Page 1

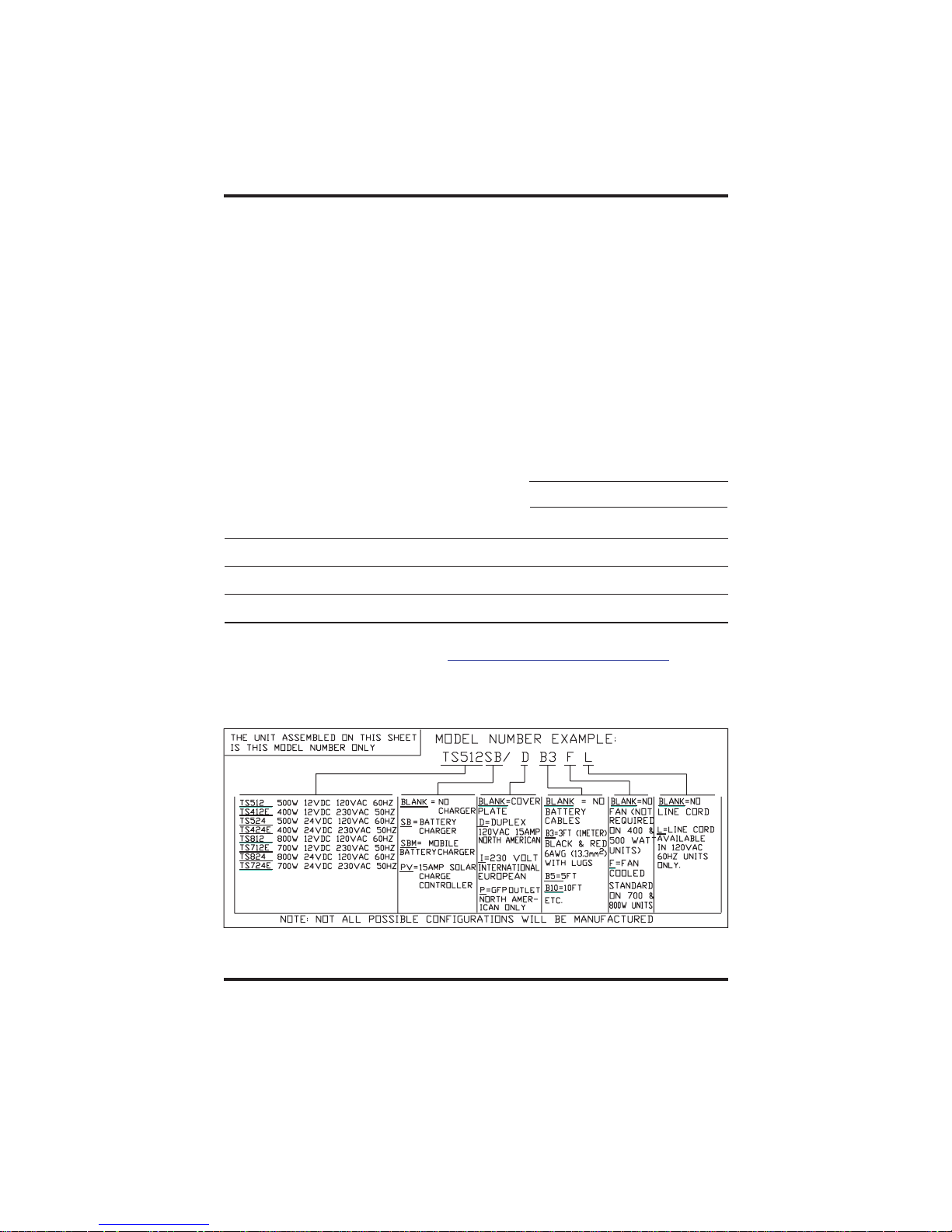

TS SeriesTS

Introducing the TS Series Inverter

The Model TS Series microprocessor-controlled modified sinewave inverter converts DC

current into AC current. Rated at 400 to 800 watts continuous. Features include:

!

Power-saving Search mode

!

Easy installation

!

Battery voltage indicator

!

15-amp AC pass-thru circuit

!

User selectable low battery cutoff (LBCO)

!

Automatic transfer to inverter mode when AC supply is interrupted (with SB

option).

!

User selectable transfer sensitivity (with SB Option)

!

Optional dual 15-amp grounded AC outlet

!

Optional plug-in three-stage battery charger

!

Optional remote control

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

1

Page 2

Product Materials Package

Thank you for choosing Trace Engineering products to

meet your alternative-energy power needs. We make every

effort to ensure that your inverter/charger is properly

packaged for shipping and includes all the materials

requested. Every Trace inverter/charger is packaged with

the following materials:

Owner's Manual;

!

