Page 1

USER MANUAL OUTBOARD MOTOR BRACKETS

Aluminum Outboard Motor Brackets - Installation and Operating Instructions

Models T10050, T10051, T10052 and Quick Connect/Adaptor Plate T10053

CAUTION

Do not exceed the bracket’s HP or weight limits. Read instructions completely before starting assembly.

Motor bracket must remain in the “UP” position throughout installation. DO NOT operate motor

bracket unless motor is installed on bracket. This bracket is under spring tension. Exercise caution

when installing and operating.

INSTALLATION INSTRUCTIONS

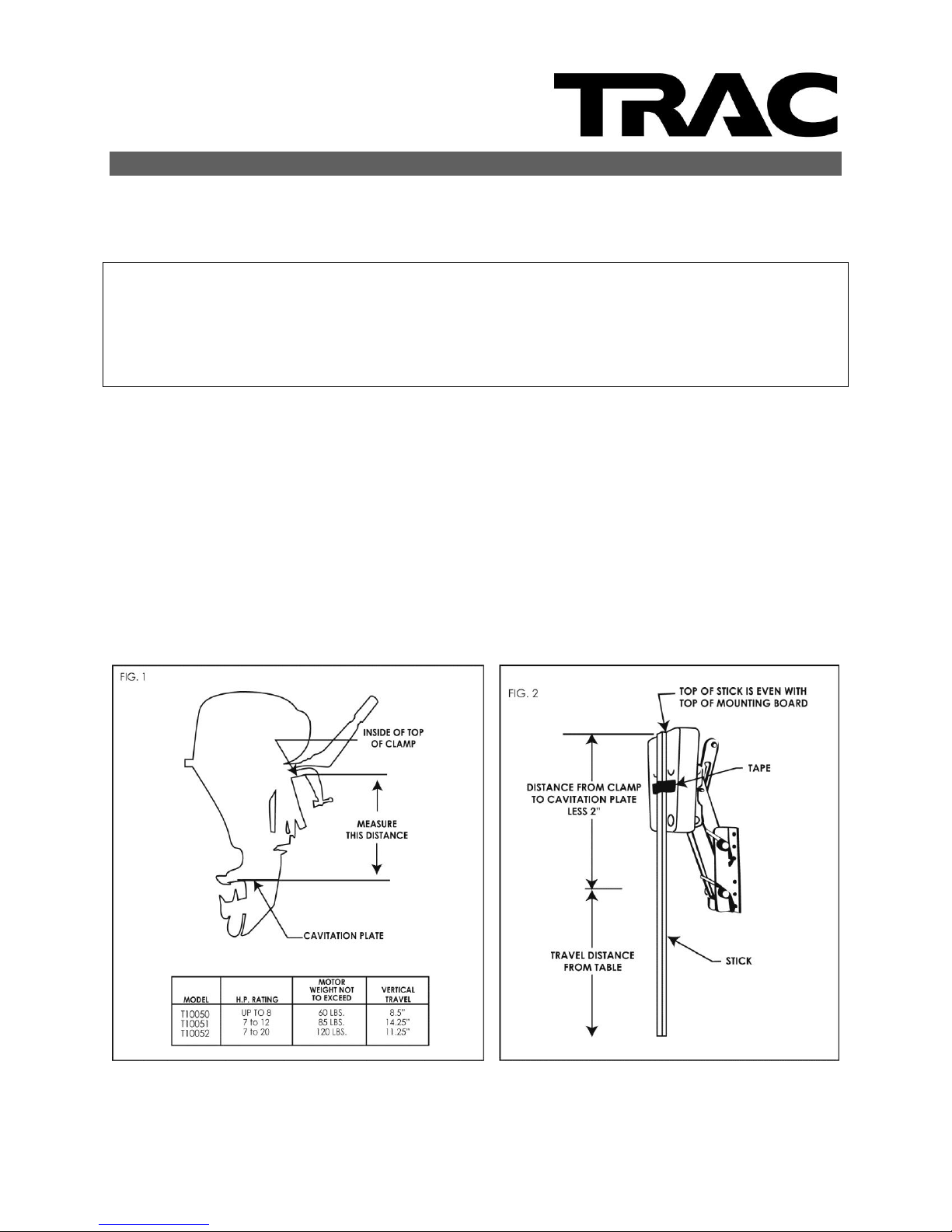

Refer to Figures 1 and 2

Measure the distance on your outboard motor between the cavitation plate and the upper inside edge

of the transom clamp. Add the total travel distance of your model bracket from the table in figure 1.

Then subtract 2 inches.

(Measure clamp to cavitation plate) add (bracket’s vertical travel) subtract 2” = _________

Cut a stick to this length and tape it to the center of the bracket board so that the stick and board are

flush at the top edge of the board as shown in figure 2.

