Page 1

T240

Autotransformer

Installation and Operation Guide

ã2000 Trace Engineering P/N 975-0002-01-02 Rev. B 04/00

Page 2

©2000 Trace Engineering

Page 3

T240 Autotransformer

Table of Contents

Section Description Page

1. INTRODUCTION ..................................................................... 1

2. INSTALLATION .......................................................................2

3. OPERATION ......................................................................... 18

4. SERVICE INFORMATION .................................................... 19

5. SPECIFICATIONS ................................................................ 20

6. WARRANTY ..........................................................................21

The T240 Autotransformer .................................................. 1

Installation ........................................................................... 2

Required Tools ................................................................ 2

Mounting ......................................................................... 2

Wiring .................................................................................. 4

Service Crimps ................................................................ 4

Connection Points ........................................................... 5

Step-up Configuration ..................................................... 8

Deep Well Pump Wiring ..................................................9

Step-Down Configuration .............................................. 10

Step-Down Connection of Stacked-pair Inverters ......... 11

Generator Output Balancing Autotransformer ..............12

Single 120 volt AC Load ........................................... 12

Dual 120 volt AC Loads ............................................ 13

Optional Circuit Breakers .............................................. 16

Wiring Check ................................................................. 17

©2000 Trace Engineering

i

Page 4

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed

during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation and

operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse existe dans cette

zone.

Faire preuve dextrême prudence lors de la réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or operation of

the unit. Follow these instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou lutilisation

de lunité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions de près.

All electrical work must be done in accordance with local, national,

and/or international electrical codes.

Before installing or using this device, read all instructions and cautionary

markings located in the T240 and the manual.

Do not expose this unit to rain, snow or liquids of any type. This product is

designed only for indoor mounting.

To reduce the chance of short-circuits when installing or working with this

product, use insulated tools.

Remove all jewelry such as rings, bracelets, necklaces, etc., while installing

this system. This will greatly reduce the chance of accidental exposure to

live circuits.

ii

©2000 Trace Engineering

Page 5

This product contains no user-serviceable parts. Do not attempt to repair

this unit.

Do not mount this device in unventilated enclosures or in an engine

compartment.

Protect the device from splashing when used in vehicular applications.

To reduce risk of electric shock, disconnect all wiring before attempting any

maintenance or cleaning.

Additional AC disconnects may be required as part of the system installa-

tion. Consult local and national electrical code requirements.

Over-current Protection, provided by a 25 amp circuit breaker, protects the

AC input/output wiring. This circuit breaker is branch circuit rated and has a

10,000 AIC rating, suitable for residential and commercial applications.

This unit is designed to be horizontally wall mounted.

The AC input and output neutral conductors are not connected (bonded) to

the chassis.

The AC input and output HOT conductor are not isolated from each other.

The chassis housing of the T240 must be connected to a permanent

grounding system as required by the National Electric Code, ANSI/NFPA 70-

1996. This is the responsibility of the system installer. A grounding terminal

strip is provided for connection of equipment grounding conductors.

UL rated as an indoor enclosure.

UL listed for sale in the U.S. and Canada under Photovoltaic Power System

Accessaries (UL1741) and Canadian standard for general use power

supplies (CSA C22.2 No. 107.1-95).

SAVE THESE INSTRUCTIONS

©2000 Trace Engineering

iii

Page 6

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation,

operation, use and maintenance of the unit are beyond the control of Trace

Engineering, the Company does not assume responsibility and expressly

disclaims liability for loss, damage, or expense arising out of or any way

connected with such installation, operation, use, or maintenance.

iv

©2000 Trace Engineering

Page 7

1.0 INTRODUCTION

The T240 Autotransformer is designed to step-up 120 volt AC to 240 volt AC

or to step-down 240 volt AC into two 120 volt AC circuits. The T240 contains

two identical windings that can be used to step-up, step-down, or balance the

output voltage of an AC power source (such as an inverter, generator or

conventional AC source) to an AC load. The unit is sized to take advantage of

Trace Engineerings inverter/charger line. The exceptionally high efficiency of

the T240 Autotransformer makes it ideal for voltage conversion from an inverter,

generator or conventional AC source.

The T240 Autotransformer utilizes a highly-efficiency transformer constructed

of high temperature materials and M-6 grade steel laminations, meeting UL

Class-H standards.

The unit is housed in a powder coated, steel enclosure, suitable for indoor

installations and contains knockouts for 3/4 inch and 1 inch conduit connections

and additional breakers. One 25 amp dual breaker is supplied with the T240.

Up to six additional Square D QOU breakers can be added for additional input/

output wiring protection and control.

©2000 Trace Engineering

Figure 1

T240 Autotransformer

1

Page 8

2.0 INSTALLATION

Installation

Required Tools

Wire strippers

Phillips screw driver

Slotted screw driver

Torque wrench

Mounting

Place the T240 Autotransformer in a convenient location, close to the input

source (inverter, generator or utility). The T240 must be mounted horizontally

on a flat surface (such as a wall) in a clean, dry environment. Do not mount the

autotransformer where it will be exposed to the weather or in a wet location.

