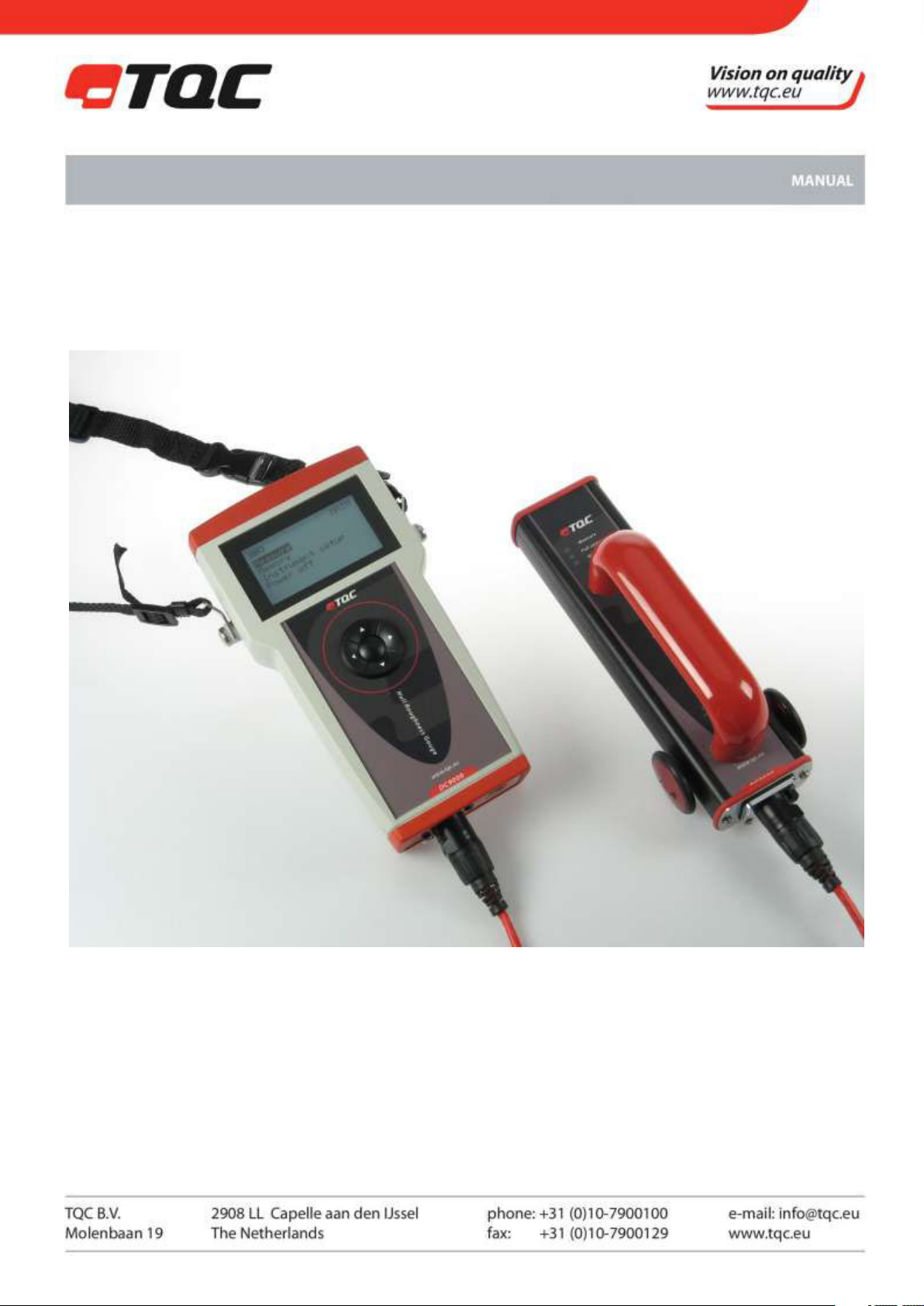

TQC HULL ROUGHNESS GAUGE

DC9000

IMPORTANT!

