Trace Engineering Legend, Legend Series II, Legend L2012, Legend L2512, Legend L3012 Owner's/operator's Manual

Page 1

Owner/Operator's Manual

Part Number 3179

Page 2

Page 3

Packaging Materials

Thank you for choosing Trace Engineering products to meet your alternative-energy power needs.

We make every effort to ensure that your inverter/charger packaging includes the following materials:

Owner’s Manual;

Red\Black\Green battery terminal covers (with hardware);

AC terminal cover (with hardware);

Trace bumper sticker;

If any of the above listed materials are missing from your package, or if it is unsatisfactory in any

manner, please call Customer Service at (360) 435-8826 or fax this page with your comments to

(360) 435-2229.

Model Number: _____________________________________

Serial Number: _____________________________________

Purchase Date: _____________________________________

Comments: _____________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Thank you for choosing Trace Engineering to meet your independent power needs. Check out our

web site at www.traceengineering.com for more information and answers to your FAQ’s.

Page 4

Page 5

Table of Contents

INTRODUCING THE LEGEND SERIES II.............................................................1

IMPORTANT SAFETY INSTRUCTIONS...............................................................2

GENERAL PRECAUTIONS........................................................................................2

PERSONAL PRECAUTIONS......................................................................................4

FEATURES ............................................................................................................7

PROTECTION CIRCUITRY........................................................................................7

Automatic Low Battery Cut Out.......................................................................7

Automatic High Battery Cut Out......................................................................7

High Temperature Cut Out..............................................................................7

Over Current Cut Out......................................................................................8

Battery Type Optimization...............................................................................8

Charge Rate Regulation ..................................................................................8

Shore Power Amps Monitoring........................................................................9

VAC Dropout ...................................................................................................9

SEARCH MODE CIRCUITRY ....................................................................................9

IMPULSE PHASE CORRECTION .............................................................................10

TRUE RMS VOLTAGE REGULATION......................................................................10

CRYSTAL CONTROLLED TIME BASE......................................................................11

STAND-BY BATTERY CHARGER ............................................................................11

TRANSFER SWITCHING SPEED.............................................................................11

AUTOMATIC INVERTER TO CHARGER TRANSITION..................................................11

UNIT IDENTIFICATION .......................................................................................12

MODEL IDENTIFICATION .......................................................................................12

SERIAL NUMBER..................................................................................................13

CONTROLS & INDICATORS ..............................................................................15

QUICK INSTALL..................................................................................................19

INSTALLATION ...................................................................................................23

LOCATING THE INVERTER.....................................................................................23

VENTILATION.......................................................................................................23

MOUNTING..........................................................................................................24

DC WIRING.........................................................................................................25

Safety Instructions.........................................................................................25

DC Cabling Connections...............................................................................25

Ground Cable Connection.............................................................................27

Battery Cable Sizing......................................................................................28

DC Over Current Protection..........................................................................28

Page 6

AC WIRING ........................................................................................................31

AC and DC Wiring Separation......................................................................31

AC Wire Connections....................................................................................31

Ground Fault Interrupting Outlets (GFCI’s)...................................................33

Neutral-to-Ground Switching.........................................................................35

Disabling Neutral Ground Switching.............................................................37

OPERATION........................................................................................................38

BATTERIES.........................................................................................................41

TERMINOLOGY....................................................................................................41

TYPES................................................................................................................42

Starting Batteries ..........................................................................................42

Deep-Cycle Batteries....................................................................................42

Sealed Gel Cell.............................................................................................42

ENVIRONMENT....................................................................................................43

Location.........................................................................................................43

Enclosures ....................................................................................................43

Temperature..................................................................................................43

BATTERY BANK SIZING........................................................................................44

Estimating Battery Requirements .................................................................44

Battery Bank Sizing Example & Worksheet..................................................45

MONTHLY MAINTENANCE.....................................................................................47

Preparation....................................................................................................47

Attire..............................................................................................................47

Tools .............................................................................................................47

Equipment.....................................................................................................48

Supplies ........................................................................................................48

Procedure......................................................................................................48

Battery Enclosure and Batteries ...................................................................48

Terminals & Lugs..........................................................................................48

Cables...........................................................................................................49

CABLING & HOOK-UP CONFIGURATIONS...............................................................49

Parallel Connection.......................................................................................50

Series Connection.........................................................................................50

Series – Parallel Connection.........................................................................51

THREE-STAGE BATTERY CHARGER..............................................................52

CHARGING PROFILE............................................................................................52

GENERATOR REQUIREMENTS ..............................................................................54

THEORY OF INVERTER OPERATION...............................................................55

WAVEFORM........................................................................................................55

REGULATION.......................................................................................................56

Page 7

APPLICATIONS...................................................................................................57

RESISTIVE LOADS................................................................................................57

INDUCTIVE LOADS ...............................................................................................57

PROBLEM LOADS.................................................................................................58

OPTIONS..............................................................................................................61

THE RC6 REMOTE CONTROL ..............................................................................61

THE RC7 REMOTE CONTROL ..............................................................................62

BATTERY TEMPERATURE SENSOR (BTS) .............................................................63

BATTERY CABLES................................................................................................63

APPENDIX A: TROUBLESHOOTING.................................................................65

APPENDIX B: OTHER PRODUCTS FROM TRACE ENGINEERING................67

APPENDIX C: REFERENCE TABLES & GRAPHS............................................69

TYPICAL POWER CONSUMPTION OF COMMON APPLIANCES ...................................69

ENGLISH TO METRIC WIRE CONVERSION CHART ..................................................70

MINIMUM RECOMMENDED BATTERY CABLE SIZE (IN FREE AIR)..............................70

RECOMMENDED MINIMUM AC WIRE SIZES...........................................................71

COMMON BATTERY CHARGING RATES..................................................................71

LEGEND SERIES II CHARGING GRAPH ..................................................................72

LEGEND SERIES II EFFICIENCY CURVE.................................................................73

LEGEND PERFORMANCE GRAPH ..........................................................................74

APPENDIX D: SPECIFICATIONS.......................................................................75

APPENDIX E: DIMENSIONS ...............................................................................77

APPENDIX F: LIMITED WARRANTY .................................................................79

APPENDIX G: LIFE SUPPORT POLICY ............................................................82

INDEX...................................................................................................................83

Page 8

TABLE OF FIGURES

Figure 1, Power Output Versus Temperature...................................................................24

Figure 2, Battery to Inverter Cable Connection..............................................................26

Figure 3, DC Wiring Diagram..........................................................................................30

Figure 4, AC Terminal Block............................................................................................31

Figure 5, AC Wiring Diagram..........................................................................................32

Figure 6, Typical Mobile Installation Diagram................................................................34

Figure 7, Neutral-to-Ground Switching without external AC source...............................35

Figure 8, Neutral-to-Ground Switching with External AC...............................................36

Figure 9, Disabling Neutral-to-Ground Switching...........................................................37

Figure 10, Three-Stage Charging Profile.........................................................................52

Figure 11, RC6 Remote Control Faceplate Display.........................................................61

Figure 12 , RC7 Remote Control ......................................................................................62

TABLE OF TABLES

Table 1, Minimum Recommended Battery Cable Size (In free air)...................................28

Table 2, Current Carrying Ability of Wire In Free Air at 75°C.......................................29

Table 3, Recommended Minimum AC Wire Sizes .............................................................33

Table 4, Typical Appliance Watts .....................................................................................46

Table 5, Bulk and Float Setpoints.....................................................................................54

Page 9

INTRODUCING THE LEGEND SERIES II

Introducing the Legend Series II

The Legend Series II inverter/chargers are specially designed for after market installation in

recreational vehicles.

The Legend Series II inverter/chargers feature:

ü Easy installation

ü 2000, 2500, or 3000 watt continuous power output

ü Automatic three-stage battery charging

ü Over-current, over-temperature, and high/low battery voltage protection

ü UL listed to UL 458 standards

ü 5-year limited warranty

ü Front-panel wiring terminals for maximum accessibility

ü Optional RC6 remote On/Off, voltmeter, ammeter, charge status and error indicator

ü Optional full-function, programmable RC7 remote control provides digital metering and user

configuration

ü Adjustable charging rate and battery type selection

ü Adjustable power-saving search mode

ü Automatic battery temperature compensation (with battery temperature sensor [BTS]

option).

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

1

Page 10

IMPORTANT SAFETY INSTRUCTIONS

Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains important safety and operating instructions as prescribed by UL specifications

for inverters used in land vehicle applications. This manual covers inverters and inverter/chargers

models: L2012, L2512, and L3012 Legend Series II inverter/chargers.

The entire Legend series of inverters is UL listed to the general UL specification #458 covering power

inverters for land vehicle applications.

General Precautions

1. Before using the inverter/charger, read all instructions and cautionary markings on (1) the

inverter/charger, (2) the batteries, and (3) all appropriate sections of this instruction manual.

2. CAUTION - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead

calcium, gel cell, or absorbed mat type rechargeable batteries. Other types of batteries may

burst, causing personal injury and damage.

3. Do not expose inverter/charger to rain, snow or liquids of any type. The inverter is designed

for interior mounting only. Protect the inverter from splashing when used in vehicle

applications.

4. Do not disassemble the inverter/charger; take it to a qualified Trace Engineering Service

Center when service or repair is required. Incorrect re-assembly may result in a risk of

electric shock or fire.

5. To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or

cleaning. Turning off the inverter will not reduce this risk.

6. WARNING - RISK OF EXPLOSIVE GASES

WORKING IN VICINITY OF A LEAD ACID BATTERY MAY BE DANGEROUS.

BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL OPERATION. FOR

THIS REASON, IT IS OF UTMOST IMPORTANCE THAT EACH TIME BEFORE

SERVICING EQUIPMENT IN THE VINCINTITY OF THE BATTERY, YOU READ THIS

MANUAL AND FOLLOW THE INSTRUCTIONS EXACTLY. Provide ventilation to outdoors

from the battery compartment. The battery enclosure should be designed to prevent

accumulation and concentration of hydrogen gas in “pockets” at the top of the compartment.

Vent the battery compartment from the highest point. A sloped lid can also be used to direct

the flow to the vent opening location.

To reduce the risk of battery explosion, follow these instructions and those published by

battery manufacturer and any manufacturer of any equipment you intend to use in the

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

2

Page 11

IMPORTANT SAFETY INSTRUCTIONS

vicinity of batteries. Review cautionary markings on these products and all other products

being used.

7. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be no less than

10 AWG (5.3 mm2) copper wire and rated for 75°C or higher. Battery cables must be rated for

75°C or higher and should be no less than the minimum wire size recommended by this manual.

Crimped and sealed copper ring terminal lugs with a 5/16” hole should be used to connect the

battery cables to the DC terminals of the inverter/charger. Soldered cable lugs are also

acceptable. See section Batteries and Chargers for correct battery cable size and length for your

application.

8. Torque all AC wiring connections to 15-20 inch-pounds. Torque all DC cable connections to 1012 foot-pounds.

9. CAUTION: To reduce the risk of fire, use only input circuits provided with the correct ampere

branch circuit protection in accordance with the National Electric Code, ANSI/ NFPA70

10. Use the correct tools to make AC/DC wiring connections: wire strippers, ½” (13mm) open-end

wrench or socket, Phillips screw driver #2, and ¼” flat blade screwdriver (6mm).

11. This inverter/charger should be used with a battery supply of 12-volts DC nominal voltage.

12. Do not install this inverter/charger on or near flammable materials (plywood, chemicals, gasoline,

etc.)

13. The unit is designed for mounting on a flat surface only. Do not mount on a wall or hang

inverted.

14. No AC or DC disconnects are provided as an integral part of this inverter. Both AC and DC

disconnects must be provided as part of the system installation. See Installation section on Page

23 of this manual.

15. No overcurrent protection for the battery supply is provided as an integral part of this inverter.

Overcurrent protection of the battery cables must be provided as part of the system installation.

See Installation section of this manual.

16. No overcurrent protection for the AC output wiring is provided as an integral part of this inverter.

Over-current protection of the AC output wiring must be provided as part of the system

installation. See the Installation section of this manual.

17. GROUNDING INSTRUCTIONS - This inverter/charger should be connected to a grounded,

permanent wiring system. For most installations, the negative battery conductor should not be

bonded to the vehicle chassis ground. Connection of the large green chassis ground terminal on

the side of the inverter will create the battery negative to vehicle chassis ground. All installations

should comply with all national and local codes and ordinances.

18. AC Grounding Instructions – The inverter/charger includes neutral to ground switching for the AC

electrical system. The AC system in mobile installations must have the neutral physically

isolated from the ground throughout the load distribution powered by the inverter.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

3

Page 12

IMPORTANT SAFETY INSTRUCTIONS

Personal Precautions

1. Someone should be within range of your voice to come to your aid when you work near

batteries.

2. Have plenty of fresh water and soap nearby in the event that battery acid contacts skin,

clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working

near batteries. Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid

enters eyes, immediately flood eyes with running cool water for at least 15 minutes and get

medical attention immediately.

5. Baking soda neutralizes lead acid battery electrolyte. Vinegar neutralizes spilled NiCad and

NiFe battery electrolyte. Keep a supply on hand in the area of the batteries.

6. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

7. Be extra cautious when working with metal tools on and around batteries. It could shortcircuit the batteries or other electrical parts, producing a spark that could cause an

explosion.

8. Remove personal metal items such as rings, bracelets, necklaces and watches when

working with a battery. A battery can produce a short-circuit current high enough to weld a

ring, or the like, to metal causing severe burns.

9. Never attempt to charge a frozen battery.

10. If a remote or automatic generator-start system is used, disable the automatic starting

circuit, and/or disconnect the generator from its stating battery while servicing to prevent

accidental starting during servicing.

11. If necessary to remove any batteries, always remove the grounded terminal from the

battery first. Make sure all accessories are off, so as not to cause an arc.

12. Be sure area around battery is well ventilated.

13. Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

14. Study all battery manufacturer's specific precautions (such as removing or not removing

cell caps while charging) and recommended rates of charge.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

4

Page 13

IMPORTANT SAFETY INSTRUCTIONS

15. Add ONLY distilled water in each cell until battery acid reaches level specified by battery

manufacturer. This helps purge excessive gas from cells. Do not overfill. For a battery

without cell caps, carefully follow manufacturer's recharging instructions.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

5

Page 14

Page 15

FEATURES

Features

All Legend Series II inverters include extensive protection circuitry, Search Sense Mode, Impulse

Phase Correction, true RMS voltage regulation, crystal-controlled timing, three-stage battery

charging, and an internal AC transfer relay.

Protection Circuitry

The inverter is protected from high-battery voltage, low-battery voltage, over-heating, and overcurrent conditions. When the inverter senses one of these situations, it will protect itself by

disconnecting from the loads, and will signal an error condition by a red flashing of the LED indicator.

The low-battery cutout, high-battery shut down, and over-temperature protection circuitry resets

automatically. If an over-current condition continues for more than 20 seconds, the inverter will

shutdown and must be reset with the power button. If the error condition is remedied before the 20second period has elapsed, the inverter will automatically reset.

Automatic Low Battery Cut Out

The Legend inverter/charger protects your batteries from damage caused by over-discharging by

automatically shutting itself off when battery voltage falls to a preset level. This feature is called the

Low Battery Cut Out (Auto LBCO). Your Legend inverter/charger comes from the factory with the

Auto LBCO enabled; LBCO voltage is set at 11.1 volts. You can adjust the cutoff voltage to 8.5 volts

(Auto LBCO disabled) using the optional RC7 remote control. See The RC7 Remote Control section

on Page 62 for more information about the configuring LBCO.

Automatic High Battery Cut Out

When battery voltage rises above 15.6 volts, the inverter shuts down to protect electronics that may

be operating off of it (high battery voltage results in high AC peak voltage). The inverter automatically

resumes operating when battery voltage drops below 15.6 volts. High battery voltage can occur only

through using an unregulated charging source, such as an unregulated solar or other DC generator

or alternator. To remedy this problem, disconnect any external charging sources.

High Temperature Cut Out

The inverter is protected from overheating due to excessive loading or charging. When the internal

temperature of the inverter exceeds its design limits, the inverter will disconnect itself and shut down.

After a sufficient cooling period, the inverter will automatically reset and resume operation. Some

causes of high internal temperatures include excessive loading, high ambient temperatures,

inadequate ventilation, and an inoperative cooling fan. To remedy, reduce loads or reduce ambient

temperatures by relocating, insulating, and/or ventilating the inverter enclosure (See the Installation

section on Page 23 for more information).

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

7

Page 16

FEATURES

Over Current Cut Out

Series II inverter/chargers are protected from over-current conditions. When the load being run

demands more current than the inverter can safely supply, the inverter will momentarily shutdown,

turn off if it encounters an over-current condition for approximately 20 seconds (a prolonged shortcircuit) or if the AC output is connected to another AC power source (shorepower or generator).

Battery Type Optimization

Series II inverter/chargers are designed to prevent damage to and extend the useful life of your

batteries by regulating the charging voltage and duration. To do this, the inverter/charger must be

configured for the type of batteries in the system. The Series II is pre-configured for optimum

charging of gel cell type batteries at 14.1 volts in bulk charging mode, and 13.5 volts in float charging

mode. For liquid lead-acid batteries, you can reset the Series II using the RC7 remote control to bulk

charge at 14.5 volts and float charge at 13.4 volts. For a complete discussion of batteries and battery

charging techniques, see the Batteries and the Three-Stage Battery Charger sections of this manual.

Charge Rate Regulation

Batteries can overheat if the charge rate is too high. The Series II inverter/charger protects your

batteries by enabling you to limit the charge rate using the RC7 remote control. The charge rate is

set at the factory to 100% of maximum, which may be up to 140 amps depending upon the model

you have purchased (see Appendix D: Specifications to determine the maximum possible charge

rate for your model). For smaller battery banks, this may be too high.

The highest charge rate recommended is determined by dividing the battery bank’s amp hour

capacity by a factor of three or five (3 for gel cell - 5 for lead acid).