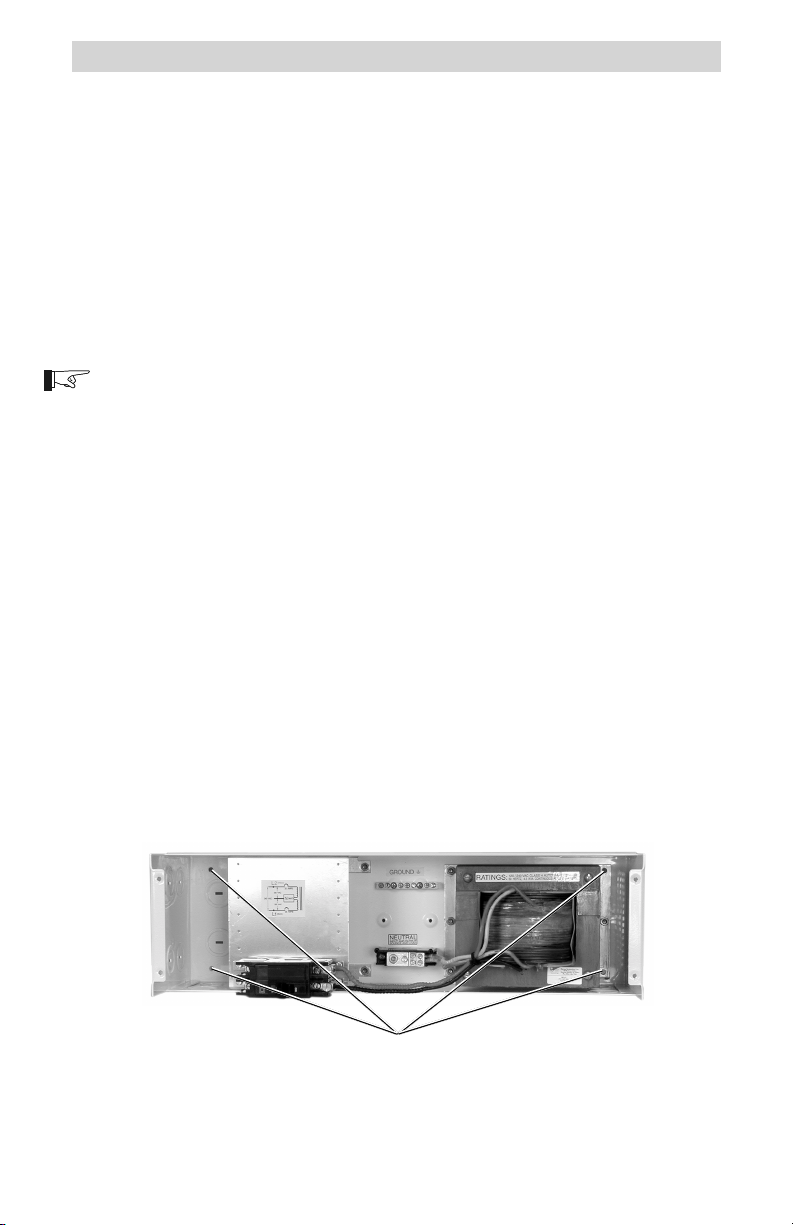

NOTE: The T240 weighs approximately 50 pounds. Use appropriate wall

anchors or backing material (plywood, 2 x 4s, etc.) that will support its weight.

Procedure:

Use a level and mark the location for mounting the unit on the wall.