Trace bumper sticker;

!

If any of the above listed materials are missing from your

package, or if it is unsatisfactory in any manner, please

call Customer Service at 360-435-8826 or fax this page

with your comments to 360-435-2229.

Model Number:

Serial Number:

Comments:

Check out our web site at for

www.traceengineering.com

more information and answers to your FAQ's.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This booklet contains important instructions for Model TS Series that should be followed

during installation and maintenance of the unit.

General Precautions

Before using this device, read all instructions and cautionary markings on (a) the device,

(b) the batteries and (C) all appropriate sections of this instruction booklet. Refer to the

Battery Council International for installation and servicing instructions for batteries.

CAUTION - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead

calcium, gel cell, or absorbed-mat type rechargeable batteries. Other types of batteries

may burst, causing personal injury and damage.

Do not expose the device to rain, snow or liquids of any type. This device is designed for

indoor mounting only. Protect the device from splashing when used in vehicle applications.

Do not mount this device in unventilated enclosures or in an engine compartment.

Do not disassemble this device: take it to a qualified Trace Service Center when service or

repair is required. Incorrect re-assembly may result in a risk of electric shock or fire.

Before using this device, read all instructions and cautionary markings in this booklet and

on the equipment.

To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or

cleaning. Turning off the device may not reduce this risk. As long as AC input power is

present, the charger section will be operable (if installed) regardless of the on/off switch

position. Solar modules produce power when exposed to light - disable or disconnect

before servicing any connected equipment.

WARNING - WORKING IN VICINITY OF A LEAD ACID BATTERY IS

DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES DURING

NORMAL OPERATION.

Provide ventilation to the outdoors from the battery compartment. Design the battery

enclosure to prevent accumulation of "pockets" of hydrogen gas at the top of the

compartment. Vent the battery compartment from the highest point.

No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be no less

than 14 AWG (2.082 mm) copper wire and rated for 75C or higher. Battery cables must be

rated for 75C or higher and must be no less than #6 AWG.

Torque all AC wiring connections to 16 inch-pounds (1.8 N-m). Torque all DC cable

connections to 13 foot- pounds (157 inch-pounds) (17 N-m).

Special Notices

Tools required to make AC wiring connections: Wire strippers, Phillips screw driver #2,

slotted screw driver ¼" (6MM) blade, and a torque wrench.

This inverter is for use with a nominal battery-supply voltage of either 12-volt DC or 24-volt

DC. See unit label for appropriate voltage required.

For battery installation and maintenance: read the battery manufacturer's installation and

maintenance instructions prior to operating. Do not mount on or near flammable materials

(plywood, chemicals, gasoline, etc.)

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

3

Page 4

No AC or DC disconnects are provided as an integral part of this device. Both AC and DC

disconnects must be provided as part of the system installation, if required.

No over-current protection for the battery supply is provided as an integral part of this

device. Over-current protection of the battery cables must be provided as part of the

system installation.

No over-current protection for the AC output wiring is provided as an integral part of this

device. Over-current protection of the AC output wiring must be provided as part of the

system installation.

Caution: To reduce the risk of fire, use only input circuits provided with 20-ampere

branch circuit protection in accordance with the National Electrical Code,

ANSI/NFPA70.

DC GROUNDING INSTRUCTIONS - This device must be connected to a grounded,

permanent wiring system. For most installations, the negative battery conductor must be

bonded to the grounding system at one (and only one) point in the system. All US

installations must comply with national and local codes and ordinances.

AC GROUNDING INSTRUCTIONS The AC system in mobile installations must have the

neutral isolated from the grounding throughout the load distribution circuits.

