TQC CureView

Gradient Oven

AB8000 REV02

Gradient oven with GOC and

Ideal Finish control

Operating Instructions

(V1.2 0918)

IMPORTANT! Before taking this instrument

in use we strongly advise you to read this

manual carefully.

INDEX

1. General

1.1 Importance of operating manual

1.2 User-responsibility

1.3 Responsibility of personnel

1.4 Dangers

1.5 Designated purpose

1.6 Copyright

1.7 Manufacturer’s/Supplier’s address

2 Safety Instructions

2.1 Meaning of Symbols

2.2 Availability of Safety Information

2.3 Training of Personnel

2.4 Dangers from Electrical Energy

2.5 Points of Special Danger

2.6 Care, Maintenance, Repairs

2.7 Modifications to the Equipment

2.8 Cleaning of the Instrument and Disposal

of Materials

3 Transport and Storage

3.1 Packing

3.2 User: Check on Receipt

3.3 Reporting Transport Damage and

Documentation

3.4 Storage and Protective

Measures when not in use

4 Instrument Data

4.1 Name / Article

4.2 Scope of Supply

4.3 Technical Data

4.4 Dimensions and Weight

4.5 Basic Unit

4.6 Accuracy

4.7 Noise Level

4.8 Accessories and Spares

5 Installation and Assembly

5.1 Installation and Operation

5.2 Preparation of Energy Connections

5.3 Mains Connection

10 Installation Criteria

4 14

10.1 Climate

10.2 Power Supply

10.3 Worktable

10.4 Exhaust System

10.5 Installation Procedure

11 Thermal Dynamics

11.1 General

11.2 Basics of Gradient Ovens

5

11.3 Substrate Material

11.4 Surrounding / Environmental Conditions

11.5 Ramping

12 TQC Gradien Oven Control Software

12.1 Introduction

12.2 Prerequisite

12.3 Program Configuration

12.4 Modes and Stages

12.5 Configure a test in Setup Mode

12.5.1 General Setup

6

12.5.2 Pre-cooling Setup

12.5.3 Heating Setup

12.6 Execute a test in Run Mode

12.7 Initialization

12.8 Place Panel

12.9 Pre-cooling Oven

12.10 Heating

7/8

12.11 Lift Panel

13 Maintenance

13.1 Heater Replacement

13.2 Controller Replacement

10 Disclaimer

Annex A Operator Qualication List

9

Annex B Maintenance List

15

16/20

21/26

27

29/30

31

6 Instrument Controls and Functions

7 Instrument Preparations

7.1 Test Panels

7.2 Calibration Interval

7.3 Lamp Maintenance

7.4 Software

8 Operation

8.1 Preparatory Work

8.2 Sample Preparation

8.3 Start the Instrument

9 Care and Maintenance

9.1 Inspection and Maintenance

9.2 Disposal of Materials

9.3 Customer Service

10

11

12

13

3 |

1 GENERAL

This TQC CureView Manual is created in multiple parts. This to give the

operator the best experience with the TQC CureView. It is

essential that the full manual is read and understood prior to

commencing operation of the TQC CureView.

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and

possible applications of the instrument. It contains important instructions

about how to use the instrument safely and economically; according to

the purpose designated. Following these instructions is not only essential

to avoid risks. It also reduces repair costs and down-time and increases the

products reliability and service-life.

Anyone who works with the instrument shall follow the instructions in this

manual, particularly the safety related instructions. Additionally local rules

and regulations relating to environmental safety and accident prevention

should be observed. It is mandatory that users have read and understand

this manual prior to first operation of the TQC CureView.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are

familiar with the general instructions on how to work safely and

to prevent accidents. The use of the instrument should have been

instructed duly. The safety chapter and the warnings in this

manual should have been read and understood; acknowledged

as evidenced by their signature.

The TQC CureView Gradient oven is exclusively designed to perform

thermal testing to within its thermal design envelope of painted and

coated test panels as described within the specifications. Other applications

constitute improper use. TQC will not be held liable for damage resulting

from improper use.

Designated purpose also includes properly observing all instructions in the

operation manual, and adherence to inspection and maintenance

schedules. TQC is entitled to request these form when warranty claims are

made and during inspections to ensure safe operation and evaluate correct

usage.

1.6 Copyright

The copyright of this operating manual remains with TQC. This operating

manual is intended solely for the user and his personnel. Its instructions

and guidelines may not be duplicated, circulated or otherwise passed on to

others, neither fully, nor partly. Infringement of these restrictions may lead

to legal action may be taken if this restrictions are infringed upon.

1.7 Manufacturer’s/Supplier’s address

TQC – Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10 7900 100

F +31 (0)10 7900 129

b) Regularly check the safety-awareness of personnel at work.

c) Only allow user maintenance on the instrument such as lamp

replacement and thermal board replacement / exchange only to

be performed by TQC qualified or appointed personnel.

Maintenance by unqualified personnel can result in serious

damage to the instrument and will not be accepted as claimable

warranty.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument

should pay attention to the general regulations relating to working safety

and accident prevention. The safety chapter and the warnings in this manual

should have been read and understood; acknowledged as evidenced by

their signature, as can be placed in the Operator qualification list Annex A.

