Page 1

Installation and Operator’s

Manual

RC7 & RC7GS

Remote Controls

Rev. 1.3x

ã

1999 Trace Engineering P/N 822-4 Rev. A 9/99

System Status:

Float Charging

Page 2

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

Page 3

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

i

RC7 & RC7GS Remote Controls

Table of Contents

Section Description Page

1. Introduction ...............................................................1

Features .............................................................1

ON/OFF Control

Meters

Controls

Status Monitoring

2. Installation .................................................................3

3. Operation ...................................................................5

Front Panel ............................................................5

Indicators and Controls

Status LEDs

Inverter LED

Charge LED

Batt. Full LED

Error LED

LCD Display

Push-buttons

On/Off

Setup/Menu Item Push-button

Meter Mode Push-button

Settings Push-button

RC7 and RC7GS Setup Menu ..............................9

Sense Search

Auto LBCO

Battery Capacity

Battery Type

Charge Rate

Set Shore Power

RC7 Setup

LCD Contrast

External Shunt

Fuelgauge Cutout

Page 4

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

ii

3. Operation (continued)

RC7GS Setup Menu ..............................................14

Set Clock (RC7GS Only)

Select Genset

Generator Start

Generator Stop

Begin Gen Quiet and End Gen Quiet

Saving your Setup Choices .................................18

RC7 and RC7GS System Status Displays ..........19

AC Source Messages ...................................19

Waiting for AC

Genset Status:

Pending, Cranking and Genstart

Starter Cooldown and Gen Start

Gen Set Error Messages ..............................20

Gen Won’t Start

Gen Quiet Fault

Low AC Input V

Inverter Mode Messages ..................................20

Charger Mode Messages .................................23

Bulk Charging

Absorption Charging

Float Charging

Equalizing Charging

Inverter/Charger Error Messages....................25

Over Temperature

Overload

High Battery Voltage

Low Battery Voltage

DCLD Lockout Error

Charger Fault

Meters Display.......................................................28

Average Shunt Amps

Battery Voltage

Inverter/Charger Current

AC Output Voltage

AC Input Amps

Battery Temperature

Transformer Temperature

FET Temperature

Estimated Battery Capacity

Page 5

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

iii

3. Operation (continued)

System Status Messages .....................................31

Battery State of Charge

Time Left to Run

Time Left to Charge

Set Shore Power

Generator Start/Stop

Generator Connection ..........................................33

Onan Quiet Diesel

Power Tech Wiring Diagrams (2 and 3-wire)

PowerTech 2-wire

PowerTech 3-wire

RC7 and RC7GS Setup Menu ..............................36

RC7 and RC7GS User Menu ................................37

Storage Checklist..................................................38

Preparation for Storage

Interior Storage

Exterior Storage

4. Service Information ..................................................39

Page 6

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed

during the installation and maintenance of this product.

To reduce the r isk of electrical shock, and to ensure the safe installation and

operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

CAUTION - This procedure is critical to the safe installation or

operation of the unit. Follow these instructions closely.

NOTE - This statement is important. Follow instructions closely.

·

All electrical work must be done in accordance with local, national,

and/or international electrical codes.

·

Before installing or using this device, read all instructions and cautionary

markings located in (or on) the manual, the controller, the batteries,

and the PV array.

·

Do not expose this unit to rain, snow or liquids of any type. This

product is designed only for indoor mounting.

·

To reduce the chance of short-circuits when installing or working with

the inverter, the batteries, or the PV array, use insulated tools.

·

Remove all jewelry such as rings, bracelets, necklaces, etc., while

installing this system. This will greatly reduce the chance of accidental

exposure to live circuits.

·

The inverter contains more than one live circuit (batteries, PV

array, generator, etc.). Power may be present at more than one source.

·

This product contains no user-serviceable parts. Do not attempt to

repair this unit.

SAVE THESE INSTRUCTIONS

iv

Page 7

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

1

1.0 INTRODUCTION

Features

The RC7 and RC7GS (Generator Start) are control units that allow remote

operation of any RV, Legend Series II, Tr uck Series II, and Mar iner inverter/

chargers rated from 2000 to 3000 watts.

NOTE: The generator start functions (GS) only apply to the RV Series inverter/

charger.

NOTE: The inverter and remote control must have software version 1.3x.

The RC7 and RC7GS feature:

• Simple menu driven programming for full control of all inverter/charger

functions

• A three-level menu to prevent accidental setting changes

• Meters to display voltage and current

• RJ11 phone jack connection to inverter

• Internal memory to retain inverter/charger menu settings even with a

loss of power

• An Intelligent battery fuelgauge displaying percent of battery charge

and the time left to run

• Error message and informative information displays used to optimize

system performance

• Remote ON/OFF inverter operation

Figure 1

RC7 Front Panel

Page 8

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

2

All operating controls and indicators for the RC7 and RC7GS are located on

the front panel of the remote control. The inverter, software Rev. 1.3x must be

installed in both the inverter and remote. Refer to the instructions in the RVU-2

Software Upgrade Kit manual if an upgrade is required.

NOTE: The RC7 and RC7GS are identical remote controls; however, the RC7GS

has additional features for controlling a generator. These features are noted in

this manual as available for the “RC7GS only.”

On/Off Control

The inverter portion of the inverter/charger can be switched OFF or ON

using the remote control. The standby charger in the inverter is automatic and

always ready and available for charging whenever ac power is applied.

Meters

The RC7 and RC7GS remotes feature several meters that monitor the

operating conditions of the power center. These meters include: Average Shunt

Amps, Battery Voltage, Inverter-Charger Current, AC Output Voltage, AC Input

Amps, Battery Temperature, Transformer Temperature, FET Temperature, and

Estimated Battery Capacity.

Controls

The RC7 and RC7GS allow the inverter to be switched ON or OFF with the

press of a push-button on the remote. Both devices can be used to configure the

inverter/charger to the specific system and preferences including Battery

Capacity, Batter y Type, Charger Rate, Low Battery Cutout, Shore Power Amps,

External Shunt, Fuelgauge Cutout, and Display Contrast. In addition, the RC7GS

starts and stops of the genset automatically or manually, allows the setting of

generator make and model, sets a “quiet time” during which the genset will not

start automatically, and has manual overrides for auto gen start.

Status Monitoring

The RC7 and RC7GS remotes monitor operating conditions including: the

ac supply, inverter operation, charger operation, batter y condition, generator

condition (RC7GS only), Time Left to Run, and Time Left to Charge..

1.0 INTRODUCTION

Page 9

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

3

2.0 INSTALLATION

Installation Procedure:

