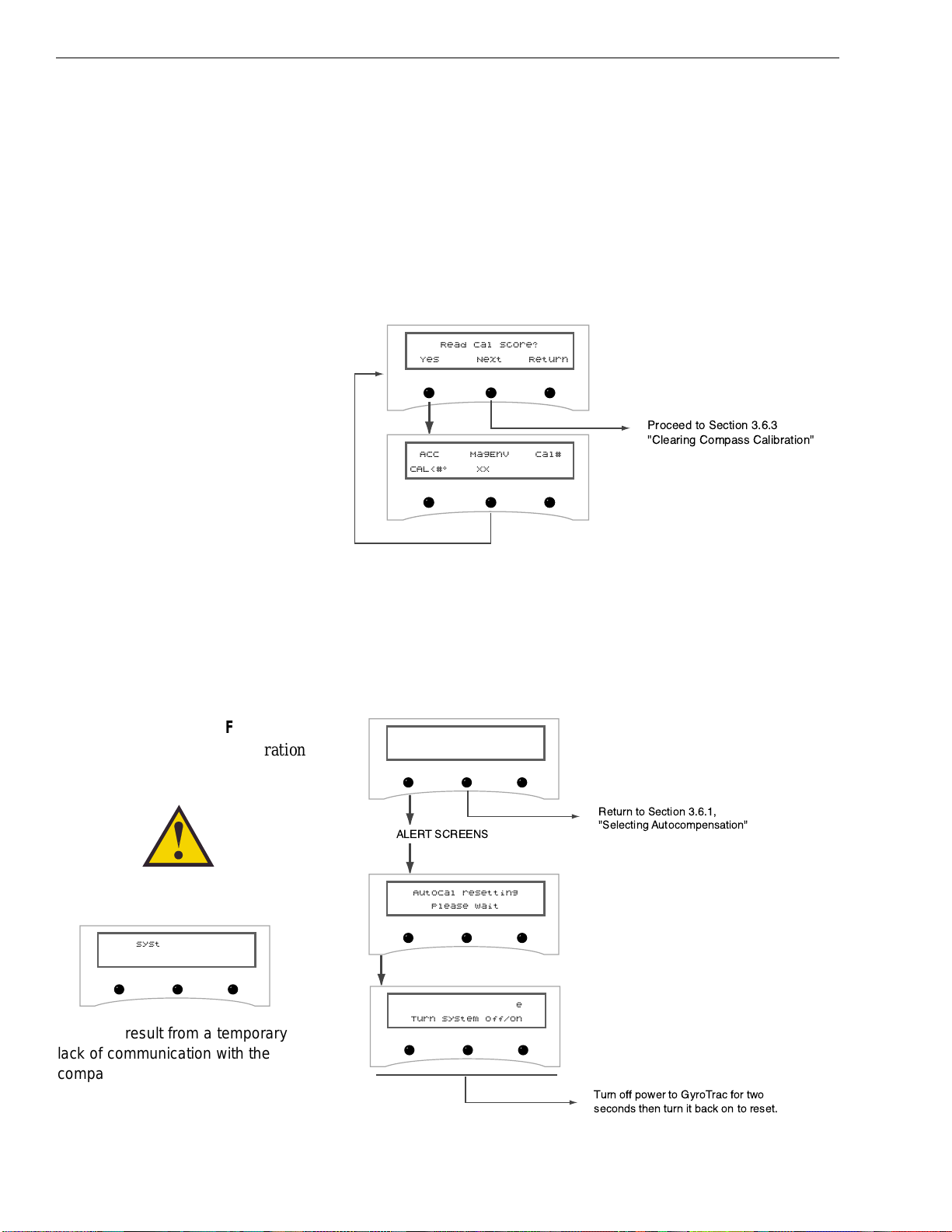

3.6.1 Selecting Autocompensation . . . . . . . . . . . . . . . . . . . . . . .3-17

3.6.2 Reading the Calibration Score . . . . . . . . . . . . . . . . . . . . .3-18

3.6.3 Clearing Compass Calibration . . . . . . . . . . . . . . . . . . . . .3-18

ii

Page 11

3.7 Antenna Status Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.7.1 Antenna Status Data Screens . . . . . . . . . . . . . . . . . . . . . .3-20

3.8 Control Antenna Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.8.1 Manually Controlling the Antenna . . . . . . . . . . . . . . . . . . .3-22

3.8.2 Restarting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.8.3 Turning Sleep Mode On/Off . . . . . . . . . . . . . . . . . . . . . . .3-23

3.8.4 Turning Instant On Mode On/Off . . . . . . . . . . . . . . . . . . . .3-24

3.8.5 Installing a New Satellite Pair . . . . . . . . . . . . . . . . . . . . . .3-25

3.8.6 Setting Latitude and Longitude . . . . . . . . . . . . . . . . . . . . .3-27

3.8.7 Selecting the Active Satellite . . . . . . . . . . . . . . . . . . . . . . .3-28

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1 Causes and Remedies for Common Operational Issues . . . . . .4-1

4.1.1 Blown Fuse, Low Power, or Wiring . . . . . . . . . . . . . . . . . . .4-2

4.1.2 Vessel Turning Dur ing Star tup . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.3 Incorrect Satellite Configuration

(European Systems Only) . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.4 Satellite Signal Blocked . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.5 Outside Satellite Coverage Zone . . . . . . . . . . . . . . . . . . . .4-3

4.1.6 Radar Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.7 Incorrect or Loose RF Connectors . . . . . . . . . . . . . . . . . . .4-4

4.1.8 Multiswitch Interference . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.1.9 Passive Multiswitch Used (North American

Systems Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2 GyroTrac-specific Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3 IRD Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.4 Antenna Gyro and LNB Faults . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.5 Computer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.6 Maintenance Port Parser Commands . . . . . . . . . . . . . . . . . . . . .4-7

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 Warranty/Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

iii

54-0147 Rev. G

Page 12

5.3 TracVision G4 Field Replaceable Units . . . . . . . . . . . . . . . . . . .5-2

5.4 PCB Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.4.1 CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.4.2 RF Detector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.5 Antenna Gyro Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.6 Elevation Motor and Belt Replacement . . . . . . . . . . . . . . . . . . .5-9

5.6.1 Drive Belt Removal and Replacement . . . . . . . . . . . . . . . .5-10

5.6.2 Elevation Drive Motor Removal and Replacement . . . . . . .5-10

5.7 Antenna LNB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.7.1 European LNB Replacement . . . . . . . . . . . . . . . . . . . . . .5-11

5.7.2 U.S.-style LNB Replacement . . . . . . . . . . . . . . . . . . . . . . .5-12

5.8 GyroTrac Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

5.9 Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Appendix A System Specifications . . . . . . . . . . . . . . . . . .A-1

A.1 Antenna Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 GyroTrac Compass Specifications . . . . . . . . . . . . . . . . . . . . . . .A-2

Appendix B TracVision G4 Baseplate

Mounting Holes Template . . . . . . . . . . . . . . . .B-1

Appendix C ADCU Flush Mount Panel Template . . . . . . . . . .C-1

Appendix D Comprehensive TracVision G4 System

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . .D-1

Appendix E Optional KVH Displays . . . . . . . . . . . . . . . . . .E-1

E.1 Optional Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . .E-1

E.2 Mounting the Pointer Analog and Digital Displays . . . . . . . . . .E-2

E.2.1 Mounting the Display Backlighting Control . . . . . . . . . . . . .E-3

E.2.2 Wiring the Pointer Analog and Digital Displays . . . . . . . . . .E-3

E.2.3 Wiring the Backlight Control Switch . . . . . . . . . . . . . . . . . .E-4

E.3 Mounting the Rotating Card Display . . . . . . . . . . . . . . . . . . . . .E-4

iv

Page 13

E.3.1 Bracket Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-4

E.3.2 Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-5

E.3.3 Wiring the Rotating Card Display . . . . . . . . . . . . . . . . . . . .E-5

Template E-1 Rotating Card Display Bracket Mounting . . . . . . . .E-9

Template E-2 Rotating Card Display Panel Mounting . . . . . . . . .E-11

Appendix F Predefined Satellite Configurations . . . . . . . . .F-1

Appendix G Startup Data Sequences . . . . . . . . . . . . . . . . .G-1

Appendix H Data Outputs . . . . . . . . . . . . . . . . . . . . . . . .H-1

H.1 Sine/Cosine Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-1

H.2 Serial Port Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-1

H.3 Furuno Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-4

H.3.1 Optional Stepper Components . . . . . . . . . . . . . . . . . . . . . .H-4

Appendix I Maintenance Port Parser Commands . . . . . . . . .I-1

I.1 System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

I.2 Manual Positioning Commands . . . . . . . . . . . . . . . . . . . . . . . . . .I-2

I.3 Operational Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

I.4 Tracking and Conical Scan Commands . . . . . . . . . . . . . . . . . . .I-4

I.5 Sensor Module Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-5

I.6 RF Board Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-6

I.7 Installation Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-8

I.8 Debug Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-9

List of Figures

Figure 1-1 TracVision G4 System Configuration . . . . . . . . . . . . . . . .1-1

Figure 2-1 Antenna Unit Elevation . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-2 Antenna Unit Base Dimensions . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-3 Baseplate/Foam Seal Orientation (Bottom View) . . . . . . .2-6