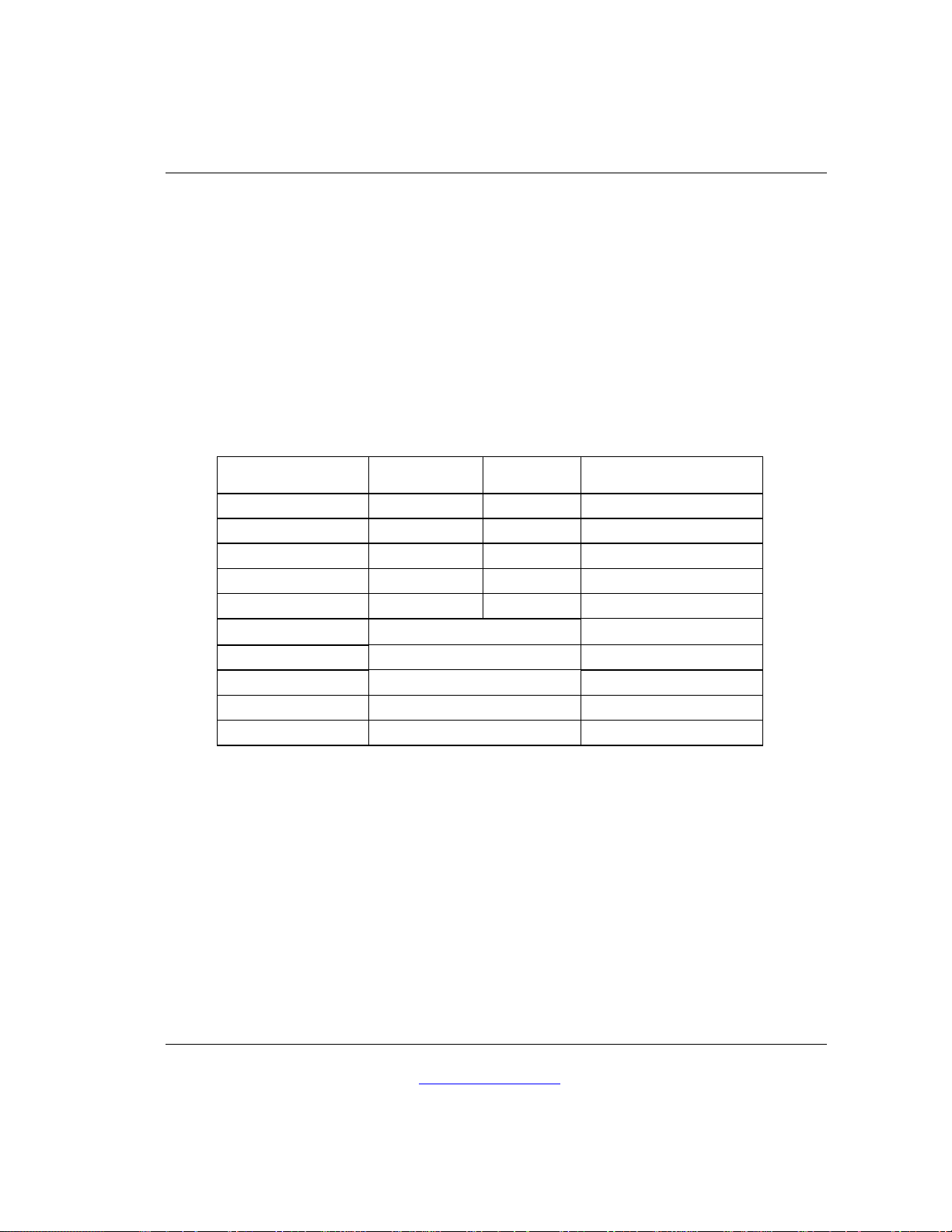

Battery Bank Capacity in Amp Hours Recommended Charge Rate in Amps

gel cell liquid lead-acid

125 40 25

250 80 50

500 140 100

Setting the charge rate at the highest recommended level is best when the objective is to charge the

batteries as quickly as possible. A much lower setting can be used in installations where AC power is

typically available for periods of several hours. There is more than sufficient time for a 400-amphour

battery bank to be recharged in 24 hours at a 25-amp setting.

Example: 25 amps X 24 hours = 600 amp/hrs.

Caution: Excessively high charge rates can overheat a battery. If battery bank capacity is low, set

the battery charge rate to the minimum setting.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

8

Page 17

FEATURES

Shore Power Amps Monitoring

Series II models monitor the current drawn by the built-in charger and any AC loads. These current

requirements may exceed the amperage rating of the shore power circuit breaker. To prevent

unnecessary tripping of this circuit breaker, the inverter limits the current draw to a maximum

between five and 30 amps, set by using the RC7 remote control. Shore power amps is pre-set at the

factory to a maximum of 25 amps.

VAC Dropout

Series II model inverter/chargers monitor the voltage of the AC power passing through to the charger

and AC loads. When AC voltage falls below a pre-set level, the inverter automatically transfers from

AC power to DC power. This dropout voltage is factory pre-set to 40 volts. You can re-set this

voltage from 40 to 100 volts using the RC7 remote control. Using a lower voltage results in less

frequent transfers from AC to DC power, but may cause undesirable operation of some AC loads,

including brown-outs and damage.

Search Mode Circuitry

The Legend Series II inverters feature circuitry that minimizes power drain by reducing the inverter’s

output to small test pulses when there is no load connected to the inverter. These pulses are used to

detect the presence of a load. When a load is detected the inverter’s output goes to full voltage. The

sensitivity of the detection threshold is adjustable from about five watts to 40 watts using the RC7

remote control. This feature is defeated (turned Off) at the factory and can only be activated using

the RC7 remote control.

Example: With the threshold set to detect a 40 watt load, a 50 watt load will bring the unit to full

output voltage. However, a 30-watt load will leave the inverter in its energy saving search mode

state. If the sensitivity is increased by setting the control to 10, a 20 watt load will bring the inverter

out of the search mode, while a five-watt load will not.

When in the search mode, the green Power LED will blink. At full output voltage, the LED will remain

lit. When the inverter is used as an un-interruptable power supply, the search mode function should

be defeated. A neon type nightlight can also be used as a good indicator to determine if the inverter

is in search mode. Simply plug the light into any AC outlet that is connected to the inverter’s output.

When the inverter is in the search mode the light will blink. If the inverter is running a load, the light

will be on continuously.

Exceptions: (Murphy’s Law) Unfortunately, things don’t always work the way the manual says they

will.

Example A: If the threshold is set to detect a 40-watt load and a 30-watt incandescent light is turned

on, the inverter will detect the light. The light is a bigger load than 40 watts when its filaments are

cold. When the light gets hot it becomes a 30-watt load. Since this is below threshold of 40-watts, the

inverter will not detect it and the light will go out. This will cause the light to cycle repeatedly.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

9

Page 18

FEATURES

Example B: If the threshold is set to detect a 30-watt load and a 40-watt fluorescent light is turned

on, the inverter will not detect the light. The light presents a smaller load than 30 watts until the gas in

the fluorescent tube ionizes.

Example C: There are some appliances that draw power even though they are turned off. TVs with

instant on circuitry microwave ovens with digital displays and VCRs are examples. These loads

present a dilemma. If the sensitivity is set higher than the combination of these loads, then an

auxiliary load must be used to bring the inverter out of the search mode before the appliances can be

turned on. If the sensitivity is set lower than this combination of loads, the loads will be left on and will

put an additional drain on the batteries. Three such 15-watt loads would amount to an additional 90

amp/hours per 24 hours in a 12 VDC system.

One solution is to turn these items off at the wall. Use an extension cord with a rocker switch, a

switch at the outlet, or the appropriate circuit breaker. Another solution might be to place all these

phantom loads on a separate circuit with its own disconnect.

This circuit determines how much power the inverter draws when there are no loads. The inverter’s

transition from the no load state to full output voltage is fast, eliminating delays when operating

devices such as hand tools. Additionally, the threshold sensitivity of the search mode is user

adjustable (with the optional RC7 remote control), and it may be disabled.

Impulse Phase Correction

This circuitry improves the shape of the output waveform while the inverter is running reactive loads.

It allows the inverter to closely duplicate the characteristics of standard public power. With this

design approach, the limitations of the modified sine wave format are largely overcome. The primary

benefit is realized when the inverter is running induction motors and fluorescent lights. Induction

motors are commonly used to run drill presses, fans, and bandsaws.

When an inductive load is driven, it tries to return a large portion of the energy that it has received.

This returned energy can be thought of as going ‘backwards’ through the household wiring to the

motor, giving the motor an extra push and making it run smoothly. Impulse phase correction

provides a similar path for this ‘backwards’ energy. The Legend line of inverter/chargers will run

small motors at full speed, start larger ones, and run both efficiently.

True RMS Voltage Regulation

With battery voltages from 11 to 15 VDC and power levels up to the continuous power rating, the

inverter will deliver true RMS regulated power. This insures that while battery voltages and power

levels change, the inverter will deliver the correct output voltage.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

10

Page 19

FEATURES

Crystal Controlled Time Base

Proper frequency regulation is assured with the use of a crystal. Battery voltage and power have no

effect on the inverter’s operating frequency.

Stand-by Battery Charger

The Stand-by feature includes an internal battery charger and automatic transfer relay. This allows

the unit to operate as a battery charger or an inverter (but not at the same time). An external source

of AC power (i.e. shore power or generator) must be supplied to the inverter’s AC input to allow it to

operate as a battery charger. When the unit is operating as a charger its AC output is powered by

the external AC source. See the Three-Stage Battery Charger section beginning on Page 52 for an

in-depth description of this charger.

Transfer Switching Speed

While this inverter is not designed specifically to operate as an un-interruptable power supply (UPS)

system, its transfer time is normally fast enough to hold up computers in the event of a power outage.

The transfer time is a maximum of 32 milliseconds (two 60Hz AC cycles). Success as UPS will vary

with computer models, and cannot be guaranteed. If this is an issue, buy a small, dedicated UPS for

the specific application.