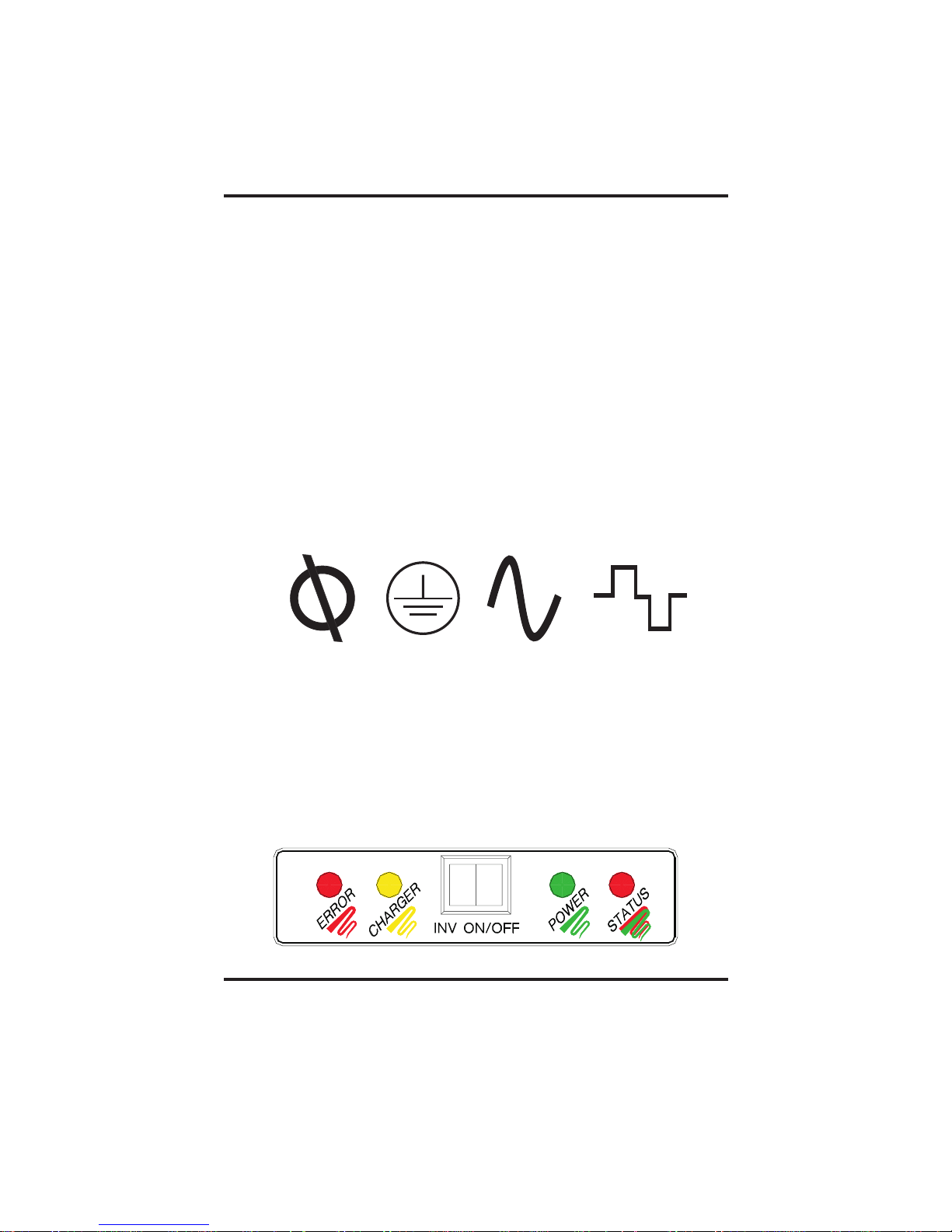

Symbols

Symbols used in this booklet and on the device itself are shown below:

Phase Chassis Ground AC Input AC Output

Controls and Indicators

The TS Series front panel features a power switch, four LEDs, and a fan on some models.

The back panel configuration varies depending upon options.

Front Panel Controls

The TS Series front panel controls and indicators include a momentary push-button Power

switch, a red error status indicator, a yellow charger status indicator, a green power light,

and a white battery status indicator.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

4

Page 5

Inv On/Off Switch Operation

The momentary push-button switch on the front panel controls the operating mode of the

inverter:

Search: Push the Inv On/Off switch once to enable Search mode. The power lamp will

flash slowly in this mode. When in Search mode, the inverter emits a pulse testing the

output circuits for loads. If a load greater than eight watts is present on the output circuit,

the inverter turns On and provides AC power to the circuit for as long as the load is present,

automatically switching back to Search mode when the load is no longer present.

On

: When in Search mode, push the Inv On/Off switch once to turn the inverter to On

mode. The inverter will produce AC power from the batteries until the low battery cut-off

voltage is reached, or until the power switch is pressed once again.

When equipped with the optional battery charger, the device will remain in On mode until

approximately 20 seconds after AC power is applied, when it will stop inverting, pass

through the current, and begin charging.

Off

: When in On mode, press the On/Off switch once to turn the inverter Off. The inverter

draws very little power when in Off mode.

LED Indicators

The front panel features four LEDs which operate in the following manner:

q

Error : - Low battery error; indicates

q

Charger: - AC is present but inverter has not

q

Power: - inverter is in Search mode.

q

Status: - battery voltage exceeds 12.8 (25.6 for 24-volt)

Slow Flash: (One per second)

battery voltage is below low battery cutoff (LBCO)..