Figure 2-4 Baseplate Connector Assignments . . . . . . . . . . . . . . . . . .2-6

v

54-0147 Rev. G

Page 14

Figure 2-5 Bolting the Antenna Unit to the Deck (Side View) . . . . . . .2-7

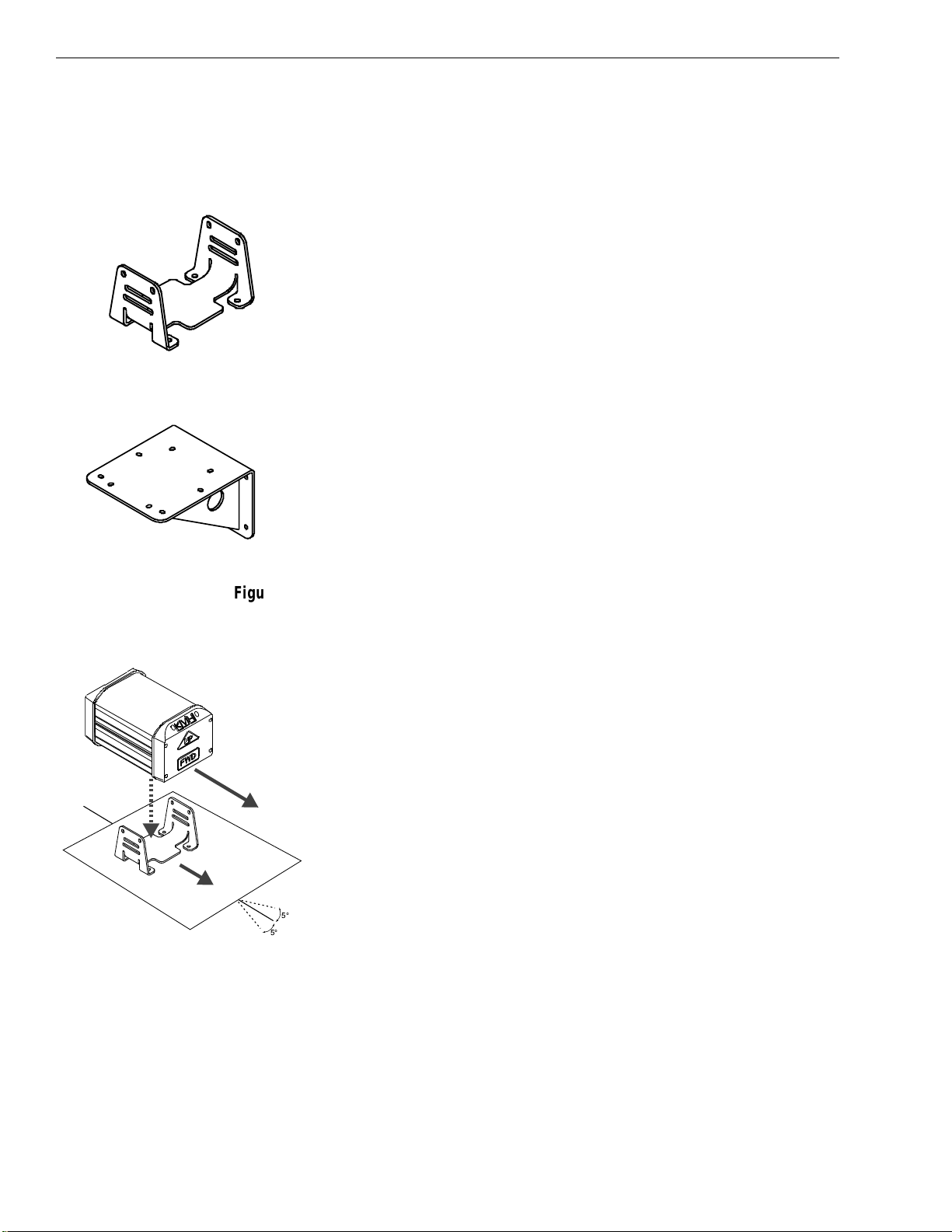

Figure 2-6 Horizontal Sensor Bracket . . . . . . . . . . . . . . . . . . . . . . . .2-8

Figure 2-7 Vertical Sensor Bracket . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Figure 2-8 Proper Orientation of the Sensor Module . . . . . . . . . . . . .2-8

Figure 2-9 Securing the Sensor Module and the

Horizontal Sensor Bracket . . . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 2-10 Optional Bracket Orientations . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 2-11 Attaching the Hor izontal and Vertical Brackets . . . . . . . .2-10

Figure 2-12 Mounting the ADCU with Velcro Attachments . . . . . . . . .2-11

Figure 2-13 Secur ing the ADCU to the Flush Mount Bracket . . . . . . .2-11

Figure 2-14 Terminal Strip Order . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Figure 2-15 Attaching the Ter minal Strips to the ADCU . . . . . . . . . . .2-12

Figure 2-16 Examples of Effective Strain Relief . . . . . . . . . . . . . . . . .2-13

Figure 2-17 TracVision G4 Wiring Arrangement . . . . . . . . . . . . . . . . .2-14

Figure 2-18 GyroTrac Wiring Arrangement . . . . . . . . . . . . . . . . . . . .2-16

Figure 2-19 DB9 Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Figure 2-20 ADCU DB9 Maintenance Port . . . . . . . . . . . . . . . . . . . .2-18

Figure 2-21 Single Multiswitch Installation

(North American systems only) . . . . . . . . . . . . . . . . . . .2-20

Figure 2-22 Multiple Multiswitch Installation

(North American systems only) . . . . . . . . . . . . . . . . . . .2-20

Figure 2-23 Sample Calibration Score Screen . . . . . . . . . . . . . . . . . .2-22

Figure 2-24 Control Antenna Mode Menu Sequence . . . . . . . . . . . . .2-24

Figure 2-25 Install Satellite Process . . . . . . . . . . . . . . . . . . . . . . . . .2-26

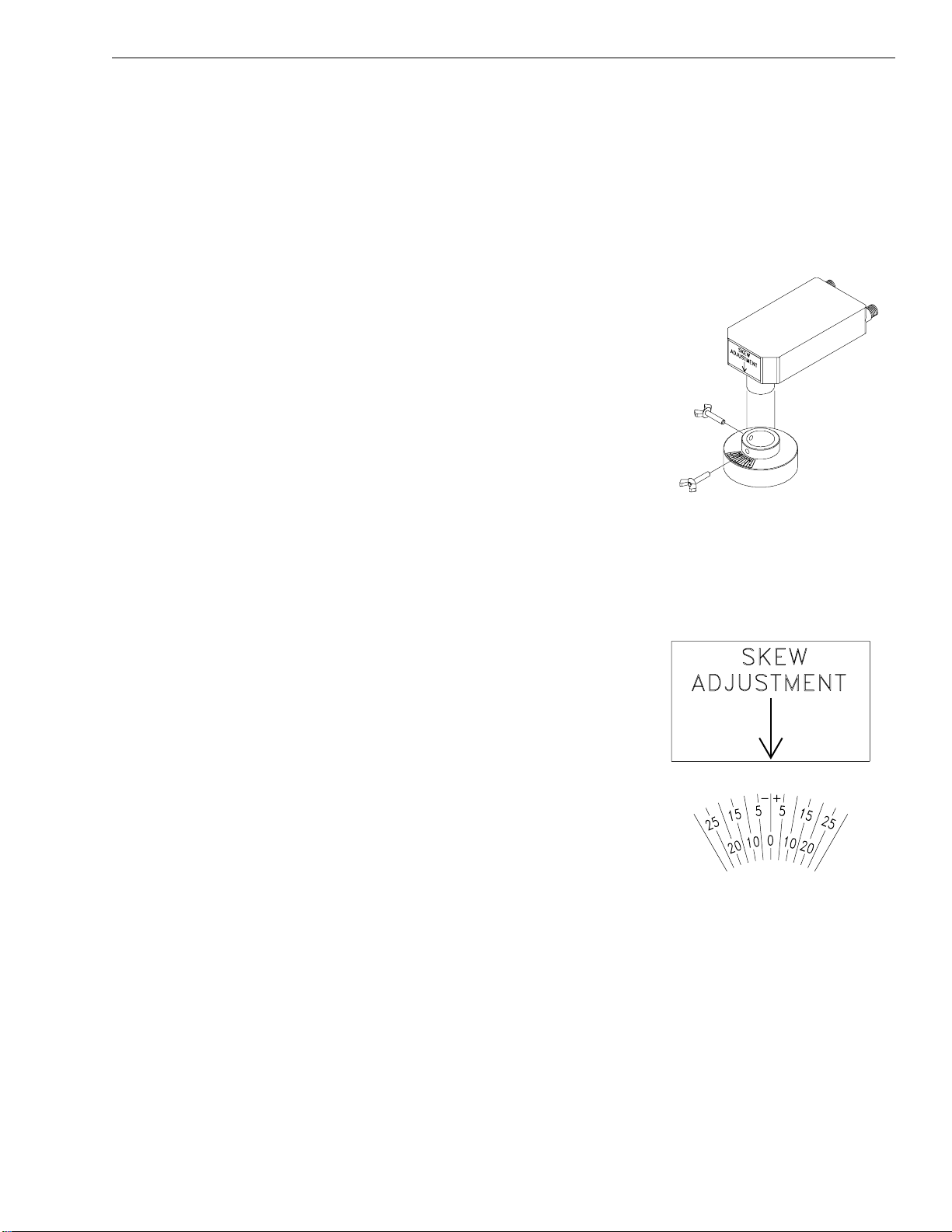

Figure 2-26 Adjusting the European LNB Skew Angle . . . . . . . . . . . .2-31

Figure 2-27 Skew Angle Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

Figure 3-1 Star tup and Self-test Sequence . . . . . . . . . . . . . . . . . . . .3-1

Figure 3-2 Star tup Error Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Figure 3-3 TracVision G4 Startup Screens . . . . . . . . . . . . . . . . . . . .3-2

Figure 3-4 Soft Key Functions and Primary Data Displays . . . . . . . . .3-3

Figure 3-5 Main Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

vi

Page 15

Figure 3-6 Sample Aler t Screens . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Figure 3-7 PIN Code Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Figure 3-8 Erase PIN Code Screen . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Figure 3-9 Incorrect Response Error Message . . . . . . . . . . . . . . . . .3-6

Figure 3-10 Non-responsive Antenna Error Message . . . . . . . . . . . . .3-6

Figure 3-11 Setting Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Figure 3-12 Data Outputs Mode Menu Sequence . . . . . . . . . . . . . . . .3-8

Figure 3-13 Setting Sine/Cosine Data Output . . . . . . . . . . . . . . . . . . .3-9

Figure 3-14 Setting Ser ial Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Figure 3-15 Setting NMEA Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Figure 3-16 Setting Fur uno Output . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Figure 3-17 Configuration Mode Menu Sequence . . . . . . . . . . . . . . .3-13

Figure 3-18 Display Brightness Controls . . . . . . . . . . . . . . . . . . . . . .3-14

Figure 3-19 Inter nal/Exter nal Reference Menus . . . . . . . . . . . . . . . .3-14

Figure 3-20 Enter ing Gyro Offset Values . . . . . . . . . . . . . . . . . . . . . .3-15

Figure 3-21 Selecting the Default Display . . . . . . . . . . . . . . . . . . . . .3-16

Figure 3-22 Selecting TracVision or GyroTrac-only Operations . . . . . .3-16

Figure 3-23 Compass Control Mode Menu Sequence . . . . . . . . . . . .3-17

Figure 3-24 Setting Autocompensation . . . . . . . . . . . . . . . . . . . . . . .3-17

Figure 3-25 Reading Calibration Score . . . . . . . . . . . . . . . . . . . . . . .3-18

Figure 3-26 Clear ing Compass Calibration . . . . . . . . . . . . . . . . . . . .3-18

Figure 3-27 Antenna Status Mode Menu Sequence . . . . . . . . . . . . .3-19

Figure 3-28 Antenna Status Data Screens . . . . . . . . . . . . . . . . . . . .3-20