Automatic Inverter to Charger Transition

The inverter automatically becomes a battery charger whenever AC power is supplied to its AC

inputs. There is a minimum 20-second time delay from the time the inverter senses that AC is

present at its input to when the transfer is made. This delay is built in to provide time for a generator

to spin-up to a stable voltage and avoid relay chattering. The inverter’s AC input is internally

connected to the inverter’s AC output while in the battery charger mode. The maximum power that

can be handled by the inverter’s internal wiring and transfer relay is 30 amps.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

11

Page 20

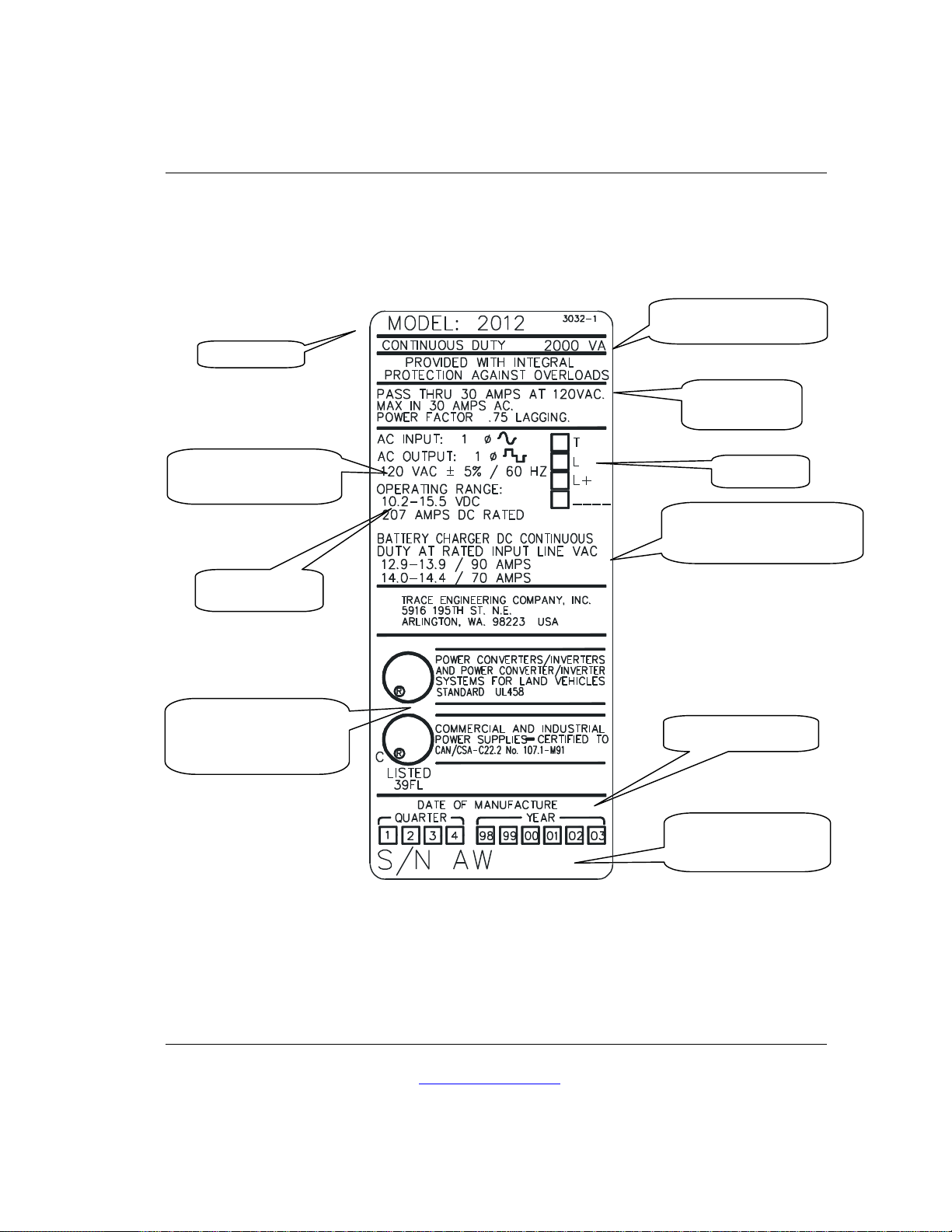

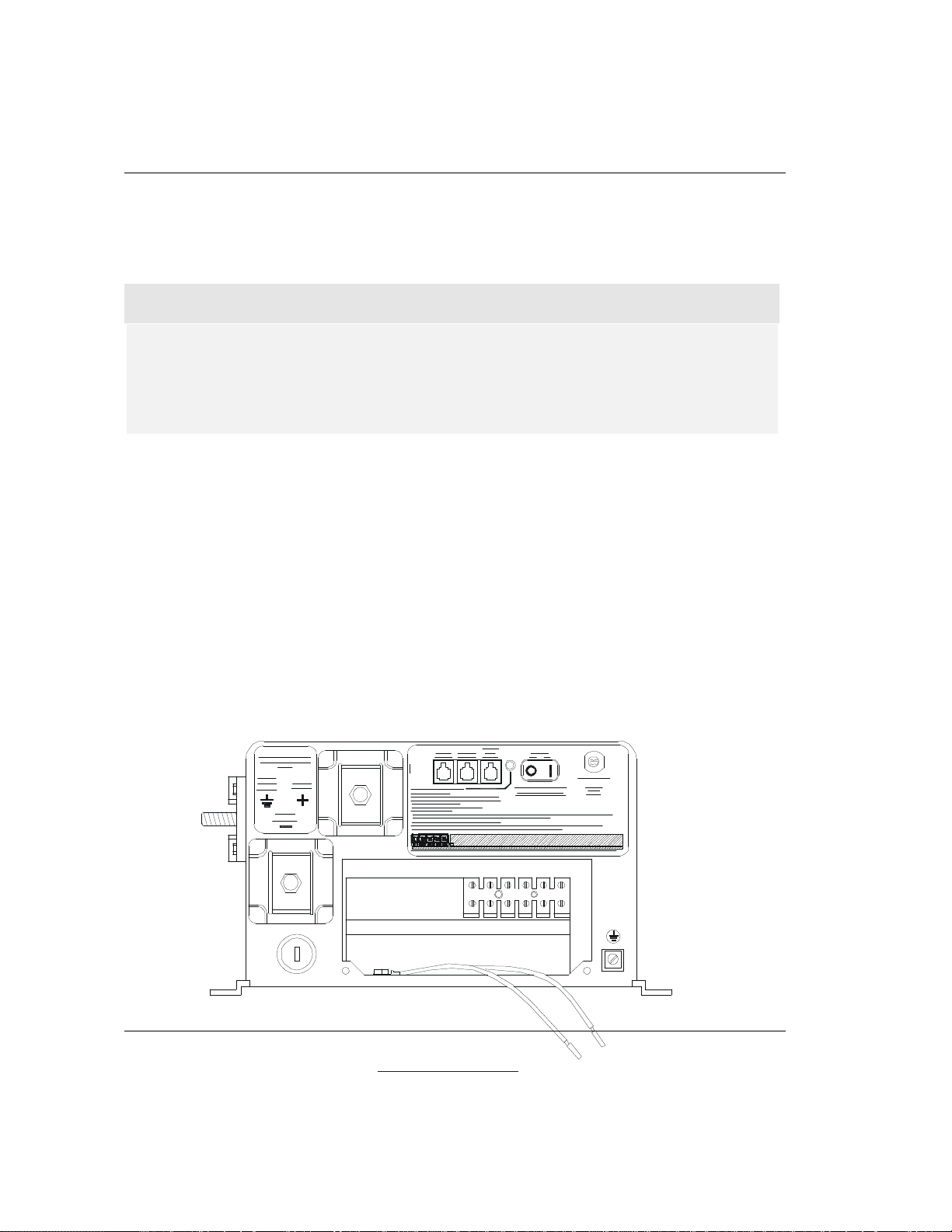

UNIT IDENTIFICATION

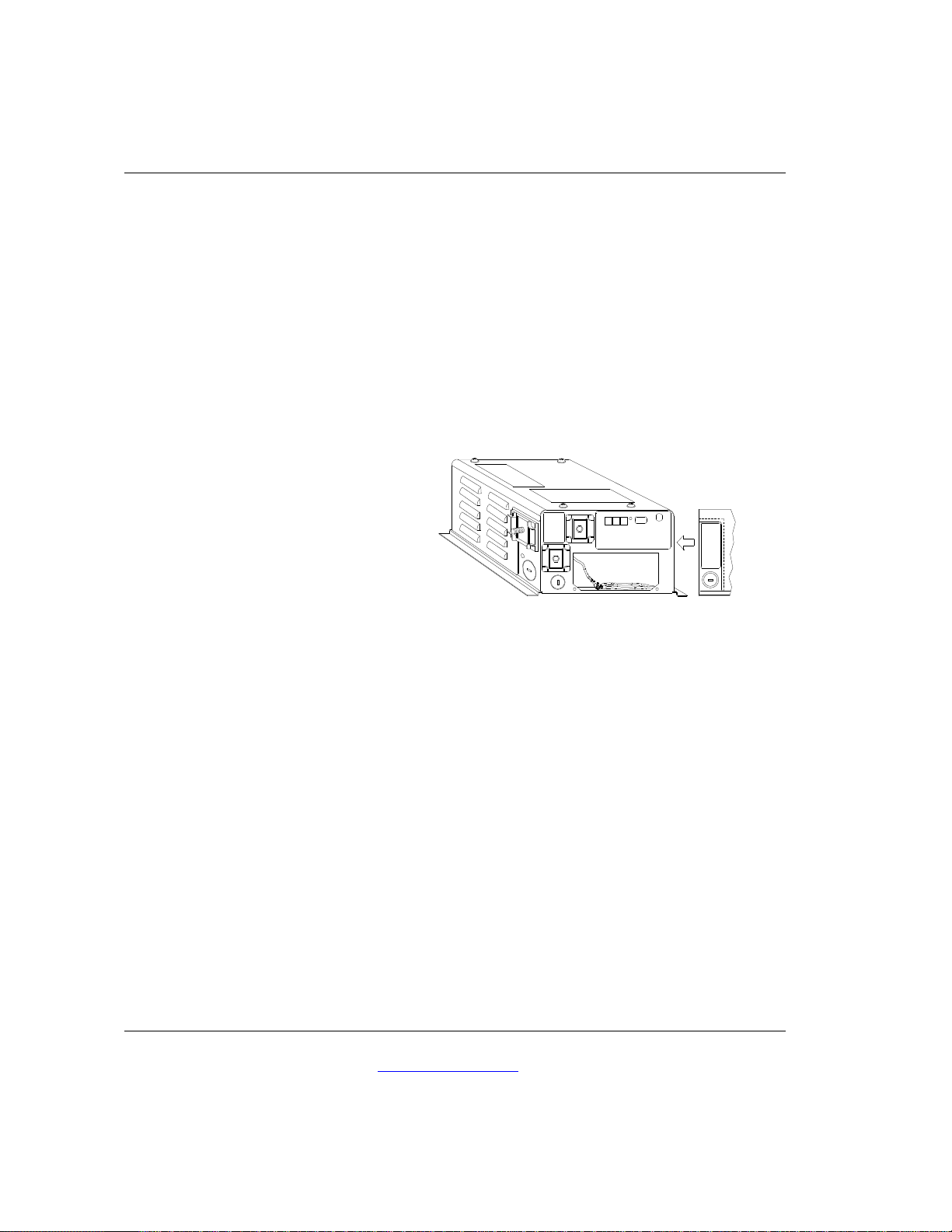

Unit Identification

This section describes the marking and location of the model and serial number for Legend Series II

inverter/chargers. Use this section to determine the type and model of your inverter/charger.

Model Identification

Trace Engineering inverters are specifically designed to meet the growing demand for high-reliability,

high-quality inverters and chargers for alternative energy systems and vehicle applications. This

manual covers the Legend Series II inverters with various options and configurations. To determine

the model and features of your inverter, check the model number found on the identification placard

on the right side of the inverter.

Consider the following unit with a L2012

model number:

L 20 12

Model Power Input Voltage

Model: The first letter indicates the model, in this case the Legend Series . Legend Series II

inverters are designed for after-market installations in recreational and other mobile vehicles. They

are housed in a white enclosure and employ neutral-to-ground switching.

Power: The first and second positions in the model number indicate the continuous AC power

output in hundreds of watts. Power levels available include 2000, 2500, and 3000 watts. In the

example above, 20 would stand for a 2000-watt (two kilowatt), continuous-output inverter.

Input Voltage: The number (12) following the power rating indicates an inverter/charger that is

designed to convert 12VDC input to 120VAC output, and charge 12VDC batteries when powered by

120VAC.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

12

Page 21

UNIT IDENTIFICATION

Model Number

Operating Range

Serial Number

The unit identification placard on the right side panel of the inverter/charger will show the serial

number, model number, listings, ratings, and date of manufacture.

Inverter Continuous Duty

Rating in Watts

Pass-Thru

Current Capacity

AC Input/Output Phase,

Waveform, Frequency and

DC Input Voltage

Testing Laboratory

Certification Number and

Standards Identification

U

U

