Page 1

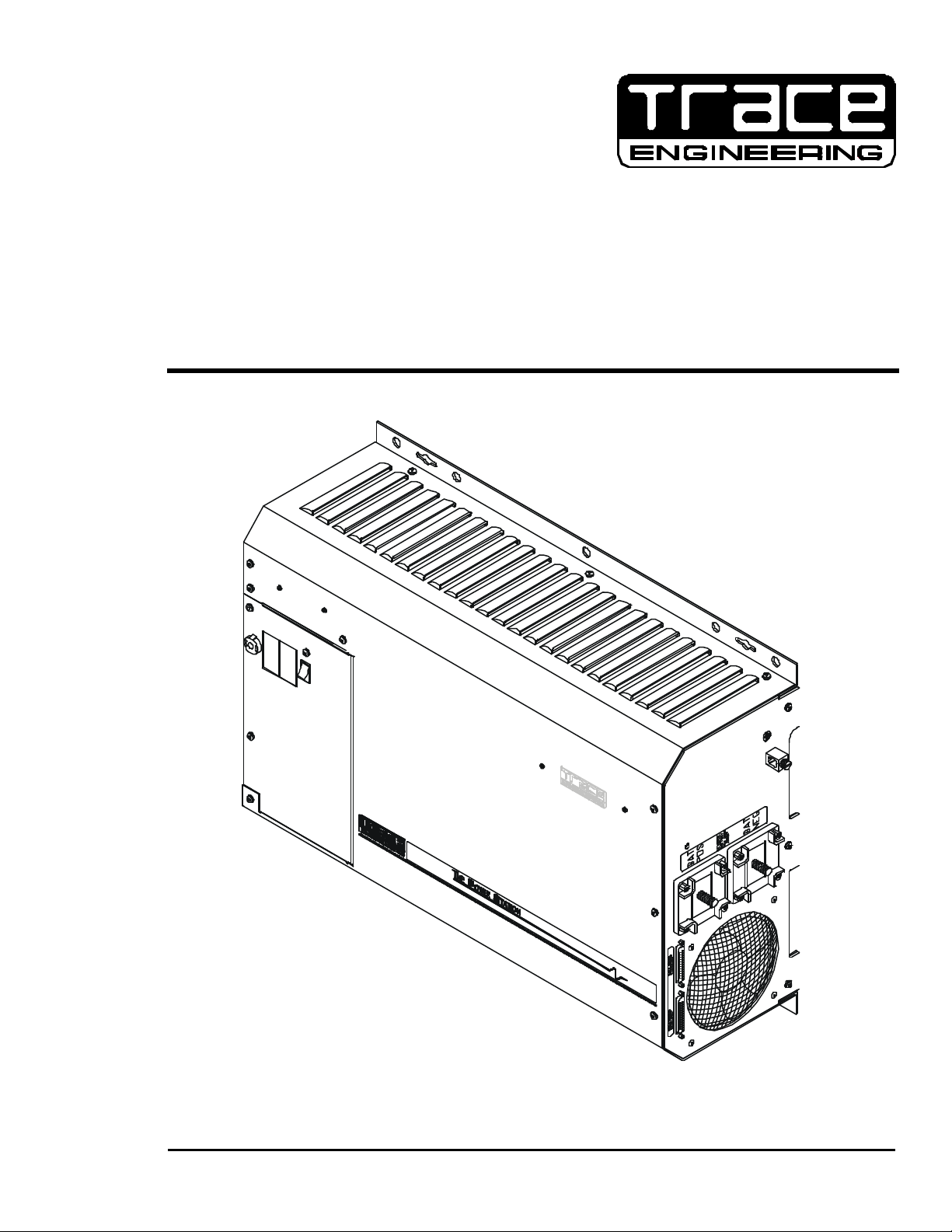

PS Series Inverter/Chargers

AE Configuration - Revision 5 Software

Owner’s Manual

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page 2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS......................................................................................................................................3

GENERAL PRECAUTIONS..........................................................................................................................................................3

SPECIAL NOTICES......................................................................................................................................................................3

PERSONAL PRECAUTIONS........................................................................................................................................................4

INTRODUCTION...............................................................................................................................................................................5

UNIT IDENTIFICATION...................................................................................................................................................................7

MODEL NUMBER.........................................................................................................................................................................8

CERTIFICATION..........................................................................................................................................................................8

CONTROLS, INDICATORS AND COMPONENTS.....................................................................................................................9

ON/OFF POWER SWITCH...........................................................................................................................................................9

INVERTER/CHARGER CIRCUIT BREAKER..............................................................................................................................10

CIRCUIT BREAKERS.................................................................................................................................................................10

‘MAXIMUM AC AMPS IN’ SWITCH ............................................................................................................................................10

LED STATUS INDICATORS.......................................................................................................................................................10

AC SIDE.....................................................................................................................................................................................13

DC SIDE.....................................................................................................................................................................................15

INSTALLATION.............................................................................................................................................................................17

LOCATION.................................................................................................................................................................................17

MOUNTING................................................................................................................................................................................18

VENTILATION............................................................................................................................................................................18

AC WIRING................................................................................................................................................................................18

DC WIRING................................................................................................................................................................................21

QUICK INSTALL.........................................................................................................................................................................26

FUNCTIONAL TEST.....................................................................................................................................................................27

MENU SYSTEM .............................................................................................................................................................................29

OVERVIEW................................................................................................................................................................................29

USER MENU MAP......................................................................................................................................................................30

SETUP MENU MAP....................................................................................................................................................................31

SWRC REMOTE CONTROL......................................................................................................................................................32

USER MENU ..............................................................................................................................................................................35

SETUP MENU............................................................................................................................................................................44

OPERATION...................................................................................................................................................................................55

THEORY OF OPERATION.........................................................................................................................................................55

POWER VS. EFFICIENCY .........................................................................................................................................................56

INVERTER CAPACITY VS TEMPERATURE .............................................................................................................................57

OPERATING MODES .................................................................................................................................................................58

INVERTER MODE......................................................................................................................................................................59

CHARGER MODE ......................................................................................................................................................................62

INVERTER/CHARGER MODE ...................................................................................................................................................68

GENERATOR SUPPORT MODE ...............................................................................................................................................70

AUTOMATIC GENERATOR CONTROL MODE .........................................................................................................................72

UTILITY BACK-UP MODE..........................................................................................................................................................80

UTILITY INTER-ACTIVE MODE.................................................................................................................................................82

ENERGY MANAGEMENT MODES............................................................................................................................................89

USING MULTIPLE INVERTERS .................................................................................................................................................92

TECHNICAL INFORMATION......................................................................................................................................................95

BATTERIES................................................................................................................................................................................95

APPLICATIONS........................................................................................................................................................................108

TROUBLESHOOTING GUIDE..................................................................................................................................................109

INVERTER/CHARGER TERMINOLOGY .................................................................................................................................114

SPECIFICATIONS AND FEATURES ........................................................................................................................................117

DIMENSIONS...........................................................................................................................................................................118

INSTALLATION DIAGRAMS ....................................................................................................................................................120

USER SETTINGS WORKSHEET.............................................................................................................................................122

APPENDIX....................................................................................................................................................................................127

OPTIONS..................................................................................................................................................................................127

OTHER PRODUCTS................................................................................................................................................................129

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

1

Page 4

TABLE OF CONTENTS

REFERENCE TABLES & GRAPHS..........................................................................................................................................130

WARRANTY/REPAIR INFORMATION ....................................................................................................................................133

LIMITED WARRANTY..............................................................................................................................................................133

WARRANTY REGISTRATION..................................................................................................................................................133

LIFE SUPPORT POLICY..........................................................................................................................................................133

WARRANTY OR REPAIR SERVICE REQUIRED ....................................................................................................................134

INDEX ............................................................................................................................................................................................135

INDEX OF FIGURES

Figure 1, Identification Label.........................................................................................................................................................7

Figure 2, Certification Label..........................................................................................................................................................8

Figure 3, Inverter Controls and Indicators ....................................................................................................................................9

Figure 4, ‘Maximum AC Amps In’ Switch And LED Status Indicators.........................................................................................10

Figure 5, PS Series AC Side.......................................................................................................................................................13

Figure 6, AC Circuit Board..........................................................................................................................................................13

Figure 7, AC Terminal Block.......................................................................................................................................................14

Figure 8, AC Ground Terminal....................................................................................................................................................14

Figure 9, PS Series DC Side.......................................................................................................................................................15

Figure 10, Airflow Intake Location..............................................................................................................................................18

Figure 11, AC Wire Connections................................................................................................................................................19

Figure 12, Warning Label...........................................................................................................................................................21

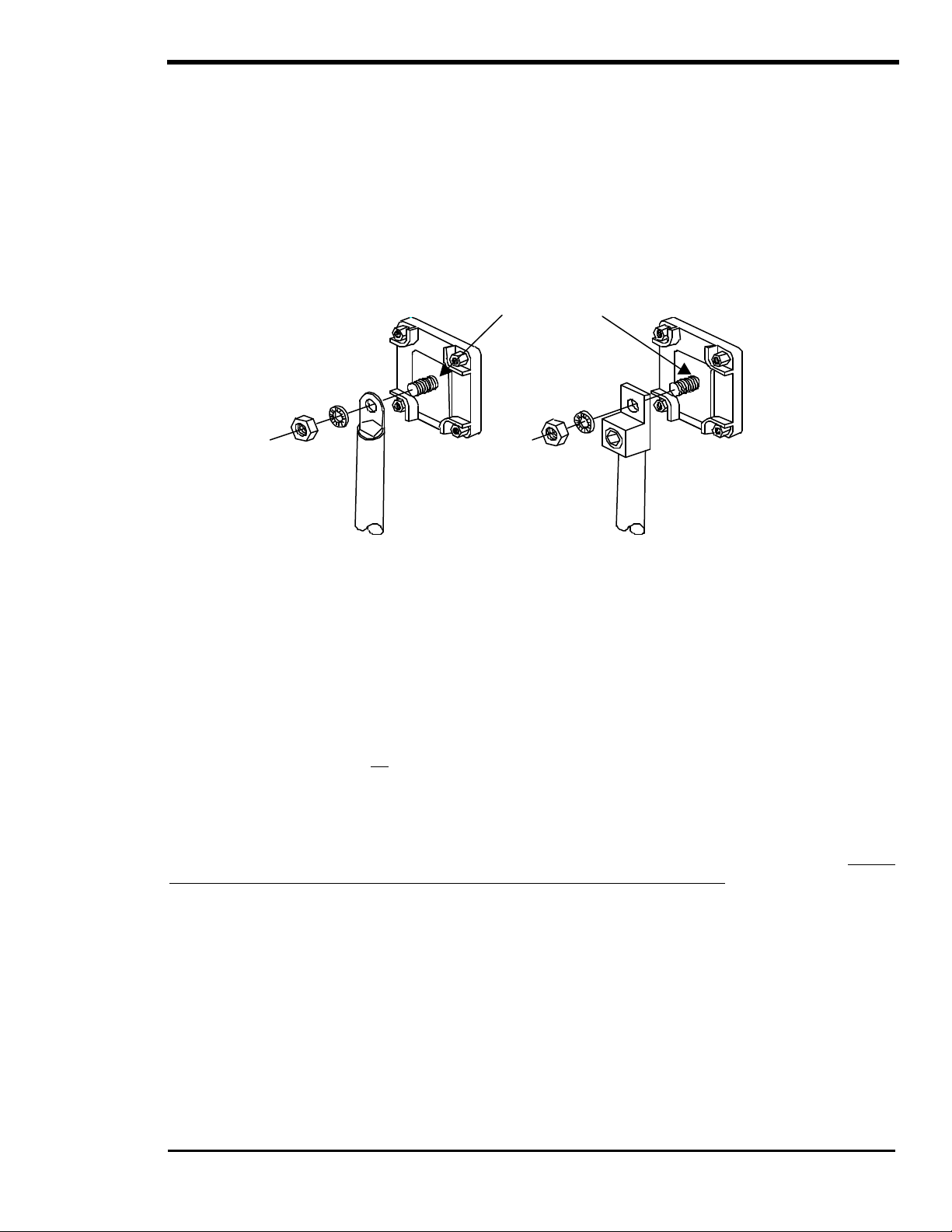

Figure 13, Battery to Inverter Cable Connection.........................................................................................................................23

