03-08-12

Model 462 IC/H/PRO/EL

Operating and Assembly

Manual

Midwest Equipment Manufacturing, Inc.

5225 Serum Plant Road

Thorntown, IN 46071

1

SAFETY RULES

Remember, any power equipment can cause injury if operated improperly or if the user does not understand

how to operate the equipment. Exercise caution at all times when using power equipment.

This symbol means Attention!!!!! It is used to point out safety precautions.

▪ Read and follow all instructions in this manual before assembly or operation of this equipment.

Failure to comply with these instructions may result in personal injury. Keep this manual for

future reference and for ordering replacement parts.

▪ Read this instruction manual carefully. Become familiar with the controls and proper use of

this equipment.

▪ Read the engine owners manual and safe operation rules before using this equipment.

▪ Never allow children less than 16 years of age to operate the Trac-Vac. Children 16 years

and older should operate only under close parental supervision.

▪ Do not allow anyone to operate this equipment without proper instruction.

▪ Do not allow passengers to ride on the Trac-Vac or on the towing vehicle.

▪ Keep children and pets out of area of operation.

▪ Check fuel before starting engine. Do Not fill fuel tank indoors, or while engine is running or

hot. Wipe off any spilled fuel before starting engine.

▪ Engine and muffler get HOT! Do Not touch! Keep debris from accumulating on or around

engine and muffler to avoid fire hazard.

▪ Allow engine to cool before storing in any enclosed area. Never store Trac-Vac with fuel in tank.

▪ Do not operate engine if air cleaner or cover is removed, except for adjustments. Removal of the

part could create a fire hazard.

▪ Keep hands, feet, face, long hair and clothing out of inlet and discharge areas. There are

ROTATING BLADES inside these openings.

▪ Make certain that all moving parts come to a complete stop before cleaning, repairing or

inspection. Disconnect spark plug wire and keep away from plug to prevent accidental starting.

▪ If Trac-Vac should become clogged with debris, SHUT OFF ALL ENGINES and wait until

impeller comes to a complete stop before attempting to remove obstruction. Disconnect spark

plug wire to prevent accidental starting.

▪ If excessive vibration occurs while operating your Trac-Vac, stop the engine immediately,

disconnect the spark plug wire and allow all moving parts to stop completely before taking the

following steps.

A. Inspect for damage.

B. Repair or replace any damaged parts.

C. Check for loose parts and tighten to assure continued safe operation.

▪ Check all hardware periodically to insure safe operation.

▪ Check cart cover periodically for wear and replace if worn or damaged.

▪ Never operate Trac-Vac without intake hose and exhaust hose attached in proper place.

▪ Do Not remove exhaust hose or attempt to empty contents of container while engine in running.

▪ Keep all shields and guards in place and securely attached.

▪ Always wear eye protection (safety glasses or goggles) when operating this equipment.

▪ Do Not stand behind unit in exhaust discharge area while engine is running.

▪ Do Not operate this equipment while intoxicated or while taking medications that could impair

reactions or senses.

▪ Operate this equipment at reduced ground speed on rough terrain, along creeks and ditches and on

slopes to prevent tipping or loss of control.

▪ Vehicle stability and braking are affected by the addition of this unit. Do not fill the Trac-Vac to

its full capacity without checking the capability of the towing vehicle to safely pull and stop with

the unit attached.

▪ Do Not operate on slopes in excess of 10 degrees. STAY OFF OF STEEP SLOPES!

▪ Follow the maintenance instructions outlined in this manual.