Fast Flash: (5/sec)

voltage has exceeded 15.1 volts for about 25 seconds.

Steady Red

exceeds rated capacity.

Slow Flash: (1/sec)

transferred to charge mode.

Fast Flash: (10/sec)

mode.

Steady Yellow

Slow Flash: (1/sec)

Steady Green

Flickering: inverter is charging.

Off

- inverter is off.

Steady Green

Fast Green Flash: (10/sec)

Slow Green Flash: (1/sec)

Slow Red Flash: (1/sec)

Fast Red Flash: (10/sec)

Steady Red

- High battery error; indicates battery

- Overload error; lights steadily when load

- charger is charging in bulk/absorption

-charger is charging in float mode.

- AC is present on output.

- 12.5 to 12.7 volts (25.0 to 25.5)

- 12.3 to 12.4 volts (24.6 to 24.9)

- 12.0 to 12.2 volts (24.0 to 24.5)

- 11.8 to 11.9 volts (23.6 to 23.9)

- less than 11.8 volts (23.6 volts for 24-volt system)

Installation

Before beginning the installation, disconnect any power supply that you will be connecting

to this device. This section describes mounting, installation, and cabling,

Mounting

Mount this device on a shelf or table in a clean, dry, well-ventilated location close to the DC

supply. DO NOT locate this device in the same enclosure with batteries. Liquid lead-acid

batteries may produce explosive gases and must be well ventilated. Sealed batteries may

be located in the same enclosure. Allow adequate clearance around this device for proper

ventilation.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

5

Page 6

DC Cabling

Use #6 AWG battery cables, Cables are available in 3, 5,

and 10 foot lengths (BC3, BC5, BC10). Strip the

insulation about ½“ (12 mm) from the end of each wire.

Using a Phillips screwdriver, remove the six screws from

the top and side of the inverter and remove the cover.

Loosen the uppermost strain relief by rotating the cap

counter-clockwise, and insert the stripped end of the

the cable lug marked ”Battery Plus” on the PCB. Using a straight-blade screwdriver,

tighten the screw in the lug to 12 foot-pounds, then tighten the strain relief. Repeat for the

Battery Minus (-) cable. Replace the cover and reinstall the cover screws.

positive (+) battery cable through the strain relief and into

AC Cabling

On AC outlet equipped models, just plug-in the load or appliance to the pre-wired outlet on

the back panel of the inverter. On units equipped with a factory-installed battery charger,

wire the AC input circuit to the charger board as shown in the section of this

booklet (some configurations may include a pre-wired AC line cord).

Options

User Configuration Options

The standard TS series inverter requires no user configuration. When you have the

standby battery charger option or the PV controller option, you can configure the TS Series

for your specific system requirements. Configuration options include battery discharge

voltage (LBCO), AC voltage transfer sensitivity, and battery type. To change configurations,

disconnect any AC or DC power supply and loads from the unit and remove the cover from

the chassis. Remove or install the jumpers from the configuration pins as shown in the

illustration at right. If the unit is equipped with the SB charger option or the PV option, it

may be necessary to remove the option board to gain access to the configuration jumpers.

See the illustration on Page 9 to locate the configuration pins on the main printed circuit

board (PCB)

Jumper

On

Off

Discharge

You can set the inverter to stop inverting when the battery to which it is connected has been

discharged to 11.7 volts for 5 minutes (shallow discharge) or to 10.6 volts for one minute

(deep discharge). The factory setting is Deep discharge Shallow discharge means less

battery stress and more charge/ cycles. Deep discharge allows the batteries to be

discharged almost completely. This usually results in somewhat shorter battery life, but

fewer charge/discharge cycles. To select Shallow Discharge, remove the jumper from the

configuration pins. For Deep Discharge, the two pins must be connected by the jumper.

Pins

Depth

Transfer Sensitivity (SB Option Only)

The TS inverter can be configured to begin inverting whenever grid voltage falls to 95 volts

RMS (UPS mode) or to delay transfer until line voltage falls to 80 volts RMS (Gen mode).

The factory default, UPS mode, is relatively intolerant of line voltage fluctuations to prevent

A jumper is a small, rectangular piece of plastic with two square

holes in it that fit over two pins as shown in the illustration at left.

A jumper contains an internal conductor that joins the two pins,

completing a circuit. When the jumper is removed, the circuit is

interrupted. Jumpers are often used for changing configuration

parameters. When a jumper is not connecting two pins, it can be

stored by slipping it over just one of the pins instead of both. This

will have no effect upon the configuration, but will keep the

jumper handy for future use.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

6

Page 7

computer brownouts, and is preferred when operating devices that are sensitive to voltage

fluctuations. GEN mode is preferred when line voltage is provided by a generator, some of

which provide AC power with significant fluctuations in RMS voltage. To select UPS mode,

connect the two pins with the jumper provided. For Gen mode, remove the jumper from the

pins. Store the jumper by leaving it on one pin only. Transfer time from grid to inverter is

about 8 to 12 milliseconds.