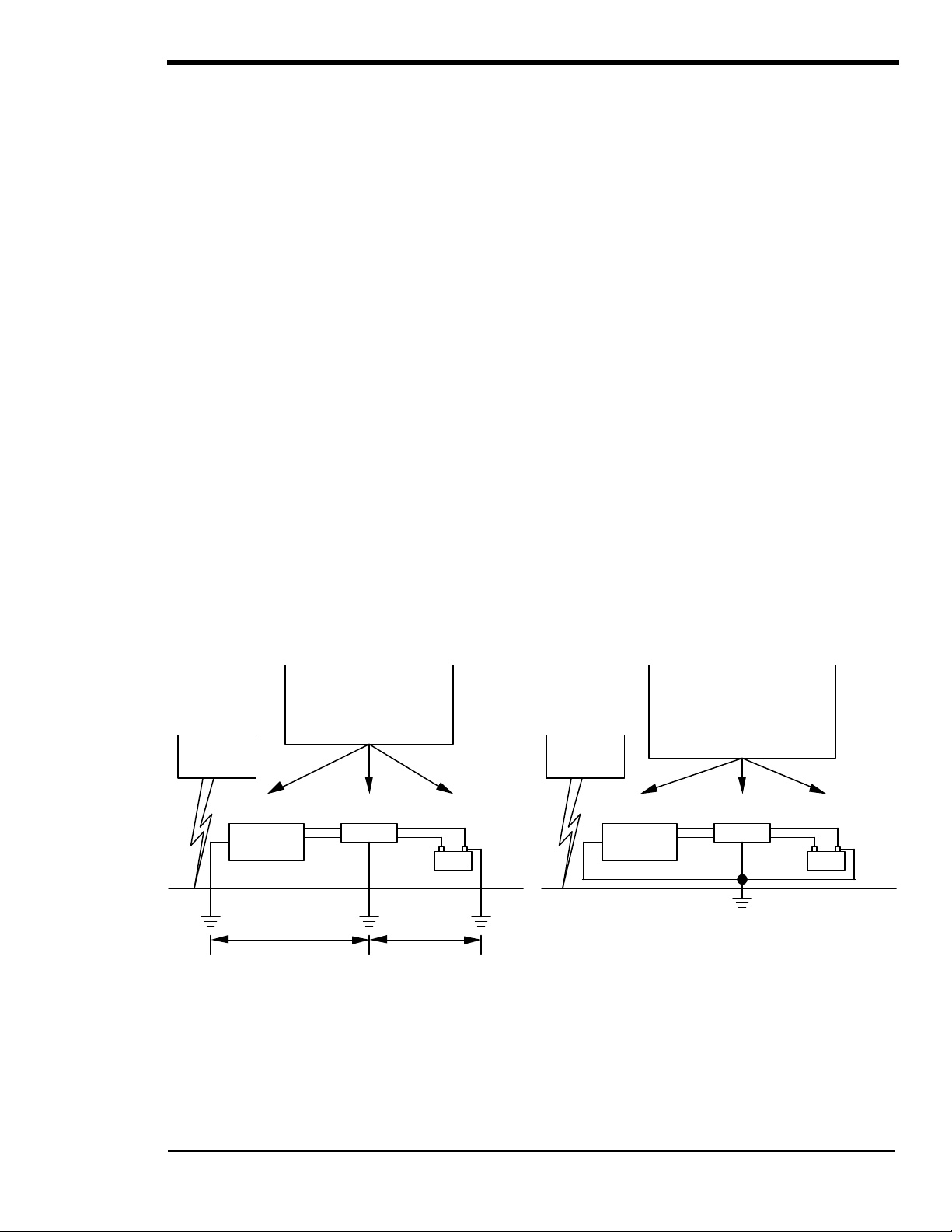

Figure 14, Multiple Point Ground System ...................................................................................................................................25

Figure 15, Single Point Ground System......................................................................................................................................25

Figure 16, SWRC (Remote Control) ...........................................................................................................................................32

Figure 17, Trace PS Series Inverter/Charger Simple Block Diagram..........................................................................................55

Figure 18, Trace PS Series Inverter/Charger Output Waveform.................................................................................................56

Figure 19, Inverter Capacity vs. Temperature............................................................................................................................57

Figure 20, Three-Stage Battery Charging...................................................................................................................................62

Figure 21, BTS (Battery Temperature Sensor)...........................................................................................................................63

Figure 22, Relay RY7 and RY8 Sequence.................................................................................................................................75

Figure 23, Two-Wire Start Wiring Diagram.................................................................................................................................76

Figure 24, Three Wire Start Wiring Diagram (HONDA Type).....................................................................................................77

Figure 25, Three Wire Start Wiring Diagram (ONAN Type)........................................................................................................77

Figure 26, Selling Power from a DC Charging Source; Hypothetical Time of Day Operational History......................................84

Figure 27, Selling Power Stored in the Batteries; Hypothetical Time of Day Operational History...............................................85

Figure 28, Utility Interactive Line-Tie System with Battery Backup (120VAC models)................................................................87

Figure 29, Overvoltage Protection for Battery............................................................................................................................88

Figure 30, Series Configuration: 6-Volt Battery Wiring.............................................................................................................104

Figure 31, Series Configuration: 12-Volt Battery Wiring...........................................................................................................104

Figure 32, Parallel Configuration: 12-Volt Battery Wiring.........................................................................................................105

Figure 33, Series-Parallel Configuration: 6-Volt Battery Wiring................................................................................................106

Figure 34, Series-Parallel Configuration: 12-Volt Battery Wiring..............................................................................................106

Figure 35, AC Waveforms ........................................................................................................................................................115

Figure 36, PS Series Dimensions.............................................................................................................................................118

Figure 37, PS Series Bottom Plate Mounting Dimensions........................................................................................................119

Figure 38, PS Series – Showing Knockout Sizes for AC Wiring...............................................................................................119

Figure 39, PS Series Installation Diagram – Stationary Backup System..................................................................................120

Figure 40, PS Series Installation Schematic.............................................................................................................................121

Figure 41, AWG Wire Size.......................................................................................................................................................131

INDEX OF TABLES

Table 1, Recommended Minimum AC Wire Sizes To Breaker/Fuse Size at 75° C.....................................................................19

Table 2, Minimum Recommended Battery Cable Size Vs. Cable Length...................................................................................21

Table 3, Battery Cable to Maximum Breaker/Fuse Size.............................................................................................................22

Table 4, AC Input Default Settings .............................................................................................................................................64

Table 5, Battery Charger Default Settings..................................................................................................................................65

Table 6, Charging Setpoints for Common Battery Types ...........................................................................................................66

Table 7, Typical Wattage of Common Appliances....................................................................................................................100

Table 8, Battery Charging: Charging Setpoints ........................................................................................................................101

Table 9, Battery State of Charge Voltage Table.......................................................................................................................102

Table 10, Battery Cable Inductance.........................................................................................................................................107

Table 11, Typical Power Consumption of Common Appliances...............................................................................................130

Table 12, AWG to Metric Wire Conversion Chart.....................................................................................................................130

Table 13, Battery Cable to Maximum Breaker/Fuse Size.........................................................................................................131

Table 14, AC Input Default Settings .........................................................................................................................................131

Table 15, Battery Charger Default Settings..............................................................................................................................132

Table 16, Minimum Recommended Battery Cable Size Vs. Cable Length...............................................................................132

Table 17, Recommended Minimum AC Wire Sizes (75° C)......................................................................................................132

Table 18, Safety Ground Wire Size Table................................................................................................................................132

Page

2

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page 5

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This manual contains important safety and operating instructions as prescribed by UL Standards for the

Trace Engineering PS Series Inverter/Chargers for use in residential and commercial applications. This

manual specifically covers products with the revision 5.* (* refers to all revisions from 5.0 to 5.9) software.

GENERAL PRECAUTIONS

1. Before using the PS Series Inverter/Charger, read all instructions and cautionary markings on:

(a) the inverter/charger;

(b) the batteries and;

(c) all appropriate sections of this manual.

2. CAUTION - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead calcium,

gel cell, absorbed glass mat, or NiCad/NiFe type rechargeable batteries. Other types of batteries may

burst, causing personal injury and damage.

3. Do not expose inverter/charger to rain, snow or liquids of any type. The inverter is designed for indoor

mounting only. Protect the inverter from splashing if used in vehicle applications.

4. Use of an attachment not recommended or sold by Trace Engineering for the PS Series

Inverter/Charger may result in a risk of fire, electric shock, or injury to persons.

5. Do not disassemble the inverter/charger. Take it to a qualified service center when service or repair is

required. Incorrect re-assembly may result in a risk of electric shock or fire.

6. To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning.

Turning off the inverter will not reduce this risk. Solar modules produce power when exposed to light.

Cover them with opaque material before servicing any connected equipment.

7. WARNING – RISK OF EXPLOSIVE GASSES

(a) WORKING IN VICINITY OF A LEAD ACID BATTERY IS DANGEROUS. BATTERIES

GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS

REASON, IT IS OF UTMOST IMPORTANCE THAT EACH TIME BEFORE SERVICING

EQUIPMENT IN THE VICINITY OF THE BATTERY, YOU READ THIS MANUAL AND FOLLOW

THE INSTRUCTIONS EXACTLY.

(b) To reduce risk of battery explosion, follow these instructions and those published by the battery

manufacturer and manufacturer of any equipment you intend to use in the vicinity of the battery.

Review cautionary markings on these products and on engine.

SPECIAL NOTICES

1. Tools required to make AC and DC wiring connections: Wire strippers; 1/2" (13MM) open-end or

socket wrench; Phillips #2 screwdriver; flat blade 1/4" (6MM) screwdriver.

2. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be copper wire and

rated for 75 °C or higher. The maximum wire size for the AC terminals is #6 AWG (4.11 mm diameter).

Battery cables must be rated for 75°C or higher. Crimped and sealed copper ring terminal lugs with a

5/16 hole should be used to connect the battery cables to the DC terminals of the inverter/charger.

Soldered cable lugs are also acceptable.

3. Torque all AC wiring connections to 20 inch-pounds. Torque all DC cable connections to 10-15 footpounds. Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could shortcircuit the batteries or other electrical parts resulting in sparks that could cause an explosion.