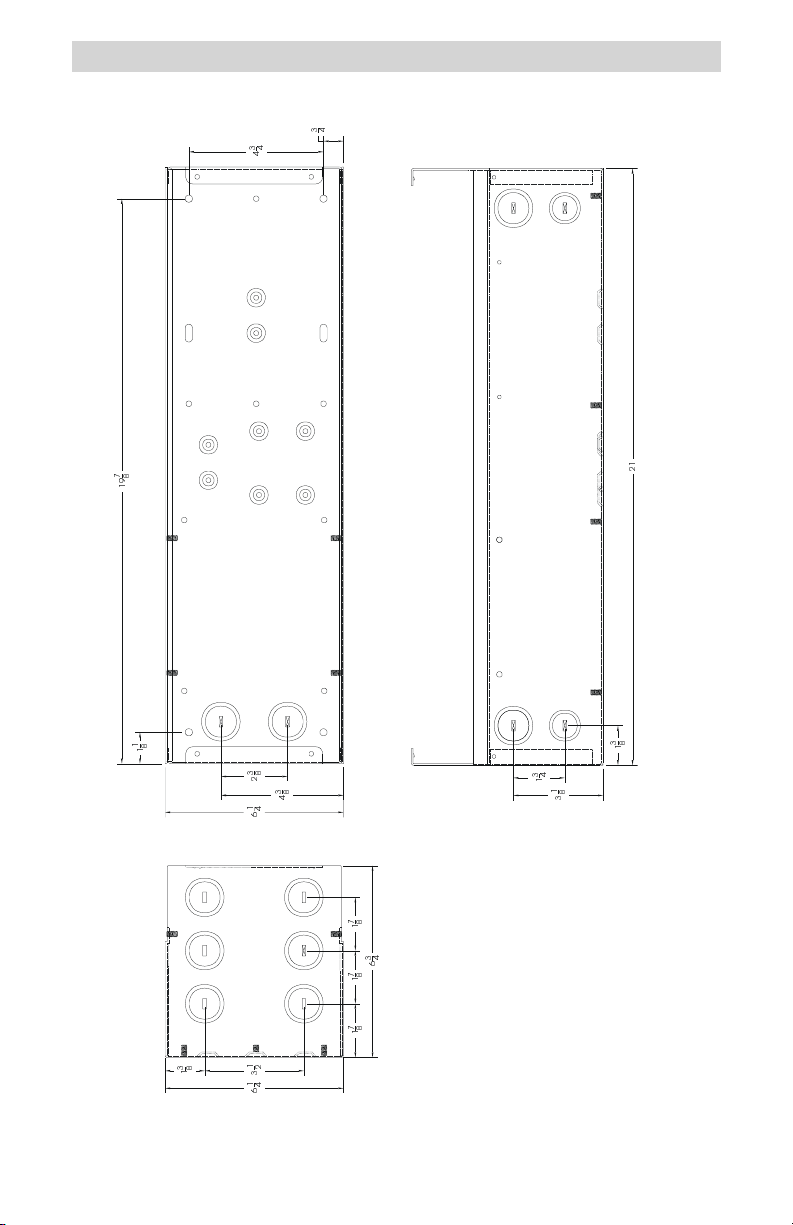

Measure out the four mounting screw holes according to Figure 3.

Drill out the mounting holes using a #18 (0.170 inch) drill bit.

Remove the front cover of the autotransformer by removing the four

Phillips screws. Do not lose the screws!

Use a #10 x 3/8 (or 1/2) inch long screw and washer (and appropriate

anchors if necessary) and mount the autotransformer securely to the wall

or backing material (plywood, 2 x 4s, etc.).

Remove the appropriate knockouts for the conduit. Install the conduit

between the autotransformer and input source (inverter, generator, etc.)

and output to load. Use separate conduit for input and output wiring.

Mounting Holes

Figure 2

Mounting Holes

2

©2000 Trace Engineering

Page 9

2.0 INSTALLATION

Figure 3

Installation Drawing

©2000 Trace Engineering

3

Page 10

2.0 INSTALLATION

Wiring

WARNING: WIRING SHOULD BE PERFORMED ONLY BY QUALIFIED

PERSONS.

WARNING: BEFORE WIRING THE AUTOTRANSFORMER, ENSURE THAT

ALL SOURCES OF POWER ARE DISCONNECTED. NEVER WORK ON A

LIVE CIRCUIT.

CAUTION: THE CONFIGURATION OF THE AUTOTRANSFORMER IS FOR

STEP-UP, STEP-DOWN OR CURRENT BALANCING. IT DOES NOT

PROVIDE ISOLATION BETWEEN INPUT AND OUTPUT. DO NOT USE THE

AUTOTRANSFORMER AS AN ISOLATION DEVICE.

NOTE: All source connections (inverter, generator or utility) are connected to

the left-hand side of the installed circuit breaker (see illustrations). All loads

connect to the service crimp on the right-hand side of the breaker.