Figure 3-29 Control Antenna Mode Menu Sequence . . . . . . . . . . . . .3-21

Figure 3-30 Manual Antenna Control Procedure . . . . . . . . . . . . . . . .3-22

Figure 3-31 Restart Antenna Menu . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Figure 3-32 Sleep Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Figure 3-33 Instant On Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Figure 3-34 Install Satellite Pair Process . . . . . . . . . . . . . . . . . . . . . .3-25

Figure 3-35 Set Latitude/Longitude Procedure . . . . . . . . . . . . . . . . .3-27

Figure 3-36 Select Active Satellite . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

vii

54-0147 Rev. G

Page 16

Figure 4-1 Troubleshooting Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Figure 4-2 ADCU Fuse Locations (Top Cut Away) . . . . . . . . . . . . . . .4-4

Figure 4-3 DB9 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 5-1 TracVision G4 Antenna Unit (Baseplate Cut Away) . . . . . .5-3

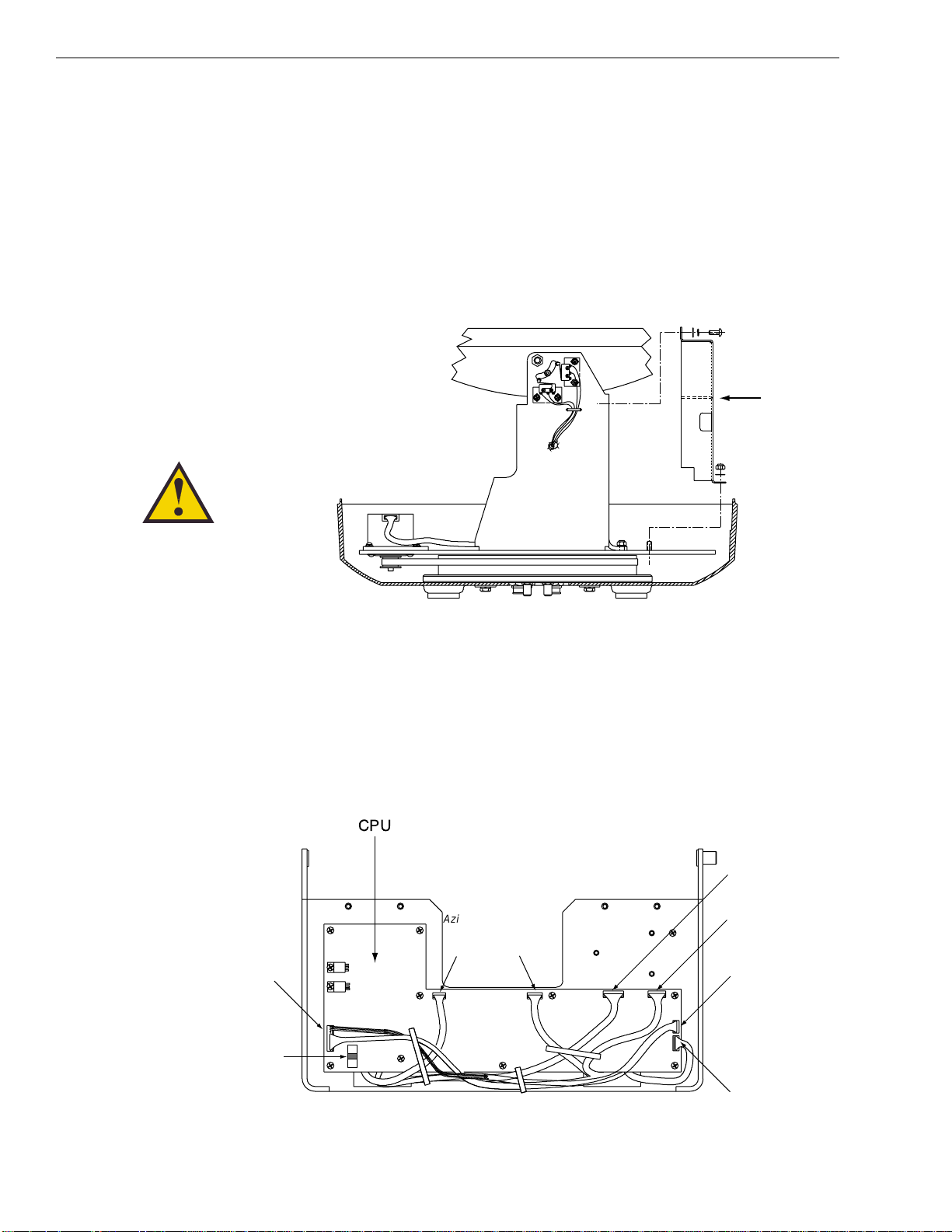

Figure 5-2 PCB Cover Plate Removal . . . . . . . . . . . . . . . . . . . . . . . .5-4

Figure 5-3 PCB Connector Locations (Rear View) . . . . . . . . . . . . . . .5-4

Figure 5-4 PCB Mounting (Top View) . . . . . . . . . . . . . . . . . . . . . . . .5-5

Figure 5-5 Data and RF Flash Cables . . . . . . . . . . . . . . . . . . . . . . . .5-5

Figure 5-6 RF Cable Ferrules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Figure 5-7 New RF Board Installation . . . . . . . . . . . . . . . . . . . . . . . .5-6

Figure 5-8 Elevation Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . .5-9

Figure 5-9 European LNB Removal . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Figure 5-10 U.S.-style LNB Removal . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Figure 5-11 Data Cable Terminal Arrangement . . . . . . . . . . . . . . . . .5-13

Figure 5-12 Shipping Restraint Placement . . . . . . . . . . . . . . . . . . . .5-14

Figure E-1 Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Figure E-2 Mounting the Analog/Digital Displays . . . . . . . . . . . . . . . .E-2

Figure E-3 Mounting the Display Backlighting Control Switch . . . . . .E-3

Figure E-4 Wiring the Backlight Control Switch . . . . . . . . . . . . . . . . .E-4

Figure E-5 Rotating Card Display – Removing the Backplate . . . . . .E-5

Figure E-6 Rotating Card Display – Terminal Str ip Wiring . . . . . . . . .E-6

Figure E-7 Rotating Card Display – PC Board Jumpers

and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

Figure H-1 Stepper Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-4

Figure H-2 Optional 6-70v Stepper Voltage Converter

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-6

List of Tables

Table 1-1 TracVision G4 Packing List . . . . . . . . . . . . . . . . . . . . . . . .1-2

Table 2-1 Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Table 2-2 Recommended ADCU-to-Ship’s Power

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

viii

Page 17

Table 2-3 Lengths of Provided Below-decks Cables . . . . . . . . . . . . .2-2

Table 2-4 Antenna Unit Kitpack Contents . . . . . . . . . . . . . . . . . . . . .2-4

Table 2-5 GyroTrac Kitpack Contents . . . . . . . . . . . . . . . . . . . . . . . .2-7

Table 2-6 GyroTrac/Autopilot Sine/Cosine Wiring

Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Table 2-7 Possible Compass Accuracy Levels . . . . . . . . . . . . . . . .2-22

Table 2-8 Key IRD Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Table 2-9 Available Satellite Pairs – Europe

(European LNB required) . . . . . . . . . . . . . . . . . . . . . . . .2-25

Table 2-10 Available Satellite Pairs – North America

(U.S.-style LNB required) . . . . . . . . . . . . . . . . . . . . . . . .2-25

Table 2-11 SATCONFIG Parser Command . . . . . . . . . . . . . . . . . . .2-28

Table 2-12 Satellite Transponder Data Sequence . . . . . . . . . . . . . . .2-28

Table 2-13 Satellite Transponder Default Data . . . . . . . . . . . . . . . . .2-29

Table 2-14 Sample Satellite Configuration Data . . . . . . . . . . . . . . . .2-30

Table 3-1 Available Satellite Pairs - Europe

(European LNB required) . . . . . . . . . . . . . . . . . . . . . . . .3-26

Table 3-2 Available Satellite Pairs - North America

(U.S.-style LNB required) . . . . . . . . . . . . . . . . . . . . . . . .3-26

Table 5-1 TracVision G4 Field Replaceable Units . . . . . . . . . . . . . . .5-2

Table 5-2 GyroTrac Field Replaceable Units . . . . . . . . . . . . . . . . .5-13

Table 5-3 Data Cable Wiring/Terminal Assignments . . . . . . . . . . . .5-13

Table A-1 TracVision G4 Antenna Physical Specifications . . . . . . . .A-1

Table A-2 TracVision G4 Power Specifications . . . . . . . . . . . . . . . . .A-1

Table A-3 TracVision G4 Performance Specifications . . . . . . . . . . . .A-1

Table A-4 TracVision G4 GyroTrac Performance

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Table A-5 TracVision G4 GyroTrac Environmental

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Table A-6 TracVision G4 GyroTrac Interface Specifications . . . . . . .A-3

Table E-1 Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Table E-2 Display Cable Connections . . . . . . . . . . . . . . . . . . . . . . .E-3

Table E-3 Rotating Card Display – Ter minal Strip Wiring Details . . .E-6

Table H-1 NMEA1 Magnetic Heading Output . . . . . . . . . . . . . . . . . .H-2

ix

54-0147 Rev. G

Page 18

Table H-2 NMEA2 Magnetic Heading Output . . . . . . . . . . . . . . . . . .H-2

Table H-3 NMEA3 True Heading Output . . . . . . . . . . . . . . . . . . . . .H-3

Table H-4 KVH Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-3

Table H-5 Cetrek Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-4

Table H-6 Stepper Interface Specifications . . . . . . . . . . . . . . . . . . .H-5

Table I-1 System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Table I-2 Manual Positioning Commands . . . . . . . . . . . . . . . . . . . . .I-2

Table I-3 Operational Commands . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

Table I-4 Tracking and Conical Scan Commands . . . . . . . . . . . . . . .I-4

Table I-5 Sensor Module Commands . . . . . . . . . . . . . . . . . . . . . . . .I-5

