TRACO POWER TEX 120-112, TEX 120-124 Installation Instructions Manual

http://www.tracopower.com

Rev: 5.6/4915

INSTALLATION INSTRUCTIONS

TEX 120 Series Industrial Power Supply

Table 1

Order Code

Rated Input

Voltage

Output

Power max.

Output

** Output Voltage

Adjustment Range

recommended Circuit

breaker (Characteristic C)

TEX 120-112

100 – 240Vac

50 / 60Hz

Universal Input

96 Watt

12.0VDC / 8.0A

12.0 – 15.0VDC

5A

TEX 120-124

120 Watt

24.0VDC / 5.0A

24.0 – 28.0VDC

5A

** Adjustable by potentiometer with a screwdriver.

The equipment can be connected to TN-S, TT and IT power systems

Table 2

Input current:

@ Vin=115VAC

@ Vin=230VAC

Power Consumption

@ Vin=115VAC

@ Vin=230VAC

TEX 120-112

2.2A typ.

1.0A typ.

TEX 120-112

114 Watt typ.

112 Watt typ.

TEX 120-124

2.4A typ.

1.2A typ.

TEX 120-124

140 Watt typ.

136 Watt typ.

Table 3

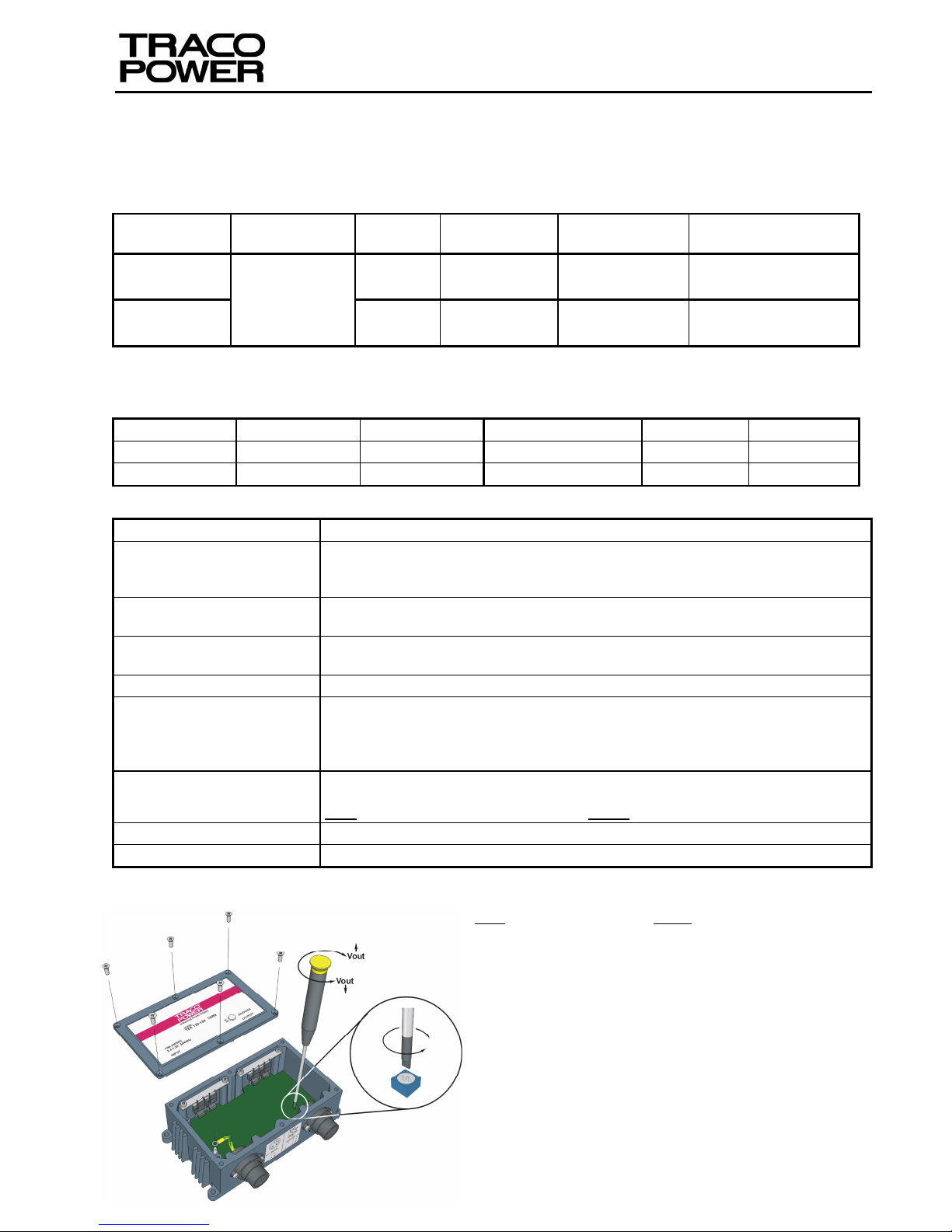

Output Voltage adjustment:

Note: The integrity of the seal cannot be guaranteed once the cover

has been removed in the field!

To adjust the output voltage, the case cover must be removed. Carefully loosen

and remove all six screws, then remove the cover. The output voltage of the unit

can be adjusted by turning the potentiometer screw, using an insulated

screwdriver. By turning the screw clockwise (cw) the output voltage will increase;

by turning the screw counter-clockwise (ccw), the output voltage will decrease.

The output voltage level should only be adjusted with the output connected to a

load, (similar to the load used in the application). After adjusting the output

voltage to the required value, the case must be carefully reassembled. Place the

cover over the case and ensure that the rubber-sealing gasket is undamaged,

and is correctly positioned. Secure the lid with the six screws. Tighten the screws

gradually, moving diagonally from one to another. The recommended tightening