1. Select an appropriate location to install the remote control.

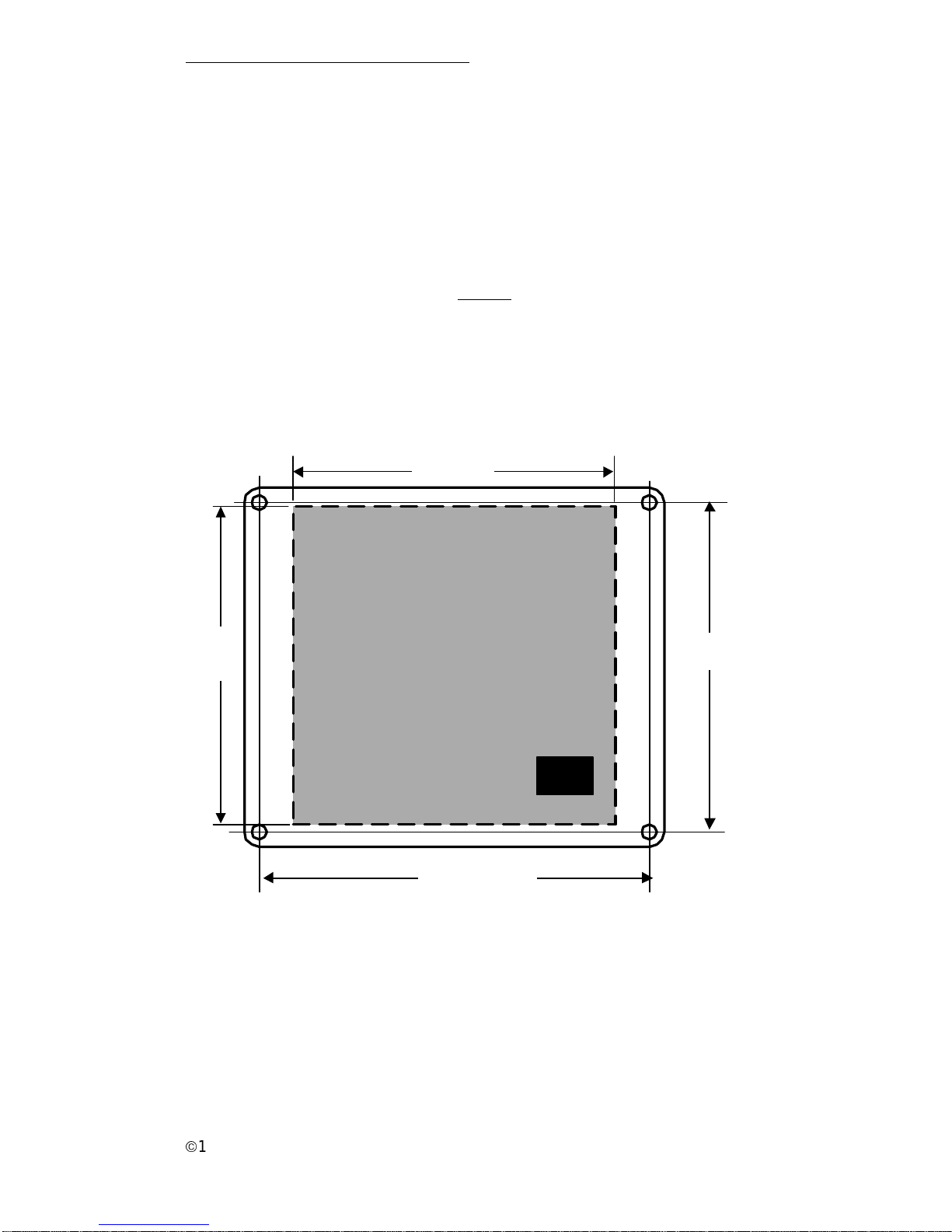

2. Refer to the drawing (Figure 2) for hole and cutout dimensions or install

the remote in a standard double-gang outlet box.

3. Run the cable between the RC7 remote and the inverter/charger. Do NOT

use standard telephone cable.

4. Place the ON/OFF switch on the inverter to the OFF position and

disconnect the ac power.

Figure 2

Installation Dimensions

CUT O UT THIS AREA

PHONE

JACK

4-1/8"

4"

5-3/ 16 " c-c

4-1/ 4" c-c

FR ONT VIEW

822-4A- 011

Page 10

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

4

2.0 INSTALLATION

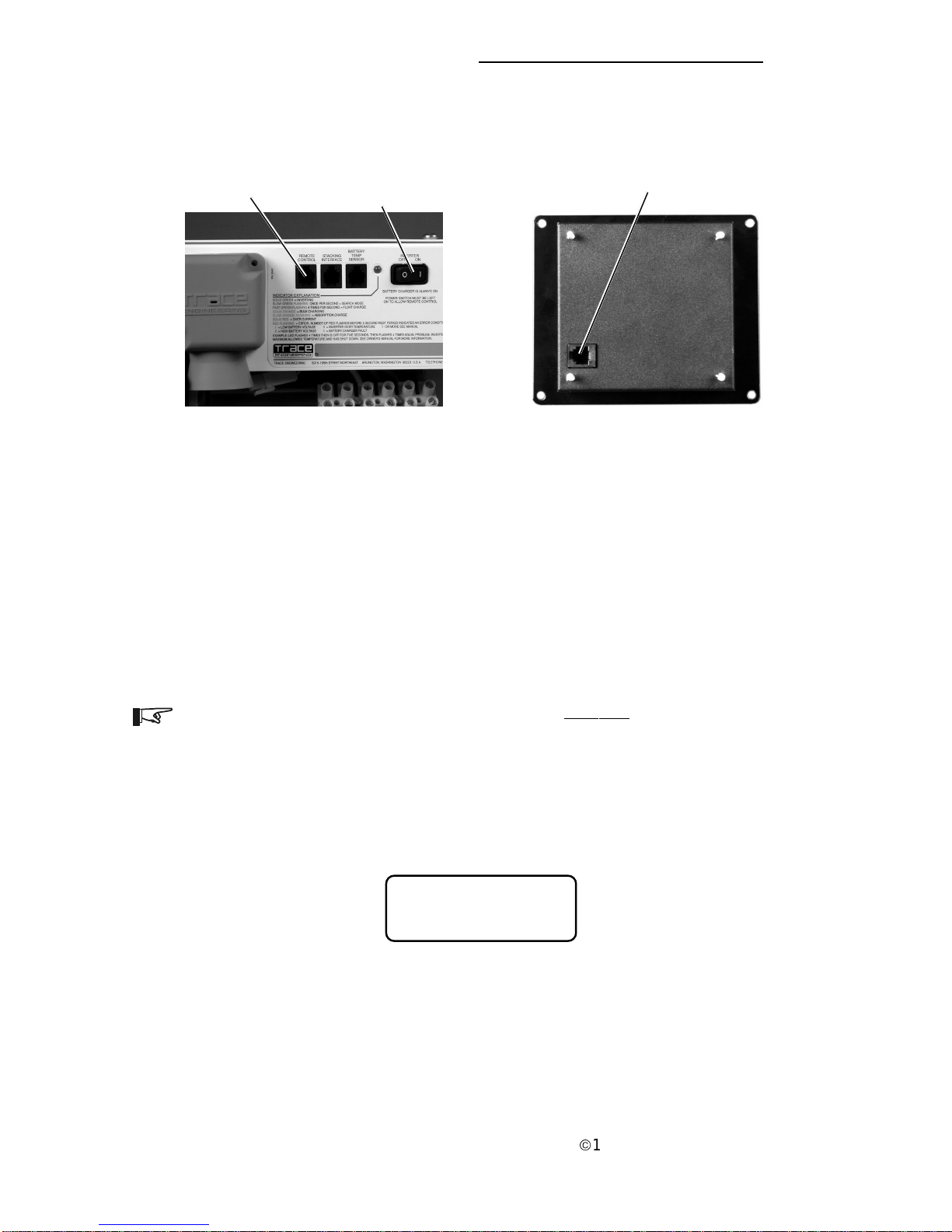

4. Connect the communications cable into the RJ11 port on the inverter/

charger marked “REMOTE CONTROL.” Connect the other end of the

cable into the jack on the remote (Figure 3).

5. Secure the remote to the wall or outlet box using the appropriate screws

(4 required).

6. Wait for the LCD display to show the message “Waiting for AC.”

7. Place the ON/OFF switch on the inverter to the ON position.

NOTE: The remote will not operate the inverter if the inverter’s ON/OFF switch is

in the OFF position.

8. Reconnect the inverter to the ac source. After a brief delay, the remote

will display a system status message similar to Figure 4.

Figure 3

Remote Control Connectors

“REMOTE CONTROL”

RJ11 Connector

RJ11 Connector

Inverter/Charger RC7 RC7GS Remote Control (back view)

ON/OFF Switch

Figure 4

System Status Message (in LCD display)

System Status:

AC Available

Page 11

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

5

3.0 OPERATION

Figure 5

Front Panel Controls and Indicators

Front Panel

1. Indicators and Controls

The RC7 and RC7GS front panels contain LEDs, LCD display and pushbuttons for viewing status and system setup. All operating power for the remote

control is provided by the inverter/charger via the supplied cable.

2. Status LEDs

There are four LEDs on the front panel which light solid or flash during

operation, indicating the system’s status. Upon initial power-up of the inverter, all

LEDs will flash as the unit goes through a self-test. After the initial power-up test

completes, the LEDs will indicate the current state of the inverter and charger.

Use these LEDs along with the LCD display for detailed system status.

Status LEDs

Inverter (green)

Charge (yellow)

Batt. Full (yellow)

Error (red)

Alphanumeric LCD Display Panel

ON/OFF Push-button

Menu Down Push-button

Menu Up Push-button and

Meter Mode

Settings Selection

Push-button

Inverter

Charge

Batt. Full

Error

822-4A-001

Figure 6

Status LEDs

Page 12

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

6

3. Inverter LED

The green Inverter LED indicates the inverter is switched ON and ready to

provide backup power. If there is no ac power, the inverter LED will be ON solid,

indicating that the inverter/charger is in the inverter (ON) mode.

Inverter LED Other LEDs or Devices Meaning

ON (solid) Inverter ON

Flashing Charge LED (flashing) Inverter ready (charging)

Slow Flash Load Sense Searching

Flashing Error LED ON + Buzzer Inverter Error

OFF Inverter Switched OFF

4. Charge LED

The Charge LED indicates the current battery charge mode.

Charge LED Other LEDs or Devices Meaning

ON (solid) Bulk Charging

Slow Flash Absorption Charging

Fast Flash Batt. Full LED ON Float Charging

Very Fast Flash Equalize Charging

OFF Inverter Mode (no charging)

5. Batt. Full LED

The Batt. Full LED indicates the state of charge on the batteries. This LED

will not illuminate until the batteries have charged up to at least 90%. The

duration of the LED’s ON time will increase until the batteries reach 100%, which

at that time, the LED will be ON solid. In the inverter mode, the OFF time

duration of the LED will increase until the batteries discharge to below 90% at

which time the LED will extinguish.

