Page 1

What You Can't Hear Is What You Need

To Hear!

Operator's Manual

6/06 AM06016

PRINTED IN U.S.A.

Page 2

The Marksman™ ultrasonic diagnostic tool converts and amplifies inaudible ultrasonic

sound into audible "natural" sound. It operates on the principle of detecting high frequency ultrasonic waves, which are created by friction from all moving parts, whether

solid, liquid or gaseous. These "sounds" reside far above the range of the human ear

and tend to be highly directional.

This directional aspect of ultrasonic waves allows one to isolate a suspect signature

sound from other background noises and detect its exact location. This sound analysis

can be used for efficiently investigating five major areas of repair and preventive maintenance in all transportation and industrial applications.

1) Air leaks

Both vacuum and compressed air leaks create an energy packet or wave front which can

result in an ultrasonic emission with a differential of 1 psi and/or a hole down to 0.005

inches.

2) Gas and liquid turbulence

Turbulence associated with steam trap and internal valve leaks, cavitation, and blockages in liquid and air/gas lines.

3) Electrical discharge

Electrical discharge associated with insulation breakdown, tracking, corona, and arcing.

4) Mechanical wear

State of mechanical wear in bearing and race assemblies, shafts, and gears (also indicating the state of lubrication).

5) Sound generation

Can be used in conjunction with sound generators to detect container cracks and seals,

door seals and compartments. (The Marksman ultrasonic emitter is matched to the

Marksman receiver).

There exists a need to evaluate mechanical devices and/or systems for the purpose of

determining the onset of their failure. As a practical matter, the failure of a component

within a larger device does not only apply to the component itself, but can also cause

devastation to the entire mechanism. Thus, the need to predict such failure is of even

more importance.

Faults, malfunctions, and/or flaws in mechanical, electrical, and pneumatic devices, as

well as in container type objects, start as small defects or leaks. The physical size of

these defects is so relatively small that the sounds they produce are above the range of

human hearing. Most commonly, these faults generate sounds in the 38,000 to 43,000

cycles per second range, generally referred to as being in the ultrasonic range.

To employ the ultrasound methodology in a usable manner, it is imperative the listener be

able to have access to an audible sound that bares a resemblance to the natural sound

of the defect. A mechanical bearing with a defective ball should sound like such.

Likewise, a microscopic leak in a compressed air system should sound like a gas leak.

Simply converting the ultrasound frequencies to audible frequencies is not sufficient with regard to rendering a usable signal. It is for this reason the Marksman

incorporate a process whereby the audible signal bears a close likeness to the natural incoming sample. We call this process "Sound Signature Technology," whereby a

gas leak sounds like a gas leak and a defective bearing sounds like one.

The Marksman uses a technology called heterodyning to convert the ultrasonic range into

the audible range. The Marksman is unaffected by everyday sounds such as wind, voices or traffic, which can further mask the technician's ability to listen for a potential problem. The Marksman also incorporates AGC (automatic gain control), which allows one to

study ultrasonic sounds associated with the higher level roar of a valve leak down to, literally, the blink of an eye. With AGC, there is no need for high/low sensitivity switches,

since the internal circuitry automatically seeks the optimum level of gain for the given situation. This ultimately allows the Marksman to be picked up and learned immediately

without having to fiddle with knobs to seek correct settings.

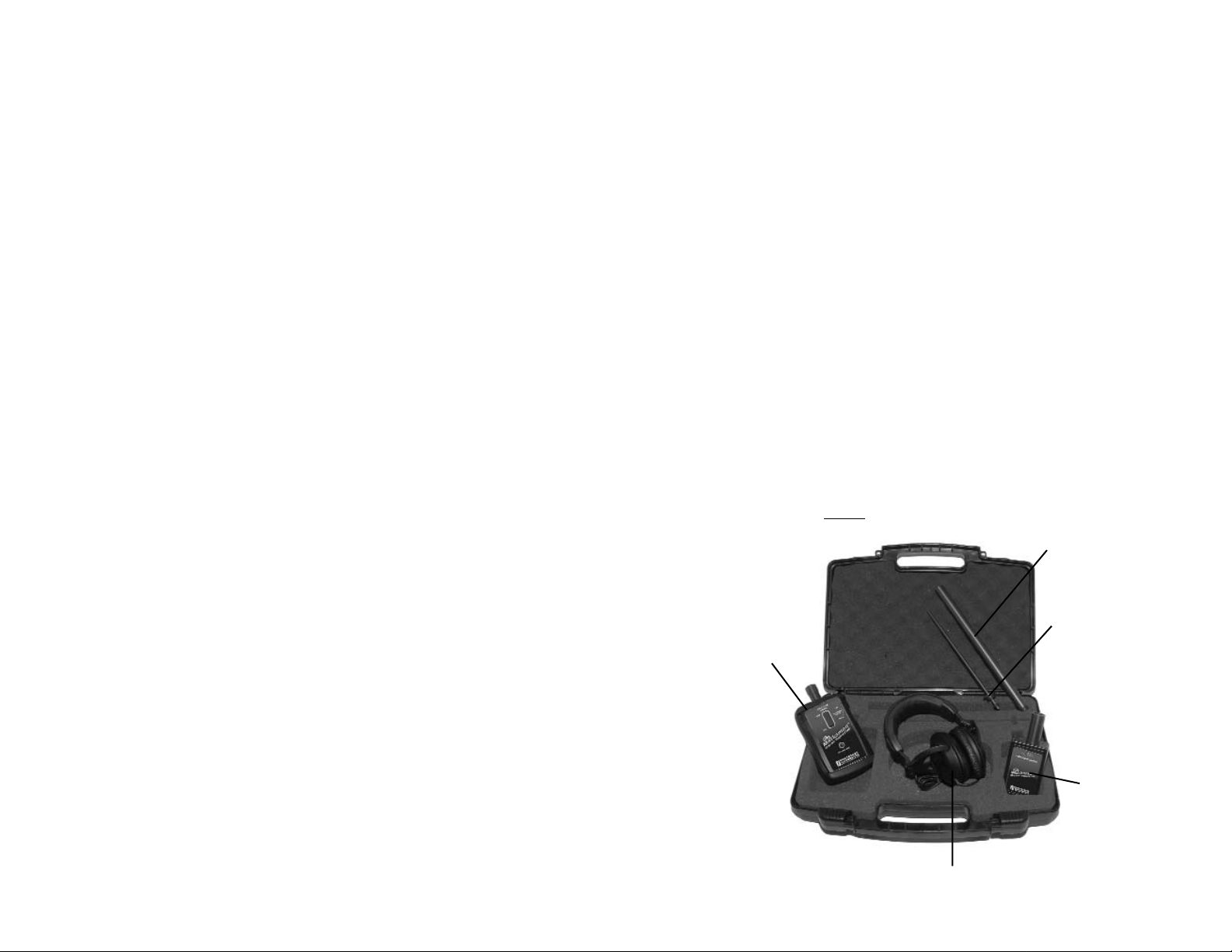

Kit Configurations and Components

Master Kit –– Contains:

1. The Marksman ultrasonic receiver. An easy-to-use unit that incorporates audio feed

back and a 10 bar LED indicator for intensity of signal. The receiver has a permanently

fixed 2" directional receiver port, 3.5 mm stereo jack port, and a rotary on/off volume

control switch.

2. Two anodized probes: a 12" air probe and a precision length contact probe.

3. A full-sized headphone set with a 3.5mm stereo jack.

4. A rugged carrying case with form-fitting foam for storage and transportation.

5. The ultrasonic emitter. Sends out a 40Khz pulse for use in testing seal integrity in nonpressurized vessels.

6. Two 9 volt batteries.

PLEASE NOTE: The Marksman Receiver-Only Kit is also available, which contains

everything in the Master Kit except

the ultrasonic emitter.

Ultrasonic Receiver

Ultrasonic Emitter

Contact Probe

Air Probe

Headphones

English

Page 3

Ultrasonic Emitter

The emitter gives off a warble output centered at 40Khz. This output cannot be heard by

the human ear. If the red indicator is on, the unit is emitting.

Air and Contact Probes

The air and contact probes are precision parts, designed to optimize the response of the

Marksman receiver. The 12" air probe extends reach and isolates one leak among multiple suspect areas. Do not modify the probes in any way and never use the probes for

other than described in this manual.

Batteries

Zinc or Alkaline batteries are preferred. To replace the battery in the receiver, the protective rubber boot has to be removed first. The rubber boot is easier to remove when

warm because it is more flexible. To remove, push the bottom edge of the boot off the

inner enclosure and pull the enclosure out. Please observe polarity. Replace the boot in

the reverse manner. When replacing the emitter battery, be careful not to strain or pinch

the wires. Always remove the battery during a period of long storage. Also, please

dispose of batteries in a manner dictated by your local laws.

IMPORTANT TIPS

Receiver and Emitter Port Openings

The port openings of the receiver and emitter contain the heart of the Marksman's operation, a precision transducer. During use, guard against any foreign matter entering

these areas.

Calibration

The Marksman has been optimally tuned at our factory and should require no

re-calibration during its life under normal conditions.

LED Display

The LED display allows you to zero in on a steady-state source of ultrasonic sound, such

as when locating an air or vacuum leak or using the emitter. Simply watch for a rise or

drop in the bar levels to pinpoint the source of the problem.

Miscellaneous

To prolong battery life, turn off the Marksman when not in use, avoid rough handling, and

keep away from the elements. Use the carrying case for protection and for transporting.

Safety Precautions

While the Marksman allows you to focus on diagnosing a problem in a fast and

effective manner, never lose focus of your surroundings.

1. Always remember that the Marksman and probes are an extension of your hand.

Keep the probes and your hands a safe distance from moving parts and electrical

areas.

2. Never over-reach or de-stabilize your footing while using the Marksman.

3. Stand a proper distance from electrical and moving parts.

4. Always be aware of the headphone cord when near moving parts.

5. Never use the air or contact probes as a lever, pry bar or for other unintended pur

poses.

6. Never use the contact probe for diagnosing electrical problems.

7. Wearing headphones hinders one's ability to listen to your surroundings –– Always

be alert!

OPERATING INSTRUCTIONS

1. Plug the headphone jack into the receptacle located on the face of the panel.

2. Thread either the air probe or contact probe into the receiver port. Refer to the

"Typical Scanning Methods/Tips" section for optimum probe choice.

3. Turn the rotary knob clockwise to "ON" and watch for the LED bar to settle to the

bottom position. Turn up the volume until you can just hear the background noise

(hiss). Please note: Increasing the volume does not

increase the unit's detection

sensitivity. Setting the volume control too high can lead to operator fatigue.

4. When using the air probe, point the probe in the direction of your free hand while

lightly rubbing your forefinger and thumb together 2+ feet away. The response

should be the sound of sandpaper on wood. You can vary the distance and

increase/decrease the level of volume accordingly. While performing this function,

become familiar with the directional sensitivity of the probe while sweeping the probe

past your fingers at various distances. If using the contact probe, adjust the

sensitivity while lightly rubbing your finger along the tip of the rod.

Typical Scanning Methods/Tips

The Marksman provides information in two ways: qualitative, through the ability to "hear"

the signature ultra-sounds produced by various types of equipment, and the ability to see

the feedback level on a graduated LED bar readout.

