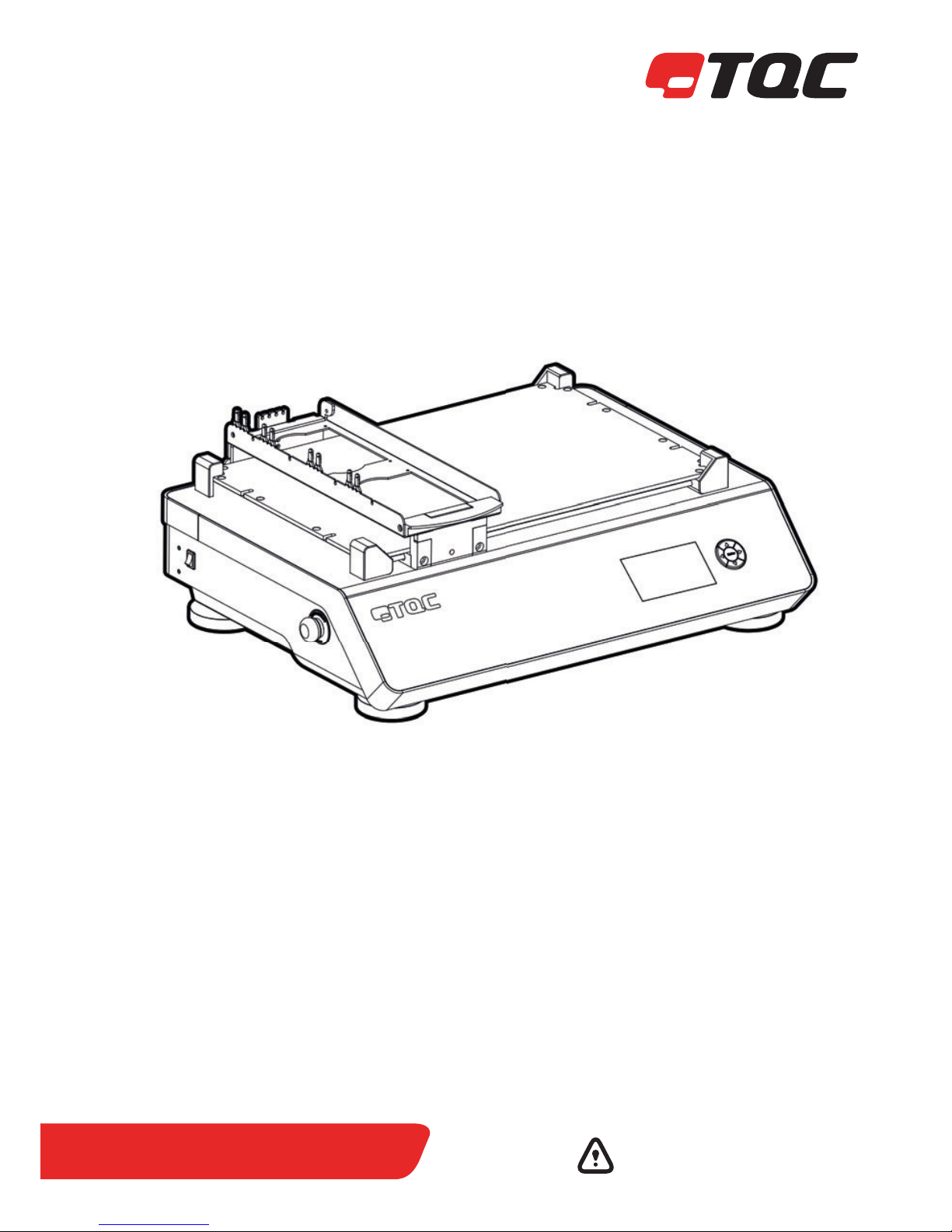

TQC Scrub Abrasion and

Washability Tester

(AB6000, AB6010)

Operating Instructions (V1.1 0118)

IMPORTANT! Before taking this instrument

in use we strongly advise you to read this

manual carefully.

3 |

TQC will grant a warranty for a period of 12 months for the TQC Scrub

Abrasion and Washability Tester and 12 months for all related equipment

from the date of delivery in respect of any evidence of faulty workmanship

and materials.

