http://www.tracopower.com Rev:1.0/ 1615

15 sec

10 mi n

AC-IN

OK

Bat OKDC OK

Ba ttery

Remote

ON/OFF

Temp.

Sensor

1234

5

678910

INSTALLATION INSTRUCTIONS

TSPC240-124UPS Uninterruptible Power Supply

Output Current

Mode

I

out

Nominal

@ 24.0 - 26.0V

I

out

Boost

@ 23.4 - 23.8V

Normal 10A* 12A**

Buffer 10A* 12A**

* Ambient temperature up to +60°C. Observe output current de-rating with Input Voltage. Refer to Datasheet.

** Ambient temperature up to +40°C. Observe output current de-rating with Input Voltage. Refer to Datasheet.

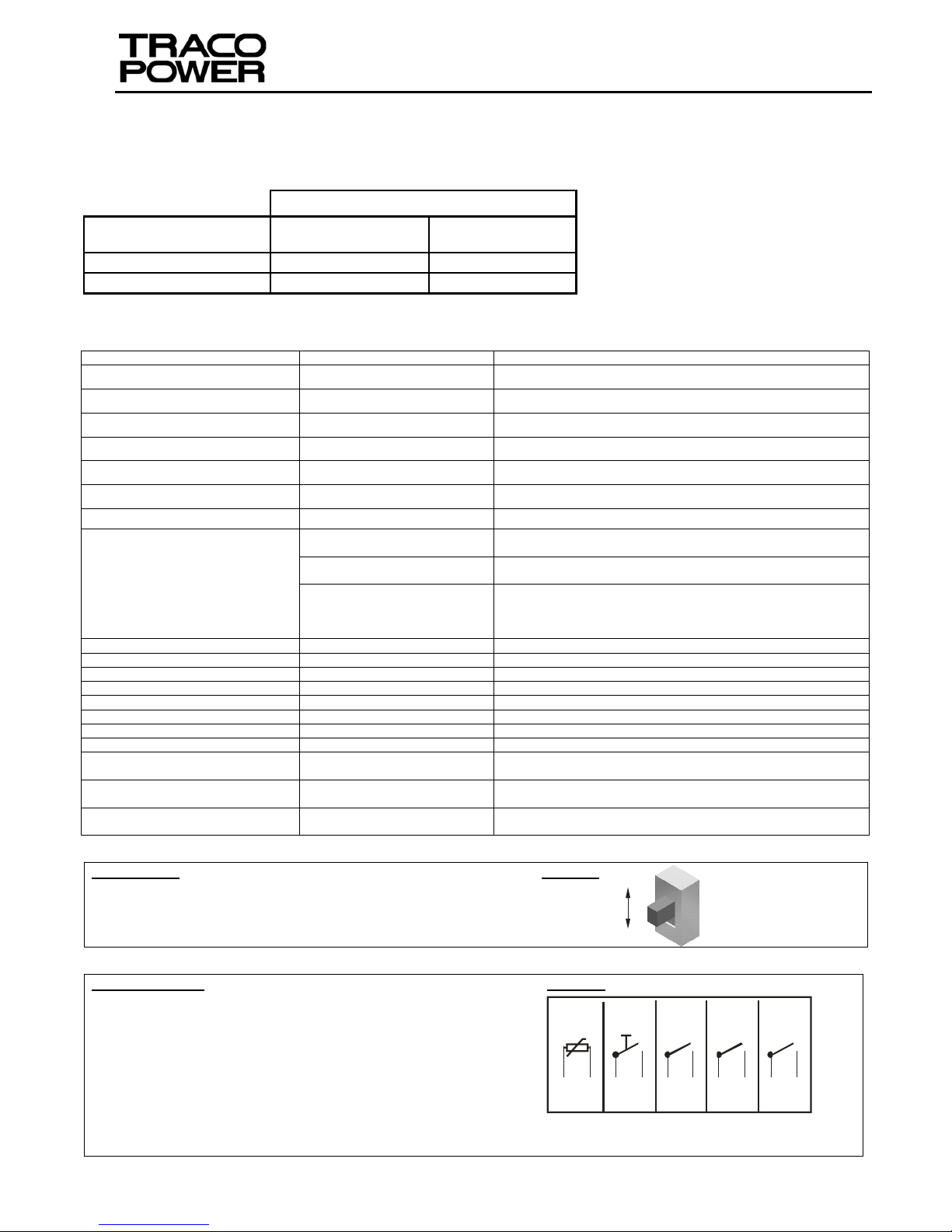

User Settings: Figure 1:

Battery Test Interval:

15 seconds or 10 minutes user selectable with switch

Signal Connector: Remark: Tightening torque 0.19Nm for all contacts. Figure 2:

Temp.Sensor: Connect external sensor for automatic end of charge

battery compensation.

Battery Remote ON/OFF: Enables remote disconnection of the

battery.

DC OK: Closed contact indicate that the output voltage is higher

than 82-90% of the nominal output voltage (24V).

BAT OK: Closed contact indicates that the battery is charged and

has low resistance (100mΩ max). During battery operation, open contacts indicate

that the battery is approaching (within approx.. 1V) the disconnection voltage level.

AC-IN-OK: Closed contact when the AC supply voltage is present. Open contacts indicate loss of AC Supply Voltage or overload at low AC supply

voltage levels.