Batt. Full LED Other LEDs or Devices Meaning

Solid Battery Fully Charged (100%)

Flashing Battery Charged 90% or

higher

OFF Battery Below 90% Charge

6. Error LED

The Error LED indicates that there is a problem with the inverter/charger or

batteries. Check the LCD display to find and correct the nature of the problem.

Error Other LEDs or Devices Meaning

ON (solid) Check System

3.0 OPERATION

Page 13

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

7

7. LCD Display

The LCD display is a 16 x 2 lines (32 characters total) back lit, alphanumeric display, used for setting up the system operation as well as viewing current

status or error messages. Scrolling through the display items is accomplished by

using the push-buttons below the display.

3.0 OPERATION

System Status:

Equalizing

822-4A-002

8. Push-buttons

There are four pressure-sensitive push-buttons on the front panel of the

RC7 and RC7GS used to control the inverter and enter system operating

parameters.

Figure 7

LCD Display

Meter Mode

On / Off Menu Item Settings

Setup

822-4A-003

Figure 8

Push-button Controls

a. On/Off

The On/Off push-button controls the inverter section of the inverter/charger.

Press this button once to turn the inverter ON or OFF. The charger section of the

inverter is not affected by this function and maintains the batteries whenever ac

power is present. On RC7GS models, this push-button also controls the

generator. Refer to Generator Start/Stop. Use this control when you do not want

the inverter to supply backup power in the event of an ac line failure. Ac output

power is available only as long as the ac line is present.

NOTE: Pressing this push-button disables the inverter function. Ac backup power

will NOT be available during a utility outage. The green INVERTER LED must be

flashing (with ac utility applied), indicating the inverter is in a ready state.

Pressing this push-button while the green LED is ON solid (indicating backup

mode), will cause the loss of the inverter output.

822-4A-004

On / Off

Figure 9

Inverter ON/OFF Push-button

Page 14

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

b. Setup/Menu Item Push-button

The Setup/Menu Item push-buttons accesses the system setup menus.

Press and hold both push-buttons for approximately 5 seconds or until the

display clears, then release the buttons. Press the UP or DOWN arrow buttons to

scroll through the menu items. To exit the Setup mode, press and hold both

push-buttons for approximately 5 seconds until the LCD display changes back to

the System Status display.

NOTE: Menu items are described later in the manual.

822-4A-005

Meter Mode

Menu Item

Setup

Figure 10

Setup/Menu Item Push-buttons

c. Meter Mode Push-button

The Meter Mode push-button (above) accesses the various operating

parameters such as output voltage, amperage, temperature, etc. To access the

Meter Mode, press and hold the Meter Mode push-button for approximately

5 seconds.

d. Settings Push-button

The Settings push-button scrolls through the various menus. Press this

button while in the Setup mode to move through the menu items one at a time. If

the desired item or setting is passed, continue pressing the Settings push-button

until the item or setting reappears. This push-button is also used to enable and

disable the equalize charge mode.

Settings

822-4A-006

Figure 11

Settings Push-button

3.0 OPERATION

8

Page 15

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

RC7 and RC7GS Setup Menu

The Setup menu configures the RC7 and RC7GS to specific operating

system parameters. To access the Setup menu press and hold the UP and

DOWN arrows push-buttons for approximately 5 seconds until the LCD display

clears. Choose the desired configuration settings for the system from the

appropriate menu. Exit the Setup Menu by pressing both the UP and Down

arrow push-buttons for approximately 5 seconds. The new settings will be saved

in nonvolatile memory 20 seconds after exiting the Setup mode (if nothing is

changed during the waiting period).

The initial menu that will appear in the LCD display is the Search Sense

menu shown below.

Search Sense:

Defeat

Figure 12

Initial LCD Display Item

The following menu items appear in the exact sequence they appear on the

RC7. Refer to pages 36-37 for the complete menu structure.

1. Search Sense

Search Sense enables or disables the power-saving “search” mode logic

circuitry. Refer to the inverter’s Operator’s manual for a complete description of

the Search Sense mode.

To configure the Search Sense mode, use the RIGHT arrow push-button

(Settings), to scroll to the desired setting. The default setting is

Defeat

.

Defeat disables the Search Sense function. The remaining selections,

specify the minimum wattage load that must be present on the inverter to qualify

as a load and bring the inverter out of the search mode. After selecting, press

the DOWN arrow to access the next menu.

Figure 13

Search Menu Selections

3.0 OPERATION

9

Search Sense:

Defeat

Search Sense:

About 5W load

Search Sense:

...10W load

Search Sense:

...40W load

Search Sense:

> 40W load

••••

Page 16

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

10

2. Auto LBCO

Automatic Low Battery Cut Out (Auto LBCO) prevents the inverter from

draining the batteries below 10.9 V dc (with no load on the output). When this

mode is enabled (ON), the inverter shuts OFF when the batteries reach

10.9 V dc. When it is disabled (OFF), the inverter remains ON until the batteries

reach a voltage of 8.5 V dc, at which point the inverter will shut off. When ac

input is available again, the inverter automatically resets and begins charging the

batteries. The default setting is OFF.

Press the RIGHT arrow (Settings) to select the desired function. After

selecting, press the DOWN arrow to scroll to the next menu or the UP arrow to

move to a previous menu.

3. Battery Capacity

Battery Capacity refers to the battery’s reser ve capacity in amp-hours. The

RC7 approximates the battery state-of-charge (SOC) and run-time then

estimates the battery capacity (Auto) over several charge/discharge cycles.

However, setting the capacity manually assures a more accurate initial SOC and

run-time calculations. The default setting is Auto.

The Battery Capacity setting also sets the absorption charge time where the

batteries are charged at the bulk voltage.

Auto ------------ 110 minutes (1.8 hours)

125 A hrs------ 60 minutes (1 hour)

250 A hrs------ 90 minutes (1.5 hours)

375 A hrs------ 120 minutes (2 hours)

500 A hrs------ 150 minutes (2.5 hours)

1000 A hrs ---- 180 minutes (3 hours)

Figure 14

Auto LBCO Selections

Figure 15

Battery Capacity Selections

Bat Capacity:

Auto

Bat Capacity:

125 A-hrs

Bat Capacity:

250 A-hrs

Bat Capacity:

375 A-hrs

Bat Capacity:

500 A-hrs

Bat Capacity:

1000 A-hrs

Auto LBCO:

OFF

Auto LBCO:

ON

3.0 OPERATION

Page 17

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

4. Battery Type

To ensure the batteries are receiving the proper charge voltage, the Battery

Type must be selected for the type of batteries used in the system: GEL Cell,

Liquid Lead Acid and AGM. The default setting is GEL Cell.

This voltage varies depending on the batteries used, as specified below.

BATTERY TYPE BULK V DC FLOAT V DC EQUALIZE V DC

GEL Cell 14.1 V dc 13.6 V dc Defeated

Liquid Led Acid 14.6 V dc 13.4 V dc 15.5 V dc

AGM 14.4 V dc 13.4 V dc 15.5 V dc

Figure 16

Battery Type Selections

Battery Type:

GEL Cell

Battery Type:

Liquid Lead Acid

Battery Type:

AGM

5. Charge Rate

The battery charger’s maximum output current can be specified using the

Charge Rate menu. The default is 100% of the maximum charge rate. Refer to

the inverter/charger Operator’s manual for specific system settings.

Figure 17

Charge Rate Selections

Charge Rate:

100% of max

Charge Rate:

90%

Charge Rate:

80%

Charge Rate:

20%

Charge Rate:

10%

••••

11

3.0 OPERATION

Page 18

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

12

6. Set Shore Power

The inverter monitors the ac power being drawn by both the battery charger

and the ac loads connected to the inverter. If the current draw approaches the

shore power circuit breaker rating, the battery charger reduces the amount of

current supplied to the batteries to provide the maximum current to the ac loads.

Set Shore Power ensures the battery charger does not exceed the shore power

circuit breaker rating. This setting should match the shore power or generator’s

circuit breaker rating. The default setting is 30 amps.

Figure 18

Set Shore Power Selections

7. RC7 Setup

The RC7 LCD screen displays system status and error messages that occur

during normal operation. From the Setup menu select:

Last Key (default) to display the last system status message displayed after

exiting the Setup menu.

Rolling Display to automatically show system status, state-of-charge, time

left to run, time left to charge, set shore power and gen start/stop (RC7GS only).

Power Saver to shut off the LCD display and LEDs after five minutes

without a key-press or new error message. Pressing any key will reactivate the

LCD display and LEDs for another five minutes. Errors during the power saver

mode will “wake-up” the remote.

RC7 Setup:

Last Key

RC7 Setup:

Power Saver

RC7 Setup:

Rolling Display

Set Shore Power

30 Amps

Set Shore Power

25 Amps

Set Shore Power

20 Amps

Set Shore Power

5 Amps

Set Shore Power

15 Amps

Set Shore Power

10 Amps

Figure 19

Set Shore Power Selections

Page 19

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

8. LCD Contrast

The LCD Contrast menu adjusts the contrast to accommodate changing

lighting conditions and viewing angle. The default setting is Max. Contrast.

