Page 1

C-Series

Multifunction DC Controllers

Installation and Operation Guide

©2000 Xantrex Technology Inc.

P/N 975-0004-01-01 Rev. B 11/00

Page 2

©2000 Xantrex Technology Inc.

Page 3

C-Series

Multifunction DC Controllers

Table of Contents

Section Description Page

1. INTRODUCTION ............................................................. 1

2. FEATURES ..................................................................... 5

3. INSTALLATION............................................................... 10

Operating Modes

Photovoltaic Charge Control Mode

Automatic PV Array Night Disconnect

Diversion Control Mode

DC Load Control Mode

Over-Temperature Protection

Electronic Over-Current Protection

Battery Temperature Compensation

LED Status Indicator

Charge or Diversion Control Mode Indications

Solid Green

Blinking Green

Load Control Indications

Solid Red

Blinking Red

Slowing Blinking Orange

Equalization Mode Indication

Alternating Red and Green

Error Mode Indication

Fast Blinking Orange

Mounting

Wiring

Minimum Recommended Wire Size

Maximum One-way Distance and Wire Size

PV Charge Control Mode Cabling

Diversion Control Mode Cabling

DC Load Control Mode Cabling

Grounding

Configuring the C-Series

Automatic/Manual Battery Equalization and

Low Voltage Reconnect

Operating Mode

Reset Switch

Voltage

©2000 Xantrex Technology Inc.

i

Page 4

Table of Contents (Continued)

Section Description Page

3. INSTALLATION (continued)

4. OPTIONS ........................................................................ 35

5. OPERATION ................................................................... 38

6. BATTERIES .................................................................... 41

Adjusting the C-Series

Setting Voltage Parameters

Testpoints for Voltage Settings

Equalization

Manual Equalization

Automatic Equalization

Temperature Compensation

Setting LVR and LVD (Load Control Mode)

Setting Diversion Control Mode

C-Series LCD Meter Displays

Installing the DVM/C40

Mounting the CM/R

Three-Stage Battery Charging

Bulk

Absorption

Float

Equalization

Automotive Batteries

Maintenance-Free Batteries

Deep-Cycle Batteries

Sealed Batteries

NiCad and NiFe Batteries

Battery Sizing

8. DIVERSION LOADS ....................................................... 43

9. SPECIFICATIONS .......................................................... 46

10. SERVICE INFORMATION .............................................. 47

11. WARRANTY .................................................................... 48

ii

Charge Controller

Load Controller

Diversion Charge Controller

Diversion Load Types

©2000 Xantrex Technology Inc.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be

followed during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation

and operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse

existe dans cette zone. Faire preuve dextrême prudence lors de la

réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or

operation of the unit. Follow these instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou

lutilisation de lunité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions

deprès.

· All electrical work must be done in accordance with local, national, and/or

international electrical codes.

· Before installing or using this device, read all instructions and cautionary

markings located in (or on) the manual, the inverter, the controller, the

batteries, and the PV array.

· Do not expose this unit to rain, snow or liquids of any type. This product is

designed only for indoor mounting.

· To reduce the chance of short-circuits when installing or working with the

inverter, the controller, the batteries, or the PV array, use insulated tools.

· Remove all jewelry such as rings, bracelets, necklaces, etc., while

installing this system. This will greatly reduce the chance of accidental

exposure to live circuits.

· The controller contains more than one live circuit (batteries and PV array).

Power may be present at more than one source.

· This product contains no user serviceable parts. Do not attempt to repair

this unit unless fully qualified.

SAVE THESE INSTRUCTIONS !

©2000 Xantrex Technology Inc. iii

Page 6

BATTERY SAFETY INFORMATION

· Always wear eye protection, such as safety glasses, when working with

batteries.

· Remove all loose jewelry before working with batteries.

· Never work alone. Have someone assist you with the installation or be

close enough to come to your aid when working with batteries.

· Always use proper lifting techniques when handling batteries.

· Always use identical types of batteries.

· Never install old or untested batteries. Check each batterys date code or

label to ensure age and type.

· Batteries are temperature sensitive. For optimum performance, they

should be installed in a stable temperature environment.

· Batteries should be installed in a well vented area to prevent the possible

buildup of explosive gasses. If the batteries are installed inside an

enclosure, vent its highest point to the outdoors.

· When installing batteries, allow at least 1 inch of air space between

batteries to promote cooling and ventilation.

· NEVER smoke in the vicinity of a battery or generator.

· Always connect the batteries first, then connect the cables to the inverter

or controller. This will greatly reduce the chance of spark in the vicinity of

the batteries.

· Use insulated tools when working with batteries.

· When connecting batteries, always verify proper voltage and polarity.

· Do not short-circuit battery cables. Fire or explosion can occur.

· In the event of exposure to battery electrolyte, wash the area with soap

and water. If acid enters the eyes, flood them with running cold water for

at least 15 minutes and get immediate medical attention.

· Always recycle old batteries. Contact your local recycling center for proper

disposal information.

iv

©2000 Xantrex Technology Inc.

Page 7

1.0 INTRODUCTION

Introduction

The C35/C40/C60 (C-Series) controllers are among the finest controllers

available and can be used with 12, 24, or 48 volt DC systems (depending upon

model) as PV charge controllers, DC diversion controllers, or DC load

controllers (low voltage disconnect). These capabilities make the C-Series the

only DC controllers youll need! Numerous standard features are provided to

maximize the performance of the system:

· Solid-state Pulse Width Modulated (PWM) charging process with three-

stage control, temperature compensation, and manual or automatic

equalization to maximizes system performance and increase battery life.

· Meets National Electrical Code (NEC) and other international controller

specifications.

· UL listed for the U.S. (UL Standard 1741 (draft) 1998), and Canada

(CSA-C22.2 No. 107.1-95).

· Electronic overload and short circuit protection with automatic and manual

reset capability increases the reliability of unattended systems by eliminating

blown fuses and tripped circuit breakers.

· Field adjustment of charge setpoints is provided by rotary controls with

removable knobs, reducing the potential for setpoint tampering. Calibrated

scales and test points allow precise adjustments of settings.

· Optional external battery temperature compensation sensor (BTS) for

automatic adjustment of charge setpoints (required by UL draft standard

1741 and strongly recommended for sealed batteries).

· Over-temperature protection for the electronic circuitry when used in hot

environments (over 113 °F/45 °C).

· Indoor-type, powder-coated enclosure for wall mounting.

· Multicolor LED with easy to read mode/status label.

· Optional LCD meter for remote or direct mounting on the controller. May be

mounted up to 1000 feet away.

· 2-year limited warranty.

©2000 Xantrex Technology Inc.

1

Page 8

1.0 INTRODUCTION

Operating Modes

The C-Series controller can operate as either a photovoltaic charge

controller, a diversion controller, or a DC load controller. The controller cannot

operate in more than one mode at the same time. If several modes are required

in a system, a dedicated controller must be used for each mode.

Photovoltaic Charge Control

When this mode is selected, the status LED will indicate either blinking

green or solid green. It will alternate red/green when in equalization mode.

Diversion Control Mode

When this mode is selected, the status LED will indicate either blinking

green or solid green.

DC Load Control Mode

When this mode is selected, the status LED will typically indicate blinking

red or solid red as the controller turns the DC loads OFF when battery

voltage is low.

Photovoltaic Charge Control Mode

Depending on the model, the controller can regulate up to 60 amps of

continuous photovoltaic (PV) array current at 12 or 24 volts (C60), or 12, 24 or

48volts DC (C40) for charging batteries. This rating includes the NEC required

deratings. When used in this mode, ensure that the operating mode jumper is

on the charge control pins. To enable the Photovoltaic Charge Control Mode,

see Configuring the CSeries in the installation section of this manual.

If the PV arrays output increases above the rated amp level due to

reflection or edge of cloud effect, the controller will continue to operate until the

heatsink reaches a maximum safe operating temperature. This will take several

minutes to occur depending upon the ambient temperature involved. When the

heatsink reaches the maximum safe temperature, the controller will reduce the

current, cooling the transistors and the heatsink.

If the current from the PV array reaches 85 amps, the controller will turn off

to protect the circuitry. In the event of a shutdown, the controller automatically

resets itself after 10 minutes (if overcurrent condition is no longer present).

The C-Series charge controller rapidly cycles the current source on-and-off

to control the charging current and voltage of the battery. This occurs in both the

charge control mode and the diversion control mode. The amount of time the

current source is connected to the battery is varied to control the average current

flow. This is often referred to as pulse width modulation (PWM) and allows the

current to be tapered, rather than coarsely turning the current off and on as with

relay type PV array charge controllers.

2

©2000 Xantrex Technology Inc.

Page 9

1.0 INTRODUCTION

Automatic PV Array Night Disconnect

At night, the PV array is automatically disconnected from the battery to

prevent reverse leakage of power. This eliminates the need for a blocking

diode between the battery and the PV array. If thin-film or amorphous solar

modules are being used, diodes may still be required to prevent damage from

partial shading conditions. Check the documentation provided with the PV

modules.