2

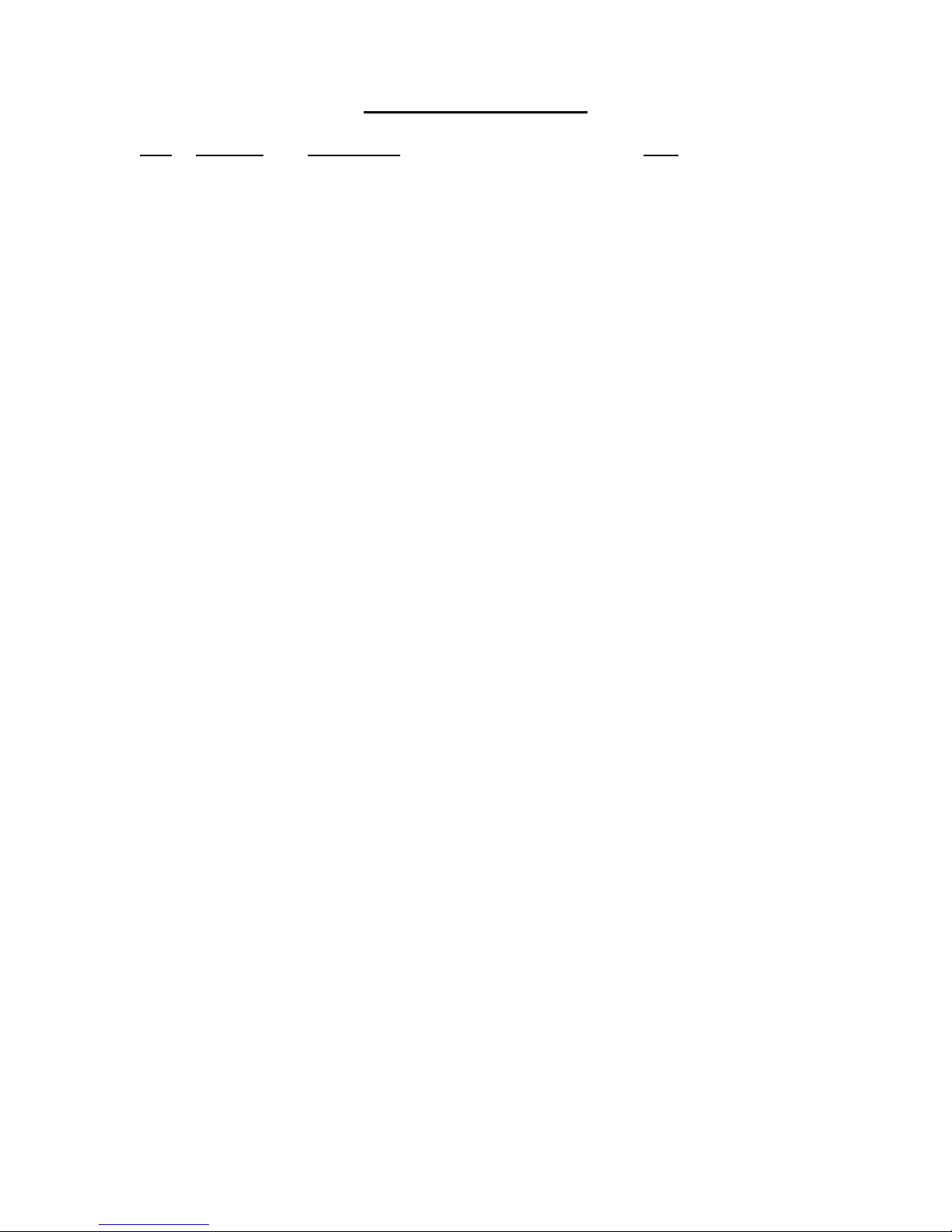

Model 462-IC/H/PRO/K/EL

Key Part No. Description Qty.

1 46250 Frame, RH 1

46251 Frame, LH

46252 Frame, Electric

2 56021 Engine, 5.5 HP Briggs Intek IC 1

56018 Engine, 6.5 HP Briggs Intek Pro

56022 Engine, 5.5 HP Honda

56017 Engine, 206CC Briggs Intek Elec.

3 56030 Turbine Housing (5.5 Briggs, Honda, El.) 1

46242 Turbine Housing (5.5 Briggs)

4 56040 Turbine (5.5 Briggs, Honda) 1

46253 Turbine (6.5 HP 1” bore)

5 56029 Turbine Washer (56040 Turbine only) 1

6 56050 Inlet, 6" 1

38050 Inlet, 6" Pro 1

7 46258 Vertical Support 1

8 3120518 Eyebolt 2

9 48038 Spring 2

10 46219 Seal 1

11 46248 Filter Shield 1

12 46218 Clevis Pin 1

13 46217 Top Support 1

14 56115 Nylon Spacer 3

15 46233 Filter Support 1

16 46228 Filter 1

17 46204 Molded Top 1

18 46235 Container Latch 1

19 46210 44 Gallon Container 1

20 46230 Container Holder 1

46231 Container Holder, LH

21 48040 Intake Nozzle 1

22 56102 6" Band Clamp 2

23 46103 Hose, 6" x 36" 1

24 86115 Muffler Deflector 1

25 56103 Hose, 6" x 48" 1

26 46*** Hitch (tractor specific) 1

27 ***-6 Chute (tractor specific) 1

28 46247 Support Brace 1

29 46*** Hitch Ass'y, 462 (Tractor Specific) 1

30 3120608 Bolt, Turbine 1

31 58075 Engine Guard 1

3130112 Bolt, Turbine, Honda

86027 Housing Spacer (Elec.) 4

45131 Decal, Warning 1

45133 Decal, White Trac-Vac 2

3

Trac-Vac Model 462-IC/H/PRO/K/EL

6-02-12

7

15

14

13

17

16

10

18

8

9

12

19

11

20

21

22

23

1

2

3

4

5

6

25

2627

24

28

30

31

4

5/16" Freenut (2x)

1/4" x 1/2" Truss Head (2x)