Table I-6 RF Board Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-6

Table I-7 Installation Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .I-8

Table I-8 Debug Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-9

x

Page 19

1 TracVision G4 System

Overview

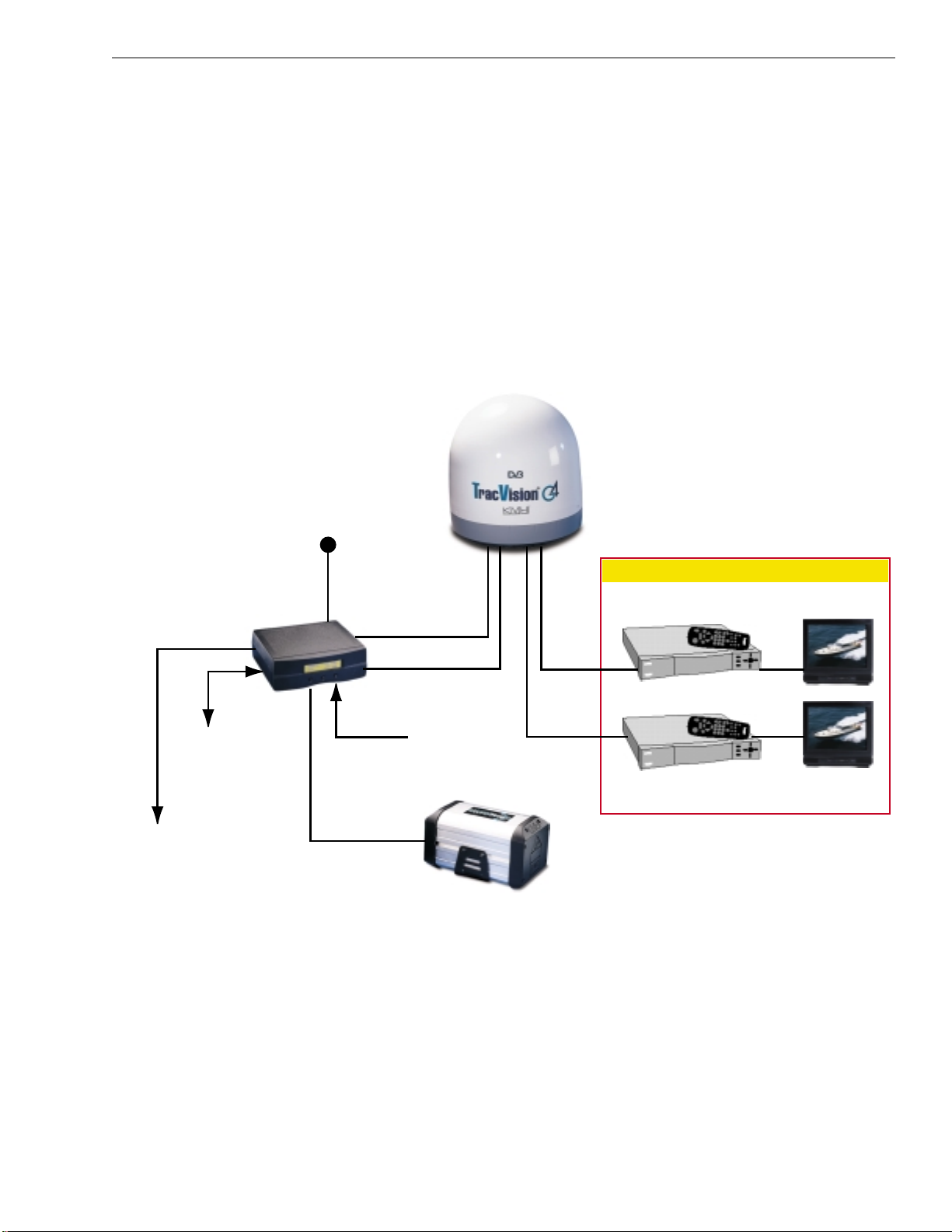

A complete satellite TV system, illustrated in Figure 1-1, includes

the TracVision G4 connected to an IRD, the GyroTrac digital gyrostabilized sensor, Advanced Digital Control Unit (ADCU), and a

television set. A desktop or laptop computer is used to configure

the system for satellite selection and conduct diagnostics. System

specifications are provided in Appendix A.

Introduction

1-1

54-0147 Rev. G

Figure 1-1

TracVision G4 System

Configuration

3.5 - 4.5 Amps

Advanced Digital

Control Unit (ADCU)

PC Diagnostics

11-16 VDC

TracVision G4 Antenna

Power

Data

GPS or

Ship's Gyro

RF

RF

Options Purchased Separately

Satellite Receiver 1

Satellite Receiver 2

TV 1

TV 2

Interfaces to:

Autopilots

Radars

Plotters

Remote Displays

GyroTrac Sensor

Page 20

1.1 Materials Provided With

TracVision G4 System

Table 1-1 lists the components and materials in the TracVision G4

shipping carton.

Component KVH Part No.

Antenna Unit 02-0989-01

†

02-0989-02*

Installation Kitpack 72-0099

Data Cable 32-0619-100

*

32-0619-50

†

PC Cable 32-0628-06

RF Cable 32-0417-50

†

Power Cable 32-0510-50

Ground Cable 32-0583-50

TracVision G4 Technical Manual 54-0147

TracVision G4 User’s Guide 54-0147-01

GyroTrac, which includes: 01-0226

Sensor Module 02-0991

ADCU 02-0961

Flush Mount ADCU Panel 20-0667

Horizontal Sensor Bracket 20-0658

Vertical Sensor Bracket 20-0666

Sensor to ADCU Cable (30 ft.) 32-0623-30

Kitpack 72-0095

*European TracVision G4 systems only

†

North American TracVision G4 systems only

1-2

TracVision G4 Installation and Technical Manual

Table 1-1

TracVision G4 Packing List

Page 21

2 Installation

TracVision G4 is designed for simple installation and setup. Just

follow these easy steps:

Step Refer to Section...

1. Choose the hardware locations 2.1

2. Mount the Antenna Unit 2.2

3. Mount the GyroTrac 2.3

4. Install the IRD Refer to IRD User Manual

5. Wire system components 2.4

6. Connect ADCU to vessel power 2.4.9

7. Calibrate the Sensor Module 2.5

8. Program the IRD (Europe only) 2.6

9. Install selected satellite pair 2.7

10. Load any user-selected satellites 2.7.1

11. Set the skew angle (Europe only) 2.8

12. Check out system 2.9

Materials and Equipment Required for Installation

• Electric drill

•

3

⁄8" (10 mm) drill bit and 3" (80 mm) hole saw

• Socket wrenches

• Flat tip and Phillips screwdrivers

• RG-11 (75 ohms) cable for extra RF signal cables

as needed (European TracVision G4 systems only)

• Crimp tool (LRC #L3011B or equivalent)

• Power cable to connect the ADCU to ship’s power

(Table 2-2 provides proper gauge and length

specifications)

• Light hammer; center punch; tape; scriber/pencil

• Terminal lug crimping tool; wire strippers

• A PC with terminal emulation software such as

PROCOMM, Windows Terminal, or Windows

95/98 Hyperterminal

2-1

Installation

54-0147 Rev. G

Plan the entire installation before

proceeding! Take into account

antenna unit placement, running

cable distances between units, and

accessibility to the equipment after

installation. Cable lengths are

detailed in Tables 2-2 and 2-3 on

the following page.

KVH recommends the use of

RG-11 (75 ohms) cable for RF

wiring. Use of non-RG-11

(75 ohms) cables will result in

degraded performance.The KVH

warranty does not cover degraded

performance due to improper

wiring.

Table 2-1

Installation Process

Page 22

Recommended ADCU to Ship’s Power Cabling

The following cable sizes are recommended for the

specified running lengths and are based on Lloyd’s and

ABYC specifications. Cable jacketing should meet marine

insulation standards while the cable should be tinned,

stranded marine stock.

Cable Length Cable Gauge

to 50 ft (15 m) 14 AWG (1.5 mm2)

+50 ft (+15 m) 12 AWG (2.5 mm2)

Below-decks Cable Lengths

The major considerations in locating the below-decks equipment

are accessibility and cable lengths between units. Lengths of these

cables are as follows:

Cable (Function) KVH Part # Length

Data Cable (ADCU to Antenna Unit) 32-0619-100* 100 ft (30 m)

32-0619-50

†

50 ft (15 m)

PC Cable (ADCU to PC) 32-0513-15 15 ft (5m)

RF Cable (Antenna to IRD) 32-0417-50

†

50 ft (15 m)

Power Cable (Power to Antenna Unit) 32-0510-50 50 ft (15 m)

Sensor to ADCU Cable (GyroTrac) 32-0623-30 30 ft (10 m)

IRD Ground to ADCU Ground Cable 32-0583-50 50 ft (15 m)

* European TracVision G4 systems only

†

North American TracVision G4 systems only

2.1 Choosing the Best Location and

Getting the Best Reception

There are several factors to consider when choosing the

respective locations of the TracVision G4 antenna unit and

GyroTrac sensor components.

2.1.1 Selecting the Best Location for the

TracVision G4 Antenna Unit

• The ideal antenna site has a clear view of the

horizon/satellite all around.

2-2

TracVision G4 Installation and Technical Manual

The radome exterior is treated

with a special finish selected for

compatibility with the dome material

and transparency to the satellite

signals. Application of additional

paints or finishes WILL degrade

performance, potentially beyond

acceptable limits.

Table 2-2

Recommended ADCU-to-Ship’s

Power Cable Specifications

Table 2-3

Lengths of Provided

Below-decks Cables

The power cable connector on the

base of the Antenna Unit cannot

accept cables thicker than 14 AWG

(1.5 mm2). Refer to Section 2.4.2,

“Providing Power to the Antenna

Unit,” for more details.

Page 23

• Tracking errors will be reduced if the antenna

forward arrow is aligned as closely as possible

with the vessel’s centerline.

• Place the Antenna Unit as close to the intersection

of the vessel’s fore-and-aft centerline and midships.

• Keep the antenna out of line with nearby radars,

as their energy levels may overload the antenna’s

front-end circuits. If necessary, position the

Antenna Unit so it is at least four feet (1.3 meters)

above or below the level of the radar.

• Make sure that the mounting surface is rigid so

that it cannot flex when the vessel vibrates. If

necessary, add a strength member to the mounting

site to stiffen it.

2.1.2 Selecting the Best Location for the

GyroTrac Sensor Components

Ideally, the GyroTrac sensor module should be mounted as low

as possible in the center of the vessel – but NOT in the bilges.

• Place the Sensor Module as far as practical

(minimum 3 ft./0.9 m) from magnetized or

magnetizable materials.

•

Maintain at least 4 feet (1.3 m) separation between

the Sensor Module and any large ferrous masses,

cables carrying high amperage direct current, or

battery banks.

• Be alert for devices that change their magnetic

characteristics when in use, such as CRTs,

computer and TV screens, radar magnetrons,

electric winches, loudspeakers, windshield wipers,

and other devices with DC motors. GyroTrac

cannot compensate for changing magnetic fields

created by these devices.

•

If it is necessary to fabricate custom mounting

brackets for the Sensor Module, they should be

made from non-ferrous materials such as wood,

brass, aluminum, fiberglass, or plastic.

2-3

Installation

54-0147 Rev. G

Be certain to isolate the Sensor

Module from ground (i.e., the ship’s

hull) by always using the fiber

washers when attaching the

Horizontal Sensor Bracket to either

a mounting surface or the Vertical

Sensor Bracket.

The Antenna Unit should not be too

high off the water (a height above

the waterline no more than half the

vessel length).