Before taking this instrument in use we strongly

advise you to read this manual carefully.

Operating Instructions for the

HULL ROUGHNESS GAUGE

MICROPROCESSOR CONTROLLED

Hull Roughness Gauge ± Instruction manual - Page 2 of 19

1 General ................................................................................................................................................. 4

1.1 Importance of operating manual ...................................................................................................... 4

1.2 User-responsibility .......................................................................................................................... 4

1.3 Responsibility of personnel ............................................................................................................. 4

1.4 Dangers .......................................................................................................................................... 4

1.5 Designated purpose ........................................................................................................................ 4

1.6 Copyright ........................................................................................................................................ 4

1.7 Manufacturer's/Supplier's address .................................................................................................. 4

2 Safety Instructions .............................................................................................................................. 5

2.1 Meaning of Symbols ....................................................................................................................... 5

2.2 Availability of Safety Information ..................................................................................................... 5

2.3 Training of Personnel ...................................................................................................................... 5

2.4 Dangers from Electrical Energy ....................................................................................................... 5

2.5 Points of Special Danger ................................................................................................................. 5

2.6 Care, Maintenance, Repairs ........................................................................................................... 6

3 Transport and Storage ........................................................................................................................ 6

3.1 Packing ........................................................................................................................................... 6

3.2 User: Check on Receipt .................................................................................................................. 6

3.3 Reporting Transport Damage and Documentation .......................................................................... 6

3.4 Storage and Protective Measures when not in use ......................................................................... 6

4 Instrument Data ................................................................................................................................... 7

4.1 Name / Article ................................................................................................................................. 7

4.2 Scope of Supply .............................................................................................................................. 7

4.3 Technical Data ................................................................................................................................ 7

4.4 Dimensions and Weight .................................................................................................................. 7

4.5 Basic Unit ....................................................................................................................................... 7

5 Installation and Assembly ................................................................................................................... 8

5.1 Installation and Operation ............................................................................................................... 8

5.2 Preparation ..................................................................................................................................... 8

5.3 Operation ........................................................................................................................................ 8

6 Instrument controls and functions ...........................................................................................

.......... 9

7 InStallation and preparations ............................................................................................................ 10

7.1 Batteries ....................................................................................................................................... 10

7.2 Connect your equipment ............................................................................................................... 10

7.3 Protect yourself and your equipment ............................................................................................. 10

7.4 Switching on your gauge ............................................................................................................... 10

8 Menu display information and operation ......................................................................................... 11

8.1 Main menu .................................................................................................................................... 11

Hull Roughness Gauge ± Instruction manual - Page 3 of 19

8.2 Instrument setup ........................................................................................................................... 11

8.2.1 Setup time and Date .............................................................................................................. 11

8.2.2 Setup acoustics ...................................................................................................................... 11

8.2.3 Setup display ......................................................................................................................... 12

8.3 Memory ......................................................................................................................................... 12

8.3.1 Batch options ......................................................................................................................... 12

8.3.2 Renaming batches ................................................................................................................. 12

8.4 Measure ........................................................................................................................................ 13

8.4.1 Accept series ......................................................................................................................... 14

8.4.2 Assign measurement-series to hull sections ........................................................................... 14

9 Calibration .......................................................................................................................................... 15

9.1 Calibrate gauge ............................................................................................................................ 15

9.2 Procedure ..................................................................................................................................... 15

9.3 Program ref. std. ........................................................................................................................... 16

10 Setting COM ports ........................................................................................................................... 17

10.1 COM ports 1,2,3 & 4 ................................................................................................................... 17

10.2 COM ports 5 and above .............................................................................................................. 17

10.2.1 If COM port 1-4 are currently occupied ................................................................................. 17

10.2.2 If COM ports 1-4 are currently not occupied ......................................................................... 18

11 HRG Windows application .............................................................................................................. 18

11.1 Installation ................................................................................................................................... 18

11.2 Processing data with the HRG application .................................................................................. 18

12 Care and Maintenance ..................................................................................................................... 19

12.1 Inspection and Maintenance ....................................................................................................... 19

12.2 Disposal of Materials ................................................................................................................... 19

12.3 Customer Service ....................................................................................................................... 19

13 Disclaimer ........................................................................................................................................ 19

Hull Roughness Gauge ± Instruction manual - Page 4 of 19

1 GENERAL

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and possible applications of the

instrument. It contains important instructions about how to use the instrument safely and economically;

according to the purpose designated. Following these instructions is not only essential to avoid risks. It

also reduces repair costs and down-time and increases the products reliability and service-life.