1.4 Dangers

This instrument has been designed and constructed in accordance with

state-of-the-art technology and the acknowledged safety regulations.

Nevertheless, working with the instrument may cause danger to the life and

health of the operator or to others, or damage to the instrument or other

property. Therefore the instrument should only be used for its designated

purpose, and in a perfect technical condition. Any defect that could

have a negative effect on safety should be repaired and recorded in the

maintenance list Annex B immediately.

1.5 Designated purpose

| 4

2 SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

Possible immediate

danger to the life or

health of personnel.

A dangerous situation

could be caused.

Special tips and

particular information.

2.2 Availability of Safety Information

The instruction manual should be kept in proximity to where the instrument

operates and should be visible and accessible at any time of operation.

In addition to the information contained in the instruction manual, general

and local regulations for accident prevention and environmental protection

shall be kept available and observed. Always ensure all guidelines in respect

of safety and dangers on the instrument are in readable condition.

In case of danger the instrument has to be switched off by means of the

emergency-button on the front of the instrument, then the danger should

be eliminated.

2.3 Training of Personnel

• Anyone who operates the instrument should be trained properly.

• It has to be clear who has which responsibility regarding commissioning,

set-up of maintenance and repairs, installation, and operation.

• Anyone who hasn’t finished training should be supervised by an

experienced person while working with the instrument.

If this guideline is not noted

it can lead to severe danger

to health, up to fatal injury.

Non observance of this

guideline can lead to injury

or to damage to equipment.

Guidelines to make optimal

use of the instrument.

2.6 Care, Maintenance, Repairs

• Always make sure the instrument is connected to an earthed socket.

• Maintenance and inspection should be carried out at the correct intervals

• Operating personnel should be informed before starting with

maintenance or repair work

• Always make sure the instruments power is turned off and the instrument

is not connected to a socket while adjusting any electrical component

whenever maintenance, inspection or repair work is done.

• Do not open the instrument. In case of malfunction always consult the

manufacturer.

2.7 Modications to the Equipment

• Any modifications or additions or alterations to the instrument may solely

be made with permission from the manufacturer.

• All measures involving modifications require written confirmation of

approval from TQC

• Instruments which are not in fault-free condition must immediately be

switched off

• Only use replacement parts from the original supplier. Parts used from

other sources aren’t guaranteed to take the loading and meet the safety

requirements.

2.8 Cleaning of the Instrument and Disposal of Materials

• When in use it is not always possible to avoid some spill of

paint on the work surface.

• Try to keep the instrument as clean as possible to prevent

distortions of functions.

• To clean the instrument properly use a suitable solvent to dispose

remains of paint or ink.

• Wear gloves during cleaning; Don’t spill an overdose of

solvent during cleaning.

• Cleaning materials must always be used and disposed of correctly.

2.4 Dangers from Electrical Energy

• Work on the electrical supply may only be done by a qualified electrician.

• The electrical equipment of the instrument must be checked regularly.

Loose connections and cable damaged by heat must be corrected

immediately.

• If any work is to be done on parts connected to a voltage supply, a second

person must be present to switch off the main switch if necessary.

2.5 Points of Special Danger

There is one special point of danger in the moving zone of the tool carrier:

Always be aware that the machine, components and test

panel can be hot and cause physical injuries by burning.

Keep your hands away from the heated area after the

instrument has started!

5 |

3 TRANSPORT AND STORAGE

3.1 Packing

• Please take note of pictorial symbols on the packing.

• Check for transport damages. If the packaging is damaged only accept it

with a written approval of the transporter that the package was damaged.

3.2 User: Check on Receipt

• Check packing for damage

• After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

• Any damage should be documented as accurately as possible (possibly

photographed) and reported to the relevant insurers or, in the case of sales

“delivered to customers works”, to the supplier.

3.4 Storage and Protective Measures when not in use

• The instrument must be stored in a dry place at a temperature

between 10 - 40˚C / 50 - 104˚F.

• The storage period should not be longer than 3 months. When stored

longer than 3 months please contact the manufacturer for instructions on

recommissioning.

• Store instrument in the original packing if possible.

| 6

4 INSTRUMENT DATA

4.1 Name / Article

TQC CureView – Computer controlled thermal test center.

4.2 Scope of Supply

TQC CureView

Lamp Replacement

Gloves

Power Cord

Pre-installed Laptop

+ Laptop Power Cord

+ Laptop Installation

and documentation set

Lamp Replacement Tool

(Art. nr. AB8020)

TQC GOC and

TQC Ideal Finish

Software

Allen Key 2.5 mm

Allen Key 3 mm

Allen Key 4 mm

TQC CureView Manual

3x Spare Lamps

4.3 Technical Data

Temperature range: Ambient +5˚C to 350˚C

Maximum temperature difference: 50˚C / 122˚F (between 2 elements) (Thermal properties of test panel not included)

Number of heating elements: 32 elements, individually controlled.