Model Prefix

Charger Continuous Duty

Current Rating at DC

Bulk/Float Charging Rates

L

Date of Manufacture

L

Serial Number and

Product Code: AV=3012,

AW=2012, AX=2512

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

13

Page 22

Page 23

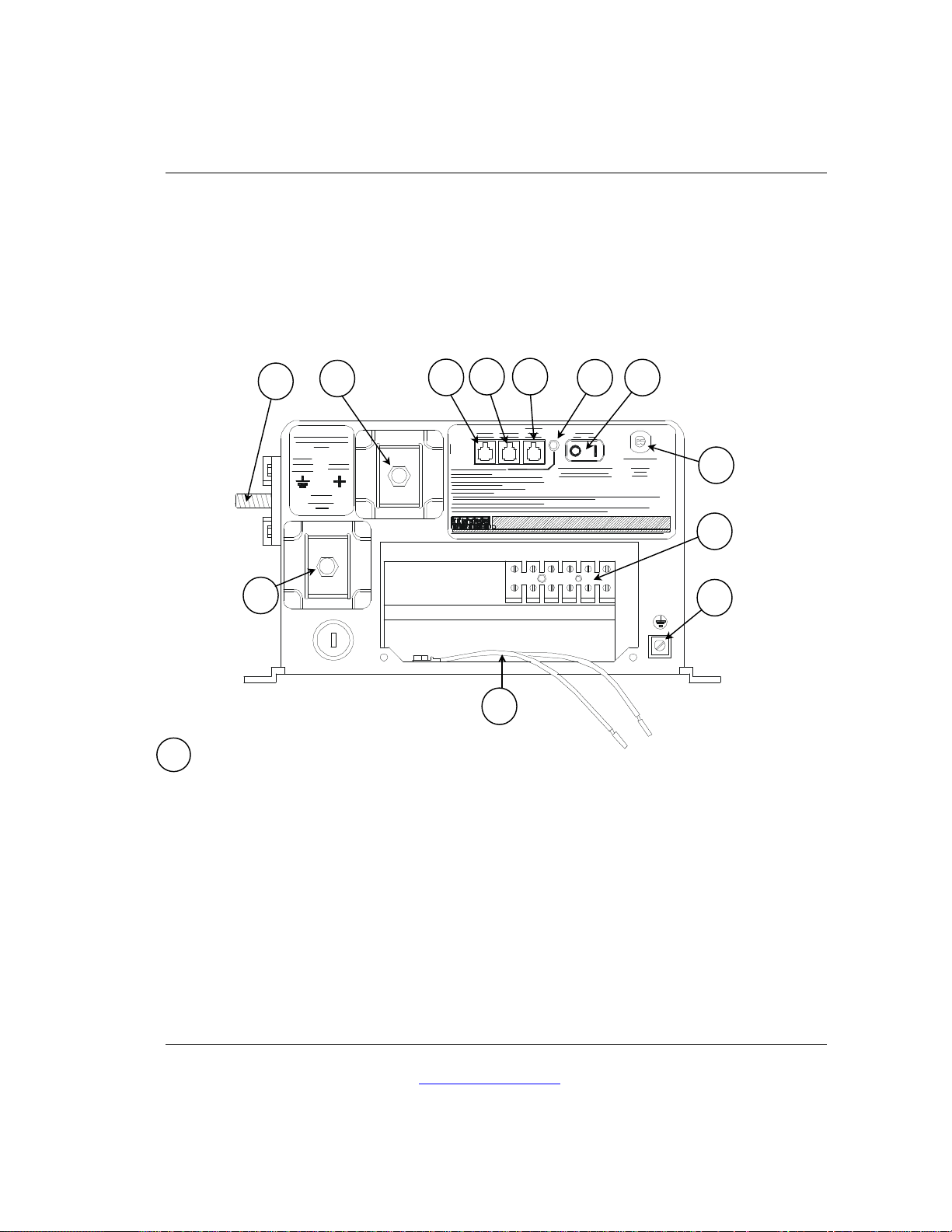

CONTROLS & INDICATORS

N

CAUTION

Controls & Indicators

The Legend Series II inverter/chargers feature a two-position On/Off rocker switch, tri-color status

indicator, battery temperature sensor (BTS) port, remote control port, and a charger circuit breaker

on the front panel.

4 3

7

6

5

2

1

12

11

8

10

9

1. On/Off Switch: Turns the inverter on or off.

ON: the inverter transforms 12-volt direct current from the batteries into 120-volt, 60 Hz alternating

current whenever AC current is not present at the AC Input Hot 1 terminal.

When 120-volt AC is present at the AC Input Hot 1 terminal, the inverter will pass the current through

to any AC loads connected to the inverter, and the standby battery charger will charge the batteries.

OFF: the inverter will not create AC power from the batteries, but will pass through AC current when

it is present at the AC Input Hot 1 terminal. The standby battery charger will charge the batteries

regardless of the position of the On/Off switch.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

15

Page 24

CONTROLS & INDICATORS

NOTE:

The three-stage standby battery charger is always “On”. Whenever AC power is

present at the AC Input Hot 1 terminal, the charger will charge the batteries

connected to the battery positive and battery negative terminals. The On/Off

switch has no effect upon the charger.

2. LED Indicator

All Legend Series II inverter/chargers feature a tri-color LED on the front panel that will light green,

orange, or red to indicate the operating mode, battery or charger status, or an error condition.

Green:

Solid: inverter is providing AC power from the batteries

Slow Flashing: (once each second) inverter is in search mode

Fast Flashing: (four times each second) charger is charging in Float mode at 13.5 volts,

the factory setting for gel cell batteries. Float mode for liquid lead-acid batteries is 13.4 volts,

configured using the RC7 remote control. See the Three-Stage Battery Charger section on

Page 52 for a complete description of three-stage battery charging, and on Page 62, The

RC7 Remote Control section.

Orange

Solid: charger is in Bulk mode, the initial charging mode. Bulk mode for gel cell batteries is

set at the factory at 14.1 volts. Bulk mode voltage for liquid lead-acid batteries is set at 14.5

volts. Use the RC7 remote control to configure the inverter for liquid lead-acid batteries.

Flashing: charger is in Absorption charge. In Absorption stage, the charger maintains the

Bulk voltage at up to the maximum charge rate for 90 minutes.