The air and contact probes are used to optimize the response depending on the type of

inspection. The air probe is best used for detecting ultrasounds associated with a pressure leak or an electrical corona, while the contact probe is best to detect the ultrasounds

generated from within a casing such as in a gear, bearing, pump, valve, or steam trap

housing.

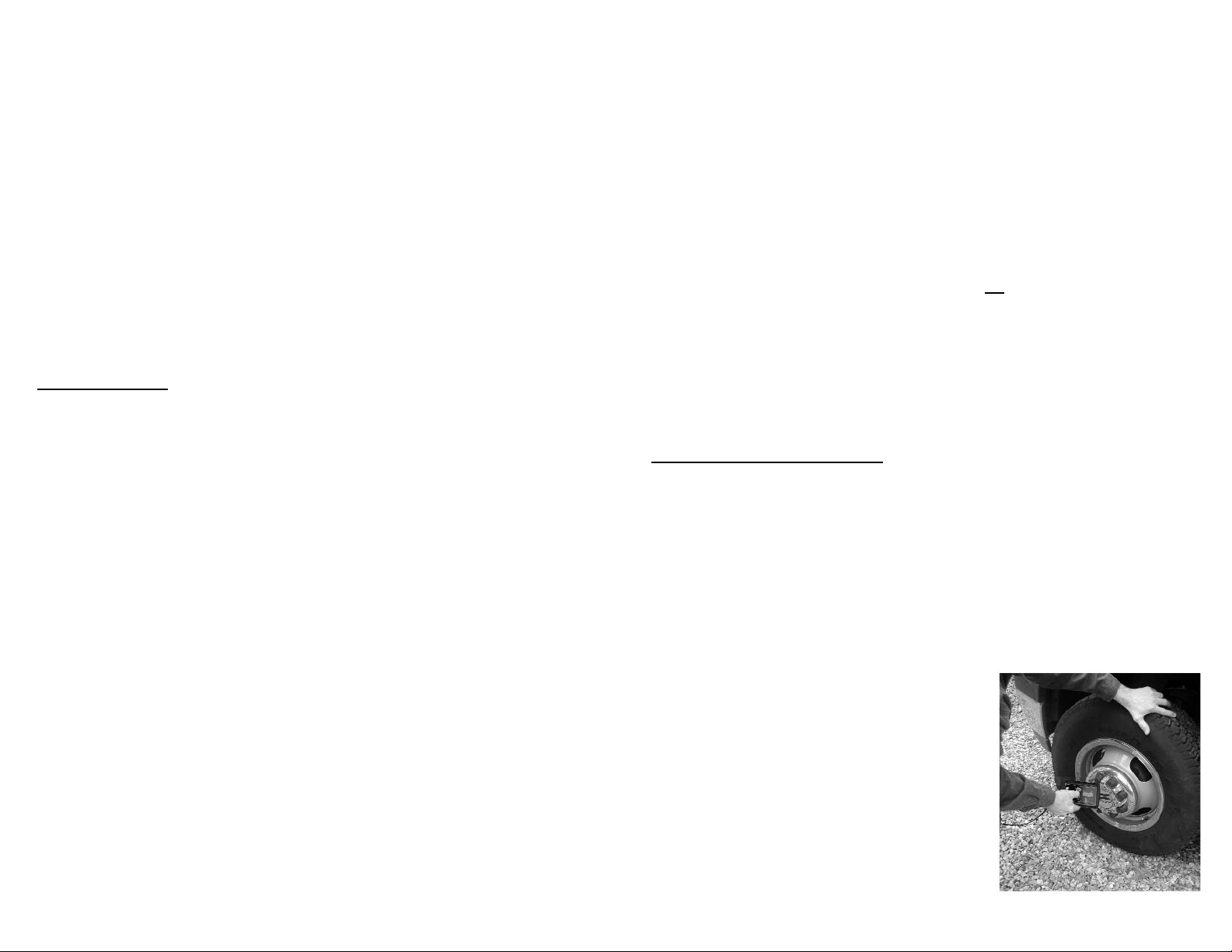

MECHANICAL MALFUNCTIONS

The photo to the right shows a typical way to inspect a potential wheel bearing problem.

In this case, the air probe is used since the wheel is

being turned while listening for the sound of the bearings. The tip of the probe is kept 2-3 inches from the

inspection area. Response can sometimes be optimized by removing the wheel and using the contact

probe to touch the stationary center hub. This applies

to motor housings, as well when checking motor bearings. The contact probe is also used in the same manner for investigating fuel injectors and coil-over-shock

suspension systems. Touch the tip of the metal probe

to the surface area being tested. Correct operation

sounds one way. Malfunction sounds another way.

You will easily hear the difference.

Page 4

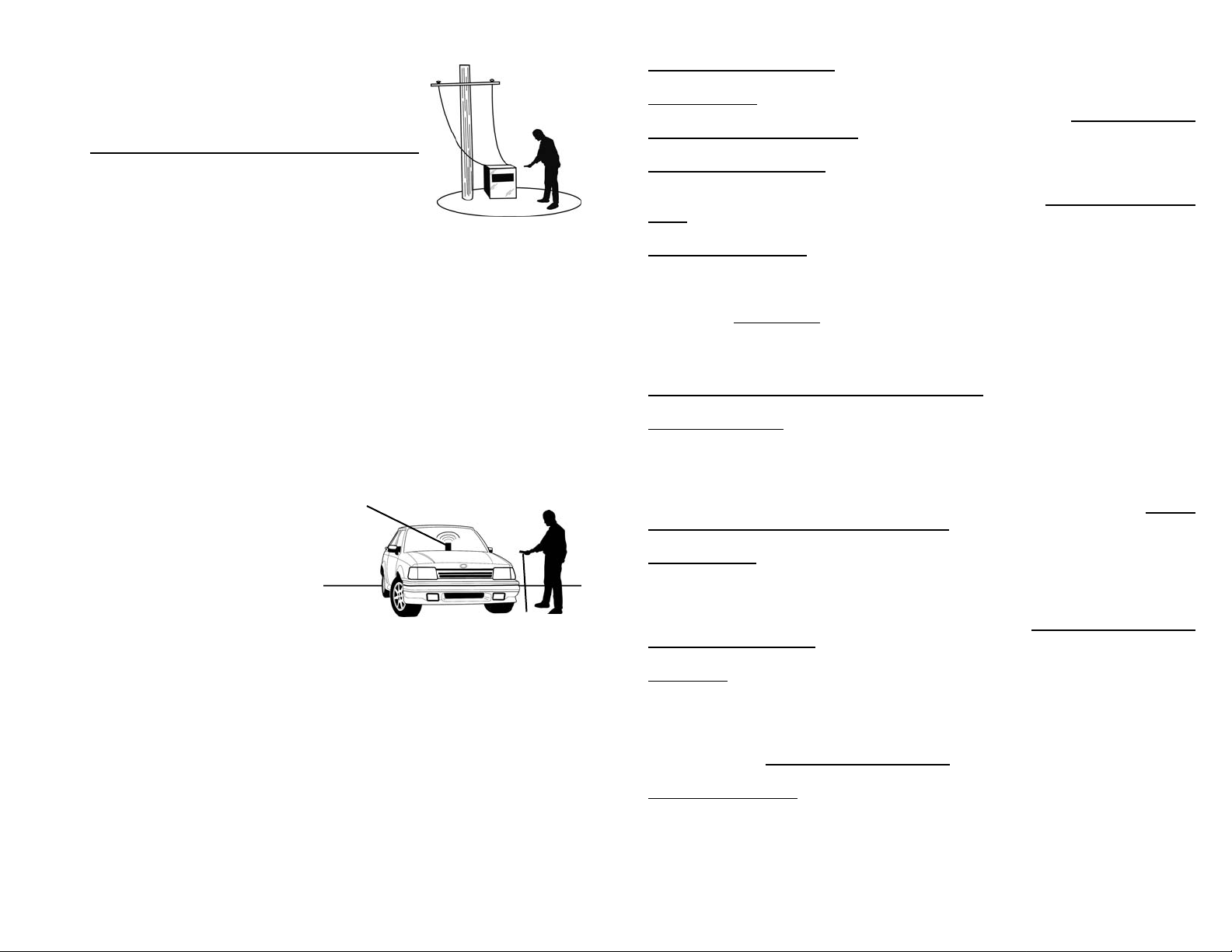

ELECTRICAL CORONA DISCHARGE

At right is a typical application using the Marksman to detect

possible electrical malfunctions by listening to the electrical

corona discharge associated with power switches and breaker

boxes. As with all potentially dangerous situations, use

caution. Use the hollow air probe or use the receiver alone

when inspecting electrical conditions and always keep a safe

distance between the air probe tip and the metal panel surfaces. The Marksman is highly sensitive to picking up voltage

breakdowns. The resultant ultrasonic sound has been

described as sounding like "frying bacon."

PRESSURIZED AND VACUUM LEAKS

Applications for pressurized type inspections are endless including: compressed air or

gas of any kind, air brake systems, pipes/lines, steam systems, water lines, manifolds,

and likewise all vacuum systems. Note: Ultrasonic detection relies on detecting the

sounds associated with the turbulence of the fluid or gas exiting a hole or orifice under a

differential pressure. It is independent of the type of gas or fluid. The Marksman will readily detect air and vacuum leaks typically caused by bad gaskets, worn valve seats and

cracks in pipes, hoses or fittings.

NON-PRESSURIZED LEAKS

Non-pressurized vessels or containers cannot generate ultrasonic sounds. The supplied

ultrasonic emitter is used to broadcast an ultrasonic noise, which is optimized to the frequency response of the Marksman receiver. Some examples are: leaks in heating and

cooling system ducts and pipes, tanks, windshields, weather-stripping and whole house

integrity.

1. Turn on the emitter and place it in the

enclosed environment to be evaluated.

The emitter will fill the interior with a

piercing warble sound. Note: Since the

output is in the ultrasonic range, you will

not hear it without the receiver.

2. Walk around the exterior of the enclosed

environment while sweeping the receiver around the suspect areas. Compromised

areas will be revealed by the change in tone and intensity, both audibly and

visually, by listening and watching the changes on the LED display.

USING THE LED DISPLAY FOR LOCATING LEAKS

Please note that the volume control is independent of the LED display during an inspection. Depending on the amount of ultrasonic signature being detected, you can use both

the level of intensity on the LED display and the audible amount of sound through the

headphones. As you get closer to the problem, decrease the volume. As the sound get

louder, repeat the process until you have pinpointed the location.

VEHICLE APPLICA

TIONS

VACUUM LEAKS: Place the hollow air probe on the unit and listen and watch the LEDs.

You can pinpoint the location of vacuum leaks quickly and easily. Use the hollow air

probe or use the receiver alone.

FIND THAT ENGINE NOISE. The Marksman will locate those engine noises and let you

find where they are truly coming from. Ultrasound does not transfer within engine components due to the directional characteristics of ultrasound. Use the solid cont

act

probe.