Max. panel width: 98 mm / 3.86 inch

Max. panel length: Max 570 mm / 22.44 inch

Max. panel thickness: max. 1.0 mm / 0.03 inch

Effective test are: 500 x 74 mm / 19.69 x 2.91 inch

4.4 Dimensions and Weight

Depth: 595 mm / 23.43 inch

Width: 760 mm / 29.92 inch

Height: 296 mm / 11.65 inch

Net weight: approx. 31 kg / 68.34 inch

4.5 Basic Unit

Power Supply: 220 - 240 V, 50 - 60 Hz (single phase / split phase)

Power consumption: max. 3000 Watt

Display: None, status indication by 2 LED indicator buttons.

Safety: Emergency Button,

Function: 2 LED lit buttons, and computer control

4.6 Accuracy

Controller accuracy: 0.1˚C

Time control: 0.1 s/h

Heated accuracy: 3 ˚C

4.7 Noise Level

The continuous noise level from the instrument does not exceed 70 dB.

7 |

4.8 Accessories and Spares

Accessories

AB8025 CureView Gradient Oven Test Panels, set of 50 pcs

AB8026 CureView ISO 2812-5 Panel Adapter, suitable for Holding Panels size 500 mm x 100 mm

Spare parts

AB8016 Halogen Gold Reflector Infrared Heating Lamp (set of 10 pcs)

AB8020 Lamp Replacement Tool

AB8030 Nextrema Glass Test Surface

CM1105 USB Cable

AB8103 Power Supply Cable for CureView

| 8

5 INSTALLATION AND ASSEMBLY

5.1 Installation and Operation

The instrument has to be installed in a suitable place, preferably on a sturdy

table or work area, with normal ambient temperature. Special fixings are not

required. Exhaust for non-forced expel of fumes should be present. Carefully

unpack the apparatus and the accessories and check complete supply. Place,

if necessary, a spirit level on the work surface and adjust the height of the

feet. See also chapter 9.

5.2 Preparation of Energy Connections

The instrument is equipped with a safety tested mains supply cable and may

only be connected to plug sockets with earth connection complying with

the safety regulations.

Before connecting the instrument, check whether the supply

voltage corresponds to the local supply voltage. If it does

not, the instrument must not be connected under any

circumstances.

5.3 Mains Connection

The mains connection is located at the rear of the instrument. Plug in the

female plug in the socket on the rear of the housing. The ON/OFF Switch is

located at the right hand side near the end of the instrument.