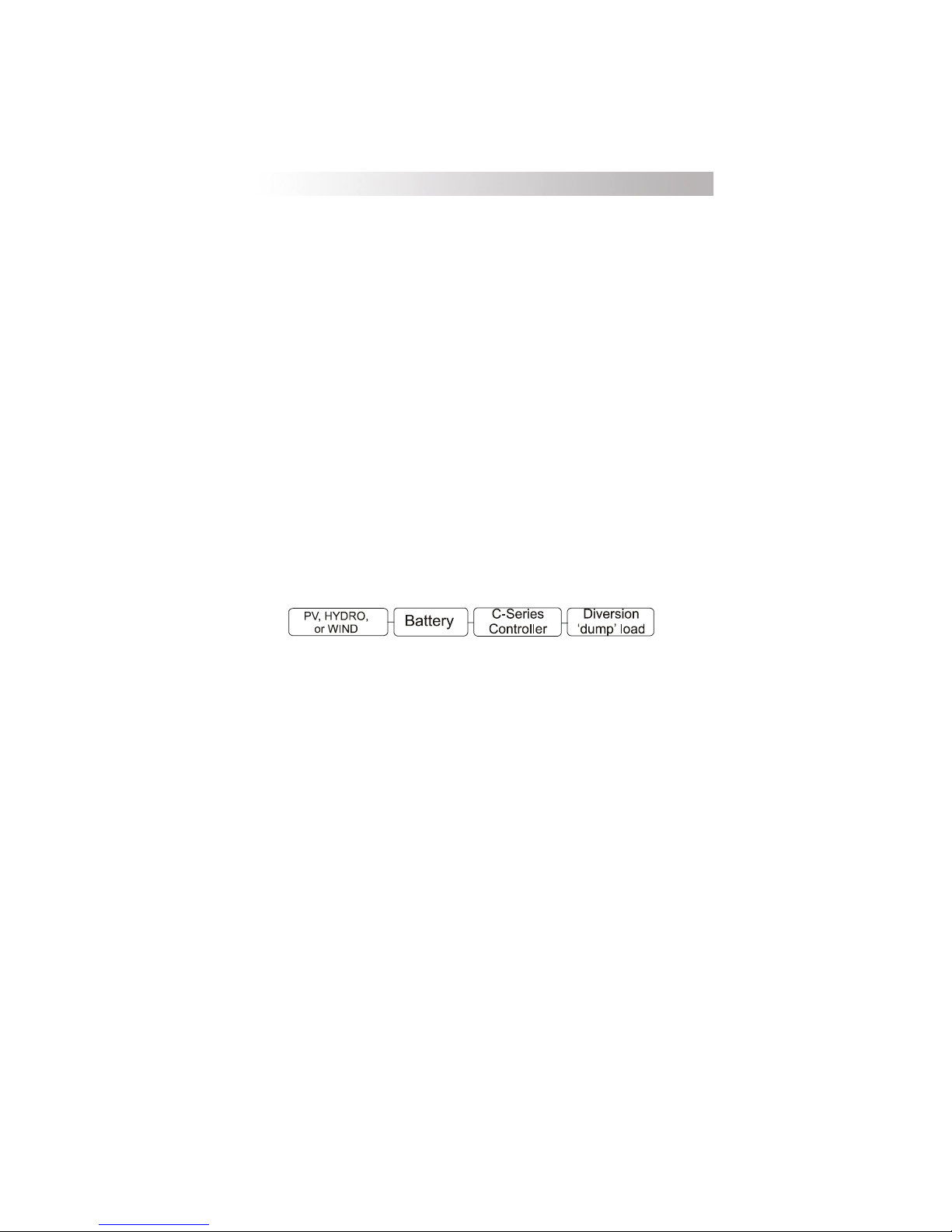

Diversion Control Mode

The C-Series can operate as a diversion control to manage battery charging

from alternative-energy sources such as wind or hydroelectric generators.

Systems utilizing solar arrays do not have a requirement for diversion loads since

a solar module can be open-circuited without damage. However, even with a

solar based system it may be desirable to use excess power to operate DC

loads. When used in this way, the C-Series controls a diversion load to redirect

the excess power generated instead of allowing it to flow into the battery. This

prevents damage to the charging source from an over-speed condition which

could occur if the charging source is suddenly disconnected from all loads as

series relay regulators do. Consult your dealer for load and regulator size

recommendations.

When the controller operates as a diversion regulator, it provides threestage regulation of battery voltage, with temperature compensation and automatic or manual equalization. See the Three-Stage Battery Charging section

for more information on this process.

Diversion mode requires a separate dump load to regulate the battery.

This load must be able to absorb more power than the charging source is able to

produce at its peak output, or the DC voltage will become unregulated. The

dump load must be available for the diversion of power at all times. Resistivetype heating elements are the best diversion loads. Special direct current

water heating elements are available. Light bulbs and motors are not recommended as diversion loads because they are unreliable.

When used in diversion mode, ensure that the operating mode jumpers are

on the charge control pins. See Configuring the CSeries in Section 3 of this

manual.

Current draw of the diversion load is very important. Problems may arise

from operating with a load that is too small or too large. A diversion load that is

too small will not be able to absorb all the excess power from the current source

once the batteries are full.

Diversion loads in excess of 85 amps are capable of absorbing more power

than the C-Series is designed to handle, resulting in an over-current shut down.

During this time, the unit will not regulate electrical flow in the system, and battery

damage may result.

A diversion load that draws about 25% more current than the charging

sources maximum output capability is usually suitable for use with the C-Series.

©2000 Xantrex Technology Inc.

3

Page 10

1.0 INTRODUCTION

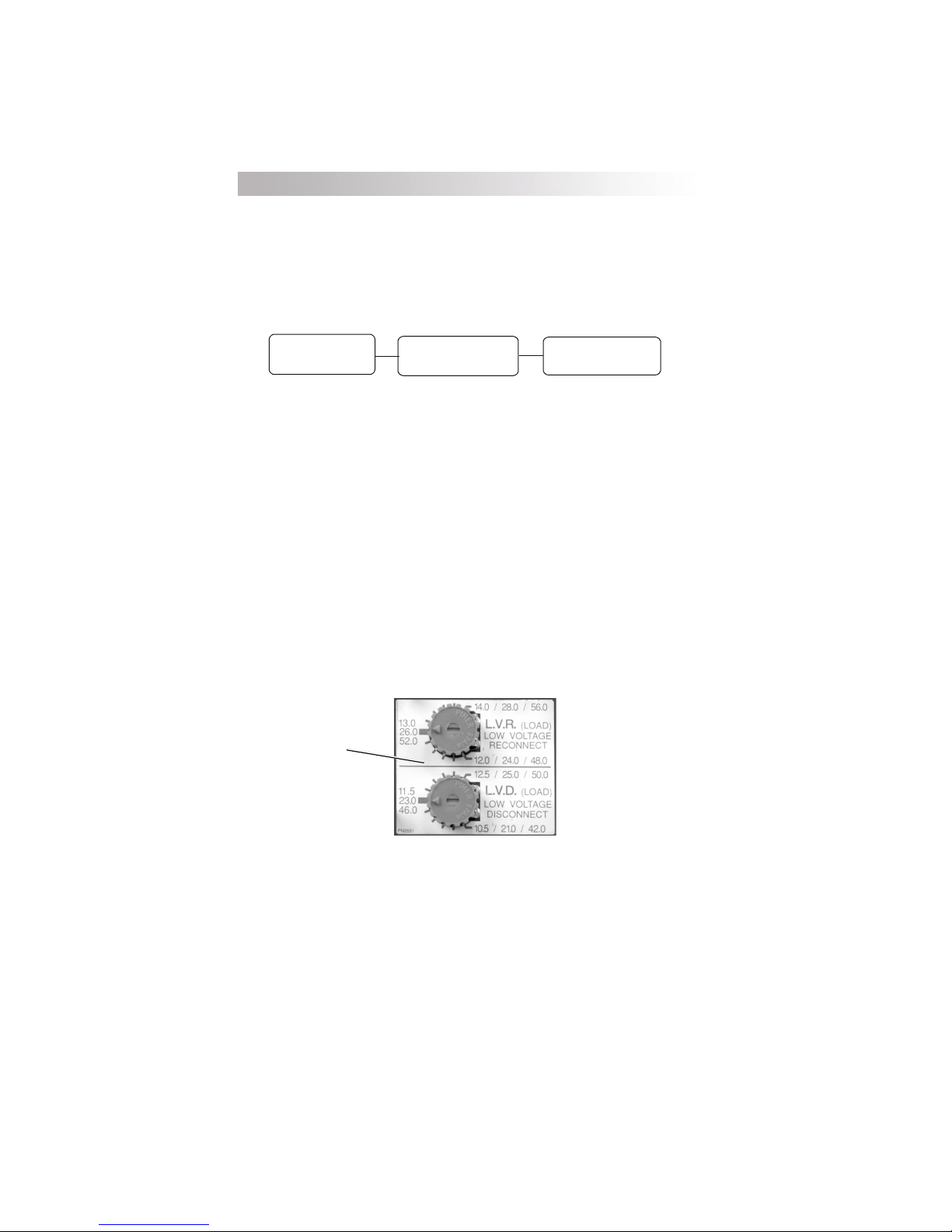

DC Load Control Mode

The C-Series can also operate as a load control (also called a low voltage

disconnect) to manage the discharging of the battery. A load controller

prevents damage to the battery from over-discharge during periods of poor

weather or excessive loads.

Battery

When used in load control mode, ensure that the operating mode jumpers

are on the load control pins. See Configuring the C-Series section of this

booklet.

The controller delays disconnecting the DC loads for 6 minutes after the

voltage drops below the low voltage disconnect (LVD) setting. Loads are

either automatically or manually reconnected when battery voltage exceeds the

low-voltage reconnect (LVR) setting for 6 minutes. The EQUALIZE jumper

determines manual or automatic reconnect when the C-Series is used as a load

controller.

When used as a DC load controller, the settings of the LVR and LVD are

controlled by two rotary potentiometers on the circuit board. The scale on the

adjustment potentiometers differ from the scale used for other functions. A

decal with the appropriate adjustment scale is included with the C-Series and

shown below. Place this scale over the pots when using the C-Series as a

load controller. Do not temperature-compensate these settings. Do not install

the optional battery temperature compensation sensor.

Attach sticker over

potentiometers for

Load Control Settings

C-Series

Controller

DC Load

4

Sticker Displaying Load Control Voltage Settings

Figure 1

©2000 Xantrex Technology Inc.

Page 11

2.0 FEATURES

Features

The C-Series features include over-temperature protection, electronic over-

current protection, and automatic battery temperature compensation.