Should a delivered consignment prove to be contrary to contract upon

inspection, the customer shall grant TQC the opportunity hereunder of

removing the fault, or else the customer may demand replacement. Because

of size and weight of the instrument TQC will strive to give remote support.

Should the supply or delivery of any improvement or replacement not prove

possible, the customer may choose between having the purchase price

reduced or in demanding the contract of sale to be rescinded (conversion).

Damage resulting from natural wear and tear, mechanical or chemical

damage, an act of God or non compliance with the operating instructions

shall be excluded from the warranty as well as mechanical interference by

the customer or by third parties with TQC Scrub Abrasion and Washability

Tester and related equipment without TQC’s written permission. No liability

will be accepted for defects, damage or injury caused due to use not carried

out in accordance with the manufacturer’s user instructions.

To claim warranty, the rejected product has to be sent to TQC together with

the original invoice, any exchange before the product has been returned

to TQC is not possible. TQC reserve the right to repair, exchange or supply

an equivalent substitute. TQC is not liable for handling or transport costs.

Warranty on the purchase price is limited, all liability for consequential

damages or changes in technology is expelled.

This product complies to

- Machinery Directive 2006/42 / EC

- Low Voltage Directive 2006/95 / EC

- EMC Directive 2004/108 / EC

This product is RoHS 2 compliant (2011/65/EU)

WARRANTY

5 |

1 General

1.1 Importance of operating manual

1.2 User-responsibility

1.3 Responsibility of personnel

1.4 Dangers

1.5 Designated purpose

1.6 Copyright

1.7 Manufacturer’s/Supplier’s address

2 Safety Instructions

2.1 Meaning of Symbols

2.2 Availability of Safety Information

2.3 Dangers from Electrical Energy

2.4 Modifications to the Equipment

3 Transport and Storage

3.1 Packing

3.2 User: Check on Receipt

3.3 Reporting Transport Damage and

Documentation

3.4 Storage and Protective

Measures when not in use

4 Instrument Data

4.1 Name / Article

4.2 Scope of Supply

4.3 Technical Data

4.4 Dimensions and Weight

4.5 Basic Unit

5 Instrument Controls and Functions

5.1 Instrument Layout

5.2 Connecting a Mouse and Keyboard

6 Instrument Preperations

6.1 Installation

6.2 Tool Holders and Tools

6.3 Fluid Tubes

7 Navigation

7.1 Menu

7.2 Number Input

7.3 Text Input

8 Operation

8.1 Starting the Instrument

8.2 Run

8.2.1 Run

8.2.2 Manual Movement

8.3 Run Setup

8.3.1 Manual

8.3.2 Alarms

8.3.3 Pumps

8.3.4 Custom Presets

8.3.5 New Custom Preset

8.3.6 Standard Presets

8.3.7 Select Length

8.3.8 Test Positioning

8.3.9 Flush System (AB6000 only)

9 Instrument Setup

9.1 Instrument Setup Menu

9.2 Units

9.3 Alarms

9.4 Display Brightness

9.5 System Information

9.6 Reset

10 Mechanical

10.1 Test Beds

10.2 Sample Clamp Frames

10.3 Tool Holders

10.4 Tools

10.4.1 Small Sponge (AB5012)

10.4.2 Wild Boar Brush (AB5010)

10.4.3 Nylon Brush (AB5011)

10.4.4 Abrasive Pad Tool (AB5013)

10.4.5 Universal Material Clamp (AB5020)

10.4.6 MEK / Crockmeter Tool (AB5060)

10.4.7 Large Sponge Tool (AB5050)

10.4.8 TQC Cloth Holder (AB5055)

10.4.9 Metal Shim (AB5025)

10.4.10 Glass Bed (AB5180)

10.4.11 Heavy Weight Support Tool (AB5032)

10.4.12 Tubing (AB5115 and AB5113)

11 Care and Maintenance

11.1 Disposal of Materials

11.2 Customer Service

12 Disclaimer

Annex A Standards Conguration Table

Annex B Chemical Resistance

Annex C Operator Qualication List

Annex D Maintenance List

6 21/22

23/27

28

29

30/31

32/43

45

47

7

8

9

10/11

12

13

14/20

INDEX

| 6

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and

possible applications of the instrument. It contains important instructions

about how to use the instrument safely and economically; according to

the purpose designated. Following these instructions is not only essential

to avoid risks. It also reduces repair costs and down-time and increases the

products reliability and service-life.