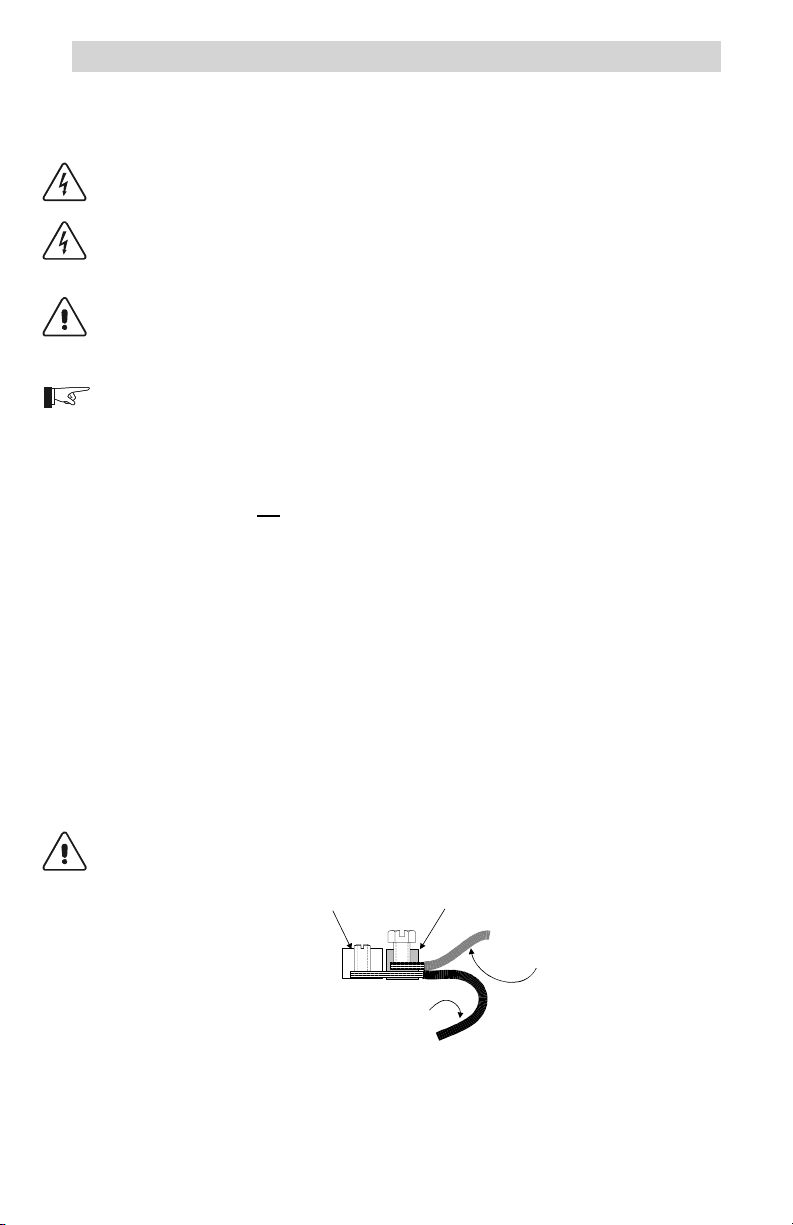

Service Crimps

The service crimps provide a convenient means to connect the

autotransformer. Do not use the screw terminals on the breakers for making

connections. Do not remove factory wiring.

Pull back the insulation on the TRANSFORMER wire so it is exposed

inside the service crimp.

Strip off approximately 1/2 inch of the insulation from the wire to be

installed and insert the bare wire into the crimp.

Slide the crimp up to the circuit breaker terminal as far as it will go.

Place the wire in the crimp and ensure the existing wires insulation is fully

exposed. Torque the crimp screw to 45 inch/pounds.

After torquing, ensure the service crimp is tight on both wires and is not

able to twist or be moved.

CAUTION: UNUSED SERVICE CRIMPS SHOULD BE TIGHTENED TO THE

EXISTING WIRE AND TAPED, SO IT CAN NOT SHORT TO OTHER

TERMINALS OR THE CASE.

Breaker Lug

Existing Factory Wiring

Service Crimp

975-C00-004

Added

LOAD

Wire

Figure 4

Installation Drawing

4

©2000 Trace Engineering

Page 11

2.0 INSTALLATION

Connection Points

The connection points for input/output wiring is as follows:

All 240 volt AC (input or output) wires connect to the left-hand side of the

breaker, points A and C (Figures 6 and 7).

All 120 volt AC wires connect to the service crimps located on the breaker,

points B and D (Figures 6 and 7).

All neutral wires connect to the NEUTRAL block in the T240.

All ground wires connect to the GROUND block in the T240.

The ganged circuit breaker used in the T240 opens both circuit breakers if

either one receives a current draw in excess of its rating (i.e., 25 amps).

Any exceptions are noted in the procedure.

NOTE: Due to continued product improvement, parts availability, etc.,

photographs used in this manual may vary slightly from actual current

production models.

GROUND block NEUTRAL block

©2000 Trace Engineering

240 Volt AC

Input/Output

Factory Wiring DO NOT

REMOVE OR ADD WIRES

TO THESE TERMINALS!

Figure 5

Step-up Configuration Connections

120 Volt AC Input/Output

service crimps

5

Page 12

2.0 INSTALLATION

Connection Identification Points (continued)

Figures 6 and 8 identify the wiring points in the T240 Autotransformer:

A Only 240 volt AC (L1) input/output connections are made on this

B This is the service crimp on the lower ganged breaker. Only 120

C Only 240 volt AC (L2) input/output connections are made on this

D This is the service crimp on the upper ganged breaker. Only

GROUND This is the ground block contained in the T240. All ground wires

NEUTRAL This is the neutral block contained in the T240. All neutral wires

circuit breaker terminal.

volt AC input/output wires connect to this service crimp.

circuit breaker terminal.

120 volt AC input/output wires connect to this service crimp.

connect to this block for both source and load.

connect to this block for both source and load (except as noted in

the procedures).

GROUND

C

A

6

D

B

Figure 6

Connection Point Identification

NEUTRAL

©2000 Trace Engineering

Page 13

2.0 INSTALLATION

D

Neutral Block

B

Service Crimp

975-S00-002A

Service Crimp

L2

L1

Upper Breaker

C

NEUTRAL

Lower Breaker

A

GROUND

Ground Block

Figure 7

Connection Point Identification Schematic

©2000 Trace Engineering

7

Page 14

2.0 INSTALLATION

Step-up Configuration

This configuration allows for a 240 volt AC load to be supplied from a

120 volt AC input source. The voltage output of the autotransformer doubles

(from 120 to 240 volts AC) and the total output current available is one half.