9. External Shunt

When two inverter/chargers are utilized in a system, an additional RC7 can

be used as a battery “fuel gauge.” This requires an external shunt. Refer to the

inverter/charger’s Operator’s manual for instructions on installing an external

shunt. The Exter nal Shunt menu selects the fuelgauge unit. The default is None.

Figure 20

LCD Contrast Selections

10. Fuelgauge Cutout

The Fuelgauge Cutout menu sets the battery voltage zero percent state of

charge (0% SOC) with no load. This is the point at which the battery has zero

reserve amp-hours remaining. The Fuelgauge meter uses this number to

determine the 0% battery state-of-charge voltage. The default is 9.5 VDC.

Figure 21

External Shunt Selections

Figure 22

Fuelgauge Cutout Selections

External Shunt:

None

External Shunt:

This Inverter

External Shunt:

Other Inverter

Fuelgauge Cutout:

9.5VDC=0%SOC

Fuelgauge Cutout:

10.3VDC=0%SOC

Fuelgauge Cutout:

11.7VDC=0%SOC

Fuelgauge Cutout:

11.8VDC=0%SOC

••••

••••

LCD Contrast:

Max Contrast

LCD Contrast:

87%

LCD Contrast:

62%

LCD Contrast:

Min Contrast

••••••••

3.0 OPERATION

13

Page 20

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

14

RC7GS Setup Menu

The RC7GS (Generator Start) features several additional setup menu

selections related to automatic generator starting, stopping and generator quiet

time.

1. Set Clock (RC7GS only)

Some generator functions are based on the time of day. The clock must be

properly set to ensure the programmed function will perform at the correct time.

The clock uses 24-hour time and ranges from 00:00 to 23:59.

To access the Set Clk menu, scroll down past the generator menus by

pressing the DOWN arrow. A flashing cursor appears below (and behind) the

hour (H) or minute (M) characters in the display. Every eight seconds the cursor

alternates positions. When the cursor is under the hour digit, press the Settings

push-button to increment the hours to the current hour (00 to 23). When the

cursor is under the minutes digit, press the Settings push-button to increment the

minutes to the current minute (0 to 59). Press and hold the Settings push-button

to quickly increment the time, or press and release to increment the selected

digit by one unit at a time.

Figure 23

RC7GS Front Panel

Figure 24

Set Clock Display

Set Clk: 0-23:59

HH:MM

Hour selected

Increments Digit

(Settings push-button)

Page 21

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

2. Select Genset

After setting the clock, press the UP arrow once to access the Select

Genset menu. Select the type and model of the generator by pressing the

Settings push-button (RIGHT arrow) until the genset’s name and model is

displayed in the LCD readout. The default is Onan QuietDiesel.

NOTE: Not all generators are supported.

CAUTION: Other 30 through Other 80 are reserved for future use and must not

be selected.

3. Generator Start

After setting the clock and selecting a generator, set the parameters for

automatically starting the genset based upon a battery voltage or State-ofCharge (SOC). Press the UP arrow and scroll through the menus to access the

Generator Start menu. Press the Settings push-button (RIGHT arrow) until the

required setting is in the LCD display.

NOTE: The Auto Gen parameters can not set unless the clock is set-up first.

The default Generator Start selection is Manual (Push On). This setting

disables all automatic start functions. Any other selection from the Generator

Start menu, enables the RC7GS to automatically start the generator based upon

the battery’s state-of-charge.

Figure 25

Select Genset Display

Select Genset:

Onan QuietDiesel

Select Genset:

PowerTech 2-Wire

Select Genset:

PowerTech 3-Wire

Select Genset:

Other 80

••••••••

Figure 26

Generator Start Menu Selections

Generator Start:

Manual (Push ON)

Generator Start:

Auto at 40% SOC

Generator Start:

Auto at 60% SOC

Generator Start:

Auto at 11.0 VDC

Generator Start:

Auto at 12.2 VDC

••••

3.0 OPERATION

15

Page 22

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

Figure 28

Generator Start/Stop (on User Menu)

4. Generator Stop

The RC7GS can be configured to shut down the generator automatically

when the batteries reach 90 to 99% SOC, or when the charger initiates the

Absorption or the Float mode of charging. Refer to the inverter/charger’s

Operator’s manual for a detailed description on charging modes. The default is

Manual (Push Off).

Figure 29

Generator Start/Stop (on User Menu)

The generator can be stopped at any time by accessing the user menu until

the “Gen Start/Stop: Press (On/Off)” menu is displayed. Press the ON/Off pushbutton on the RC7GS front panel until the generator stops.

NOTE: The generator will start immediately if the auto-star t parameters are still

met.

3.0 OPERATION

Generator Stop:

Manual (Push OFF)

Generator Stop:

Auto at 90% SOC

Generator Stop:

Auto at 95% SOC

Generator Stop:

Auto at 99% SOC

Generator Stop:

Auto at Absorb

Generator Stop:

Auto at Float

The generator can be started or stopped at any time by pressing the DOWN

arrow push-button (User Menu) until the Gen Start/Stop menu is displayed.

Press and hold the On/Off push-button on the RC7GS front panel until the

generator starts or stops. Release the push-button as soon as the generator

starts. If the inverter/charger senses an ac supply while the remote control

On/Off push-button is pressed, it will shut down the generator.

NOTE: If the genset is manually started from the remote, a manual override is

initiated and the generator will NOT stop automatically. Shut down the generator

manually.

Figure 27

Generator Start/Stop (on User Menu)

Gen Start / Stop:

Press (ON / OFF)

822-4A-004

On / Off

Gen Start / Stop:

Press (ON / OFF)

822-4A-004

On / Off

16

Page 23

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

5. Begin Gen Quiet and End Gen Quiet

The period of time during which the generator is prevented from starting

automatically can be defined using the RC7GS.

To specify the begin quiet time, scroll to the Begin Gen Quiet: 00:00

by using the UP and DOWN arrow push-buttons. Set the Begin Gen Quiet start

time. The selected digit for hours or minutes will be underlined and highlighted

(refer to the Set Clock section for details on setting the time).

Figure 30

Start Generator Quiet Time

Press the DOWN arrow to access the End Gen Quiet: 00:00 menu and

select the appropriate end time.

Figure 31

End Generator Quiet Time

NOTE: If the generator is running at the begin quiet time, it will be shut down

automatically. If the auto-start parameters are met during quiet time, the buzzer

will sound and the LCD displays the message “Gen Quiet Fault.” The generator

will start automatically at the end of the quiet time.

Begin Gen Quiet

00:00

End Gen Quiet

00:00

NOTE: Setting begin and end time to 00:00 defeats the quiet time mode.