Parameter Condition Settings

Nominal AC Input Range [VAC] High line 220-240

Input AC Voltage Range [VAC] High line 187-264

Nominal AC Input Range [VAC] Low line 100-120

Input AC Voltage Range [VAC] Low line 85-132

Input Frequency Range [Hz] 47 - 63

Output Voltage [V] Normal Mode 24.0-26.0V (adjusted by POT)

Output Voltage [V] Buffer Mode 23.4-23.8V (Internally set)

Electrical Connections

& Wire Size

AC Supply Input

1 - 4 mm

2

[AWG17-AWG11]

Tightening Torque 0.6Nm

DC Output

2 - 10 mm

2

[AWG14-AWG7]

Tightening Torque 1.76Nm

Battery Input

2.5 - 10 mm

2

[AWG13-AWG7] Nominal Power

4 - 10 mm

2

[AWG11-AWG7] Boost Power

max. resistance 10mΩ

Tightening Torque 1.76Nm

Battery Charging Current [A] Normal Mode 0.8…1.2

Nominal Battery Voltage [V] 25°C Ambient 13.6 (Factory Set)

Battery Adjustment Range [V] Normal Mode 13.0…14.4

Battery Test Current [A] Normal Mode 2.5A for 60ms (typ)

Battery Test Interval [s] Normal Mode 15s or 8..10mins (Set by switch: Fig.1)

Battery Warning Voltage [V] Buffer Mode 10.4...11.4

Battery Disconnection Voltage [V] Buffer Mode 9.1…10.2

Thermal Protection Buffer Mode 100°C (at back of chassis)

Automatic Battery Temperature

Compensation Range

Normal Mode -15°C…50°C (external sensor temp. Fig.2)

Battery Remote ON/OFF Buffer Mode

Switch 5V/5mA (min) to GND (Fig.2)

Level: 0…0.5V

Signal Relay Contact Rating

(Resistive Load)

Signal Monitoring 60VDC 0.5A (Fig.2)

http://www.tracopower.com Rev:1.0 / 1615

Safety Instructions:

¾ Before installation read these instructions carefully and com-

pletely. This installation instruction cannot account for every

possible condition of installation, operation or maintenance.

Further information can be obtained from your local distributor

office or from the product datasheet, which can be

downloaded from our website:

www.tracopower.com/products/tspc240ups.pdf

¾ Before any installation, maintenance or modification work

ensure that the main switch is switched off and prevented

from being switched on again. Non-observance, touching of

any live components or improper handling of this power

supply can result in death, severe personal injury or

substantial property damage. Proper and safe operation is

dependent on proper storage, handling, installation and

operation.

¾ Compliance with the relevant national regulations (in the USA,

Europe and other countries) must be ensured. Before

operation is started the following conditions must be ensured:

By use of stranded wires, all strands must be fastened in

the terminal blocks. (Potential danger of contact with the

case)

Power supply and mains cables must be sufficiently fused.

All output wires must be rated for the equipment output

current and must be connected with the correct polarity.

Sufficient cooling must be ensured.

¾ Never work on the equipment if power is supplied! Risk of

electric arcs and electrical shock, which can cause death,

severe personal injury or substantial property damage.

¾ Warning: Hazardous voltages and components storing a very

substantial amount of energy are present in this power supply

during normal operating conditions. However, these are

inaccessible. Improper handling may result in an electric

shock or serious burns! Do not open the equipment until at

least 5 minutes after it has been disconnected from the

power supply on all po les.

Only trained personnel may open the equipment.

Do not introduce any objects into the equipment.

Adjustment potentiometer(s) may only be actuated using

an insulated screwdriver.

Keep away from fire and water

Pollution degree 2 environment

CAUTION: “FOR USE IN A CONTROLLED ENVIRONMENT”

Installation Instructions:

¾ This equipment is designed for professional indoor

systems. In operation the equipment must not be

accessible. It may be installed and put into service by

qualified personnel only.

¾ The correct mounting position for optimal cooling

performance must be observed. Do not cover any

ventilation holes. Leave a free space of minimum 80mm

(3.15in.) above and below the power supply and on each

side of the power supply a minimum space of 25mm

[0.98in] which allows air convection. Observe power

derating.

¾ ATEX: To comply with the ATEX directive following

installation instructions have to be observed:

These power supplies are constructed in accordance

with the safety requirements of EN60079-0:2012 &

EN60079-15:2010, Ex nA nC IIC T4 Gc.

These power supplies units can be installed in switch

cabinets or protective housings that meet the

requirements of EN 60079-15 or if applicable EN

60079-0 (housing protection type min. IP54)

The permissible ambient temperature range is -20°C to

+70°C. Observe load derating.

For installation in switch cabinets or in protective

housings, it must be ensured that the stipulated

maximum temperatures are not exceeded on these

power supplies.

Do not operate voltage adjustment, unless area is

known to be non-hazardous.

The power supply units are Unit Group II Category 3G

components (ex components) as defined by RL

94/9/EG (ATEX 95) Appendix I. A separate conformity

on the end-equipment which contains these

components evaluation process must be performed.

For use / Installation also the requirements defined in

EN60079-14 must be observed.

¾ Recycling: The unit contains elements that are suitable for

recycling, and components that need special disposal. You

are therefore requested to make sure that the power

supply will be recycled environment friendly at the end of

its service life.

Loading...

Loading...