Trace Engineering PM DR 250 S, PM DR 175, PM DR 175 Dual, PM DR 250 Dual, PM SW 175 S Assembly Instructions Manual

...Page 1

Power Module System

Assembly Instructions

How To Use This Manual (inside cover)

Inverter Systems ...Chapter Four

Electrical Components … Chapter Five

Cabinet Components … Chapter Six

5916 195th Street NE, Arlington WA USA 98223 (360) 435-8826

Part Number 3471

Page 2

How to Use this Manual

Go to Chapter Four and select the assembly instructions for the

desired system.

Single DR system .... Page 4-4

Dual DR system … Page 4-8

Single SW system .... Page 4-10

Dual SW system .... Page 4-12

Three-phase SW system .... Page 4-14

Go to Chapter Five and select the assembly instructions for each

electrical component listed in the system.

Go to Chapter Six and select the assembly instructions for each

cabinet component listed on the system assembly instructions.

Gather all cabinet and electrical components and tools listed on

the system assembly instructions.

Arrange all instruction sheets in the order suggested on the

system assembly instructions.

Assembly your system.

Page 3

Table of Contents

Introducing the Power Module System .....1-1

IMPORTANT SAFETY INSTRUCTIONS .....2-1

General Precautions ............................2-1

Personal Precautions ............................2-2

Underwriters Laboratory (U.L.) Compliance Requirements.........2-3

Power Module Installation ...........3-1

Powering Up the System ..........................3-1

Stacked Pair Inverters ...........................3-2

Power Module Systems .............4-1

Power Module Fastener Facts .......................4-2

PM DR 175/250 Single Inverter Diagram ..................4-4

PM DR 175/250 Dual Diagram .......................4-8

PM SW 175/250 S Diagram ........................4-10

PM SW 175/250 Dual Diagram ......................4-12

Sinewave 3 - Phase System........................4-16

3-Phase Assembly Sequence .......................4-17

Electrical Components Assembly Instructions 5-1

PMO-AC15/20/60 Front View ........................5-3

PMO-AC60 3-Phase Breaker ........................5-5

PMO-C40, C40K & VLC40 for DR Systems ................5-7

PMO-C40, C40K & VLC40 for DR Systems ................5-8

PMO-40, C40k & VLC40 for Sinewave Systems ..............5-9

PMO-DC20/60/110 ............................5-11

PMO-DC20/60/110 ............................5-12

PMO-DC175/250 .............................5-13

PMO-DC175/250 .............................5-14

PMO-DCBB/Kit/SW/DR ..........................5-15

PMO-DCBB/Kit/(SW)(DR) .........................5-16

PMO-DCBB ................................5-17

PMO-IOX60 Input/Output/Bypass Breaker ................5-19

Page 4

PMO-IOX60 ................................5-20

PMO-NEUTRAL ..............................5-21

Cabinet Components ...............6-1

PM .....................................6-3

PMADD...................................6-5

PM-EXT ...................................6-7

PMO-BLANK ................................6-9

PMO-BRACE ...............................6-11

PMO-COVER ...............................6-13

PM-DOOR .................................6-15

PM-FEET .................................6-17

PM-LID ..................................6-19

PM-LATCHES & LOCKS .........................6-21

PMO-SLIDER ...............................6-23

PMO-TRAY ................................6-25

Limited Warranty .................7-1

Life Support Policy ................7-2

Page 5

1-1

Introducing the Power Module System

The Trace Modular Power System incorporates all the components of an alternative energy installation (except

external AC and DC power sources) in a package designed to permit seamless integration of the components.

The modular approach enables you to order individual components or complete systems fully assembled, tested,

and inspected.

The Power Module System allows isolation of components, wiring, and safety circuitry in a secure cabinet that

can be weatherproofed for exterior installations. Cabinets can be stacked up to four high for integration of

batteries, inverters, controllers, circuit breakers, and associated devices. Each module can house individual or

multiple components.

The base configuration is supplied as individual components or in complete assemblies (inverters are shipped

separately) from the factory. Assembled systems can include as many or as few components as desired. For

example: use one standalone module to house vented liquid lead-acid batteries, and another to house electronic

components; or stack multiple modules to house sealed batteries and all other components in one

installation.System components provided with the modules can include AC and DC breakers, disconnects,

inverters, controllers, busses, DC shunt and bonding blocks, grounding blocks, wiring, and fasteners for field

installation. These components (and batteries) can also be shipped or acquired separately.

When ordering parts, always use the PMO- prefix.

Other Power Module System features include:

• Powder-coated aluminum enclosures

• Stainless steel mounting hardware

• Removable front-panel for easy access

• Louvered front-panel for maximum ventilation

• Single or multiple Sinewave or DR Series inverters w/hardware

• Accessories include:

ü

cabinet weather proofing kit (PMO-ODTEK)

ü

bolt-down bottom mounting brackets (PMO-FEET)

ü

access panel locks w/keys (PMO-LOCKS)

ü

module extender for extra-high batteries (PMO-EXT)

ü

durable battery tray for isolating batteries from base (PMO-TRAY)

ü

C40 multipurpose controller (PMO-C40)

ü

voltage-limiting C40 multipurpose controller (PMO-VLC40)

ü

C40 installation kit (PMO-C40K)

ü

ground-fault disconnect (PMO-GFP)

ü

add-on module for additional battery capacity (PMO-ADD)

ü

20 to 60 amp Heineman™ DC breakers

ü

15 to 60 amp Square D™ AC breakers

ü

DC negative bonding block with shunt (PMO–DCBB)

ü

modular power distribution block (PMO-PDBB)

ü

utility/generator neutral bonding block (PMO-NEUTRAL)

ü

lockable acrylic breaker covers (PMO-COVER)

ü

sliding breaker fill-plates (PMO-SLIDER)

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 6

1-2

This page intentionally left blank.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 7

General Precautions 2-1

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS !

This manual contains important safety and operating instructions. This manual also covers assembly of the

Trace Engineering line of Power Modules with both Sinewave and DR series inverters, C40 charge controllers,

AC and DC disconnects, PVGFP, and other devices. Specific operating and hookup instructions for each

separate component are provided in the individual component manuals packaged with these assembly

instructions. Before installation, review the applicable sections of this manual, and always follow the safety

practices described below:

General Precautions

1. Before using the inverter/charger, read all instructions and cautionary markings on (1) the

inverter/charger, (2) the batteries and (3) charge controllers, and (4) in this manual as well as the individual

manuals provided for each component of the system.

2. CAUTION - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead calcium, gel

cell, absorbed mat, or NiCad/NiFe type rechargeable batteries. Other types of batteries may burst, causing

personal injury and damage.

3. Do not expose the Power Module to rain, snow, or liquids of any type without proper installation of the

sealing kit, which is included with each Power Module

4. Qualified personnel (with electrical experience) should make all electrical connections. Incorrect

installation may result in a risk of electric shock or fire.

5. To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning.

Turning off the inverter will not reduce this risk; the inverter by-pass breaker must be used and the power

module must be totally disconnected from all sources. Solar photovoltaic modules produce current when

exposed to light - cover them with opaque material before servicing any connected equipment.

6. If using a power module as a battery enclosure, support the additional weight the module must carry as

described in the PMO-FEET section. The mounting feet are required as well as a concrete pad or timbers

to support the bottom tray of each cabinet stack as shown in the section on PMO-FEET (page 6-17).

7. WARNING - WORKING IN THE VICINITY OF A LEAD ACID BATTERY IS DANGEROUS. BATTERIES

GENERATE EXPLOSIVE GASES DURING NORMAL OPERATION. Provide ventilation to the outdoors

from the battery compartment. The battery enclosure should be designed to prevent accumulation and

concentration of hydrogen gas in “pockets” at the top of the compartment. Vent the battery compartment

from the highest point.

8. NEVER charge a frozen battery.

9. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be no less than 10 AWG

(2.6mm) gauge copper wire and rated for 75C or higher. Battery cables must be rated for 75C or higher and

should be no less than #4/0 AWG (11.7 mm) for PM-XX250/X systems and #2/0 AWG (9.3 mm) gauge for

PM-XX175/X systems. Crimped and sealed copper ring terminal lugs with a 5/16 hole should be used to

connect the battery cables to the negative DC shunt terminals of the Power Module (lug not needed for the

positive terminal). Soldered cable lugs are also acceptable.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 8

2-2 Personal Precautions

10. Torque all AC wiring connections to 20 inch-pounds. Torque all DC cable connections 10-12 footpounds. Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could short- circuit

the batteries or other electrical parts resulting in sparks that could cause an explosion.

11. Tools required to make AC wiring connections: Wire strippers, ½" (13MM) open-end wrench or socket,

Phillips screw driver #2, 3/16” ( 5mm) & 1/4" (6MM) slotted-screw driver, and a torque wrench.

12. The Power Module is intended to be used with a battery supply with a nominal voltage equal to the last

two digits in the inverter/charger’s model number. For example: a SW4024 is a 24 volt inverter, a DR1512 is

a 12 volt inverter. (The first two digits are Power output in hundreds of watts)

13. Instructions for mounting: See mounting instruction section of this manual. For battery

installation and maintenance: read the battery manufacturer’s installation and maintenance

instructions prior to operating.

14. DC GROUNDING INSTRUCTIONS - This Power Module should be connected to a grounded,

permanent wiring system. For most installations, the negative battery conductor should be bonded to the

grounding system at one (and only one point) in the system. All installations should comply with all national

and local codes and ordinances.

15. Fully assemble each module from the bottom up before adding the next module, up to a maximum stack

height of four modules. This includes attaching and tightening all mounting hardware. The strength and

stability of the modular system is dependent on all fasteners being connected and tightened properly.

Personal Precautions

1. Someone should be within range of your voice to come to your aid when you work near batteries.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near batteries.

Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid

enters eye, immediately flood eye with running cool water for at least 15 minutes and get

medical attention immediately.

5. Baking soda neutralizes lead acid battery electrolyte. Keep a supply on hand in the area of the batteries.

6. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

7. Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could short-circuit the

batteries or other electrical parts which may result in a spark which could cause an explosion.

8. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

battery. A battery can produce a short-circuit current high enough to weld a ring or the like to metal, causing

severe burns.

9. This is a negative grounded system. Always connect the positive or hot wires before connecting the

negative or neutral wires when installing all equipment. This will reduce the chance of shorting the wires to

the cabinet or equipment when routing wires. This is particularly important when routing the battery cables.

10. As an additional precaution, the ends of the battery cables should be taped when routing

through cabinet openings and conduit.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 9

Underwriters Laboratory (U.L.) Compliance Requirements 2-3

11. If a remote or automatic generator start system is used, disable the automatic starting circuit and/or

disconnect the generator from its starting battery while servicing to prevent accidental starting.

Underwriters Laboratory (U.L.) Compliance Requirements

The Power Module cabinet is listed (UL file#39FL under “Rainproof Modular Enclosure for use as a

photovoltaic Power System Accessory,” UL1741. The modules are shipped with a listing sticker approved

for use by UL. The sticker is valid if and only if the following compliance requirements are met in the final

installation.