17

3.0 OPERATION

Page 24

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

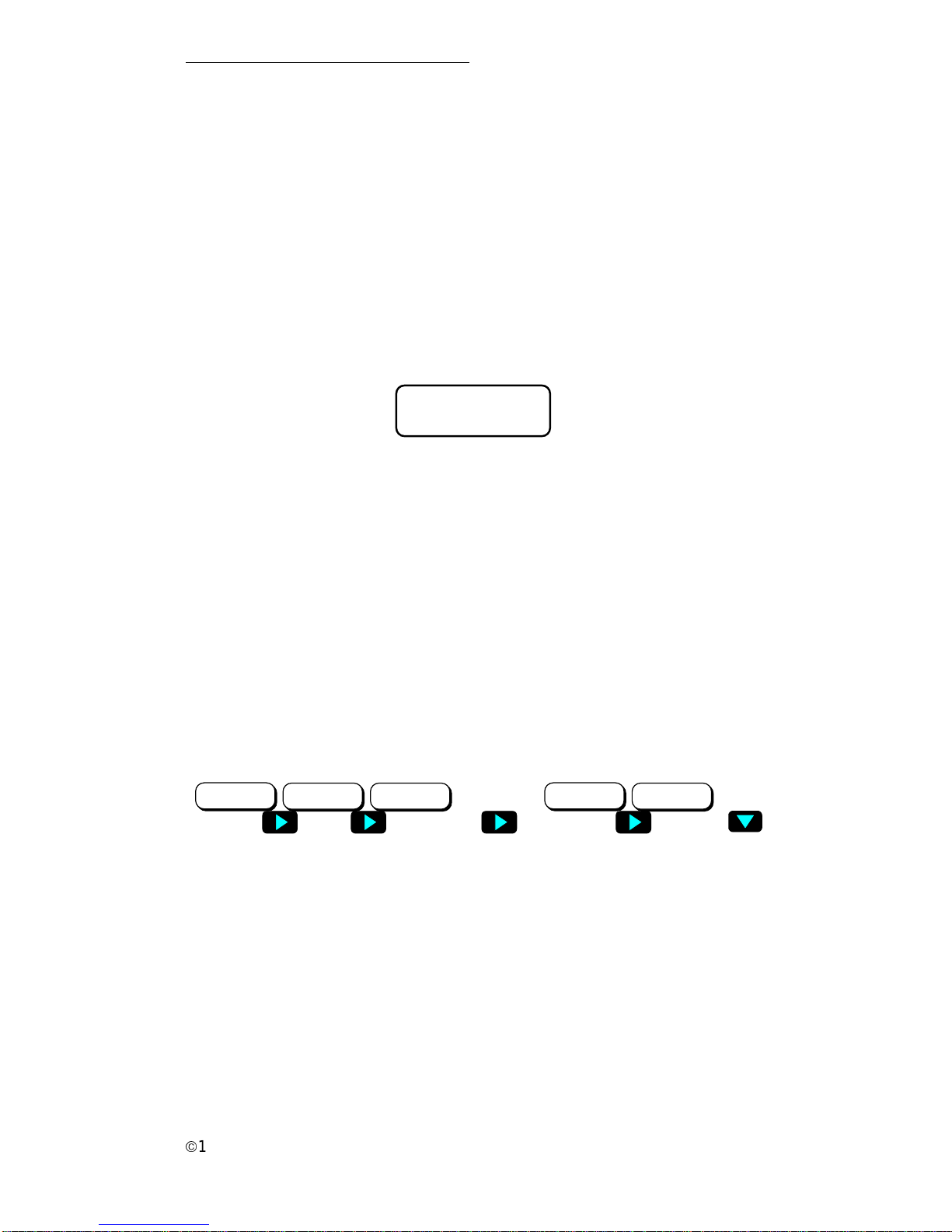

Saving Setup Choices

Once the setup options are complete, press and hold both the UP and

DOWN arrow push-buttons until the display clears (approximately 5 seconds).

The setup choices will be saved in nonvolatile memory 20 seconds after exiting

the Setup menu if no other actions are taken. These settings will be preserved

until changed.

NOTE: The GenStart settings will not be saved if the RC7GS is disconnected or

dc power is lost.

822-4A-005

Meter Mode

Menu Item

Setup

Figure 32

Press and Hold to Save Settings

3.0 OPERATION

18

Page 25

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

RC7 and RC7GS System Status Displays

The RC7 and RC7GS remote controls display the operating mode and

system status by lighting one or more LEDs located on the front panel and/or by

displaying a message on the LCD display. The four LEDs reflect the same

information as the single tricolored LED on the inverter/charger.

There are four types of system messages:

• AC source messages

• Inverter messages

• Charger messages

• Error messages

AC Source Messages

AC source messages appear when alternating current (shore power) is

present. In addition, the RC7GS ac source messages describe the current

activity, if any, of the generator.

1. Waiting for AC

Anytime the inverter is OFF and ac is not present, the LCD screen displays

“Waiting for AC.”

Figure 33

Waiting for AC

2. Genset Status: Pending, Cranking and Genstart

When the RC7GS is setup to start the generator for a specified condition

(SOC or battery voltage) and that condition has been met, the LCD displays

“Pending Genstart.”

Genset Status:

Pending Genstart

Genset Status:

Cranking Genset

When the initiating condition (SOC or battery voltage) has occurred, the

Pending Genstart message is displayed for approximately two minutes awaiting

a change in the condition or a manual override. If neither condition occurs, the

RC7GS attempts to start the generator and displays “Cranking Genset.”

Figure 34

Pending Genstart Messages

Figure 35

Cranking Genset Messages

3.0 OPERATION

19

System Status:

Waiting for AC

Page 26

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

Genset Status:

AC Available

Once the generator starts, there is a brief delay to allow the genset to reach

operating speed and for the inverter/charge to synchronize to the generator, at

which point the LCD display shows that ac is again available.

Figure 35

Cranking Genset Messages

3. Starter Cooldown and Gen Start

In the event the genset does not start within 30 seconds, a two-minute

starter cooldown message is displayed after which another attempt to start the

generator occurs. This cycle repeats itself three more times over a

12 minute period.

Genset Status:

Starter Cooldown

Figure 36

Starter Cooldown Messages

Gen Set Error Messages

1. Gen Won’t Start

If the genset does not start after the four attempts, the RC7GS displays the

message “Gen Won’t Start” and the red Error LED on the front panel lights. No

further attempts to star t the genset will occur. Correct the starting problem and

manually start the genset by setting the RC7GS to “Manual (Push On)” from the

setup menu and then set it back to the previous auto-start menu, which resets he

RC7GS.

Figure 37

Gen Won’t Start Error Message

2. Gen Quiet Fault

Whenever the RC7GS is configured to Auto Start the generator under a

specified condition and the condition occurs during the gen quiet period, the LCD

will display the Gen Quiet Fault message and the red Error LED will light. The

remote control also emits a series of beeping sounds for up to five minutes or

until the error condition is corrected. The gen quiet period can be overridden by

resetting the Gen Quiet Begin and End time to 00:00.

3.0 OPERATION

20

Genset Status:

Gen wont Start

Red Error LED lights and

error message appears

in the LCD display

Inverter

Charge

Batt. Full

Error

822-4A-001

Buzzer Sounds

NOTE: Press any arrow push-button to cancel the buzzer.

Page 27

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

NOTE: Press any arrow push-button to cancel the buzzer.

NOTE: If the genset is manually started from the RC7GS remote, a manual

override is initiated and it will not shut down automatically. “Man Stop Only!!”

(Figure 39) will be displayed in the LCD. Shut down the genset manually as

previously described.

NOTE: The Gen Quiet Fault error is not actually a system error or fault but rather

an alert that the system has reached the selected auto-start parameter during

the quit time selected.

Figure 38

Gen Quiet Fault Error Message

Genset Status:

Man Stop Only!!

Figure 39

Genset Manual Stop Only Display

3.0 OPERATION

21

The Gen Quiet Fault error is automatically reset at the end of the quiet time

period if no other action is taken.

Figure 40

Low AC Input V Error Message

3. Low AC Input V

The Low AC Input V Fault error indicates the input ac voltage is below

45 V ac (B+ is present–Power Tech generators only). The red error LED is ON

and the buzzer sounds. When the ac voltage is above 45 V ac, this error

message will disappear.

Genset Status:

Gen Quiet Fault

Inverter

Charge

Batt. Full

Error

822-4A-001

Red Error LED Lights and Error Message Appears in the LCD

Display and buzzer sounds.

Buzzer Sounds

Genset Status:

Low AC Input V

Red Error LED Lights and Error Message Appears

in the LCD Display and buzzer sounds.

Buzzer Sounds

Inverter

Charge

Batt. Full

Error

822-4A-001

NOTE: Press any arrow push-button to cancel the buzzer.

Page 28

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

22

Inverter Mode Messages

When the inverter is ON (no ac present), it is either inverting or measuring

the ac output circuits for a load meeting the specifications set up in the Search

Sense menu selection (Figure 12 and 13), (if the Search Mode is selected).

When the inverter is in the Search mode, “Searching” appears in the LCD display

and the green Inverter LED will slowly flash.

Figure 41

Inverter in Search Mode

System Status:

Searching

Green LED Slowly

Flashes and Searching

Appears in LCD

Inverter

Charge

Batt. Full

Error

822-4A-001

When the inverter/charger is in the inverter mode (no ac available),

“Inverting” appears in the LCD display and the green Inverter LED is on solid.

Figure 42

Inverter Mode

System Status:

Inverting

Green LED is on solid

and Inverting appears

in the LCD

Inverter

Charge

Batt. Full

Error

822-4A-001

3.0 OPERATION

NOTE: The Inverter LED will slowly flash during the charge mode if the inverter

is switched ON and will be OFF if the inverter is switched OFF.

Page 29

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

Charger Mode Messages

When ac (shore power) is available, the inverter/charger automatically

switches to the charger mode. There are four separate charger modes: Bulk,

Absorption, Float and Equalization. Refer to the inverter/charger Operator’s

manual for details on charger modes.

1. Bulk Charging

When the charger is charging in the Bulk mode, the LCD will display “Bulk

Charging” and the charge LED will be on solid.

Figure 43

Bulk Charging Mode

2. Absorption Charging

When the charger is charging in the Absorption mode, the LCD displays

“Absorption Chg” and the Charge LED slowly flashes. In addition, the Batt. Full

LED will start to flash when the batter y reaches 90% state-of-charge (SOC). The

ON duration of this LED increases as the batteries SOC increases and is ON

solid at 100% SOC.

Figure 44

Absorption Charging Mode

3.0 OPERATION

System Status:

Bulk Charging

Yellow Charge LED is on solid and Bulk Charging

appears in the LCD

Inverter

Charge

Batt. Full

Error

822-4A-001

23

3. Float Charging

When the charger is in the Float mode, the LCD displays “Float Charging”

and the Charge LED will quickly flash. At this point the batteries are fully charged

(100%) and the Batt. Full LED is ON solid.