4. This inverter/charger is intended to be used with a battery supply with a nominal voltage that matches

the last two digits of the model number, e.g. 12-Volt with a PS2512.

5. For instructions on mounting, see the MOUNTING section on page 18 of this manual.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

3

Page 6

IMPORTANT SAFETY INSTRUCTIONS

6. NOTE: Do not use the keyhole mounting slots for permanent installations. For battery installation and

maintenance read the battery manufacturer's installation and maintenance instructions prior to

operating.

7. No AC or DC disconnects are provided as an integral part of this inverter. Both AC and DC

disconnects must be provided as part of the system installation. Refer to the INSTALLATION section

beginning on page 17 for more information.

8. No overcurrent protection for the battery supply is provided as an integral part of this inverter.

Overcurrent protection of the battery cables must be provided as part of the system installation. Refer

to the INSTALLATION section beginning on page 17 and the DC DISCONNECT AND

OVERCURRENT PROTECTION section on page 21 for more information.

9. No over current protection for the AC output wiring is provided as an integral part of this inverter.

Overcurrent protection of the AC output wiring must be provided as part of the system installation.

Refer to the INSTALLATION section beginning on page 17 and the AC WIRING section on page 18

for more information.

10. The AC output neutral conductor and DC negative conductors are not connected (bonded) to the

inverter chassis. Both the input and output conductors are isolated from the enclosure and each

other. System grounding, if required by sections 690-40, and 690-42 of the National Electric Code,

ANSI/NFPA 70-1996, is the responsibility of the system installer. All installations must comply with

local and national electrical codes and standards.

11. GROUNDING INSTRUCTIONS - This inverter/battery charger should be connected to a grounded,

permanent wiring system. For most installations, the negative battery conductor should be bonded to

the grounding system at one (and only one point) in the system. All installations should comply with

national and local codes and ordinances. Refer to the SYSTEM GROUNDING section on page 24 for

more information.

PERSONAL PRECAUTIONS

1. Someone should be within range of your voice or close enough to come to your aid when you work

near batteries.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near

batteries. Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye,

immediately flood eye with running cool water for at least 15 minutes and get medical attention

immediately.

(a) Baking soda neutralizes lead acid battery electrolyte.

(b) Vinegar neutralizes spilled NiCad and NiFe battery electrolyte.

(c) Keep a supply on hand in the area of the batteries.

5. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

6. Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could short-circuit the

batteries or other electrical parts that may result in a spark which could cause an explosion.

7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

battery. A battery can produce a short-circuit current high enough to weld a ring or the like to metal,

causing severe burns.

8. NEVER charge a frozen battery.

9. If necessary to remove the battery, make sure all accessories are off. Then, remove the grounded

terminal from the battery first.

10. If a remote or automatic generator start system is used, disable the automatic starting circuit and/or

disconnect the generator from its starting battery while performing maintenance to prevent accidental

starting.

Page

4

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page 7

INTRODUCTION

INTRODUCTION

Congratulations! You are the proud owner of the finest inverter on the market today - and one very

complex piece of equipment. The Trace Engineering PS Series Inverter/Charger has many features and

capabilities previously either non-existent, or found only in separate products.

With proper installation, the inverter will operate satisfactorily for many applications straight out of the box

using the factory default settings. To fully utilize the inverter's generator inter-active, or utility inter-active

capabilities, it is necessary to understand the way the inverter operates and then tailor its operation via

the SWRC and the user and setup menu systems. This manual will provide the necessary information.

However, it is recommended that you consult with your authorized dealer to ensure correct installation

and maximum utilization of the numerous features of this product. If you do not understand any aspect of

the installation, contact your authorized dealer/installer for assistance.

If you intend to operate the inverter in a utility inter-active mode in which power will be sold to the utility,

you must contact the local utility office and get their approval. The utility may require additional

information that may not be included in this manual. Please contact your Trace Engineering

dealer/installer for assistance.

This manual is specific to models designed for use in Alternative Energy or Back-Up Power systems in

permanent structures, such as homes and commercial buildings. As a minimum, you should read the

sections of the manual that relate to your type of installation. The MENU SYSTEM section, beginning on

page 29, explains how to make changes to the inverter’s user/setup menus. The OPERATION section,

beginning on page 55, explains how the inverter works in each of its different modes. Focus on the

Operating Modes that relate best to your type of installation and make the appropriate selections and

adjustments. Installation diagrams are provided for many of the various applications. This menu system

provides control of the inverter, allows features to be enabled, and allows setting of operating parameters.

This is a long manual and much of it is technical. Throughout the manual terms may be used that are

unfamiliar, see the INVERTER/CHARGER TERMINOLOGY glossary on page 114 for clarification. If you

are an insomniac, properly used, this manual is guaranteed to provide several good nights of sleep.

This manual is specific to REVISION 5* PS AE software . Using the optional SWRC Remote Control,

you can verify what revision software your inverter is using by selecting third menu item under the TRACE

ENGINEERING (3) menu heading.

Note: * refers to all revisions from 5.0 to 5.9

Before beginning -

• Unpack the inverter/charger and verify that you have the correct inverter.

• Record your model number and serial number below for future reference

• Verify that you have everything listed on the Packaging Checklist sheet included in your box. If any

items are missing, please call Customer Service at (360) 435-8826.

• Complete the warranty card and mail it to Trace Engineering within 10 days from the date of purchase

Keep your bill of sale as proof of purchase, should any difficulties arise concerning the registration of

the warranty card.

• Keep the original carton and packing materials It is the best way to keep the inverter safe if it needs to

be moved.

• Read this manual and enjoy your inverter/charger!

Model Number: _________________________________

Serial Number: __________________________________

Check out our web site at www.traceengineering.com for more information and answers to your FAQ’s

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

5

Page 8

INTRODUCTION

Page

6

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page 9

CONTROLS, INDICATORS AND COMPONENTS

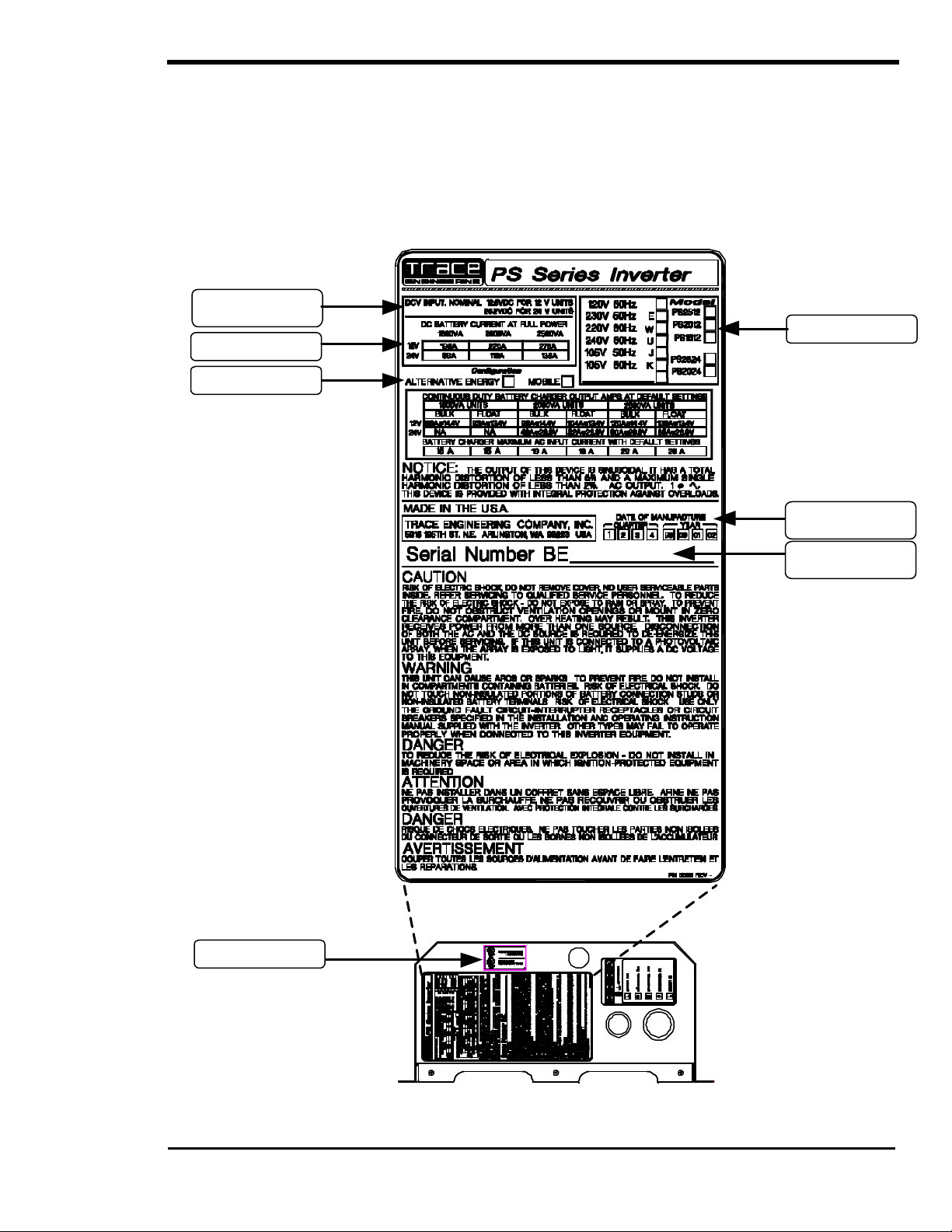

DC Input Voltage

Model Number

DC Charging Amps

Configuration

Product Code

Quarter and Year of

Certification Label

UNIT IDENTIFICATION

This section describes the marking and location of the model and serial number for the PS Series

Inverter/Chargers. Use this section to determine the type and model of your inverter/charger. The unit

Identification Label on the left side panel of the inverter/charger will show the model number, serial

number, DC charging current (maximum and default setting), AC voltage and frequency, configuration,

and date of manufacture.

Note: Ensure you have entered your serial number and model number on page 5 for future reference.

Operating Range

Manufacture

and Serial Number

Figure 1, Identification Label

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page

7

Page 10

CONTROLS, INDICATORS AND COMPONENTS

MODEL NUMBER

The model Number of your inverter determines the different features your unit may have. Consider the

following unit with a PS2512 model number:

PS 25 12 *

Model Power Nominal

AC Voltage/Options

DC Voltage

Model: The first letter(s) indicate the model, in this case the PS Series.

Power: The first and second positions in the Model Number indicate the continuous AC power output in

hundreds of VA (Volt-Amps). Power levels available start at 1800 up to 2500 Volt-Amps with different DC

voltages. In the example above, 25 would stand for a 2500 VA (2.5 kVA) continuous-output inverter.

DC Voltage (Input and Output): The number (12) following the Power rating indicates the nominal

battery voltage this inverter/charger requires. The inverter/charger uses this battery voltage to convert to

an AC voltage output, and charge the batteries that are connected when powered by the same AC

voltage. The number (24) indicates a 24v inverter/charger

AC voltage/Options: The letter(s) following the DC Voltage rating indicate the particular configuration or

particular option (s) this inverter/charger is specifically designed to provide. See the SPECIFICATIONS

AND FEATURES section on page 117 for the different voltage and frequency models available.