Over-Temperature Protection

The temperature of the controllers transistors is continuously monitored.

This protects the charge controller from damage in high temperature

environments. If excessive temperatures are detected while operating in

charge or diversion control mode, the controllers transistors are rapidly turned

off and on to reduce the charge rate. This will reduce the transistor

temperature.

As a load controller, the load is disconnected before the transistors reach

an excessive temperature. Once the temperature has dropped, the loads are

reconnected. When the over-temperature protection system has caused the

controller to shutdown, the status LED will be orange and will blink fast (about

once a second). This is the same indication shown during an over-current

condition.

Electronic Over-Current Protection

During operation, the C-Series controllers continuously monitor the current

flowing through it. If the current exceeds 85 amps, the transistor switches are

opened, stopping the flow of electricity. The detection circuitry is faster than

breakers or fuses, and they will not trip or blow when a fault occurs. When

the over-current protection system is activated, the status LED will indicate

orange and will blink fast (about once a second). This is the same indication as

produced by an over temperature condition.

The C-Series controllers automatically resets the over-current protection

system every 6 minutes. If an overload or short circuit is still present, the

controller will shut off and wait another 6 minutes. This will occur continuously

until the problem is corrected.

The reset switch on the right side of the controller allows the user to

manually reconnect the PV array or DC loads after an over-current condition

occurs. Hold the reset switch for 5 seconds to return to normal operation. If

the controller is unable to restart, check the wiring and reduce the loads

connected. There may be a delay after manually pressing the reset switch

before reconnecting the PV array.

The shunt used to measure the current flow in the C-Series is located in

the positive conductor of the circuit allowing greater flexibility in system

grounding. The negative terminals are all common to one another.

©2000 Xantrex Technology Inc.

5

Page 12

2.0 FEATURES

Battery Temperature Compensation

The optional plug-in external Battery Temperature Sensor (BTS)

automatically fine tunes the charging process of the C-Series. The BTS is

required by UL Standard 1741 and UL approval is based on its installation.

However, do not install the battery temperature sensor if you are using the

C-Series as a DC load controller. The BTS may be extended by using a

standard phone cable with RJ-11 plugs.

If the temperature sensor is installed, the regulation setpoints should be

adjusted for a battery at room temperature (2327 °C/7480 °F). The C-Series

adjusts the BULK and FLOAT setpoints 30 mV per degree Celsius for a

lead-acid type battery and 20 mV per degree Celsius for a

battery, as required per UL Standard 1741. For 24 and 48 volt systems, the

compensation is twice and four times the values listed respectively. See Table 1.

If the temperature sensor is NOT installed, the setpoints should be adjusted

for the temperature of the battery during operation. Seasonal adjustment of the

setpoints may be necessary to prevent battery damage and to ensure proper

charging. If the battery temperature sensor is installed, no seasonal adjustments

are required (see Temperature Compensation in this manual).

If the wiring to the sensor is damaged and the wires are shorted or cut, the

system will return to the non-temperature compensated settings.

Install the BTS on the side of the battery below the electrolyte level. It is

best to place the sensor between batteries and place the batteries in an insulated

box to reduce the influence of the ambient temperature outside the battery

enclosure. Ventilate the battery box at the highest point to prevent hydrogen

accumulation.

10-cell, NiCad type

6-cell,

TRAHCNOITASNEPMOCERUTAREPMETTNIOPTESREGRAHC

egatloVmetsyS

epyTyrettaB

CDV21CDV42CDV84

dicAdaeLC°/stlov030.0C°/stlov060.0C°/stlov021.0

daCiNC°/stlov020.0C°/stlov040.0C°/stlov080.0

Charger Setpoint Temperature Compensation

6

Table 1

©2000 Xantrex Technology Inc.

Page 13

2.0 FEATURES

LED Status Indicator

A multi-color LED indicates the operating status of the controller. A colorcoded label is included on the cover of the controller explaining the status LEDs

operation. When the controller is in Charge Control mode, the LED will be

green. When in Load Control mode, the LED will be red. An orange LED

indicates an error or a load disconnect condition. When battery equalization is

in process, the LED alternates between red and green.

NOTE: The green and red color of the LED only indicates the particular

operating mode and the battery voltage level. It does not indicate whether the

charging source is functioning properly.

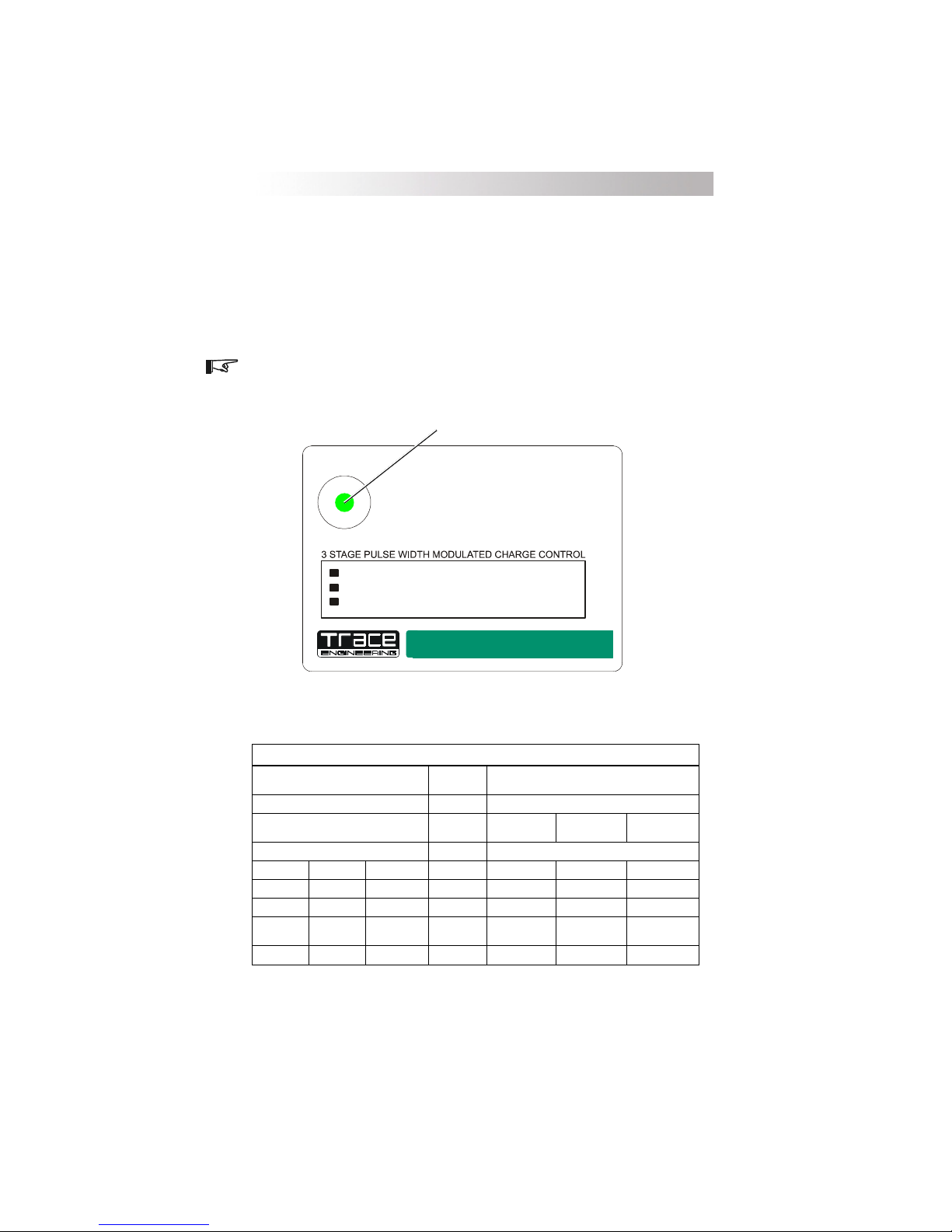

Multicolor LED Indicator

STATUS

C35

C40

C60

Green Blink Charge Control Mode

Green Solid Battery Charged

Red Blink Load Control Mode

Red Solid

Orange Blin k Slow Load Disconnected

Orange Blink Fas t

/

Green

Red

35 Amp Controller

40 Amp Controller

60 Amp Controller

Alternating - Equalization Enabled

Batte ry Dis c h arg ed

Overload/Overtemp

12/24 VDC

12/24/48 VDC

12/24 VDC

Charge / Load Controller

5916-195th STREET NE ARLINGTON WASHINGTON 98223 TELEPHONE(360)435-8826 FAX(360)435-2229

CSeries Front Panel Label

gnitteSTAOLFtayrettaB

gnitteSKLUBtayrettaB

)-(suniMgnitteSkluB )+(sulPgnitteSDVL

CDV52.0CDV05.0CDV00.1

CDV05.0CDV00.1CDV00.2

CDV57.0CDV05.1CDV00.3

57.0>

stlov21stlov42stlov84egatloVCDstlov21stlov42stlov84

05.1>

kluBwoleb

kluBwoleb

00.3>

Figure 1

)rotacidnIsutatSDELgnisU(EGATLOVYRETTAB

DEL

)edoMnoisreviD/egrahC(DELneerG

kluBwoleb

SUTATS

NOsyawlA

sknilB5

sknilB4

sknilB3

sknilB2

knilB1

51.0>

DVLevoba

CDV51.0CDV03.0CDV54.0

CDV03.0CDV06.0CDV09.0

CDV54.0CDV09.0CDV53.1

54.0>

DVLevoba

03.0>

DVLevoba

09.0>

DVLevoba

)edoMlortnoCdaoL(DELdeR

)DVL=setunim6rof(gnitteSDVLtayrettaB

54.0>

DVLevoba

53.1>

DVLevoba

©2000 Xantrex Technology Inc.