1. Stability Requirements The optional mounting feet (PMO-FEET) must be included for each

assembled cabinet. The bottom module of each cabinet must be secured with at least six 1/2" anchor

bolts through the mounting feet to a concrete pad or platform of sufficient mass and footprint to keep the

completed cabinet and the intended contents from being pushed over. It is the user’s responsibility to:

insure that the concrete pad or platform meet these requirements;

ü

maintain the anchor bolts over time;

ü

replace components as needed.

ü

Additional mounting of the upper module(s) to a wall may be needed to meet local earthquake code

requirements.

2. Grounding Continuity Requirements Individual modules, doors, and lids must be assembled as per

the details outlined in this manual with the fastening hardware supplied by Trace Engineering. The PM

modules and lid must have a star washer on the outside between the head of the carriage bolt and the

module, and on the inside between the module and the nut, to insure grounding continuity between

modules. The door latch assemblies are factory installed with earth nuts and the powder-coat is removed

on the module where the door latch contacts to insure grounding continuity of the doors. As an added

insurance, the neoprene gasket is attached to the module between the door to insure that the latch

remains in contact with the bare metal spot. It is the user’s responsibility to insure that the gasket remains

maintained over time and replace as needed.

3. Baffle Requirements The water baffle and screening is required on each door on a module containing

electronic components for all installations. The kit (PMO-ODTEK) is factory installed as per the

instructions outlined in this manual. After assembly, use the silicone rubber sealant included with the kit to

treat all seams to insure lone-term weather-proofing perfoamance. It is the user’s responsibility to

maintain the weatherproofing accessories over time, and to replace components as needed.

4. The installer/user is responsible to insure that the power module cabinets are properly installed and that

all electrical connections are made to meet local National Electric Code (NEC) and inspector’s

requirements.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 10

2-4 Underwriters Laboratory (U.L.) Compliance Requirements

This page intentionally left blank.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 11

Powering Up the System 3-1

Power Module Installation

Read all precautions at the beginning of this manual and the individual component manuals before

attempting to install the system. Because of tool clearances needed to make connections, It is easiest to

make all external connections to the PM (charge controllers, PV array, and AC inputs/outputs, before

installing the inverter. As a general rule, connections should be made along the back panel, than the side

panels, and lastly to equipment mounted on the tray.

Install the inverter to the module tray using all six stainless steel bolts, washers and nuts supplied. Insure

that the DC and AC sides of the inverter correspond with the DC and AC breaker locations in the Power

Module. When all six fasteners are secured there is no need for additional bracing of the module tray, since

the inverter chassis will add stiffness. Torque to 79 inch-pounds.

Connect the battery positive cable from the battery disconnect and the battery positive cables from all

charge controllers to the inverter DC positive lug. Torque nut to 12 ft-lbs and place a protective cover over

the terminal.

Connect the battery negative cable from the inverter, and the battery negative cables from all charge

controllers to the inverter DC negative bonding block (DCBB page ). Torque nut to 12 ft-lbs and place

protective cover over the terminal.

Make AC connections from the AC input/output/bypass inverter breaker to the inverter. All wires are marked

identical to the labels at the connectors inside the inverter. AC Utility In should be connected into AC1 and,

if a generator is used as an additional AC input it should be connected to AC2, (it will normally have an

additional AC input/output/bypass breaker).

Grounding Parameters: Connect D.C. Ground wire (8 AWG) to grounding rod. Connect the A.C. Ground at

the main AC panel ground connection if used in a residential or commercial application. NEC and local

codes determine the complete grounding requirements.

Powering Up the System

Before applying power to the Power Module for the first time, take time to check and confirm the following

key items:

1. Check to see that the AC loads and AC source are connected properly into the inverter bypass box.

2. Confirm that the battery cable polarities are proper. Connection with improper polarity is an expensive

mistake, very obvious and not covered under warranty.

3. Check the PV array connections at the array and at the Power Module. Be sure the PV array positive is

connected to the bottom of the PV array disconnect as illustrated.

4. Confirm that all connections are tight and wire size is appropriate as described above and shown on the

installation diagram. Once these checks have been completed, it is time to apply power to the system. Do so

as follows:

A. Turn the battery DC disconnect(s) to the on (up) position.

B. Turn the solar array disconnect(s) to the on (up) position.

C. Turn the inverter(s) on as outlined in the individual component manual, and check for proper

operation. If the inverter does not power up, go to step F.

D. Unlock the main AC breaker that will feed the inverter and activate the AC source used to provide

power to the system (generator or main breaker).

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 12

3-2 Stacked Pair Inverters

E. Turn the inverter bypass breaker to the position noted in the residence wiring diagram on the

bypass box that will turn the inverter system on. The Power Module system is now fully connected

and operable. Should any problems arise that are not covered in this installation manual, contact

Trace Engineering or your dealer. Note: Perform the next step only if the inverter fails to Power up

when turned on.

F. Using a multi meter, check for appropriate battery voltage at the inverter DC terminals. (This will

require removing the end cover from the inverter.) If the battery voltage is appropriate confirm proper

battery cable polarity and connection, and make sure the batteries are not completely discharged. If

the inverter still doesn’t work contact your dealer or Trace Engineering.

Stacked Pair Inverters

If your P M includes a stacked pair of inverters the physical connection of the PM is no different. However,

since 240 volts AC is available across the two inverter’s AC outputs, connection of the AC loads to the

system via the bypass breaker is a little different. Refer to the section on stacking inverters in the individual

inverters owner’s manual included with the system.

Connect the AC loads that will run from 120 volts AC, to the AC output of the individual inverters at the

bypass breaker box. It is best to try and balance the AC loads between the two inverters if possible. The

load(s) that is to run from 240 volt AC output should be connected across the two inverters outputs by

connecting the neutral wire (white) to the neutral block in the bypass box, and one hot wire to each of the