9 |

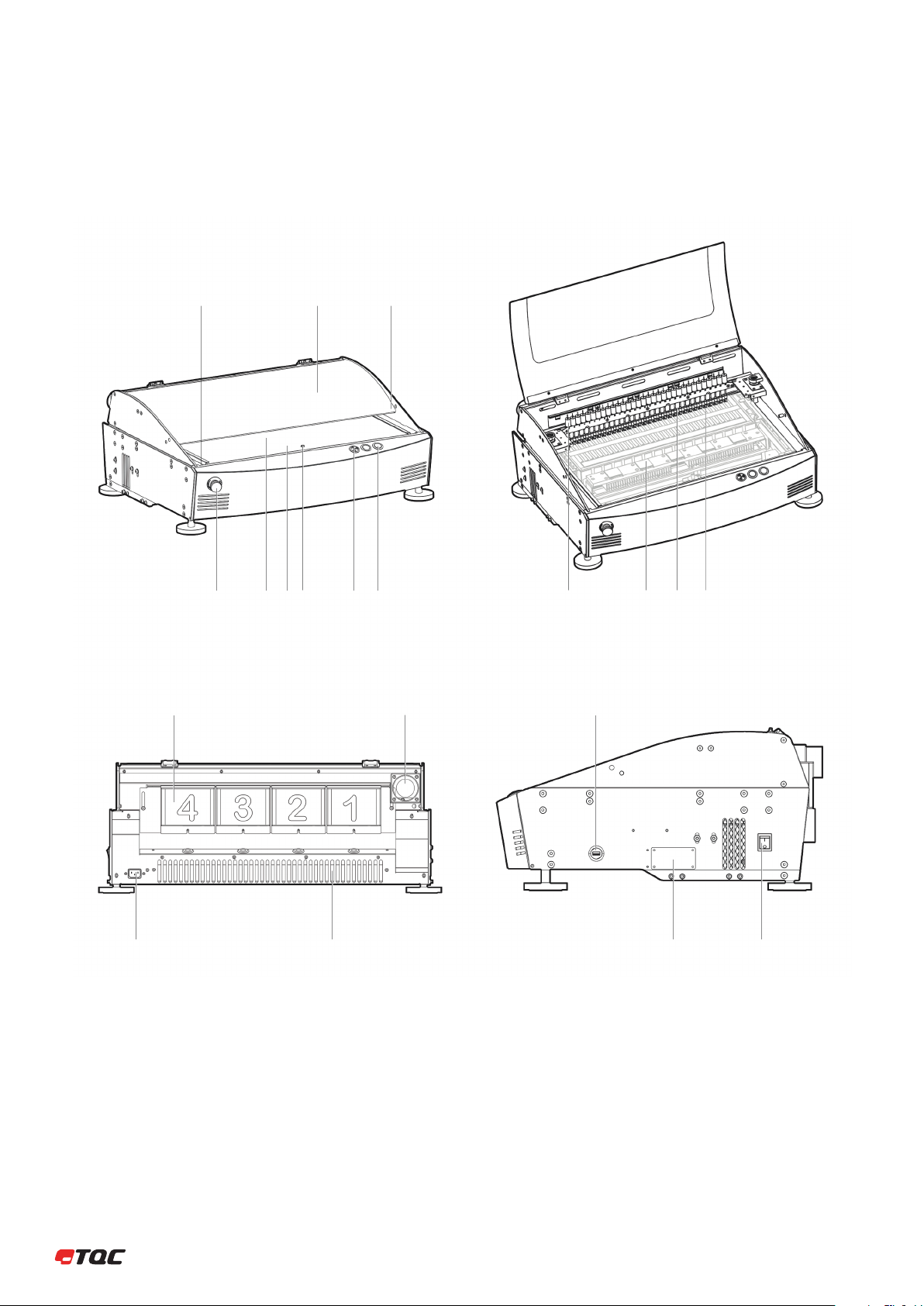

6 INSTRUMENT CONTROLS AND FUNCTIONS

1 2 3

4

14 15

5 6 7 8 9 10 11 12 13

1716

18

19 20

Panel Displacer

1

Protective Glass/Ceramic Cover

2

Canopy Safety Release

3

Emergency Stop

4

Test Surface

5

| 10

Loading Zone

6

Panel Lifter

7

Audio Alarm

8

Control Buttons

9

Thermal Sensors

10

11

Cooling Zone

12

Panel Clamp

13

Heating Zone

14

Controller Units

15

Fumex Exhaust

16

Power Supply Connection

17

Cooling Exhaust Machine

18

USB Connector

19

Identification Panel

20

Power Switch

7 INSTRUMENT PREPARATIONS

7.1 Start-up sequence

• Start the control computer or laptop.

• Once windows is launched start the TQC CureView.

• After 3 beeps the initiation of the TQC CureView in completed.

• Start the GOC software.

7.2 Test Panels

Prepare the panel as required by the test to performed. Make sure that no

wet/uncured paint or any other chemicals are applied at the area’s used by

the probes or pins. Only below depicted area can be used.

570 mm

x 12 mm

98 mm

x 35 mm x 35 mm

7.3 Calibration interval

The TQC CureView is supplied with 4 controllers each measuring and

controlling 8 channels. TQC advises to have an annual calibration interval.

Contact TQC or a local representative for information on how to calibrate the

TQC CureView.

7.4 Lamp maintenance

The carefully selected TQC Infra red heaters have a life expectancy of at least

5000 burn hours. In end this depends on the use of the lamps.

The replacement of the lamps should be performed as mentioned in the

chapter: “Replacing the Heater lamps” and should only be done by

authorized personnel.

7.5 Software

The TQC CureView operates in conjuction with Gradient Oven Control and

Ideal Finish software.

500 mm

74 mm

x 12 mm

11 |

8 OPERATION

8.1 Preparatory Work

• Turn the machine on as described earlier.

8.2 Sample preparation

Prepare a sample suitable for conducting the tests as required, and suitable

for the TQC CureView.

8.3 Start the instrument

Start the instrument following the steps listed in Section 12.

| 12

9 CARE

• Always clean the instrument after use.

• Clean the instrument using a soft dry cloth. Never clean the instrument

by any mechanical means such as a wire brush or abrasive paper. This may

cause, just like the use of aggressive cleaning agents, permanent damage.

• Do not use compressed air to clean the instrument.

Make sure that no paint or other liquids are spilled on the

electronics or left in the holes.

9.1 Disposal of Materials

Disposal of materials used in the operation of the instrument or for auxiliary

functions and exchanged items should be dealt with safety and in a manner

that will not harm the environment. Follow the local regulations.

9.2 Customer Service

Customer service is provided on request by

TQC – Molenbaan 19 , 2908LL Capelle aan den IJssel - The Netherlands,

T +31(0)10 7900100, F +31 (0)10 7900129 or by local representatives.

13 |

10 INSTALLATION CRITERIA

The TQC CureView is designed to operate in general lab conditions on a

sturdy worktable. In order to create the safest work environment possible

below requirements should met.

10.1 Climate

It is recommended to operate the TQC CureView in a temperature stable

environment. Due to the general tests performed with the TQC CureView a

climate controlled environment is advised having 20-25˚C / 68-77˚F and

40 – 60 %rH. Other ranges of temperature and humidity can limit the

minimal programmable temperature of the machine. For example if the

ambient temperature is 35˚C / 95˚F the minimal programmable temperature

is approximately 10˚C / 50˚F higher.

10.2 Power Supply

The TQC CureView is designed to operate at 220 - 240V / 50/60Hz power

supply, this due to the power consumption of 3500W. For the 230V /60Hz

equipped countries the 3500W is together with the laptop the maximum

power that can be drawn from a fuse. The CureView should be run on a

dedicated fuse. The TQC CureView cannot be connected to 110V power

supply. When the TQC CureView is intended for use in 110V countries the

CureView needs to be connected to Split phase power supply. Please

consort a suitable trained technician to verify the power supply.

There should be a second power plug available to

connect the laptop.