Page 2

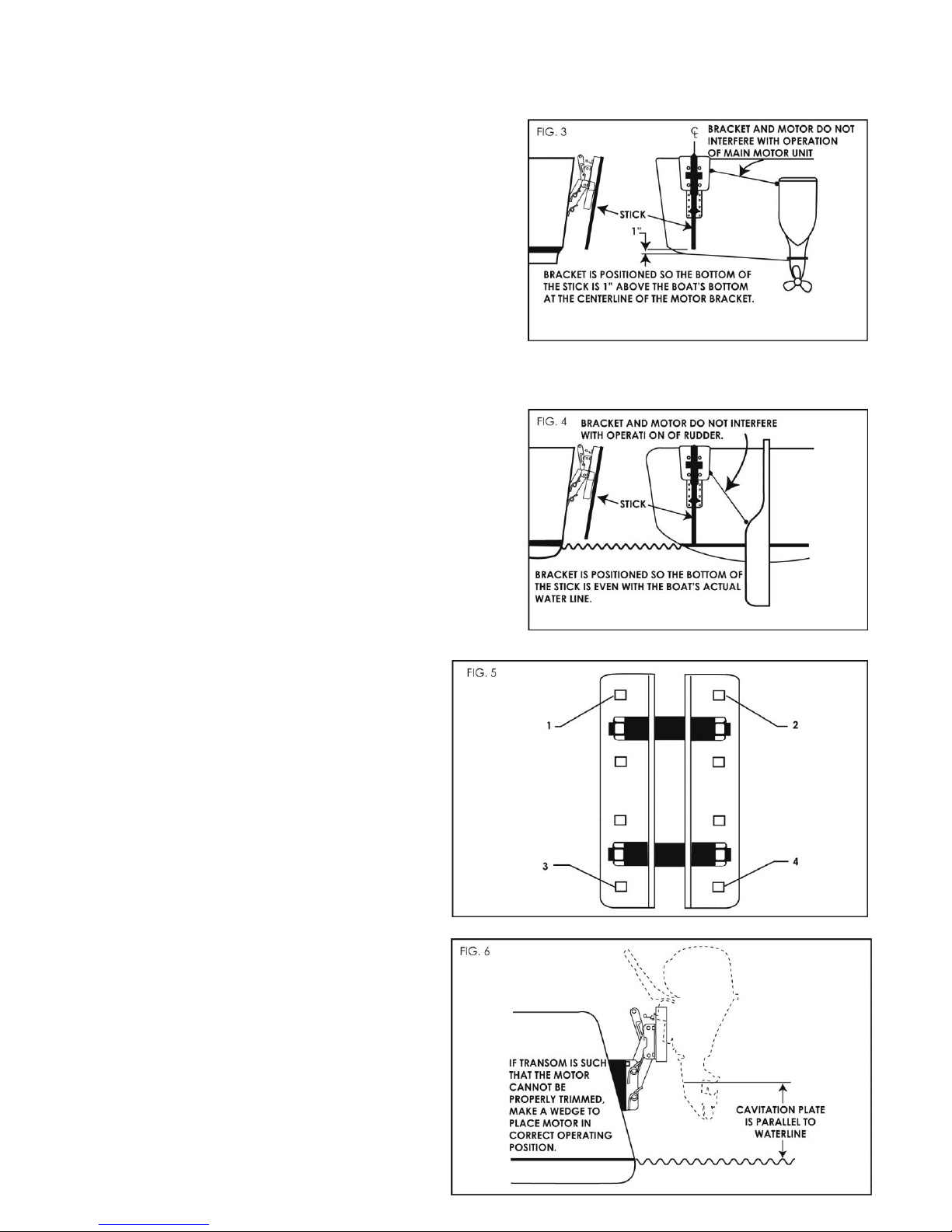

Refer to Figure 3

Choose the most appropriate side of your transom for

installing the bracket. Position your bracket so it won’t

interfere with the turning operation of your primary

motor, rudder, or anything else installed on your boat’s

transom.

Power Boats – Position the outboard motor bracket on

the transom with the mounting flanges flat against the

transom. Position the bracket so the bottom of the stick

is one inch above the boat’s bottom.

Refer to Figure 4

Sailboats - Position the outboard motor bracket on the

transom with the mounting flanges flat against the

transom. Position the bracket so the bottom of the stick

is even with the boat’s waterline.

Refer to Figure 5

Alter the bracket has been properly

positioned, mark the upper and lower bolthole locations using the bracket as a template

on your transom. Drill the four marked holes

with a 3/8" drill bit, making sure to hold the

drill at right angles to the transom.

Refer to Figure 6

Check the angle of the transom on your boat

and determine it the motor to be used can be

trimmed so the cavitation plate is parallel to

the waterline. lf not make a wedge shaped

spacer out of suitable material.