Red

Solid: an over-current event has occurred. An over-current condition is caused by too

many loads on the unit (excessive current demand). When this occurs, the inverter/charger

instantaneously detaches from the loads. If, after a ten-second delay, the current demand

on the unit is not excessive, the unit will automatically resume inverting. If the current

demand remains excessive, the unit will shut itself off and must be manually restarted by

turning the unit Off, then On again.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

16

Page 25

CONTROLS & INDICATORS

Flashing: (followed by a five-second pause) an error condition has occurred

Once = battery voltage is below Low Battery Cut-Out factory setting of 11.1 volts

(see Protection Circuitry section on Page 7 for a description of LBCO). The inverter

will automatically restart when battery voltage rises to 12.5 volts.

Twice = battery voltage is over 15.6 volts and inverter has shut down (see Page 7).

The inverter will automatically resume operating when battery voltage has dropped

below 15.6 volts.

Three = inverter is overheating and has shut off to protect itself. Reduce loads or

provide adequate ventilation. The inverter will automatically restart when cool.

Four = a charger fault has occurred. Return unit to an authorized Trace Service

Center for servicing.

Five or more: Not used with the Legend Series inverter/chargers.

3. BTS Port: An optional battery temperature sensor (BTS) can be plugged in at the RJ-11 four-

conductor connector. The BTS provides information that enables the three-stage standby

battery charger to “fine tune” the battery charge rates for better charging performance, greater

efficiency and longer life.

4. Stacking Port (not used). The Series II model is not a stackable unit.

5. Remote Control Port: The Legend Series II can be controlled up to 50 feet from the unit by

plugging in a remote control (RC6 or RC7). See the Options section for a complete description

of the RC6 and RC7 remote controls.

• The RC6 reports DC voltage, charging or inverter current, and turns the inverter on and off..

• The RC7 is a full function, programmable remote control with backlit LCD, battery capacity

and other meters.

6. Battery Positive Terminal

7. Vehicle Chassis Ground Terminal

8. Battery Negative Terminal

9. AC Safety Ground

10. External Chassis (equipment) Ground

11. AC Terminal Block

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

17

Page 26

CONTROLS & INDICATORS

12. Charger Circuit Breaker: 25 amps in the L2012 and L2512, 30 amps in the L3012. Press

breaker to reset.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

18

Page 27

QUICK INSTALL

Quick Install

Experienced installers, licensed electrical contractors, and knowledgeable laymen may follow the

installation overview in this section. All others are urged to read the entire Installation section before

installing the inverter/charger.

1. Unpacking – Before beginning, unpack the inverter/charger,

record the serial number on the inside cover of this booklet

and on the warranty card. Retain packing materials for

future use. Ensure that all components listed on the

Packaging Materials sheet are included. If any

components are missing, please call Customer

Service at (360) 435-8826.

2. Mounting – Mount the unit securely in a horizontal

position in a clean, dry, ventilated enclosure. Do

not mount the unit in the same enclosure as vented

or maintenance-free type vented batteries. Bolt the

unit down securely. Allow adequate clearance to allow

access to the front panel.

3. DC Cabling

• Ensure that the On/Off switch on the front panel of the inverter is in the Off position before you

begin the installation.

• Connect a cable from the positive terminal of the battery or battery bank to the battery positive

(red) terminal of the inverter. See Minimum Recommended Battery Cable Size (In free air) in

Appendix C to determine the proper size cable to use for the inverter model and length of run

needed for your specific application. The National Electric Code (NEC) requires the use of a DC

fuse or disconnects in this cable within 18-inches of the batteries. See Appendix C to determine

the correct size fuse or breaker to use.

• Connect an appropriate sized cable from the battery’s negative terminal to the negative (black)

terminal on the inverter. Torque all terminals to 12 foot-pounds.

• Connect a cable from the Vehicle Chassis Ground (green terminal) on the inverter to chassis

ground (usually the frame of the vehicle).

4. DC Loads

• Connect a cable from the positive battery terminal to the positive buss of your DC load center.

• Ground all of your DC loads to your vehicle’s chassis, or connect a cable from the ground bus of

the DC load center to the vehicle chassis.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

19

Page 28

QUICK INSTALL

N

CAUTION

5. AC In Cabling

• See Recommended Minimum AC Wire Sizes in Appendix C to determine the appropriate AC

wire size.

! Caution:

This inverter/charger includes neutral to ground switching for the AC electrical

system. The AC system in mobile installations must have the neutral physically

isolated from the ground throughout the load distribution powered by the

inverter.

• Disconnect any and all sources of AC power from the vehicle.

• Remove the knockout from the front or either side of the inverter chassis and install a strain relief

or conduit in which to route the AC cabling in and out.

• Connect the black wire from an appropriately sized three-conductor AC cable from the hot side

of the AC power supply (shore power connector) to the terminal labeled “AC Input Hot 1” on the

inverter.

• Connect the white wire from the neutral side of the AC power source to the terminal labeled “AC

Input Neutral” on the inverter.

• Connect the green wire from the ground of the AC power source to one of the two green wires

(AC Safety Ground) bolted to the chassis of the inverter/charger.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

20

Page 29

QUICK INSTALL

6. AC Out Cabling

• Connect the black wire of a three-conductor AC cable between the terminal marked “AC Output

Hot 1” to the hot bus of your AC load center or AC sub-panel.

• Connect the white wire from the terminal marked “AC Output Neutral” to the neutral bus of your

AC load center or sub-panel.

• Connect the remaining green wire bolted to the chassis of the inverter to the safety ground bus of

the AC load center or sub-panel.

7. Wrap up

• Secure all wiring with wire ties or other non-conductive fasteners to prevent chafing or damage

from movement and vibration. Use strain relief’s, grommets, or conduit to prevent damage to the

wiring where it passes through bulkheads or any apertures. Tighten all connections to 10-15 foot

pounds.

• Check to see that the inverter front panel switch is in the “Off” position, then reconnect to the AC

power source.

• Turn the inverter to the “On” position and check inverter operation (See Operation section)

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

21

Page 30

Page 31

INSTALLATION

Installation

In this portion of the manual, we will look at requirements and recommendations for installing a

Legend Series II inverter/charger. Keep in mind that these are only guidelines. Common sense, the

National Electrical Code and local building codes are the final authority.

Locating the Inverter

Inverters are sophisticated electronic devices and should be treated accordingly. When selecting the

operating environment for the inverter, don’t think of it in the same terms as other equipment it works

with, e.g. batteries, diesel generators, gas generators, washing machines etc. It is a highly complex

microprocessor controlled device. Generically speaking, it is a cousin to stereo equipment, television

sets, and computers. The use of conformal-coated circuit boards, plated copper bus bars, powder

coated metal components, and stainless steel fasteners improves tolerance to hostile environments.

However, in a condensing environment (one in which humidity and temperature change cause water

to condense on components) all the ingredients for electrolysis are present — water, electricity, and

dissimilar metals. In a condensing environment, the life expectancy of the inverter is indeterminate

and the warranty is voided.

! Caution:

It is in your best interests to install the inverter in a dry, protected location away

from sources of high temperature and moisture. Exposure to saltwater is

particularly destructive, potentially hazardous, and not covered by warranty.

Locate the inverter as close to the batteries as possible in order to keep the battery cable length

short. However, do not locate the inverter in the same compartment as vented batteries. Batteries

generate hydrogen sulfide gas, which is very corrosive to electronic equipment and everything else.

They also generate hydrogen and oxygen. If accumulated, this mixture will ignite by an arc caused

by the connecting of battery cables or the switching of a relay. Mounting the inverter in a ventilated

enclosure with sealed batteries is acceptable.

Ventilation

Installation of the inverter in a properly ventilated enclosure is mandatory for proper operation of the

unit. Installation in an enclosure that is too tight or poorly ventilated will result in lower peak power

output, reduced surge capability, and potentially shorter inverter life. This is due to the inverter

reaching its thermal shutdown point sooner than normal from lack of ventilation.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

23

Page 32

INSTALLATION

4kw

Power

3kw

Output

2kw

1kw

0 10 20 30 40 50 60 70 80 90 100

Ambient Temperature in °Celsius

Figure 1, Power Output Versus Temperature

Figure 1, Power Output Versus Temperature is for the L3012. It outlines the ambient temperature

needed in order for the inverter to perform to its published specifications.

The chart shows the output capabilities of the inverter, which is dependent on the ambient

temperature in the enclosure where the inverter is located. The dark line represents the maximum

power that may be expected from the inverter for a given ambient temperature. Testing has shown

that the volume of the enclosure is not as important as the overall ventilation. As long as a minimum

airspace of 1 ½ - inches is maintained around the sides of the inverter, and three inches at the back of

the inverter with the cooling fan, adequate ventilation should be maintained. Because the top of a

Legend Series II inverter is not vented, clearance between the enclosure and the top of the inverter is

not relevant.

The fan at the end of the inverter enclosure is for cooling. This fan pressurizes the inverter and

ventilates through the side vents of the unit. A fresh air intake opening should be provided directly to

the fan if possible, and an exhaust port directly opposite that will allow cool outside air to flow through

the inverter and back out of the enclosure.

Mounting

UL specification 458 (land vehicle installations) requires that the inverter be mounted on a flat

surface. The purpose of this requirement is to orient the inverter so that its bottom cover has no

holes that would allow burning material to be ejected in the event of an internal fire.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

24

Page 33

INSTALLATION

DC Wiring

Safety Instructions

The inverter’s maximum peak current requirements and the charger’s output current capabilities are

high. If battery cables are too small and/or connections are loose, efficiency and maximum output

power are degraded. Small cables or loose connections can also cause dangerous overheating of

the wire and/or terminals.