inverter bypass box AC load points

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 13

4-1

Power Module Systems

PM Systems

Single DR Inverter Diagram ............3

Dual DR Inverter Diagram .............5

PM SW 175/250 S Diagram.............7

Dual Sinewave Inverter Diagram .........9

Sinewave 3 - Phase System ...........11

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 14

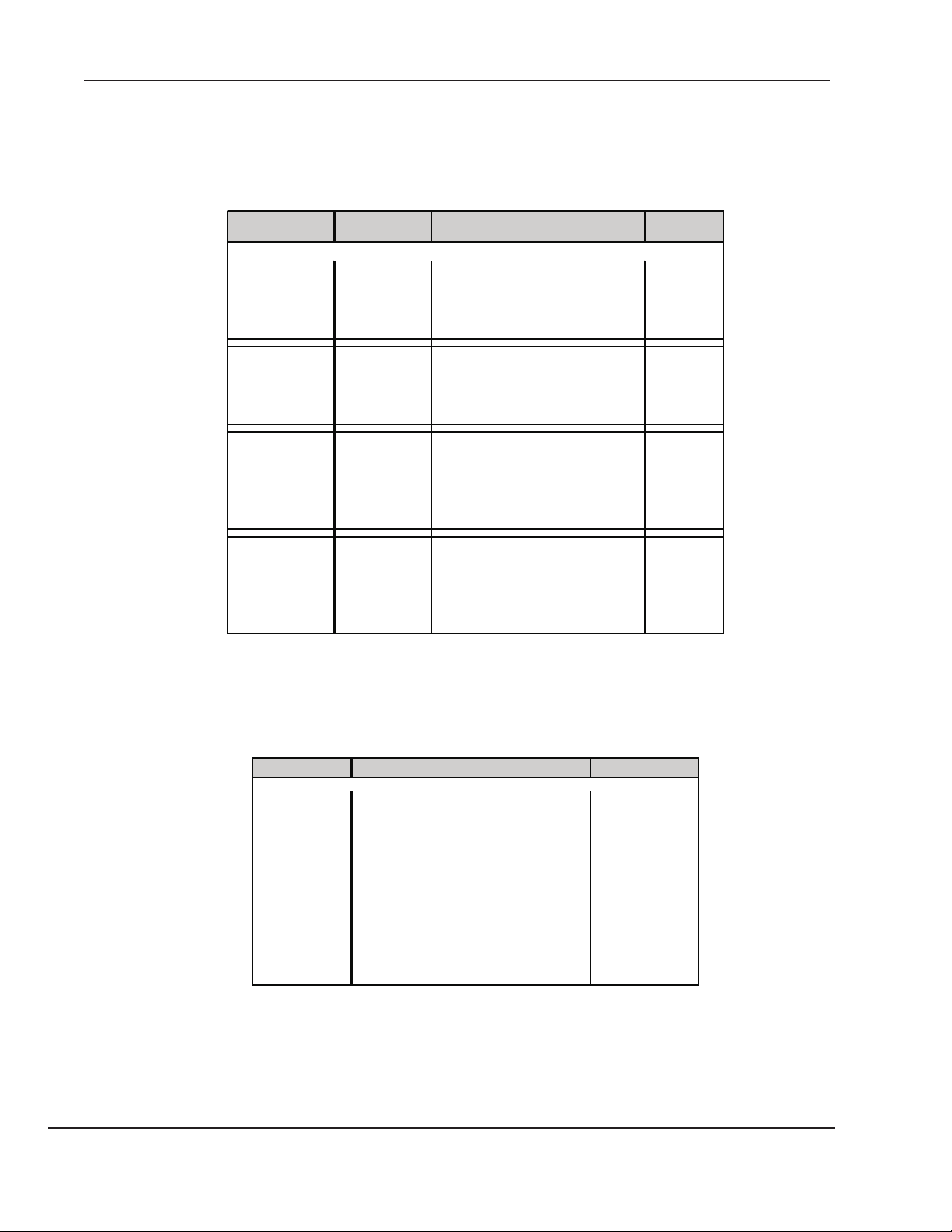

4-2 Power Module Fastener Facts

Power Module Fastener Facts

Table 1, Fastener Description and Application

Where Used Trace PN Description Quantity

Inverter to PM 425 1/4-20 x 3/4" SS bolt 6

468 1/4" SS flat washer 12

2147 1/4" SS external star washer 12

444 1/4-20 SS hex nut 6

PM-FEET 3191 #10-24 x 1" SS carriage bolt 14

485 1/4" SS internal star washer 14

442 #10-24 SS hex nut 14

465 #10 SS flat washer 14

PMO-ADD 3190 #10-24 x 1/2" SS carriage bolt 14

485 1/4" SS internal star washer 14

2147 1/4" SS external star washer 14

465 #10 SS flat washer 14

442 #10-24 SS hex nut 14

PM-LID 3191 #10-24 x 1" SS carriage bolt 6

485 1/4" SS internal star washer 6

2147 1/4" SS external star washer 6

465 #10 SS flat washer 6

3329 #10-24 SS wingnut 6

Table 2, Fastener Torque Values

Trace PN Description Torque value

3190 #10-24 x 1/2" SS carriage bolt 25 in-lbs

3191 #10-24 x 1" SS carriage bolt 25 in-lbs

465 #10 SS flat washer N/A

442 #10-24 SS hex nut 25 in-lbs

3329 #10-24 SS wingnut Finger tight

425 1/4-20 x 3/4" SS cap screw 80 in-lbs

468 1/4" SS flat washer N/A

485 1/4" SS internal star washer N/A

2147 1/4" SS external star washer N/A

444 1/4-20 SS hex nut 80 in-lbs

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 15

4-3

Single DR System

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 16

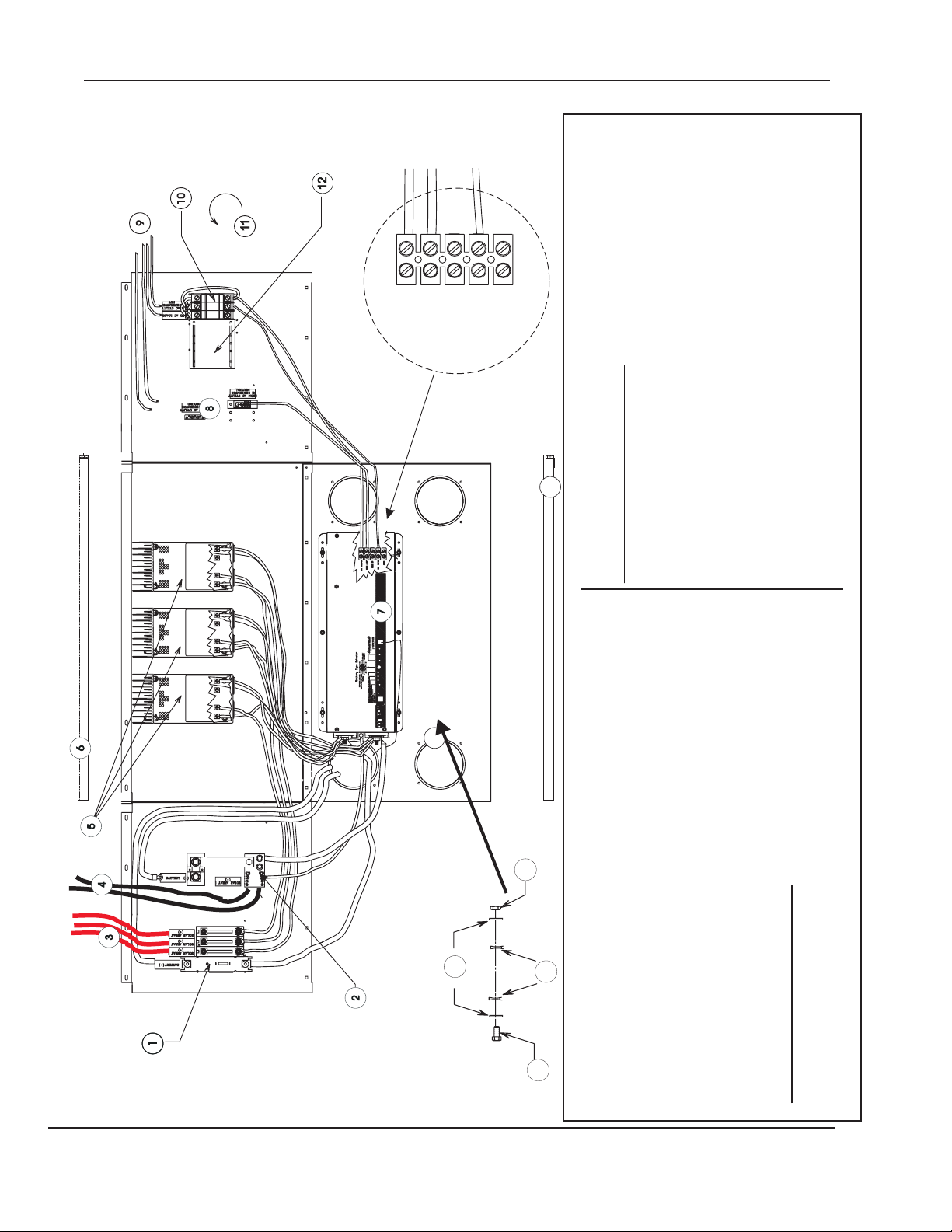

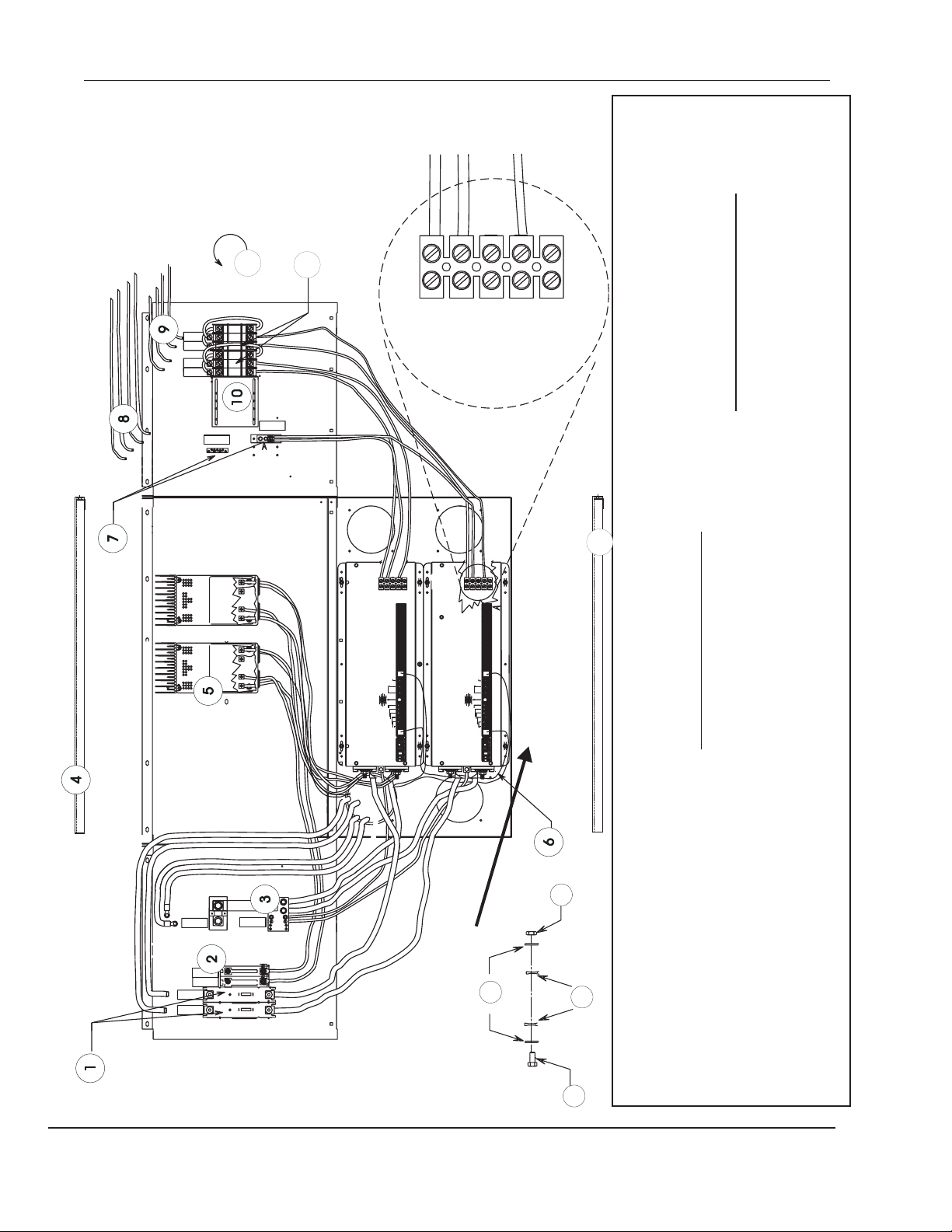

4-4 PM DR 175/250 Single Inverter Diagram

Hot In

Hot Out

Neutral Out

Neutral In

Ground

13

14

3 US PV wiring (not included)3

#Qty Part No. Description

4 AR US DC ground cabling; one to PV array ground, other to earth ground rod

5 AR optional C40’s (not included) up to three.

6 1 LID enclosure top

7 1 US DR Inverter not included

8 1 AC Neutral AC neutral bonding block, with AC ground bonding block

9 AR US AC wiring (not included)

10 1 IOX60 AC input/output/bypass lockout disconnect

11 2 COVER, PMO- weather-tight, locking switch cover

12 2 SLIDER, PMO- unused breaker opening cover

13 1 FEET, PMO- brackets to secure the power module to the base or pad

14 4 Edge guard Cut to length and install around cable passages in the base to prevent

chaffing.

These fasteners are used for attaching the inverter to the floor of the cabinet:

A 6 425 ¼ - 20 X ¾” HH SS bolt

B 12 2147 ¼” external tooth starwasher

C 12 468 ¼” flat washer

PM DR 175/250 Single

D

B

C

A

All configurations use 6 AWG THHN wire for AC and PV wiring. Inverter cables are 4/0

for DR2412 and 3624. DR1512, 1524, and 2424 inverters use 2/0 cable. User red heat

shrink for positive and black heat shrink for negative. Refer to the DR Owner’s Manual for

cable sizing. Each assembly also includes the door (not shown). Refer to the individual

components assembly descriptions. Follow the assembly sequence as shown on the

reverse side of this page. When ordering parts for your system, always prefix the desired

part number with the letters PMO-. AR means As Required; US means User Supplied.

Qty Part No. Description

#

I nverter Diagram

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

1 1 DC175 175 amp DC circuit breaker used with DR1512, 1524, OR 2424

DC250 250 amp DC circuit breaker used with DR2412 or3624

2 1 DCBB DC bonding block with shunt

Page 17

PM DR 175/250 Single Inverter Diagram 4-5

PM DR 175/250 S Assembly Sequence

1. Feet (Page 6-17)

2. Edge guards

3. C40 if equipped (Page 5-7)

4. Neutral and ground bonding block (left panel for SW, right panel for DR, Page 5-21)

5. DC bonding block (left for DR, right for SW, Page 5-15)

6. DC shunt

7. DC bus bars

8. DC175/250 (Page 13)

9. DC20/60/110 (Page 12)

10. IOX60 (Page 19)

11. any additional AC or DC breakers

12. Slider (Page 23)

13. Cover (Page 13)

14. connect ground conductors

15. AC output cables

16. AC neutral cables

17. DC cables

18. Decals

19. Lid (Page 19)

20. Door (Page 15)

Assembly Instructions: Invert PM and install feet; turn PM upright to continue. Remove appropriate

component instruction sheets and arrange in order of installation. Gather all tools and components

listed in the instructions and place them nearby. Prepare components as instructed on the

component assembly pages and set aside. When all cables, components, fasteners, etc. are

prepared and handy, assemble each component in the sequence as shown, referring to the

component assembly instructions as required.