Page 3

Refer to Figure 7

If the transom is less than 2" thick, a backing

plate should be installed on the inside of the

transom for greater needed rigidity. Attach

your motor bracket to the transom by coating

the flat surfaces of the mounting flanges, the

backing plate, and both sides of the drilled

holes with a marine adhesive/sealant. Secure

the bracket to the transom with the supplied hardware as illustrated. The bracket is now ready to

receive the outboard motor.

OPERATING INSTRUCTIONS

To lower the bracket bear down on motor and release locking lever by pushing the handle towards the

mounting board, allowing the guide pin to slide in its safety groove. The handle will snap locked when

fully extended in the "up" or "down” position. The bracket springs counter balance most of the motor

weight; however, a slight push or lift is necessary to raise or lower the motor.

ALWAYS LOWER MOTOR SLOWLY. All four arms on the bracket should be tight, but not too much to

prevent smooth up and down action.

CAUTION! IMPORTANT GUIDELINES:

1. Install motor bracket in “up” position.

2. Always remove your motor from the bracket when trailering. Failure to do so could result in

damage to boat, motor and bracket.

3. Do not exceed the stated motor HP rating or weight.

4. Always use a safety cable to connect the motor to boat.

5. Operate motor at low speed.

6. Avoid turning motor at full throttle, refrain from sharp turns.

7. Operate motor in lowest position possible for best performance.

8. Never raise or tilt motor when in use.

9. Keep pivoting bolts greased to insure smooth operation.

IMPORTANT RECOMMENDATIONS

A lubricant coating on all bolts and nuts will increase corrosion resistance. Keep pivot points lubricated.

Remove your motor from the bracket when trailering your boat. Use a safety cable when operating

your motor. If a spacer is used, keep it sealed to increase longevity.

Page 4

MODEL T10053 ADAPTER PLATE INSTALLATION INSTRUCTIONS

(sold separately)

Prior to installation, be certain to read instructions completely. This quick

connect / adaptor plate works only with T10050, T10051 and T10052

aluminum motor brackets.

Slide motor bracket into adapter plate as shown in Figure 8 and secure it in

position by turning locking handle as indicated in Figure 8. Follow bracket

installation instructions to correctly position the bracket and adaptor plate

as a unit. Use the adaptor plate holes as a template to mark bolt-holes.

ADAPTOR PLATE INSTALLATION INSTRUCTIONS

FOR A MOTOR BRACKET WHICH IS ALREADY INSTALLED

If the adaptor plate is to be installed where an outboard motor bracket is already installed, remove the

bracket from the boat and seal the existing holes with plugs and a marine adhesive/sealant. Position the

plate on the transom so the bracket will be in the same position as before. Follow installation instruction

above.

LIMITED WARRANTY

This limited warranty is provided by TRAC Outdoor Products Co (TRAC) to the original consumer purchaser (purchaser) of the

new (not refurbished) TRAC Outboard Motor Bracket. This limited warranty is not transferable to any other party. TRAC will at

it option repair or replace any part of the TRAC Outboard Motor Bracket which may be found by TRAC to be defective within

two (2) years of original purchase. TRAC does not pay for the shipping cost from original purchaser to TRAC. You will have to

ship the items to us for repair or replacement. For warranty repair or replacement, the purchaser will provide dated proof of

purchase (sales receipt) and promptly notify TRAC of the request for warranty action. The purchaser will notify TRAC by email

at info@TRAC-Outdoor.com or by calling 615-641-2542 for warranty action. Purchasers will be provided a Return Goods

Authorization (RGA) to include with return for warranty work which will be shipped at the purchaser’s expense to the address

provided. The purchaser must use reasonable care in maintenance and operation of the product in accordance with this

manual. Failure to follow the instructions in the manual will void the warranty. This warranty covers defects in material or

workmanship of the TRAC Outboard Motor Bracket only. This warranty does not cover failure that results from misuse,

improper installation, accident, abuse, neglect, modification, or improper maintenance. There are no other express or implied

warranties. Any damage to watercraft or trailer resulting from proper or improper use of this TRAC Outboard Motor Bracket is

not covered under this warranty. Costs of installation or repair by service centers or marine repair facilities are not covered by

this warranty. This is the exclusive remedy and any liability for any and all incidental or consequential damages or expenses

whatsoever is excluded. Some states do not allow limitations on how long an implied warranty lasts, or do not allow exclusion

or limitation of incidental or consequential damages, the above limitations may not apply to you. This limited warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

TRAC Outdoor Products Co

6039 Dana Way

Antioch, TN 37013

www.trac-outdoor.com

info@trac-outdoor.com

(615) 641-2542

Loading...

Loading...