Configuration:

AE: These models are designed for use in Alternative Energy or Back-Up Power systems in permanent

structures such as homes and commercial buildings. These units are used where the neutral is required

to be “polarized” (or connected) permanently to the safety ground at the AC panel.

MOBILE: These models are designed for use in mobile (RV/Marine) applications. They feature 120 VAC,

60 Hz output and employ automatic ground-to-neutral switching which “polarizes” the inverter’s AC output

when operating in Inverter mode and allows the external AC source to “polarize” the neutral when the

inverter is in Charge mode.

CERTIFICATION

Figure 2, Certification Label

The 120 VAC/60 Hertz models of the PS Series Inverter/Chargers (AE Configured) are Listed to UL

Standard 1741, Power Conditioning Units for use in Residential and Commercial Photovoltaic Power

Systems. This label is your guarantee that this inverter/charger has been tested by UL to nationally

recognized Safety Standards and found to be free from reasonably foreseeable risk of fire, electric shock

and related hazards. These units are also Listed to CAN/CSA-22.2 No. 107.1-M91, which means these

models have been evaluated to Canadian safety requirements, which may be somewhat different from

U.S. safety requirements.

This inverter/charger is intended to be installed in a residential or commercial application. This unit should

not be installed in an application for which it is not listed (i.e. Land Vehicles or Marine Craft). The inverter

may not be damaged; however, it would not comply with safety code requirements and may cause other

problems. .

Page

8

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page 11

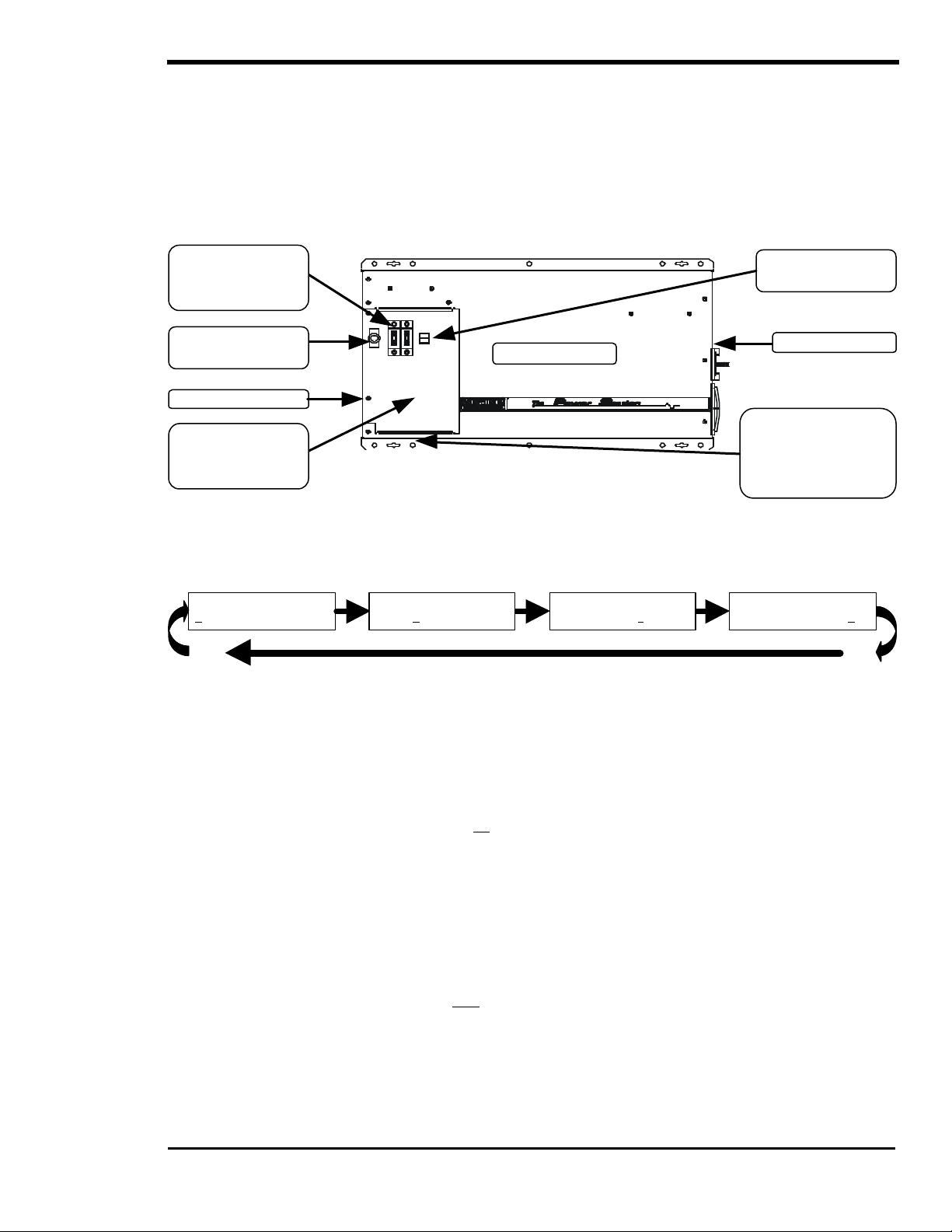

CONTROLS, INDICATORS AND COMPONENTS

‘Maximum AC

On/Off Power

AC SIDE

DC SIDE

AC Circuit Board

FRONT SIDE

Inverting/Charger

CONTROLS, INDICATORS AND COMPONENTS

Shown below are the controls and indicators on the PS Series Inverter/Charger. They enable you to

control and monitor the operating mode and system status of your inverter/charger. The controls on the

PS Series Inverter/Chargers are very straightforward. They feature a momentary On/Off Power switch, an

inverting/charger circuit breaker, four LED status indicators, a two-position switch for determining

maximum AC input current level and connecting ports for other optional accessories.

The figure below shows the location of the different controls and the Status Indicators .

Branch Circuit

Breakers

(Optional)

AC Circuit Breaker.

Switch

(Inside, under

Access Panel)

Switch and LED

Status Indicators

Figure 3, Inverter Controls and Indicators

ON/OFF POWER SWITCH

Amps In’

SET INVERTER

OFF SRCH ON CHG

This switch allows turning the inverter ON and OFF, enabling the SEARCH mode or selecting the charger

only mode CHG. The on/off button also resets the inverter in the event it shuts down completely due to a

fault condition. The inverter always starts in the OFF position when powered up. Each push changes the

mode you are in, continue pressing the ON/OFF power switch until you have your desired selection.

Monitor the INVERT (yellow) LED to determine what mode you have selected.

• OFF: Disables the inverter. This is the default position of the inverter upon power-up. When the

OFF position is selected, no power will be provided to the AC loads even if an AC source is

available. The red ERROR LED will be on, this indicates that there is no AC available on the output

and the INVERT (yellow) LED will be off.

• SRCH: Enables the automatic load search mode control system. This system will turn on the

inverter if a large enough load is connected. If not enough AC loads are detected, the INVERT

(yellow) LED will blink slowly (one blink/sec). No power will be provided to the AC loads, even if an

AC source is available. The sensitivity threshold is defaulted to 48 watts.

SET INVERTER

OFF SRCH ON CHG

SET INVERTER

OFF SRCH ON CHG

SET INVERTER

OFF SRCH ON CHG

• ON: Allows the inverter to provide AC voltage to the output and energize the AC loads either from the

battery or from any “synchronized” AC source available on the input. The INVERT (yellow) LED will be on.

• CHG: Allows the inverter to operate only as a battery charger. AC power will be available to the AC

loads only if an AC source is available and “synchronized”. This mode is used to prevent discharge of

the batteries by the AC loads when a utility outage occurs. The INVERT (yellow) LED will double blink

each second (double blink/sec) to indicate that you are in CHG mode. This mode is only available

when the SET GRID USAGE menu item is in the FLT mode under the INVERTER SETUP (9) menu

heading. When a different mode is selected, this position will be locked out and it will be necessary to

use the SET POINTS buttons on the optional SWRC remote to move the cursor. Selecting the CHG

mode disables the Automatic Generator Start features.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page

9

Page 12

CONTROLS, INDICATORS AND COMPONENTS

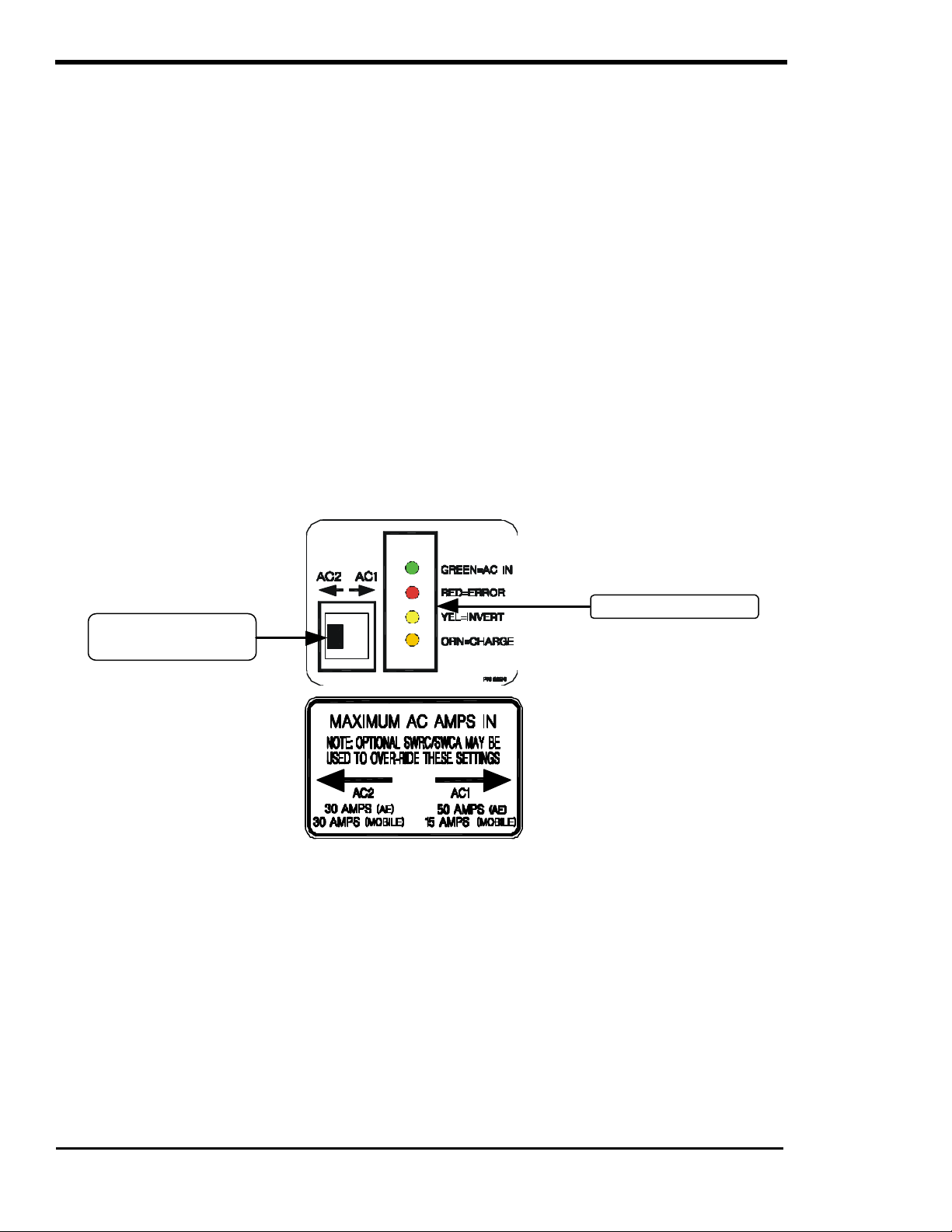

‘Maximum AC Amps In’

LED Status Indicators

INVERTER/CHARGER CIRCUIT BREAKER

This circuit breaker protects the unit’s internal wiring while the unit is inverting or charging. It is not used

for the pass-through current, which is rated for 50 amps AC. This is not a branch circuit rated breaker,

output breakers are required. Press the breaker to reset.