If uncertain of the best location

for the sensor module, make a

temporary installation and conduct

a compass calibration (as

described in Section 2.5,

“Calibrating the Sensor Module”).

Any necessary adjustments to the

sensor location can be made

based on the calibration scores.

Page 24

Mounting on Steel Vessels

The GyroTrac sensor module is a digital magnetic compass and

great care is required when positioning the unit on steel-hulled

craft. The ideal location is in the wheelhouse or above decks.

Mount on an aluminum pole or bracket, well away from

magnetic fields such as cranes, derricks, motors, radomes,

antennas, etc. DO NOT mount the sensor module on a steel or

iron platform. Use aluminum, brass, plastic, or wood.

2.2 Installing the Antenna Unit

Specifics of installation will vary with vessel design but the

following procedures are applicable in most situations and will

result in a secure and effective installation.

Table 2-4 lists the components provided in the Antenna Unit

Installation kitpack.

Part Qty.

1

⁄4-20 hex screws 4

1

⁄4 flat washers 8

1

⁄

4-20 self-locking nuts 4

Plastic screw covers 6

Antenna base seal gasket 1

Tie-wraps 2

Core clamp 1

Tips for Successful Antenna Unit Placement and Mounting

• The mounting surface should be essentially flat,

free of vibration and flexing, and strong enough to

carry the complete assembly (30 lbs/13.6 kg).

• The antenna unit need not be located exactly on

the vessel’s fore-and-aft axis, but its centerline

reference MUST be parallel to it.

• Be sure to account for the radome height and the

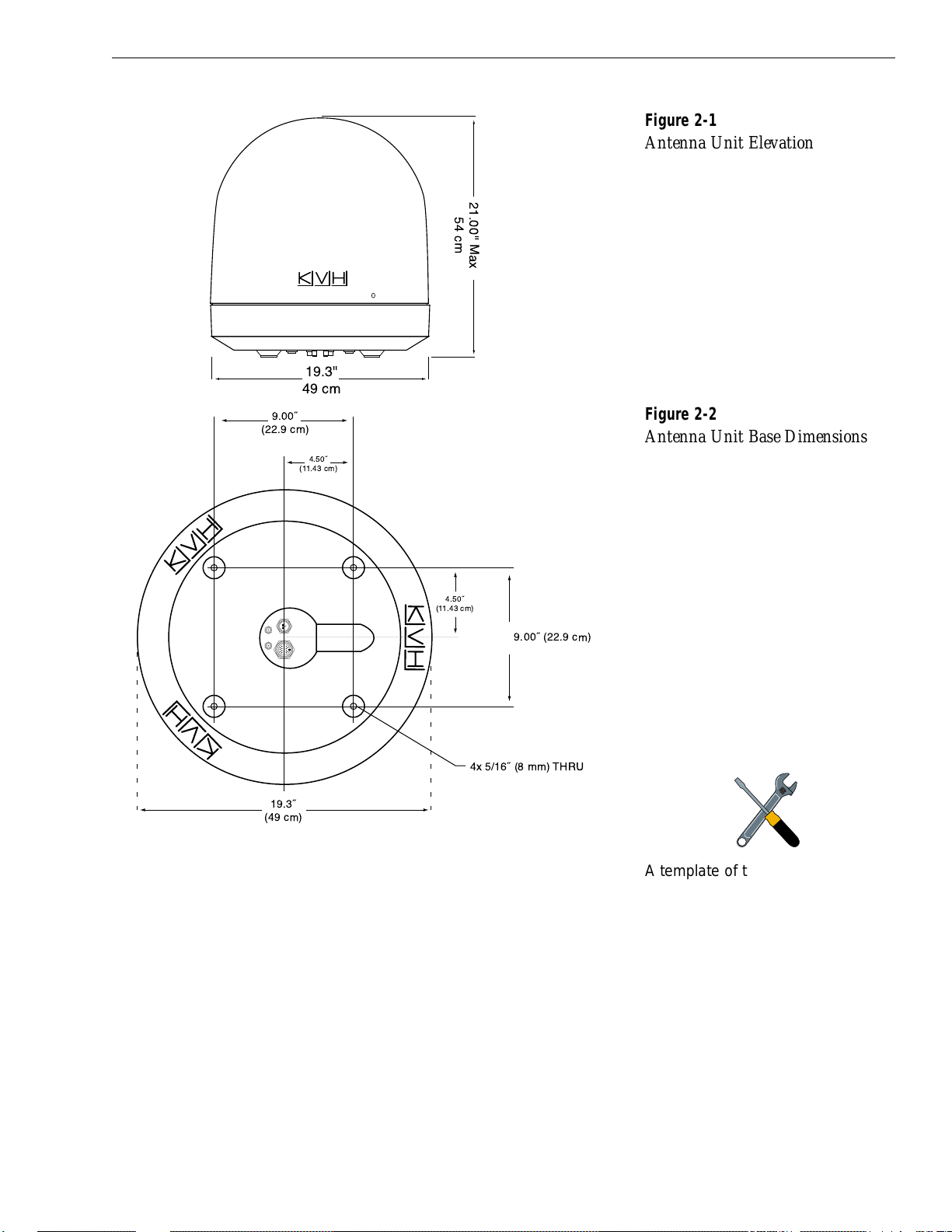

base dimensions, illustrated in Figure 2-1 on the

following page.

2-4

TracVision G4 Installation and Technical Manual

Table 2-4

Antenna Unit Kitpack Contents

Always lift the antenna unit by the

gray baseplate structure, not the

radome. Also be careful not to

strike the exposed connectors

extending from the bottom of the

baseplate or allow them to carry

the weight of the antenna unit.

Page 25

Antenna Unit Mounting Procedure

1. Using the base dimensions presented in Figure 2-2

or the template provided in Appendix B, lay out

the four mounting bolt holes. Check the layout to

make certain the baseplate will be parallel with the

vessel’s fore/aft axis.

2. Drill four

3

⁄8" (10 mm) bolt holes. Mark a

3" (80 mm) diameter circle in the center of the

pattern and cut out to make a passage for the

cables to connect to the baseplate. Smooth the

edges of the hole to protect the cables.

2-5

Installation

54-0147 Rev. G

9.00ý

Figure 2-1

Antenna Unit Elevation

Figure 2-2

Antenna Unit Base Dimensions

A template of the baseplate

mounting holes has been provided

in Appendix B.

(22.9 cm)

19.3"

49 cm

4.50ý

(11.43 cm)

21.00" Max

54 cm

4.50ý

(11.43 cm)

4x 5/16ý (8 mm) THRU

19.3ý

(49 cm)

9.00ý (22.9 cm)

Page 26

2-6

TracVision G4 Installation and Technical Manual

3. Place the foam seal in position on the mounting

surface with the hole centered over the cable access

cutout and the paper backing on the bottom. Do not

remove the paper backing at this time. Align the

seal with the vessel’s fore-and-aft line and the small

end pointed forward as shown in Figure 2-3. Scribe

a line all around the seal.

4. Remove and save the three screws holding the

radome to the baseplate. Carefully lift the radome

straight up until clear of the antenna assembly and

set it aside in a safe place.

5. Position the baseplate assembly in place over the

mounting holes and cable access. Ensure that all

holes line up and that the connectors are centered

over the cable access. Make any necessary

adjustments before seating the foam seal in place

permanently.

6. Clean the surface where the foam seal will be

placed. Remove the paper backing from the foam

seal to expose the contact cement. Lay the foam seal

in place, adhesive side down, and press down

firmly to bring the adhesive into full contact along

the bottom. Ensure the narrow end points toward the

bow.

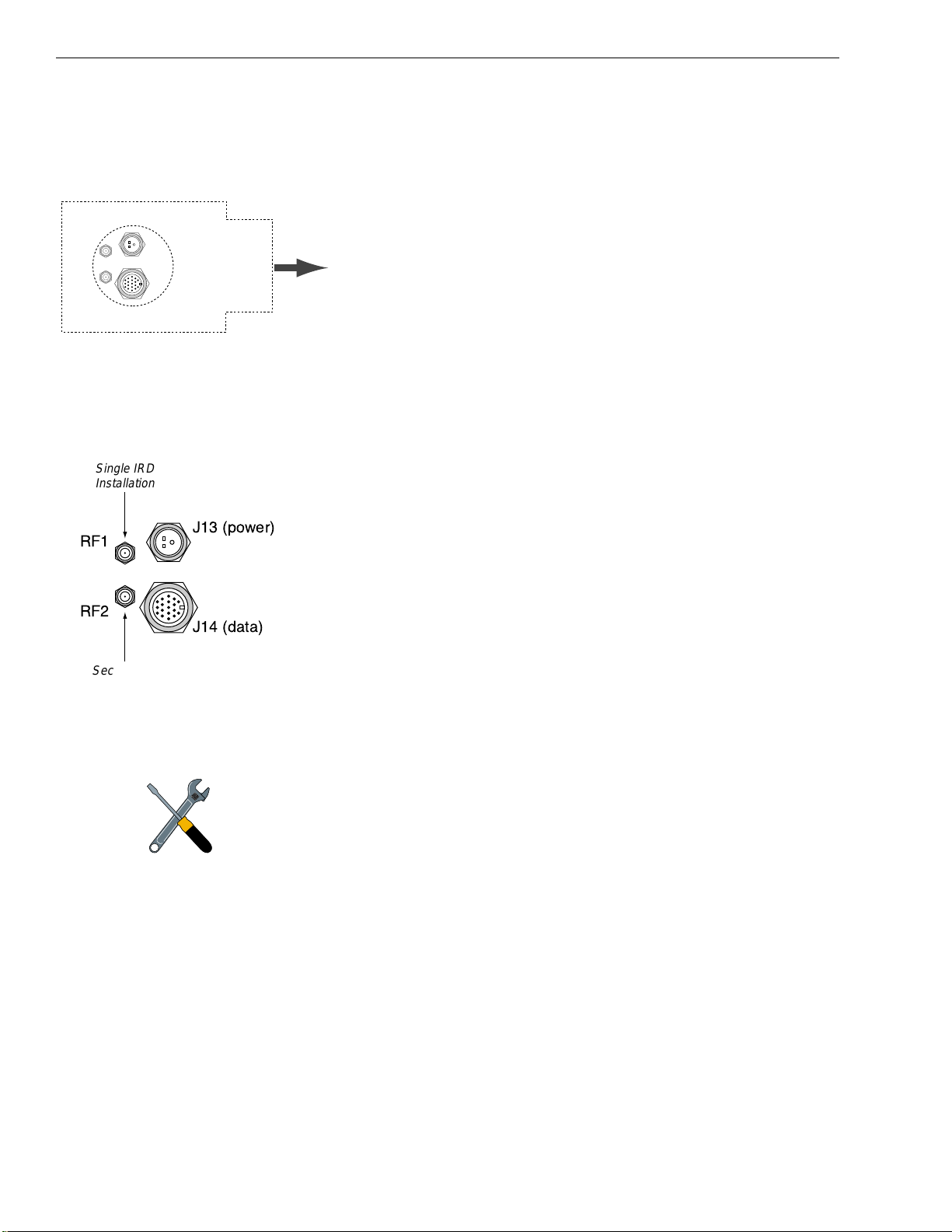

7. Bring the Data Cable, RF Cable(s), and Power Cable

up through the access hole and connect them to the

baseplate. Turn the connectors down securely, but

don’t use excessive force; finger-tight is sufficient.