torque is 0.6Nm (5.310lb·in).

Operational Input Voltage

AC: 85Vac – 264Vac, 50 / 60Hz. DC: 85Vdc* – 375Vdc (*Observe derating)

Operating temperature range:

Natural Air Convection

Cooling

-40°C – +85°C max (Atex: -40°C - +70°C) (*Observe derating)

-40°F – +185°F max (Atex: -40°F - +158°F) (*Observe derating)

Output Power Derating:

above +60°C 2%/

K

above 140°F 2%/

K

Storage temperature range:

-40°C – +85°C max

-40°F – +185°F max

Parallel Operation:

Only possible with external decoupling diode.

Connectors on the user side:

(see Fig. 2 & Fig. 3)

Input Cable Assembly: See Fig.2 (Tracopower P/N: TEX–IP–ASSY, 3 x 1.3mm²)

Input Connector: Binder Circular Connector Series 693: 99-4222-14-04

Output Cable Assembly: See Fig.3 (Tracopower P/N: TEX–OP–ASSY, 7 x 0.8mm²)

Output Connector: Binder Circular Connector Series 693: 99-4217-160-07

Wiring: Material Copper

Temp: -40°C – +125°C (-40°F – + 257°F)

Input: 3 x 0.8mm2– 2mm2max (AWG 18 – AWG 14) (1 x Live; 1 x Neutral; 1 x Protective Earth)

Output: 7 x 0.8mm2– 1.3mm2max (AWG18–AWG 16) (3 x +V

out

; 3 x –V

out

; 1 x Protective Earth).

Input: TEX-IP-ASSY Cord Diameter = 10 – 12mm / Output:TEX-OP-ASSY Cord Diameter = 12 – 14mm

Case protection:

IP67 (according to IEC 60529), NEMA 6P, UL50 4X

Case material:

Die-Cast Aluminium (chassis and cover)

Fig. 1

http://www.tracopower.com

Rev: 5.6/4915

Safety Instructions:

Before installation read these instructions carefully and

completely. This installation instruction cannot account for

every possible condition of installation, operation or

maintenance. Further information can be obtained from

your local distributor’s office or from the product datasheet,

which can be downloaded, from our website:

http://tracopower.com/products/tex120.pdf.

The mains supply voltage connection, must be in

accordance to IEC 62103, EN 50178 and IEC 60364, VDE

100.