Battery Voltage LED Indications

Table 2

7

Page 14

2.0 FEATURES

Charge Control or Diversion Control Mode Indications

Solid Green

The battery is being charged in the FLOAT stage. The status LED remains

ON solid unless the batteries drop below the float voltage setting for an

accumulative period of one hour. This allows the user to confirm that the

system reached the float stage during the charging process when checked at

the end of the day. Reaching the float stage frequently is a good indication of

proper system operation and will maximize battery life and performance.

Blinking Green

The controller is in the CHARGE CONTROL or DIVERSION CONTROL

mode and the battery is not fully charged. As the battery voltage approaches

the BULK setting, the status LED will blink green several times (up to five) and

then pause, indicating the battery voltage is approaching the bulk setting and

provides an indication of the battery condition. Refer to Table 2 on the previous

page to determine the battery voltage.

NOTE: A single green flash indicates the battery is below the bulk voltage

setting. It does NOT indicate the batteries are charging.

Load Control Indications

Solid Red

The controller is in the DC LOAD CONTROL mode and the battery

voltage has reached the Low Voltage Disconnect (LVD) setting. After a

6-minute delay, DC loads will be disconnected unless the user reduces the

loads to a point that the battery voltage exceeds the LVD setting.

Blinking Red

As battery voltage approaches the LVD setting, the LED will blink red

several times (up to five) and then pause providing an indication of battery

voltage. Refer to Table 2 on the previous page to determine the battery voltage.

Slow Blinking Orange

The controller is in the DC LOAD CONTROL mode and has disconnected

the loads due to reaching the LVD setting. The user can press the reset switch for

a maximum 10-minute grace period, or can wait until the voltage rises above

the Low Voltage Reconnect (LVR) setting to allow an automatic reset to occur.

8

©2000 Xantrex Technology Inc.

Page 15

2.0 FEATURES

Equalization Mode Indication

Alternating Red and Green

The controller is in the EQUALIZE mode. It will automatically stop the

equalization process after accumulating two hours of operation at a voltage

above the BULK setting. The user can stop the equalization process at any time

by pressing the reset switch until the status LED stops alternating red and green.

Error Mode Indication

Fast Blinking Orange

The controller detected an over-current or an over-temperature condition

and the loads are disconnected. The controller will try to automatically restart

the loads after a 6-minute delay. If the controller will not restart, turn off all

loads and press the reset switch. If it then restarts, the loads may be too large.

A delay up to five seconds may occur before the controller attempts to restart

after pressing the reset switch.

©2000 Xantrex Technology Inc.

9

Page 16

3.0 INSTALLATION

Installation

The C-Series controllers are state-of-the-art precision electronic

instruments. Installation, environment, mounting, and wiring must be

accomplished in accordance with applicable local and national electrical codes.

The instructions that follow are applicable to the typical installation. For special

applications, consult a qualified electrician or your Trace dealer. Installation

procedures will vary according to your specific application.

Mounting

The C-Series controllers are designed for indoor mounting. Care should be

taken in selecting a location and when mounting the enclosure. Avoid mounting

it in direct sunlight in order to reduce heating of the enclosure and subsequent

high operating temperatures. The enclosure should be mounted vertically on

awall.

Mounting and enclosure dimensions are shown in Figure 2 (the C-35

controller does not feature an external heat sink). Remove the faceplate on the

controller and locate the upper two screw locations on the wall. The back of

the enclosure is provided with keyholes for mounting. Leave the screw heads

backed out approximately 1/4 inch (6 mm) or less. Place the controller onto the

screws and pull it down into the keyhole slots. Then insert the two lower

screws to lock the enclosure onto the wall. Provide either strain-relief clamps

or conduit to prevent damage to the circuit board and terminal block from pulling

on the wires. The cover should be replaced and retained with the screws

provided (#10-32 x 3/8" SMS).

In outdoor installations, the C-Series units must be installed in a rainproof

enclosure to eliminate exposure to rain or water-spray. The use of conformalcoated circuit boards, plated terminals, powder-coated metal components, and

stainless steel fasteners improves tolerance to hostile environments.

CAUTION: INSTALL THE C-SERIES CONTROLLER IN A DRY, PROTECTED

LOCATION AWAY FROM SOURCES OF HIGH TEMPERATURE, MOISTURE,

AND VIBRATION. EXPOSURE TO SALTWATER IS PARTICULARLY

DESTRUCTIVE. CORROSION OF THE CIRCUIT BOARD IS NOT COVERED BY

THE WARRANTY.

10

©2000 Xantrex Technology Inc.

Page 17

3.0 INSTALLATION

Heatsink not included

on C-35.

8

Figure 2

CSeries Dimensions

Do not locate the C-Series controller in a sealed compartment with the

batteries. Batteries can vent hydrogen sulfide gas, which is corrosive to

electronic equipment. Batteries also generate hydrogen and oxygen gas that

can explode when exposed to a spark.

If using sealed batteries, the controller can be mounted in the same

enclosure as long as it is adequately ventilated.

©2000 Xantrex Technology Inc.

11

Page 18

3.0 INSTALLATION

Wiring

Disconnect battery and PV sources before wiring. Set the voltage

selection jumper to the appropriate setting before energizing the system (see

User Configuration Options for instructions). Incorrect settings may result in

damage to the system as charging regulation will not occur. Torque the

terminals to 20 inch-pounds for 14-10 AWG (25 for 8 AWG, 35 for 6 AWG) once

the wires have been installed. Replace the cover.

12 Volt Position

24 Volt Position

48 Volt Position

(C40 only)

C40 C35 and C60

Figure 3

Voltage Selection Jumper

12 Volt Position

24 Volt Position

Battery Positive + PV +/Load +

Common Negatives

Figure 4

Battery Connection Terminals

NOTE: Regardless of configuration, only the positive conductor from a PV array

OR a DC load may be connected to the terminal marked PV POS/LOAD.

12

©2000 Xantrex Technology Inc.

Page 19

3.0 INSTALLATION

Minimum Recommended Wire Size

The minimum recommended wire gauge is #8 AWG (for C35 and C40) with

a 75 °C insulation rating and #6 AWG, 90 °C wire for the C60. The terminals on

the C-Series will accept up to #2 AWG (33.6 mm

however, UL specifications only allow the use of up to #6 AWG (13.3 mm

maximum. No crimp-on terminals or lugs are required.

Each model of the CSeries controller is rated for a maximum continuous

current of 35, 40 or 60 amps. Since PV outputs can vary due to the array size

or sunlight striking it, the safe minimum wire size should be based on the

maximum current ratings. The NEC requires conductors and over-current

devices be operated at no more than 80% of their rating. Refer to Table 3

below for a listing of the minimum wire size to use for each model.

2

) copper or aluminum wire,

2

)

RELLORTNOCEZISERIWMUMINIM

53CGWA8#spma54

04CGWA8#spma05

*06C)eriwC°09(GWA6#)ytud%001detsil(spma06

**06C)eriwC°57(GWA4#)ytud%001detsil(spma06

GNITAR

ECIVEDTNERRUC-REVO

Table 3

Minimum Wire Size

NOTE: *To meet UL requirements, use #6 AWG, 90 °C wire and a 60 amp LISTED

100% DUTY over-current device for the C60 controller.

** Not approved by UL for direct connection into the controller. Use a splicer

block as specified below and #6 AWG (90 °C wire) to connect to the

controllerterminals.

If there is a significant distance between the PV array and the controller

and/or the controller and the battery, larger wires can be used to reduce the

voltage drop and improve performance. Refer to Table 4.

To use a larger size wire, use a splicer block (terminal block) intended for

this purpose. This allows the larger cable size from the batteries to be

spliced to the smaller wire size connected to the controller. Split-bolt kerneys

can also be used for wire splices. Follow manufactures recommendations for

torque and mounting (if required). Splicer blocks and split-bolt kerneys are

available from alternative energy suppliers.

©2000 Xantrex Technology Inc.

13

Page 20

3.0 INSTALLATION

Maximum One-way Distance and Wire Size

NOTE: NEC article 690 and local electrical codes should be consulted for wire

sizing and any additional installation requirements. For a C60 use a 60 amp,

100% Continuous Duty breaker and #6 AWG, 90 °C wire. Larger wire sizes

may be used to improve performance, but are NOT approved by UL to be

installed in the controller (use a splicer block as previously described on

page13 of this manual). Match the breaker to the wire if using larger

gaugewire.

Refer to Table 4 and find your maximum current in the left column, and the

one way distance from your power source (feet/meters) to the C-Series controller

(or the distance from the C-Series controller to your load) on the same line, then

read the wire size required at the top of the column.

The wiring, over-current protection devices (fuses and circuit breakers) and

installation methods used must conform to all national and local electrical codes

requirements.

Wiring should be protected from physical damage with conduit or a strain

relief clamp. You should pull the temperature sensor cable through the conduit

first as the connector may not fit if other wires have been pulled first.

As a minimum, a 60 amp DC rated current limiting fuse or circuit breaker

should be provided near the battery for protection from short circuits. To meet

NEC requirements, use a 60 amp circuit breaker listed for 100% duty for the C60.

To meet UL requirements, use #6 AWG copper wires rated for 90 °C for the C60.

14

©2000 Xantrex Technology Inc.