10.3 Worktable

A suitable and sturdy table needs to be selected with sufficient depth and

clearance above the table to operate the TQC CureView. No power supplies,

sockets or such may be placed behind the CureView that could block or

be affected by the heat exhaust in the rear of the CureView. The worktable

should be able to support 40 kg / 88.18 lbs of load and allow for placement

of the CureView with following clearances. The height of the table should be

selected such that ergonomic and safe operation is the machine is possible.

Please consult local guidelines and regulations.

10.4 Exhaust system

The CureView has a self-powered fume exhaust system mounted on the

rear. This system is created to allow fumes emanating from the test panel to

be expelled safely. The CureView may be connected to an already existing

ventilation system when this is a system without forced convection. If

the ventilation system has forced convention care should be taken not to

disturb the flow of air in the CureView.

10.5 Installation procedure

Verify that above criteria are met. If above criteria are met proceed as

followed:

Remove all packaging material from the CureView and store it

1

for possible later use.

2

Lift the CureView onto the the worktable by lifting it with 2

persons. Each grabing the machine from the side.

3

Connect the exhaust.

4

Connect the power supply.

5

Place the USB cable.

6

Install the supplied laptop.

7

Connect the USB cable to the laptop

8

Power up the TQC CureView.

> 600 mm

Exhaust

fumes

< 150 mm

9

Power up the laptop.

10

Verify that 2 beeps are sounded from the gradient oven.

11

Start the Gradient Oven Control software.

12

No error message should be shown.

| 14

11 THERMAL DYNAMICS

11.1 General

Even though the CureView is designed to the highest specifications possible

the CureView has limitations. We simply are not able to go beyond the laws

of physics. In order to explain some of the limitations of the TQC CureView

the following chapter will include some of the intricacies of thermal

dynamics involved with using the CureView.

11.2 Basics of Gradient Ovens:

The TQC CureView is a new generation of Gradient-ovens that allows for

significantly more advanced tests and doesn’t require preheating. The

implementation of the latest heating techniques in the TQC CureView

provide a different heat transfer compared to that of older systems with

conventional heating. The direct IR-irradiation by the TQC CureView allows

for a significantly more efficient heating than traditional gradient oven

systems. Due to this new heating system multiple components and

procedures had to be changed in the machine. Below is a simplified image

highlighting the difference in build of conventional systems and the new

TQC CureView.

Conventional heating IR-heating

Due to the difference in construction the heat transfer is significantly

different. Where the older systems work based on conduction of heat the

TQC CureView is based on transmittance of energy by IR-radiation. Older

Gradient ovens often suffer from loss in efficiency by improper contact

between the heating element, glass-bed and/or test panel. Because older

models have the thermocouple installed directly at the heater, they have

been compensated for the offset that occurs due to the different contacts

required to transfer the heat. Any small misalignment or other problem will

result in a loss of efficiency. This will cause significant differences in the

temperature of the test-panel. The TQC CureView is created such that it

regulates the heaters based on the temperature probe that is positioned on

top of the panel, thus at the actual spot where the temperature is relevant.

When comparing old and new systems side by side there might be a

temperature offset that has to be accounted for. This off-set is due to

deviation from older machines. Where test were set to be performed at

180˚C / 356˚F they could actually have been performed at 150˚C / 302˚F.

This off-set varies depending on the condition of the old machines.

To determine this off-set it is recommended to measure the actual

temperature obtained on the surface of the test panel.

Due to the new and improved heating systems no preheating is required.

This eliminates an irregular heating of the panel and allows for a repeatable

ramping of the temperature on the panel. The ramping is controlled and will

follow the same slope for all temperatures. The ramping for the heating can

be programmed in the Gradient oven. Below graph shows a default slope

being equal for all set point temperatures.

All following examples of ramping and heating graphs are

generalized and not correlated to a specic substrate or

ramp speed unless otherwise stated.

11.3 Substrate material

The main influence for differences between tests is the substrate that tests

are performed on. Different substrates react differently to heat. Some

substrate function as an isolator and others as an excellent conductor of

heat. This ability or it’s lack to conduct heat determine the maximal

temperature difference between 2 heaters. On a well conducting material

the difference between 2 elements is lower than on a less conducting

substrate. The property of metals to conduct heat is a temperature

dependent function. If a gradient from 25˚C to 125˚C / 77˚F to 257˚F

is obtainable this doesn’t mean that 125°C to 225°C / 257˚F to 437˚F is

possible as well or vice versa. In order to test for the suitability of a program

and/or substrate it is advised to run a test-run on uncoated substrate prior

to performing the real test.

Full thermal properties of a substrate can be calculated. Full calculations

and factors can be found in the “ Handbook of Chemistry and physics.”

Calculating the thermal response of panels is however tricky due to the

large number of variables.

11.4 Surrounding / environmental conditions.

The TQC CureView has been designed such that it will keep draft away

from the panel but still allow the panel to be visible. Though the Cureview

is designed to eliminate as many influences as possible. Small fluctuations

in the heating behavior can be caused by changes in temperature and

humidity of the surrounding air. These parameters not only influence

the heating capabilities of the CureView but in more significant manner

the evaporation of samples as tested according the ISO 2812-5 or curing

of powder coatings. Stable laboratory conditions are required to create

reproducible results. Please consult internal guidelines or international

standards for the required climatic conditions required for the performed

test.