CIRCUIT BREAKERS

An optional, field installable, Breaker Kit can be ordered which will allow direct hook-up up of up to two

circuits without the use of a separate sub-panel. The Breaker Kit is available with a single 15 or 20 amp

branch circuit rated breaker.

‘MAXIMUM AC AMPS IN’ SWITCH

This switch determines the AC current level at which the inverter begins to back-off the battery charger or

operates in parallel to reduce the load on a generator. This prevents the overloading of the AC source

and prevents nuisance tripping of the AC source circuit breakers. Typically, this is set to the size of the

AC source's (Utility Power or Generator) circuit breaker feeding the inverter or the maximum output

amperage ability of the AC source.

The switch can be switched to the AC1 side to limit the input current to 50 Amps or to the AC2 side to limit

the input current to 30 amps.

The maximum AC input amp size can be adjusted to different settings in the SET GRID (AC1) AMPS AC

and the SET GEN (AC2) AMPS AC menu items using the optional SWRC remote.

switch

Figure 4, ‘Maximum AC Amps In’ Switch And LED Status Indicators

LED STATUS INDICATORS

All PS Series Inverter/Chargers feature four LED status indicators - located on the unit’s front side panel that will enable you to monitor the operating mode and system status of your inverter/charger by lighting

one or more of the LED’s. The different colored LED’s will light based on the condition or operating mode

of the inverter/charger. Refer to the LED colors below to determine you unit’s status.

GREEN = AC IN

ON: An AC source has been applied to the AC input terminals of the inverter. When an AC source is

connected to the input terminals the green LED indicator will come on. After a delay period has passed

and once synchronized, the inverter will close an internal relay to connect the AC source to the AC loads

and the inverter will begin to charge the battery and the orange LED indicator will turn solid.

Page

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

10

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page 13

CONTROLS, INDICATORS AND COMPONENTS

RED = ERROR

ON: Indicates that there is no AC voltage available on the output. The red error LED is used in conjunction

with the yellow (invert) LED to determine the operating mode of the inverter. If the red LED is on and the

yellow (invert) LED is off, then the inverter is in standby (DC power connected but not turned on) and is

ready to turn on. With the red LED on and the yellow LED blinking twice a second with a one second pause,

then the inverter is in the CHG (charge only) mode and waiting for AC to be connected to the input. If the

red LED is on and the yellow (invert) LED is flashing rapidly (4 times/second), this indicates that an error

condition exists. Refer to the INVERT (yellow) LED for more information on error causes.

YELLOW = INVERT

OFF – INVERTER/CHARGER IS OFF: The inverter is off and not operational. This is the default position

of the inverter upon power-up. No AC output is available.

ON – INVERTER/CHARGER ON: The inverter is operational and AC output is available. Inverter is

providing AC power from the batteries or the input AC source is providing pass-thru power to the output.

ONE BLINK/SEC – SEARCH: The yellow LED will blink once each second to indicate the inverter is in

search mode and is looking for an AC load greater than the SEARCH WATTS setting (default = 16 watts).

DOUBLE BLINK/SEC – CHARGE ONLY MODE (CHG): The yellow LED will double blink then pause for

a second to indicate that the unit is in Charge Only mode.

RAPID BLINK (4/SEC) – ERROR MODE: The yellow LED will blink rapidly to indicate that an operating

error has occurred. This can be caused by over-load or over-current, over-temperature (transformer or

heatsink), high or low battery voltage, AC source wired to the output, or an external (stacked) error. When

the inverter senses one of these situations, it may protect itself by disconnecting from the loads. There

are also advisory and numerous generator-related errors that will not disconnect the AC loads. Refer to

each error cause below to help determine your particular error cause.

ERROR CAUSES (AC OUTPUT WILL BE DISCONNECTED):

If an over-current condition exists, the inverter will shutdown and must be reset with the power button. If

the error condition is based on over-temperature (transformer or heatsink), or high or low battery voltage

the error protection circuitry resets automatically.

Low Battery voltage : Your battery voltage is below the LOW BATTERY CUT OUT (LBCO) VDC setting

and the inverter has shut off to prevent over-discharge of the battery. Allow the battery to recharge or

connect to an AC source such as a back-up generator. The inverter will reset when the battery exceeds

the LBCO setting.

Low inverter voltage : Your inverter/charger monitors the minimum AC voltage level of the AC output.

This assures a continuous supply of quality Alternating Current to your electrical loads. The inverter AC

output voltage level is determined by the SET INPUT LOWER LIMIT VAC setting. If the AC voltage falls

below this setting continuously for 32 seconds the inverter disconnects from the loads and turns on the

error LED. The cause for this error could be high battery voltage or an excessively large load.

High Battery voltage : The inverter turns off due to a high battery voltage condition determined by the

HBCO (HIGH BATTERY CUT-OUT) setting. This can be caused by the solar array or other charging

source not being regulated. Check the controller for proper operation. Some controllers have a “equalize”

setting which over-rides the normal operation, allowing the battery voltage to be unregulated. Return the

controller to the “normal” setting and check for proper operation. If you are using NiCad type batteries,

you will need to increase the HBCO setting. The inverter will automatically reset once the battery voltage

has dropped 1.5 volts below the HBCO setting.

Over-temperature (Transformer or Heatsink) : The transformer or power transistors have exceeded

their safe operating temperature and the inverter has turned off. When operating as a battery charger, the

inverter will reduce its charging rate to prevent overheating. As an inverter, overheating can be caused by

attempting to operate too large of a load for too long, a failure of the inverter cooling fans, or that the air

flow into or out of the inverter is being blocked. The inverter will automatically reset once it has cooled.

While the inverter has shut down, AC power from any AC source may not continue to pass through the

inverter to power AC loads. Any power management provided by the inverter will not be able to occur

while the inverter is off.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page

11

Page 14

CONTROLS, INDICATORS AND COMPONENTS

Over-current: The load requirement has exceeded the maximum output AC amps. To clear this fault,

disconnect the loads and restart the inverter. To restart the inverter after an overcurrent fault condition,

press the On/Off Power Switch only one time. Reconnect the loads one at a time to find the load or

combination of loads that caused the problem. If the inverter will not restart with all the AC loads

disconnected, remove all AC wiring from the terminal block and try to restart again. If it restarts, the

problem is with the wiring. If it does not restart, refer to the other error causes to determine the error.

AC source wired to output: Reports that an AC voltage source was connected directly to the AC output.

This can be caused by improper wiring or incorrect installation of the inverter. This condition is much

worse than a short circuit and may cause damage to the inverter. Disconnect all wiring from the AC input

and output to find the cause. After the cause has been found and corrected, you can restart the inverter

by selecting OFF and then ON or SRCH with the On/Off Power Switch

External error (stacked): A problem has occurred with the series interface cable or one of the inverters

operated in series. Check the cable for damage and replace it to see if the problem is corrected. Also,

check the connecting input and output AC wiring.

ERROR CAUSES (WILL NOT CAUSE AC OUTPUT TO BE DISCONNECTED).

Low AC input voltage: Your inverter/charger monitors single cycle voltage problems from the AC

source. The low AC voltage level is determined by the SET INPUT LOWER LIMIT VAC setting. If the AC

voltage falls below this setting the INVERT (yellow) LED will flash rapidly and remain on for 3 minutes.

This error is an advisory error only and will not drop the AC input.

High AC input voltage: Your inverter/charger monitors single cycle voltage problems from the AC

source. The high AC voltage level is determined by the SET INPUT UPPER LIMIT VAC setting. If the AC

voltage rises above this setting the INVERT (yellow) LED will flash rapidly and remain on for 3 minutes.

This error is an advisory error only and will not drop the AC input.

Generator failed to start: Indicates that the automatic generator start system was not able to

successfully start the generator. The system completes five start cycles and requires that the generator

operate for a minimum of 5 minutes before the starting attempts counter is cleared. To manually clear this

error, press the green GEN MENU button on the SWRC to access the SET GENERATOR menu item,

then select OFF and then AUTO or ON.

Generator stopped due to V/F: Indicates that the automatic generator start system was not able to

successfully connect to the generator after it was running. If the generator runs for 10 minutes without

operating in the AC voltage and frequency tolerance windows, then the automatic start system stops the

generator and indicates an error condition. To manually clear this error, press the green GEN MENU button

on the SWRC to access the SET GENERATOR menu item, then select OFF and then AUTO or ON.

Gen Max Run Time: An ERROR LED will turn on if the generator run time has exceeded the SET

MAXIMUM RUN TIME setting. This setting is intended to indicate excessive generator operation because

the system has not been able to fully charge the battery. Operating heavy loads while charging, an

unstable generator or even low electrolyte levels in the battery can cause this. If the default value results

in repeated error conditions, then increasing the setting may be necessary for your application. This may

occur with systems that have very large batteries that require long charge periods or systems with small

generators that have limited battery-charging ability. This ERROR is an advisory indication only and will

not stop the generator. You can reset this ERROR LED by selecting OFF and then ON from the SET

GENERATOR menu item, accessed by pressing the green GEN MENU button on the SWRC.

Gen speed error: Indicates that the automatic generator start system has detected that the generator

frequency is not well adjusted. This error condition will cause the red ERROR LED to illuminate, but will

not cause the automatic generator start system to shut down. If the inverter can not synchronize to the

generator after a 10-minute period, then the GEN SPEED ERROR condition will be reached.

ORANGE = CHARGE

ON: This orange LED will be lighted when the unit is charging. The inverter is charging at a constant

current, causing battery voltage to rise near the BULK VOLTS DC setting (default = 14.4 VDC). Once at

this level, the current will taper off until the battery charger has maintained the batteries near the BULK

VOLTS DC setting for the time period of the ABSORPTION TIME setting, at which time it then regulates

the charging process at the FLOAT VOLTS DC setting.

