Page 1

EZ-Ject™ Multi-Dose A/C Dye Injection System

TP-9850, TP-9860 and TP-9870 Dye Cartridges

U.S. Patent Nos. 6,056,162 and 6,050,310

Fluoro-Lite/P® (for R-134a/PAG systems) and Fluoro-Lite/E® (Universal for R-12 and R-134a systems) dyes meet or exceed SAE

standard J2297 for the stability and compatibility of fluorescent dyes for refrigerant leak detection in R-134a/PAG A/C systems.

Since the use of a fluorescent leak detection dye requires the addition of a chemical substance into the A/C system which may or may

not be compatible with the system, such dyes should not be used unless they are either expressly endorsed by the A/C system and/or

vehicle manufacturer or meet the requirements of SAE J2297.

• Do not operate the A/C system while the dye injector is being connected or used

• Do not connect the dye injector to a system that is evacuated

• The system must contain enough refrigerant to operate the compressor and circulate the dye in order to find leaks

• Wear protective glasses or goggles while using the EZ-Ject

IMPORTANT

The EZ-Ject dye cartridge contains dye that fluoresces under ultraviolet or UV/blue light when mixed with the A/C lubricant. F or best

results, use a high-intensity Tracerline

leaks clearly visible.

EZ-Ject hoses must be purged and charged with dye before they are used. The hose assemblies must always be full of dye before

they are used.

1. Completely unscrew the handle on the EZ-Ject injector. Remove the large cap from the cartridge and screw the cartridge into the

injector.

2. Holding the cartridge vertically with the small cap on top, remove the cap and screw the cartridge firmly to the check valve on the

hose assembly.

3. Insert the adapter/purge fitting into the quick coupler on the hose.

4. Turn the handle to advance the plunger until a small amount of dye exits the assembly. Remove the adapter/purge fitting.

The hose assembly is now purged, ready for use and will remain full of dye. NOTE: If the dye charge is lost, repeat

steps 3 and 4. Do not connect the dye injector to a system that is evacuated.

5. a. R-134a SYSTEMS—connect the R-134a quick coupler at the end of the hose assembly to the appropriate service port on

the vehicle.

b. R-12 SYSTEMS—

• When using TP-9870 universal dye only, screw the adapter/purge fitting to the low-side service port on the vehicle and

connect the quick coupler attached to the hose assembly.

• When using TP-9850 mineral oil dye, connect the TP-9846 R-12 hose assembly to the low-side access fitting on the

vehicle.

6. Turn the plunger to inject the dye. See “Dye Dose” below.

7. Disconnect the hose assembly from the service port and wipe both clean.

8. Start the engine and run the A/C system on maximum for 5 to 10 minutes to circulate the dye.

9. Turn the engine OFF. Inspect possible leak areas with the lamp. Leaks will glow a bright yellow-green in R-12/mineral oil systems

or green in R-134a/PAG and R-134a/ester systems. The fluorescence will be brightest under low light conditions.

10. To find smaller leaks, operate the A/C system over the next 24 to 48 hours and reinspect.

DYE DOSE

Each EZ-Ject cartridge can dose 7 full-sized vehicles or up to 14 compact vehicles. Use the amount of A/C system lubricant, if known,

to determine dye dose.

System Refrigerant/Lubricant Dye Dose System Size

®

inspection lamp and wear fluorescence-enhancing glasses to protect your eyes and to make

DYE INJECTION CAUTIONS

CAUTION

TM

dye injector and working on any vehicle system

Up to 2 lb (0.9 kg) refrigerant

Up to 5 fl oz (150 ml) lubricant

2.1 to 5 lb (1.0 to 2.3 kg) refrigerant

5 to 10 fl oz (150 to 300 ml) lubricant

5.1 lb (2.3 kg) or more refrigerant

10 fl oz (300 ml) or more lubricant

1 line on cartridge

2 lines on cartridge

3 or more lines on cartridge

(1 additional line per each 5 oz)

Compact vehicle

Standard vehicle

Larger vehicles

Page 2

Do not mix dyes. Always use the dye cartridge with its designated hose assembly. The hose assembly can be stored

containing dye.

• TP-9850 for R-12/mineral oil systems

• TP-9860 for R-134a/PAG systems

• TP-9870 Universal dye is compatible with all refrigerants and lubricants

CLEAN UP/REINSPECTION

After the leaks are repaired, clean the remaining dye from the leak sites with a cloth and Tracer Products’ GLO-AWAY™ dye cleaner or

a general purpose shop cleaner. Check with the lamp to be sure all dye is removed. Residual dye could give a false leak indication.

Run the A/C system another 5 to 10 minutes and reinspect with the lamp. No glow means that all the leaks have been found and

repaired.

DYE CAUTIONS

• Keep out of reach of children.

• Wipe all dye spills immediately. May damage paints and finishes. May stain hands and clothing.

• Store in a cool place away from sunlight.

