Page 1

Truck Series 770K Kit

for Volvo Trucks

Installation Guide

1999 Trace Engineering P/N 976-0001-00-01 Rev. A 10/99

Page 2

Page 3

Truck Series 770K Kit

Truck Series 770K Kit

Installation Guide

T able of Contents

Section Description Page

1. Installation ................................................................. 1

2. Service Information...................................................... 9

3. Warranty ....................................................................... 10

1999 Trace Engineering

i

Page 4

Truck Series 770K Kit

IMPORT ANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed

during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation and

operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

CAUTION - This procedure is critical to the safe installation or

NOTE - This statement is important. Follow instructions closely.

• All electrical work must be done in accordance with local, national,and/or

international electrical codes.

• Before installing or using this device, read all instructions and cautionary

markings located in (or on) the manual, the batteries, and the inverter.

• Do not expose this unit to rain, snow or liquids of any type. This product is

designed only for indoor mounting.

• To reduce the chance of short-circuits when installing or working with

the inverter or the batteries, use insulated tools.

• Remove all jewelry such as rings, bracelets, necklaces, etc., while installing

this system. This will greatly reduce the chance of accidental exposure to

live circuits.

• The inverter contains more than one live circuit (AC and batteries).

Power may be present at more than one source.

• This product contains no user-serviceable parts. Do not attempt to repair

this unit.

Use extreme caution when performing these tasks.

operation of the unit. Follow these instructions closely.

SAVE THESE INSTRUCTIONS

ii

1999 Trace Engineering

Page 5

Truck Series 770K Kit

1.0 INST ALLATION

Pre-installation

1. Unpack the kit to make sure you have everything and familiarize yourself

with each component. If parts are missing or damaged contact the point of

purchase immediately.

2. Review your truck and identify the locations of:

the battery box

potential DC, and battery temperature sensor cable runs

interior mounting locations for the inverter/charger and the RC8 remote

control

3. Gather the following tools and installation accessories:

SAE open end wrenches and socket set

screw driver set

½” drill motor, drill bit set and 2” hole saw

utility knife

wire cutters and stripers

measuring and fish tape

needle-nosed pliers

masking tape

#10 AWG green wire & #10 AWG crimp-on ring terminal

silicon

1 ½” dia. flexible plastic split conduit

9” & 12” nylon ties

large cable cutters and cable crimpers (optional)

4/0 welding cable and crimp-on ring terminals (optional)

1” dia. shrink tubing (optional)

heat gun or gas torch (optional)