ELECTRICAL

SYSTEMS

: Separations in high-tension spark plug wire conductors can

be quickly identified from the corona discharge "snapping" sound emitted. The same

applies to arcing within electrical motors and accessories. Also, listen to connection

points for the "snapping" or "frying bacon" sound; this is a sound a poor connection

makes under electrical load

. Circuits are best tested under operation and full load.

The Marksman unit is also great at locating short circuits. Shorts give off a "frying" or

"snapping" sound also. As you are checking for shorts or connection problems, do not

forget to wiggle the wiring! Those electrical problems will now call out to you. Save time!

Use the hollow air probe or use the receiver alone

.

IGNITION SYSTEMS: Listen to today's ignition systems. You can hear the coils and

plugs firing. This is by far the best and quickest method for diagnosing Coil Over Plug

(COP) systems. It also works great on Distributorless Ignition Systems (DIS). You will

hear the snapping of the plugs firing in the headset. After some experience testing ignition systems, you can tell if you have a plug or wire problem by the sound alone. When

checking DIS systems, make sure you listen at both ends of the wire if you can. Use the

solid contact probe or use the receiver alone.

EV

AP SYSTEMS: Checking for leaks in evaporative emissions systems is simple. Start

by pressurizing the EVAP system (don't exceed the recommended pressure!). Now,

sweep all the hoses and components of the system and listen for a hissing noise that

would indicate a leak. Once the general area of the leak has been determined, move

closer with the receiver to pinpoint the exact leakage source. Use the hollow air probe

or use the receiver alone.

INJECTORS: Place the solid contact probe onto the injector to test and listen while the

engine is running. You can hear the injector working plus hear the fuel flow. You may also

want to shut the engine off and listen to make sure that the injector is not leaking fuel past

the injector nozzles. If fuel is flowing, it will create a rushing noise in the headset. Agood

clean injector will make a sharp ringing clicking tone, while a dirty injector will have a muffled clicking tone. Use the solid cont

act probe

.

AIR BRAKE SYSTEMS: The Marksman detector can help locate leaks quickly in both

vacuum assisted and air brake systems. In many cases, leaks can be detected from a

considerable distance. After building up full pressure (in the case of air brakes), a casual sweep of the vehicle from one end to the other using the receiver can often locate the

leak. Use of the headphones will reduce noise interference from the shop. If the first

sweep does not locate the leak, trace out the entire air system piping at close range (1-

Emitter

Receiver

Page 5

2 feet) with the receiver. Once the general area of the leak has been determined, the

receiver probe is very useful to pinpoint the exact location of the leak. For maximum

effectiveness, be sure that pressure is maintained in the brake system during the entire

search. If no leaks are discovered, check the air horn, windshield wiper and other airactuated equipment. Leaks in these accessories can produce an abnormal gauge drop.

Use the hollow air probe or use the receiver alone

.

TIRES

: Sweep the tire, including the rim and valve system, to search for leaks. Asweep

with the Marksman receiver will locate even the smallest of leaks. The receiver normally finds leaks of sufficient magnitude before they cause downtime on the highway. In

addition, you can put a soap solution on tires and listen for the bubbles to pop. Use the

hollow air probe or use the receiver alone.

LEAKING ENGINE VALVES: All valves should emit a sound in a very close meter and

sound pattern when the probe is placed on the intake manifold opposite the intake port.

A suspect valve can then be positively checked, with the engine off, by bringing that particular cylinder to full compression and placing the probe on the valve stem. The "hiss"

of escaping gas across the valve seat will be distinctly audible on the leaking valve.

Using the same procedure can check exhaust valves, however, signal intensity will be

much greater. Use the solid cont

act probe.

EXHAUST SYSTEMS: With the engine idling, pulsation in the exhaust system can be

detected with the receiver. Leak points normally give off a much louder and sharper

sound. Use the hollow air probe or use the receiver alone

.

DOOR AND WINDOW GASKETS, BODY WEATHER-STRIPPING, DOOR AND TRUNK

SEALS

AND FUEL T

ANKS

:

When placed inside a vehicle,

a completely empty fuel tank

or any other enclosure, the

emitter can easily locate

leaks in weather-stripping,

seals or the structure itself.

Use the hollow air probe or use the receiver alone

.

ADDITIONAL APPLICATIONS:

HYDRAULIC SYSTEMS

: Partially blocked or bypassed valves in high-pressure hydraulic

systems can be difficult and costly to find with conventional methods. Since hydraulic

systems employ very high pressures, the intensity of the ultrasonic sound given off by an

internal leak is extremely high and easily detected by the receiver. Use the hollow air

probe, solid contact probe or use the receiver alone.

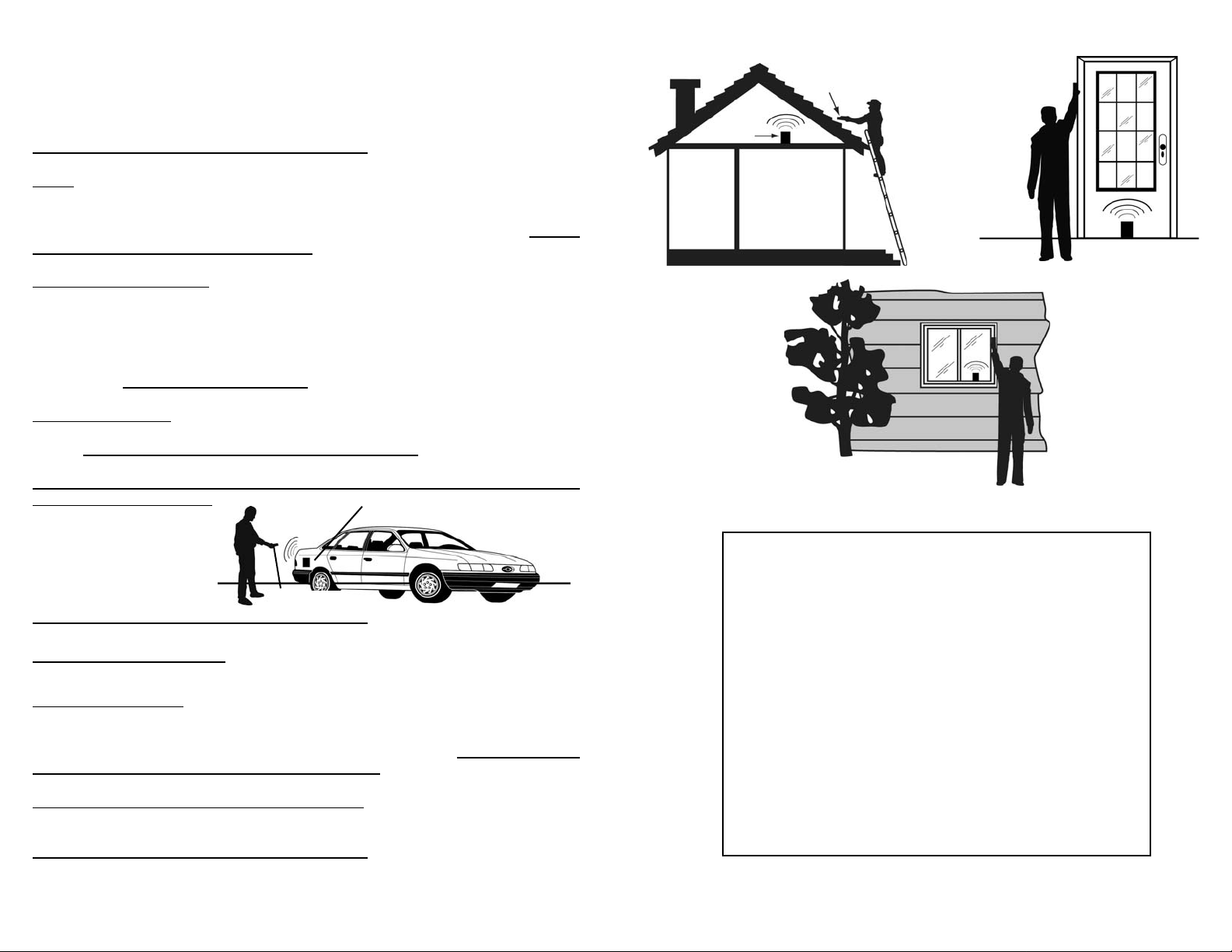

WATER LEAKS IN ROOFS, WINDOWS OR DOORS: Place the activated emitter below

the suspected leak area. Check the suspected part of the roof with the receiver to isolate where the leak originates. This will also aid in the detection of any leaks in the area.

Use the hollow air probe or use the receiver alone

. (See figures to right)

Emitter

Receiver

Emitter

Receiver

TECHNICAL SPECIFICATIONS

Dimensions: Width: 4.0" (10.2 cm)

Depth: 1.5" (3.8 cm)

Length: 6.0" (15.2 cm)

Weight: 3 lbs. (1.4 kg)

Housing: Chemical resistant ABS

with protective rubber boot

Battery Life: Approx. 20 hrs.

Power Requirement: Standard 9-Volt

Power Consumption: 26 mA, typical

Frequency Response: 36,000-44,000Hz

Circuitry: Solid state

Headphones: Full-sized noise attenuating

Headphone Connector: 3.5m phone plug

Operating Temp. Range: +10 to +60 degrees Celsius

Page 6

Ce que vous n'entendez pas est en fait ce que

vous devez entendre !

Manuel d'utilisation

L'équipement de détection ultrasonore de fuites et de diagnostic de panne Marksman™

permet de convertir et d'amplifier les ultrasons imperceptibles à l'oreille humaine en des

sons " naturels " et en une gamme de fréquences audibles. Il fonctionne en détectant les

ondes de hautes fréquences provenant de la friction de toutes les pièces en mouvement,

quelles qu'elles soient, solides, liquides ou gazeuses. Ces "sons" existent bien au-delà

de la gamme des sons perceptibles par l'oreille humaine et ont tendance à être hautement directifs.

Cet aspect directif des ultrasons vous permet d'isoler un son suspect parmi des bruits de

fond et de le localiser avec précision. Cette analyse de son peut être utilisée afin de faire

une révision poussée de cinq catégories de réparation et de maintenance préventive

dans le secteur automobile ou industriel.

1) Fuites d'air

Les fuites d'air comprimé ou de vide engendrent une énergie ou une surface d'onde qui

se traduira par un ultrason avec un différentiel d'1 psi et/ou un trou de 0,127 mm.

2) Turbulence gazeuse ou liquide

Turbulence liée aux purgeurs automatiques et aux fuites de soupapes internes, aux cavitations et obstructions au niveau des conduites de liquide, d'air ou de gaz.

3) Décharge électrique

Décharge électrique en raison d'une isolation défectueuse, un mauvais cheminement

des câbles, une effluve électrique (effet couronne) ou la production d'étincelles.

4) Usure mécanique

État d'usure mécanique des roulements et des bagues, arbres et engrenages (ainsi que

l'état de leur lubrification)

5) Sons

Le détecteur Marksman peut être utilisé parallèlement avec des générateurs de son afin

de détecter les fissures pouvant apparaître sur les contenants, le calfeutrage, les joints

de porte et divers compartiments (l'émetteur à ultrasons Marksman est apparié au récep-

teur Marksman.)