Anyone who works with the instrument should follow the instructions in this manual, particularly the safety

related instructions. Additionally local rules and regulations relating to environmental safety and accident

prevention should be observed.

1.2 User-responsibility

The user should

a) only allow persons to work with the instrument who are familiar with the general instructions on how

to work safely and to prevent accidents. The use of the instrument should have been instructed duly

The safety chapter and the warnings in this manual should have been read and understood;

acknowledged as evidenced by their signature.

b) regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument should pay attention to the

general regulations relating to working safety and accident prevention. The safety chapter and the

warnings in this manual should have been read and understood; acknowledged as evidenced by their

signature.

1.4 Dangers

This instrument has been designed and constructed in accordance with state-of-the-art technology and

the acknowledged safety regulations. Nevertheless, working with the instrument may cause danger to the

life and health of the operator or to others, or damage to the instrument or other property. Therefore the

instrument should only be used for its designated purpose, and in a perfect technical condition. Any

defect that could have a negative effect on safety should be repaired immediately.

1.5 Designated purpose

The TQC Hull Roughness Gauge is exclusively designed to perform roughness tests on painted and

coated or blasted surfaces as described within the specifications.

Other applications constitute improper use. TQC will not be held liable for damage resulting from

improper use.

Designated purpose also includes properly observing all instructions in the operation manual, and

adherence to inspection and maintenance schedules.

1.6 Copyright

The copyright of this operating manual remains with TQC.

This operating manual is intended solely for the user and his personnel. Its instructions and guidelines

may not be duplicated, circulated or otherwise passed on to others, neither fully, nor partly. Infringement

of these restrictions may lead to legal action may be taken if this restrictions are infringed upon.

1.7 Manufacturer's/Supplier's address

TQC ± Molenbaan 19, 2908 LL Capelle aan den IJssel - The Netherlands,

T +31(0)10 7900100, F +31 (0)10 7900 129

Warning

If this guideline is not noted it can lead

to severe danger to health, up to fatal

injury

Non observance of this guideline can

lead to injury or to damage to

equipment.

Guidelines to make optimal use of the

instrument.

Hull Roughness Gauge ± Instruction manual - Page 5 of 19

2 SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

Symbol Explanation

Possible immediate danger to the life or

health of personnel

Danger

A dangerous situation could be caused

Warning

Special tips and particular information

2.2 Availability of Safety Information

The instruction manual should be kept at the place where the instrument operates.

In addition to the information contained in the instruction manual, general and local regulations for

accident prevention and environmental protection shall be kept available and observed.

Always ensure all guidelines in respect of safety and dangers on the instrument are in readable condition.

In case of danger the instrument has to be switched off by means of the emergency-button on the front of

the instrument. Then eliminate danger.

2.3 Training of Personnel

x Anyone who operates the instrument should be trained properly.

x It has to be clear who has which responsibility regarding commissioning, set-up of maintenance and

repairs, installation, and operation.

x $Q\RQHZKRKDVQ¶WILQLVKHGWUDLQLQJVKRXOGEHVXSHUYLVHGE\DQH[SHULHQFHGSHUVRQZKLOHZRUNLQJ

with the instrument.

2.4 Dangers from Electrical Energy

x Work on the electrical supply may only be done by a qualified electrician.

x The electrical equipment of the instrument must be checked regularly. Loose connections and cable

damaged by heat must be corrected immediately.

x If any work is to be done on parts connected to a voltage supply, a second person must be present

to switch off the main switch if necessary.