When ordering parts, always use the PMO- prefix.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 18

4-6 PM DR 175/250 Single Inverter Diagram

This page intentionally left blank.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 19

PM DR 175/250 Single Inverter Diagram 4-7

Dual DR System

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 20

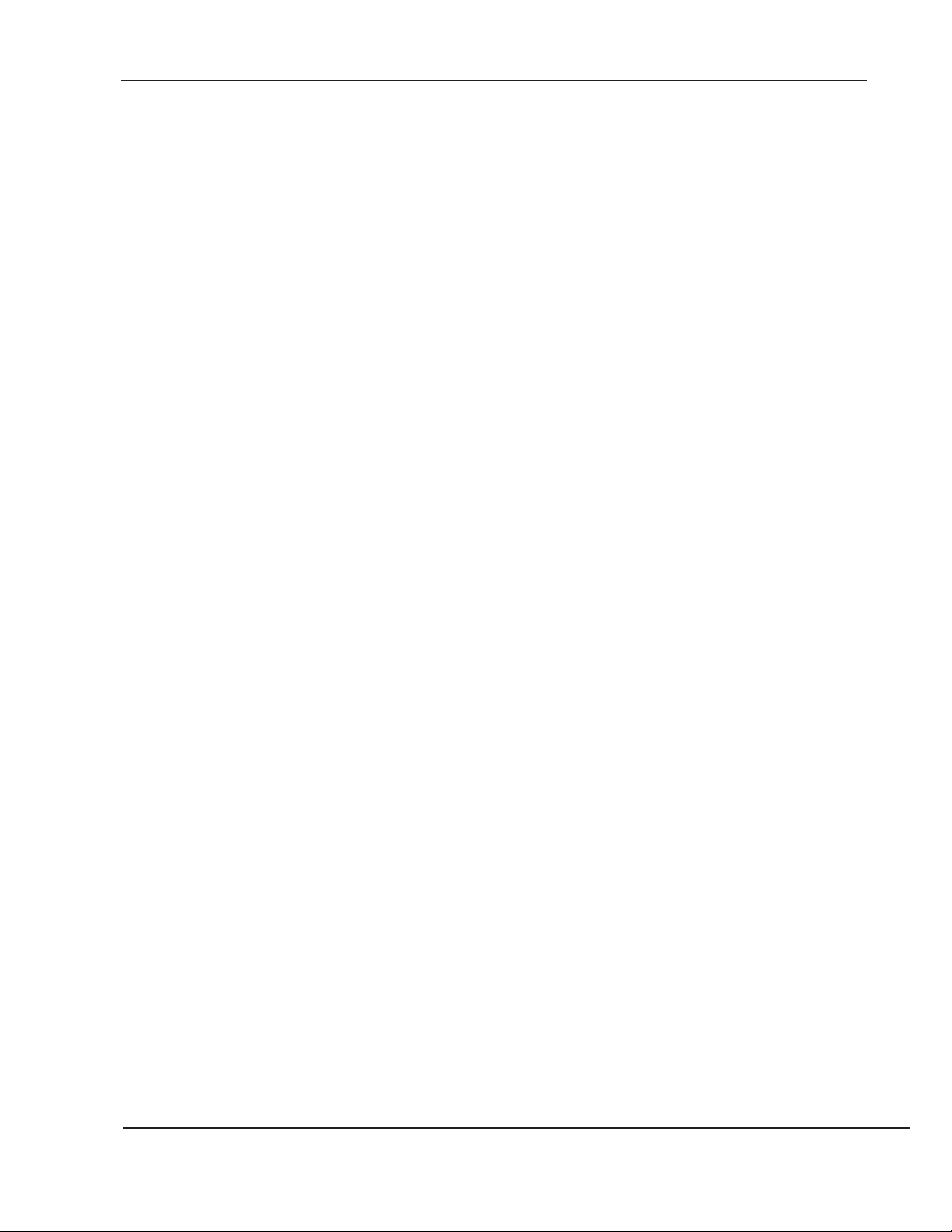

4-8 PM DR 175/250 Dual Diagram

11

HOT

RGENERAT

OMAC UTIL

ACLOADS

HOT

RGENERAT

OMAC UTIL

ACLOADS

12

Hot Out

Neutral In

Hot In

Ground

to the floor or base

disconnect circuit breaker

Neutral Out

8 AR US AC 6 AWG THHN

9 AR US AC wiring 6AWG THHN

NEUTRAL

ORGENERATOR

GROUND

ORGENERATOR

FROMAC UTILITY

FROMAC UTILITY

10 1 PMO-SLIDER covers unused breaker slots

#Qty Part No. Description

11 2 PMO-COVER flip-up cover for breakers

12 2 PMO-IOX60 input, output, bypass,

13 1 PMO-FEET brackets to secure the module

13

PV(-) Battery(-)

Battery(+) PV(+)

PV(-) Battery(-)

Battery(+) PV(+)

DR Series Inverter #1

GND

HOTIN

NEUIN

HOTOUT

NEUOUT

PowerInverter/Charger

DRSeries

BATTERYSENSE

.5K

BATTERYCAPACITY

.37K

1K

250

Amp/Hrs

ACTRANSFERTHRESHOLD

50

125

OVER-DISCHARGEPROTECTION

BATTERYCHARGER RATE

ON

OFF

EQUALIZE1

EQUALIZE2

0

MAX

1

9

8

2

MIN

3

7

4

6

5

BatteryType Selector

LEADACID

GELCELL

60

25

>100

10

PbCa-MAINTENANCEFREE

DEEPCYCLE

0

CHARGER:GRN=FLOAT/ORNBLINK=ABSORP/ORN=BULK

COMPORT

POWERON/OFF

INVERTERMODE

SEARCHMODEWATTS

OVERTEMPRED/OVERLOADGRN

BATTERYHIRED/BATTERYLOW GRN

DR Series Inverter #2

GND

NEUIN

INVINPUT

NEUOUT

INVOUTPUT

PowerInverter/Charger

DRSeries

BATTERYSENSE

.5K

BATTERYCAPACITY

.37K

1K

250

Amp/Hrs

ACTRANSFERTHRESHOLD

50

125

OVER-DISCHARGEPROTECTION

BATTERYCHARGER RATE

ON

OFF

EQUALIZE1

EQUALIZE2

0

MAX

1

9

8

2

MIN

3

7

4

6

5

BatteryType Selector

LEADACID

GELCELL

60

25

>100

10

PbCa-MAINTENANCEFREE

DEEPCYCLE

0

CHARGER:GRN=FLOAT/ORNBLINK=ABSORP/ORN=BULK

COMPORT

OVERTEMPRED/OVERLOADGRN

BATTERYHIRED/BATTERYLOW GRN

POWERON/OFF

INVERTERMODE

SEARCHMODEWATTS

Follow the assembly sequence as shown on the reverse

side of this page.

PMO-DC250 used with DR2412 or 3624

Qty Part No. Description

#

1 2 PMO-DC175 used with DR1512, 1524, or 2424

2 AR DC20, 60, 110 amp DC breakers

3 1 PMO-DCBB D C bonding block

4 1 PMO-LID

5 AR PMO-C40, VLC40, C40K

(optional - includes one DC60 each)

6 2 DR Inverter not included

7 1 PMO-NEUTRAL neutral bonding block

PM DR

Battery (-)

BATTERY (-)

(-)

SOLARARRAY 1

Solar Array (-)

(+)

SOLARARRAY 1

(+)

SOLARARRAY 1

Solar Array (+)

BATTERY (+)

BATTERY (+)

B

Battery (+)

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

D

C

All configurations use 6 AWG THHN wire for AC and PV

wiring. Inverter cables are 4/0 for DR2412 and 3624.

DR1512, 1524, and 2424 inverters use 2/0 cable. User

red heat shrink for positive and black heat shrink for

negative. Refer to the DR Owner’s Manual for cable

sizing. Each assembly also includes the door (not shown).

A

175/250 Dual Diagram

Refer to the individual components assembly descriptions.

Page 21

PM DR 175/250 Dual Diagram 4-9

PM DR 175/250 Dual Assembly Sequence

1. Feet

2. edge guards

3. C40 (if equipped)

4. neutral and ground bonding block (left panel for SW, right panel for DR)

5. DC bonding block (left for DR, right for SW)

6. DC shunt

7. DC bus bars

8. DC175/250

9. DC20/60/110

10. IOX60

11. any additional AC or DC breakers

12. Slider

13. Cover

14. connect ground conductors

15. AC output cables

16. AC neutral cables

17. DC cables

18. Decals

19. Lid

20. Door

Remove appropriate component instruction sheets and arrange in order of

installation. Gather all tools and components listed in the instructions and place then

nearby. Prepare components as instructed on the component assembly pages and

set aside. When all cables, components, fasteners, etc. are prepared and handy,

assemble each component in the sequence shown above, referring to the component

assembly instructions as required. Invert PM to install feet.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 22

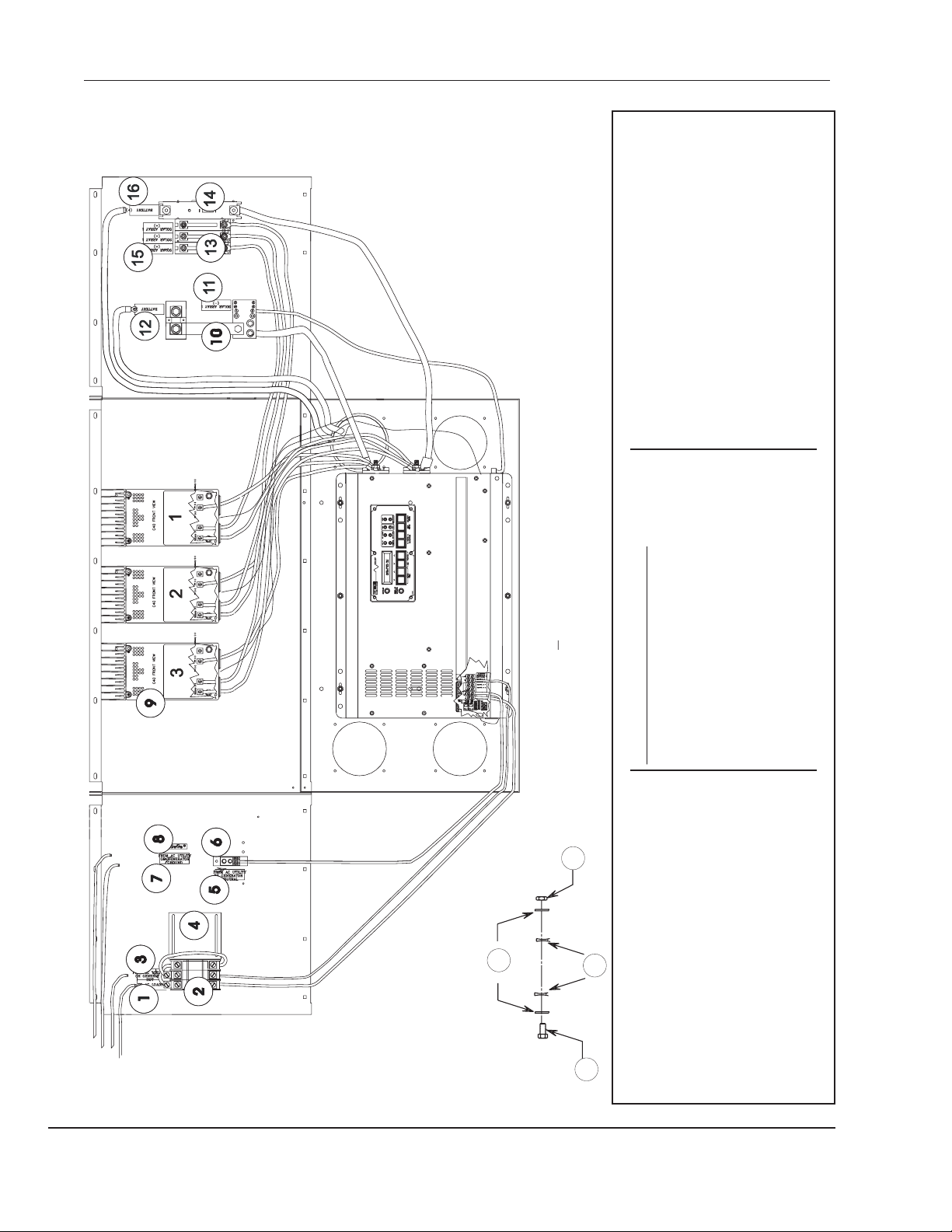

4-10 PM SW 175/250 S Diagram

2298-60 DC 60-amp circuit breaker

2249-110 DC 110-amp circuit breaker

9 AR C40 optional charge, load, diversion controller

10 1 DCBB DC ground bonding block and shunt

11 1 3238 decal “Solar Array (-)”