L'évaluation de l'état des dispositifs mécaniques et/ou des systèmes afin de prévenir

toute panne est une nécessité. D'une manière générale, si un élément d'un dispositif

plus important tombe en panne, cette panne risque d'avoir de graves conséquences sur

l'ensemble sur mécanisme. Par conséquent, il s'avère encore plus important de pouvoir

prédire telle panne à l'avance.

Les défaillances, défectuosités, dysfonctionnements, imperfections et/ou vices de fonctionnement des dispositifs mécaniques, électriques et pneumatiques ainsi que des objets

tels que les contenants et autres habillages de compartiments, apparaissent en tant que

petits défauts ou fuites. La taille de ces défauts est si petite que les sons qu'ils produisent

sont imperceptibles à l'oreille humaine. Le plus souvent, ces défauts génèrent des sons

dont la gamme est située entre 38 000 et 43 000 cycles par seconde, à savoir des ultrasons.

Pour détecter correctement une panne à l'aide d'ultrasons, il est indispensable que la

personne qui testera le mécanisme puisse percevoir un son audible qui ressemble au

son naturel du défaut. Un roulement comportant une bille défectueuse devrait toujours

avoir le même son. De la même manière, une fuite microscopique au niveau d'un circuit

d'air comprimé devrait avoir le même son qu'une fuite de gaz. Il ne suffit pas de con-

vertir les ultrasons en des fréquences audibles afin d'obtenir un signal utilisable.

Pour cette raison, le détecteur Marksman fait correspondre le signal audible à un

son qui sera d'une grande similarité à celui de l'échantillon naturel qui est recueilli. Nous appelons le processus qui fait en sorte qu'une fuite de gaz ait toujours le son

d'une fuite de gaz et un roulement à bille défectueux ait toujours le son d'un roulement à

bille défectueux, la " Technologie de signature des sons ".

Le détecteur Marksman fonctionne grâce à une technologie de changement de

fréquence simple permettant de transformer la gamme d'ultrasons en une gamme de

fréquences audibles. Le détecteur Marksman demeure inchangé par les sons de tous

les jours tels que le vent, les voix ou la circulation automobile qui risquent de nuire encore

plus à la capacité du technicien réparateur à détecter un problème potentiel. Le

détecteur Marksman comporte également une commande automatique de gain (CAG)

qui vous permet d'étudier en un clin d'oeil les ultrasons associés au vrombissement d'une

valve présentant une fuite dont le niveau de son sera supérieur. Grâce à cette commande CAG, il est inutile d'utiliser de commutateurs de sensibilité car le circuit interne

recherche automatiquement le niveau optimal de gain selon la situation. Ceci vous permet d'apprendre immédiatement à utiliser le détecteur Marksman sans avoir besoin de

jouer avec les boutons afin de rechercher les bons niveaux.

Le kit et ses éléments

Le kit maître contient:

1. Le récepteur d'ultrasons Marksman. Un appareil facile à utiliser avec affichage de

réaction audio et un écran DEL de 10 barres indiquant l'intensité du signal. Le

récepteur comporte une prise fixe de 5 cm de récepteur directionnel, une prise

stéréo de 3,5 mm et une commande de réglage de volume pour marche et arrêt.

2. Deux sondes anodisées: une sonde d'air de 30 cm et une sonde de contact de

précision.

3. Un casque d'écoute avec fiche stéréo de 3,5 mm.

4. Un étui robuste avec logements en mousse pour ranger et transporter les éléments

du kit.

5. L'émetteur d'ultrasons. Il permet d'envoyer une impulsion de 40Khz afin de tester

l'intégrité du joint à l'intérieur d'enceintes sous pression.

6. Deux piles de 9 volts.

VEUILLEZ NOTER: Le kit Marksman avec récepteur seulement est également

disponible séparément. Il contient tous les elements du kit maître sauf

l'émetteur d'ultrasons.

French

Page 7

Émetteur d'ultrasons

L'émetteur produit un hululement centré à 40Khz. Cet hululement est imperceptible à

l'oreille humaine. Si le voyant rouge est allumé, l'appareil est en train d'émettre.

Sondes d'air et de contact

Les sondes d'air et de contact sont des pièces de haute précision conçues afin d'optimiser la réponse du récepteur Marksman. La sonde d'air de 30 cm vous permet une

portée plus longue et peut isoler une fuite au sein de plusieurs zones suspectes. Ne

modifiez en aucune façon les sondes et ne les utilisez jamais pour une fin autre que pour

celles décrites dans ce manuel.

Piles

Il vous est conseillé d'utiliser des piles alcalines ou au zinc. Pour remplacer la pile du

récepteur, retirez tout d'abord l'étui en caoutchouc. L'étui en caoutchouc est plus facile

à retirer lorsqu'il est chaud car il est plus flexible. Pour le retirer, poussez sur le bord

inférieur de l'étui afin de le faire dépasser du boîtier interne puis tirez sur le boîtier pour

le retirer. Veuillez noter la polarité. Remettez en place l'étui en reprenant les instructions

en sens inverse. Lorsque vous remplacez la pile du récepteur, veillez à ne pas tirer ou

pincer les fils. Veillez à toujours retirer la pile avant de ranger l'appareil pour une

longue période. De plus, veillez à toujours éliminer les piles conformément à la réglementation locale.

CONSEILS IMPORTANTS

Orifices des prises du récepteur et de l'émetteur

Les orifices des prises du récepteur et de l'émetteur comportent le principal élément du

détecteur Marksman, à savoir un transducteur de haute précision. Lorsque vous utilisez

l'appareil, assurez-vous qu'aucun corps étranger ne pénètre à l'intérieur de ces prises.

Étalonnage

Le détecteur Marksman a été étalonné en usine afin de fonctionner d'une façon optimale

et ne devrait pas nécessiter d'étalonnage supplémentaire lors de sa vie utile lors de conditions d'utilisation normales.

Écran DEL

L'écran d'affichage DEL vous permet de cibler une source permanente d'ultrasons

comme par exemple lorsque vous localisez une fuite d'air en dépression ou lorsque vous

utilisez l'émetteur. Il vous suffit de regarder l'écran afin de voir s'il se produit une augmentation ou une baisse des niveaux afin de détecter la source du problème.

Divers

Pour prolonger la durée de vie de la pile, éteignez le détecteur Marksman lorsque vous

ne l'utilisez pas, veillez à ne pas le manipuler brusquement ou brutalement et maintenezle à l'abri des intempéries. Conservez-le dans son étui pour le protéger et afin de le transporter.

Consignes de sécurité

Bien que le détecteur Marksman vous permette de diagnostiquer

rapidement un problème avec précision, veillez à toujours prendre en

considération le milieu ambiant.

1. N'oubliez jamais que le détecteur Marksman et ses sondes sont des outils que vous

utiliserez comme s'ils faisaient partie intégrante de votre propre main. Maintenez les

sondes et vos mains à une distance sûre des pièces en mouvement et des pièces

électriques.

2. Veillez à toujours demeurer bien campés sur vos jambes afin de ne pas perdre

l'équilibre lorsque vous utilisez le détecteur Marksman.

3. Placez-vous à une distance suffisante des pièces électriques et des pièces en

mouvement.

4. Veillez à toujours à prendre en compte la présence du cordon du casque d'écoute

lorsque vous vous trouver à proximité des pièces en mouvement.

5. N'utilisez jamais les sondes d'air et de contact en tant que levier ou pour tout autre

usage.

6. N'utilisez jamais la sonde de contact afin de diagnostiquer des pannes électriques.

7. Le fait de porter le casque d'écoute risque de nuire à votre capacité d'écouter les

bruits environnants. Soyez toujours sur vos gardes!

Récepteur

d'ultrasons

Émetteur

d'ultrasons

Sonde de contact

Sonde d'air

Casque d'écoute

Page 8

MODE D'EMPLOI

1. Branchez la fiche du casque d'écoute dans la prise située sur le devant du panneau.

2. Insérez la sonde d'air ou la sonde de contact dans la prise du récepteur. Reportezvous au chapitre " Méthodes de balayage typiques et conseils " afin de choisir la

bonne sonde.

3. Tournez le bouton dans le sens des aiguilles d'une montre jusqu'à "ON" (marche) et

attendez que la barre descende jusqu'au bas de l'écran. Augmentez le volume

jusqu'à ce que vous entendiez un bruit de fond (sifflement). Veuillez noter: Le fait

d'augmenter le volume n'augmentera p

as la sensibilité de détection de l'appareil. Le

fait de régler le volume trop haut risque de fatiguer l'utilisateur.

4. Lorsque vous utilisez la sonde d'air, orientez la sonde dans le sens de votre main

libre tout en frottant légèrement votre index et votre pouce l'un contre l'autre à plus

de 60 cm de la sonde. La réponse devrait avoir même son que le bruit du papier de

verre lorsque vous le passez sur du bois. Vous pouvez varier la distance et

augmenter ou réduire le volume en conséquence. Tout en effectuant ces essais,

familiarisez-vous avec la sensibilité directionnelle de la sonde tout en balayant la

sonde devant vos doigts à différentes distances. Si vous utilisez la sonde de contact,

réglez la sensibilité tout en frottant doucement votre doigt le long du bout de la tige.

Méthodes de balayage typiques et conseils

Le détecteur Marksman vous fournit des informations de deux façons : d'une façon qualitative, en vous permettant d' " entendre " la signature ultrasonique produite par les différents types d'équipements et en vous permettant de voir le niveau de réaction sur

l'écran gradué.

Les sondes d'air et de contact sont utilisées afin d'optimiser la réponse audio selon de

type d'inspection. La sonde d'air fonctionne le mieux lorsque vous l'utilisez pour détecter

les ultrasons associés à une fuite de pression ou à une effluve ou décharge par effet

couronne. La sonde de contact fonctionne le mieux lorsqu'elle est utilisée pour détecter

les ultrasons générés à l'intérieur d'un boîtier tel qu'un boîtier d'engrenage, de roulement,

d'une pompe, d'une soupape ou d'un purgeur de vapeur.

PANNES MÉCANIQUES

La photo à droite montre une façon typique d'inspecter une roue présentant un problème

de roulement. Dans ce cas précis, l'utilisateur se sert de la sonde d'air en tournant la

roue tout en écoutant le bruit des roulements. Maintenez le bout de la sonde à 5 ou 7

cm de l'endroit que vous désirez inspecter.

La réponse audio peut parfois être optimisée en retirant

la roue et en utilisant la sonde de contact afin de toucher le moyeu fixe situé au centre. Ceci s'applique également aux carters de moteur et aux roulements du

moteur. Utilisez la sonde de contact de la même

manière afin de vérifier les injecteurs de carburant et

les amortisseurs à ressort. Touchez le bout de la

sonde métallique sur la surface que vous êtes en train

de vérifier. Vous entendrez facilement la différence

entre un appareil qui fonctionne correctement et un

appareil qui présente un problème.

DÉCHARGE PAR EFFET COURONNE

Le dessin à droite indique comment utiliser le détecteur

Marksman afin de détecter un problème électrique en écoutant

la décharge électrique par effet couronne des commutateurs

d'alimentation et des boîtiers des disjoncteurs.