2.5 Points of Special Danger

There are some special points of danger:

Always use supplied neck-strap to free your hands while working on scaffolds or

platforms

Hull Roughness Gauge ± Instruction manual - Page 6 of 19

2.6 Care, Maintenance, Repairs

x Maintenance and inspection should be carried out at the correct intervals

x Operating personnel should be informed before starting with maintenance or repair work

x Do not open the instrument. In case of malfunction always consult the manufacturer.

2.7 Modifications to the Equipment

x Any modifications or additions or alterations to the instrument may solely be made with permission

from the manufacturer.

x All measures involving modifications require written confirmation of approval from TQC

x Instruments which are not in fault-free condition must immediately be switched off

x 2QO\XVHUHSODFHPHQWSDUWVIURPWKHRULJLQDOVXSSOLHU3DUWVXVHGIURPRWKHUVRXUFHVDUHQ¶W

guaranteed to take the loading and meet the safety requirements.

2.8 Cleaning of the Instrument and Disposal of Materials

x When in use it is not always possible to avoid some spill of paint on the work surface.

x Try to keep the instrument as clean as possible to prevent distortions of functions.

x To clean the instrument properly use a suitable solvent to dispose remains of paint or ink.

x WHDUJORYHVGXULQJFOHDQLQJ'RQ¶WVSLOODQRYHUGRVHRIVROYHQWGXULQJFOHDQLQJ

x Cleaning materials must always be used and disposed of correctly.

3 TRANSPORT AND STORAGE

3.1 Packing

Please take note of pictorial symbols on the packing.

3.2 User: Check on Receipt

Check packing for damage

After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

Any damage should be documented as accurately as possible (possibly photographed) and reported to

the relevant insurers or, in the case of sales "delivered to customers works", to the supplier.

3.4 Storage and Protective Measures when not in use

The instrument must be stored in a dry place at a temperature between 10 - 40°C.

Store instrument in the original packing if possible.

Hull Roughness Gauge ± Instruction manual - Page 7 of 19

4 INSTRUMENT DATA

4.1 Name / Article

DC9000 TQC Hull Roughness Gauge ± Microprocessor Controlled Hull Roughness Gauge.

4.2 Scope of Supply

x TQC Hull Roughness Control unit with neck-strap

x TQC Hull Roughness Sensor

x TQC Hull Roughness Sensor Cable

x DC9015 Calibration plate

x USB thumb drive with software

x USB connection cable for PC

x 4 x AA batteries included

4.3 Technical Data

Memory capacity: 4000 series of measurements

Power Supply: Batteries, 4 x AA batteries

Display: LCD 80mm, illuminated

Interface: Menu driven interface with 4-way directional push button by Rotation /

Pushing

.

4.4 Dimensions and Weight

Sensor Depth: 205 mm

Sensor Width: 80 mm

Sensor Height: 40 mm

Sensor weight: approx. 630 g

Control unit Depth: 200 mm

Control unit Width: 115 mm

Control unit Height: 40 mm

Control unit weight: approx. 350 g

4.5 Basic Unit

Power Supply: Batteries, 4 x AA batteries ( included )

Power consumption:

Display: LCD 80mm, illuminated

Safety: Neck-strap

Interface: Menu driven interface with 4-way directional push button by Rotation /

Pushing

Hull Roughness Gauge ± Instruction manual - Page 8 of 19

5 INSTALLATION AND ASSEMBLY

5.1 Installation and Operation

Carefully unpack the apparatus and the accessories and check complete supply. Please assemble your

equipment before climbing upon scaffolds or platforms. Use supplied neck-strap to securely attach the

apparatus and prevent possible damage from falling.

5.2 Preparation

Your unit comes with a fresh set of worldwide easily available AA batteries already installed.

Connect the sensor and control unit with the supplied sensor cable. The direction of the cable is not

important, both sides of the cable are identical male plugs and interchangeable. Firmly press the plugs in

corresponding connectors on both the sensor and control unit. The plug is properly connected and locked

into place when you hear / feel a click.