Observe Battery Polarity! Place the battery cable ring terminals over the bolt and directly against

the inverter’s battery terminals. A 'snap' caused by arching may occur-this is normal. Red is positive

(+), Black is negative (-) Use a 1/2-inch wrench or socket to tighten the 5/16 SAE nut to 10-15

foot/pounds. Do not place anything between the flat part of the inverter terminal and the battery

cable ring terminal or overheating may occur. Do not apply any type of anti-oxidant paste to

terminals until after the battery cable wiring is tightened to 10–15 foot-pounds!

Caution!

This inverter is not reverse polarity protected! If the positive terminal of the

battery is connected to the negative terminal of the inverter the probable result

is failure of the unit. This type of failure is very obvious and is not covered

under warranty. Double check when making battery connections!

Use the largest gauge wire and the shortest possible length when choosing battery cables. Tape the

battery cables together every few inches with non-conductive electrician’s tape or nylon tie-wraps.

This reduces the inductance of the wire resulting in a better waveform and less current in the

inverter’s filter capacitors. This directly relates to output efficiency and inverter life span. High

inductance in battery cabling is like placing a spring into the system between the battery bank and

inverter. This spring absorbs, stores, and releases energy opposite to that flowing in the system. In

this way efficiency and electrical characteristics are degraded.

Note

Never disconnect the battery cables while the inverter is delivering power or

battery charger is operating. The On/Off switch has no effect upon the charger.

It turns Off only the inverter. To disconnect the batteries for service. a) turn off

the power switch, b) disconnect all AC power, c) disconnect the battery cables.

DC Cabling Connections

Color-code your battery cables with colored tape or heat shrink tubing. The standard is red for

positive (+) and black for negative (-).

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

25

Page 34

INSTALLATION

2/0 Aluminum Mechanical Lug

Cables must have crimped and/or soldered copper compression lugs unless aluminum mechanical

lugs are used. We suggest using high quality UL listed Trace Engineering battery cables. These

cables are available in a specific assortment of sizes from 1 ½ to 10 feet, and in 2/0 or 4/0 AWG.

They are color-coded and have pressure crimped, sealed ring terminals. Contact your Trace dealer

to order.

Do not place anything between

battery cable lug and terminal

surface. Assemble exactly as shown

2/0 Copper Compression Lug

Figure 2, Battery to Inverter Cable Connection

.

Figure 2, Battery to Inverter Cable Connection illustrates proper connections for the Legend Series II

inverter/chargers. Points of caution are:

ü Do not connect the battery negative (-) terminal to the vehicle chassis; connect it to the

battery negative terminal of the inverter.

ü Do not connect the DC load negatives to the battery negative (-), connect only to the

chassis ground terminal on the inverter or to the vehicle chassis.

These connections are necessary in order for the RC7 remote control fuel gauge to work properly.

All current into or out of the battery must pass through the internal shunt, which is between the

chassis ground and battery negative terminals.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

26

Page 35

INSTALLATION

Copper Compression Lugs: Commonly available at hardware, welding, and auto parts retailers,

compression lugs must be crimped onto each cable using an appropriate crimping tool. These lugs

are not available from Trace Engineering. Suggested sources and part numbers are:

Hollingsworth, Pompano Beach, FL305-979-2050

Part # Description

TL3061 2/0 Ring Terminal

TL3062 4/0 Ring Terminal

H40 8 AWG to 250MCM Air-Operated Crimping Tool

Thomas & Betts

K973 2/0 Ring Terminal

M973 4/0 Ring Terminal

RJ737 2/0 Insulated Ring Terminal

RL737 4/0 Insulated Ring Terminal

TBM6 Hand Operated Crimping Tool (order dies separately)

Dies: #11809 for crimping 2/0 non-insulated lugs

#11811 4/0 non-insulated lugs

#11826 2/0 insulated lugs

#11828 4/0 insulated lugs

Mechanical Lugs: Aluminum mechanical lugs are available from electrical hardware suppliers and

do not require crimping. Suggested sources and part numbers are:

Part # Description

ILSCO

TA-2/0 2/0 Lug

TA-250 (preferred) 250 MCM Lug

Thomas &Betts

62205 2/0 Lug

62212 250 MCM Lug

Panduit

LAMA2/0-14 2/0 Lug

LAMA250-56. 250 MCM Lug

Ground Cable Connection

You probably noticed that the Trace Legend Series II inverter/chargers have a third battery terminal

labeled “Vehicle Chassis Ground” (the green terminal on the left side of the unit). The purpose of this

third terminal is be sure that all DC load current into or out of the battery bank will flow through the

internal shunt of the inverter. The internal shunt is connected between the black battery negative

terminal and the green chassis ground terminal of the inverter (See Figure 3, DC Wiring Diagram on

Page 30.)

Because all DC loads in a vehicle are generally connected to a common chassis ground and not

directly to the battery negative (in a negative ground system), all DC current in the system will at

some point pass through the chassis and then into the battery bank. If the inverter is in this loop the

net current flow is easily monitored. Thus, the RC7 remote control’s battery fuel gauge feature is

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

27

Page 36

INSTALLATION

Model #

Amps

Fuse Size

One Way

One Way

One Way

possible. You may connect the system without going through the chassis ground terminal, but the

RC7’s fuel gauge feature will not work properly.

Battery Cable Sizing

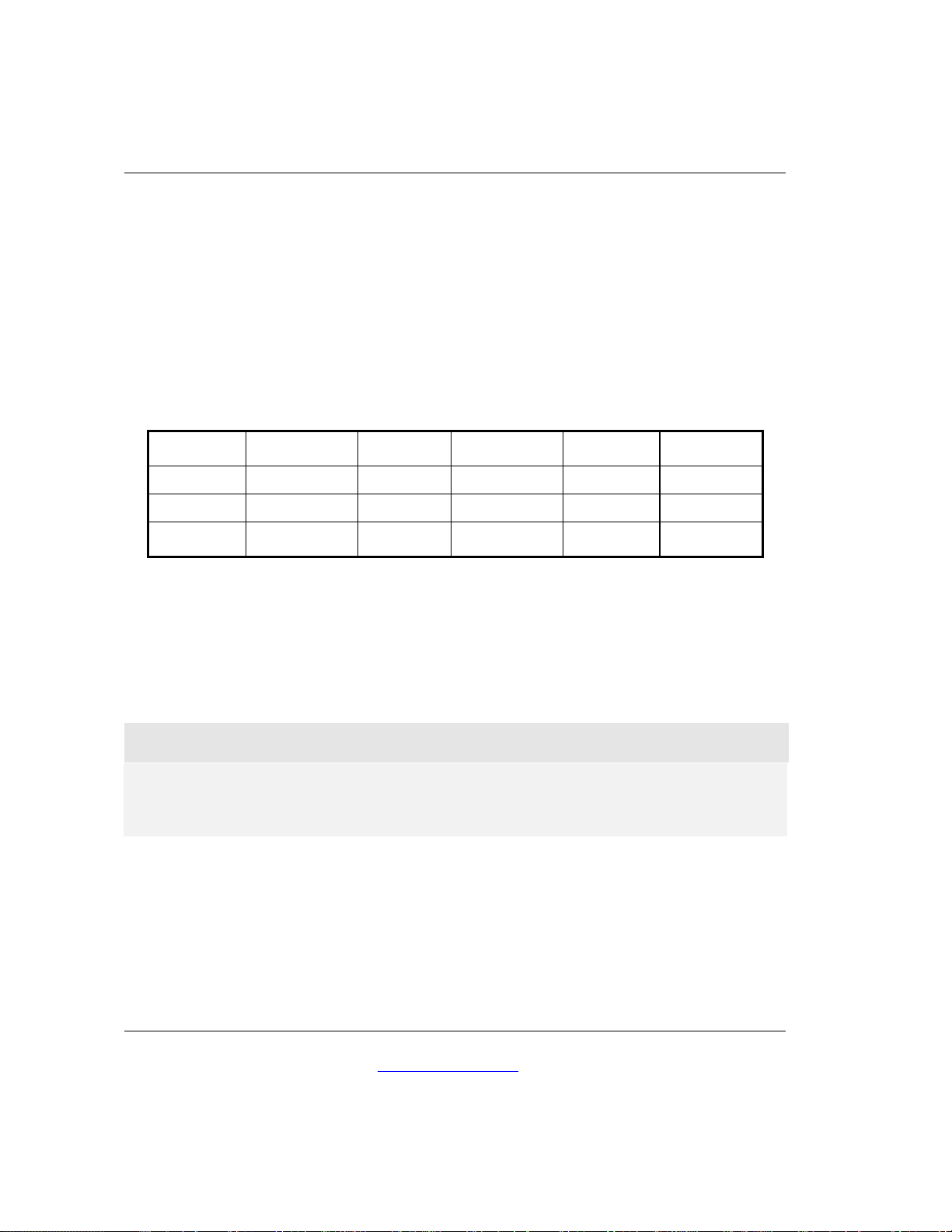

The bigger the battery cables the better. Undersized cables result in additional stress on the inverter,

lower efficiency, reduced surge power and lower peak output voltage. Don’t use cables that are too

small in diameter. The following table gives recommended cable sizes for the various cable-run

lengths and inverter voltages.