Anyone who works with the instrument shall follow the instructions in this

manual, particularly the safety related instructions. Additionally local rules

and regulations relating to environmental safety and accident prevention

should be observed. It is mandatory that users have read and understand

this manual prior to first operation of the TQC Scrub Abrasion and

Washability Tester.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are

familiar with the general instructions on how to work safely and

to prevent accidents. The use of the instrument should have been

instructed duly.

b) Regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument

should pay attention to the general regulations relating to working safety

and accident prevention. The safety chapter and the warnings in this manual

should have been read and understood

; acknowledged as evidenced by

their signature as can be placed in the Operator Qualification list Annex C.

1.4 Dangers

This instrument has been designed and constructed in accordance with

state-of-the-art technology and the acknowledged safety regulations.

Nevertheless, working with the instrument could cause danger to the

life and health of the operator or to others, or damage to the instrument

or other property. Therefore the instrument should only be used for its

designated purpose, and in a perfect technical condition. Any defect that

could have a negative effect on safety should be repaired and recorded.

1.5 Designated purpose

TQC Scrub Abrasion and Washability Tester is exclusively designed to

perform washability tests of painted and coated test panels as described

within the specifications. TQC will not be held liable for damage resulting

from improper use.

Designated purpose also includes properly observing all instructions in the

operation manual, and adherence to inspection and maintenance

schedules. TQC is entitled to request these form when warranty claims are

made and during inspections to ensure safe operation and evaluate correct

usage.

1.6 Copyright

The copyright of this operating manual remains with TQC. This operating

manual is intended solely for the user and his personnel. Its instructions

and guidelines may not be duplicated, circulated or otherwise passed on to

others, neither fully, nor partly. Infringement of these restrictions may lead

to legal action may be taken if this restrictions are infringed upon.

1.7 Manufacturer’s/Supplier’s address

TQC – Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10 7900 100

F +31 (0)10 7900 129

1 GENERAL

7 |

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

2.2 Availability of Safety Information

The instruction manual should be kept in proximity to where the instrument

operates and should be visible and accessible at any time of operation.

In addition to the information contained in the instruction manual, general

and local regulations for accident prevention and environmental protection

shall be kept available and observed. Always ensure all guidelines in respect

of safety and dangers on the instrument are in readable condition.

In case of danger the instrument has to be switched off by means of the on /

off switch at the left back side of the instrument or by unplugging the mains

power, then the danger should be eliminated.

2.3 Dangers from Electrical Energy

• Work on the electrical supply may only be done by a qualified electrician.

• The electrical equipment of the instrument must be checked regularly.

Loose connections and cables damaged by heat must be corrected

immediately.

• Always make sure the instrument’s power is turned off while adjusting any

electrical component.

Make sure that no paint or other liquids are spilled on the

electronics

2.4 Modications to the Equipment

• Any modifications or additions or alterations to the instrument may solely

be made with permission from the manufacturer otherwise the warranty

will be void.

• Instruments which are not in fault-free condition must immediately be

switched off

• Only use replacement parts from the original supplier. Parts used from

other sources aren’t guaranteed to take the loading and meet the safety

requirements.

Possible immediate

danger to the life or

health of personnel.

If this guideline is not noted

it can lead to severe danger

to health, up to fatal injury.

A dangerous situation

could be caused.

Non observance of this

guideline can lead to injury

or to damage to equipment.

Special tips and

particular information.

Guidelines to make optimal

use of the instrument.

2 SAFETY INSTRUCTIONS

| 8

3.1 Packing

• Please take note of pictorial symbols on the packing.

• Check for transport damages. If the packaging is damaged only accept it

with a written approval of the transporter that the package was damaged.

3.2 User: Check on Receipt

• Check packing for damage

• After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

• Any damage should be documented as accurately as possible (possibly

photographed) and reported to the relevant insurers or, in the case of sales

“delivered to customers works”, to the supplier.

3.4 Storage and Protective Measures when not in use

• The instrument must be stored in a dry place at a temperature

between 10 - 40˚C / 50 - 104˚F.