Note: To release the sensor cable from both sensor and control unit push the little fuse button beside

both connectors. The plug should be able to eject from the connector without the use of excessive force.

Use supplied neck-strap to securely attach the apparatus and prevent possible damage from falling.

5.3 Operation

The whole unit is operated by one single 4-way directional push button. You can press this button to

confirm menu options or rotate it in order to navigate through the menu options.

Turn on your device. Press the Jog knob once to power up the Hull roughness Gauge. If correctly

powered up the display briefly shows the TQC logo and the current firmware version.

You are presented following screen when the gauge is ready:

6 INSTRUMENT CONTROLS AND FUNCTIONS

2

3

Hull Roughness Gauge ± Instruction manual - Page 9 of 19

1

1. Hull Roughness sensor

2. Sensor cable attachment

3. Soft rubber non-slip wheels

4. Status indication / warning lights

5. Neck-strap to securely carry your gauge

6. Hull Roughness Control unit

7. Hull Roughness Sensor cable

8 Illuminated LCD

9. 4-way directional push button

,QGLFDWLQJ/('IRUµ0HDVXUH¶

11. IQGLFDWLQJ/('IRUµ)XOOVHULHV¶

12. IndicatiQJZDUQLQJ/('IRUµ+LJK6SHHG¶

13. Hull Roughness Surface profile probe

5

8

9

6

7

13

10

11

12

4

Hull Roughness Gauge ± Instruction manual - Page 10 of 19

7 INSTALLATION AND PREPARATIONS

Carefully unpack the apparatus and the accessories and check complete supply. Please assemble your

equipment before climbing upon scaffolds or platforms. Use supplied neck-strap to securely attach the

apparatus and prevent possible damage from falling.

7.1 Batteries

Your gauge runs on standard alkaline AA batteries. These batteries are easily

available worldwide by local suppliers. The Hull Roughness gauge needs 4 AA

batteries to operate.

Note: Only use standard AA alkaline batteries to ensure proper functioning of

your gauge. The use of rechargeable batteries is not recommended because

they tend to suffer from to big voltage drops possibly influencing measuring

results.

Your gauge is supplied with a set of 4 AA batteries.

7.2 Connect your equipment

Connect the sensor and control unit with the supplied sensor cable. The direction of the cable is not

important, both sides of the cable are identical male plugs and interchangeable. Firmly press the plugs in

corresponding connectors on both the sensor and control unit. The plug is properly connected and locked

into place when you hear / feel a click.

Note: To release the sensor cable from both sensor and control unit push the little fuse button beside

both connectors. The plug should be able to eject from the connector without the use of excessive force.

7.3 Protect yourself and your equipment

Please assemble your equipment before climbing upon scaffolds or platforms. Use supplied neck-strap to

securely attach the apparatus. Using the neck-strap is for your own safety and allows you to free one

hand while it also prevents your gauge from falling.

7.4 Switching on your gauge

A single press on the 4-way directional push button will present you with the start-up screen. You are

welcomed by our TQC logo and the current firmware version is displayed.

8 MENU DISPLAY INFORMATION AND OPERATION

8.1 Main menu

The TQC Hull Roughness Gauge has an advanced menu

structure. The Main Menu allows the user to access all the

features available.

To select a function turn the Jog shuttle

till the selector is on the item and push the Jog shuttle to

confirm your choice.

8.2 Instrument setup

The setup menu allows you to calibrate your gauge. The

calibrate procedure is explained in chapter 9 on page 15 of

this manual. The other options need to be set once before

first time use of your gauge.

8.2.1 Setup time and Date

Hull Roughness Gauge ± Instruction manual - Page 11 of 19

Please set the correct time in your gauge. ( 24 hour format).

Use the 4-way directional push button to select the digit

you would like to change. Confirm your selection with a

single press on the 4-way directional push button. Use

up- and down buttons till the desired digit is displayed.

Confirm your selection with a single press on the 4-way

directional push button and Continue with the next digit.

Please set the correct date in your gauge.

( DD/MM/YYYY format )

Use the 4-way directional push button to select the digit

you would like to change. Confirm your selection with a

single press on the 4-way directional push button. Use

up- and down buttons till the desired digit is displayed.