12 1 3232 decal “ Battery (-)”

13AR 2957-20 DC 20-amp circuit breaker

14AR 2079-175/250 DC 175 or 250 amp circuit breaker

15AR decal “Solar Array (+)”

16AR 3231 decal “Battery (+)”

A 6 425 ¼ - 20 X ¾” HH SS bolt

B 12 468 ¼” flat washer

C 12 2147 ¼” external tooth flat washer

D 6 444 ¼-SSHHnut

Qty P/N Description

#

1 1 decal “To AC Hot Loads”

2 AR IOX60 AC input/output/bypass disconnect

w/lockout

3 AR 3200 decal “From AC Hot Utility/Generator”

4 2 Slider unused breaker opening cover

5 1 3194 decal “From AC Utility/Generator

Neutral”

6 1 Neutral AC neutral bonding block

7 1 decal “From AC Utility/Generator

Ground”

8 1 N/A ground bonding block (part of Neutral)

PM

D

B

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

C

A

All configurations use 6 AWG THHN wire for AC and PV

SW 175/250 S Diagram

wiring. Inverter cables are 4/0 for DR2412 and 3624.

DR1512, 1524, and 2424 inverters use 2/0 cable. User

red heat shrink for positive and black heat shrink for

negative. Refer to the DR Owner’s Manual for cable

sizing. Each assembly also includes the door (not

shown). Refer to the individual components assembly

descriptions. Follow the assembly sequence as shown

on the reverse side of this page.

Page 23

PM SW 175/250 S Diagram 4-11

SW System Assembly Sequence

1. Feet

2. edge guards

3. C40 (if equipped)

4. neutral and ground bonding block (left panel for SW, right panel for DR)

5. DCBB bonding block (left for DR, right for SW)

8. DC175/250

9. DC20/60/110

10. IOX60

11. any additional AC or DC breakers

12. Slider

13. Cover

14. ground conductors

15. AC output cables

16. AC neutral cables

17. DC cables

18. Decals

19. Lid

20. Door

Invert PM to install feet; revert to continue. Remove appropriate component instruction

sheets and arrange in order of installation. Gather all tools and components listed in

the instructions and place then nearby. Prepare components as instructed on the

component assembly pages and set aside. When all cables, components, falters, etc.

Are prepared and handy, assemble each component in the sequence shown, referring

to the component assembly instructions as required.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 24

4-12 PM SW 175/250 Dual Diagram

Battery (+)

BATTERY(+)

BATTERY(+)

(+)

(+)

SOLARARRAY1

SOLARARRAY1

TOAC LOADS

ORGENERAT

ORGENERAT

HOT

HOT

FROMAC UTIL

FROMAC UTIL

ACLOADS

FROMAC UTILITY

ORGENERATOR

GROUND

FROMAC UTILITY

ORGENERATOR

NEUTRAL

11

MASTER SW INVERTER #1

TEMP

EXTERNAL

BATTERY

J2

RY10RY11

RY8COM

RY8NO

ACHOTIN1

ACHOTIN2

(GENERATORIN)

NEUTRALIN2

NEUTRALIN1

ACCONNECTIONS

TB2

COM

COM

NC

NO

NO

NC

UPPER

RY11

RY10

RY9

COM

RY7

COM

LOWER

NC

NO

NC

NO

C40FRONT VIEWC40FRONT VIEW

controlpanel

AC1INGOOD BULK

ERROR

LINETIE

CONTRAST

VDC24.1

AMPS70

BATTERYTEMP35C

OVERCURRENTAC2INGOOD FLOAT

INVERTING

RESETTO

FACTORY

DEFAULTS

MENU

MENU SETPOINTS

ON/OFF

GEN

MENU

MENU

ITEM

HEADINGS

HAL9000

Battery (-)

Solar Array (+)

BATTERY(-)

Solar Array (-)

(-)

SOLARARRAY1

PMO-ELEC-MOD

(+)

(+)

(+)

(+)

(+)

SOLARARRAY1

SOLARARRAY1

SOLARARRAY1

SOLARARRAY1

C40FRONT VIEWC40FRONT VIEWC40FRONT VIEWC40FRONT VIEW

Battery(+) PV(+)Battery(+) PV(+)Battery(+) PV(+)

C40FRONT VIEW

1234

5

SOLARARRAY1

TEMP

EXTERNAL

BATTERY

J2

RY10 RY11

RY8COM

RY8NO

AC HOT OUT

NEUTRAL OUT

NEUTRALIN 2

TB2

COM

COM

NO

NO

NC

NC

UPPER

RY11

RY10

RY9

COM

RY7

LOWER

COM

NC

NO

NC

NO

AC HOT IN 1

AC HOT IN 2

(GENERATORIN)

NEUTRALIN 1

ACCONNECTIONS

11

SLAVE SW INVERTER #2

TEMP

EXTERNAL

BATTERY

J2

RY10RY11

RY8COM

RY8NO

ACHOTIN1

ACHOTIN2

(GENERATORIN)

NEUTRALIN2

NEUTRALIN1

ACCONNECTIONS

TB2

COM

COM

NC

NO

NO

NC

UPPER

RY11

RY10

RY9

COM

RY7

COM

LOWER

NC

NO

NC

NO

PM SW 175/250 Dual Diagram

All configurations use 6 AWG THHN wire for AC and PV wiring. Inverter

cables are 4/0 for SW2512, 4024 and 5548. Use 2/0 for SW4048. Use

red heat shrink for positive and black heat shrink for negative. Each

assembly also includes the door (not shown). Refer to the individual

components for assembly descriptions. Follow the assembly sequence as

shown on the reverse side of this page. All AC & DC breakers are located

in the top cabinet. Lower cabinet contains PV Solar Array DC breakers if

equipped with C40 Controllers. Install inverters last, beginning with the

bottom cabinet, after securing the modules in place. Use the fasteners

listed in A, B, C, D. Starwashers are used to lock fasteners and assure

ground continuity.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

controlpanel

AC1INGOOD BULK

ERROR

LINETIE

CONTRAST

VDC24.1

AMPS70

BATTERYTEMP35C

OVERCURRENTAC2INGOOD FLOAT

INVERTING

RESETTO

FACTORY

DEFAULTS

MENU

MENU SETPOINTS

ON/OFF

GEN

MENU

MENU

ITEM

HEADINGS

HAL9000

A

#

Qty Part No. Description

1 2 IOX60 AC input/output/bypass disconnect

2 2 SLIDER

3 1 NEUTRAL AC neutral and ground bonding block

4 AR C40 optional

5 1 DCBB DC ground bonding block

6 2 COVER

7 2 2079-250 250-amp DC breaker or

8 AR 2298 PV Solar DC disconnects

9 AR C40’s

10 AC connections detail

11 2 Sinewave inverters

A 6 425 ¼ - 20 X ¾” HH SS bolt

B 12 2147 ¼” external tooth starwasher

C 12 468 ¼” flat washer

D 6 444 ¼-SSHHnut

2116-175 175-amp DC breaker

B

C

D

Page 25

PM SW 175/250 Dual Diagram 4-13

PM SW 175/250 Dual System Assembly

Sequence

1. Feet (Page 6-14)

2. Edge guards

3. C40 (Page 5-7 if equipped)

4. Neutral and ground bonding block (Page 5-21, left

panel for SW, right panel for DR)

5. DC bonding block (Page 5-15, left for DR, right for

SW)