Before any installation, maintenance or modification work

ensure that the main switch is switched off and prevented

from being switched on again. Normally, live components

cannot be touched, but while adjusting the output voltage

live components can be touched. Non-observance,

touching of any live components or improper handling of

this power supply can result in death, severe personal

injury or substantial property damage. Proper and safe

operation is dependent on proper storage, handling,

installation and operation.

Compliance with the relevant national regulations (in the

USA, Europe and other countries) must be ensured.

Before operation is started the following conditions must

be ensured:

Connection to mains supply in compliance with national

regulations (VDE0100 and EN50178).

By use of stranded wires, all strands must be fastened

in the terminal blocks. (Potential danger of contact with

the case)

Power supply and mains wires must be sufficiently

fused.

Degree of protection I to IEC536.The non-fused protec-

tive earth connection must be connected to the FG

terminal (Protection Class I).

All output wires must be rated for the power supply out-

put current and must be connected with the correct

polarity.

Sufficient cooling must be ensured.

Never work on the power supply if power is supplied!

Risk of electric arcs and electrical shock, which can cause

death, severe personal injury or substantial property damage.

Warning: Hazardous voltages and components storing a

very substantial amount of energy are present in this

power supply during normal operating conditions. However,

these are inaccessible. Improper handling may result in an

electric shock or serious burns! Do not open the power

supply until at least 5 minutes after it has been disconnected from the mains on all poles.

Class I Equipment (Chassis earthed)

Do not operate voltage adjustment when an explosive

atmosphere may be present

Do not disconnect while circuit is alive, unless area is

known to be non-hazardous.

Recycling: The unit contains elements that are

suitable for recycling, and components that need

special disposal. You are therefore requested to make

sure that the power supply will be recycled at the end

of its service life.

These power supplies are constructed in accordance with

the safety requirements of EN60079-0:2009 &

EN60079-15:2010, Ex nA IIC T4 Gc.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

may be impaired.

The power input and output cables must NOT touch the

enclosure during operation of the equipment.

Only trained personnel may open the power supply. Once the

cover is opened, the warranty is void!

Do not introduce any objects into the power supply. The output

voltage adjustment potentiometer may only be actuated using

an insulated screwdriver.

Keep away from fire

WARNING: – POTENTIAL ELECTROSTATIC CHARGING HAZARD –

Prevent unintentional contact with a dry cloth.

Do NOT clean surfaces with a dry cloth!

Clean ONLY with a damp cloth.

Installation Instructions:

User-side connector/Cable assemblies shown in Fig. 2 and

Fig. 3 on page 3.

Copper conductors rated min. 60/75C only are to be used.

Wire size 18-14 AWG only are to be used. (See Table 3)

These devices are intended for installation on industrial

machines in accordance with the "Electrical Standard for

Industrial Machinery" (NFPA79). Due to the nature of these

devices they may not be suitable for installation accordance

with the "National Electrical Code" (NFPA70).

The suitability of the use of flexible cord per CEC, PART I,

Rule 4-010, is to be determined by the local inspection

authority having jurisdiction. For Hazard Location, this

device must be installed within a suitable enclosure.

This power supply is designed for professional outdoor

systems as well as indoor systems. It may be installed and

put into service by qualified personnel only.

Do not operate without PE connection! To comply with EMC

and safety standards (CE mark, approvals) the power supply must be operated only if PE terminal is connected to the

non-fused earth conductor.

The correct mounting position for optimal cooling perform-

ance must be observed. Do not cover any ventilation

holes. Leave a free space of minimum 50mm (2in.) above

and below the power supply. Observe power derating.

The internal fuse is not accessible, as the user may not re-

place it. If this internal fuse has blown, the power supply

has an internal defect and, for safety reasons, must be

shipped to the local distributor. In case this internal fuse

has to be replaced in the field, replace only with same type

and rating of fuse for continued protection against risk of

fire.

When no connector is connected to the unit, the connectors

shall be sealed with the cover caps to maintain the degree

of protection.

Cover cap for Input connector 08-2301-000-000

Cover cap for Output connector 08-2302-000-000

Loading...

Loading...