Confirm your selection with a single press on the 4-way

directional push button and Continue with the next digit.

Note: Your time and date settings are

AutoSaved.

8.2.2 Setup acoustics

The sound level can be adjusted to your needs. You can set the

gauge to either: Signals off / Low volume and high volume.

Use up- and down buttons to select the desired acoustics level

and confirm with a single press on the 4-way directional push

button.

Note: Your acoustics settings are

AutoSaved.

Hull Roughness Gauge ± Instruction manual - Page 12 of 19

8.2.3 Setup display

You can change both backlight and contrast settings.

Use up- and down buttons WRVHOHFWHLWKHUµ%DFNOLJKW¶RUµ&RQWUDVW¶

and confirm with a single press on the 4-way directional push

button.

Use left- and right buttons WRDGMXVWWKHµ%DFNOLJKW¶RUµ&RQWUDVW¶

level. Confirm with a single press on the 4-way directional push

button.

Note: Your display settings are AutoSaved.

8.3 Memory

Measurements can be stored in different batches. The

Hull Roughness Gauge can store up to 8 batches that

can be named individually.

Click the 4-way directional push button once to select a

batch. A checkmark will appear before the selected

batch.

Click the 4-way directional push button once more in

order to access the batch options.

8.3.1 Batch options

Allows you to either name/rename batches, delete batches and

send batches to a personal computer for further data analysis.

8.3.2 Renaming batches

&OLFNµ5HQDPH¶WRJLYHWKHEDWFKDQDPH

Use the 4-way directional push button to select the character you

would like to change. Confirm your selection with a single press on

the 4-way directional push button. Use up- and down buttons till the

desired character is displayed. Confirm your selection with a single

press on the 4-way directional push button and Continue with the

next character.

Note: Your batch names are AutoSaved.

8.3.2.1 Clear

Clear allows you to erase all measurements of the selected batch.

A single press on the 4-way directional push button will prompt you

with a confirmation screen. Confirm the clearing of all batch data

with a single press on the 4-way directional push button.

Warning: Your data is permanently erased!

Hull Roughness Gauge ± Instruction manual - Page 13 of 19

Note: Depending on the amount of data, deleting

data can take up to a minute. Please wait for the

progress bar to fully complete the process.

8.3.2.2 Send data to PC

In order to process your measured data it is essential to

send your data to a PC. Before sending the data following

precautionary measures need to be taken:

1. Connect your gauge with the PC

2. Open the HRG application

3. Select the proper COM port

4. &OLFNµ2SHQSRUW¶

5. When a connection is established you can confirm to

Send your batch data by a single press on the 4-way

directional push button.

6. Your raw data appears in the HRG application

7. 3UHVVµ'DWD-!([FHO¶

Note: More information on setting COM ports is

available in chapter 10 on page 16.

8.4 Measure

Once a batch is selected to store your measurements it is

time to start your first measurements. Press start to

advance.

In the following screen you can see your selected batch

QDPHµ6HULHs¶LQGLFDWHVWKHWDNHQUXQVRIPHDVXUHPHQWV

Role the Hull Roughness sensor RYHUWKHKXOO¶VVXUIDFHILUPO\

pressing the sensor to the surface. One full run is taken

over a length of approximately 90cm.

Keep moving the sensor over the surface until the indication LED

µ)XOOVHULHV¶VWDUWVWREOLQN$IXOOUXQZLOODOVREHLQGLFDWHGE\D

beep if acoustics are enabled.

Note: To enable acoustics see chapter 8.2.2 on

page 11 of this manual.

Hull Roughness Gauge ± Instruction manual - Page 14 of 19

8.4.1 Accept series

After each measurement the Average Hull Roughness (AHR) of

the last series and the AHR of all series is displayed.

If you encounter measurement errors or want to measure the last

+XOOVHFWLRQRQFHDJDLQVLPSO\SUHVVµ%DFN¶DQGUHdo your

PHDVXUHPHQW,I\RXDJUHHZLWKWKHUHVXOW\RXFDQFOLFNµ$FFHSW¶

In the next step you can allocate your series of measurements

to the proper hull section.