Page 21

3.0 INSTALLATION

nwohSnoitacilppACDV21

)sretem(teeFniecnatsiD )sretem(teeFniecnatsiD

GWA21GWA01GWA8GWA6

spmA

.tf8.8

.tf41

01

21

41

61

81

02

52

03

53

04

54

05

06

)m86.2(

.tf3.7

)m32.2(

.tf3.6

)m29.1(

.tf5.5

)m86.1(

.tf9.4

)m94.1(

.tf4.4

)m43.1(

.tf2.22

)m72.4(

)m77.6(

.tf6.11

.tf5.81

)m45.3(

)m46.5(

.tf01

.tf9.51

)m50.3(

)m58.4(

.tf7.8

.tf9.31

)m44.2(

)m42.4(

.tf8.7

.tf4.21

)m83.2(

)m87.3(

.tf7

.tf1.11

)m31.2(

)m83.3(

.tf6.5

.tf9.8

)m17.1(

)m17.2(

.tf7.4

.tf4.7

)m34.1(

)m62.2(

.tf4.6

)m59.1(

.tf6.5

)m17.1(

GWA4 GWA3 GWA2 GWA1 GWA0/1 GWA0/2

.tf1.65

.tf3.53

)m67.01(

.tf4.92

)m69.8(

.tf2.52

)m86.7(

.tf1.22

)m47.6(

.tf6.91

)m79.5(

.tf6.71

)m63.5(

.tf1.41

)m03.4(

.tf8.11

)m95.3(

.tf1.01

)m80.3(

.tf8.8

)m86.2(

.tf8.7

)m83.2(

.tf1.7

)m61.2(

.tf3.6

)m29.1(

.tf9.07

)m90.71(

)m86.2(

.tf7.64

.tf1.95

)m32.41(

)m16.12(

.tf1.04

.tf6.05

)m22.21(

)m24.51(

.tf0.53

.tf3.44

)m76.01(

)m05.31(

.tf2.13

.tf4.93

)m15.9(

)m10.21(

.tf0.82

.tf4.53

)m35.8(

)m97.01(

.tf4.22

.tf3.82

)m38.6(

)m36.8(

.tf7.81

.tf6.32

)m76.5(

)m91.7(

.tf0.61

.tf2.02

)m88.4(

)m61.6(

.tf0.41

.tf7.71

)m72.4(

)m86.2(

.tf5.21

.tf7.51

)m18.3(

)m97.4(

.tf2.11

.tf2.41

)m14.3(

)m33.4(

.tf3.9

.tf8.11

)m38.2(

)m06.3(

pordegatloV%3<arofecnatsiDeriWyaw-enOmumixaM

2ybecnatsidylpitluM,smetsySCDV42roF

4ybecnatsidylpitluM,smetsySCDV84roF

noitacificepseziseriw

.tf6.98

.tf5.211

)m13.72(

)m92.43(

.tf6.47

.tf7.39

)m47.22(

)m65.82(

.tf0.46

.tf4.08

)m15.91(

)m93.42(

.tf0.65

.tf3.07

)m70.71(

)m34.12(

.tf8.94

.tf5.26

)m81.51(

)m50.91(

.tf8.44

.tf2.65

)m66.31(

)m31.71(

.tf8.53

.tf0.54

)m19.01(

)m86.2(

.tf9.92

.tf5.73

)m11.9(

)m7.31(

.tf6.52

.tf1.23

)m08.7(

)m87.9(

.tf4.22

.tf1.82

)m38.6(

)m65.8(

.tf9.91

.tf0.52

)m70.6(

)m26.7(

.tf9.71

.tf5.22

)m64.5(

)m68.6(

.tf9.41

.tf7.81

)m45.4(

)m7.5(

mumixamriehtsdeecxetisaLUybdevorppatoneraseziSeriWesehT

.tf7.141

.tf8.522

)m91.34(

)m28.86(

.tf1.811

.tf2.881

)m00.63(

)m63.75(

.tf2.101

.tf3.161

)m58.03(

)m61.94(

.tf6.88

.tf2.141

)m10.72(

)m40.34(

.tf7.87

.tf5.521

)m99.32(

)m52.83(

.tf9.07

.tf9.211

)m16.12(

)m14.43(

.tf7.65

.tf3.09

)m82.71(

)m25.72(

.tf2.74

.tf3.57

)m93.41(

)m59.22(

.tf5.04

.tf5.46

)m43.21(

)m66.91(

.tf4.53

.tf5.65

)m97.01(

)m22.71(

.tf5.13

.tf2.05

)m06.9(

)m03.51(

.tf3.82

.tf2.54

)m36.8(

)m87.31(

.tf6.32

.tf6.73

)m91.7(

)m5.11(

One-way Wire Distance and Wire Size

©2000 Xantrex Technology Inc.

Table 4

15

Page 22

3.0 INSTALLATION

PV Charge Control Mode Cabling

Photovoltaic arrays generate current whenever light strikes the surface of

the array. Before connecting the C-Series controller, cover or disconnect the

array to prevent any current from being generated.

· Remove one or more of the knockout plugs on the controllers case and

feed the connecting wires through it.

· Connect the PV arrays positive (+) output to the terminal marked PV POS/

LOAD at the bottom of C-Seriess circuit board and tighten the lugs.

· Connect the PV arrays negative () output to the terminal marked

COMMON NEGATIVES and tighten the lugs.

· Connect the battery positive (+) cable to the terminal marked BAT POS and

tighten the lugs.

· Connect the negative () battery cable to the terminal marked COMMON

NEGATIVES and tighten the lugs.

· Secure the cabling with strain reliefs after allowing a little slack inside the

case to prevent damage to the controllers circuit board.

Battery Positive +

16

PV Array Positive +

Figure 5

PV Charge Control Mode Wiring

©2000 Xantrex Technology Inc.

Battery Negative PV Array Negative

Page 23

PV Array

Circuit Breaker

PV +

CONTROLLER

PV CHARGE CONTROL

BATTERY

POSITIVE +

PV +/

LOAD +

MODE

PV -

BATTERY +

Circuit Breaker

3.0 INSTALLATION

COMMON

NEGATIVES

BATTERY -

PV Charge Control Wiring Diagram

©2000 Xantrex Technology Inc.

–+

BATTERY

3553-W01-00A

Figure 6

17

Page 24

3.0 INSTALLATION

Diversion Control Mode Cabling

When using the C-Series unit as a diversion or DC load controller, the DC

load needs to be connected to the controller terminals marked as PV POS/LOAD

and COMMON NEGATIVE. The common negatives can be reversed or wired

with an appropriately sized single conductor to a more convenient location

such as a DC load center negative bus.

· Connect your DC current source (PV, wind, hydro, etc.) directly to

abattery.

· Connect an appropriately-sized cable from the positive battery terminal to

the controller terminal marked BAT POS.

· Connect a cable from the negative battery terminal to the terminal marked

COMMON NEGATIVES on the controllers circuit board.

· Connect a cable from the controllers terminal marked PV POS/LOAD to the

positive terminal of your DC diversion load.

· Connect a cable from the controllers terminal marked COMMON NEGA-

TIVES to the negative terminal of your DC diversion load.

· Tighten the terminal lugs to 20 inch-pounds for #14-10 AWG (25 for

#8 AWG, 35 for #6 AWG). Allow a little slack on the cables within the

controller and secure the wiring with strain reliefs.

NOTE: Do not use light bulbs for diversion loads. Use only resistive loads such

as air- or water-cooled heating elements.

Battery Positive + Battery Negative Diversion Load

18

Positive +

Diversion Load

Negative

Figure 7

PV Load Diversion Wiring

©2000 Xantrex Technology Inc.

Page 25

PV Array

CONTROLLER

LOAD DIVERSION MODE

BATTERY

POSITIVE +

PV +/

LOAD +

NEGATIVES

DIVERSION

LOAD

BATTERY +

3.0 INSTALLATION

COMMON

BATTERY -

PV +

Circuit Breaker

Load Diversion Wiring Diagram

©2000 Xantrex Technology Inc.

Circuit Breaker

–+

BATTERY

PV -

3553-W02-00A

Figure 8

19

Page 26

3.0 INSTALLATION

DC Load Control Mode Cabling

· Connect the positive battery cable to the terminal marked BAT POSITIVE

on the controller.

· Connect the negative battery cable to the terminal marked COMMON

NEGATIVES.

· Connect a cable between the PV POS/LOAD terminal on the controller and

the positive terminal on the DC load.

· Connect a cable between the controllers COMMON NEGATIVES terminal

and to the negative terminal of the load.

Battery Positive + Battery Negative DC Load Positive + DC Load Negative

Figure 9

Load Control Wiring

20

©2000 Xantrex Technology Inc.

Page 27

CONTROLLER

DC LOAD CONTROL MODE

BATTERY

POSITIVE +

PV +/

LOAD +

COMMON

NEGATIVES

3.0 INSTALLATION

BATTERY -

BATTERY +

Circuit Breaker

Load Control Wiring Diagram

LOAD -

Circuit Breaker

LOAD +

BATTERY

Figure 10

_

DC LOAD

+

–+

3553-W03-00A

©2000 Xantrex Technology Inc.

21

Page 28

3.0 INSTALLATION

Grounding

The C-series controllers are designed to work with both negative ground

and ungrounded electrical systems. The metal chassis of this charge/load

controller must be grounded for either system by connecting it with a copper wire

to a grounding electrode such as a ground rod driven into the earth.

If a negative ground system is desired, connect the negative current

carrying conductor to the grounding system at one point in the system. Consult

local and national electrical codes for more information and any additional

requirements.

22

©2000 Xantrex Technology Inc.

Page 29

3.0 INSTALLATION

Configuring the C-Series

Three sets of jumpers are located on the right side of the controllers

circuit board. These jumpers control equalization, low voltage reconnect,

battery voltage, and operating modes. They must be set correctly for the unit to

operate to its maximum potential.

Figure 11

Jumpers

The C-Series controllers are equipped with several of these jumpers.

Each are discussed in the appropriate section of this manual. The factory

default settings are shown below.

04C06C,53C

Factory Default Settings for C-Series Controllers

©2000 Xantrex Technology Inc.

egatloVyrettaB

RVL/ezilauqE

edoMgnitarepO

CDstlov21CDstlov21

launaM

noitazilauqE

lortnoCegrahClortnoCegrahC

launaM

noitazilauqE

Table 5

23

Page 30

3.0 INSTALLATION

NICAD SETTING

SELECTION RESISTOR

EQ/LVR JUMPER

CHARGE/LOAD

CONTROL JUMPER

RESET SWITCH

24

Configuration Jumpers Location

Figure 12

©2000 Xantrex Technology Inc.