Comme en présence de toute situation potentiellement

dangereuse, faites preuve de précaution. Utilisez la sonde

d'air creuse ou uniquement le récepteur lorsque vous

inspectez un système ou une pièce électrique et veillez à ce

qu'il y ait toujours une distance de sécurité suffisante entre le

bout de la sonde d'air et la surface métallique du panneau. Le

détecteur Marksman est très sensible et peut détecter facilement toute interruption de tension. Les ultrasons générés ont

un son semblable à du " bacon en train de frire ".

FUITES EN PRESSION ET EN DÉPRESSION

Vous pouvez également utiliser le détecteur Marksman pour vérifier les circuits d'air comprimé ou de gaz de toute sorte, les systèmes de freinage pneumatique, les tuyaux et conduites, les installations de chauffage à la vapeur, les conduites d'eau, les rampes à gaz

et tous les systèmes en dépression.

Remarque : La détection par ultrasons se fait en détectant les sons associés à la turbulence du liquide ou du gaz sortant au niveau d'un trou ou d'un orifice et soumis à une

pression différentielle et ceci indépendamment du type de gaz ou de liquide. Le

Marksman détectera immédiatement les fuites d'air ou de vide provoquées par un joint

défectueux, un siège de valve usé ou l'apparition de fissures

dans des tuyaux, des conduites ou des raccords.

SYSTÈMES NON SOUS PRESSION PRÉSENTANT UNE FUITE

Les enceintes et contenants qui ne sont pas sous pression ne peuvent générer d'ultrasons. L'émetteur d'ultrasons fourni sert à émettre un bruit ultrasonique qui sera ensuite

optimisé à la meilleure fréquence pour le récepteur du détecteur Marksman.

Par exemple: les fuites des gaines et conduits de chauffage et de climatisation, de réservoirs, de pare-brises, de bourrelets de calfeutrage et de l'isolation de votre domicile.

1. Mettez en marche l'émetteur et placez-le

dans l'espace clos que vous désirez

vérifier. L'émetteur remplira l'intérieur de

cet espace d'un son très aigu.

Remarque: En raison de sa gamme

ultrasonique, vous le pourrez pas

l'entendre sans utiliser le récepteur.

2. Faites le tour de l'extérieur de cet

espace clos en marchant tout en

effectuant un balayage avec le récepteur autour des zones suspectes. Les zones à

problèmes vous seront révélées par la différence de ton et d'intensité. Vous pourrez

entendre et voir ces différences en écoutant et en regardant les changements au

niveau de l'écran.

Émetteur

Récepteur

Page 9

UTILISER L'ÉCRAN D'AFFICHAGE DEL POUR LOCALISER UNE FUITE

Veuillez noter que la commande de réglage de volume est indépendante de l'écran DEL

lors de l'inspection. Selon la taille de la signature ultrasonique détectée, vous pouvez

utiliser le niveau d'intensité sur l'écran DEL ainsi que le son audible grâce aux casque

d'écoute. Au fur et à mesure que vous vous rapprochez du problème, réduisez le volume.

Au fur et à mesure que le son devient plus fort, répétez l'opération jusqu'à ce que vous

détectiez avec précision la position de la fuite.

POUR USAGE AUT

OMOBILE

FUITE EN DÉPRESSION: Placez la sonde d'air creuse sur l'appareil et écoutez et

regardez l'écran DEL. Vous pouvez localiser facilement et rapidement la position exacte

d'une fuite de vide. Utilisez la sonde d'air creuse ou uniquement le récepteur

.

TROUVER ENFIN CE BRUIT DE MOTEUR QUI VOUS TRACASSE: Le détecteur

Marksman localisera les bruits du moteur et vous permettra de déterminer exactement

leur provenance. Les ultrasons ne peuvent être utilisés au sein des éléments du moteur

en raison de leurs propriétés directives. Utilisez la sonde de cont

act.

CIRCUITS ET SYSTÈMES ÉLECTRIQUES

: L'écartement entre les fils conducteurs des

bougies de haute tension peut être rapidement identifié à partir du claquement émit par

la décharge à effet couronne. Il en va de même en cas d'étincelles au sein des moteurs

électriques et des accessoires. De plus, veuillez écouter avec attention les points de raccordements afin de vérifier si un son de " claquement " ou de " friture " se fait entendre.

Ce son indique une mauvaise connexion lors d'une charge électrique.

Il est recommandé

de tester les circuits lorsqu'ils fonctionnent à pleine charge.

Le détecteur Marksman est idéal pour détecter les courts-circuits. Les courts-circuits

émettent également un son de " claquement " ou de " friture ". Lorsque vous vérifiez qu'il

n'y a pas de courts-circuits ou de problèmes au niveau des connexions, n'oubliez pas de

tester le câblage en le bougeant avec les doigts! Ces problèmes électriques vous

sauteront désormais aux yeux. Économisez du temps ! Utilisez la sonde d'air creuse

ou uniquement le récepteur.

ALLUMAGE

: Écoutez les dispositifs d'allumage actuels et vous pourrez entendre le fonctionnement des bobines et des bougies. Il s'agit en effet de la meilleure manière de diagnostiquer les problèmes pouvant apparaître au niveau des bobines sur bougies. Le

détecteur Marksman fonctionne également parfaitement avec tout allumage électronique

intégral. Vous entendrez dans les écouteurs, le claquement des bougies lors de leur

mise à feu. Si vous avez déjà une certaine 'expérience en matière d'essais de dispositifs d'allumage, vous pouvez déterminer immédiatement s'il s'agit d'un problème de

bougie ou de fil rien qu'au son. Lorsque vous vérifiez un allumage électronique intégral,

assurez-vous de bien écouter les deux extrémités du fil si vous le pouvez. Utilisez la

sonde d'air creuse ou uniquement le récepteur.

SYSTÈMES DE CONTRÔLE DE L'ÉV

APORATION DE CARBURANT

: Il est très facile

de détecter une fuite au sein du système de contrôle de l'évaporation de carburant.

Commencez en mettant en pression le système de contrôle de l'évaporation de carburant (ne pas dépasser la pression recommandée !). À présent, balayez tous les tuyaux

et les éléments du système et écoutez afin de vérifier si un sifflement se fait entendre,

ceci indiquerait qu'il existe une fuite. Après avoir déterminé la zone générale de la fuite,

approchez le récepteur plus près afin de localiser avec précision la source exacte de la

fuite. Utilisez la sonde d'air creuse ou uniquement le récepteur.

INJECTEURS: Placez la sonde de contact sur l'injecteur pour le tester et écoutez

lorsque le moteur tourne. Vous pouvez entendre l'injecteur fonctionner ainsi que l'écoulement du carburant. Il est également recommandé de couper le moteur et d'écouter

afin de vous assurer que l'injecteur ne présente pas une fuite de carburant au-delà des

bouts de l'injecteur. Si le carburant s'écoule, vous entendrez un bruit strident au niveau

des écouteurs. Si l'injecteur est propre et en bon état, vous entendrez une tonalité aigue

avec des claquements alors qu'un injecteur sale aura une tonalité étouffée. Utilisez la

sonde de contact.

SYSTÈMES DE FREINAGE PNEUMA

TIQUE: Le détecteur Marksman peut vous aider

à détecter rapidement des fuites dans les systèmes de freinage hydraulique assisté par

dépression. Dans la plupart des cas, les fuites peuvent être détectées à une distance

importante. Il est souvent possible de détecter la fuite en balayant superficiellement le

véhicule d'un bout à l'autre en utilisant le récepteur une fois que les freins sont complètement sous pression (s'il s'agit de freins à air). Utilisez le casque d'écoute afin de

réduire le bruit ambiant de l'atelier. Si vous ne détectez rien après le premier balayage,

contrôlez toute la tuyauterie du circuit de freins à air en maintenant le récepteur entre 30

et 60 cm de la tuyauterie. Après avoir déterminé la zone générale de la fuite, utilisez la

sonde afin de localiser la fuite avec précision. Pour une efficacité maximum, assurezvous que la pression du système de freinage demeure constante pendant toute la durée

de la recherche. Si vous ne découvrez aucune fuite, vérifiez l'avertisseur sonore pneumatique, l'essuie-glace et tout autre équipement qui fonctionne à l'air comprimé. Les

fuites apparaissant au niveau de ces accessoires risquent de produire une chute anormale de la jauge. Utilisez la sonde d'air creuse ou uniquement le récepteur

.

PNEUS: Essuyez le pneu ainsi que la jante et sa valve afin de rechercher toute fuite.

Balayez le pneu en utilisant le détecteur Marksman afin qu'il puisse détecter la fuite la

plus infime. Le récepteur détectera normalement des fuites avant que leur taille ne vous

fasse perdre du temps au bord de l'autoroute. Vous pouvez également verser une solution savonneuse sur les pneus et vérifier sur des bulles apparaissent. Utilisez la sonde

d'air creuse ou uniquement le récepteur.

SOUP

APES DU MOTEUR

: Toutes les soupapes devraient émettre un son en forme de

vagues très serrées lorsque vous placez la sonde sur la tuyauterie d'admission située

face à l'orifice d'admission. Vous pouvez détecter avec certitude une soupape suspecte

en coupant le moteur, en veillant à ce que la soupape soit à pleine compression et en

plaçant la sonde sur la queue de soupape. Vous entendrez parfaitement un sifflement

indiquant qu'il existe une fuite de gaz au niveau du siège de la soupape. Utilisez la même

méthode afin de vérifier les soupapes d'échappement mais attendez-vous à ce que l'intensité du signal soit beaucoup plus forte. Utilisez la sonde de cont

act.

SYSTÈMES D'ÉCHAPPEMENT

: Avec le moteur au ralenti, vous pourrez détecter toute

pulsation au niveau du système d'échappement en utilisant le récepteur. Les fuites

auront normalement un son beaucoup plus fort et beaucoup plus aigu. Utilisez la sonde

d'air creuse ou uniquement le récepteur.

Page 10

JOINTS DE POR

TIÈRE ET DE FENÊTRE, CALFEUTRAGE DE CARROSSERIE, JOINTS

D'ÉT ANCHÉITÉ DE PORTE ET DE COFFRE, RÉSERVOIRS DE CARBURANT :

Lorsque vous placez l'émetteur à l'intérieur d'un véhicule,

d'un réservoir ou de tout autre

espace clos, l'émetteur pourra facilement localiser toute

fuite présente dans le calfeutrage de la carrosserie, dans

les joints ou dans la structure

elle-même. Utilisez la sonde d'air creuse ou uniquement le récepteur

.

AUTRES USAGES

:

SYSTÈMES HYDRAULIQUES: Il s'avère parfois difficile et coûteux de détecter une

valve partiellement obstruée ou qui ne fonctionne pas au sein des circuits hydrauliques

à haute pression en utilisant les méthodes classiques. En raison des hautes pressions

auxquelles sont soumis les circuits hydrauliques, l'intensité du son ultrasonique émit par

la fuite interne est extrêmement élevé et pourra être facilement détecter par le récepteur.

Il vous est possible d' utiliser la sonde d'air creuse, la sonde de cont

act ou unique-

ment le récepteur.