Figure 2-4 illustrates the connector assignments.

Do not use teflon gel on the cable fittings as it

reduces signal strength at higher frequencies.

8. Remove the foam shipping restraint from the

Antenna Unit.

9. Place the baseplate over the holes drilled in the

foundation, ensuring the forward arrow points

toward the bow. Rotate the azimuth mechanism

plate to expose each mounting hole. When rotating

the azimuth mechanism by hand, go slowly. Hitting the

stops with excessive force will damage the azimuth limit

switch.

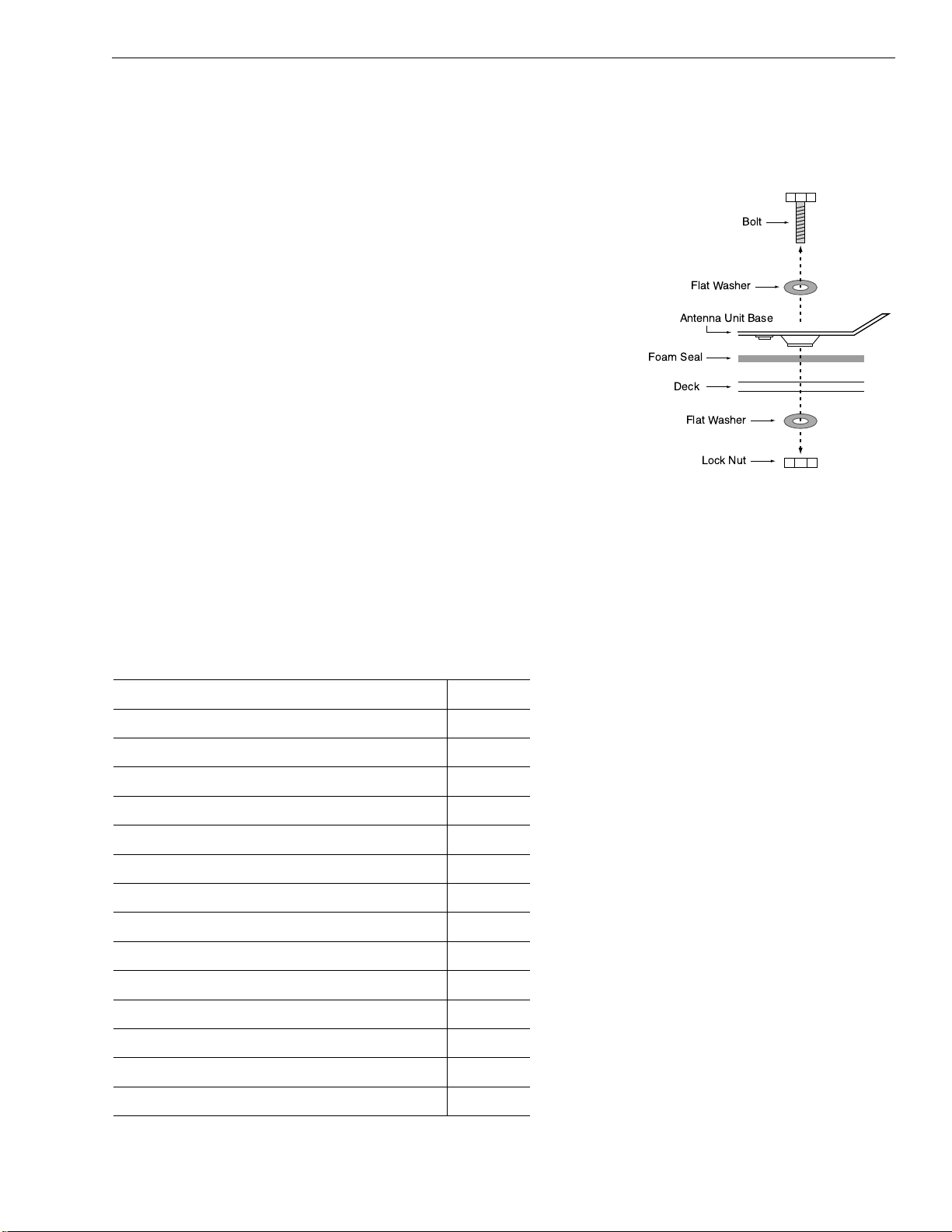

10. Place a flat washer from the kitpack on a bolt and

insert the bolt into its hole from above as shown in

Figure 2-5 on the following page.

Figure 2-4

Baseplate Connector Assignments

Figure 2-3

Baseplate/Foam Seal Orientation

(Bottom View)

The foam shipping restraints must

be removed before power is

applied. Save the foam pieces for

reuse and be sure to install it

whenever the Antenna Unit is

moved from place to place.See

Section 5.9, “Preparation for

Shipment,” for instructions on

preparing for shipment.

Foam Seal

J13 (power)

RF1

RF2

J14 (data)

Bow

Single IRD

Installation

RF1

RF2

J13 (power)

J14 (data)

Second IRD

Installation

Page 27

Installation

2-7

54-0147 Rev. G

11. Apply a flat washer and lock nut from underneath

as shown in Figure 2-5.

12. Tighten securely until the foam seal is compressed

as far as it will go and all four feet are bottomed

against the mounting surface.

13. For European systems, please refer to Section 2.8,

“Setting the Skew Angle.” North American systems

may proceed to step 14.

14. Replace the radome over the baseplate. Align the

radome screw holes with the nut holders, insert

the screws and tighten. Install a protective plastic

screw cap from the kitpack over each screw.

Several spare protective caps are provided.

2.3 Installing the GyroTrac

The following sections provide detailed instructions for installing

TracVision G4’s GyroTrac Sensor Module and ADCU.

2.3.1 GyroTrac Installation Kitpack

Table 2-5 lists the materials provided in the GyroTrac kitpack.

Part Qty.

#8 Fiber Washer 10

#8 Flat Washer 10

#8 Self-locking Nut 5

#10 Flat Washer 5

#10 Lock Washer 5

#10 Pan (Phillips head) Screw 5

#8 Pan (Phillips head) Screw 5

#8 Lock Washer 5

#8 Pan (Phillips head) Screw BP 5

Velcro Self-adhesive Backing 8

Velcro Washer 4

4" Tie-wrap Clamp 5

Tie-wrap Screw Mount 6

Connector Wire Terminal Strip 5

Sensor Module to ADCU Power Wire Ferrite 1

Table 2-5

GyroTrac Kitpack Contents

Figure 2-5

Bolting the Antenna Unit to

the Deck (Side View)

Bolt

Flat Washer

Antenna Unit Base

Foam Seal

Deck

Flat Washer

Lock Nut

Page 28

2-8

TracVision G4 Installation and Technical Manual

2.3.2 Mounting the Sensor Module

The GyroTrac Sensor Module comes equipped with two

mounting brackets. The first is the Horizontal Sensor Bracket,

which attaches directly to the Sensor Module housing, and must

be used in all mounting arrangements.

The Vertical Sensor Bracket allows the Sensor Module to be

mounted on a vertical surface. The following steps detail the

correct use of each bracket.

These brackets should enable the Sensor Module to be

placed as level in pitch and roll as possible. If you are unable

to place the Sensor Module in a level arrangement, refer to

Section 3.5.3, “Entering Gyro Offset Values” to compensate.

Horizontal Bracket Only

1. Choose a mounting location free of excessive

vibration and flexing.

2. The module must be oriented so that the forward

reference on the end cap is pointed forward and

parallel to the vessel’s fore-and-aft axis (to ±5°).

The proper orientation is illustrated in Figure 2-8.

3. Position the Horizontal Sensor Bracket so that the

Sensor Module will be properly oriented when

placed in the bracket.

4. Use the holes in the bracket feet to spot for

mounting screws. Center punch and drill 4 holes

with a

1

⁄8" (0.125" or 3.5 mm) bit.

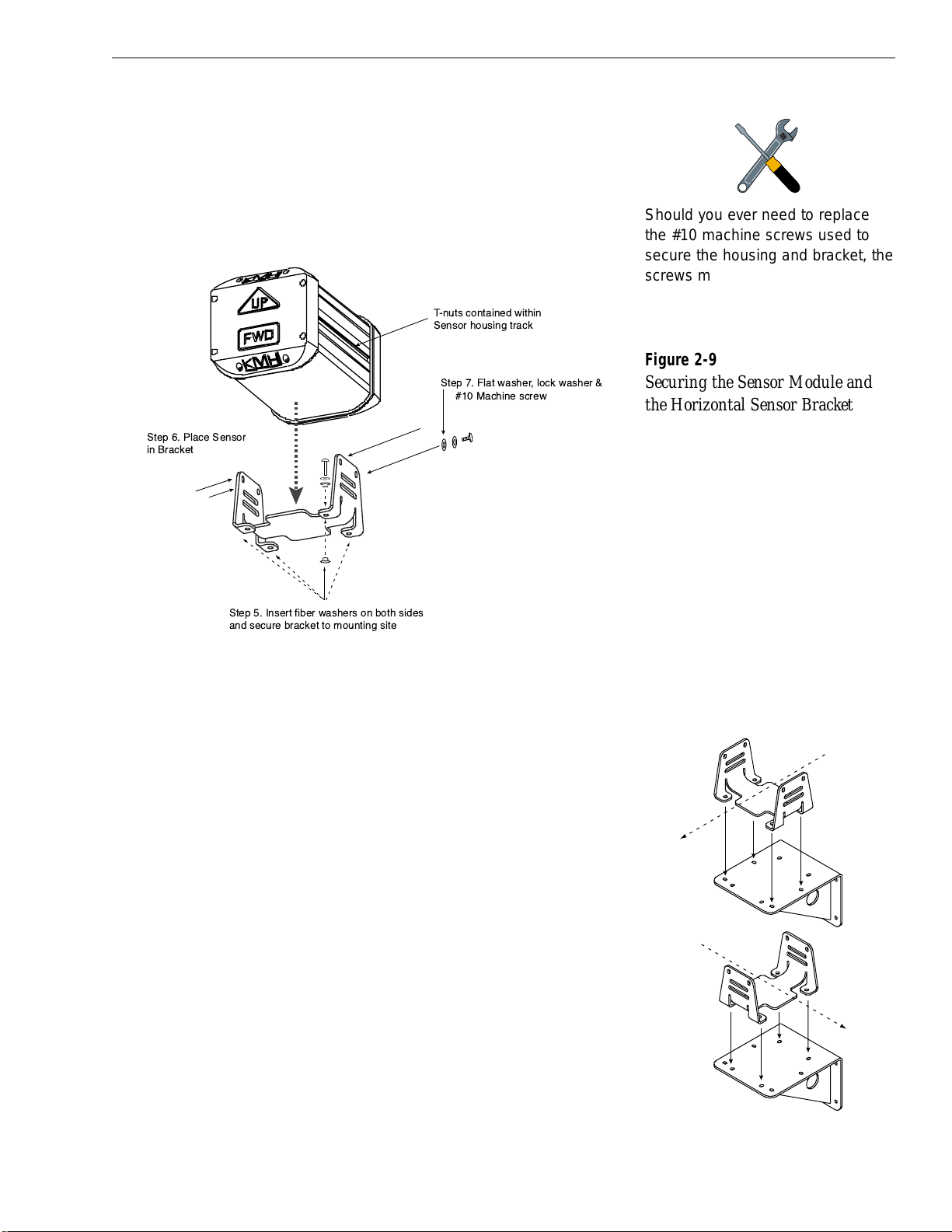

5. As illustrated in Figure 2-9, position the bracket

over the mounting holes.

