TQC CYLINDRICAL BEND TEST 100MM INCL MANDREL SET

SP1820

1 SAFETY PRECAUTIONS

• Make sure to keep fingers and other body-parts clear from the

bending area when performing a test.

• Make sure all actions such as the clamping and bending are

carried out without using any heavy forces

• Don’t exceed the max. Panel thickness.

• Check the mandrel visually for mechanical damages or marks.

2 PRODUCT DESCRIPTION

The TQC Cylindrical Bend Test is a very robust yet elegant testing instrument to indicate the elasticity,

elongation and adhesion of a paint film at bending stress. The TQC Cylindrical Bend Test is designed to perform

tests according to the latest ISO standards. ISO 1519: “Assessing the resistance of a coating, paint, varnish or

related products to cracking and/or detachment from a surface when, subjected to bending around a cylindrical

mandrel under standard conditions.

3 STANDARDS

Complies to ISO 1519, type 2 bender. Look up the appropriate standard for a correct execution of the test. Also

refer to ISO 1512-ISO 1514-ISO 2808-ISO 3270.

4 WHAT’S IN THE BOX?

• TQC Cylindrical Bend Test 100 mm

• Desk holder wit set of 14 mandrels with a diameter of 2, 3, 4, 5, 6, 8, 10, 12, 13, 16, 19, 20, 25 and 32 mm.

5 PREPARATIONS

• Apply the paint film on a test panel of max. 100 x 150 mm. , and a thickness of max. 1mm. Coat and dry

film carefully.

• Install the apparatus on the table with the clenching wheel on the left side.

6 PERFORM A MEASUREMENT

Remarks

• The test results strongly rely on the selected test panel, thickness of the coating, drying conditions and

ambient conditions. (See ISO1519)

• Also refer to ISO 1512-ISO 1514-ISO 2808-ISO 3270.

• Note any deviations for a reproducible test result.

1|

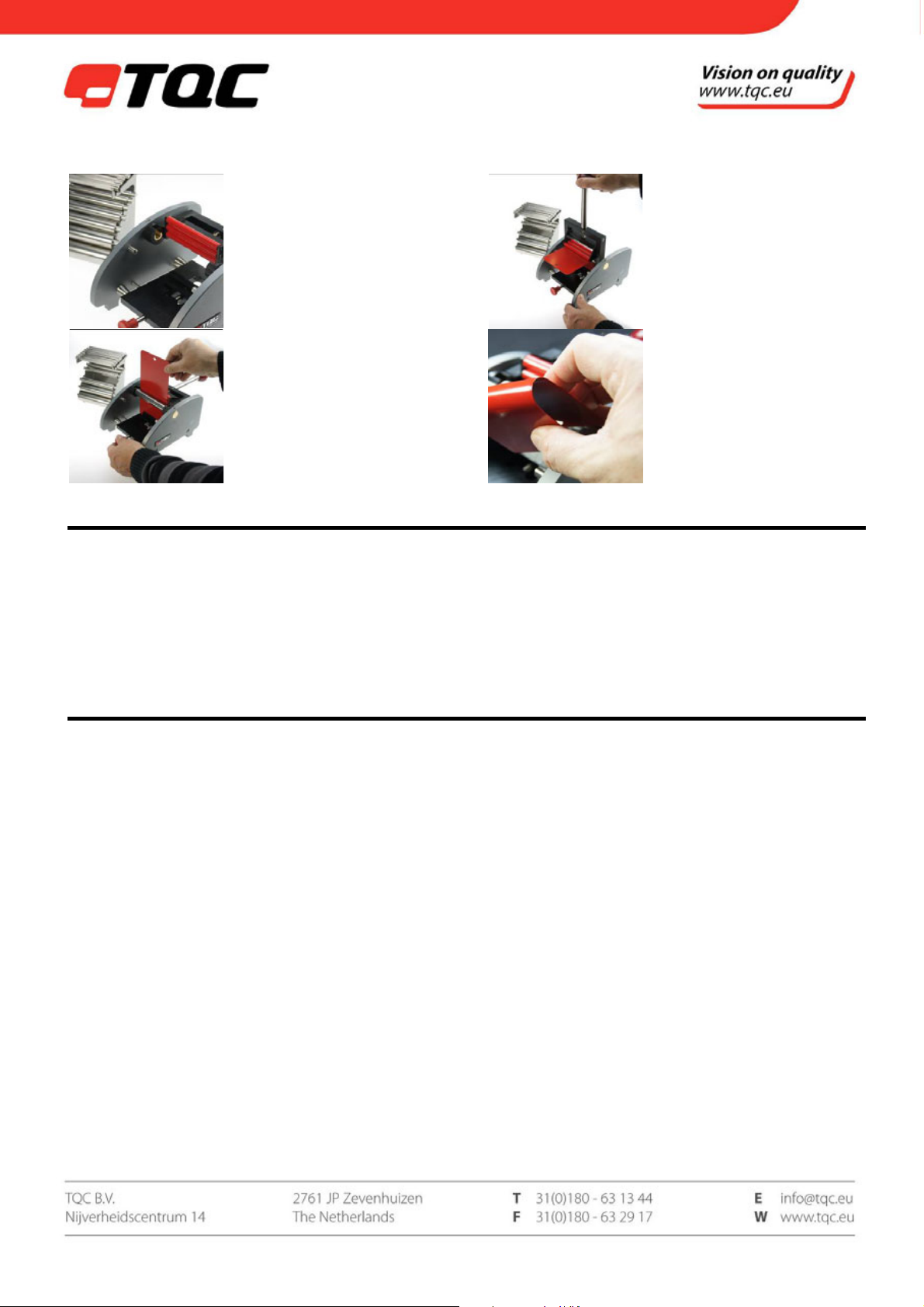

1. Sufficiently open the apparatus

to insert the mandrel with the

correct dia. turning the handle

of the pressure rollers anti

3. Pull the handle, and with a

smooth movement, taking

1 - 2 seconds, make an even

180° bend.

clockwise.

2. Place and secure a test-panel in

the apparatus, positioned

against the mandrel. Fix it

4. Release the test-panel from

the test-apparatus and

examine results immediately.

upright into the clamp. The

coated side of the panel should

face outwards once the bend

has been made.

7 MAINTENANCE

• Though robust in design, this instrument is precision-machined. Never drop it or knock it over

• Always clean the instrument after use.

• Clean the instrument using a soft dry cloth. Never clean the instrument by any mechanical means such

as a wire brush or abrasive paper. This may cause, just like the use of aggressive cleaning agents,

permanent damage.

• Do not use compressed air to clean the instrument.

8 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

2|

Loading...

Loading...