DEEP > 10.6 V

SHALLOW > 11.7 V

UPS = 95V RMS

GEN = 80V RMS

DC

DC

AC

AC

SEALED FLOODED

14.3 14.7 Bulk Volts

60 min 60 min Absorption Time

13.6 13.4 Float Volts

Battery Type (SB Option Only)

The TS Series can charge either liquid lead-acid (flooded) batteries or sealed, gel or

absorbed glass batteries. The difference is in the charge voltages. The unit comes from

the factory pre-configured for sealed batteries. To change to flooded batteries, remove the

jumper from the pin pair labeled Sealed/Flooded.

Selecting the Best Battery

There are many types and sizes of batteries available, including starting, deep-cycle,

sealed gel, and absorbed glass mat. Which battery is best for your installation depends

upon your unique circumstances. In order to help you choose, a discussion of these types

of batteries is found in this section.

Starting Batteries

Starting batteries are designed for high cranking power, not deep cycling. Don't use them.

Deep Cycle Batteries

This type of battery is best suited for use with inverters because they tolerate a greater

depth-of-discharge before being recharged. The most common type is the non-sealed,

liquid-electrolyte battery, which have removable cell caps for monitoring the electrolyte

level. When a cell is low, add only distilled water. Check the electrolyte level at least

monthly. Top-up after recharging.

A popular and inexpensive deep-cycle battery is the six-volt golf cart battery rated at 220

amp-hours. These can be cycled repeatedly to 80% of their capacity without damage. The

TS512 is a 12-volt system, therefore you must connect at least two of these batteries in

series in order to produce 12 volts. The TS524 is a 24-volt system and required four of

these batteries.

Some systems use the L16 type of battery: six-volt batteries rated at 350 amp-hours

available from a number of manufacturers. At 17 inches in height and up to 130 pounds

each, they may be difficult to place in mobile or marine installations.

Type 8D batteries are available in either starting or deep-cycle construction. Most common

are the starting version used to start very large truck engines. Make sure you purchase the

deep-cycle version. These deep-cycle versions are 12-volts and are rated at 200 amp

hours or so. Type 4D batteries are very similar in construction, but about one-third smaller.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

7

Page 8

Sealed Gel Cell

Sealed gel cell batteries do not use battery caps because the electrolyte is in the form of a

gel. This allows the batteries to be mounted in any position without spilling. Other

advantages are: no maintenance, long life (800 cycles claimed) , and low self-discharge.

The disadvantage is high initial cost and the possibility of damage from overcharging. Don't

confuse sealed batteries with maintenance-free batteries - the latter are typically standard

liquid electrolyte batteries with no caps for adding water; when the electrolyte gets low you

replace the battery. For best results, use the Battery Temperature Sensor (BTS) option with

sealed batteries.

Monthly Maintenance

Check the level of the electrolyte in each battery at least once a month. It must be above

the top of the plates, but not completely full. Most batteries have a split plastic cup under

the caps, which the electrolyte should just touch when full. Don't overfill the batteries, or

the electrolyte will spill out of the batteries when recharging. Refill batteries with distilled

water only - "spring" water and regular tap water may have high levels of minerals that can

poison the battery chemistry and reduce battery life.

Check the battery cable connectors for tightness and corrosion. To remove corrosion,

disconnect the cables and carefully rinse with a mild solution of baking soda and water. DO

NOT ALLOW THE SOLUTION TO ENTER THE BATTERY. Rinse the top of the battery

with clean water when finished. Remove stubborn corrosion with a wire brush. Any

automotive parts store will have a wire brush tool specifically designed for cleaning cable

lugs and battery terminals.

To prevent corrosion from forming on the battery terminals and cable lugs, coat them (only

after installing the cables) with liquid neoprene or anti-corrosion grease available from any

quality marine, automotive or battery equipment supplier. Do not apply any material

between the terminal and the cable lugs - the connection must be metal-to-metal. Apply

the protective coating only after the bolts are tight.

Inter-Battery Cabling

Batteries may be connected in series, in parallel, or both depending upon your purpose.

To increase voltage, connect two or more batteries in series as shown in the diagram

below. The voltage of the combined batteries will be the sum of the voltage of all the

batteries. The amp-hour capacity will remain unchanged. To increase amp-hour capacity,

connect two or more batteries in parallel as shown in diagram B. The amp-hour capacity of

the combined batteries will be the sum of each individual battery, but the voltage will remain

unchanged.