11.5 Ramping

The TQC CureView can be set for custom ramping speeds. A Ramping

indicates the speed in degree per second the CureView will heat a panel.

The selected ramping will influence the amount of heat generated by the

lamps. The generated heat needs to flow from the bottom of the panel to

the top prior to being detected by the probes. This process depends on

the thermal properties of the test panel. Thickness, material type, surface

finishing and set end temperature all influence the thermal response. If the

ramping is set to high there might be an overshoot of the set temperature.

In the following graph the vertical axis shows the temperature in ˚C and the

horizontal axis displays the time (s). All set temperatures follow the same

ramp. Adjusting the ramp value can control the ramp slope.

15 |

12 CONTROL SOFTWARE MANUAL

12.1 Introduction

This document describes the TQC Gradient Oven Control Software (GOC)

version 1.11, which allows you to setup and run elevated temperature tests

in the Gradient Oven. The GOC is driving the instruments actuators, heaters

and sensors. The GOC works in conjunction with the TQC Ideal Finish analysis

software (IFA), which receives and displays the temperature profile data from

the GOC.

12.2 Prerequisite

In order to view and analyze temperature profiles the TQC Ideal Finish

Analysis Software version 6.0 or higher has to be present on the same

computer.

12. 3 Program conguration

Before starting a test it is good practice to configure two settings of the GOC

located in the tools menu.

Setup mode

Run mode

Tools -> Option

GOC File Locations:

Specify where the GOC configuration files shall be saved to a storage device,

file extension *.goc.

The configuration file describes various test parameters that are used during

a test, for example panel name, duration and temperature parameters of the

test. All these parameters are configured in the software setup mode.

Default temperature Units:

Specify in which temperature units the GOC shall display its values by

default.

12.4 Modes and stages

The Gradient Oven Control software has two modes a setup mode and a

run mode. The program starts up in the setup mode showing the setup

stage enumerator, which guides the user through the setup in four steps.

Once setup is completed and the run is started the program will switch to

run mode, showing the run stage enumerator with the thirteen stages from

begin to the end of the test.

12.5 Congure a test in setup mode

The setup stage enumerator shows the four stages that are configured

manually and which can be saved to a storage device for future use. The

basic commands New, Open and Save to handle configuration files are

grouped together in the menu bar and in the tool bar.

New:

Create a new test configuration.

Open:

Open a saved test configuration file.

Save:

Save a test configuration to file on a storage device.

| 16

Save As…:

Save a test configuration to file with another name on a storage device.

12.5.1 General setup

Use the general setup page to specify a name for the panel under test. In IFA

the name of panel will be used as identification for the temperature profile.

Use Temperature units to override the default setting in this configuration

only.

Start run:

Command to switch the program in run mode and skip any remaining steps

from the setup mode stage enumerator. Use this command to switch to run

mode instantly for example after opening a configuration file.

Cancel run:

Command to cancel the current run and switch to program to setup mode.

Use the red button on the front of the gradient oven to obtain the same

result.

12.5.2 Pre-cooling setup

The gradient oven cooling zone consists of five Peltier cooling elements

that can cool down the panel under test. The cooling zone is not

temperature controlled and only driven by a predefined power and

duration. Use the pre-cooling setup to configure the cooling power and

duration in the cooling zone that shall be applied to the panel under test

prior to the heating stage.

Power (%):

Defines the amount of cooling in percentage of the gradient oven cooling

system.

Duration (s):

Defines the amount of time in seconds that the cooling shall be applied.

Proceed:

Command to step to the next stage in the setup mode stage enumerator,

obtain the same result as selecting a stage by mouse. The command will

switch the program into run mode if the Pre-cooling stage was previously

selected. Use the green button on the front of the gradient oven to obtain

the same result.

17 |

12.5.3 Heating setup

The gradient oven heating zone consists of thirty two heating elements,

which are displayed in one record in the program. Each heating element

has its own temperature set point. The duration is set for all thirty two

heating elements at once. The individual heating settings allow applying a

temperature gradient over the length of the panel, whereas multiple records

allow applying a temperature gradient in time.

Use the column Set All to add an identical value to all heaters at once.

Add gradient:

Command to configure a temperature gradient from and to a specie

temperature, the control will automatically calculate all values between the

lowest and highest temperature setting.

Clone column to right:

Command to copy one heater to all other heaters to the right of the

selected heater.

Delete row:

Command to delete the selected row.

Import PFS:

Command to import IFA profiles, generated from GOC or from CurveX

measured temperature data.

Select PFS File:

Command to select the IFA temperature profile for import. After import the

Mapping tab shows the imported temperature profile for each probe on

the left and the gradient oven heaters to which these probes will link on the

right.

Add row after current selection:

By default a row is inserted before the selected row, check this option to

insert a row after the current selection.

Start at heater:

Specify the heater from which the gradient shall begin.

Begin temperature:

Specify the start temperature at the heater specified at Start at heater.

End at heater:

Specify the heater at which the gradient shall end.

End temperature:

Specify the stop temperature at the heater specified at End at heater.