- Insert fiber washers into both sides of mounting

bracket.

- Insert #8 flat washers and #8 Type BP pan head

screws into the holes.

6. Place the Sensor Module in the bracket with the

proper orientation (up/forward).

Figure 2-8

Proper Orientation of

the Sensor Module

Figure 2-6

Horizontal Sensor Bracket

Figure 2-7

Vertical Sensor Bracket

TOWARD BOW

5¡

5¡

Page 29

Installation

2-9

54-0147 Rev. G

7. Thread #10 machine screws through lock washers,

flat washers, and bracket, and then into the captive

extrusion T-nuts within the Sensor Module

housing as illustrated in Figure 2-9.

Horizontal and Vertical Bracket

1. Choose a mounting location free of excessive

vibration and flexing.

2. The module must be oriented so that the forward

reference on the end cap is pointed forward and

parallel to the vessel’s fore-and-aft axis. See

Figure 2-8 for reference. The brackets are designed

so that the Sensor Module may be mounted

perpendicular (option 1) or parallel (option 2) to

the mounting surface as pictured in Figure 2-10.

3. The module must be level with the vessel’s deck.

This placement can be fine tuned by using the

ADCU pitch and roll data. Adjust the brackets so

that the pitch and roll are 0 (zero) when the vessel

is docked and under normal load.

Figure 2-10

Optional Bracket Orientations

Figure 2-9

Securing the Sensor Module and

the Horizontal Sensor Bracket

Should you ever need to replace

the #10 machine screws used to

secure the housing and bracket, the

screws must be no longer than

3

⁄

8"

(10 mm) to avoid damaging the

housing.

T-nuts contained within

Sensor housing track

Step 7. Flat washer, lock washer &

#10 Machine screw

Step 6. Place Sensor

in Bracket

Step 5. Insert fiber washers on both sides

and secure bracket to mounting site

Option 1

Vessel

Centerline

Option 2

Vessel

Centerline

Page 30

2-10

TracVision G4 Installation and Technical Manual

4. When choosing a location for the unit, make

certain that there is sufficient overhead clearance

for both brackets and the Sensor Module.

5. Use the holes in the Vertical Sensor Bracket to

spot for mounting screws. Center punch and drill

4 holes with a

1

⁄

8" (0.125" or 3.5 mm) bit.

6. Secure the Vertical Sensor Bracket to the vertical

surface with #8 flat washers and #8 screws.

7. Attach the Horizontal Sensor Bracket to the

Vertical Sensor Bracket as shown in Figure 2-11.

- Position the Horizontal Sensor Bracket over the

mounting holes in the Vertical Sensor Bracket.

- Insert fiber washers into both sides of mounting

bracket.

- Insert #8 flat washers and #8 Type BP pan head

screws into the holes.

8. Place the Sensor Module in the bracket with the

proper orientation (up/forward).

9. Thread #10 machine screws through lock

washers, flat washers, and bracket, and then into

the captive extrusion T-nuts within the Sensor

Module housing.

2.3.3 Mounting the ADCU

The ADCU may be mounted in one of two ways: either directly

to a horizontal surface using Velcro fasteners or flush to a control

panel. Both the fasteners and the Flush Mount Bracket are

included as part of the GyroTrac package.

Some tips for installing the ADCU:

• The ADCU should be placed in a dry location that

is convenient for the user.

• It is not susceptible to magnetic interference nor

must it be situated on a level surface.

•

It should be placed so the LCD display is visible

and buttons are accessible.

• Allow room at the back to connect cables to the

rear panel.

Figure 2-11

Attaching the Horizontal

and Vertical Brackets

#8 Pan Head Screw

#8 Flat Washer Fiber Washer

#8 Self-locking Nut

Page 31

2-11

Installation

54-0147 Rev. G

Velcro Fastening

1. Choose a flat, stable location.

2. Remove the two strips of velcro fabric from the

kitpack. Clean the bottom of the housing with a

mild detergent and water to remove oils, etc. Peel

the protective backing from the strips and apply

them to the bottom of the housing at each of the

four corners.

3. Position the four hook disks where the ADCU will

be mounted. Drill screw holes for the disks and

attach. Press the ADCU firmly into place so the

loop material engages the hook disks.

Flush-mounting the ADCU

1. A template has been provided in Appendix B as a

guide to mark and cut the proper hole for the

Flush Mount Bracket. Cut the hole and make

certain the bracket and ADCU will fit easily.

2. Attach the Flush Mount Bracket to the ADCU by

loosening the two screws on the underside of the

ADCU. Slide the Flush Mount Bracket backward

over the ADCU until the two notches meet the

screws as shown in Figure 2-13.

3. Tighten the screws to secure the ADCU to the

bracket.

Figure 2-13

Securing the ADCU to the

Flush Mount Bracket

Figure 2-12

Mounting the ADCU with

Velcro Attachments

Place fabric strips

Attach hook disks

Place ADCU/fabric

on top of hook disks

Page 32

4. After completing the wiring described in

Section 2.4, “Wiring the TracVision G4 System

Components,” insert the ADCU and bracket into the

hole and secure the unit.

2.4 Wiring the TracVision G4

System Components

Virtually all wiring for the TracVision G4 connects at the rear panel

of the GyroTrac ADCU. Included in the GyroTrac kitpack are five

terminal strips with terminal connectors numbered 1 through 60.

After wires are secured within the terminal connectors, the strips

will be slotted into the rear panel of the ADCU as illustrated in

Figure 2-15.

2-12

TracVision G4 Installation and Technical Manual

Figure 2-15

Attaching the Terminal Strips

to the ADCU

Figure 2-14

Terminal Strip Order

12-Connector Terminal Strips

(included in kitpack)

48 47 383940414243 3744454660 59 505152535455 49565758

Connectors 60 - 37

12 1110987612543 13 14 232221201918 24171615 25 26 353433323130 36292827

Connectors 1 - 36

DB9 Low-speed

Data Port

REAR

14

13

1

201918171615

121110

98765432

363534

3332

31302928

2726

25

242322

21

Page 33

Tips for Successful and Safe Wiring

• When inserting a wire into the terminal connector,

make certain wire insulation is not pinched in the

connector.

• After inserting and securing wire, tug gently to

ensure that the connection is solid.

•

Position cables behind the ADCU so that they

connect neatly to the terminal strips.

• Do not tin (solder) the wire ends.

Effective Strain Relief for ADCU Terminal Connections

Due to both the potential number of wires that will be connecting

to the rear of the ADCU and the dynamic environment aboard

ship, it is critical that the terminal connections are properly strain

relieved using tie-wraps (a number of which are included with

the GyroTrac kitpack).

Some things to consider when strain relieving cables:

• There should be no tension on the wires

connecting to the terminal strip. Removing slack is

important but the wires should not be taut.

• If the cable is equipped with a ferrite, the ferrite

should be as close as possible to the terminal

connections.

•

Strain relieve wires and cables as close to the

ferrite as possible. A good arrangement includes a

tie-wrap behind the ferrite (on the side furthest

from the ADCU); an ideal design includes a tiewrap on either side of the ferrite.

2-13

Installation

54-0147 Rev. G

Figure 2-16

Examples of Effective

Strain Relief

Double-check all wiring. Be certain

to plug terminal strips into the

correct positions. If wiring is

incomplete or incorrect or the

terminal strips exchange positions,

serious electrical damage can

occur to the TracVision G4 Antenna

Unit, the GyroTrac, and interfacing

electronics.

Terminal Connector Strip

Good Strain Relief

Arrangement

Tie-wrap

Ferrite

Ideal Strain Relief

Arrangement

Tie-wrap

Page 34

2.4.1 Wiring the Antenna Unit to the

GyroTrac ADCU

Each cable provided with TracVision G4 should be routed and

dressed before terminating at the ADCU. Note that the Data and

Power cables have individual wires on one end. These can be

trimmed to a shorter length if desired.

The TracVision G4 satellite TV system connects directly to the

ADCU via the top two terminal connector strips as follows:

A comprehensive wiring diagram of the entire TracVision G4

system has been provided for technical reference in Appendix C. A

color quick reference guide to wiring your TracVision G4 has

also been printed on the front cover of this manual.

2.4.2 Providing Power to the Antenna Unit

For single-switch convenience, the ADCU has been designed to

serve as a junction box between ship’s power and the Antenna

Unit as illustrated in Figure 2-17. However, the Antenna Unit can

2-14

TracVision G4 Installation and Technical Manual

Color wiring quick reference guides

have been provided on the front

and back covers of this manual.

Figure 2-17

TracVision G4 Wiring

Arrangement

Remove any unused wires from the

Data Cable.

Instructions for wiring the ADCU

to ship’s power are provided in

Figure 2-18 and in Section 2.4.9,

“Connecting the ADCU to Vessel

Power.”