1999 Trace Engineering

1

Page 6

Truck Series 770K Kit

1.0 INST ALLATION

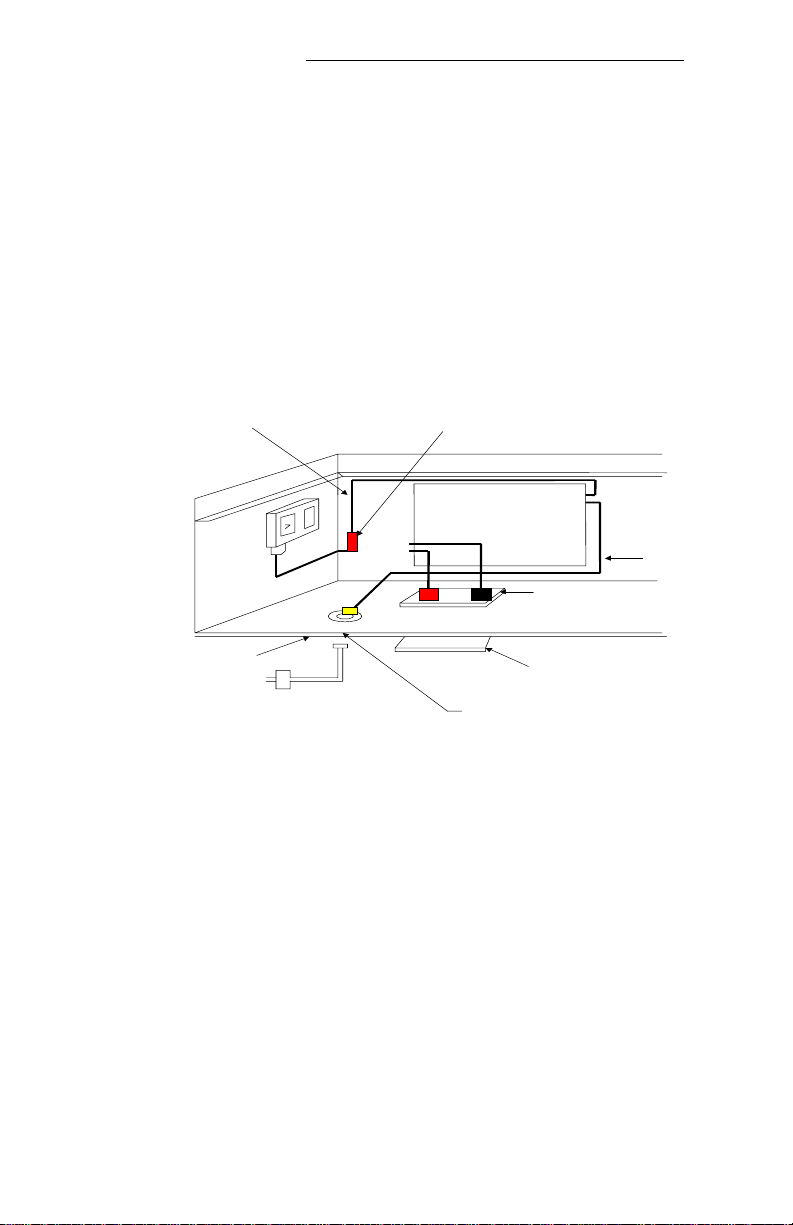

AC OUT-PUT FROM

INVERTER/CHARGER

OUT SIDE FLOOR LINE

CAB POW ER AC INPUT

EXISTIN G 770 C A B P O W ER

BULKHEAD C ONN ECTOR

INVERTER/CHARGER

CAB FLOO R INSIDE FLOOR LINE

Figure A

Basic Installation and Wiring

AC POWER

INPU T TO

THE

INVERTER

TOP FLOOR PASSTHROUGH FLANGE

BOTTOM F LOO R PASSTHROUGH FLANGE

2

1999 Trace Engineering

Page 7

Truck Series 770K Kit

1.0 INST ALLATION

1. Disconnect the positive and negative battery cables at the batteries.

2. Locate a position in or immediately around the positive cable end of the

battery box to mount the fuse-block assembly.

make sure to leave room at both ends to attach the 4/0 battery cables

remove the clear plastic cover from fuse-block assembly and set it aside

place the fuse-block assembly in a desired location

mark mounting hole locations with a pencil or awl

drill four ¼” holes in the battery box and mount the fuse-block assembly

using the included hardware

3. From below the cab, disconnect the external AC input connector.

remove the large nut and washer

4. From inside the cab, lift the AC input harness out of the floor (storage

compartment)

leave the other end connected to the cab power box located on the

driver’s side wall of the same storage compartment

5. Mark the location for the inverter/charger mounting bracket.

mount the bracket in the front-left corner of driver’s side storage

compartment approximately 6” to 8” away from the front wall

note the vertical part of the bracket mounts away from you and faces

toward interior bulkhead wall

once the location is identified, climb under the truck and make sure the

area is clear of:

- structural supports

- wire harnesses

- exhaust system components

using the bracket as a template, drill four ¼” mounting holes through the

floor of the cab

insert four ¼” X 1” bolts through the mounting bracket and floor

and secure using fender washers, lock washers and then nuts

NOTE: Looking down at the top of the pass-through, the positive (red) connection should be on the left and the negative (black) connection on the right.

6. Locate the floor pass-through block adjacent to the mounting bracket (see

diagram). Tight turns with heavy 4/0 cable are required so leave yourself

enough room.

once the location is identified, climb under the truck and make sure area

is clear of:

- structural supports

- wire harnesses

- exhaust system components

remove the pass-through block template from the box and tape it over the

determined mounting location

drill the ¼” pilot holes

drill out the four corner holes with a 5/16” bit

use a 2” hole saw to cut out the remaining three holes

1999 Trace Engineering

3

Page 8

Truck Series 770K Kit

1.0 INST ALLATION

Figure B

Pass-Trough Template

Figure C

Lower Pass-Through Block

Figure D

Pass-Through Block - Lower Assembly

4

1999 Trace Engineering

Page 9

RC8 Remote Control Template

Page 10

RC8 Remote Control Template

Remove this page from the manual

and place it over the mounting location.

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

Page 11

Floor Pass-through Template

Page 12

Floor Pass-through Template

Remove this page from the manual

and place it over the mounting location.