T

OITS, FENÊTRES OU POR

TES PRÉSENT ANT UNE FUITE

: Placez l'émetteur sous la

zone suspecte. Vérifiez la zone suspecte du toit en utilisant le récepteur afin de localiser

avec précision l'origine de la fuite. Ceci vous aidera également pour toute fuite dans la

même zone. Utilisez la sonde d'air creuse ou uniquement le récepteur. (Voir dessins

ci-dessous)

Émetteur

Récepteur

Émetteur

Récepteur

CARACTÉRISTIQUES TECHNIQUES

Dimensions: Largeur: 10,2 cm

Pronfondeur: 3,8 cm

Longueur: 15,2 cm

Poids: 1,4 kg

Boîtier: ABS résistant aux produits

chimiques avec étui en caoutchouc

Durée de vie de la pile: Environ 20 heures

Tension: 9 volts, standard

Consommation: 26 mA, typique

Réponse en fréquence: De 36 000 à 44 000Hz

Circuits: À semi-conducteurs

Casque d'écoute: Avec atténuation de bruit

Connecteur du casque: Fiche de 3,5 mm

Plage de température

de fonctionnement: De +10° à +60° Celsius

Page 11

Spanish

¡No oye lo que necesita oir!

Manual del

Operador

La herramienta ultrasónica de diagnóstico Marksman™ convierte y amplifica el sonido

ultrasónico inaudible en sonido "natural" audible. Opera con base en el principio de

detección de las ondas ultrasónicas de alta frecuencia, que se crean por la fricción de

toda parte en movimiento, bien sean sólida, líquida o gaseosa. Estos "sonidos" se

encuentran muy por encima del rango de frecuencia que capta el oído humano y tienden a ser altamente direccionales.

Este aspecto direccional de las ondas ultrasónicas, permite aislar un sonido sospechoso, con señal que lo identifica y del cual se sospecha, de otros ruidos de fondo y

detectar su ubicación exacta. Este análisis de sonido se puede usar para investigar de

manera eficiente cinco áreas principales de reparación y mantenimiento preventivo en

toda aplicación industrial y de transporte

1) Fugas de Aire

Las fugas de aire, tanto al vacío como comprimido, crean un paquete de energía o

frente de onda que puede producir una emisión ultrasónica con discriminación de presión de hasta 1 psi o de perforación de hasta 0,127 mm.

2) Turbulencia gaseosa y líquida

La turbulencia asociada con fugas en las trampas de vapor y en las válvulas internas,

o la producida por cavitación u obstrucciones en las líneas de líquidos o gases.

3) Descarga eléctrica

La descarga eléctrica asociada a falla del aislamiento, trochas de deterioro en aislantes

sólidos, corona eléctrica y arco eléctrico

4) Desgaste mecánico

Estado del desgaste mecánico en conjuntos de cojinetes y anillos, ejes y engranajes

(indicando también su estado de lubricación).

5) Generación de sonido

Se puede usar junto con generadores de sonido para detector grietas y sellos en contenedores, sellos de puertas y compartimentos. (El emisor ultrasónico Marksman está

diseñado para trabajar con el receptor Marksman).

Existe la necesidad de evaluar los dispositivos y sistemas mecánicos, con el propósito

de determinar el comienzo de su falla. Prácticamente, la falla de un componente dentro

de un mecanismo grande, no solamente afecta el componente mismo, sino que también puede causar gran destrucción en todo el sistema. Por lo tanto, la necesidad de

predecir tal falla es incluso de mayor importancia.

Las fallas, malos funcionamientos, o deficiencias en dispositivos mecánicos, eléctricos

y neumáticos, así como también en objetos tipo contenedor o recipiente, empiezan

como pequeños defectos o fugas. El tamaño físico de estos defectos es tan relativamente pequeño que los sonidos que producen están por encima del rango de la audición humana. Muy comúnmente, estas fallas generan sonidos dentro del rango de

38.000 y 43.000 ciclos por segundo, al que generalmente se define como rango

ultrasónico.

Para emplear la metodología ultrasónica de manera usable, es imperativo que quien

escucha esté en capacidad de acceder a un sonido audible que revele un parecido con

el sonido natural del defecto. Un cojinete mecánico con una esfera defectuosa sonará

como tal. Igualmente, una fuga microscópica en un sistema de aire comprimido,

deberá sonar como una fuga de gas. El simple hecho de convertir las frecuencias

ultrasónicas en frecuencias audibles, no es suficiente para producir una señal

que se pueda usar. Es por esta razón que Marksman incorpora un proceso mediante el cual la señal audible se asemeja al sonido natural que el defecto produce.

A este proceso lo llamamos "Tecnología de Señal de Sonido", mediante el cual una

fuga de gas suena como una fuga de gas, y un cojinete defectuoso suena como tal.

El Marksman usa una tecnología llamada de conversión heterodina para convertir el

rango ultrasónico en rango audible. El Marksman no se ve afectado por los sonidos

normales tales como viento, voces o tráfico, que pueden dificultar aún más la capacidad del técnico para escuchar un problema potencial. El Marksman también incorpora

un AGC (control de ganancia automática), que permite estudiar los sonidos ultrasónicos asociados con el chillido estridente de una fuga en una válvula, hasta literalmente

un parpadear de ojos. Con el AGC no hay necesidad de interruptores de alta y baja

sensibilidad, porque el sistema de circuitos internos automáticamente busca el nivel

óptimo de ganancia para la situación dada. Esto permite la recepción y ajuste inmediatos del Marksman, sin tener que manejar perillas para buscar las graduaciones correctas.

Configuraciones y Componentes del Kit

Kit Maestro –– Contiene:

1. El receptor ultrasónico Marksman. Es una unidad fácil de usar que incorpora

retroalimentación de audio y un indicador LED de 10 barras para mostrar la

intensidad de la señal. El receptor tiene un puerto receptor direccional de 5 cm,

permanentemente fijo, un puerto de receptáculo estéreo de

3.5 mm, y un interruptor giratorio de control de volumen para encender y apagar.

2. Dos sondas anodizadas: una sonda de aire de 30 cm y una sonda de precisión, de

contacto por longitud.

3. Un juego de audífonos de tamaño normal, con un enchufe estéreo de 3.5 mm.

4. Un maletín fuerte con espuma formada a los componentes, para almacenamiento

y transporte.

5. Un emisor ultrasónico que envía un pulso de 40 Khz., para ser usado en la prueba

de integridad de sellos en contenedores o recipientes no presurizados.

6. Dos pilas de 9 voltios.

Page 12

POR FAVOR TENGA EN CUENTA: El kit de equipo receptor únicamente de Marksman

también se ofrece, el cual contiene todo lo que el Kit Maestro incluye con excepción

del emisor ultrasónico.

Emisor Ultrasónico

El emisor emite una salida ululante centrada en 40 Khz. Esta salida no la puede

escuchar el oído humano. Si el indicador rojo está encendido, la unidad está emitiendo.

Sondas de Aire y de Contacto

Las sondas de aire y contacto son partes de precisión, diseñadas para optimizar la

respuesta del receptor Marksman. La sonda de aire de 30 cm extiende su alcance y

aísla una fuga entre múltiples áreas sospechosas. No modifique las sondas de manera

alguna y nunca les de un uso diferente al descrito en este manual.

Pilas

Se prefieren las pilas de zinc o alcalinas. Para reemplazar la pila en el receptor,

primero hay que retirar el manguito protector de caucho. Es más fácil retirar el manguito protector cuando está caliente porque es más flexible. Para retirarlo, presione el

borde del fondo del manguito, sacándolo del compartimiento interior y hale el compartimiento hacia fuera. Por favor fíjese en la polaridad. Vuelva a colocar el manguito siguiendo el procedimiento anterior a la inversa. Cuando cambie la pila del emisor, tenga

cuidado de no estirar ni pinchar los alambres. Siempre retire la pila cuando vaya a

almacenar la unidad por tiempo prolongado. Igualmente, descarte las pilas de

acuerdo con las instrucciones de las leyes locales.

SUGERENCIAS IMPORTANTES

Aberturas en los Puertos Receptor y Emisor

Las aberturas de los puertos del receptor y el emisor contienen el núcleo fundamental de

la operación del Marksman: un transductor de precisión. Durante el uso, proteja la unidad

contra todo material extraño que pueda entrar por estas áreas.

Calibración

El Marksman ha sido óptimamente sintonizado en nuestra fábrica y no deberá requerir

nueva calibración durante su vida útil, bajo condiciones normales.

Pantalla LED

La pantalla LED le permite a usted enfocar una fuente de condición estable de sonido

ultrasónico, tal como cuando se localiza una fuga de aire a presión o al vacío, o cuando

se usa el emisor. Simplemente observe cuando se elevan o caen los niveles de la barra

indicadora, lo cual localiza precisamente la fuente del problema.

Misceláneas

Para prolongar la vida de la pila, apague el Marksman cuando no lo tenga en uso, evite

al manejo rudo, y manténgalo protegido contra los elementos. Use el maletín para proteger y transportar la unidad.

Precauciones de Seguridad

Aunque el Marksman le permite concentrar su atención en el diagnóstico de un

problema de manera rápida y efectiva, nunca desatienda lo que lo rodea.

1. Recuerde siempre que el Marksman y las sondas son una extensión de su mano.

Mantenga las sondas y sus manos a una distancia segura de las partes móviles y

de las áreas eléctricas.

2. Nunca se extralimite y fíjese donde se para, de manera que no pierda el equilibrio

cuando esté usando el Marksman.

3. Manténgase a una distancia adecuada de las partes eléctricas y móviles.

4. Esté siempre alerta del cordón de los audífonos cuando se acerque a partes

móviles.

5. Nunca use las sondas de aire o de contacto como palanca, barra de apalan

camiento u otros propósitos para los cuales no se han diseñado.

6. Nunca use la sonda de contacto para diagnosticar problemas eléctricos.

7. El uso de los audífonos obstaculiza su habilidad para escuchar los ruidos que lo

rodean, –– ¡Esté siempre alerta!

INSTRUCCIONES DE OPERACIÓN

1. Enchufe el conector del audífono en el receptáculo localizado en la cara del panel.

2. Enrosque la sonda de aire o de contacto dentro del puerto receptor. Refiérase a la

sección "Métodos / Consejos Típicos de Escudriñamiento", para la óptima

escogencia de sonda.

3. Gire la perilla en el sentido de las manecillas del reloj hasta "ON" (encendido) y

observe hasta que la barra LED se detenga en la posición inferior. Suba el

Receptor

Ultrasónico

Emisor

Ultrasónico

Sonda de Contacto

Sonda de Aire

Audífonos

Page 13

volumen hasta que apenas pueda escuchar el ruido de fondo (siseo). Por favor

note: El aumento de volumen no aumenta la sensibilidad de detección de la

unidad. Graduar el volumen demasiado alto puede hacer que el operador se

fatigue.

4. Cuando use la sonda de aire, diríjala en la dirección de su mano libre mientras

frota ligeramente su dedo índice contra su dedo pulgar a una distancia de 2 pies o

más. La respuesta deberá ser el sonido de papel de lija sobre madera. Usted

puede variar la distancia y aumentar / disminuir el nivel del volumen en concordancia.