Page

12

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page 15

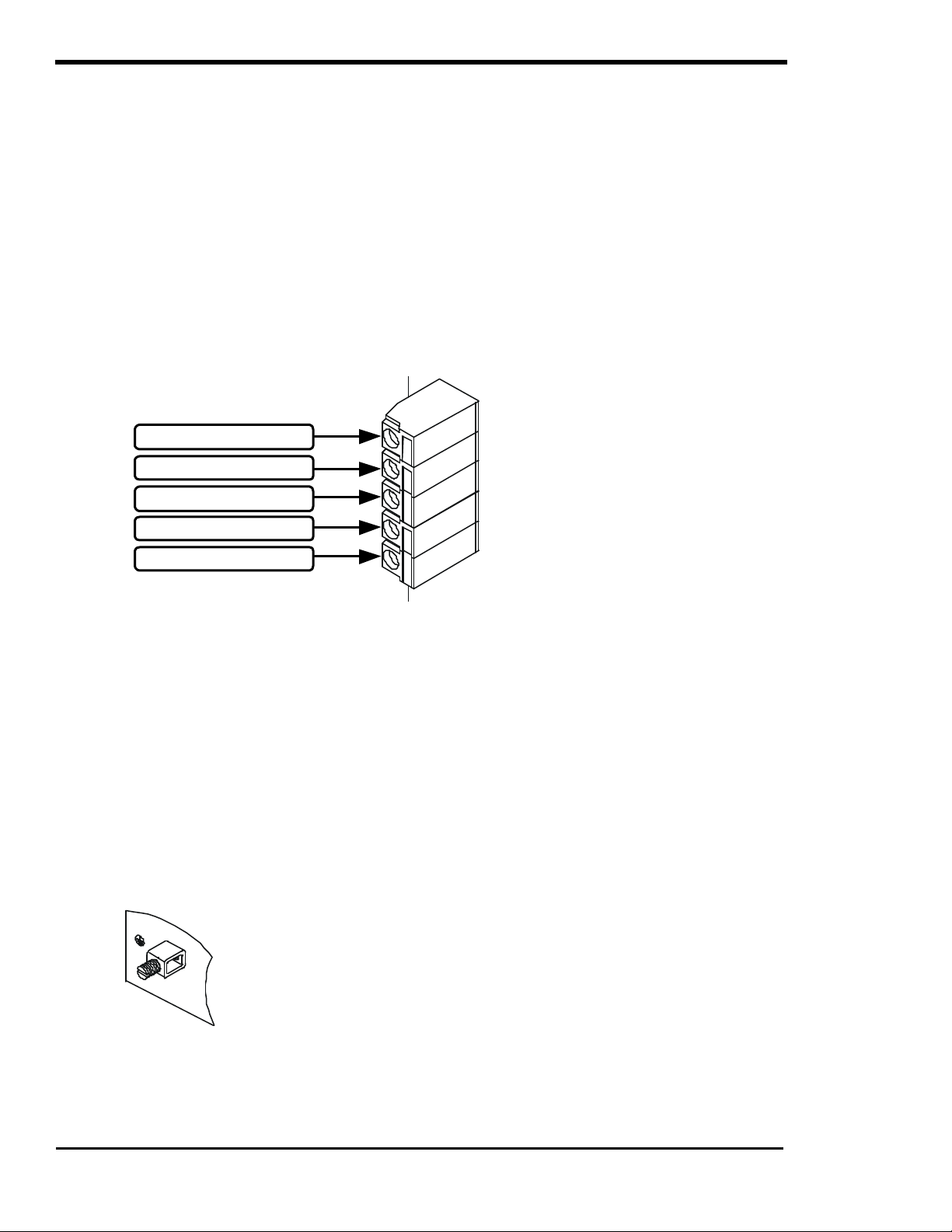

CONTROLS, INDICATORS AND COMPONENTS

AC Ground

Accessory

AC terminal block

AC circuit board

ACCESS

AC TERMINAL

AC SIDE

knockout

AC knockouts

(located inside)

(located inside)

Terminal

(located inside)

Figure 5, PS Series AC Side

AC CIRCUIT BOARD

By removing the Access Panel, you will be able to gain access to the AC circuit board, which includes the

AC terminal block and four RJ11 jacks for connecting specific optional components.

PANEL

Figure 6, AC Circuit Board

RC8AUX GEN BTS

BLOCK

AUX - RJ11 connection jack for the optional plug-in Auxiliary Relay Module. The Auxiliary Relay Module

consists of two voltage-controlled relays and is used to simplify installations that have battery voltage

related tasks to perform. The relays are single pole double throw, five amp relays. Both the normally

closed and normally open contacts are available for each relay. The operation of each relay is individually

controlled and adjustable with a SWRC via the user menu. The auxiliary relays on the AUXILIARY

RELAY MODULE operate independently of the inverter or charger.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page

13

Page 16

CONTROLS, INDICATORS AND COMPONENTS

cover - is used to connect the exposed chassis of the inverter to the

AC grounding system. This terminal accepts wires from #14 AWG to

GEN - RJ11 connection jack for the optional plug-in Generator Relay Module. The Generator Relay

Module consists of signal relays and allows connection and automatic control of “two-wire” type

generators. The relays are single pole double throw, five amp relays. Both the normally closed and

normally open contacts are available for each relay. The operation of each relay is controlled and

adjustable with a SWRC via the user menu.

RC8 - RJ11 connection jack for the optional plug-in RC8 remote. Allows remote On/Off control of the

inverter at a distance of up to 50 (RC8/50) or 100 (RC8/100) feet away, functionally identical to the On/Off

Power Switch on the inverter.

BTS - RJ11 connection jack for the plug-in external Battery Temperature Sensor (BTS). The BTS

automatically fine-tunes the charging process of the battery charger in relation to temperature. If the

temperature sensor is NOT installed and if the battery is subjected to large temperature variations, a

shorter battery life cycle may be expected.

AC TERMINAL BLOCK

AC HOT OUTPUT

AC NEUTRAL OUTPUT

AC NEUTRAL OUTPUT

AC NEUTRAL INPUT

AC HOT INPUT

Figure 7, AC Terminal Block

A five pole terminal block is provided for hardwiring the inverter’s AC output the AC input connections. It

is located on the left-hand side of the inverter, enclosed under the access panel. The terminal block will

accept wire up to #6 AWG.

Depending on your unit’s configuration (See the UNIT IDENTIFICATION section on page 7 to determine

your unit’s particular configuration) the AC input and output neutrals are configured differently.

This manual is specific to models designed for use in Alternative Energy or Back-Up Power systems in

permanent structures, such as homes and commercial buildings. All of the PS Series units marked with the

Alternative Energy configuration are designed with the three NEUTRAL terminals being common to each

other and can be used in any combination or order. It is often simpler to only connect one AC neutral wire to

the inverter and make the other neutral connections at a central point such as at an AC load center, etc. The

additional AC NEUTRAL OUTPUT is provided for use when installing the optional Branch Breaker Kit.

AC GROUND TERMINAL

The AC Safety Ground Terminal - assessable through the AC access

#2 AWG.

Figure 8, AC Ground Terminal

Page

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

14

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page 17

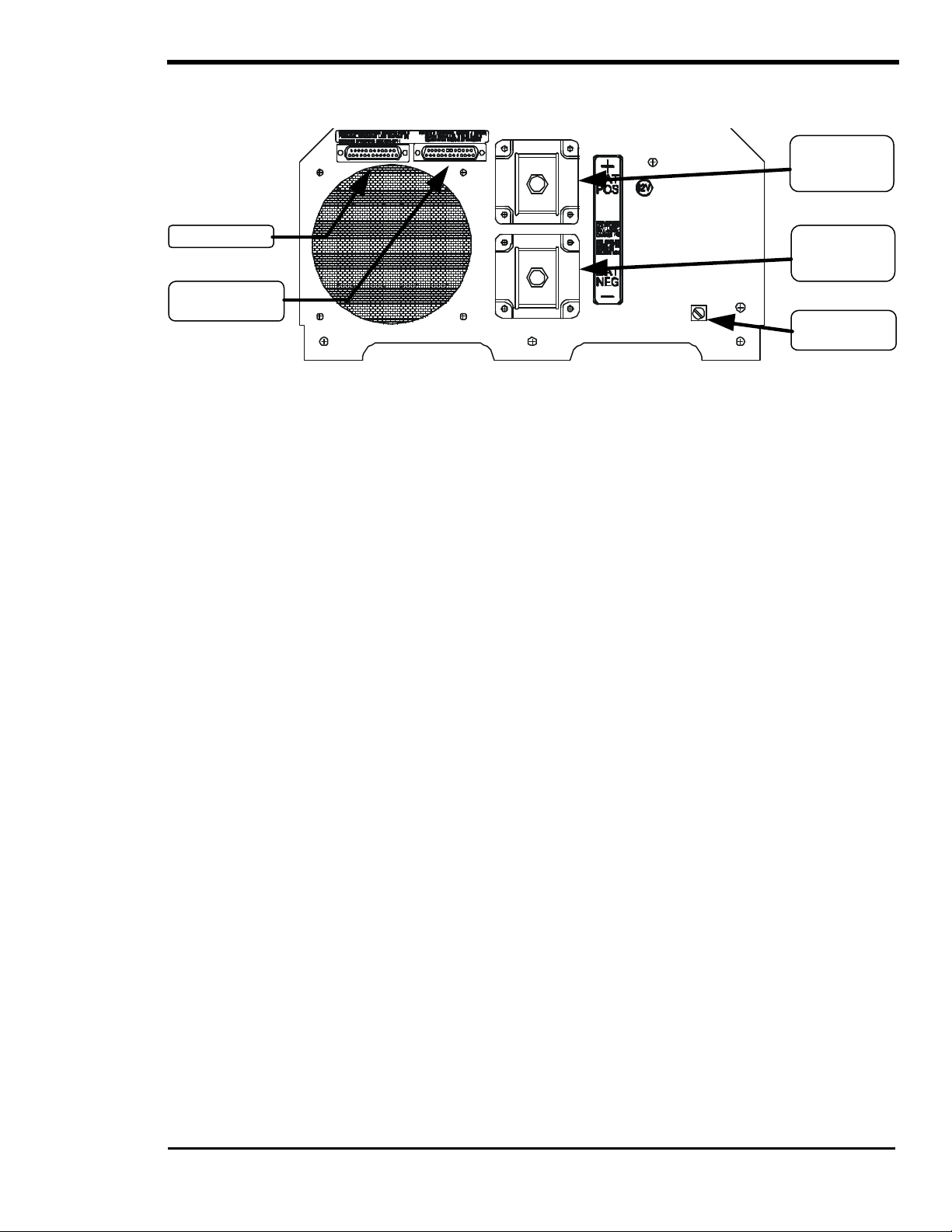

DC SIDE

Positive

Negative

DC Ground

Remote Port

CONTROLS, INDICATORS AND COMPONENTS

Battery Cable

Hook-Up

Stacking Port

SWRC or SWCA

Battery Cable

Hook-Up

Connection

Figure 9, PS Series DC Side

STACKING PORT

The stacking port allows two PS Series Inverter/Chargers (AE configuration models only) to be used in

the same system. The inverters can be used in a “SERIES” configuration to operate 240 VAC loads and

to connect to 120/240 VAC power systems. A series stacking interface cable (SWI) is required to connect

the series stacking ports of the inverters. This port is also used to connect two units in a “PARALLEL”

configuration. The parallel stacking interface cable (SWI/PAR) allows two inverters to be connected to

provide twice the continuous and surge capability at the same AC voltage. See the USING MULTIPLE

INVERTERS section on page 92 for more information.

REMOTE PORT

The PS Series can be controlled remotely from the unit by plugging in a SWRC remote control or SWCA

communications adapter. See the OPTIONS section starting on page 127 for a complete description of

the SWRC and SWCA.