Procedure

The wire terminals accept wire sizes from #14 AWG to #2 AWG. Use the

proper size wire for the load connected.

120 Volt AC Input (source)

NOTE: Refer to the previous instructions on connecting wires to the service

crimp.

Connect the 120 volt AC HOT wire (from an inverter, generator or

utility) to service crimp (point B) of the breaker as shown in Figure 8.

Connect the neutral wire (from an inverter, generator or utility) to the

NEUTRAL block in the autotransformer.

Connect the ground wire (from an inverter, generator or utility) to the

GROUND block in the autotransformer.

240 Volt AC Outputs (load)

Connect a black wire from the L1 connection on the breaker (point A),

to the loads L1 connection.

Connect a red wire from the L2 connection on the breaker (point C),

to the loads L2 connection.

Connect a white wire from the NEUTRAL block in the autotransformer

to the loads neutral connection.

Connect a green wire from the GROUND block in the autotransformer

to the loads ground connection.

L2

OUT

D

G

120 VAC

Source

Ground

C

N

HOT

G

G

A

OUT

N

L1

N

NEUTRAL

Service

Crimp

B

Service Crimp

L2

N

240 VAC

Load

G

L1

975-S00-003

Figure 8

Step-up Configuration Schematic

8

©2000 Trace Engineering

Page 15

2.0 INSTALLATION

Deep Well Pump Wiring

This wiring configuration allows the control switch for the pump to be

connected between the 120 volt AC source and the HOT input of the T240. In

this arrangement, there is no transformer idle power consumption when the

switch is open and the pump is not running. The control switch can be either a

float, pressure or manual type.

Procedure

120 Volt AC Inputs (source)

NOTE: Refer to the previous instructions for connecting wires to the service

crimp on page 4 and Figure 4.

Connect the pumps control or pressure switch to the service crimp

(point B) on the lower breaker.

Connect the 120 volt AC HOT wire (from an inverter, generator, or

utility) to the free end of the control switch.

Connect the neutral wire (from an inverter, generator or utility) to the

NEUTRAL block in the autotransformer.

Connect the ground wire (from an inverter, generator or utility) to the

GROUND block in the autotransformer.

240 Volt AC Outputs (load)

Connect a black wire from the L1 connection on the breaker (point A),

to the pumps L1 connection.

Connect a red wire from the L2 connection on the breaker (point C),

to the pumps L2 connection.

Connect a white wire from the NEUTRAL block in the autotransformer

to the pumps neutral connection.

Connect a green wire from the GROUND block in the autotransformer

to the pumps ground connection.

Ground

G

Control Switch Wiring for Deep Well Pump

©2000 Trace Engineering

120 VAC

Source

G

D

N

NEUTRAL

N

Service

Crimp

Service

Crimp

B

Control Switch

L2

L2

240 VAC

G

Deep

Well

N

Pump

L1

L1

975-S00-005

L2

OUT

N

HOT

C

A

L1

OUT

Figure 9

9

Page 16

2.0 INSTALLATION

240 Volt AC Source120 Volt AC to Loads (Step-down Configuration)

This configuration allows a 120 volt AC load to be supplied from a

120/240 volt AC input source such as a utility grid. The voltage output of the

autotransformer halves (from 240 to 120 volts AC) and the total output current

available for the 120 volt AC output doubles. This arrangement is useful for

splitting the current of a battery charger between each leg of the 240 volt AC

source, reducing losses in the wiring. This is especially important in long cable

runs or when charging from a 120/240 volt AC output generator.

240 Volt AC Input (source)

Connect the L1 AC HOT wire (from the utility grid) to point A on the

lower breaker as shown in Figure 10.

Connect the L2 AC HOT wire (from the utility grid) to point C on the

upper breaker as shown in Figure 10.

Connect the neutral wire (from the utility grid) to the NEUTRAL block

in the autotransformer.

Connect the ground wire (from the utility) to the GROUND block in the

autotransformer.

120 Volt AC Output (load)

Connect a black wire from the service crimp (point B), to the loads

HOT connection.

NOTE: Refer to the previous instructions located on page 4 and Figure 4 for

connecting wires to the service crimp.

10

Connect a white wire from the NEUTRAL block in the autotransformer

to the loads neutral connection.

Connect a green wire from the GROUND block in the autotransformer

to the loads ground connection.

D

L2

120/240 VAC

Source

(grid)

G

L2

L1

*NOTE: For 240 VAC only source

installations, the neutral wire is not

N*

Ground

G

G

G

required.

120 VAC

LOAD

(inverter/

charger)

C

A

N

120 VAC HOT

OUTPUT TO LOAD

N*

NEUTRAL

N

B

975-S00-006

Service

Crimp

Service

Crimp

L1

Figure 10

Step-down Configuration Schematic

©2000 Trace Engineering

Page 17

2.0 INSTALLATION

Step-down Connection of Stacked-pair Inverters

The T240 can also be used to step down the voltage from a stacked pair of

DR or SW Series inverters. In this configuration, the neutral of the inverters

must be isolated from the neutral block of the T240 Autotransformer, or the

inverters may over-current trip when they synchronize to an AC generator. This

configuration may not be in compliance with the NEC. Consult your local and

national electrical codes for requirements. This configuration provides double

the output current at 120 volts AC.