SYSTEM VOLTAGE

JUMPER

Page 31

3.0 INSTALLATION

Automatic/Manual Battery Equalization (EQ) and Low

Voltage Reconnect (LVR)

Enables automatic or manual battery equalization in Charge Control mode,

and automatic or manual reconnect in the event of low voltage at the BAT POS

terminal in Load Control mode. When AUTO is enabled in Load Control mode,

the unit will reconnect automatically when voltage at the BATTERY POSITIVE

terminal exceeds the LVR setting. Factory setting is manual equalization and

manual reconnect.

12 Volt Position

24 Volt Position

48 Volt Position

C40 C35 and C60

12 Volt Position

24 Volt Position

Figure 13

Voltage Selection Jumper

Operating Mode

This jumper determines the operating mode: PV Charge Control and

Diversion Control mode, or Load Control mode. Factory setting is Charge

Control mode.

Figure 14

Operating Mode Jumper

Reset Switch

Press and hold to manually initiate or suspend battery equalization in

Charge Control mode. Press and release to reset following an error condition.

Press and release to reconnect following a low-voltage disconnect event. If

voltage remains below the LVD setting, the unit will disconnect after a 6-minute

grace period.

Figure 15

Reset Switch Jumper

©2000 Xantrex Technology Inc.

25

Page 32

3.0 INSTALLATION

Voltage

This jumper determines the voltage of the system that the controller will be

used with. Connect the two pins adjacent to the legend for the voltage of your

system: 12, 24, 48. Factory setting is 12 volts for the C35, C40 and C60. The

maximum DC voltage allowed is 125 VDC for a C40, and 55 VDC for the C35

and C60.

If the optional LCD meter (DVM/C40 or CM/R) is attached to the C-Series

controller, be sure to set the jumper on the back of it for the appropriate system

voltage. The jumper for limiting power consumption and dimming the CM display

is also located on the back of the LCD Displays.

12 Volt Position

24 Volt Position

48 Volt Position

C40 C35 and C60

Figure 16

Voltage Selection Jumper

12 Volt Position

24 Volt Position

26

©2000 Xantrex Technology Inc.

Page 33

3.0 INSTALLATION

Adjusting the C-Series

The charging rate and voltage reconnect/disconnect setting of the controller

are adjustable via two rotary potentiometer controls. The knobs are removable

to reduce the likelihood of tampering with the settings. Calibrated scales are

provided to allow setting of the control without requiring the use of a digital

voltmeter. Visual adjustment allows an accuracy of ± 0.1 volts.

Setting Voltage Parameters

In Charge Control mode, you can adjust the bulk and float charging voltage

by adjusting the potentiometers (pots) located in the bottom center of the

controllers circuit board (for more information regarding bulk and float charging

rates, see the Three-Stage Battery Charging Process section of this manual).

The potentiometer scale for bulk charge voltage is calibrated from 13.0 to

15.0volts (when the voltage jumper is set for a 12 volt system) in increments

of 0.2volts, from 26.0 to 30.0 volts (24 volt system) in increments of 0.4 volts,

or from 52.0 to 60.0 volts (48 volt system) in increments of 0.8 volts. For float

charge voltage, the potentiometer scale is calibrated from 12.5 to 14.5 volts

(12volt system), 25.0 to 29.0 volts (24 volt system), and from 50.0 to 58.0 volts

(48 volt system) with the same increments as above.

BULK and FLOAT Voltage Adjustment Potentiometers

©2000 Xantrex Technology Inc.

Charge/Diversion Control Mode

Figure 17

27

Page 34

3.0 INSTALLATION

Testpoints for Voltage Settings

At midrange on these scales, a testpoint is provided for use with a DC

digital voltmeter for assuring more accurate adjustment. The pots are equipped

with removable knobs to prevent accidental adjustments by the curious or

uninformed. If the knobs are missing, a 5/64" hex-head driver can be used to

adjust the settings. A digital voltmeter can be connected from the COMMON

NEGATIVE terminal on the circuit board and the small testpoint located to the left

of each adjustment pot at the nine oclock position. The testpoint provides a

reading from 0 to 2 volts; this value must be added to the lower value of the

adjustment range (Bulk=13.0, Float=12.5, LVR=12.0, LVD=10.5). Multiply this

value by 2 for 24 V and by 4 for 48 V.

For example, to set the bulk voltage to 14.4 volts, adjust the potentiometer

until the DVM displays 1.4 volts (13.0 V + 1.4 V = 14.4 V). To set bulk to 28.2,

adjust the pot until the DVM displays 1.10 volts (1.10 x 2 [24 volt] = 2.2 + 26.0 =

28.2). When using NiCad type batteries, add another 2 (12-volt), 4 (24-volt) or 8

(48-volts) to the settings.

TESTPOINTS

for DC multimeter

(center legs of potentiometer)

Connect the negative lead of

DVM to the COMMON

NEGATIVE terminal

DC Testpoints for Bulk and Float

Figure 18

If you are using the unit as a DC load controller, be sure to set the

potentiometers as shown in the DC Load Control section of this manual. The

upper knobs settings are reduced by 1 volt, resulting in a range of 14.0 VDC to

12.0 VDC (for a 12-volt system). The lower knobs settings are reduced by

2volts, resulting a range of 12.5 to 10.5 VDC (for a 12-volt system).

Load Control Mode (sticker)

Figure 19

DC Load Control Adjustment Sticker

28

©2000 Xantrex Technology Inc.

Page 35

3.0 INSTALLATION

Equalization

CAUTION: DO NOT EQUALIZE GEL OR SEALED TYPE BATTERIES!

The C-Series offers either manual or automatic triggering of the equalization

process (the default setting is manual). Automatic equalization is enabled by

moving the jumper located on the right side of the circuit board above the reset

switch. When automatic has been selected, an equalization charge will occur

every 30 days (holding the voltage 1 volt for 12-volt systems, 2 volts for 24-volt

systems, and 4 volts for 48-volt systems, above the bulk setting for 2 hours).

During the equalization process the status LED indicates equalization by

alternately blinking green and red. (Equalization is not recommended for NiCad

batteries and is disabled when the R46 resistor is cut).

Auto Equalize

Manual Equalize

Manual Equalize Jumper

Setting

Equalization Settings

Figure 20

Manual Equalize Switch

(when in Manual mode)

R46Cut for NiCad

applications

©2000 Xantrex Technology Inc.

Figure 21

Equalization Settings

29

Page 36

3.0 INSTALLATION

Manual Equalization

Manual equalization of the battery can be enabled by pressing the reset

switch on the right side of the C-Series for 10 seconds. The status LED

indicator will begin to alternate between red and green once equalization is

enabled. The equalization process will continue until the batteries have been

held at or above the bulk setting for two hours of accumulated time. During the

equalization process, the battery voltage will be limited to 1volt above the bulk

setting for 12-volt systems (2 volts for 24-volt systems, and 4 volts for 48-volt

systems). Once the battery voltage has been at or above the bulk setting for a

cumulative period of two hours, the C-Series will return to the float stage of the

charging process.

Front Panel LED

(flashes red/green

during Equalization)

Reset Switch Access

Figure 22

C40 Front and Side Panel

To stop the equalization process, press the reset switch. The status LED

will stop alternating between red and green. If the equalization process was

shorter than one hour, the controller will continue with a bulk charge cycle and

then hold the battery at the bulk setting for one hour (the absorption stage) before

returning to the float setting.

During the equalization process the status LED will alternate between red

and green and will not provide any other mode/status indication. Large battery

banks may need several equalization cycles to fully stir the electrolyte and charge

the cells. These cycles should follow one another until the battery voltage

reaches the upper limit for the full two hours.

30

©2000 Xantrex Technology Inc.

Page 37

3.0 INSTALLATION

Automatic Equalization

CAUTION: DO NOT EQUALIZE GEL OR SEALED TYPE BATTERIES!

The C-Series controllers can automatically trigger an equalization charge

every 30 days. The status LED will indicate that the equalization process is

occurring. The equalization process will continue until the voltage has been

held above the bulk setting for a cumulative period of two hours. This might

take several days on larger systems with big batteries and small PV arrays.

The battery voltage only needs to exceed the bulk setting for the timer to start

countingthe voltage may not reach the equalization voltage setting.

To enable automatic equalization, the jumper located on the right side of the

circuit board must be moved to the AUTO setting. The default setting of the

C-Series controllers is for manual equalization. To disable the automatic

equalization system, move the equalize jumper.

To manually stop the equalization process, press the reset switch on the

right side of the unit until the status LED stops alternating between red and

green. If the equalization process was shorter than one hour, the controller will

continue with a bulk charge cycle and then hold the battery at the bulk setting for

one hour (the absorption stage) before returning to the float setting. Once a

manual equalization has been triggered, the 30-day period to the next automatic

equalization will be restarted. To prevent automatic equalization, move the

equalize jumper to the manual position.

Manual Equalize Jumper

Setting

Equalize Jumper and Reset Switch

©2000 Xantrex Technology Inc.

Auto Equalize

Manual Equalize

Manual Equalize/Reset Switch

Figure 23

31

Page 38

3.0 INSTALLATION

Temperature Compensation

If a Battery Temperature Sensor (BTS) is installed, the charge controlling

process will be automatically adjusted for the battery temperature. Set bulk and

float voltage for a battery at normal room temperature 7480 °F (2327 °C).

Actual voltage may vary above or below these settings due to adjustment for

battery temperature.

If no Battery Temperature Sensor (BTS) is installed and the batteries will be

operating in very hot or very cold conditions, adjust the bulk and float settings to

allow for the battery temperature. The recommended adjustments can be

found in the table below. The setting should be lowered for ambient

temperatures above 80 °F (27 °C) and raised for ambient temperature below

75°F (23 °C). If significant seasonal variations are common, you will have to

change the settings several times a year to prevent battery damage and ensure

proper operation.