BATTERY POSITIVE & NEGATIVE TERMINALS

These terminals are where you connect your battery cables. WARNING: Ensure your battery/cable

polarity is correct, this inverter is not reverse polarity protected. If the positive terminal of the battery

is connected to the negative terminal of the inverter and vice versa, the result will be instantaneous failure

of nearly every power transistors. Color-code the cables with colored tape or heat shrink tubing [the

standard is red for positive (+) and black for negative (-)] and double-check the polarity with a voltmeter

before making the battery connections.

DC EQUIPMENT/CHASSIS GROUND TERMINAL

This connection is used to connect the exposed chassis of the inverter to the DC grounding system. The

terminal accepts wires from #14 AWG to #2 AWG.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page

15

Page 18

CONTROLS, INDICATORS AND COMPONENTS

Page

16

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Rev. D: November 23, 1999

Part No. 3597

Page 19

INSTALLATION

INSTALLATION

This section is very important, since it tells you how to properly install your PS Series Inverter/Charger. It

becomes very frustrating when your inverter system does not perform properly, simply because care was

not taken during installation. Please read this entire section carefully. You will save time and avoid

common mistakes.

This section also describes the requirements and recommendations for installing the PS Series

Inverter/Charger. In the U.S., the National Electrical Code (NEC) defines the standards for both the AC

and DC wiring in residential and commercial applications. It will list the requirement for wire sizes,

overcurrent protection and installation methods and requirements. There are still many other variables not

covered by the NEC. Most are determined by the level of automatic operation, the amount of external AC

and DC power to be controlled and the loads to be operated.

The NEC standards and regulations are described here in general for your convenience, and are not

represented as comprehensive or complete. For comprehensive and complete official standards and

regulations, write the addresses listed below:

NFPA - National Fire Protection Association

National Electrical Code Handbook

1 Batterymarch Park,

PO Box 9101

Quincy, MA 02269-9101

617-770-3000.

Before beginning the installation of the PS Series Inverter/Charger, read all instructions. Disconnect all

sources of AC and DC power to prevent accidental shock. Disable and secure all AC and DC disconnect

devices and automatic generator starting devices.

All installations should meet local codes and standards and be performed by qualified personnel

such as a licensed electrician. Although the DC electrical system may be “low voltage”, significant

hazards may be present, particularly from short circuits of the battery system. Inverter systems by their

nature involve power from multiple sources (inverter, generator, utility, batteries, solar arrays etc.) that

add hazards and complexity that can be very challenging.

After you have finished installing your unit, continue with the FUNCTIONAL TEST section on page 27. This

functional test should be completed prior to configuring your unit’s Menu System for your specific operation.

LOCATION

Inverters are sophisticated electronic devices and should be treated accordingly. Treat the inverter as you

would any fine piece of electronic equipment. When selecting the location to install the inverter, don't think of

it in the same terms as the other interfacing equipment, e.g. batteries, diesel generators, motor generators,

washing machines etc. This is a highly complex microprocessor controlled device. There are nearly 500,000

silicon junctions in its output devices and integrated circuits. The crystal oscillator runs at 4 megahertz. The

drive circuitry timing is accurate to a thousandth of a second. Genetically speaking, it is a cousin to stereo

equipment, television sets or computers. The use of conformal-coated circuit boards, plated copper bus

bars, powder coated metal components, and stainless steel fasteners improves tolerance to hostile

environments. However, in a corrosive or condensing environment (one in which humidity and/or

temperature change cause water to form on components) all the ingredients for electrolysis are present water, electricity and metals. In a corrosive or condensing environment, the life expectancy of the

inverter is indeterminate and the warranty is voided if corrosion is the cause of failure.

Caution: It is in your best interests to install the inverter in a dry, protected location away from sources of

fluctuating or extreme temperatures and moisture. Exposure to saltwater is particularly destructive and

potentially hazardous.

Locate the inverter as close to the batteries as possible in order to keep the battery cable length short.

However, do not locate the inverter above the batteries or in the same compartment as vented batteries.

Batteries generate hydrogen sulfide gas , which is very corrosive to electronic equipment and everything

else. They also generate hydrogen and oxygen. If accumulated, an arc caused by the connecting of

battery cables or the switching of a relay could ignite this mixture. Mounting the inverter in a ventilated

enclosure with sealed batteries is acceptable.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

17

Page 20

INSTALLATION

This inverter can create RFI (Radio Frequency Interference). Keep this in mind when determining the

placement of the inverter. You should locate the inverter as far away as possible from any electronic

devices that may be susceptible to RFI.

MOUNTING

UL Standard 1741 requires that the inverter be mounted on a vertical surface (on a wall) and that the

keyhole slots not be used as the only method of mounting. The purpose of the wall mounting requirement

is to orient the inverter so that its bottom cover, which has no holes, will not allow burning material to be

ejected in case of an internal fire. Use 1/4” minimum diameter bolts for mounting. The mounting must be

capable of supporting twice the weight of the inverter in order to comply with UL 1741.

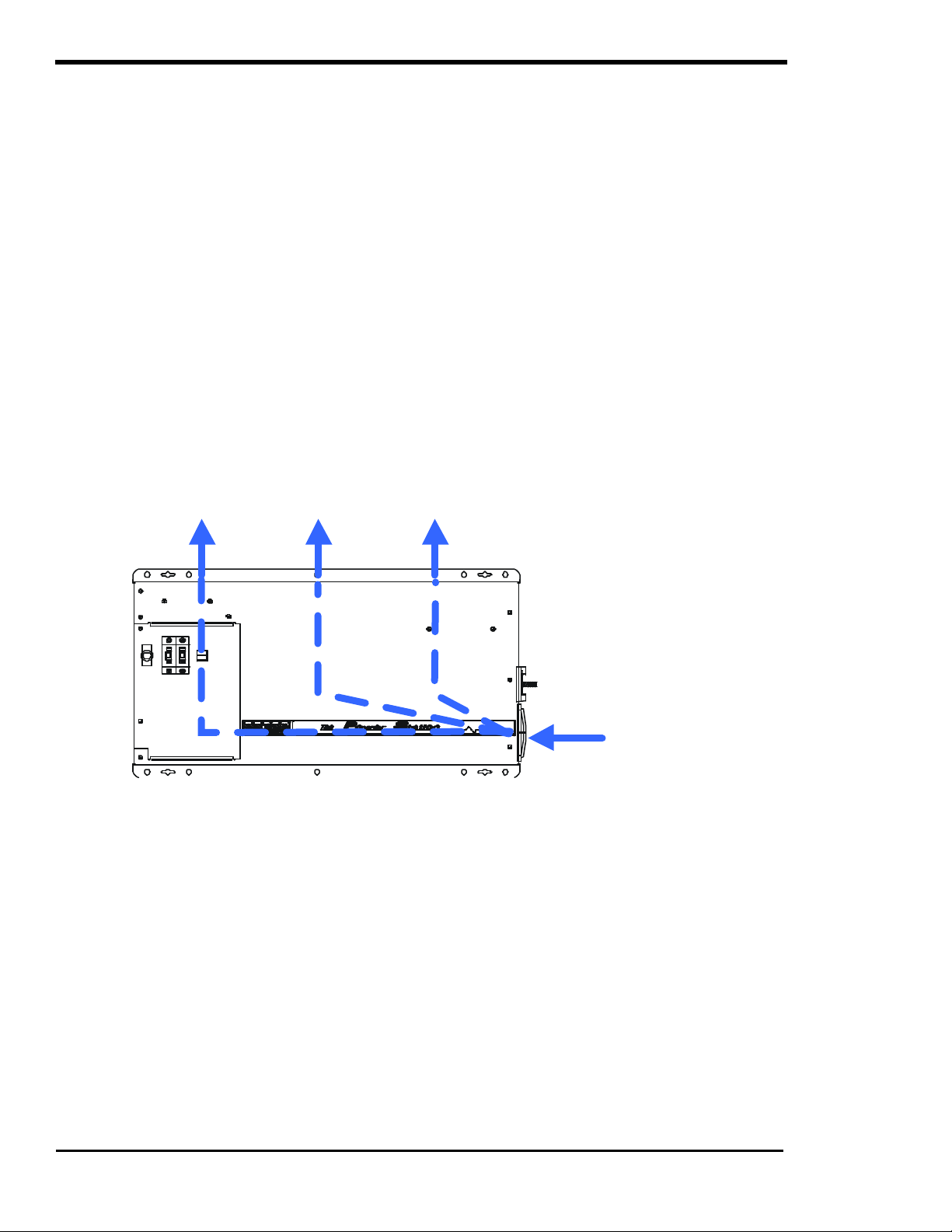

VENTILATION

Installation of the inverter in a properly ventilated area/enclosure is necessary for efficient operation of the

unit. The inverter’s thermal shutdown point will be reached sooner than normal in a poorly ventilated

environment and will result in a lower peak power output, reduced surge capability, and potentially shorter

inverter life. Note: Do not operate the inverter in a closed-in area or restrict ventilation in any way.

Testing has shown that the volume of the area/enclosure is not as important as the overall ventilation. A

minimum airspace clearance of 1-½ inches around the top and 3 inches of clearance at the right side of

the inverter will provide adequate ventilation. Because the bottom of the PS Series chassis is not vented,

clearance between the enclosure and the bottom of the inverter is not critical. A fresh air intake port

should be provided directly to the right side and an exhaust port on the top side will allow cool outside air

to flow through the inverter and back out of the enclosure.

AIR FLOW

Figure 10, Airflow Intake Location

AC WIRING

This section describes AC wiring requirements and recommendations; including AC connections; wire

sizing; overcurrent devices; GFCI’s; external relays; hookup procedure; and neutral-to-ground switching.

Your local electrical code and the National Electrical Code (NEC) define the standards for AC installation

wiring, but there are still many installation variables to be considered. Consult the local code and the NEC

for the proper wire sizes, connectors and conduit. All installations should meet all local codes and

standards and be performed by qualified personnel such as a licensed electrician.

AC WIRE CONNECTIONS

IMPORTANT PRECAUTIONS - The AC OUTPUT of the inverter must at no time be connected

directly to utility power or a generator. This condition can be far worse than a short circuit. If the

inverter survives this condition, it will shut down until corrections are made.

A five position terminal block is provided to make the AC connections. The terminal block is located on

the left-hand side of the inverter, enclosed under an access panel (see page 9 for exact location). The

terminal block is used to hardwire all AC connections.

Page

18

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page 21

INSTALLATION

Before making any AC connections, make sure that the inverter is disconnected from the battery (or

battery bank). Feed the wires through conduit fittings located on the left side or left bottom side of the

inverter. (Note: Conduit fittings must be purchased separately and are required by code to comply with

residential and commercial installations).

The NEC requires that disconnect switches be provided in the AC input and output wiring circuits. AC

circuit breakers in an AC load center can be used to meet this requirement. The wiring both in and out of

the inverter must also be protected from short circuits and overloads by a fuse or circuit breaker. Consult

the NEC or your local code for more information and for other wire sizes. Table 1 on page 19 gives

suggestions for wire sizing.

ACCESSORY INPUT

AC GROUND OUT

AC HOT OUT

AC NEUTRAL OUT

AC GROUND IN

AC HOT IN

AC NEUTRAL IN

Figure 11, AC Wire Connections

The three neutral terminals are common to each other and can be used in any combination or order. It is

often easier to only connect one AC neutral wire to the inverter and make the other neutral connections at

a central point such as in the AC load center, etc. The extra output neutral is used if installing the optional

Branch Breaker Kit. Consult your local code for more information and acceptable wire sizes and

configurations.