6. DC175/250 (Page 5-14)

7. DC20/60/110 (Page 5-12)

8. IOX60 (Page 5-19)

9. any additional AC or DC breakers

10. Slider (Page 6-23)

11. Cover (Page 6-18)

12. connect ground conductors

13. AC output cables

14. AC neutral cables

15. DC cables

16. Decals

17. Lid (Page 19)

19. Door (Page 15)

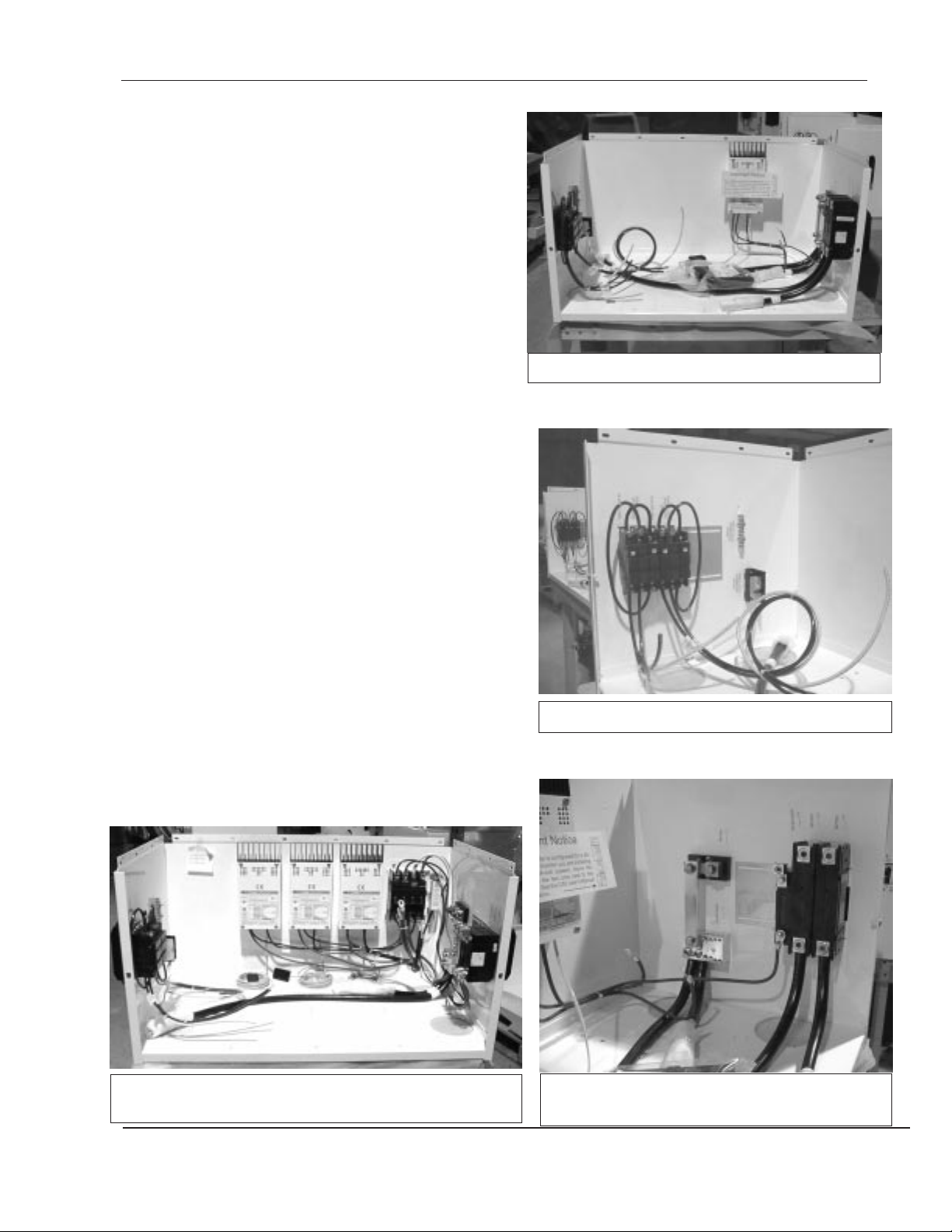

PM 175/250 D Front View

Invert PM to install feet; revert to continue. Remove

appropriate component instruction sheets and arrange in

order of installation. Gather all tools and components listed

in the instructions and place then nearby. Prepare

components as instructed on the component assembly

pages and set aside. When all components are prepared

and handy, assemble each component in the sequence

shown above, referring to the component assembly

instructions as required.

Front view of PM SW 175/250 D showing standard

components plus PVGFP and three C40’s w/BTS’s

PM 175/250 D Left Panel

PM SW 175/250 D right side panel including

DCBB, DC175/250, and PV

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 26

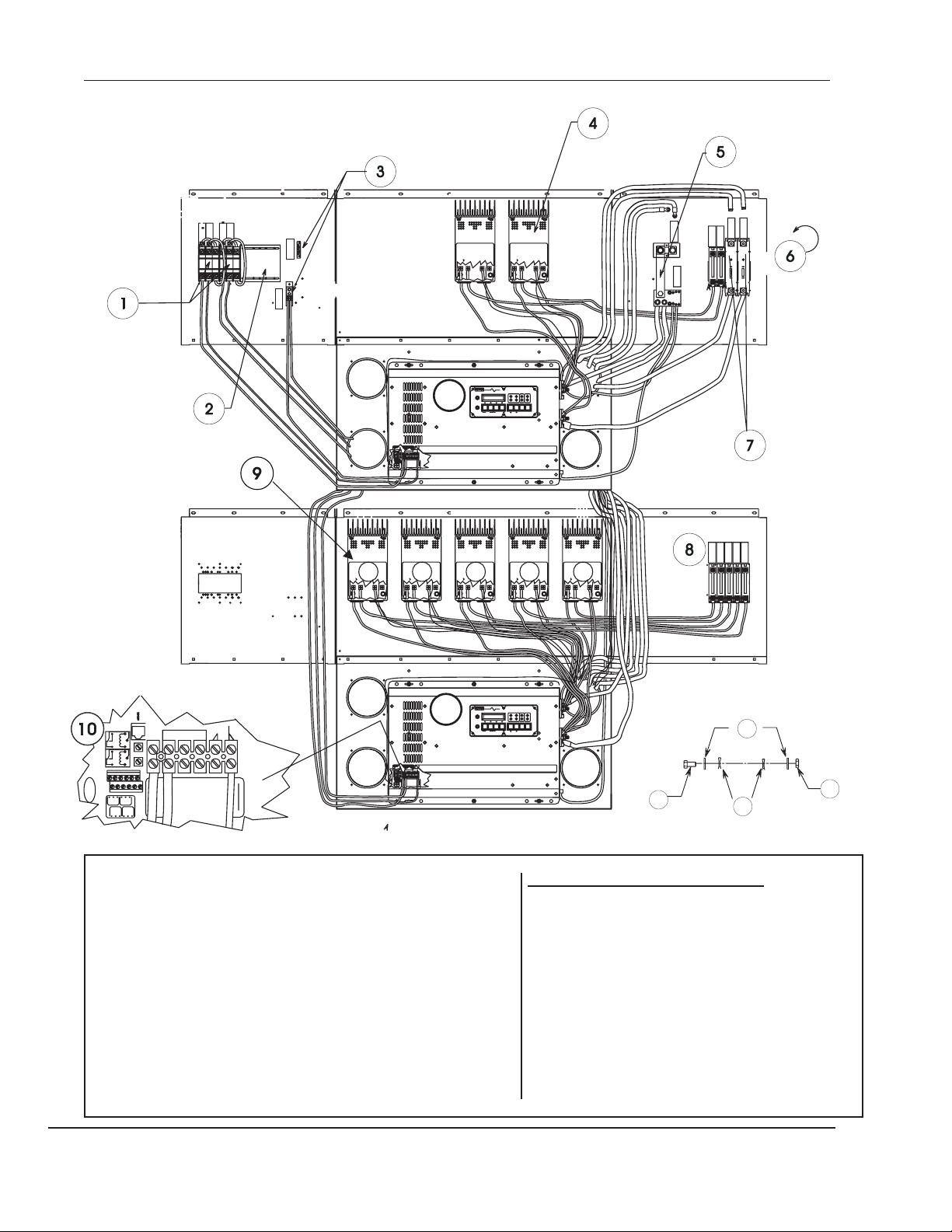

4-14

Three-Phase Power Module

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 27

Three-Phase Power Module 4-15

1

11

2

12

3

13

4

4

5

9

6

14

7

4

4

8

10

15

16

17

14

15

4

18

B

A

C

D

19

17

20

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 28

4-16 Sinewave 3 - Phase System

Sinewave 3 - Phase System

The Three-Phase Sinewave Power Module system consists of one PM module joined to two PM-ADD

enclosures. System includes three Door panels w/latches, screen and edge guard kit, one LID and an

outdoor sealing kit (not shown). The top most SW inverter is the master (Phase A) inverter connected to

the two slave inverters with a special 3-phase interface cable.

# Qty P/N PM OR PMO- Description

1 1 COVER acrylic breaker cover, see detail

2 1 IOX60 60-amp, Phase A bypass breaker

3 1 AC60-3 60-amp, 3-phase AC breaker

4 5 SLIDER unused breaker opening cover

5 1 NEUTRAL neutral bonding block includes ground bonding block shown above

6 1 MONITOR 3-phase monitor (optional); pass bypass breaker output from each inverter through the monitor,

7 1 DCBB ground bonding block; connect a black, 4/0 cable from the bottom of this block to each inverter battery

8 3 DC175or250 DC circuit breaker; connect a red 2/0 or 4/0 cable from the battery bank positive terminal to the

9 1 SWXXXX Phase A Sinewave inverter (master inverter)

10 1 COVER Lockable acrylic cover over the DC breakers; include Warning decal

11 1 COVER Cover for Phase B and C bypass breakers w/bypass warning decal

12 1 IOX60 Phase B bypass breaker

13 1 IOX60 Phase C bypass breaker

14 AR C40’s Optional C40 charge controllers. Mount in the sequence shown.

15 AR DC20/60/110 Optional PV array DC circuit breakers.

16 1 SWXXXX Phase B Sinewave inverter (slave)

17 2 COVER Lockable cover used over PV array breakers; see detail

18 1 BLANK Covers unused breaker opening in left wing panel of Phase C inverter enclosure.

19 1 SWXXXX Phase C Sinewave inverter (slave)

20 1 FEET Set of drilled brackets for mounting system to an appropriate foundation

3 DOOR Door assemblies (not shown)

1 ODTEK Sealing kit (not shown)

1 Screen and edgeguard kit (not shown)

1 Fastener kit; contains fasteners for stacking module and securing inverters

1 LID Lid for top module (not shown)

1 Three-phase interface cable (adjacent to 9-16-19)

INVERTER FASTENING DETAIL:

then to bottom of 60-amp, 3-phase AC breaker.

negative terminal. Connect a black 4/0 cable from the top of this assembly to each negative battery bank

terminal

top of each breaker; connect a red 4/0 cable from the bottom of each breaker to the positive battery

terminal of each Inverter.

A 6 425 ¼ - 20 X ¾” HH SS bolt

B 12 2147 ¼” external tooth starwasher

C 12 ¼” flat washer

D 6 444 ¼-SSHHnut

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 29

3-Phase Assembly Sequence 4-17

3-Phase Assembly Sequence

1) Assemble each PM module according to the instructions found on each respective assembly sheet: Phase C module assembly

instructions; Phase B module assembly instructions; Phase A module assembly instructions.

2) Mount a 3-phase Sinewave inverter into Phase C module using the six bolts, 12 starwashers, 12 lock washers, and12 nuts provided

for this purpose.

3) Secure Phase C module to prepared pad using the lag bolts and washers as described on the FEET assembly instructions sheet.

4) Attach the prepared Phase B module to the Phase C module using all 14 fasteners. See Phase B module assembly instructions

5) Place the Phase C module AC wiring between the Phase C inverter and the bypass breaker in the Phase B module. Refer to the

IOX60 sheet for instructions.

6) Mount the Phase B inverter on the floor of the Phase B enclosure; don’t bolt it down yet. Connect Phase B module AC wiring between

the Phase B inverter and the IOX60 bypass.

7) Mount the Phase A module on top of the Phase B module. Secure with all 14 fasteners.

8) Connect Phase B and Phase C DC cabling between the inverters and the DC250 breakers in the Phase A cabinet.

9) Place the Phase A inverter in place on the floor of the Phase A module; don’t bolt it down yet.

10) Connect all Phase A AC cabling to the remaining IOX60 bypass.

11) Connect all Phase A DC cabling remaining to the DC breakers and C40’s where used.

12) Secure the Phase A inverter to the floor of the Phase A module with the fasteners provided for this purpose.

13) Plug the 3-Phase interface cable into the connector labeled “Series Stacking” on each inverter. The connector marked “A” plugs into

the Phase A inverter, “B” into Phase B inverter, and “C” into Phase C inverter.

14) Install the weatherproofing gasket on the facing edge of all three modules, and across the bottom edge of all three panels.

15) Turn all AC and DC breakers to the OFF position. DO NOT SKIP THIS STEP.