A. Series Cabling:

6-volt + 6-volt = 12 volt.

B. Parallel Cabling:

220 ah + 220 ah = 440 ah

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

8

Page 9

White = Neutral

Remove AC routing wire

to install option board

Green = Ground

Black = Hot

Configuration

pins

OUTAC

White

Green

Black

SB Option

PCB

RED (+)

BLACK ( )−

BTS

BTS

Jack

INAC

White

Green

Black

Jack

RC8

RC8

Jack

Jack

Remove plug and install circuit breaker

connect black wires to circuit breaker

Options

Field-installed options for the TS Series include either a three-stage standby battery

charger (SB option), a battery temperature sensor (BTS option), and a remote control (RC8

option).

Standby Battery Charger

The Stand-By (SB) charger option features a three-stage automatic battery charger with AC

pass-through relay mounted on a PCB that can be field installed, includes an AC power

supply cord and circuit breaker, and enables transfer sensitivity, battery selection, and

depth of discharge.

Battery voltage is varied during the three stage battery charging process, as follows:

BULK

-During this initial stage of charging, the Charge LED flashes about once each

second and the inverter charges at a constant current. This causes the battery voltage to

rise over time. When battery voltage reaches the bulk voltage setting (see

Configuration Options

for voltage settings), the charger begins the absorption stage of

charging.

ABSORPTION

-During this phase, the charge current gradually reduces while the battery

voltage is held constant for two hours at the bulk voltage During the ABSORPTION stage,

the Charge LED flashes rapidly.

User

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

9

Page 10

Charging

Started

Absorption StageBulk Stage

Bulk Voltage

Float Stage

Float Voltage

DC Voltage

DC&ACCurrent

Max Charge

Amps Setting

Constant Current

80-90% Capacity

Tw o-Hour Ab sorption Period

Constant Voltage

100% capacity

Reduced Current and Voltage

FLOAT - During this stage the voltage of the battery is held at the FLOAT voltage setting.

Full current from the PV array can be provided to the loads connected to the battery during

the float stage. When the battery voltage has reached the FLOAT stage, the status LED

will be steady green.

When the battery voltage drops below the FLOAT setting for a cumulative period of one

hour, a new BULK cycle will be triggered. This typically occurs each night. If the battery

is full at the start of the day, it will receive an ABSORPTION charge for one hour and then

be held at the FLOAT setting for the remaining period of the day. Should the battery

voltage drop below the FLOAT setting for a cumulative period of one hour, another BULK

and ABSORPTION cycle will be initiated.

This three-stage charging process results in faster charging compared to on-off relay type

or constant voltage solid-state regulators. The final FLOAT voltage setting reduces battery

gassing, minimizes watering requirements and ensures the complete battery recharging.

Warning: Do not connect the AC power cord to

the AC out terminal. You may damage the unit.

Inverter to Charger Transition

On inverter models equipped with the three-stage internal standby battery charger, the

charger and an automatic transfer relay allows operation as either a battery charger or an

inverter, (but not both at the same time). An external source of AC power (e.g. shore

power, generator, and/or utility grid) must be supplied to the inverter AC input in order to

allow it to operate as a battery charger. As long as AC power is supplied to the charger, it

operates regardless of the position of the On/Of switch. When operation as a charger, the

inverter’s AC output is provided by the external source.

The inverter automatically becomes a battery charger after a 10-second delay whenever

AC power is supplied to it. This delay is built-in to provide time for a generator to spin-up to

a stable voltage and avoid relay chattering.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

10

Page 11

The inverter’s AC input connects internally to the inverter’s AC output while in the battery

charger mode. A 15-amp pass-through relay accomplishes this switching, protected by a

15-amp circuit breaker.

Battery Temperature Sensor

An optional battery temperature sensor (BTS) can be fieldinstalled at anytime. Remove the lid of the chassis as described

in the Optional Standby Battery Charger section. At the bottom

right-hand edge of the TS board are two RJ11 plug jacks. The

top-most jack is labeled ‘BTS.’ Remove one of the 7/8 -inch

knockout plugs in the chassis endplate and install the BTS

through this opening and plug it into this jack. Sandwich the

BTS sensor between any two of the batteries in your system.

The BTS will enable the SB charger to ‘fine tune’ the charging

voltage based on temperature and lengthen battery life

RC8 Remote On/Off Switch

The optional RC8 remote control unit duplicates the Power On/Off Switch on the

inverter/charger and is coupled to the inverter. It connects directly to the six-conductor RJ15

phone jack labeled RC8 on the bottom right of the inverter PCB (see illustration on Page

9). Use the Trace remote cable provided with the RC8 because it is tin-plated stranded

cable with gold-plated connectors.