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

Page 13

Truck Series 770K Kit

1.0 INST ALLATION

7. Remove the round rubber grommets from the top and bottom flange of the

pass-through block and set them aside for later.

Screw the brass DC studs into the top half of the pass-through block.

Place the top flange into the holes in the cab floor

8. Apply a bead of silicon around the entire outside edge of the bottom passthrough block and around the three internal round holes.

9. Prepare four ¼” X 1” bolts with lock washers. From underneath the truck,

place the bottom flange over the brass studs and bolt it into place.

10. Locate an unpainted location on the frame rail for the chassis ground wire.

cut a length of #10 AWG green wire that is long enough to go from the

location on the frame rail up through the hole in the pass-through block

- be sure to leave several feet of wire inside the cab for later use

crimp a #10 AWG ring terminal on the end of the ground wire and attach

it securely to the unpainted frame rail location

feed the other end through the hole in the pass-through block

11. Take the black plastic battery temperature sensor (with the bright yellow

telephone cord) out of the plastic bag.

remove the backing material to expose the adhesive

clean a spot between two batteries and attach the sensor to one of them

12. Leaving the batteries disconnected, plan the DC battery cable runs:

from the positive battery terminal to one end of the fuse-block

from the other end of the fuse-block to the positive stud on the floor-

pass-through block

from the negative battery terminal to the negative stud on the floor-

pass-through block

battery temperature sensor cable to the opening in the floor-

pass-through block

NOTE: Make sure cable runs are clear of the exhaust system and that you

allow enough slack for movement of the cab.

1999 Trace Engineering

Figure E

Fuse Block Assembly

5

Page 14

Truck Series 770K Kit

1.0 INST ALLATION

Figure F

Fish Tape

RC8

REMOTE CONTROL

Inverter Status

Push

On/Off

Solid Red ------------- Inverting or Charging

Blinking Slow -- -- -- -- -- -- -- Search Mode

Blinking Fast - - - - - - - - - - - - - - - - - - Error

Figure G

RC8 Remote

AC

HOT

IN

Black

Wire

AC

NEU

IN

White

Wire

or Bare

Green

AC

NEU

OUT

White

Wire

AC

HOT

OUT

Black

Wire

Figure H

Inverter Terminal Block

6

1999 Trace Engineering

Page 15

Truck Series 770K Kit

1.0 INST ALLATION

13. Make (or purchase) 4/00 battery cables of the appropriate length. Welding

cable is best as it is the most flexible.

fit the battery cables with flexible plastic conduit over areas where cables

may be subject to chaffing

install the positive and negative battery cables to the correct studs on

the floor-pass-through block using 3/8” fine thread nuts and lock

washers

NOTE: Do not insert a washer between the cable terminal and the brass stud.

install the positive battery cable from the floor pass-through block to one

end of the fuse-block

attach the short positive cable to the other end of the fuse-block using the

included lock washers and nuts

NOTE: Do not connect positive cable to battery at this time.

secure the battery cables and battery temperature sensor cable to the cab

supports and frame rails with nylon tie straps

14. Take one of the round rubber grommets and place the cables in the

appropriate slot:

the small round hole is for the green ground wire

the rectangular slot is for the flat yellow battery temperature sensor cable

the other two holes are unused

15. Remove the RC8 remote control switch from its packaging and locate

the mounting template. The recommended mounting location is as follows:

looking at the sleeper control panel, locate the remote control on the flat

surface immediately to the left of the rotary fan on/off switch

tape the template over the desired mounting location

drill 1/8” mounting holes

drill the ¼” pilot hole for the hole saw

remove the template

cut the 2” opening with the hole saw

feed fish tape up to hole and attach one end of yellow cable. Pull it down

into driver’s side storage compartment

Plug the other end of the yellow cable into the back of the remote control

until it snaps into place.

Place the remote control into mounting hole and screw into place using

the included hardware

16. Connect the RC8 remote control and battery temperature sensor cables by

inserting them into the RJ-11 jacks on the front of the inverter/charger.

Whenproperly seated they will click into place.