Figure 45

Float Charging Mode

System Status:

Float Charging

Yellow Charge LED fast flashes and Float Chg appears in LCD.

Batt. Full LED is ON solid.

Inverter

Charge

Batt. Full

Error

822-4A-001

System Status:

Absorption Chg

Yellow Charge LED slowly flashes and Absorption Chg

appears in LCD. Batt. Full LED flashes according to the SOC

(between 90-100%).

Inverter

Charge

Batt. Full

Error

822-4A-001

Page 30

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

4. Equalizing Charging (Liquid Lead Acid and AGM Batteries ONLY)

To activate the Equalize mode, press and hold the Settings push-button

(RIGHT arrow) until the LCD display clears and “Equalizing” appears

(approximately 6 seconds). The Charge LED will increase its flashing rate to

approximately 8 flashes per second (flickering). The Equalize charge will

continue for 3 hours and then automatically change back to Float.

NOTE: Equalizing the batteries should only be done when the batteries are fully

charged (i.e., from Float mode) and only on liquid lead acid or AGM batteries.

Vent caps on batteries (lead acid only) should be removed prior to running the

Equalize mode. If the Equalization charge mode is cancelled, (by pressing and

holding the Settings push-button for approximately 6 seconds) the LCD display

will indicate the System Status as Absorption chg for approximately 30 seconds

before returning to Float charging.

CAUTION: Only Liquid Lead Acid or AGM batteries should be equalize charged.

Running an equalize charge on batteries other than liquid lead acid or AGM

types could permanently damage them.

CAUTION: Do not attempt to remove vent caps on AGM batteries. Doing so may

void the warranty.

CAUTION: All dc loads should be disconnected dur ing the equalize charge

period due to the higher voltage applied to the batteries (15+ volts dc). Refer to

the inverter manual Equalize Charging section for details.

NOTE: The equalizing mode is defeated if GEL cell is selected as the battery

type.

Figure 46

Equalizing Mode

24

System Status:

Equalizing

Yellow Charge LED quickly flashes (8/second), Equalizing

appears in LCD, and Batt. Full LED is ON solid.

Inverter

Charge

Batt. Full

Error

822-4A-001

Page 31

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

Inverter/Charger Error Messages

Error messages display when a fault is detected with either the inverter or

charger. The red Error LED lights, and the buzzer sounds. Error messages for

the inverter/charger display the error condition as well as a suggested remedy.

1. Over Temperature

The “Otemp / Less Load” System Status message indicates the inverter/

charger transformer and power components have exceeded a safe operating

temperature. Reduce the load on the inverter. When the unit has cooled, it will

automatically reset and resume operation. If this condition occurs often, make

sure the inverter is in a cool location, has adequate ventilation and the cooling

fan is operational.

Figure 47

Error Display–Over Temperature

2. Overload

The “Overload” System Status message is displayed when the load on the

inverter/charger exceeds the maximum power rating of the unit. Reduce the load

and restart the inverter/charger by pressing the ON/OFF push-button on the RC7

twice.

Figure 48

Error Display–Overload

25

System Status:

Otemp / Less Load

Inverter

Charge

Batt. Full

Error

822-4A-001

Error Condition

Remedy

Error LED ON

Buzzer Sounds

System Status:

Overload

Inverter

Charge

Batt. Full

Error

822-4A-001

Error LED ON

Error Condition

Buzzer Sounds

3.0 OPERATION

NOTE: Press any arrow push-button to cancel the buzzer.

NOTE: Press any arrow push-button to cancel the buzzer.

Page 32

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

4. Low Battery Voltage

The “Lobat/Start Chrg” System Status message is displayed when the

battery voltage drops below a safe level. The red Error LED illuminates and the

Buzzer sounds. The inverter shuts off to prevent damage to the batteries.

Provide an ac supply (such as shore power or a generator) to the inverter/

charger to automatically start charging the batteries.

Figure 50

Error Display–Low Battery Voltage

26

System Status:

Lobat/Start Chrg

Inverter

Charge

Batt. Full

Error

822-4A-001

Error LED ON

Error Condition

Remedy

Buzzer Sounds

NOTE: Press any arrow push-button to cancel the buzzer.

3. High Battery Voltage

The “Hibat/Stop Chrg” System Status message is displayed when the

battery voltage is too high. Switch off any other charging sources to allow the

voltage level to drop. The inverter automatically resets and resumes operation

when the battery reaches a safe voltage level. This condition usually occurs only

when an additional charging source is used to charge the battery bank.

Figure 49

Error Display–High Battery Voltage

System Status:

Hibat/Stop Chrg

Inverter

Charge

Batt. Full

Error

822-4A-001

Error LED ON

Error Condition

Remedy

Buzzer Sounds

NOTE: Press any arrow push-button to cancel the buzzer.

Page 33

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

6. Charger Fault

The “Charger Fault” System Status message is displayed when an internal

error is detected in the inverter/charger during charging. In addition, the red Error

LED is ON and the buzzer sounds. After 15 minutes, the charge relay

disconnects and the inverter section is shut down. The LCD displays “System

Status: Overload.”

This fault indicates there is a hardware failure in the charger circuitry of the

inverter/charger. If this message appears, contact Trace Engineering or the

nearest Service Center.

Figure 52

Error Display–Charger Fault

27

3.0 OPERATION

System Status:

Charger Fault

Inverter

Charge

Batt. Full

Error

822-4A-001

Error LED ON

Error Condition

Buzzer Sounds

5. DCLD Lockout Error

The “DCLD Lockout Err” System Status message is displayed when the

+12 V dc supplied to the “DCLD” input wire of the inverter/charger is lost and the

DCLD feature is activated. In addition, the red Error LED will light and the buzzer

will sound for approximately four minutes.

The DCLD (DC Load Disconnect) feature can be used to shut off the

inverter/charger whenever +12 V dc is not available on this terminal.

NOTE: Older units require a hardware modification to activate this feature. Refer

to the instructions in the upgrade kit for DCLD.

NOTE: The DCLD is not an error or fault with the system. It is an alert, indicating

that the inverter is not running.

Figure 51

Error Display–DCLD Lockout Error

System Status:

DCLD Lockout Err

Inverter

Charge

Batt. Full

Error

822-4A-001

Error LED ON

Error Condition

Buzzer Sounds

NOTE: Press any arrow push-button to cancel the buzzer.

NOTE: Press any arrow push-button to cancel the buzzer.

Page 34

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3. Inverter/Charger Current

This meter displays the actual dc current supplied to the batteries when it is

charging (+) and current drawn from the batteries when it is inverting (–).

Figure 55

Meter Mode Display–Inverter/Charger Current

Inv / Chg Current:

+ / - 0 Amps DC

Meters Display

The RC7 and RC7GS have built-in meters that monitor inverter/charger

activities. To view these meters, press and hold the Meter Mode push-button (UP

arrow) for five seconds until the display clears. Use the DOWN arrow pushbutton to scroll through the meter displays. The information contained in these

displays can be useful for troubleshooting the system.

1. Average Shunt Amps

This meter displays the averaged current flowing through the internal shunt

(external shunt if more than one inverter/charger is used) to and from the

batteries.

Figure 53

Meter Mode Display–Average Shunt Amps

2. Battery Voltage

This meter displays the current battery voltage level. Use this meter to

check the condition of the batteries or monitor the levels under load.

Avg Shunt Amps:

+ / - 0 Amps DC

Battery:

00.0 V olts DC

Figure 54

Meter Mode Display–Battery Voltage

28

3.0 OPERATION

Page 35

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

3.0 OPERATION

4. AC Output Voltage

This meter displays the actual inverter ac output voltage measured at the

ac output. When in the charger mode, the meter will read “0 VAC.” Search mode

is indicated by “< 40 VAC” appearing in the display.

Figure 56

Meter Mode Display–AC Output Voltage

Inverter Output:

0 VAC

5. AC Input Amps

This meter displays the actual ac current (in amps) flowing through the

inverter’s AC INPUT HOT 1 terminal.

AC Input:

1 Amps AC

Figure 57

Meter Mode Display–AC Input Amps

6. Battery Temperature

This meter displays the external temperature of the battery bank when

equipped with a Battery Temperature Sensor (BTS). The scale is divided into

counts, which do not directly correspond to the Fahrenheit or Celsius

temperature scale. A higher reading indicates a lower temperature. This meter is

useful for service technicians.

Battery Temp:

000 Counts

Figure 58

Meter Mode Display–Battery Temperature

29

Page 36

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

30

7. Transformer Temperature

This meter displays the internal temperature of the inverter/charger’s

transformer. The scale is divided into counts, which do not directly correspond to

the Fahrenheit or Celsius temperature scale. A higher reading indicates a lower

temperature. This meter is useful for service technicians.

Xformer Temp:

000 Counts

Figure 59

Meter Mode Display–Transformer Temperature

8. FET Temperature

This meter displays the relative temperature of the Field Effect Transistors.