3/8" x 2 1/8" Clevis Pin

1/2" x 2 1/2" Hexbolt

1/4" Whizlock Nut (2x)

Filter

Intake Nozzle

Fig. 7

(

1/4" x 1/2" Truss Head (2x)

1/4" Whizlock Nut (2x)

Not Pictured

Fig. 4

(

OHV

HP

5.5

5.5

OHV

HP

1/2" x 2 1/2" Hexbolt

1/2" Nylon Locknut

1/8" Cotter Pin

1/2" Nylon Locknut

Fig. 9

Fig. 8

5/16" Whizlock Nut (2x)

Fig. 6

Not Pictured

Fig. 5

Fig. 1

Eyebolt (2x)

Fig. 3

Fig. 2

5/8" x 1 1/2" Carriage Bolt

3/8" Whizlock (3x)

3/8" x 2 1/2" Hexbolt (2x)

5/8" Hexnut

5/8" Split Lockwasher

Locktab

3/8" x 1" Hexbolt

5

Fig. 12

Fig. 13

Fig. 14

between hose and top.

make a good tight seal

hose clamp. This will

the hose up behind the

Note: Bunch a few ribs of

3/8" x 2 1/4" Clevis Pin

1/8" Cotter Pin

Cut hose to fit

Fig. 10

Fig. 11

6

Model 462-IC/H/PRO/K Assembly Instructions:

1. Mount hitch (26) to tractor. Each different tractor has its own specific hitch so the

look and method of attachment may be slightly different than pictured, but the hitch

should always be mounted with the lip upward. Many come with specific instructions

in the box with the hitch. (Fig 1)

2. Attach frame (1) onto hitch (29) by hooking lip of frame box onto lip of hitch and

sliding the frame to the right or left until hole in bottom of hitch box aligns with hole

in drawplate of the hitch installed in step 1. Secure with 5/8” x 1 1/2” carriage bolt,

5/8” split lock washer and 5/8” hex nut. Once secured, pivot lock tab over corner of

lip on the frame (1) and tighten bolt. (Fig. 2)

3. Slip vertical support (7) into receiver tube on frame (1), with offset towards tractor

(away from frame) as shown. Align slot in support brace (28) with hole about

halfway up vertical support (7) and loosely secure with 3/8” x 2 1/2” hexbolt and

whizlock nut. Adjust the height of the vertical support until the lower hole in the

brace aligns with the hole in the top of the box on the frame (1). Loosely secure the

upright with a 3/8” x 2 1/2” hexbolt and whizlock nut and the bottom of the brace

with a 3/8” x 1” hexbolt and whizlock nut. (Fig. 3)

4. Mount air turbine assembly onto frame (1) with four 5/16” x 1 1/4” hexbolts, 5/16”

flatwashers and 5/16” locknuts. (Fig. 4)

5. Attach container holder (20) to frame with two 5/8” x 1” hexbolts and locknuts.

Tighten bolts until ring supports the container (19) in a tilted position. (Fig. 5)

6. Attach eyebolts (8) to brackets on vertical support by trapping brackets between 5/16”

hexnut and 5/16” whizlock. Rotate eyebolts so that eyelets face from front to back.

(Fig. 6)

7. The molded top assembly has been partially assembled by the factory. Fit the filter

(16) over the filter support inside the top. Slide intake nozzle (21) through hole in top

from the inside out with the lip inside. Attach the latch (18) to molded top with two

1/4” x 3/4” truss head screws and whizlock nuts. (Fig. 7)

8. Place container in container ring. Set top assembly down onto container. Align 1/2”

swivel hole in top assembly (hole furthest from top) with top hole in vertical support.

Secure with 1/2” x 2 1/2” hexbolt and 1/2” nylon locknut. Tighten until slight drag

can be felt when pivoting assembly. (Fig. 8)

9. Pivot top assembly back until the springs (9) can be attached to upper spring retainers

on top support and to the eyebolts on vertical support installed in step 6. Once springs

are attached, pull top assembly down onto container and immediately slip 3/8” x

2 1/4” clevis pin through locking hole in top support and secure with 1/8” cotter key.

This locking pin will not allow top to rotate all the way around and allow the springs

to come off. Rotate container until container latch (18) lines up with a handle on

container (19) and secure latch by locking it over handle. Note: latch may have to be

adjusted to be tight on handle. Once achieved, tighten bolts in vertical support (7) and

vertical support brace (27). (Fig. 9 & 10)

10. Attach discharge hose (23) to intake nozzle in molded top with 6” band clamp (22)

Note: try to bunch a few ribs of hose up between the band clamp and the molded top

to achieve a more airtight attachment. Once achieved, attach the other end of exhaust

hose to the exhaust on the blower housing with the other 6” band clamp (22)

provided. (Fig. 11)

7

11. Attach intake hose (25) to inlet on blower housing with 8” band clamp (24). (Fig. 12)

12. Attach chute to mower deck. The chutes are also deck specific so your chute may

look and attach differently than what is pictured. Usually the chutes require mounting

an adapter to the deck to accept the bracket on the chute or for the chute to pin into it.