NOTE: Do NOT compensate the settings when using the C-Series controller as

a DC load controller.

TRAHCNOITASNEPMOCERUTAREPMETTNIOPTESREGRAHC

egatloVmetsyS

epyTyrettaB

CDV21CDV42CDV84

dicAdaeLC°/stlov030.0C°/stlov060.0C°/stlov021.0

daCiNC°/stlov020.0C°/stlov040.0C°/stlov080.0

Temperature Compensation

Temperature compensation is based on battery type: 5 mV/cell for lead

acid type batteries and 2 mV/cell for alkaline type batteries (NiCad or NiFe).

32

Table 6

©2000 Xantrex Technology Inc.

Page 39

3.0 INSTALLATION

Setting LVR and LVD (Load Control Mode)

To change the low voltage disconnect (LVD) and low voltage reconnect

(LVR) settings, use the same BULK and FLOAT potentiometers.

When the C-Series is wired for DC Load Control mode, the potentiometers

scale calibration is altered from what is printed on the circuit board. A sticker

is provided with the C-Series with the proper scale calibrations for the Load

Control mode. The BULK potentiometer becomes the Low Voltage Reconnect

(LVR), and the FLOAT potentiometer becomes the Low Voltage Disconnect

(LVD). Place the sticker provided over the potentiometers. The knobs may

have to be removed for sticker placement, then reinstalled. The sticker is

packed inside the C-Series (bottom of unit).

DC Load Control Adjustment Sticker

Figure 24

If the sticker is lost, follow these instructions for voltage calibration using the

scale printed on the C-Series circuit board.

From the scale shown on the circuit board for the LVR setting (BULK

setting when in Charge Control mode), subtract 1 volt for 12-volt systems,

2volts (for 24-volt systems), and 4volts (for 48-volt systems).

From the scale shown for the LVD setting (FLOAT setting in Charge

Control mode), subtract 2 volts for the 12-volt system, 4 volts for a 24-volt

system, and 8 volts for a 48-volt system.

Subtract the proper voltages

from the values printed on the

circuit board, if the sticker is

missing

Figure 25

DC Load Control Adjustment Sticker

MANUAL reconnect of the loads is allowed when voltage has not exceeded

the LVR setting. To reconnect the loads, press the reset button on the right

side of the unit. If the voltage is below the LVR level, the DC load can be

reconnected for approximately 6 minutes. Multiple reconnects are allowed, but

the on time duration will vary with battery voltage. The EQUALIZE jumper

allows the controller to be set for AUTO reconnect of the dc load when the

voltage exceeds the LVR setting.

NOTE: The LED will light red only in Load Control mode; never in Charge or

Diversion mode (unless it is reversed upon reinstallation).

©2000 Xantrex Technology Inc.

33

Page 40

3.0 INSTALLATION

Setting Diversion Control Mode

When the C-Series controller is configured for Diversion Control mode, you

can set the voltage at which the unit begins diverting current (high voltage

diversion). The unit will continue diverting excess current to the diversion load

until the source voltage falls to the Bulk setting. After two hours at the Bulk

setting, the unit will reduce the battery charging voltage to the Float voltage

setting. This will usually result in more current being diverted to the diversion

load.

The flashing rate of the LED indicates the battery state of charge. Solid

green indicates the battery is fully charged (float mode). Five flashes indicates

the battery is in Bulk mode. As the flashing rate decreases, the battery is

discharged to a lower voltage level (i.e., somewhere below the Bulk voltage

setting). Table 7 indicates the approximate level the battery is below the Bulk

voltage setting.

As an example, if the system battery voltage is 24 volts and the internal

Bulk voltage setting is set for 26 volts, you can calculate approximately how much

below the Bulk setting the batteries are by subtracting the number in Table7

from 26 (the internal Bulk setting). With the LED indicating two blinks, the

battery voltage is approximately 24.5 volts (26 volts Bulk setting minus

1.50volts in the table). With the LED indicating one blink, the battery voltage

is

somewhere below the 24.5 volts, indicating the battery may be seriously

damaged.

NOTE: The LED will light green only in Diversion and Charge Control mode

(unless it is reinstalled backwards).

34

)rotacidnIsutatSDELgnisU(EGATLOVYRETTAB

DEL

)edoMnoisreviD/egrahC(DELneerG

gnitteSTAOLFtayrettaB

gnitteSKLUBtayrettaB

)-(suniMgnitteSkluB )+(sulPgnitteSDVL

CDV52.0CDV05.0CDV00.1

CDV05.0CDV00.1CDV00.2

CDV57.0CDV05.1CDV00.3

57.0>

stlov21stlov42stlov84egatloVCDstlov21stlov42stlov84

05.1>

kluBwoleb

kluBwoleb

00.3>

kluBwoleb

SUTATS

NOsyawlA

sknilB5

sknilB4

sknilB3

sknilB2

knilB1

51.0>

DVLevoba

CDV51.0CDV03.0CDV54.0

CDV03.0CDV06.0CDV09.0

CDV54.0CDV09.0CDV53.1

54.0>

DVLevoba

03.0>

DVLevoba

09.0>

DVLevoba

Table 7

Battery Voltage LED Indications

©2000 Xantrex Technology Inc.

)edoMlortnoCdaoL(DELdeR

)DVL=setunim6rof(gnitteSDVLtayrettaB

54.0>

DVLevoba

53.1>

DVLevoba

Page 41

4.0 OPTIONS

C-Series LCD Meter Displays

Two optional LCD digital meter displays are available for the C-Series

controllers; the DVM/C40 replaces the standard faceplate on the C-Series

controller and the CMR/50 or CMR/100 mounts remotely. The remote version is

available with either 50 foot or 100 foot cables. Longer runs may be possible

(up to 1000 ft/305m) because the communication is a serial-data type link.

These displays include a two-line, 32-character LCD and a status LED

indicator.

The LCD displays provide the following information:

· PV Array or DC load pass-through current: 0 to 85 amps DC

· Battery voltage: 4 to 100 volts DC

· Watts: 0 to 3600 watts (volts times amps)

· Amp-hours: 0 to 65536 Ah; can be reset to 0

· Totalizing amp-hours: 0 to 65536 Ah; resets to zero when power is

disconnected

· Status LED: green, red, or orange

If the C-Series controller is disconnected from the battery or the meter

cable, the meter will be reset when it is powered up. Press and hold the pushbutton on the front of the meter to manually reset the amp-hour meter. Press and

release this button to turn the backlight on or off. An adjustable potentiometer

on the back of the meter enables you to adjust the contrast of the LCD display.

When installing the meter, be sure to set the jumper on the printed circuit board

over the pin set to match the controller board for the system voltage, either 12,

24, or 48 volts.

Watts (volts x

amps)

Supply or Load

Current (a m ps)

Resettable amphours

Status LED

01.5 0019 13.1

00004.3 00013.2

Actual Battery

Voltage

T otalizing Amps:

resets to zero

at battery or

load disconnect

Amp-hour reset &

backlight button. Press

and hold for 10

seconds to reset.

Press and relea se f or

backlight.

Figure 26

DVM/C40 Front Panel

©2000 Xantrex Technology Inc. 35

Page 42

4.0 OPTIONS

Installing the DVM/C40

To install the faceplate LCD:

· Disconnect all power sources and remove the factory-installed

faceplate by removing the four Phillips-head screws.

· Pull out the LED indicator near the bottom left corner of the controllers

printed circuit board (PCB) just above the BATTERY POSITIVE +

connector.

· Plug the yellow cable on the CM display into the six-conductor modular

RJ15 connector adjacent to the LED that you just removed.

· Align the faceplate and reinstall the screws.

If the LED must be replaced in the future, it will operate in either orientation,

except if replaced incorrectly, the color of the status LED will be reversed.

The connecting cable for the display is a six-conductor telephone cable with

modular type connectors (RJ15). Although any telephone-type cable will work,

the cables provided with the displays use stranded and tin plated wire for better

performance and longer life.

Remove LED (pull out)

36

Install Yellow DVM/C40

Cable

Figure 27

Remove LED and Install Cable

©2000 Xantrex Technology Inc.

Page 43

4.0 OPTIONS

Mounting the CM/R

The CM/R is a remotely-mounted digital LCD multimeter, which can be

permanently installed in a wall or cabinet. The unit can also be surfacemounted with relief behind it, and it can be located up to 1000 feet (305 meters)

from the C-Series controller itself. If the CMR appears inaccurate or unusual on

runs over 100 feet from the controller, remove the jumper located below the

voltage configuration pins on the back of the CM/R. This dims the LCD

backlight, reduces power consumption and improves meter accuracy.

©2000 Xantrex Technology Inc.

37

Page 44

5.0 OPERATION

Three-Stage Battery Charging

Battery voltage and current vary during the three-stage charging process

as follows.

BULK

During this stage, the batteries are charged at the bulk voltage setting and

maximum current output of the DC source. When the battery voltage reaches

the BULK voltage setting, the controller activates the next stage (absorption).

During the bulk charging process, the status LED (green) may blink from one to

five times before pausing. The more times it blinks consecutively, the closer the

battery voltage is to the BULK voltage setting.

ABSORPTION

During this stage, the voltage of the battery is held at the BULK voltage

setting until an internal timer has accumulated one hour. Current gradually

declines as the battery capacity is reached. During the ABSORPTION stage,

the status LED (green) blinks five times, then pauses and repeats.

FLOAT

During this stage, the voltage of the battery is held at the FLOAT voltage

setting. Full current can be provided to the loads connected to the battery

during the float stage from the PV array. When the controller has reached the

FLOAT stage, the status LED (green) will be solid green.