Use Table 1, below, to determine the proper size wire you require for your installation. These

recommendations may not meet all local code or the NEC requirements, consult your applicable electrical

code for more information regarding acceptable fuse and cable sizes.

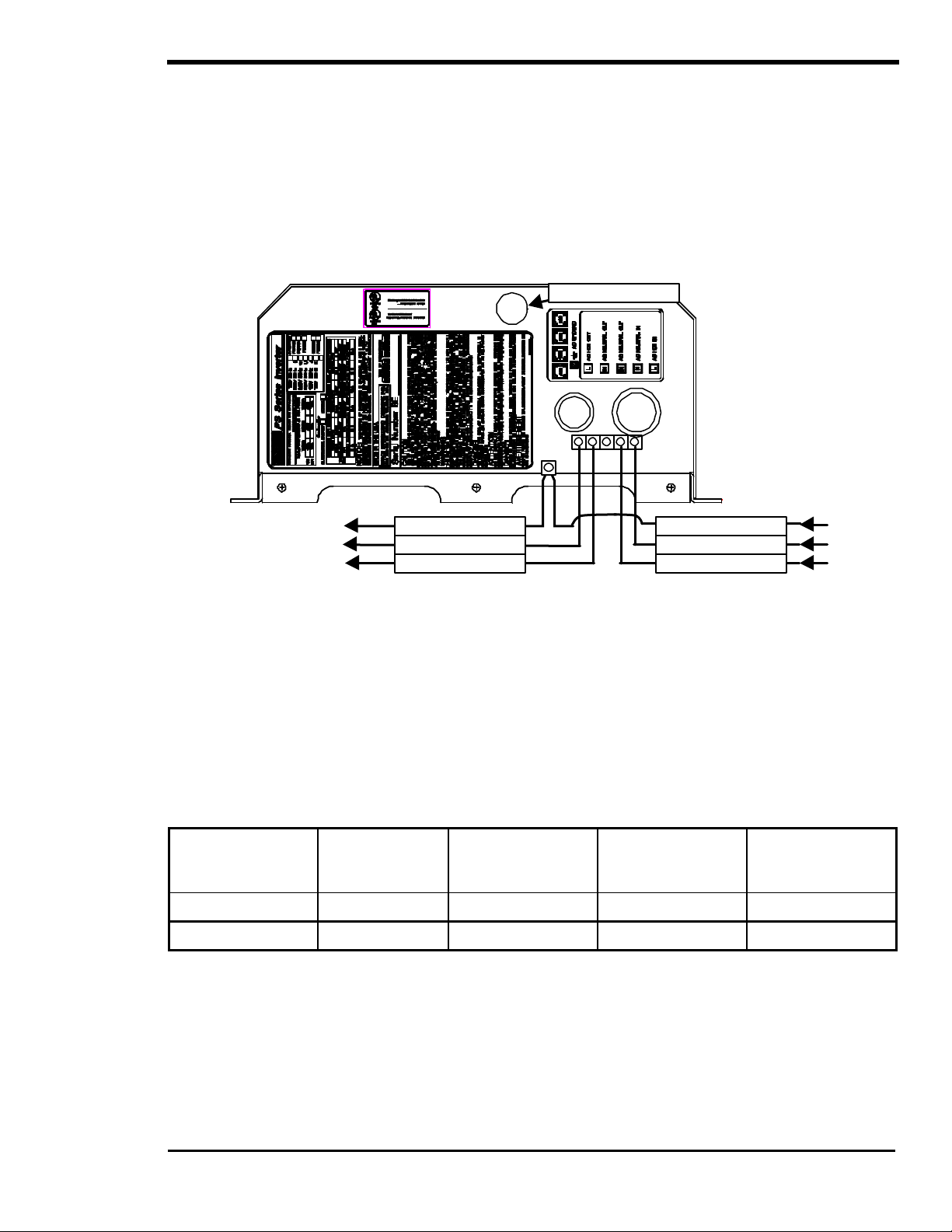

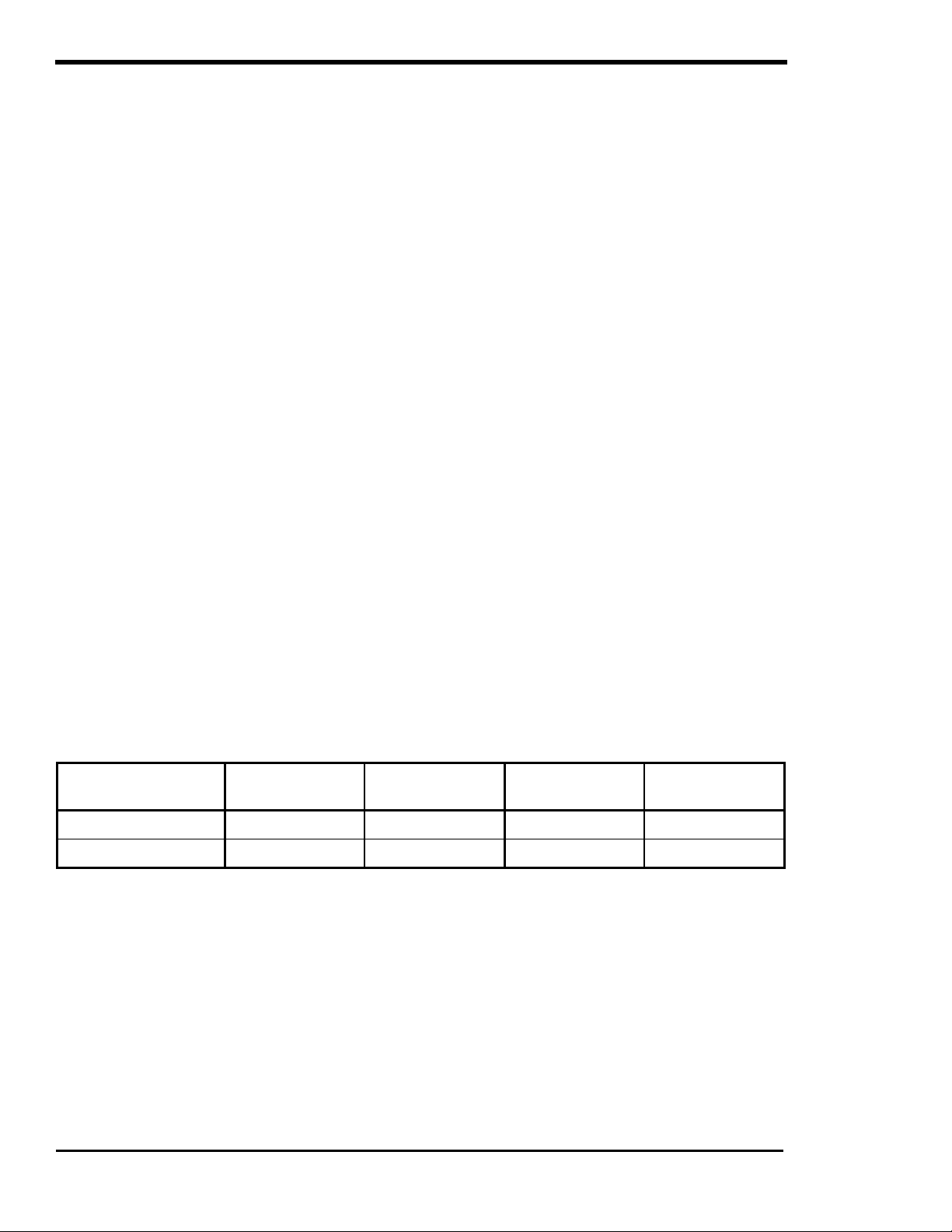

Table 1, Recommended Minimum AC Wire Sizes To Breaker/Fuse Size at 75° C

INVERTER MODEL

FULL

PASS-THRU

CAPABILITY

MAXIMUM

FUSE/BREAKER

REQUIRED

CABLE SIZE

REQUIRED

IN CONDUIT

CABLE SIZE

REQUIRED

IN “FREE AIR”*

PS2512/PS2524 50 amps 60 amps # 6 AWG (THHN) # 8 AWG (THHN)

PS2212E/PS2524E 30 amps 30 amps # 10 AWG (THHN) # 12 AWG (THHN)

* The term "free air" is defined by the NEC as cabling that is not enclosed in conduit or a raceway. Cables

enclosed in raceways or conduits have substantially lower continuous current carrying ability due to

heating factors.

Copyright Trace Engineering Company, Inc.

5916 - 195th Street N.E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

PS Series Inverter/Charger

Part No. 3597

Rev. D: November 23, 1999

Page

19

Page 22

INSTALLATION

AC INSTALLATION GUIDELINES

The following steps are a basic guideline for connection of the AC wiring into and out of the inverter.

1. Disconnect the inverter from the battery bank (if already connected), by either removing the DC side

fuse, or opening the DC disconnect. Then remove the AC wiring compartment cover from the front of

the inverter by removing the two screws on the cover.

2. If conduit will be utilized (consult code, it may be required in your installation), determine which

knockout(s) will be utilized and remove them from the inverter. The knockout sizes are shown in

Figure 38, PS Series – Showing Knockout Sizes for AC Wiring on page119. Using appropriate

conduit connectors, fasten the conduit to the inverter. Feed all AC wiring through the conduit and into

the inverter AC terminal block. Be sure to leave yourself several extra inches of wire to work with.

Remember that you need at least two sets of three conductor wiring, one for AC Hot, neutral, and

ground into the inverter, and another for AC hot, neutral and ground out of the inverter to the loads.

Torque all AC terminals to 10 to 15 inch-pounds .

3. Connect the hot (black) and neutral (white) wires from the AC source to the AC HOT IN and AC

NEUTRAL IN terminals in the AC terminal block. The safety ground (green) should be connected to

the terminal stud labeled “AC Ground” bolted to the chassis. Repeat the procedure for the AC wiring

going to the AC sub-panel which will power the loads, except connect these wires to terminals labeled

the AC HOT OUT and AC NEUTRAL OUT.

4. Inspect all wiring for proper installation and then replace and secure the access cover.

IMPORTANT PRECAUTION

The AC output of the inverter must at no time be connected directly to utility power or a generator.

This condition can be far worse than a short circuit. If the inverter survives this condition, it will shut down

until corrections are made. Connection to a utility or generator must be only done internally by the

inverters built-in relays. This allows the inverter to first synchronize to the other AC sources waveform,

preventing damage. Connect the utility or generator only to the provided AC HOT IN and AC NEUTRAL

IN terminals. When the inverter output is connected directly to an external source, the inverter will shut

down and indicate an error. With the SWRC connected, the ERROR CAUSES menu heading will show a

YES for the AC SOURCE WIRED TO OUTPUT menu item. Either determine the source of the AC or call

a qualified electrician to correct the situation.

EXTERNAL AC TRANSFER RELAYS

It is not acceptable to switch the AC input from one AC source to another while the inverter is

connected. While the inverter is connected, switching the AC input from one source to another can result

in a loss of synchronization that can cause a severe overcurrent condition that is far worse than short

circuiting the inverter. If a transfer relay is used, it must provide a center “OFF” (“break before make”)