8.4.2 Assign measurement-series to hull sections

After accepting the measurement results each series of

measurements can be assigned to a specific hull section.

Either a starboard or portside image of the ship is displayed. Use

the 4-way directional push button to select the corresponding hull

section and click to assign your series to this hull section.

To switch between starboard and portside images select:

µSB < - > PSµ (Starboard vs. Portside)

Click the 4-way directional push button to switch the displayed

image.

Already measured sections are indicated with a small square.

Once a hull section has been measured you could

overwrite the section data. Select the square marked

section and click the 4-way directional push button once

to overwrite older measurements.

Note: Overwrites are permanent, you are not

asked or warned with a confirmation screen.

.

Hull Roughness Gauge ± Instruction manual - Page 15 of 19

9 CALIBRATION

To ensure proper measurements it is required to

regularly calibrate your gauge. Your gauge comes

supplied with a calibration plate which contains the

reference standard.

Note: Calibration should only be performed

in similar climatic conditions as where the

actual measurements will take place.

Note: For proper calibration allow both

units to adjust to the ambient temperature

for at least ten minutes. Switch your control

unit on and choose instrument set-up, choose calibrate,

choose calibrate gauge. Keep your control unit switched

on and leave it in calibration mode.

9.1 Calibrate gauge

Selecting the LQVWUXPHQWVHWXSPHQXRSWLRQµ&DOLEUDWH¶,

calibrate JDXJH¶refers you to this manual for further

instructions.

The gauge needs to be calibrated on 4 different points.

As soon as you bypass the screen referring to this

manual you need to perform the zero reference

calibration.

Note: Please watch supplied reference standard closely and notice the different slots.

0000

0500

1500

2500

From left to right: 0000, 0500, 1500 & 2500 micron reference plates.

Note: Proper calibration takes patience and attention. Never try to hurry the procedure. Since

the hull roughness gauge measures in microns, a small mistake causes great irregularities in

measurements

9.2 Procedure

1. Position the Hull Roughness Surface profile sensor onto the reference standard until it reaches

the zero reference plate.

2. Start the calibration procedure on the control unit. If the reference standard is properly positioned

yRXUJDXJH¶VVFUHHQVKRXOGGLVSOD\DUHIHUHQFHYDOXHFORVHWR,ILWGRHVHQWHU2.,ILW

GRHVQ¶WFKHFNLIthe sensor is located above the zero reference plate and try again. *

3. Slide the sensor unit until LW¶VSRVLWLRQHGRQthe 0500 micron reference plate. Then enter OK on

the control unit.

4. Repeat step 3 for the 1500 and the 2500 micron reference plate.

5. Finally if all reference points are set, confirm your new calibration E\SUHVVLQJµSynchronize¶ If

\RXSUHVV³&DQFHO´WKHcomplete procedure will be cancelled.

Hull Roughness Gauge ± Instruction manual - Page 16 of 19

*Note: If your gauge has never been calibrated or deviates a lot from the reference values

repeating the complete calibration process multiple times will improve both accuracy and

calibration.

9.3 Program ref. std.

This advanced feature should only be used if you have equipment to exactly measure your reference

standard.

This feature should only be changed if the reference standard deviates from the standard

0000, 0500, 1500 & 2500 micron reference.

Hull Roughness Gauge ± Instruction manual - Page 17 of 19

10 SETTING COM PORTS

The computer system will automatically assign a COM port number to the gauge. Please check Windows

µ'HYLFH0DQDJHU¶WRlearn the assigned COM port.

Tip: Windows shortcut to µ'HYLFH0DQDJHU¶

Windows key + Pause key

8QIROGµ3RUWV&20/37¶The gauge is recognized as:

µUSB Serial Port &20«¶

If you have failed to recognize the Hull Roughness Gauge

within Windows Device Manager reconnect your gauge and

pay close attention to the list in Windows Device Manager as

the gauge will reappear here.