The scale is divided into counts, which do not directly correspond to the

Fahrenheit or Celsius temperature scale. A higher reading indicates a lower

temperature. This meter is useful for service technicians.

FET Temp:

000 Counts

Figure 60

Meter Mode Display–FET Temperature

9. Estimated Battery Capacity

This meter displays the estimated battery amp-hour capacity based upon

the average amp-hours used and the rate and duration of the charging cycles.

Multiply the reading by eight to arrive at the approximate battery capacity. This is

only an approximation and becomes more accurate as the number of charge/

discharge cycles increases (approximately 15–20 charge/discharge cycles).

NOTE: If battery power is removed from the inverter, the calculation process

restarts. 15–20 charge/discharge cycles must complete to reach accurate battery

capacity.

Est. Bat. Cap:

00 Amp-hrs(x8)

Figure 61

Meter Mode Display–Estimated Battery Capacity

Page 37

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

System Status Messages

After installing the RC7/RC7GS, the LCD screen displays operating system

status messages which is the default screen after exiting all other setting or

meter functions. Operating parameters include; Battery State-of-charge (SOC),

Time Remaining to Run, Time Left to Charge and Set Shore Power. The Gen

Start-Stop switch is also available from these displays (RC7GS only).

Press the DOWN arrow to scroll through each display. When the last menu

item is reached, the display wraps back to the first menu item in a continuous

loop.

1. Battery State of Charge

This meter displays the estimated state-of-charge (SOC) of the battery or

battery bank. The SOC is based on the estimated battery capacity. Since

discharging the batteries to less than one half of their amp-hour capacity may

damage the batteries, the meter estimates the 0% SOC and protects the

batteries from over discharge.

The display can be viewed as a percent-of-capacity or bar graph by

pressing the Settings push-button (RIGHT arrow).

Figure 62

Battery State of Charge Displays (Percent and Bar Graph)

2. Time Left to Run

This meter displays the estimated hours the batteries will support the load

before requiring recharging. The meter is accurate to 1/10 of an hour

(6 minutes).

Time Left to Run:

x.x Hours

Figure 63

Time Left to Run Display

Batt State of Charge:

xx% Full

Batt State of Charge:

E [] [] [] [] [] [] [] [] [] F

31

3.0 OPERATION

Page 38

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

32

3. Time Left to Charge

This meter displays the estimated hours required to charge the batteries to

full capacity. The meter is accurate to 1/10 of an hour (6 minutes).

Time Left to Charge:

x.x Hours

Figure 64

Time Left to Charge Display

4. Set Shore Power

This meter sets the shore power input (from 5-30 amps) so the total current

draw from the charger does not exceed the circuit breaker rating, to provide the

maximum current to the ac loads. Use the Settings push-button (RIGHT arrow)

to change this setting to match the circuit breaker rating of the ac power source.

NOTE: The maximum current draw from the 3000 kVA unit’s charger is 28 amps.

NOTE: This setting does not prevent the loads from exceeding the shore circuit

breaker rating.

Figure 65

Set Shore Power Display

5. Generator Start/Stop

The generator can be manually started or stopped from this display by

pressing the On/Off push-button on the RC7GS front panel.

NOTE: Starting the generator from this display overrides all auto-start/stop

function and displays “Man/Stop Only!!” on the User Status menu. Stopping the

generator returns the auto start/stop functions.

Figure 66

Generator Start/Stop Display

Set Shore Power:

5 Amps

Set Shore Power:

30 Amps

822-4A-004

On / Off

Gen Start / Stop:

Press (ON / OFF)

Page 39

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

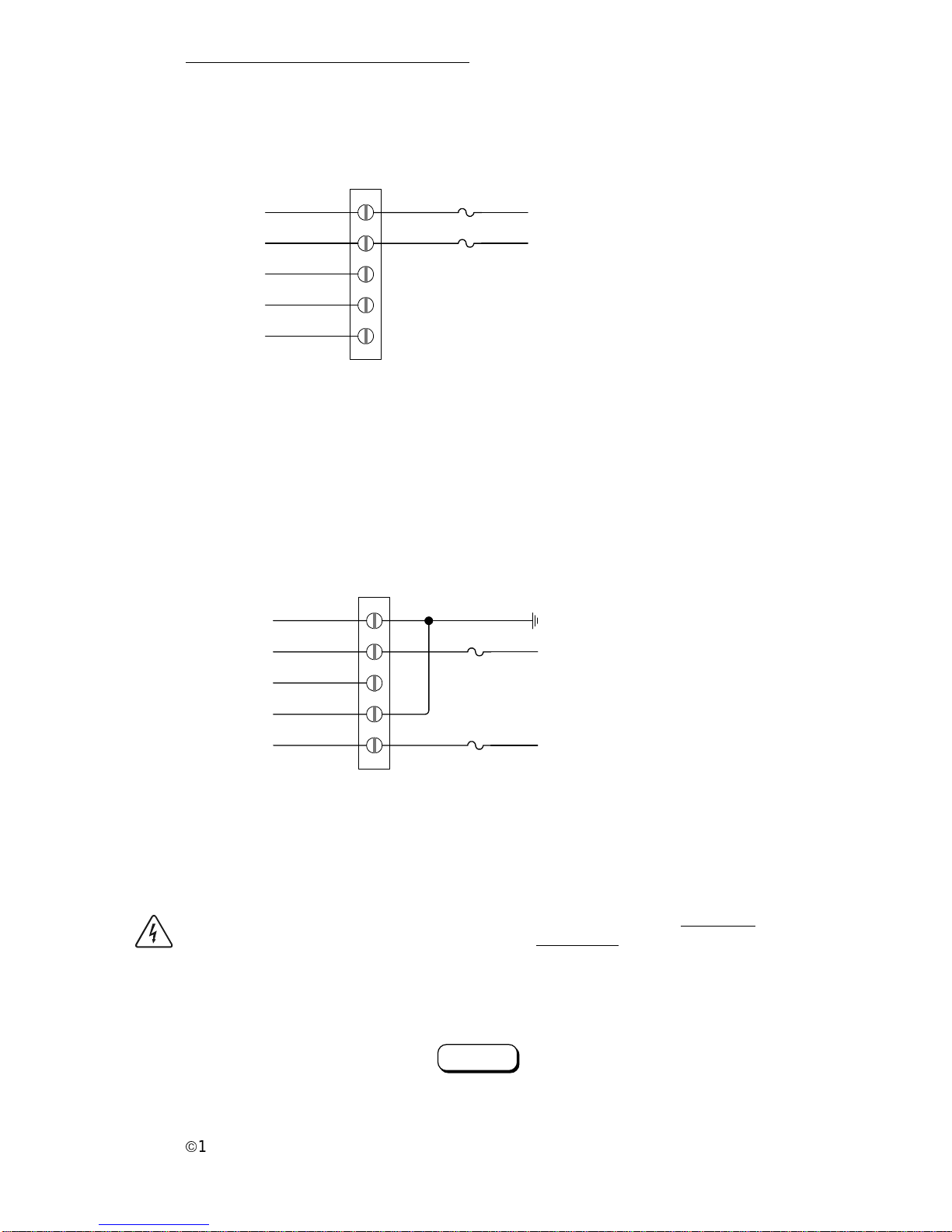

Generator Connection (RV Series onl y)

Proper installation and setup of the ac generator is essential for the correct

operation of the inverter/charger. The RC7GS contains the proper software code

to work with various generators listed in the LCD display.

NOTE: The RV Series inverter/charger must be at Software Rev. 1.3x to

interface correctly with the RC7GS.

Connect the generator to the inverter as shown in the following diagrams.

Select the generator type and model, as previously described under “Select

Genset” on page 15.

NOTE: The terminal strip for connecting the generator is shown below. Refer to

the RV Series inverter/charger Operator’s manual for complete wiring details.

Figure 67

Genset Connections on RV Series Inverter/Charger Terminal Strip

GEN RUN 2

GEN RUN 1

GEN RUN 3

GEN START 2

GEN START 1

Figure 68

Onan Quiet Diesel Connections

E

C

A

GENSET

CONNECTOR

INVERTER/CHARGER

COM.

GEN START 1

N.O.

GEN START 2

N.C.

GEN RUN 3

COM.

GENRUN 1

N.O.

GEN RUN 2

822-4A-008

START

STOP

GROUND

5 A

5 A

1. Onan Quiet Diesel - HDKAJ, HDKAK, 7.5/8/10 and 12.5 kw

Connect the generator as shown below.

3.0 OPERATION

33

Page 40

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

34

2. Power Tech Wiring Diagrams (2 and 3-wire)

Before wiring for the Power Tech option, read all instructions and

cautionary markings located in the RV Series inverter/charger Operator’s

manual.

NOTE: Rev. 1.3x must be installed in both the inverter and RC7GS remote.