Mientras realiza esta función, familiarícese con la sensibilidad direccional de la

sonda mientras barre con la sonda más allá de sus dedos a diversas distancias. Si

usa la sonda de contacto, ajuste la sensibilidad mientras frota ligeramente su dedo

a lo largo de la punta de la varilla.

Exploración Típica - Métodos y Sugerencias

El Marksman suministra información de dos maneras: cualitativamente, a través de su

habilidad para "oír" los ultra sonidos, de señal característica, emitidos por varias clases

de equipos, y su capacidad para mostrar el nivel de retroalimentación en una barra graduada LED.

Las sondas de aire y de contacto se usan para optimizar la respuesta de acuerdo con el

tipo de inspección. La sonda de aire se usa mejor para detectar los sonidos ultrasónicos

asociados con una fuga de presión o una corona eléctrica, mientras que la sonda de contacto es la más apropiada para determinar los sonidos ultrasónicos generados desde

dentro de una carcasa, tal como en un engranaje, un cojinete, una bomba, o una válvula, o dentro del cuerpo de una trampa de vapor.

DESPERFECTOS MECÁNICOS

La fotografía de la derecha muestra la forma típica de inspeccionar un problema potencial en el cojinete de una rueda. En este caso, la sonda de aire se usa mientras se hace

girar la rueda y se espera escuchar el sonido de los

cojinetes. La punta de la sonda se mantiene a una distancia de 5 a 7 cm del área de inspección. Algunas

veces la respuesta se puede optimizar removiendo la

rueda y usando la sonda de contacto para tocar el

cubo estacionario del centro. Este procedimiento también es aplicable a la inspección de carcasa de

motores, lo mismo que a la verificación de los cojinetes

del motor. La sonda de contacto también se usa de la

misma manera para investigar inyectores de combustible y bobinas sobre sistemas de suspensión. Con

la punta de la sonda metálica toque el área de la

superficie que se está probando. La operación correcta suena en una forma. El mal funcionamiento suena

en forma muy distinta. Usted oirá fácilmente la diferencia.

DESCARGA DE LA CORONA ELÉCTRICA

A la derecha se ve una aplicación típica usando el Marksman

para detector posibles malos funcionamientos eléctricos,

escuchando la descarga de la corona eléctrica asociada con

los interruptores de corriente y cajas de disyuntor de circuito.

Como en todas las situaciones potencialmente peligrosas, se debe actuar con precaución. Use la sonda

hueca de aire o use el receptor únicamente cuando inspec-

cione condiciones eléctricas y mantenga siempre una distancia de seguridad entre la punta de la sonda de aire y las

superficies metálicas del panel. El Marksman es altamente

sensible para detectar fallas de voltaje. El sonido ultrasónico

resultante se ha descrito como el de "freír tocineta".

FUGAS PRESURIZADAS Y AL VACÍO

Las aplicaciones para las inspecciones de mecanismos de tipo presurizado son infinitas

e incluyen: aire o gas comprimido de cualquier tipo, sistemas de frenos de aire, tuberías,

sistemas de vapor, líneas de agua, distribuidores, así como también todos los sistemas

similares pero al vacío. Nota: La detección ultrasónica se basa en la detección de

sonidos asociados con la turbulencia del fluido o gas saliendo de un hueco u orificio bajo

una presión diferente. Esto es independiente del tipo de gas o fluido. El Marksman detectará rápidamente las fugas de aire o vacío, típicamente causadas por malos empaques,

asientos o sellos gastados de válvulas y rajaduras en tubos, mangueras, acoples o

conexiones.

FUGAS NO PRESURIZADAS

Los recipientes o contenedores no presurizados no pueden generar sonidos ultrasónicos. El emisor ultrasónico que se ofrece se usa para emitir un sonido ultrasónico optimizado para la respuesta de frecuencia del receptor Marksman. Algunos ejemplos de su

utilización son: la detección de fugas en los conductos y tubos de sistemas de calentamiento o enfriamiento, integridad de tanques, parabrisas de vehículos, masillas o

burletes y en el cerramiento hermético de la casa.

1. Encienda el emisor y colóquelo dentro del ambiente cerrado que se va a evaluar.

El emisor llenará el interior con un sonido

de trino muy agudo. Nota: Como lo

emitido está en el rango ultrasónico, usted

no lo oirá sin usar el receptor.

2. Camine alrededor del exterior del ambiente

cerrado mientras recorre con el

receptor alrededor de las áreas sospe

chosas. Las áreas comprometidas se

revelarán con el cambio de tono e

intensidad, tanto audible como visual, al

escuchar en los audífonos y observar los cambios en la pantalla LED.

Emisor

Receptor

Page 14

USO DE LA PANTALLA LED PARA LOCALIZAR FUGAS

Por favor tenga en cuenta durante la inspección que el control de volumen es independiente de la pantalla LED. Dependiendo de la cantidad de señal ultrasónica que se

está detectando, usted puede usar tanto el nivel de intensidad en la pantalla LED,

como el volumen audible del sonido a través de los audífonos. Amedida que usted se

acerca al problema, (y el sonido aumenta) reduzca el volumen, y vaya repitiendo el

proceso hasta que haya definido apropiadamente la ubicación del problema.

APLICACIONES EN VEHÍCULOS

FUGAS EN VACÍO: Coloque la sonda hueca de aire en la unidad y escuche y observe

la pantalla de LED. Usted puede identificar la ubicación de las fugas en vacío rápida y

fácilmente. Use la sonda hueca de aire o use el receptor solamente.

ENCUENTRE ESE RUIDO EN EL MOTOR: El Marksman localizará esos ruidos del

motor y le permitirá encontrar de dónde provienen realmente. El sonido ultrasónico no

se transfiere dentro de los componentes del motor debido a las características direccionales del sonido ultrasónico. Use la sonda de cont

acto sólido.

SISTEMAS ELECTRICOS: Las separaciones en conductores de cable de alta tensión

para bujías se pueden identificar rápidamente con base en el sonido emitido "de

chasquido o ruido seco" de la descarga de la corona. Lo mismo se aplica al arco eléctrico dentro de motores o accesorios eléctricos. Igualmente, escuche en los puntos de

conexión el sonido "de chasquido" o "de freír tocineta"; este es el sonido que hace una

conexión defectuosa bajo carga eléctrica

. Los circuitos se prueban mejor bajo

operación y carga completa.

La unidad Marksman también es excelente para localizar cortocircuitos. Los cortocir-

cuitos también producen un sonido "de freír" o "de chasquear". Cuando esté buscando

cortocircuitos o problemas de conexión, ¡no olvide mover el alambrado! Ahora los problemas eléctricos lo llamarán a usted. ¡Ahorre tiempo! Use la sonda hueca de aire o

use el receptor solamente.

SISTEMAS DE ENCENDIDO: Escuche los sistemas modernos de encendido. Usted

puede oír las bobinas y las bujías encendiendo. Este es el método mejor y más rápido

de diagnóstico para los sistemas de "Bobina Sobre Bujía". También funciona muy bien

en los Sistemas de Encendido sin Distribuidor (DIS). Usted oirá en el receptor el

"chasquido" de las bujías encendiendo. Una vez que haya adquirido alguna experiencia probando sistemas de encendido, con el sonido únicamente usted podrá determinar

si tiene algún problema en la bujía o en el cable. Cuando revise los sistemas DIS,

asegúrese de escuchar, si es posible, los dos extremos del cable. Use la sonda de

cont

acto sólido o use el receptor solamente.

SISTEMAS de EVAPORACION: Es fácil buscar fugas en los sistemas de emisiones de

evaporación. Inicie la operación presurizando el sistema de Evaporación (¡pero sin

exceder la presión recomendada!). Ahora, recorra, "barriendo", todas las mangueras y

componentes del sistema y escuche si hay algún sonido de "siseo" que pueda indicar

una fuga. Una vez que se ha determinado el área general de la fuga, acérquese con el

receptor para identificar la fuente exacta de la fuga. Use la sonda hueca de aire o el

receptor solamente.

INYECT

ORES

: Coloque la sonda de contacto sólido sobre el inyector que desea probar y escuche con el motor en marcha. Usted puede oír el inyector funcionando y

además oír el flujo de combustible. Es posible que usted también desee apagar el

motor y escuchar para asegurarse de que el inyector no está dejando salir el combustible después de las boquillas del inyector. Si el combustible está fluyendo, esto

creará un sonido de chorro en los audífonos. Un buen inyector limpio producirá un tono

agudo de clic timbrando, mientras que un inyector sucio tendrá un tono de clic amortiguado. Use la sonda de cont

acto sólido.

SISTEMAS DE FRENOS DE AIRE: El detector Marksman puede ayudar a localizar

fugas rápidamente tanto en sistemas de frenos de aire como en los asistidos por vacío.

En muchos casos, las fugas se pueden detectar desde una distancia considerable.

Después de lograr una presión total (en el caso de frenos de aire), un barrido casual

del vehículo de un extremo al otro, usando el receptor puede con frecuencia ser suficiente para localizar la fuga. El uso de los audífonos reducirá la interferencia de ruido

proveniente del taller. Si la primera barrida no localiza la fuga, rastree de cerca (de uno

a dos pies de distancia) toda la tubería del sistema de aire, usando el receptor. Una

vez que se ha determinado el área general de la fuga, la sonda receptora es muy útil

para identificar la localización exacta de la fuga. Para máxima efectividad, asegúrese

de mantener la presión en el sistema de frenos durante toda la exploración. Si no descubre fugas, revise el claxon de aire, el limpiador de parabrisas y demás equipos movidos por aire. Las fugas en estos accesorios pueden producir una caída anormal del

medidor. Use la sonda hueca de aire o use solamente el receptor

.

LLANTAS: Barra la llanta, incluyendo el aro y el sistema de válvulas para buscar las

fugas. Un barrido con el receptor Marksman localizará incluso la más pequeña de las

fugas. El receptor normalmente encuentra fugas de suficiente magnitud antes de que

causen demoras en la autopista. Además, usted puede poner solución de jabón en las

llantas y escuchar si se detecta el estallido de las burbujas. Use la sonda hueca de aire

o solamente el receptor.

VÁL

VULAS DEL MOTOR CON FUGA

: Todas las válvulas deben emitir un sonido dentro de un patrón muy cercano de medición y sonido cuando la sonda se coloca en el

múltiple o distribuidor de entrada opuesto al puerto de entrada. Una válvula sospechosa puede entonces revisarse positivamente, con el motor apagado, llevando tal

cilindro particular a compresión total y colocando la sonda en vástago de la válvula. El

"siseo" del gas escapando a través del asiento de la válvula será claramente audible

en la válvula con fuga. Usando el mismo procedimiento se pueden revisar las válvulas

de salida, sin embargo, la intensidad de la señal será mucho mayor. Use la sonda sól

-

ida de contacto.

SISTEMAS DE ESCAPE: Con el motor marchando en neutro, la pulsación del sistema

de escape se puede detectar con el receptor. Los puntos de fuga normalmente producen un sonido más alto y agudo. Use la sonda hueca de aire o solamente el

receptor.