Duration:

Specify the duration of this gradient heating cycle.

| 18

The link between probes and heaters can be changed by drag and drop a

heater onto the desired probe.

Use the white/red close window command to remove a heater from the

assigned probe, the heater will move to the Not allocated to a probe

section at the bottom of the window.

Click the Heater windows to rotate the heater order.

File Details:

Use the file tab to view the imported temperature probes in a graph.

12.6 Execute a test in run mode

In the Post-cooling setup the two commands start run and proceed will act

the same way and switch the program into run mode.

Start run:

Command to instantly switch the program into run mode and begin

execution of the configured panel test. Once in run mode this command is

disabled and the cancel run command is enabled, which allows cancel of the

test in any run mode enumerator stage.

Proceed:

Command to begin execute the configured panel test.

Fume fan:

Command to control the exhaust fume fan. Use this control to flow off fume

that may originate from the running test.

12.8 Place panel

The gradient oven carrier is waiting in the loading area allowing placement

of the panel into the carrier.

Once this stage is completed press Proceed.

12.9 Pre-cooling oven

In this stage the gradient oven clamp is lowered onto the heaters to

verify that the heating zone is cooler than the configured oven test panel

temperature. Each probe must measure an actual temperature that is

lower than the target temperature before the gradient oven transports the

panel any further. In case the system temperature is higher the gradient

oven internal fan will switch on at 100% until all probes are measuring a

temperature lower than the configured temperature.

Cancel run:

Command to cancel the current run and switch to program to setup mode.

Use the red button on the front of the gradient oven to obtain the same

result.

12.7 Initialization

In this stage the gradient oven will get ready for run mode. The run stage

enumerator shows the thirteen stages that a panel test follows. The stages

include loading the panel into the oven loading area, where after the panel

is transported to the cooling area followed by a transport to the heating area.

After the test the process is reverted and the panel returns to the loading

area.

Congure a target temperature that is at least higher than

ambient temperature in order to avoid the oven to wait for

a condition that can’t be met.

Transport panel

The panel is transported from loading to cooling area.

Cooling

The panel is cooled down according to the configured Pre-cooling setup.

Transport panel

The panel is transported from cooling to heating area.

Clamp panel

The panel is clamped onto the glass bed by the weight of the probes.

19 |

12.10 Heating

In this stage the gradient oven starts the heating cycle according to the

configured heating setup.

Measured temperatures:

The graph displays the measured temperature (blue) vs the configured set

temperatures.

Congured temperatures:

The graph display the set temperatures.

Unclamp panel

The heating stage is ended, the clamp is lifted and the probes are moved

upwards in order to free the panel for transport.

12.11 Lift Panel

The panel is ready and presented to the user for analysis.

Lift panel:

Command to lift or lower the panel in the loading area.

Return to conguration:

Command to switch from Run mode to Setup mode where the next run is

configured.

Transport panel

The panel is transported from heating to cooling area.

Cooling

The panel is cooled down according to the configured Post-cooling setup.

Transport panel

The panel is transported from cooling to loading area.

| 20

13 MAINTENANCE

The TQC CureView is created such that a minimum of maintenance is

required on an annual basis. Due to the temperature resistant materials used

for the production only a hand full of components need to be checked and

maintained. Maintenance of the TQC CureView should only be performed

by competent personnel.

21 |

13.1 HEATER REPLACEMENT

The TQC CureView uses IR heaters to heat the panel. These heaters have a limited life expectancy of

5000 burn hours. It is advised to replace the heaters on an annual basis. Older heaters can influence

the performance of the TQC CureView and limit the ramping capabilities of the TQC CureView, or

cause a significant loss in efficiency. Following procedure should be followed for replacing the

heaters.

1

Turn machine off by using the switch

button on the right side of the instrument.

2

Disconnect power supply and USB cable.

Frequency:

Annual replacement (adviced) or

individual lamp replacement

By:

Supervisor / TQC representative

3

Unscrew frontpanel allen keys

(2.5 mm) located one on each side to release

front cover.

4

Slide front cover down and tilt to front.

7 8 9

Remove the front pressure pin bar.

By unscrewing the allen key (3mm) on each

side and sliding it forward.

5

Loosen the 2 allen keys (3mm) that hold

the panel lifter in place, and lower the

panel lifter until it is below the glass bed.

Slide the glass bed forward. This might take a

little effort because the plate is still clapped

at some placed.

| 22

6

Open the glass top cover and loosen the

2 allen keys positioned on the rear corners

of the glass bed.

Gently lift the middle deflector and store it.

10 11

Gently remove the front deflector by

sliding it out upwards from between the

lamps.

Before proceeding always wear the

supplied cotton gloves to prevent

contamination from the hands to be

transferred to the lamps. Contamination

on the heaters will signicantly reduce the

lifetime expectancy.

Gently remove the back deflector by

sliding it out upwards from between the

lamps.

12 13 14

Place the special heater tool between the

heater and the socket, and lift the lamp

out of its socket. Lift the front side of the

heater with two hands. Pull it slightly

to the front to release it from the rear

socket and lower it out from under the rear

deflector.