Procedure

Inverter Inputs to T240

Connect the HOT output of Inverter #1 to point A on the lower

breaker.

Connect the HOT output of Inverter #2 to point C on the upper

breaker.

Connect the ground wire from the inverters to the GROUND block in

the T240.

T240 Output to 120 Volt AC Load

Connect the ground wire from the load to the GROUND block in the

T240.

Connect the neutral wire from the load to the NEUTRAL block in the

T240.

Connect the HOT wire (120 volt AC) from the load to the service

crimp on lower breaker (point B).

Connect the inverters as specified in the inverters operation manual

for stacked (120/240 volt AC) operation.

HOT

I

In

120 V ac Output

L2

240 VAC

N

Generator

G

L1

HOT

In

Step-down Configuration Schematic (Dual Inverters)

©2000 Trace Engineering

nverter #2

I

nverter #1

120 V ac Output

HOT

Neutral

Ground

HOT

Out

Neutral

Ground

Out

HOT

N

G

HOT

N

G

Figure 11

240 VAC

L2

D

L2

Service

C

L1

A

G

Ground

N

G

120 VAC

LOAD

(high

current)

120 VAC HOT

OUTPUT TO LOAD

G

NEUTRAL

N

B

975-S00-007A

Crimp

Service

Crimp

L1

11

Page 18

2.0 INSTALLATION

Generator Output Balancing Autotransformer

Single 120 Volt AC Load

This configuration allows the 120/240 volt AC generator output to be

equally divided (balanced) between its L1 and L2 outputs. In this example, the

generator is using both its L1 and L2 outputs to supply a high current 120 volt

AC load. Balancing the generator in this way improves generator performance

and life, plus results in higher battery charge rates.

Procedure

Connect the L1 output of the generator to the lower breaker (point A).

Connect the L2 output of the generator to the upper breaker (point C).

Connect the ground wire from the generator to the T240 GROUND block.

Connect the neutral wire from the generator to the T240 NEUTRAL block.

Connect the inverters 120 volt AC input to the service crimp on the lower

breaker (point B).

Connect a ground wire from the inverter to the GROUND block in the

T240.

Connect a neutral wire from the inverter to the NEUTRAL block in the

T240 .

Follow the instructions for wiring the inverter to the loads as specified in

the inverters operation manual.

12

©2000 Trace Engineering

Page 19

2.0 INSTALLATION

D

L2

C

Service

Crimp

L2

120/240 VAC

Generator

G

L1

G

Ground

G

N

N

A

NEUTRAL

N

Service

Crimp

B

Inverter/Charger

HOT In

Neutral In

Ground

Neutral Out

HOT Out

L1

120 VAC Loads

HOT

Neutral

Ground

975-S00-008

Figure 12

Generator Output Balancing (single 120 volt AC load)

NOTE: The ability of the T240 to balance the load depends upon the generators

windings and voltage regulation it receives on each leg. If the voltages are not

equal, or if there are other loads on the legs, then the currents in each leg will not

be equal.

To absolutely equal the load, disconnect the neutral connection of the T240 to the

generator. This un-bonds the output neutral from ground. This neutral should be

considered as a HOT wire and treated as such. This configuration may not be

compliant with the NEC, but will balance the load on the 240 volt AC side.

©2000 Trace Engineering

13

Page 20

2.0 INSTALLATION

Generator Output Balancing Autotransformer

Dual 120 Volt AC Loads

This configuration allows the 120/240 volt AC generator output to be

equally divided (balanced) between its L1 and L2 outputs. In this case, the

generator is using both its L1 and L2 outputs to supply two separate 120 volt

AC loads. If one leg of the generator is pulling a heavier load than the other,

both legs equally divide the current, thereby balancing the generators output.

Procedure

240 Volt AC Inputs From the Generator

Connect the L1 (HOT) output of the generator to the terminal on the

lower breaker (point A).

Connect the L2 (HOT) output of the generator to the terminal on the

upper breaker (point C).

Connect the ground wire from the generator to the GROUND block in

the T240.

Connect the neutral wire from the generator to the NEUTRAL block in

the T240.

120 Volt AC Outputs to Inverters or Loads

Connect the 120 volt AC input wire for Inverter #1 to the service crimp

(point B) on the lower inverter.

Connect the ground wire from the inverter #1 to the GROUND block

in the T240.

14

Connect the neutral wire from Inverter #1 to the NEUTRAL block in

the T240.

Connect the 120 volt AC input wire for Inverter #2 to the service crimp

(point D) on the upper inverter.

Connect the ground wire from the inverter #2 to the GROUND block

in the T240.

Connect the neutral wire from Inverter #1 to the NEUTRAL block in

the T240.