The front panel of the RC8 also shows the status of different modes of the inverter. The red

LED on the front directly mimics the green LED on the inverter/charger. The following

indications are shown by the RC8:

0

Steady Red: unit is in inverter or charger(if installed) mode

0

Slow blinking Red (1-3 flashes): unit is in search mode

0

Rapidly blinking Red : indicates overcurrent condition. Unit will shut Off after

8-12 seconds of an overcurrent condiition.

RC8 Remote Installation

Cut a 1-7/8" diameter hole. At least 1½" of clearance is required behind the hole. Next drill

the two holes needed to screw the installation to the wall. After routing the Trace remote

cable, plug it into the six-conductor, RJ15 phone jack on the TS main PCB.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

11

Page 12

Rear Panel Configuration

The TS series rear panel configuration is determined by the model and options selected.

Some models will have one or more of the features listed below:

0

Duplex Outlet Option (D): a 120-volt, 15-amp

models.

0

Duplex Outlet Option (I):

on some models.

0

GFCI Outlet Option (P): Ground Fault Circuit Interrupt outlet is required on

some U.S. models.

0

Outlet plate: blank plate provided when no outlet is installed, AC Out cable

must be hardwired to the TS PCB as shown in these instructions.

0

15-amp input circuit breaker provided as part of the standby battery charger

option.

0

AC-In Power Cord Option (L): 14/3 120-volt AC stranded-copper power cable

with molded standard U.S.. plug provided only with standby battery charger

option.

0

Battery Cable Option (B#): #6 AWG stranded copper cable, insulated with black

(negative) or red (positive) vinyl for polarity identification. Available in three, five

or 10 foot lengths. Specify BC3, BC5, or BC10

0

Zinc strain relief: provided only with standby charger option.

230-volt, 15-amp for export models outlet is provided

outlet is provided on some

End panel showing optional

duplex outlet, AC supply cord,

and SB option circuit breaker

.

Circuit Breaker (provided with

SB option) Press to reset

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

Chassis Ground:

connect to earth

ground and/or battery

negative.

AC-In power cord for SB charger option

12

Page 13

models

24-volt

for

Float

kg)

mm)

lbs (10.4

X 136.525

on 25 centigrade)°

(based on 25 centigrade)°

(based

Model 412E 424E 512 524 712E 724E 812 824

Model 412E 424E 512 524 712E 724E 812 824

amps n/a n/a 16@1ms n/a n/a n/a n/a n/a

v/a 400 400 500 500 700 700 800 800

current

Power v/a 400 400 500 500 700 700 800 800

Surge current amps n/a n/a 16@1ms n/a n/a n/a n/a n/a

Power

Surge

Efficiency 92% 95% 92% 95% 92% 94% 90% 92%

Peak Efficiency 92% 95% 92% 95% 92% 94% 90% 92%

Peak

all models

for

amps .25a .50a .25a .50a .25a .50a .25a

Watt

amps 17a 43a 21a 60a 30a 70a 35a

Mode ~1

Power 34

Current

Idle @12.6v/25.2v .50

Rated

Search

Input

In Search Mode ~1 Watt for all models

At Idle @12.6v/25.2v .50 amps .25a .50a .25a .50a .25a .50a .25a

At Rated Power 34 amps 17a 43a 21a 60a 30a 70a 35a

In

At

At

DC Input Current

DC

VdC 10-15 20-30 10-15 20-30 10-15 20-30 10-15 20-30

Volts 12 24 1224 12 2412 24

VAC) 230 230 120 120 230 230 120 120

DC

Range

Input

Voltage

Voltage

Nominal Input DC Volts 12 24 12 24 12 24 12 24

Input Voltage Range VdC 10-15 20-30 10-15 20-30 10-15 20-30 10-15 20-30

Output Voltage VAC) 230 230 120 120 230 230 120 120

Input

Output

Nominal

models

All models

all

watts

ññ ññ ññññ

ñ

ññ ññ ññññ

ñ

Regulation 0.04%

Regulation 6% 6% 6% 6% 6% 6% 6% 6%

Sense ~8

Voltage Regulation 6% 6% 6% 6% 6% 6% 6% 6%

Frequency Regulation 0.04% all models

Load Sense ~8 watts All models

Voltage

Frequency

Load

- 23.4

/21.2

models

12-volt

all models

for

AC for

- 11.7

amps

Cutoff 101.6

Battery

Relay 15

Low

Auto Low Battery Cutoff 101.6 - 11.7 for 12-volt models /21.2 - 23.4 for 24-volt models