The pin on the bottom of the heater

must be positioned correctly. For a more

uniform heat distribution these are

mounted alternating. On the uneven

positions on the back side and at the

even to the front.

Take the new heater from its protective

package and place it in the same way as

the original heater was positioned using

the heater placement tool.

Place the front deflector. Place the back deflector.

15 16

Align the placed heater such that it is

pointing upward. Assure all other lamps

are correctly aligned as well.

23 |

Place the middle deflector. Make sure the front of the glass bed in

17

Slide the glass bed gently back in place.

18

Make sure it properly aligns to slide it in the

last 1-2 cm.

19

inline with the aluminum housing.

20

Gently tighten the 2 rear allen keys that

hold the glass bed in place.

23 24 25

Replace the front cover and slide it

upwards to fix it in place.

21

Replace the front pressure pin bar, and fix

the 2 allen keys.

Fix frontpanel allen keys (2.5 mm) located

one on each side to release front cover.

22

Move the panel lifter back up. Make sure

it sits.

Connect power supply and USB cable.

Verify with a test run that all lamps are

functioning again.

| 24

13.2 CONTROLLER REPLACEMENT

The TQC CureView is equipped with 4 temperature control units. These units allow for simple repairs

and or placement of newly calibrated units. The calibration of these units is transferrable to the

Gradient oven the controller will be placed on. Though appearing universal the controllers need to be

placed at a specific location on the CureView. The locations are marked on the rear of the units. The

units control the following heaters:

Unit 1 Heaters / probes 1- 8 Unit 3 Heaters / probes 17 - 24

Unit 2 Heaters / probes 9 - 16 Unit 4 Heaters / probes 25 - 32

Turn machine off.

1

2

Disconnect power supply and USB cable.

Frequency:

Annual if required for calibration or

individual for defect probe replacement.

By:

Supervisor / TQC representative

3

Unscrew the 2 allen keys (3mm) holding

the rear cable cover in place.

Slide the cover downward and tilt it out.

4

Unscrew the nut (7mm) below the

7

controller.

5

Disconnect the BUS-connector cable from

the controller.

8

Repeat steps 5, 6 and 7 for all controllers

that need to be disconnected.

6

Disconnect the power and heater lead

cables from the controller.

9

Loosen the 2 allen keys (3mm) on each

side of the controller holder plate.

Allowing the plate with the controllers to

slide down.

25 |

Open the cover of the CureView. Push the spring behind the probe block

10

11 12

backward.

Push back the base of the probe block at

the notch and lift the probe block out.

13

Lift the controller and guide the probe

block out through the back of the

CureView.

16

Reconnect the connectors. Take care

the TQC-BUS connector(s) is/are placed

correctly.

Take care not to switch the controllers or

place them at the wrong locations. Do

not exert force on the cables connecting

the probe to the controller.

Raise the controller holder plate and

17

tighten the allen keys (3mm) on each

side.

1514

Fix the nut below the controller.Replace the controller with a new one.

18

Tilt and slide in the rear cable cover back

in place. Fix the 2 allen keys to hold it in

place.

If the cables prevent a smooth

positioning. Use the allen key to gently

push the cables down. To allow to slide

the cable cover back in place.

| 26

14 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and

any person using the product for any purpose other than that specifically

recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so

at his own risk. Whilst we endeavor to ensure that all advice we give about

the product (whether in this manual or otherwise) is correct we have no control over either the quality or condition of the product or the many factors

affecting the use and application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any liability whatsoever

or howsoever arising for the performance of the product or for any loss or

damage (other than death or personal injury resulting from our negligence)

arising out of the use of the product. The information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

27 |

ANNEX A | OPERATOR QUALIFICATION LIST

Supervisor list (allowed to perform lamp replacement and such).

Date Name Signature SignatureInstructed by

29 |

Operator list.

Date Name Signature SignatureInstructed by

| 30

ANNEX B | MAINTENANCE LIST

Date Action Name Signature

Installed at test location.

First run performed.

31 |

TQC B.V.

Molenbaan 19

2908 LL, Capelle aan den IJssel

Nederland

+31 (0) 10 – 7900 100

+31 (0) 10 – 7900 129

info@tqc.eu

www.tqc.eu

TQC GmbH

Nikolaus-Otto-Strasse 2

Hilden, D-40721

Duitsland

+49 (0)2103-25326-0

+49 (0)2103-25326-29

info.de@tqc.eu

www.tqc.eu

TQC ITALIA s.r.l.

Via Cesare Cantu’ ,26

SEREGNO, (MB) 20831

Italië

+39 0362-1822230

+39 0362-1822234

info@tqcitaly.it

www.tqc.eu

TQC UK

Po Box 977A

Surbiton, KT1 9XL

Engeland

+44 208 255 0143

-

janet@tqc.eu

www.tqc.eu

TQC-USA Inc.

4053 S. Lapeer Road / Suite H

P.O. Box 108 Metamora, Michigan 48455

USA

+1 810-678-2400

+1 810-678-2422

joel@tqc-usa.com

www.tqc-usa.com

TQC Norge AS

Øvre Langgt. 26

Tønsberg, 3110

Noorwegen

+47 333 10220

+47 333 10221

info@tqc.no

www.tqc.no

Loading...

Loading...