16) Turn the shorepower 3-phase AC circuit breaker to which you are attaching the Trace 3-Phase Power Module to the OFF position

and lock it to ensure that it cannot be turned to the On position.

17) Connect the AC cabling between the Trace 3-Phase Power Module and the shorepower 3-phase supply circuit breaker.

18) Inspect all AC and DC wiring connections and cabling to verify that all connections are properly completed.

19) When satisfied that all cabling connections are correct, perform the start-up procedure as described in the Trace Engineering

Three-Phase Power Module Installation and Operation Guide.

20) When satisfied with the operation of the Trace Three-Phase Power Module System, install the LID onto the Phase A module and

secure with all 6 fasteners.

21) Install a prepared DOOR panel on the Phase C module, then the Phase B module, and finally on the Phase A module. Lock all six

door LATCHES and remove keys. Provide the owner the Trace Engineering Three-Phase Power Module Installation and Startup Guide,

plus the SymCom Model 777 Electronic Overload Relay installation instructions, the Trace Engineering Sinewave Owners Manual, and

all other warranty cards and instructions.

22) Have a refreshing beverage and enjoy!

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 30

4-18 3-Phase Assembly Sequence

#6 Three-Phase Monitor

#1 Cover Detail

#17 Cover Detail

#2&3 Detail

#11 PhaseB&CCover

#15 PV Array Breakers

Detail

#10 Phase A Detail

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

#8, DC Breakers

#12 & 13 Detail

Page 31

3-Phase Assembly Sequence 4-19

Phase C Module Assembly Instructions

Phase C module consists of a PM-ADD (page 6-5)

with two Blanks, edge guards, screens, one Sinewave

inverter, one DOOR with latches, FEET, a “Phase C”

decal, any excess C40’s and PV Array breakers, and

associated assembly hardware. Install the FEET first

(page 6-17), then the edge guards and screens, then

the Blanks ( page 6-9). Place the module on the pad

or platform and mark the location of each of the 10

anchor bolts ( page 6-18). Remove the module and

install the inverter in it. Drill anchor holes in the pad

and install expansion anchors. Place Phase C module

on the pad and install the lag screw anchors to secure

it in place. Attach “Phase C” decal to the front center

of the tray.

Phase B Module Assembly Instructions

Phase B module consists of a PM-ADD (which includes a DOOR),

equipped with two 60-amp IOX60 bypass breakers, one COVER, one

SLIDER, one BLANK, and edge guards. Assemble the Phase B

module on the workstand by first installing the two IOX60 bypass

breakers (page 5-19), then add a SLIDER to the unused breaker

openings (page 6-23), and edgeguards to the openings in the bottom.

Then install a BLANK (page 6-9) on the right side-panel and a

COVER (page 6-13) over the side-panel with breakers. Complete by

adding the appropriate decals.

If any C40’s ( page 5-9) and their associated DC breakers (page

5-12) are to be installed, the BLANK will not be required. Instead, an

additional SLIDER and COVER will be necessary.

Tools Required: 5/16 & 3/8” wrench and/or socket w/ratchet,#1&

# 2 straight-blade screw drivers, crimping and stripping tools.

Phase A Module Assembly Instructions

Phase A module includes a PM with FEET, DOOR, and LID, the

Phase A bypass breaker (page 5-19), a 60-amp 3-phase AC

breaker (page ), a neutral bonding block to which all three

neutrals from the inverters are connected (page 5-21), a DCBB

(page 5-16), a DC175/250 circuit breaker (page 5-13) for each of

the three inverters, two SLIDERs (page 6-23), two COVERs

(page 6-13), any optional equipment such as C40,s (page 5-9),

PVGFP (page ) or the 3-Phase Monitor, and related cabling and

fasteners. When adding optional equipment, it may be

necessary to locate some of the additional equipment in the free

space available in the other modules.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 32

4-20 3-Phase Assembly Sequence

This page intentionally left blank.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 33

5-1

Electrical Components Assembly Instructions

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 34

5-2

Table of Contents

AC15/20/60 Front View ..............5-3

AC15/20/60 Front and Left View .........5-4

AC15, 20, 60 Assembly Sequence .....................5-4

AC60 3-Phase Breaker ..............5-5

AC15, 20, 60 Assembly Sequence .....................5-6

C40, C40K & VLC40 for DR Systems .......5-7

Wiring Instructions .............................5-7

C40, C40K & VLC40 for DR Systems .......5-8

C40, C40k & VLC40 for Sinewave Systems ...5-9

Wiring Instructions .............................5-9

DC20/60/110 ...................5-11

DC20/60/110 ...................5-12

DC175/250 ....................5-13

DC175/250 ....................5-14

DCBB/K/SW....................5-15

DCBB .......................5-16

DCBB .......................5-17

IOX60 Input/Output/Bypass Breaker ......5-19

IOX60 .......................5-20

NEUTRAL .....................5-21

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 35

PMO-AC15/20/60 Front View 5-3

60-amp AC

Circuit Breaker

To AC Loads

Mount bracket

first, then

breaker

PMO-AC15/20/60 Front View

Used to connect an external AC source or load, these

breakers are installed as shown in the diagram above, and

wired according to your purpose. See diagrams on this and

the next page. Strip wire approximately .425” both ends

and cut to appropriate length.

PDBB

Preferred when used as subpanel. Maximum three

20-amps or four 15-amp breakers.

# Qty Part No. Description

1 1 3371 decal, “AC LOADS”

2 2 401 6-32 X 3/8” HH SS bolt

3 2 492 #6 starwasher, external teeth

4 2 wire lugs.

5 1 3299 15 amp QOU breaker

6 2 466 #6 SAE SS washer

7 2 440 6-32 HH SS nut

8 1 3171 service crimp

9 1 3202 decal: “To AC Hot Loads”

10 21” 2322 6 AWG Black THHN wire

3258 20 amp QOU breaker

3087 60 amp QOU breaker

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 36

5-4 PMO-AC15/20/60 Front View

AC15, 20, 60 Assembly Sequence

1. Remove set screws from lugs on top and bottom of circuit

breaker

2. Rotate lugs 180° and replace set screws.

3. Attach service lugs to top lugs only

4. Attach a mounting bracket to the top and bottom of the PM in

the desired location. Insert a 6-32 x 3/8” bolt (401) equipped with

a #6 starwasher (492) into the appropriate bolt hole (top and

bottom) from the outside of the side panel; slide the bracket over

the bolt from the inside so that the ears are offset to the inside of

the enclosure. Slide a #6 SAE flat washer (466) over the bolt,

followed by a 6/32 nut (440). Do not tighten, just catch a few

threads.

5. Tilt the top of the circuit breaker while sliding it onto the ears of

the top mounting bracket. Repeat for the bottom mounting

bracket.

6. Align the circuit breaker with either the top or the bottom of the

breaker opening.

7 Tighten the mounting brackets onto the PM and torque to

10-15 foot pounds.

From Generator

To AC2

As Generator Breaker

8. When all circuit breakers and bypass disconnects are

mounted, install a SLIDER of unused breaker openings.

9. Install PM-SLIDER over the exterior of the circuit breaker

opening (do not over tighten)

10. Apply a decal (3371 “AC Loads”) over each AC load circuit

breaker.

11 Attach AC cabling and torque to 45 inch-pounds

As AC subpanel, three 20-amp or

four 15-amp maximum

To AC Loads

As independent bypass

to AC loads

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 37

PMO-AC60 3-Phase Breaker 5-5

PMO-AC60 3-Phase Breaker

The 60-amp, three-phase AC breaker is used with

three-phase power modules only. It is mounted in the left

wing panel of the Phase A module, next to the Phase A

bypass breaker. It accepts its input from the three-phase

monitor, (when used) or directly from each individual

inverter bypass breaker (IOX60). A decal describing the

startup and shutdown procedure is mounted above the

breaker on the inside of the breaker cover.

AC60 3-phase breaker shown on right next to the

Phase B bypass breaker

The AC-60 three-phase circuit breaker is shown

in the top illustration. The exterior of the breaker

installation is shown on the left illustrating the

decals that describe the start-up and shut-down

procedure and the appropriate position of the

bypass breaker.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 38

5-6 PMO-AC60 3-Phase Breaker

Motor Minder

Ground Bonding Block

3-Phase AC Breaker

Phase A Bypass

Neutral Bonding Block

AC15, 20, 60 Assembly Sequence

6. Align the circuit breaker with either the top or the

1. Remove set screws from lugs on top and bottom of circuit

breaker

2. Rotate lugs 180° and replace set screws.

3. Attach service lugs to top lugs only

4. Attach a mounting bracket to the top and bottom of the PM

in the desired location. Insert a 6-32 x 3/8” bolt (401) equipped

with a #6 starwasher (492) into the appropriate bolt hole (top

and bottom) from the outside of the side panel; slide the

bracket over the bolt from the inside so that the ears are offset

to the inside of the enclosure. Slide a #6 SAE flat washer (466)

over the bolt, followed by a 6/32 nut (440). Do not tighten, just

catch a few threads.

5. Tilt the top of the circuit breaker while sliding it onto the ears

of the top mounting bracket. Repeat for the bottom mounting

bracket.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

bottom of the breaker opening.

7 Tighten the mounting brackets onto the PM and

torque to 10-15 foot pounds.

8. When all circuit breakers and bypass disconnects

are mounted, install a SLIDER over unused breaker

openings.

9. Install PM-SLIDER over the exterior of the circuit

breaker opening (do not over tighten)

10. Apply a decal (3371 “AC Loads”) over each AC

load circuit breaker.

11. Attach AC cabling

Page 39

PMO-C40, C40K & VLC40 for DR Systems 5-7

Drill out the dimples at distance shown with 11/64” bit for

lower mounting holes only. Fasten with 10-32 x 1/2” bolts,

12

INVERTER (+)

9”

14

3.5”

INVERTER ( )−

13

6

15

11

16

WIRE

4

5

6

11” 12”

14”

23”

20” 26” 32” 38”

27”

18”

24”

33” 39” 45”

30”

PMO-C40, C40K & VLC40 for DR Systems

Place double-sided tape on the back panel of the C40 in the location

shown. Drill the dimples in the back plane of the PM in the approximate

location shown. When installing multiple C40’s, install them in the

sequence shown above the wire length table. Bundle excess or loose

wires.

Wiring Instructions

1. Follow the assembly instructions before wiring. Route the positive wire

through conduit (not included) to the DC side of the Power Module and

connect to the top of the PV array disconnect. Do not connect the array

positive directly to the C40 charge controller. Use a minimum of 6 AWG

wire. If more than one charge controller is utilized, the modules in the

array should be divided equally between the controllers.

2. Connect the PV array negative to the bonding block. Connect the

frames of the PV Modules to the bonding block through ground wiring. The

PV negative and battery negatives are connected at the negative bonding

block. Do not connect the charge controller battery negative directly to the

battery.