Transfer Relay 15 amps AC for all models

Auto

Transfer

dc 15 8 15 8 25 13 30 15

cooling option option option option yes yes yes yes

Rate amps

fan

Charge

Internal fan cooling option option option option yes yes yes yes

Max Charge Rate amps dc 15 8 15 8 25 13 30 15

Max

Internal

X 139.7mm

Bulk, Absorption,

(355.6mm

D

Stage:

lbs (7.71kg) 23

W X 5.375”

X 5.5”

H

Dimensions 14“ H X 5.5” W X 5.375” D (355.6mm X 139.7mm X 136.525 mm)

Dimensions 14“

Weight 17

Shipping Weight 17 lbs (7.71kg) 23 lbs (10.4 kg)

Shipping

Profile 3

Charge Profile 3 Stage: Bulk, Absorption, Float

Charge

SPECIFICATIONS

SPECIFICATIONS

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

13

Page 14

Troubleshooting

Symptoms Problem Remedy

No AC power output AC routing wire disconnected reconnect wire See page 9

No warning LED’s

Battery voltage at the inverter's Check voltage, fuses or

terminals is too high or low breakers,cable connections

No power output Load too small for Search

Search LED flashing circuit to detect turn unit on

slowly

Power output LED Overload Remove or reduce loads

Flashing rapidly allow inverter to cool

or erratically before restarting

Power output is low Low battery

inverter

on and off and on Loose or corroded battery - Check and clean connections

Inverter shuts down Output of inverter wired back

after 20 seconds its own input output wiring

Charger is inoperative AC input voltage does not Check AC input for proper

Low charge rate Low AC input voltage Use larger generator, speed up

turns loads and recharge

Mode

connections

Loose AC output Check all AC output

connections

to

match inverter spec voltage and frequency of your

Charger voltage Refer to owner's manual for

improperly set

peak

(164 volts peak required for generator, check AC input

full charger output) wiring size cable too

AC current output of generator

too small to handle load

defeat search mode,

Check condition of batteries

connections

Check for proper AC input and

120 VAC models need

model,

>90 VAC to operate.

proper setting

too long

Reduce loads

small or

Low surge power Weak batteries, battery Refer to cable and battery

Error LED on steady Overload Let unit cool down,

No power at SB Charger relay stuck Have unit serviced

charger terminals

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

too small or too long mendations in owner's

cables recom

manual

reduce loads

14

Page 15

Warranty

Limited 2 Year Warranty

NOT FOR USE WITH LIFE SUPPORT EQUIPMENT

Trace Engineering Company warrants its power products against defects in

materials and workmanship for a period of two (2) years from the date of

purchase and extends this warranty to all purchasers or owners of the product

during the warranty period. Trace does not warrant its products from any and all

defects: (1) arising out of material or workmanship not provided by Trace

Engineering, or (2) resulting from abnormal use of the product or use in violation

of the instructions, or (3) in products repaired or serviced by other than Trace

Engineering repair facilities, or (4) in components, parts, or products expressly

warranted by another manufacturer. Trace Engineering agrees to supply all parts

and labor or repair or replace defects covered by this warranty with parts or

products of original or improved design, at its option, if the defective product is

returned to any Trace Engineering authorized warranty repair facility or to the

Trace Engineering factory in the original packaging, with all transportation costs

and full insurance paid by the purchaser or owner.

No equipment will be accepted without a Return Merchandise Authorization

(RMA). Call Customer Service at 360-435-8826 or FAX 360-435-2229 (email:

www.traceengineering.com)to obtain an RMA and shipping instructions.

ALL REMEDIES AND THE MEASURE OF DAMAGES ARE LIMITED TO THE

ABOVE. TRACE ENGINEERING SHALL IN NO EVENT BE LIABLE FOR

CONSEQUENTIAL, INCIDENTAL, CONTINGENT OR SPECIAL DAMAGES,

EVEN IF TRACE ENGINEERING HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. ANY AND ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED ARISING BY LAW, COURSE OF DEALING, COURSE OF

PERFORMANCE, USAGE OF TRADE, OR OTHERWISE, INCLUDING BUT

NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO A

PERIOD OF TWO (2) YEARS FROM THE DATE OF PURCHASE.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, OR THE EXCLUSION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGE. SO THE ABOVE LIMITATIONS MAY NOT APPLY

TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

15

Page 16

Copyright Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3141

th

5916 195 Street, NE Fax (360)435-2229 Effective Date: July 15, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

16

Loading...

Loading...