·

Both 2-wire and 3-wire Power Tech Generators require a B+ (Battery

Positive) wire from the generator to the inverter to indicate the generator is

running.

·

Power Tech supplies a gray wire on both 2-wire and 3-wire marked “12V

power or +12V with engine running.” This wire must be connected to the

white B+ wire in the inverter’s ac wiring compartment. The connector is a

two-wire molex connector with a white and gray wire attached, which is

taped to the chassis in the left-hand side of the ac section of the inverter.

Figure 69

Molex Connector Identification

2-Wire Molex

Connector

(located in ac

compartment)

GRAY

(not used)

WHITE

(from gray Gen B +)

NOTE: The main board in the inverter must be a REV H or higher (S/N # AN

00655 or higher for RV2012; AS00085 or higher for RV2512; and AJ01001 or

higher for RV3012) to work with Power Tech generators.

Page 41

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

a. PowerTech 2-wire

Connect the generator as shown below.

b. PowerTech 3-wire

Connect the generator as shown in below.

INVERTER/CHARGER

COM.

GEN START 1

N.O.

GEN START 2

N.C.

GEN RUN 3

COM.

GENRUN 1

N.O.

GEN RUN 2

822-4A-010

START

STOP

GROUND

5 A

5 A

GROUND

BLUE (start wire)

YELLOW (stop/preheat wire)

3-WIRE CONFIGURATION

Figure 68

PowerTech 2-Wire

Figure 70

PowerTech 3-wire

INVERTER/CHARGER

COM.

GEN START 1

N.O.

GEN START 2

N.C.

GEN RUN 3

COM.

GENRUN 1

N.O.

GEN RUN 2

822-4A-009

5 A

5 A

RED (from start/stop switch)

2-WIRE CONFIGURATION

WHITE/RED (from start/stop switch)

WARNING: WHEN STORING AN RV/RC7GS EQUIPPED VEHICLE INDOORS,

ENSURE THE AUTO GEN START FEATURE IS DISABLED BY RESETTING

THE GENERA T OR START FUNCTION TO “MANUAL (PUSH ON).” REFER TO

THE RC7GS SETUP MENU SECTION. FAILURE TO DO SO MAY ALLOW THE

GENERA T OR TO RUN WHEN THE AUTO-START PARAMETERS ARE MET

PRODUCING DANGEROUS EXHAUST FUMES.

Figure 71

Select MANUAL Start for Storage

Generator Start:

Manual (Push ON)

3.0 OPERATION

35

Page 42

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

3.0 OPERATION

36

Search Sense:

Default

Auto LBCO

OFF

Bat Capacity:

Auto

RC7 and RC7GS Setup Menu

Press and hold both menu item keys for 5 seconds

Search Sense:

About 5W load

Auto LBCO

ON

Bat Capacity:

125 A-hrs

Search Sense:

...10 W load

Bat Capacity:

250 A-hrs

Search Sense:

...40 W load

Bat Capacity:

375 A-hrs

Search Sense:

> 40 W load

Bat Capacity:

500 A-hrs

Bat Capacity:

1000 A-hrs

Battery Type:

GEL Cell

Charge Rate

100% of max

Battery Type:

Liquid Lead Acid

Bat Capacity:

90%

Battery Type:

AGM

Bat Capacity:

80%

Bat Capacity:

20%

Bat Capacity:

10%

Set Shore Power

30 Amps

Set Shore Power

25 Amps

Set Shore Power

20 Amps

Set Shore Power

5 Amps

RC7 Setup:

Last Key

LCD Contrast:

Max Contrast

RC7 Setup:

Power Saver

LCD Contrast:

87%

RC7 Setup:

Rolling Display

LCD Contrast:

62%

LCD Contrast:

Min Contrast

External Shunt:

None

External Shunt:

This Inverter

External Shunt:

Other Inverter

Fuelgauge Cutout:

9.5VDC=0%SOC

Fuelgauge Cutout:

10.3VDC=0%SOC

Fuelgauge Cutout:

11.7VDC=0%SOC

Fuelgauge Cutout:

11.8VDC=0%SOC

Generator Start:

Manual (Push ON)

Generator Start:

Auto at 40% SOC

Generator Start:

Auto at 60% SOC

Generator Start:

Auto at 11.0 VDC

Generator Start:

Auto at 12.2 VDC

Generator Stop:

Manual (Push OFF)

Generator Stop:

Auto at 90% SOC

Generator Stop:

Auto at 95% SOC

Generator Stop:

Auto at 99% SOC

Generator Stop:

Auto at Absorb

Generator Stop:

Auto at Float

Begin Gen Quiet

00:00

End Gen Quiet

00:00

Select Genset:

Onan QuietDiesel

Select Genset:

PowerTech 2-Wire

Select Genset:

PowerTech 3-Wire

Select Genset:

Other 80

Set Clk: 0-23:59

00:00

RC7GS only

Note: The SETTINGS arrow moves across the columns - the UP and DOWN

arrows scroll through the headings.

Set Shore Power

15 Amps

Set Shore Power

10 Amps

Page 43

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

System Status:

Waiting for AC

RC7 and RC7GS Users Menu

System Status:

AC Available

System Status:

Searching

System Status:

Inverting

System Status:

Bulk Charging

System Status:

Absorption Chrg

System Status:

Float Charging

System Status:

Equalizing

System Status:

Hi Bat / Stop Chrg

System Status:

Lo Bat / Start Chrg

System Status:

DCLD Lockout Err

System Status:

Charger Fault

Genset Status:

Pending Genstart

Genset Status:

Cranking Genset

Genset Status:

Man Stop Only!!

Genset Status:

Gen wont Start

Genset Status:

Low AC Input V

Genset Status:

Starter Cooldown

Genset Status:

Gen Quiet Fault

RC7GS only

Avg Shunt Amps:

+ / - 0 Amps DC

FET Temp:

000 Counts

Est. Bat. Cap:

xx Amp-hrs (x 8)

System Status Display Meters Display

AC Source Inverter Mode Charger Mode Error Mode

System Status:

Otemp / Less Load

System Status:

Overload

Battery:

00.0 V olts DC

Inv / Chg Current:

+ / - 0 Amps DC

AC Input:

0 Amps AC

Inverter Output:

VAC 0

Battery Temp:

000 Counts

Xformer Temp:

000 Counts

Batt State of Charge:

xx% Full

Batt State of Charge:

E [] [] [] [] [] [] [] [] [] F

Time Left to Run:

x.x Hours

Time Left to Charge:

x.x Hours

Set Shore Power:

x.x Amps

Gen Start / Stop:

Press (ON / OFF)

System Status Messages

3.0 OPERATION

37

Page 44

ã

1999 Trace Engineering

RC7 & RC7GS Remote Controls

38

Storage Checklist

NOTE: This applies only to the RV Ser ies inverter/charger with RC7GS Remote.

Proper storage procedures extends the life of the batteries and ensures the

coach is ready for operation when needed. The following checklist is for battery

related storage activities.

Preparation for Storage

Interior Storage

• Check that all batteries are fully charged.

• Disable the Auto Gen. feature.

• Configure the RV to the correct shore service settings.

• Connect the shore power cord to a live outlet (confirm it is live).

• Switch the RV unit OFF using the remote’s On/Off push-button

(charger only mode).

• Switch OFF all unnecessary ac and dc loads.

WARNING: DO NOT STORE THE COACH INDOORS WITH THE AUTO GEN

START FEATURE ENABLED. THE GENERATOR PRODUCES DANGEROUS

FUMES WHEN IT IS RUNNING.

Exterior Storage

For exterior storage, follow the same steps as above. If shore power is not

available, enable the Auto-Gen Start feature and ensure that enough fuel is

available to run the generator for charging the batteries. The generator will

automatically start and stop, depending on the battery’s state-of-charge.

3.0 OPERATION

Page 45

ã

1999 Trace Engineer ing

RC7 & RC7GS Remote Controls

4.0 SERVICE INFORMATION

Trace Engineering takes great pride in its products and makes every effort to

ensure your unit fully meets your RV powering needs.

If your product needs repair, contact our Service department at: (360) 4358826 to obtain an RMA# and shipping information; or fax this page with the

following information to: (360) 474-0616. Please provide:

Model Number: _____________________________________

Serial Number: _____________________________________

Purchase Date: _____________________________________

Problem: ___________________________________________

Include a telephone number where you can be reached during business

hours and a complete return shipping address (P.O. Box numbers are not

acceptable).

Name:_____________________________________________

Address:___________________________________________

City:_______________________________________________

State / Province:_____________________________________

Zip / Postal Code:____________________________________

Phone: ( )_______________________________________

Country:____________________________________________

If you would like to send us a photo and tell us about the system you are

building, such as application, loads, size, operating environment and alternative

power source, we’d like to hear from you.

visit our website at: www.traceengineering.com

39

Page 46

Page 47

Page 48

visit our website at: www.traceengineering.com

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

Loading...

Loading...