3. Route all battery temperature sensor cables through the opening in the

tray of the module at the bottom right rear behind the DC disconnect

breakers. This allows the BTS cable(s) to be routed along

with the battery cables. There may be multiple

temperature sensors depending on the total number of

charge controllers and inverters in the system. Utilize all

available temperature sensors to maximize system

performance. Connect the temperature sensors to the

charge controllers through one of the openings in the rear

of the PM with a plastic grommet protecting the edge.

Place all temp sensors on the same battery and in the

middle of the battery bank.

Qty Part No. Description

#

1 AR C40 or VLC40

2 2 3220 1.375” bushing

3 AR PMO-BTS battery temperature sensor

4 AR 2323 6 AWG cable* Red cable to DC175/250

5 AR 2323 6 AWG cable* Black cable to DCBB

6 AR 2323 6AWG cable* Red cable to PV

disconnect

7 2 6-32 SS nut

8 2 485 ¼” starwasher

9 1 1974-1 2/0 lug

10 2 492 #6 starwasher

11 2 401 6-32 HH SS capscrew

12 AR 3240 decal “Inverter (+)”

13 AR 3238 decal “Inverter (-)”

14 AR 2430 #6 AWG ring terminal

15 AR 2430 #6 AWG ring terminal

16 AR 716-1 #6 AWG ring terminal ¼” hole

10”

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 40

5-8 PMO-C40, C40K & VLC40 for DR Systems

PMO-C40, C40K & VLC40 for DR Systems

This view illustrates the installation, mounting, and cabling

of the C40 options looking toward the left-hand cabinet

panel. PMO-C40 multipurpose controller includes a

user-selectable PV Charge Controller mode, a DC Load

Control mode, and a Diversion Load Control mode (the

controller can operate in only one mode at a time). In

addition, the PMO-C40 includes a 60 amp DC Heineman™

CD breaker, #6 AWG wiring with ring terminals, and all

mounting hardware. A 22-page operating manual for the

C40 controller is also included. The PMO-VLC40 is a

voltage limiting controller. It includes all of the items that

come with the PMO-C40, but uses a modified C4O for

systems that use PV modules generating high open circuit

voltage (over 70 volts DC) without batteries. The VLC40

# Qty Part No. Description

1 6” 3304 1” double-backed tape

2 4 486 #10 starwasher

3 4 411 10-32 x ½” HH SS bolt

4 2323 6 AWG cable w/ #3238 decal & 2430

ring terminal

5 2323 6 AWG cable w/ ring terminal & 716-1

6 2323 6 AWG cable w/ #3204 decal & 2430

ring terminal

7 1 PMO-DCBB DC bonding block

8 1 3224 Solar Array decal

9 4 442 10-32 HH SS capscrew

10 4 486 #10 star washer

11 1 2298 60-amp DC breaker

12 1 3233 ”Solar Array 1” decal

Tools Required: knife or scissors,#1 and #2 straight-blade screwdriver,

5/16 & 7/16” socket, wrench, or nut driver, wire-stripping pliers, ¼” socket

or wrench.

automatically limits voltage to less than 70 volts DC.

PMO-C40K Installation Kit. The PMO-C40K installation kit

includes everything that the PMO-C40 includes except the

C40 itself, and the C40 operating manual.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 41

PMO-40, C40k & VLC40 for Sinewave Systems 5-9

Drill two half-shears at distance shown with 11/64” bit for lower

mounting holes only. Fasten with 10-32 x 1/2” bolts,

3.5”

10”

12

INVERTER (+)

9”

INVERTER ( )−

13

From PV Array Positive (+)

10

11

6

14

15

16

WIRE

4

5

6

Wire Length Table. Wire length is based upon the mounting

location of the C40. Do not exceed four C40’s with DC175

disconnect, or five C40’s with a DC250 disconnect. Do not

exceed DC disconnect’s current rating

.

PMO-40, C40k & VLC40 for Sinewave Systems

The wiring scheme shown in this view meets NEC code requirements by

using the battery disconnect of the inverter as the overload/disconnect

device. Alternative methods of wiring the C40’s may be needed depending

upon your application. Kits are shipped with maximum wire lengths

pre-cut. Trimmed the uncrimped end to the length found in the Wire

Length table according to the C40’s mounting position.

Place double-sided tape on the back panel of the C40 in the location

shown. Drill the dimples in the back plane of the PM in the approximate

location shown. When installing multiple C40’s, install them in the

sequence shown above the wire length table. Bundle excess or loose

wires. This option requires the use of a bare grounding conductor between

the DCBB and a rod or pipe driven into the earth.

Qty Part No. Description

#

1 AR PMO-C40/K charge, load, or diversion controller

2 2 3220 1.375” thermoplastic knockout bushing

3 1 PMO-BTS battery temperature sensor with cable

4 AR 2323 6 AWG THHN red cable to inverter positive terminal

5 AR 2323 6 AWG THHN Black negative cable to inverter

6 AR 2323 6 AWG THHN Red positive cable to PV circuit breaker

7 2 442 6-32 HH SS nut

8 2 486 #10 starwasher

9 1 1974-1 2/0 barrel lug Connect the PV (+) to this lug.

10 4 492 #6 starwasher

11 2 401 6-32 HH SS bolt

negative terminal

12 AR 3240 decal “Inverter (+)”

13 AR 3238 decal “Inverter (-)”

14 AR 2430 #6 AWG ring terminal

15 AR 2430 #6 AWG ring terminal

16 AR 716-1 #6 AWG ring terminal w/ ¼” hole

17 XXX wire tie (not shown)

*Refer to wire length table to determine length of each cable by its position.

Mount C40s in sequence shown above table. AR = as required.

Wiring Instructions

1. Follow the assembly instructions before wiring. Route

the PV array positive wire through conduit (not included)

to the DC side of the PM and connect to the top of the PV

array disconnect. Do not connect the array positive

directly to the C40 charge controller. If more than one

charge controller is utilized, the modules in the array

should be divided equally between the controllers.

2. Connect the PV array negative to the ground bonding

block (DCBB). Connect the frames of the PV modules to

the ground bonding block through the negative array

cables. The PV negative and battery negatives are

connected at the ground bonding block. Do not connect

the charge controller battery negative directly to the

battery.

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

Page 42

5-10 PMO-40, C40k & VLC40 for Sinewave Systems

the items that come with the C40, but uses a modified C40

3. Route all battery temperature sensor (BTS) cables through the opening

in the tray of the module at the bottom right rear behind the DC disconnect

breakers. This allows the BTS cables to be routed along with the battery

cables. There may be multiple temperature sensors depending on the

number of charge controllers and inverters in the system. Utilize all

available temperature sensors to maximize system performance. Connect

for systems that use PV modules generating high

open-circuit voltage (over 70 volts DC) without batteries.

The VLC40 automatically limits voltage to less than 70 volts

DC. The PMO-C40K installation kit includes everything that

the PMO-C40 includes except the C40 and the C40

operating manual.

the temperature sensors to the charge controllers through one of the

Qty Part No. Description

openings in the rear of the PM with a plastic grommet protecting the edge.

Place all temp sensors on the same battery and in the middle of the battery

bank.

The top view illustrates the installation, mounting, and cabling of the C40

option looking toward the right-hand cabinet panel. The C40 multipurpose

controller has three modes: PV charge control mode, DC load control

mode, and diversion load control mode (the controller can operate in only

one mode at a time). In addition, the C40 option includes a 60-amp

Heineman™ DC breaker, #6 AWG wiring with ring terminals, and all

mounting hardware. A 24-page operating manual for the C40 controller is

also included. The VLC40 is a voltage limiting controller. It includes all of

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

#

1 6” 3304 1” square of double-backed tape

2 2 486 #10 starwasher

3 2 411 10-32 x ½” HH SS bolt

4 AR 2323 6 AWG cable w/ 3204 decal & 2430 ring

5 AR 2323 6 AWG cable with 2430 ring terminal &

6 AR 2323 6 AWG cable & 716-1 ring terminal to

7 1 DCBB DC bonding block

8 1 3224 “Solar Array (-)” decal

9 2 442 10-32 HH SS capscrew

10 2 486 #10 star washer

11 1 2298 60-amp Heineman™ DC breaker

12 1 3233 ”Solar Array (+)” decal

3228 decal to inverter negative terminal

terminal to inverter positive terminal

60-amp Heineman DC breaker

Page 43

PMO-DC20/60/110 5-11

3

To DC Loads

2

To Battery (+)

From PV array (+)

To C40 PV (+)

positive terminal

From C40 battery

positive terminal

DCXX as a disconnect for an PV array positive.

To Battery (+)

From DC Charging Source

To Battery (+)

2

2

DCXX as disconnect between charging source and battery

DCXX as a disconnect between battery positive and load

PMO-DC20/60/110

your PV positive to the top of the breaker, and routea6AWG

cable from the bottom of the DCXX to the top of your

Assembly: DC20/60/110 circuit breaker/disco connects are installed

DC175/250 breaker.

adjacent to the DC175/250 breakers on the right side panel for SW

systems and on the left side panel for DR systems. Begin the installation

by removing the topmost nut and one flat washer on the back of the circuit

Tools Required: ¼”, 7/16” & 3/8” socket or wrench; #2

flat-blade screwdriver; wire stripper, crimping tool.

breaker and install the barrel lug over the stud. Replace the flat washer

Qty Part No. Description

followed by the starwasher and the nut, then tighten. Insert the breaker in

the side panel from the inside and secure with two 6-32 x 3/8” machine

screws with #6 internal tooth starwashers. When used with the C40

charge controller, connect the C40 Battery (+) terminal to the bottom of the

DCXX and your PV array positive to the barrel lug at the top of the DCXX

to complete the installation. When a charge controller is not used, connect

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

#

1 1 2957 20 amp breaker or

2 19” 2323 #6 AWG Red THHN wire used with 20, 60-amp

3 2 716-1 #6 AWG ring terminal w/ ¼” hole

4 1 1974-1 barrel lug terminal

2298 60 amp breaker or

2249 110 amp breaker

3302 #2 AWG Red THHN use with 110-amp

3300 #2 AWG ring terminal

Page 44

5-12 PMO-DC20/60/110

DCXX

breaker

with barrel

lug

10

installed

PMO-DC20/60/110

Tools Required: ¼”, 7/16” & 3/8” socket or wrench, 1/4” flat-blade

screwdriver

installed adjacent to the DC175/250 breakers on the right side panel for

SW systems and on the left side panel for DR systems. Begin the

installation by removing the topmost nut and one flat washer on the back of

the circuit breaker and install the barrel lug over the stud. Replace the flat

washer followed by the starwasher and the nut, then tighten. Insert the

breaker in the side panel from the inside and secure with two 6-32 x 3/8”

machine screws with #6 internal tooth starwashers. Install the 6 AWG

cable between the hot side of one of the DC175/250 breakers and the

Copyright Trace Engineering Co., Inc. Telephone (360) 435-8826 Part Number 3471

5916 195th Street, NE Fax (360) 435-2229 Released: Thursday, April 29, 1999

Arlington, WA 98223 USA www.traceengineering.com

. Assembly: DC20/60/110 DC circuit breaker/disconnect is

bottom of the DC20/60/110 and the DC60. For PV

systems, connect the DC60 between the PV array and