Most of the time the adapters pick up existing holes on the deck but occasionally they

do not. If they do not clip or pin the chute into the adapter, hold the chute up to the

deck and adjust to the best fit. Once best fit is achieved, mark and drill holes through

the deck, if 1/4” hardware is to be used drill with 9/32” bit, if 5/16” hardware is to be

used drill with 11/32” bit and if 3/8” hardware is to be used drill with 13/32” drillbit.

After drilled, attach with hardware provide. (Fig. 13)

13. Cut intake hose to fit and attach free end of intake hose (25) to discharge chute with

8” band clamp (24). (Fig. 14)

14. Read engine-operating instructions before starting.

8

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Engine fails to start

1. Spark plug wire disconnected

2. Fuel tank empty

3. Faulty spark plug

1. Connect wire to spark plug

2. Fill tank with clean fuel

3. Clean, adjust gap or replace

Loss of power or

erratic operation

1. Spark plug wire loose

2. Blocked fuel line

3. Water or dirt in fuel system

4. Dirty air cleaner

5. Unit running on choke

1. Connect & tighten spark plug wire

2. Clean fuel line

3. Disconnect fuel line at carburetor

drain fuel tank. Refill with fresh

fuel

4. Service air cleaner (refer to engine

manual)

5. Move choke lever to OFF position

Engine overheats

1. Engine oil level low

2. Operating below full RPM

1. Fill crankcase with proper oil

2. Run throttle full open.

Excessive vibration

1. Damaged turbine or loose

parts

1. Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts & nuts. Make necessary

repairs. If vibration continues, have

unit serviced by an authorized dealer.

Unit won't pick up.

1. Discharge chute clogged

2. Foreign object lodged in

turbine.

3. Container full

1. Stop engine & disconnect spark plug

wire. Clean inside of discharge

chute.

2. Stop engine and disconnect spark

plug wire. Remove lodged object

in turbine.

3. Stop engine and empty container.

NOTE: Please contact the nearest authorized service dealer for repairs beyond the minor adjustments above.

9

OPERATING PROCEDURE

1. Follow engine manufacturer's instructions in preparing engine for operation.

2. Inspect area to be vacuumed and pickup all harmful objects and litter. Rocks and other harmful debris

can do serious damage to vacuum assembly and cause bodily injury.

3. For best vacuuming results operate tractor at manufacturer's recommended speed for best cutting. If

grass is high, mow first and vacuum on the second pass.

4. When mowing keep discharge chute to the outside of cutting area for better cut and efficient pickup of

grass clippings and leaves.

5. Your vacuum is preset to run at approximately 3800-RPM, at no load. Do not slow down engine.

6. SHUT OFF ENGINE TO UNLOAD.

7. When operating tractor on slope or grade, exercise extreme caution. Do not cut across grade or slope.

Mow directly up and down hills.

8. Periodically check all fasteners for tightness.

9. Listen for unusual vibration of engine or air turbine. If excessive vibration is present, STOP engine and

check for damage to turbine fan.

10. Always shut off tractor engine and vacuum engine before servicing.

11. Replace deflector shield when discharge chute is removed.

12. When removing clogs, SHUT OFF ALL ENGINES.

EXTENDED STORAGE PROCEDURES

1. Wash and clean vacuum, and lubricate any lubrication points.

2. Drain fuel from the tank and run vacuum until fuel is exhausted in carburetor.

3. Drain and change the engine oil.

4. Clean tires and check pressure. Raising and supporting unit with weight off tires is recommended.

5. When storing a unit with Rubbermaid containers, leave containers latched to top.

TRAC VAC WARRANTY POLICY

Midwest Equipment Manufacturing, Inc. will repair or replace, free of charge, any part,

or parts that are defective in material or workmanship or both for a period of one year

residential use, and 90 day’s for commercial and rental use. The purchaser will pay

transportation charges on parts submitted for replacement under warranty. For warranty

service, contact your local dealer from whom the unit was purchased. There are no other

express or implied warranties. Some states do not allow limitations on how long an

implied warranty lasts, and some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation and exclusion may not apply

to you. This warranty gives you specific legal rights and you may also have other rights,

which vary from state to state.

MIDWEST EQUIPMENT MANUFACTURING, INC.

5225 Serum Plant Rd.

Thorntown, IN 46071

Phone: 1-800-Trac-Vac

Web Page: www.trac-vac.com E-Mail: sales@midmfg.com

Loading...

Loading...