38

Charging

Started

0 volts

DC Current

0 amps

Time

DC Voltage

Bulk Stage

Increasing Voltage Constant Voltage Reduced Voltage

Max Amps

Constant Current Reducing Current Reduced Current

Absorption Stage Float Stage

Bulk Volts Setting

Absorption Time

Float Volts Setti n g

Figure 28

Charging Parameters

©2000 Xantrex Technology Inc.

3553-G04-00A

Page 45

5.0 OPERATION

)rotacidnIsutatSDELgnisU(EGATLOVYRETTAB

DEL

)edoMnoisreviD/egrahC(DELneerG

gnitteSTAOLFtayrettaB

gnitteSKLUBtayrettaB

)-(suniMgnitteSkluB )+(sulPgnitteSDVL

CDV52.0CDV05.0CDV00.1

CDV05.0CDV00.1CDV00.2

CDV57.0CDV05.1CDV00.3

57.0>

stlov21stlov42stlov84egatloVCDstlov21stlov42stlov84

05.1>

kluBwoleb

kluBwoleb

00.3>

kluBwoleb

SUTATS

NOsyawlA

sknilB5

sknilB4

sknilB3

sknilB2

knilB1

51.0>

DVLevoba

CDV51.0CDV03.0CDV54.0

CDV03.0CDV06.0CDV09.0

CDV54.0CDV09.0CDV53.1

54.0>

DVLevoba

03.0>

DVLevoba

09.0>

DVLevoba

)edoMlortnoCdaoL(DELdeR

)DVL=setunim6rof(gnitteSDVLtayrettaB

54.0>

DVLevoba

53.1>

DVLevoba

Battery Voltage LED Indications

Table 8

When battery voltage drops below the FLOAT setting for a cumulative

period of one hour, a new BULK cycle will be triggered. This typically occurs

each night. If the battery is full at the start of the day, it will receive an ABSORPTION charge for one hour and then be held at the FLOAT setting for the

remaining period of the day. Should the battery voltage drop below the FLOAT

setting for a cumulative period of one hour, another BULK and ABSORPTION

cycle will be initiated.

This three-stage charging process results in faster charging compared to

on-off relay type or constant voltage solid state regulators. Faster recharging

increases the performance of the system by storing more of the PV arrays limited

output. The final FLOAT voltage setting reduces battery gassing, minimizes

watering requirements and ensures complete battery recharging.

SEIRETTABROFSTNIOPTESTAOLFDNAKLUBLACIPYT

epyTyrettaBstloVkluBstloVtaolFssecorPegrahCgnizilauqE

sgnitteStluafeD

)noitisopkcolc'oenintasbonk(

yrettaBdicAdaeLleGdelaeSCDV1.41CDV6.31.rerutcafunamtlusnoC.dednemmocertoN

yrettaBdicAdaeLMGACDV4.41CDV4.31.rerutcafunamreproCDV5.51otegrahC

eniraMIVReerF-ecnanetniaMCDV4.41CDV4.31

etylortcelEdiuqiL,elcyC-peeD

yrettaBynomitnAdaeL

*yrettaBenilaklAeFiNrodaCiNCDV0.61CDV5.41.rerutcafunamtlusnoC.dednemmoceroN

CDV0.41CDV5.31)repmujlaunam(delbasiD

CDV6.41CDV4.31.rerutcafunamreproCDV5.51otegrahC

.dekcehc

.rosneserutarepmetyrettaballatsni,seirettabdelaeshtiwsmetsysrosnoitairaverutarepmettnacifingis

ebnaclevelretawfi-ssenetairporppadetimiL

.4ybnwohssgnittesehtylpitlum,smetsystlov-84roF.2ybnwohssgnittesehtylpitlum,smetsystlov-42roF.smetsystlov-21roferanwohsseulaV

Table 9

Typical Setpoints for Batteries

tesot,elpmaxeroF.draobtiucricehtnonwohsTAOLFdnaKLUBrofseulavehtotV2ddadna64Rpilctsumuoy,seirettabeFiNdnadaCiNroF*

htiwsnoitacilpparoF.erutarepmetmoortaseirettabroferaevobaseulaV.64RgnippilcretfaV0.41otbonkKLUBehttsujda,V0.61rofKLUBeht

©2000 Xantrex Technology Inc.

39

Page 46

5.0 OPERATION

Equalization (Non-Sealed Batteries Only)

Approximately every month, some batteries may need to be equalized.

Since the individual cells of the battery are not identical, some cells may not be

fully charged when the charging process is completed. If the batteries have

been left in a discharged condition for long periods of time, the plates will have

sulfates on them from the electrolyte. If the sulfate remains on the plates for an

extended period of time, it will harden and seal off a percentage of the plate

area, reducing the capacity of the battery. By equalizing the batteries before

the sulfate hardens, the sulfate is removed from the plates.

Batteries with liquid electrolyte may become stratified. Stratification

concentrates the sulfuric acid into the bottom of the cell while the top becomes

diluted. This corrodes the lower portion of the plates, reducing battery life.

Mixing of the electrolyte by the formation of gas bubbles during the equalization

process reduces stratification.

Two methods can be used to determine if a battery needs to be equalized.

If possible, measure the voltage of each individual cell while the battery is at rest

(not being charged or discharged), a variation of 0.05 volts between cells

indicates an imbalance exists. If the battery construction prevents measurement

of the individual cell voltages, use a hydrometer. A variation of 0.020 in the

specific gravity between cells is considered significant. Both conditions can be

corrected by an equalization charge.

A proper equalization charge will not damage a vented, liquid electrolyte

type battery. It may, however, cause significant electrolyte usage and require

that the battery be refilled with distilled water to the correct level. This may be

a problem with unattended systems in remote areas which do not receive

regular maintenance. Consult the battery manufacturer for their

recommendations.

CAUTION: EQUALIZATION SHOULD BE DONE ONLY ON VENTED (NOT

SEALED OR MAINTENANCE FREE) LEAD-ACID, LIQUID-ELECTROLYTE

BATTERIES. THE BATTERY MANUFACTURER SHOULD BE CONSULTED

BEFORE ATTEMPTING TO EQUALIZE AN Y OTHER BATTERY TYPE. ADD

CLEAN, DISTILLED WATER TO THE BATTERY FOLLOWING THE

EQUALIZATION PROCESS.

DC loads may need to be disconnected by turning off circuit breakers or

removing fuses before equalization to prevent damage by the required higher

voltages used in the equalization process.

CAUTION: IF THE BATTERIES ARE EQUIPPED WITH HYDROCAPS

(CATALYTIC GAS RECOMBINER CAPS), THEY SHOULD BE REMOVED

DURING THE EQUALIZATION PROCESS. IF HYDROCAPS ARE USED, YOU

SHOULD DISABLE AUTOMATIC EQUALIZATION TO PREVENT POSSIBLE

DAMAGE.

40

©2000 Xantrex Technology Inc.

Page 47

6.0 BATTERIES

Batteries

Batteries come in different sizes, types, amp-hour capacity, voltages and

chemistries. Here are a few guidelines that will help in battery selection, and

ensure that the batteries are properly maintained. The best source of the most

appropriate settings for the C-Series will be from the manufacturer or supplier of

the batteries.

Automotive Batteries

Automotive and truck batteries are designed for high cranking power not

deep-cycling. Do not use them unless no other battery type is available. They

simply will not last long in a cycling application.

Maintenance-Free Batteries

This type of battery is often sold as a RV or marine battery, but is rarely

appropriate for use with a PV system. They typically have an additional

reserve of electrolyte, but are vented. This is not the same as a sealed battery.

Deep-Cycle Batteries

Best suited for use with PV systems, this type of battery is designed to be

more deeply discharged before being recharged. Deep-cycle batteries are

available in many sizes and types. The most common is the vented liquid

electrolyte battery.

Vented batteries usually have battery caps. The caps may appear to be

sealed, but are not. The caps should be removed periodically to check the level

of electrolyte. When a cell is low, distilled water should be added after the

battery is fully charged. If the level is extremely low, add only enough distilled

water to cover the plates before recharging. The electrolyte volume increases

during the charging process and the battery will overflow if it is filled all of the

way up before recharging. Use only distilled water because impurities will

reduce battery performance.

A popular and inexpensive deep-cycle battery is the golf cart battery. It

is a 6-volt design, typically rated at 220 amp-hours. RV and marine deep-cycle

batteries are also popular for small systems. They are usually referred to as

Group 24 or Group 27 batteries and are rated at 80 to 100 amp-hours at

12volts. Many larger systems use L16 batteries, which are usually rated at

350amp-hours at 6-volts each. They are 17 inches high and weigh about

130pounds. 8D batteries are available with either cranking or deep-cycle

construction. Purchase only the deep-cycle version. The 8D is typically rated

at 220 amp-hours at 12 volts.

©2000 Xantrex Technology Inc.

41

Page 48

6.0 BATTERIES

Sealed Batteries

Another type of battery construction is the sealed gel cell. They do not

use battery caps. The electrolyte is in the form of a gel rather than a liquid,

which allows the batteries to be mounted in any position. The advantages are

no maintenance, long life (800 cycles claimed) and low self-discharge.

Absorbed glass mat (AGM) electrolyte batteries are also acceptable. Their

electrolyte is contained in mats between the battery plates.

Sealed batteries reduce the maintenance requirements for the system and

are good for remote applications. They are much more sensitive to the

charging process and can be ruined in as little as a day of overcharging.

NiCad and NiFe Batteries

The Trace C-Series is compatible with NiCad (nickel-cadmium) NiFe

(nickel-iron) and alkaline type batteries, which must be charged to a higher

voltage level to achieve a full charge. To use the C-Series with NiCad batteries,

remove the resistor labeled R46 in the middle of the C-Series circuit board by

cutting it. Avoid damage to neighboring components. This adds 2 volts to the

printed scale on the circuit board around the BULK and FLOAT potentiometers.

When NiCad mode is selected, the equalization process is disabled.

Adjust the BULK charge voltage to the setting recommended by the battery