17. Locate the chassis ground lug on the back of the inverter/charger.

run the green chassis ground wire to the lug.

cut off any excess wire, strip ½” of green insulation from wire, insert into

the lug and tighten the set screw to secure wire

1999 Trace Engineering

7

Page 16

Truck Series 770K Kit

1.0 INST ALLATION

18. Locate the AC input wiring harness that ships with the kit (it is the harness

with the large hexagon shaped nut at one end).

referencing page 30 of the inverter/charger manual, follow the procedure

for wiring the of AC input to the inverter/charger

using the wire clamp supplied with the kit, secure the AC input power cord

into the left hole (facing the unit)

19. Locate the AC output wiring harness that ships with the kit.

referencing page 30 of the inverter/charger manual, follow the procedure

for wiring the AC output from the inverter/charger

using the wire clamp supplied with the kit, secure the AC outlet cord in

the right hole (facing the unit)

20. Using the supplied hardware install the wiring compartment access cover.

21. Center the holes on inverter/charger mounting flange over the mounting

bracket studs and secure it in place with lock washers and nuts.

22. Make (or purchase) 4/00 DC battery cables to go from the inside studs on

the floor pass-through block to the DC studs on the back of the inverter/

charger.

connect the DC battery cables to correct polarity studs on the back of

the inverter/charger using the supplied lock washers and nuts

cover the connections with the corresponding red and black DC terminal

covers (supplied)

23. Install the new AC input harness into the hexagonal hole in the floor of the

cab (using the large washer and nut from the harness removed earlier in

the installation).

reinstall the external input cord (removed earlier from underneath the

cab)

24. Connect the AC output harness from the inverter/charger to the old

hexagonal connector (removed earlier from the floor).

25. Secure the AC input and output harness wiring to the storage compartment

walls using nylon ties.

26. Connect the battery cables to the batteries according to the following

instructions:

connect the negative battery cable to the negative battery terminal (first)

connect the positive battery cable to the positive battery terminal

reinstall the battery box cover

NOTE: When you connect the positive battery cable to the positive battery

post you can expect a spark. This is caused by the internal capacitors

charging and is completely normal.

The installation in now complete. Refer to the inverter/charger owner’s manual

for complete operating procedures.

8

1999 Trace Engineering

Page 17

Truck Series 770K Kit

2.0 SERVICE INFORMATION

Trace Engineering takes great pride in its products and makes every effort to

ensure your unit fully meets your independent powering needs.

If your product needs repair, contact our Service department at: (360) 435-

8826 to obtain an RMA# and shipping information; or fax this page with the

following information to: (360) 474-0616.

Please provide:

Model Number: _____________________________________

Serial Number: (if applicable) ___________________________

Purchase Date: _____________________________________

Problem: ___________________________________________

Include a telephone number where you can be reached during business

hours and a complete return shipping address (P.O. Box numbers are not

acceptable).

Name:_____________________________________________

Address:___________________________________________

City:_______________________________________________

State / Province:_____________________________________

Zip / Postal Code:____________________________________

Phone: ( )_______________________________________

Country:____________________________________________

visit our website at: www.traceengineering.com

1999 Trace Engineering

or e-mail us at: traceengineering.com

9

Page 18

Truck Series 770K Kit

3.0 WARRANTY

Limited Warranty

Trace Engineering warrants its power products against defects in

materials and workmanship for a period of two (2) years from the date of

purchase and extends this warranty to all purchasers or owners of the product

during the warranty period. Trace does not warrant its products from any and

all defects:

(1) arising out of material or workmanship not provided by Trace

Engineering;

(2) resulting from abnormal use of the product or use in violation of

the instructions;

(3) in products repaired or serviced by other than Trace Engineering

repair facilities;

(4) in components, parts, or products expressly warranted by another

manufacturer.

Trace Engineering agrees to supply all parts and labor, or repair or

replace defects covered by this warranty with parts or products of original or

improved design, at its option, if the defective product is returned to any Trace

Engineering authorized warranty repair facility or to the Trace Engineering

factory in the original packaging, with all transportation costs and full insurance

paid by the purchaser or owner.

All remedies and the measure of damages are limited to the above.

Trace Engineering shall in no event be liable for consequential, incidental,

contingent, or special damages, even if Trace Engineering has been advised

of the possibility of such damages. Any and all other warranties, expressed or

implied, arising by law, course of dealing, course of performance, usage of

trade or otherwise, including, but not limited to, implied warranties of merchantability and fitness for a particular purpose, are limited in duration for a

period of two (2) years from the original date of purchase.

Some countries or states do not allow limitations on the term of an

implied warranty, or the exclusion or limitation of incidental or consequential

damage, which means the limitations and exclusions of this warranty may not

apply to you. Even though this warranty gives you specific legal rights, you

may also have other rights which vary from state to state.

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

10

1999 Trace Engineering

Page 19

Page 20

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

Loading...

Loading...