SENSOR DATA FEED

(to Antenna)

Data Cable

TRACVISION PORT

(to/from Antenna)

Data Cable

TXD- (Green/White)

TXD+ (White/Green)

DSS Ground (White/Orange)

DSS TXD (Gray/White)

DSS RXD (White/Gray)

TRACVISION

POWER

(to Antenna)

Power Cable

PC TO ANTENNA

DATA LINES

Data Cable

GPS NMEA (to Antenna)

Data Cable

48 47 383940414243 37444546

NOT USED

60 59 505152535455 49565758

NOT USED

Red Label

Yellow Label

Antenna Ground (Black)

Antenna Power (Red)

+11-16Vdc

PC RXD (Orange/White)

PC TXD (White/Brown)

PC Ground (Brown/White)

GTX- (White/Blue)

GTX+ (Blue/White)

N/C

Page 35

be connected to a separate switch and breaker if it is more

convenient or if the ADCU is placed more than 50 ft (15 m) from

the Antenna Unit.

If there is a need to extend the Antenna Unit-to-ship’s power

cable, refer to the following tips:

• The Antenna Unit power cable connector cannot

accept cables larger than 14 AWG (1.5 mm

2

).

• If the cable is longer than 50 ft (15 m), be sure to

verify the voltage at the antenna to ensure that

there is sufficient power to drive the antenna

under load (11-16 Vdc). If not, carefully increase

the voltage to the Antenna Unit to compensate for

any drop in power over the length of the cable and

ensure that the voltage reaching the Antenna Unit

is between 11 and 16 Vdc.

2.4.3 Connecting External Devices to

the GyroTrac ADCU

All connections between the ADCU and external devices are

made at the connector strips located on the rear of the ADCU.

Follow these guidelines when wiring additional equipment to the

ADCU:

• Make certain any additional equipment complies

with NMEA Standard 2.2.

•

Data conductor wire should be minimum 18 AWG

(0.75 mm

2

), twisted pair, stranded, tinned marine

cable.

• Do not use cables with wire diameter larger than

12 AWG (2.5 mm

2

), as the connector plugs on the

rear of the ADCU accept wire no larger than

12 AWG (2.5 mm

2

) size.

• Cables provided with optional KVH displays and

interface units are fully compatible with GyroTrac

requirements. Note that cables to other external

devices should follow the manufacturer’s

recommendations.

• For power cable specifications, refer to Table 2-2 at

the beginning of this section.

2-15

Installation

54-0147 Rev. G

If the ADCU is receiving data from

a ship’s gyro, all compass outputs

are automatically configured as

Tr ue Nor th and cannot be set as

Magnetic.

Power supplied to the TracVision

G4 MUST NOT exceed 16 Vdc or

the TracVision power supply will

suff

er serious damage!

Page 36

Appendix D provides instructions on properly wiring optional

KVH equipment to the GyroTrac system.

2.4.4 GyroTrac Wiring Diagram

Figure 2-18 presents a complete wiring diagram for each

GyroTrac terminal connector strip.

As noted in Figure 2-18, the output for Serial Ports 2 and 3 can

vary from 4800 baud to 9600 baud. This is determined

automatically based upon the selected output. Serial Port 1

provides 4800 baud output only.

2-16

TracVision G4 Installation and Technical Manual

Figure 2-18

GyroTrac Wiring Arrangement

Refer to the back cover for a color

wiring quick reference guide.

12 1110987612543

Green Label

SHIP S POWER

(11-16 VDC)

IRD Ground Wire (to IRD)

Cable #32-0583-50

SERIAL PORT #1: RS-422

(NMEA, Cetrek, KVH Data)

4800 baud

Ground (White/Green)

GYROTRAC

SENSOR MODULE

Cable #32-0623-30

Power In (Red)

Ground In (Black)

KVH Display Power

TX(+) (White/Blue)

TX(-) (Blue/White)

RX(-) (White/Orange)

RX(+) (Orange/White)

TX1A(+)

TX1B(-)

Ground

13 14 232221201918 24171615

+12v (Green/White)

25 26 353433323130 36292827

Blue Label

White Label

Ref

Ground

TX1B(-)

Ground

Sine

Sine (inverted)

Cosine

Cosine (inverted)

GPS A+

GPS B-

KVH Display Power

TX1A(+)

SINE/COSINE

(3-wire or 4-wire)

Refer to Section 2.4.5

for complete intructions

GPS or SHIP S GYRO

NMEA DATA INPUT

(RS-422 @ 4800 bps 8.N.1)

Pass-through Duplicate of

SERIAL PORT #1: RS-422

4800 baud

SERIAL PORT #3: RS-422

(NMEA, Cetrek, KVH Data)

4800 or 9600 baud

Unavailable with TracVision G4

To modify, refer to Section 3.5.4.

SERIAL PORT #2: RS-422

(NMEA, Cetrek, KVH Data)

4800 or 9600 baud

Ground

TX3B(-)

TX3A(+)

Data H

Data L

Ground

TX2B(-)

TX2A(+)

Ground

Shift H

Shift L

Ground

FURUNO

DATA

Page 37

When the TracVision G4 antenna is connected to the GyroTrac

system, GyroTrac Serial Port 3 will not provide output to other

equipment. Serial Port 3 will only provide outputs if the antenna

unit is disconnected from the ADCU and GyroTrac is configured

to operate as a standalone system as described in Section 3.5.5,

“Selecting TracVision or GyroTrac-only Operations.”

2.4.5 Wiring the GyroTrac Sine/Cosine

Interface

The GyroTrac ADCU sine/cosine interface provides the following

outputs:

• sine

• cosine

• inverse sine

• inverse cosine

• reference voltage

Because the reference voltage is a reference output, not an input,

connecting this output to another reference output from an

autopilot or other system will cause problems.

In this case, connect the following wires from the autopilot (or

other system) to the ADCU:

Autopilot/Other System Wire ADCU Terminal

Sine 12

Cosine 10

Internal Power Ground 7

(not chassis ground!)

Reference (INPUT) 8 (KVH Output)

DO NOT connect the autopilot or other system to the ADCU reference

output (ADCU terminal 8) if the autopilot has its own internal

reference. Review the user’s manual for the selected equipment.

To adjust the GyroTrac reference to match the reference of the

autopilot (or other system), connect a voltmeter to GyroTrac

ADCU terminal (#8) and the reference terminal of the autopilot

(or other system). Adjust the GyroTrac reference voltage as

described in Section 3.4.1, “Setting the Sine/Cosine Data Output,”

until the voltmeter indicates 0 VDC.

2-17

Installation

54-0147 Rev. G

Table 2-6

GyroTrac/Autopilot Sine/Cosine

Wiring Arrangement

Before connecting the Autopilot

internal ground to ADCU terminal 7,

use a low impedance voltmeter to

make certain that there is no DC

voltage between the two terminals.

A DC surge could damage one or

both systems.

The sine/cosine reference voltage is

an OUTPUT, not an INPUT.

Connecting this output to the

reference output for an autopilot or

other system can result in problems.

Section 2.4.5 provides instructions

on how to solve this problem.

Page 38

The sine/cosine interface should now operate with optimal

precision.

2.4.6 True North Capability

GyroTrac is capable of determining true north that is accurate,

under most conditions, to within ±1.0˚. This information is

obtained by providing GPS data input and reading the magnetic

variance tables.

NMEA sentences from the GPS must contain one or all of the

following sentences: VTG, VHW, or BWC. The sentence structure

must comply with the NMEA 0183 V2.20 standard and run at

4800 bps 8.N.1.

As illustrated in Figure 2-18 and the GyroTrac quick reference

wiring guide on the back cover of this manual, GPS interface

cables connect to the ADCU at terminals 23 and 24. Refer to your

GPS user manual for the correct NMEA data out configuration.

2.4.7 Connecting a PC to the ADCU

Locate cable 32-0513-15. For purposes of diagnostics and

maintenance, it is occasionally necessary to hook up a PC to the

system. This may be done using the DB9 maintenance port on the

back of the ADCU. To do so, connect the DB9 (female) to the PC

and the DB9 (male) to the ADCU.

2.4.8 Connecting an Antenna RF Signal Cable

to the IRD

The RF signal cable is fitted with F-type connectors. One end

should be connected to the plug labeled “RF1” on the base of the

TracVision G4 system. The other connector should be connected

to the IRD plug labeled “LNB” or “ANT/SAT.” If a second IRD is

to be hooked up to the TracVision G4 antenna unit, the RF cable

2-18

TracVision G4 Installation and Technical Manual

Figure 2-20

ADCU DB9 Maintenance Port

Figure 2-19

DB9 Plug

RG-11 (75 ohms) cable is required

for RF wiring. Use of non-RG-11

(75 ohms) cable will result in

degraded performance.

When the vessel is stationary,

certain GPS models may not output

the data required for GyroTrac to

determine true nor th.

Maintenance

Port (DB9)

48 47 383940414243 3744454660 59 505152535455 49565758

12 1110987612543 13 14 232221201918 24171615 25 26 353433323130 36292827

Page 39

for the second IRD should be connected to the plug labeled

“RF2” while the other end is connected to the IRD plug labeled

“LNB” or “ANT/SAT” on the second IRD.

2.4.8.1 Connecting the IRD Ground Cable

A grounding wire has been provided to connect your IRD to a

suitable ground. Attach the grounding wire to any suitable screw

on the rear panel of the IRD with a good contact with the IRD

chassis. The other end should be connected to a suitable ground,

ideally to connector 2 of the ADCU terminal (see Figure 2-18).

2.4.8.2 Connecting the Antenna RF Signal

Cables to a Multiswitch (North

American Systems Only)

Due to the signal polarization of North American satellites, it is

possible for TracVision G4 to support more than two IRDs aboard

a vessel. To install more than two IRD/TV pairs, an active

multiswitch (Channel Master model 6214IFD or equivalent) is

placed between the Antenna Unit and the IRDs. The following

sections provide details for both a single multiswitch and a

multiple multiswitch installation.

Multiswitch Installation for 3-4 IRD/TV Pairs

Figure 2-21 on the following page illustrates typical wiring

arrangements for three or four IRDs. Mount the multiswitch unit

in accordance with the manufacturer’s instruction sheet.

1. Connect the RF cable tagged "RF1" to the

multiswitch input labeled "LNB RHCP +13V".

2. Connect a second RF cable to the antenna unit’s

RF2 plug and to the multiswitch input labeled

"LNB LHCP +18V".

3. Connect the multiswitch outputs to individual IRD

inputs. Use RG-6 cable terminated with F-type

connectors for all RF connections. Terminate all

unused output connectors with 75 ohm DC blocks

(Channel Master #7184, Radio Shack #15-1259 or

equivalent).

2-19

Installation

54-0147 Rev. G

Some multiswitches (either active

or passive), such as the Channel

Master model 6214IFD, may

interfere with the 22 KHz tone sent

by DSS Plus™ IRDs to the

antenna. As a result, the antenna

may not receive the signal to

change satellites when you change

channels using your DSS Plus

remote. In this case, you will need

to use the maintenance port

satellite switch procedure explained

in Section 3.2, “Data Display and

Accessing the Main Menu.”

The IRD that is connected to the