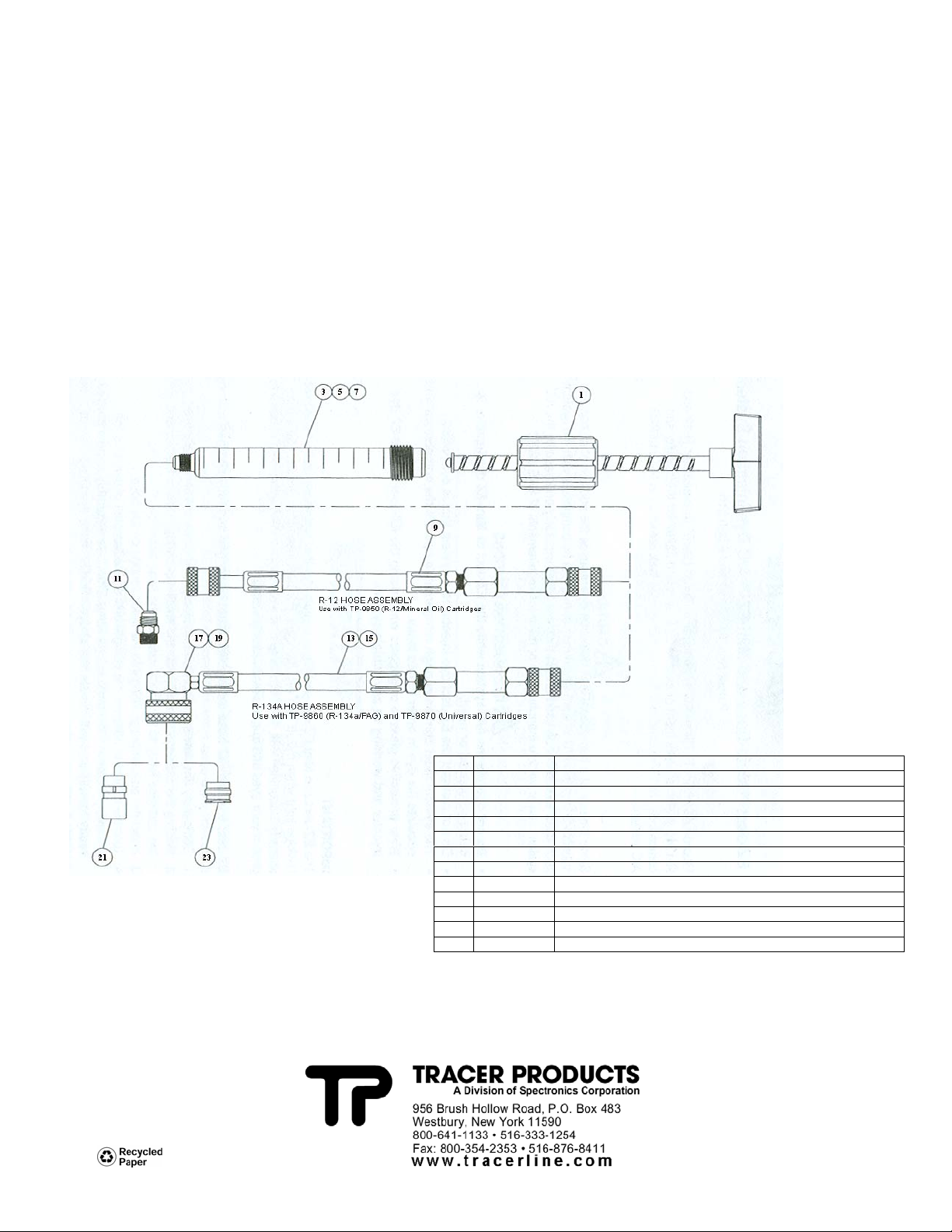

NO. PART NO. DESCRIPTION

1 TP-9845 EZ-JECT ASSEMBLY

3 TP-9850 CARTRIDGE, DYE, R-12/MINERAL OIL

5 TP-9860 CARTRIDGE, DYE, R-134A/PAG

7 TP-9870 CARTRIDGE, DYE, R-134A/ESTER “UNIVERSAL”

9 TP-9846 HOSE ASSEMBLY, R-12, WITH COUPLER

11 119690 PURGE FITTING, ¼” FLARE

13 TP-9847 HOSE ASSEMBLY, R-134A WITH COUPLER, LOW-SIDE

15 TP-9849 HOSE ASSEMBLY, R-134A, WITH COUPLER, HIGH-SIDE

17 TP-3888 QUICK COUPLER, R-134A, LOW SIDE

19 TP-9888 QUICK COUPLER, R-134A, HIGH SIDE

21 107472 ADAPTER/PURGE FITTING, R-134A, LOW-SIDE

23 107949 ADAPTER/PURGE FITTING, R-134A, HIGH-SIDE

8/05 AM05021

PRINTED IN U.S.A.

Loading...

Loading...