Table 1, Minimum Recommended Battery Cable Size (In free air)

Inverter

Typical DC

Minimum

1 to 3 feet

3 to 5 ft

5 to 10 ft

L2012 200 Amps 250A 00 00 0000

L2512 250 Amps 300A 00 0000 0000

L3012 300 Amps 400A 0000 0000 0000

The term “Free Air” is defined by the NEC as the cabling not being enclosed in conduit or raceway.

Cables enclosed have a substantially lower continuous current carrying ability due to heating factors.

The National Electric Code (NEC) requires that the cables be protected by a fuse or breaker rated to

match the cables ampacity at 75 degrees Celsius. The NEC also allows rounding up to the next fuse

size from the cable rating, i.e. 150-amp cable size rounds up to a 175-amp fuse size.

Warning!

Under-sized cables may melt or burn if the inverter is asked to produce high

power.

DC Over Current Protection

In order to comply with the UL 458 safety standard (Land Vehicle Installations) a UL approved type of

battery over-current protection is required. Fuses and disconnects must be sized to protect the

wiring in the system. The fuse is required to blow before the wire reaches its maximum current

carrying capability.

These installation parts are not supplied as part of the inverter. However, Trace Engineering offers a

DC-rated class T fuse and safety-covered fuse block which are compatible with the Legend Series II

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

28

Page 37

INSTALLATION

in Free Air

Fuse Size

inverter. The fuses are available in 110, 200, 300, and 400 amp sizes. Contact your Trace dealer to

order; see the Options section of this manual for more information.

Note

To order a fuse with fuse block from a Trace Dealer, order part number TFB

followed by the desired fuse size in amps (i.e. TFB 400). When ordering

replacement fuses, the part number is TF followed by the size in amps of the

desired fuse (i.e. TF400).

Table 2, Current Carrying Ability of Wire In Free Air at 75°C

Cable Size Maximum Rating

Maximum

# 2 AWG 170 amps 175 Amp

00 AWG 265 amps 300 Amp

0000 AWG

360 amps 400 Amp

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

29

Page 38

INSTALLATION

As an option, you may

DC Load

Fuse Block

Vehicle Chassis

Ground (green)

Internal Shunt

directly connect between

DC load center negative

and vehicle chassis

ground (green) terminal of

inverter

NOTE: In accordance with

NEC code, the fuse block

must be no more than 18

inches from the battery

bank.

Distribution

Panel

Out to DC loads

Figure 3, DC Wiring Diagram

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

30

Page 39

INSTALLATION

AC IN NEUTRAL

AC OUT NEUTRAL

AC OUT HOT

AC Wiring

The National Electrical Code (NEC) defines the standards for AC installation wiring in vehicle

applications, but there are still many installation variables; most are determined by the level of

automatic switching desired and the amount of external AC power to be switched. A qualified

electrician should do the installation.

AC and DC Wiring Separation

Do not mix AC and DC wiring in the same conduit. A separate conduit should be used for each.

Induced current in the DC conductors could cause confusion with the inverter’s microprocessor.

Where DC wiring must cross AC or vice-versa, make the wires at the crossing point 90° to one

another. Consult code for details of DC and AC wiring in vicinity to one another.

AC Wire Connections

The AC and DC terminals are located on the front panel of the chassis. A six-station terminal block is

provided to make the AC connections. The terminal block is used to hardwire the AC input and AC

output. All terminals are labeled on the inverter. Consult your local code for proper wire sizes,

connectors, conduit, etc. Table 2, "Current Carrying Ability of Wire in Free Air" gives suggestions for

wire sizing. Code requires that an external disconnect switch be used in the AC input wiring circuit.

The AC breakers in a sub panel will meet this requirement.

NOT USED

NOT USED

AC IN HOT

Figure 4, AC Terminal Block

When installing an inverter in a vehicle, do not use solid wires such as Romex because of the

potential for shortened wire life due to vibration-induced breakage. Stranded copper wire is required.

As a plus, stranded wire is generally much more flexible and thus easier to work with.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

31

Page 40

INSTALLATION

SCREW ONCHASSISBLACKHOT 1AC INWHITENEUTRALAC INGREENGROUNDSAFET

Y

2030203

0

PN2370 REV

A

LIGHTSPLUGS

INVERTER/CHARGE

R

IRCUI

TBREAKE

R

CHARGET

O

NONCN

O

RCUIT

NCNON

C

60A

HOT 1AC OUTBLAC

K

FRIG.

151

5

SUB PANEL120VACLOADS ONLY30 AMPSNEUTRALAC OUT

BLENDERTV

WHITE

1515151

5

TYPICAL 120/240VAC 3 WIRE ELECTRICAL SYSTEM DIAGRAM

30 AMP OPERATION:

C HOT IN TO AC HOT IN 1

C HOT OUT TO AC HOT OUT 1TYPICAL INVERTER LOADS

The following steps are a basic guideline for installation and connection of the AC wiring into and out

of the inverter.

1. Disconnect the inverter from the battery bank (if already connected), by either removing the DC

side fuse, or opening the DC disconnect. Then remove the AC wiring compartment cover from

the front of the inverter by removing the two screws at the bottom of the cover.

2. If conduit will be utilized (consult code, it may be required in your installation), determine which

knockout(s) will be utilized and remove them from the inverter. Using appropriate conduit

connectors, fasten the conduit to the inverter. Feed all AC wiring through the conduit and into

the inverter AC terminal block (located on the front of the inverter). Be sure to leave yourself

several extra inches of wire to work with. Remember that you need at least two sets of three

conductor wiring, one for AC Hot, neutral, and ground into the inverter, and another for AC hot,

neutral and ground out of the inverter to the loads. Torque all AC terminals to 10 to 15 inchpounds.

3. Following the wiring guide shown below, connect the hot (black) and neutral (white) wires from

the AC source (shore power or generator set) to the appropriately labeled terminals in the AC

terminal block. The safety ground (green) should be connected to the terminal stud labeled

“ground” bolted to the floor of the chassis. Repeat the procedure for the AC wiring going to the

AC sub-panel which will power the loads, except connect these wires to the terminals labeled AC

hot out.

GENERATOR

120VAC OR

120/240VAC

120/240VAC

FOR 120VAC

CONNECT A

CONNECT A

50 AMP

SHORE

SERVICE

HOT

HOT

NEUTRAL

GROUND

EXTERNAL

TRANSFER

RELAY

SWITCH

240VAC

AIR

CONDITIONER

MAIN PANEL

120/240VAC

50 AMP

C

CI

Figure 5, AC Wiring Diagram

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

32

Page 41

INSTALLATION

4. Inspect all wiring for proper installation and then replace the cover using the two 6/32nds screws

and lock washers to secure it.

Table 3, Recommended Minimum AC Wire Sizes

Inverter Model 120 VAC Input 120 VAC Output

L2012 10 gauge 12 gauge

L2512 8 gauge 10 gauge

L3012 8 gauge 10 gauge

! Important Precaution

The output side of the inverter’s AC wiring should at no time be connected to

public power or a generator. This condition is far worse than a short circuit. If

the unit survives this condition, it will shut down until corrections are made.

AC output must be isolated from ground to comply with the NEC requirement for neutral-ground

switching. This is easiest to do at the sub-panel by isolating the neutral connector block from

the frame of the subpanel with an appropriate insulator.

Ground Fault Interrupting Outlets (GFCI’s)

Trace Engineering has tested the following GFCI’s and found them to work satisfactorily with our

inverters:

LEVITON 6599

PASS & SEYMOR 1591RI 4A957

ACE Hardware ACE 33238

Some GFCI’s will nuisance trip when used with a modified square wave inverter. Trial is the only

way to tell for sure. On the above listed types, continued nuisance tripping is usually a result of a

wiring problem in the inverter AC output system. Leakage currents present somewhere in the AC

system are causing the GFCI to trip. Make a careful review of the AC wiring layout in your system

and look for possible unwanted ground paths. An error in wiring of the neutral-ground switching

system is a good place to start troubleshooting. Be sure that the AC output neutral is isolated from

the ground. A multimeter may be handy in this troubleshooting procedure.

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com Page

33

Page 42

INSTALLATION

AC Source Selector Switch –

AC Main Panel

120 Volts AC, 60Hz

Shore

Power

Generator

Water Heater

Lights

Inverter AC

To Inverter

Vehicle Chassis

House Battery

Vehicle Starting

Vehicle

Ground

Automatic or Manual

Electric Range

Air Conditioner

AC Hot IN

Microwave

Refrigerator

TV/VCR

Outlets

Fuse Block

Sub-panel

Battery Isolator

Alternator

Bank

Battery

Figure 6, Typical Mobile Installation Diagram

Trace Engineering Co. Inc. Tel (360) 435-8826 Part Number 3179

5916 195th Street, NE Fax (360) 435-2229 Effective August 6, 1998

Arlington, WA 98223 USA www.traceengineering.com

Page

34

Page 43

INSTALLATION

RY-A

RY-B

(Inverter loads)

N

E

U

GND

Neutral-to-Ground Switching

All of the Legend Series units employ neutral to ground switching as required by the NEC (National

Electric Code). The purpose for this requirement is to ensure that the neutral conductor in a threewire system is "bonded" or connected to ground at only one point. This prevents a voltage

difference from developing between the vehicle's neutral and the AC source's neutral, which may

cause an electric shock. When the unit is operating as an inverter, the AC output neutral is connected

to the chassis ground by an internal relay, creating the bond within the inverter. When operating from

an external AC power source the internal relay in the inverter opens and removes the ground from

the neutral conductor and allows the "bond" to be provided by the external AC source.

The diagram below graphically describes the ground switching system in the inverter for a unit

operating as an inverter and feeding the AC sub-panel.