Page 15

EMP

AQUES DE PUERTAS Y VENTANAS, BURLETES DE CARROCERIA, SELLOS DE

PUERTAS Y BAULES, Y DE TANQUES DE COMBUSTIBLE: Cuando el emisor se colo-

ca dentro de un vehículo, en un tanque de combustible completamente vacío o en

cualquier otro espacio cerrado, el emisor puede localizar

fácilmente fugas en los

burletes, sellos o en la estructura misma. Use la sonda

hueca de aire o solamente

el receptor.

APLICACIONES ADICIONALES:

SISTEMAS HIDRÁULICOS

: Puede ser difícil y costoso encontrar válvulas parcialmente

obstruidas o inoperantes en sistemas hidráulicos de alta presión, usando métodos convencionales. Como los sistemas hidráulicos emplean presiones muy altas, la intensidad

del sonido ultrasónico producido por una fuga interna es extremadamente alta y fácilmente es detectada por el receptor. Use la sonda hueca de aire, la sonda de con

-

t

acto sólido, o use el receptor solamente.

FUGAS DE AGUA

EN TECHOS, VENTANAS O PUERTAS:

Coloque el emisor activado

por debajo del área sospechosa de fuga. Revise la parte sospechosa del techo con el

receptor, para aislar el sitio donde la fuga se origina. Esto también ayudará en la detección de cualquier otra fuga en el área. Use la sonda hueca de aire o solamente el

receptor.(Vea las figuras a continuación)

Emisor

Receptor

Emisor

Receptor

ESPECIFICACIONES TÉCNICAS

Dimensiones: Ancho : 10,2 cm

Profundidad: 3,8 cm

Longitud: 15,2 cm

Peso: 1,4 kg

Carcasa: ABS resistente a productos quími

cos con manguito de caucho

protector

Vida de la pila: Environ 20 heures

Requisito de energía: 9 voltios estándar

Consumo de energía: 26 mA, por lo general

Respuesta de frecuencia: De 36 000 a 44 000Hz

Circuitos: Estado sólido

Casque d'écoute: Avec atténuation de bruit

Audífonos: Enchufe de 3,5 mm

Temperatura de

funcionamiento: De +10 a +60° Celsius

Page 16

German

Was Sie nicht hören können,

ist was Sie hören müssen

!

Bedienungsanleitung

Das Marksman™ Ultraschalldiagnosegerät wandelt und verstärkt unhörbaren

Ultraschall in hörbaren "natürlichen" Klang um. Es basiert auf dem Prinzip, dass von

allen beweglichen Teilen, sei es in fester, flüssiger oder gasförmiger Form, hoch frequente Ultraschallwellen festgestellt werden können. Diese "Klänge" befinden sich weit

jenseits des Hörbereichs des menschlichen Ohrs und neigen dazu, stark gerichtet zu

sein.

Dieses Richtungsverhalten der Ultraschallwellen ermöglicht es, eine verdächtige

Klangsignatur von anderen Hintergrundgeräuschen zu isolieren und deren genauen

Ursprungsort aufzuspüren. Diese Klanganalyse kann dazu verwendet werden, effizient

fünf Hauptanliegen für Reparaturen und Präventivwartung in allen T ransportwesens- und

Industrieapplikationen zu untersuchen.

1) Luftlecks

Sowohl Unterdruck- als auch Überdruckluftlecks erzeugen ein Energiepaket bzw. eine

Wellenfront, die eine Ultraschallemission mit einem Differenzwert von 1 psi bzw. einem

Loch bis zu 0,127 mm führen können.

2) Turbulenzen in Gasen und Flüssigkeiten

Turbulenzen, die mit Lecks an Kondenswasserabscheidern und Innenhülsen, Kavitation

und Blockaden in Flüssigkeits- und Luft-/Gasleitungen im Zusammenhang stehen.

3) Elektrisch Entladungen

Elektrische Entladungen, die mit Isolationsdurchschlag, Kriechstrom, Koronaentladung

und Lichtbogenbildung zusammenhängen.

4) Mechanische Abnutzung

Zustand der mechanischen Abnutzung in Lagern und Wälzringen, Wellen und Getrieben

(wobei auch der Schmierzustand angezeigt wird).

5) Tonerzeuger

Kann im Zusammenspiel mit Tonerzeugern dazu verwendet werden, um Brüche an

Behältern und Dichtungen, Türdichtungen und Abteilen zu erkennen. (Passend zum

Marksman Ultraschallerzeuger gibt es den Marksman-Empfänger).

Es besteht die Notwendigkeit, mechanische Geräte bzw. Systeme daraufhin zu überprüfen, ob deren Versagen bevorsteht. Aus praktischen Gründen wird der Ausfall einer

Komponente innerhalb eines größeren Gerätes nicht nur auf die Komponente selbst

bezogen, sondern auch auf die Zerstörung, die sie am Gesamtmechanismus anrichten

kann. Aus diesem Grund ist die Notwendigkeit, einen solchen Ausfall voraussagen zu

könne, von umso größerer Bedeutung.

Fehler und Fehlfunktionen bzw. Mängel in mechanischen, elektrischen und pneumatischen Geräten sowie in behältnisartigen Objekten fangen als kleine Defekte oder Lecks

an. Auf Grund der relativ geringen physischen Größe dieser Defekte liegen die von ihnen

verursachten Klänge in einem Bereich jenseits des menschlichen Hörvermögens. In den

meisten Fällen verursachen diese Fehler Geräusche im Frequenzbereich von 38-43 kHz,

der allgemein als Ultraschallbereich bezeichnet wird.

Um die Ultraschallmethode sinnvoll anwenden zu können, ist es äußerst wichtig, dass

der Horcher Zugriff auf eine hörbaren Klang hat, der dem natürlichen Klang des Defektes

ähnelt. Ein mechanisches Lager, das eine defekte Kugel hat, sollte sich auch so

anhören. Ähnliches gilt für ein mikroskopisches Leck in einem Druckluftsystem, das sich

wie ein Gasleck anhören sollte. Die bloße Umwandlung der Ultraschallfrequenzen in

hörbare Frequenzen reicht in Bezug auf die Erzeugung eines brauchbaren Signals

nicht aus. Aus diesem Grund hat Marksman eine Verfahrensweise implementiert,

bei der das hörbare Signal große Ähnlichkeit mit dem natürlichen, eingehenden

Befund hat. Wir nennen dieses Verfahren "Klangsignaturtechnologie", wobei sich ein

Gasleck wie ein Gasleck anhört und ein defektes Lager auch entsprechend klingt.

Das Marksman verwendet eine als Überlagerung (Heterodyning) bekannte Technologie,

um das Ultraschallspektrum in den hörbaren Bereich zu verlagern. Das Marksman wird

nicht von tagtäglichen Geräuschen wie zum Beispiel Wind, Stimmen und Verkehr beeinflusst, die sonst zusätzliche Auswirkungen auf die Fähigkeit des Technikers haben, nach

potentiellen Problemen zu lauschen. Das Marksman ist mit automatischer

Pegelanpassung (AGC - Automatic Gain Control) ausgestattet, die es dem Benutzer

erlaubt Ultraschallgeräusche, vom starken Tosen eines lecken Ventils bis hinunter zum

buchstäblichen Augenschlag zu untersuchen. Mit AGC besteht kein Bedarf mehr an

Schaltern für hohe/niedrige Empfindlichkeit, da die internen Schaltkreise automatisch

nach dem optimalen Verstärkungsgrad für die jeweils gegeben Situation suchen. Damit

ist es letztendlich möglich, das Marksman zur Hand zu nehmen und sofort die Situation

zu erkennen, ohne lange mit diversen Reglern herumhantieren zu müssen, um die

passenden Einstellungen zu finden.

Kitkonfigurationen und -komponenten

Master-Kit –– enthält:

1. Den Marksman Ultraschallempfänger. Ein einfach zu bedienendes Gerät, das

Audio-Feedback liefert und über eine LED-Leiste mit 10 Positionen die

Signalstärke anzeigt. Der Empfänger hat einen Anschluss für einen permanenten,

fest installierten 2-Zoll-Richtempfänger, einen Anschluss für einen 3,5 mm StereoKlinkenstecker und einen Ein-/Aus-Lautstärkenregelungsdrehschalter.

2. Zwei eloxierte Sonden: eine 12-Zoll Luftsonde und eine

Präzisionsstabkontaktsonde.

3. Ein normal-großer Kopfhörer mit 3,5 mm Stereoklinkenstecker.

4. Ein widerstandsfähiger Tragekoffer mit vorgeformten Schaumstoffeinlagen für

Lagerung und Transport.

5. Der Ultraschallemitter. Er strahlt ein einen 40 kHz-Puls aus, der zum Testen der

Integrität von Dichtungen in nicht unter Druck stehenden Behältern.

6. Zwei 9-Volt-Batterien.

Page 17

BITTE BEACHTEN: Das Marksman Solo-Empfänger-Kit ist auch erhältlich; es enthält

alles, was im Master-Kit enthalten ist, außer dem Ultraschallemitter.

Ultraschallemitter

Der Emitter gibt ein um 40 kHz gemitteltes Wobbelsignal ab. Das Signal ist vom menschlichen Ohr nicht wahrnehmbar. Wenn die rote Anzeige an ist, gibt das Gerät ein

Signal ab.

Luft- und Kontaktsonden

Die Luft- und Kontaktsonden sind Präzisionsteile, die darauf ausgelegt worden sind, die

Ansprechcharakteristik des Marksman-Empfängers zu optimieren. Die 12-Zoll-Luftsonde

vergrößert die Reichweite und hilft dabei, ein Leck aus der Menge der verdächtigen

Bereiche zu isolieren. Die Sonden dürfen in keinster Weise modifiziert werden und sind

gemäß der in diesem Handbuch beschriebenen Vorgaben

einzusetzen.

Batterien

Vorzugsweise sind Zink- oder Alkalibatterien einzusetzen. Um die Batterie im Empfänger

auszutauschen, muss zuerst die schützende Gummikappe abgenommen werden. Die

Gummikappe lässt sich warm leichter abnehmen, da sie dann flexibler ist. Zum

Abnehmen schieben Sie bitte die untere Ecke der Gummikappe vom Innengehäuse ab

und ziehen Sie das Gehäuse heraus. Achten Sie bitte auf die Polarität. Bringen Sie die

Gummikappe wieder entsprechend an. Lassen Sie beim Austausch der Batterie des

Emitters bitte Vorsicht walten, so dass Sie nicht versehentlich an dessen Verkabelung

ziehen oder diese einklemmen. Die Batterie ist bei längerfristiger Lagerung immer zu

entfernen. Beachten Sie bei der Entsorgung der Batterien bitte Ihre örtliche

Gesetzgebung.

WICHTIGE TIPPS

Empfänger- und Emitteranschlussöffnungen

Die Anschlussöffnungen des Empfängers und Emitters stellen den Kontakt zum Herzen

des Marksman-Betriebs her, einem Präzisionstransducer. Während des Einsatzes ist

unbedingt darauf zu achten, dass keine Fremdstoffe in diese Bereiche eintreten.

Kalibrierung

Das Marksman ist ab Werk optimal eingestellt, so dass eine Rekalibrierung unter normalen Bedingungen im Rahmen seiner Lebenserwartung nicht erforderlich sein sollte.

LED-Anzeige