Connect the inverters outputs as specified in the inverters operation

manual.

©2000 Trace Engineering

Page 21

120/240 VAC

Generator

G

2.0 INSTALLATION

Inverter/Charger

HOT 120 VAC

N

G

L2

L2

L2

N

L1

G

Ground

G

G

C

A

L1

D

Service

Crimp

N

NEUTRAL

N

N

Service

Crimp

L1

B

HOT 120 VAC

N

G

or Loads

HOT In

Neutral

Ground

Inverter/Charger

or Loads

HOT In

Neutral

Ground

Generator Output Balancing (dual 120 volt AC load)

©2000 Trace Engineering

975-S00-009

Figure 13

15

Page 22

2.0 INSTALLATION

Optional Circuit Breakers

Up to six additional Square D QOU circuit breakers can be installed in the

T240 enclosure. Front panel knockouts and predrilled holes provide for easy

mounting of additional breakers.

The example below shows these additional breakers used to protect and

control six 120 volt AC loads. Different circuit configurations can be arranged

depending upon your powering needs.

N

HOT

240 VAC

Source

G

GROUND

G

120 VAC Load

120 VAC Load

L2

D

C

L2

NEUTRAL

B

A

L1

L1

120 VAC Load

120 VAC Load

120 VAC Load

120 VAC Load

G

N

HOT

G

HOT

N

G

HOT

N

G

HOT

N

G

HOT

N

G

Step Down Arrangement Using Optional Breakers

Figure 14

NOTE: Provisions for connecting the additional neutral wires may need to be

added.

NOTE: The T240 has not been listed with UL with additional breakers installed.

16

©2000 Trace Engineering

975-S00-010

Page 23

2.0 INSTALLATION

Wiring Check

Before powering the T240 Autotransformer, recheck all wiring and ensure

it is connected to the proper terminals of the breaker or service crimps. Check

that the ground and neutral connections are properly wired and tight. Use the

schematics in this manual to trace the wire connections from the source to the

T240 and to the load.

After all the wiring has been checked, install the front cover and secure it

with the four Phillips screws removed in the beginning of the installation.

©2000 Trace Engineering

17

Page 24

3.0 OPERATION

Apply power from the source to the T240 Autotransformer.

Switch the L1/L2 breaker to ON. The loads are now energized by the

T240.

NOTE: The switch on the lower breaker controls both breakers. If either breaker

receives an over-current condition, both breakers will trip.

If additional branch circuit breakers are installed, switch them to ON if

desired.

L1/L2 Circuit Breaker

18

Figure 15

Circuit Breaker Location

©2000 Trace Engineering

Page 25

4.0 SERVICE INFORMATION

Trace Engineering takes great pride in its products and makes every effort to

ensure your unit fully meets your independent powering needs.

If your product needs repair, contact our Service department at: (360) 4358826 ext. 2223 to obtain an RMA# and shipping information; or fax this page with

the following information to: (360) 474-0616 or e-mail to:

tracewarranty@traceengineering.com.

Please provide:

Model Number: ________________________________________

Serial Number: (if applicable) _____________________________

Purchase Date: ________________________________________

Problem: _____________________________________________

_____________________________________________________

_____________________________________________________

Include a telephone number where you can be reached during business

hours and a complete return shipping address (P.O. Box numbers are not

acceptable).

Name: _______________________________________________

Address: _____________________________________________

City: _________________________________________________

State / Province: _______________________________________

Zip / Postal Code: ______________________________________

Phone: ( ) _________________________________________

Country: _____________________________________________

Register On-line

On-line warranty registration is available at: www.traceengineering.com/technical/

warranty.