10.1 COM ports 1,2,3 & 4

Please set HRG software COM port settings to the assigned

COM port. Currently only 4 COM ports are available.

If you gauge is recognized as COM 5 or higher please contact your IT department for a workaround or

continue reading next chapter µ10.2 COM ports 5 and above¶.

10.2 COM ports 5 and above

Your gauge has an assigned COM port number of 5 or higher since 1-4 are in use or have been in use by

other computer devices in the past.

10.2.1 If COM port 1-4 are currently occupied

Move one of your devices connected to COM ports 1,2,3 or 4 to port number 5 or above:

- Select the device to move in µ'HYLFH0DQDJHU¶and right click your mouse.

- Subsequently select Properties / Port settings tab / Advanced

- Edit current port number and confirm any changes you have made.

Set current COM (1-4) to 5 or higher.

Subsequently repeat previous steps to move your gauge to either COM ports 1,2,3 or 4.

Hull Roughness Gauge ± Instruction manual - Page 18 of 19

10.2.2 If COM ports 1-4 are currently not occupied

If COM ports 1-4 are currently not in use but the Hull Roughness Gauge has an assigned COM port

number of 5 or higher:

- Select the Hull Roughness Gauge in µ'HYLFH0DQDJHU¶DQGULJKWFOLFN\RXUPRXVH

- Subsequently select Properties / Port settings tab / Advanced

- Move your gauge to either COM ports 1,2,3 or 4 and confirm any changes you have made.

11 HRG WINDOWS APPLICATION

11.1 Installation

The HRG application supplied on the USB thumb drive does not require any installation. Double click the

HRG V1.01 file to launch the application.

Your Windows installation might prompt you with a "The

publisher could not be verified" PHVVDJH3OHDVHFOLFNµ5XQ¶WR

continue.

11.2 Processing data with the HRG application

This application functions as an interface between your Hull Roughness Gauge and the Microsoft Excel

Survey Report.

- 3OHDVHVHOHFWWKHSURSHU&20SRUWFKDSWHURIWKLVPDQXDODQGFOLFNµ2SHQ3RUW¶

- Use your gauge to select a batch and send it to the HRG application (chapter 8.3.2.2)

- &OLFNµ'DWD-!([FHO¶WRJHQHUDWH\RXU+XOO5RXJKQHVV6XUYH\5HSRUW

Hull Roughness Gauge ± Instruction manual - Page 19 of 19

12 CARE AND MAINTENANCE

12.1 Inspection and Maintenance

x Though robust in design, this instrument is precision-machined. Never drop it.

x Always clean the instrument after use.

x Clean the instrument using a soft dry cloth. Never clean the instrument by any mechanical means

such as a wire brush / abrasive paper. This may cause, just like aggressive cleaning agents,

permanent damage.

x Do not use compressed air to clean the instrument.

x Generally the TQC Hull Roughness Gauge does not require any maintenance.

Make sure that no paint or other liquids are spilled on the electronics or left in the holes.

Warning

12.2 Disposal of Materials

Disposal of materials used in the operation of the instrument or for auxiliary functions and exchanged

items should be dealt with safely and in a manner that will not harm the environment. Follow the local

regulations.

12.3 Customer Service

Customer service is provided on request by

TQC ± Molenbaan 19, 2908 LL Capelle aan den IJssel - The Netherlands, T +31(0)10 7900100,

F +31 (0)10 7900 129 or by local representatives.

13 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any purpose other than that

specifically recommended in this manual without first obtaining written confirmation from us as to the suitability of the product for the intended

purpose does so at his own risk. Whilst we endeavour to ensure that all advice we give about the product (whether in this manual or otherwise)

is correct we have no control over either the quality or condition of the product or the many factors affecting the use and application of the

product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability whatsoever or howsoever arising for the

performance of the product or for any loss or damage (other than death or personal injury resulting from our negligence) arising out of the use of

the product. The information contained in this manual is liable to modification from time to time in the light of experience and our policy of

continuous product development.

Loading...

Loading...