visit our website at: www.traceengineering.com

©2000 Trace Engineering

19

Page 26

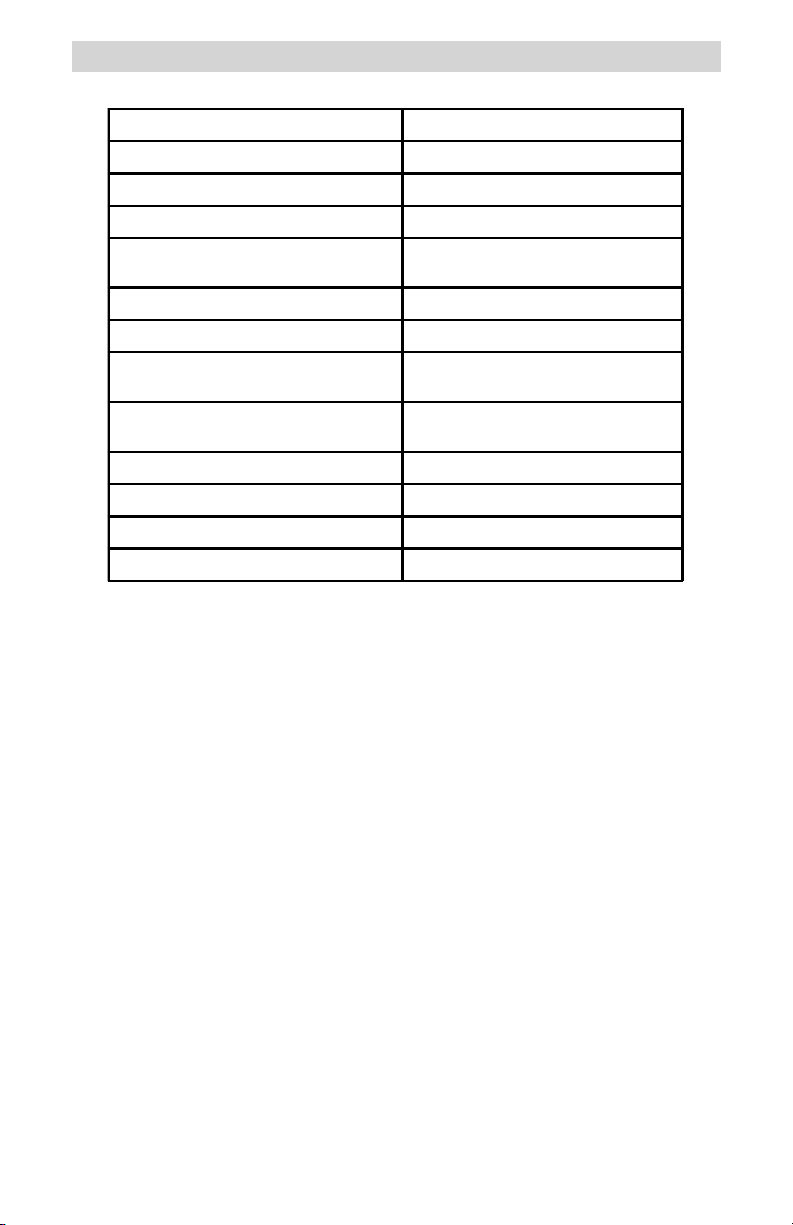

5.0 SPECIFICATIONS

Total P ow er R ating

Input/Output Voltage

Input/Output Frequency

Idle Power Consumption

Input/Output Circuit Breaker Rating

Weight

Shipping Weigh t

Dimensions

Enclosure

Hookup Wire Size

Conduit Sizes

Insertion Loss

Approvals

Specifications @ 25 °C

Specifications subject to change without notice

3900 VA continuous

120/240 volts AC ± 10%

60 Hz

< 12 W (typical)

25 A 2 pole Square D QOU Branch

Circuit Rated/10,0 00 AIC

39.4 lb (17.9 kg)

43.7 lb (19.8 kg)

6.3" H x 21" W x 7.0" D

(16 cm x 53.3 cm x 17.8 cm)

Indoor, ventilated, steel chassis,

powder coated white

#14 AWG to #2 AWG

Knockouts for 3/4" and 1" conduit

< 4 VAC at 3900 VA

UL1741, CSA C22.2 No. 107.1-95

20

©2000 Trace Engineering

Page 27

6.0 WARRANTY

Limited Warranty

Trace Engineering warrants its power products against defects in materials and

workmanship for a period of two (2) years from the date of purchase, established by

proof of purchase or formal warranty registration, and extends this warranty to all

purchasers or owners of the product during the warranty period. Trace does not

warrant its products from any and all defects:

arising out of material or workmanship not provided by Trace Engineering or

its Authorized Service Centers;

when the product is installed or exposed to an unsuitable environment as

evidenced by generalized corrosion or biological infestation;

resulting from abnormal use of the product or use in violation of the instructions;

in components, parts, or products expressly warranted by another manufacturer.

Trace Engineering agrees to supply all parts and labor to repair or replace

defects covered by this warranty with parts or products of original or improved design,

at the company's option. Trace Engineering also reserves the right to improve the

design of its products without obligation to modify or upgrade those previously

manufactured. Defective products must be returned to Trace Engineering or its

Authorized Service Center in the original packaging or equivalent. The cost of

transportation and insurance on items returned for service is the responsibility of the

customer. Return transportation (UPS Ground or equivalent) as well as insurance on

all repaired items is paid by Trace Engineering.

All remedies and the measure of damages are limited to the above. Trace

Engineering shall in no event be liable for consequential, incidental, contingent, or

special damages, even if Trace Engineering has been advised of the possibility of

such damages. Any and all other warranties, expressed or implied, arising by law,

course of dealing, course of performance, usage of trade or otherwise, including, but

not limited to, implied warranties of merchantability and fitness for a particular

purpose, are limited in duration for a period of two (2) years from the original date of

purchase.

Some states or counties do not allow limitations on the term of an implied

warranty, or the exclusion or limitation of incidental or consequential damage, which

means the limitations and exclusions of this warranty may not apply to you. Even

though this warranty gives you specific legal rights, you may also have other rights

which vary from state to state.

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

©2000 Trace Engineering

21

Page 28

Page 29

Page 30

Page 31

Page 32

5916 - 195th Street N.E., Arlington, WA 98223 Phone: (360) 435-8826 Fax: (360) 435-2229

visit our website at: www.traceengineering.com

Loading...

Loading...