• If packing is damaged upon receipt immediately inform the forwarder and

make a note on the packing list and have it signed by the forwarder. Ideally

make some pictures of the damage as well.

• Store instrument in the original packing if possible.

3 TRANSPORT AND STORAGE

9 |

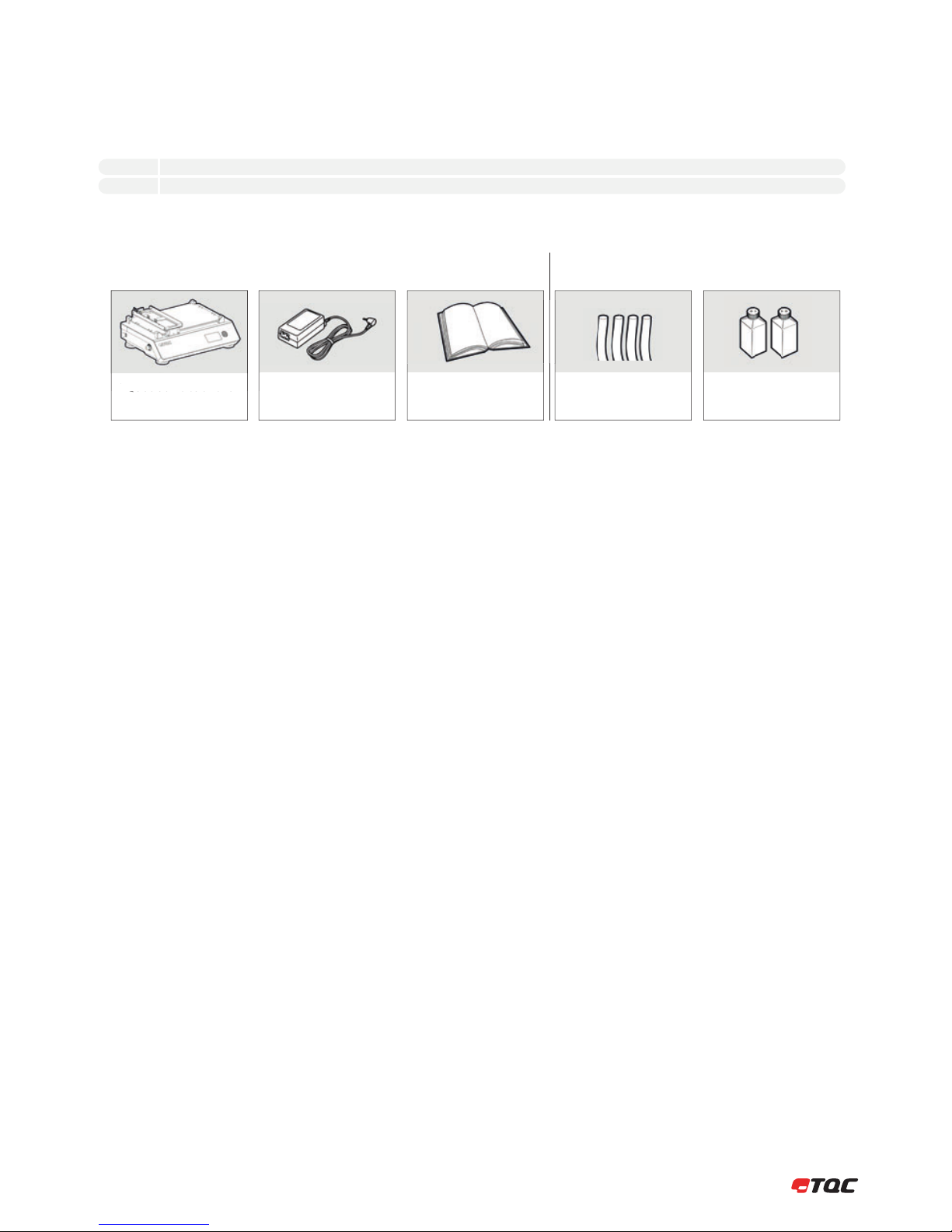

4 INSTRUMENT DATA

TQC Scrub Abrasion and

Washability Tester

24 V Adapter +

Power Cable

Manual Tubing

Fluid Containers

Standard supplied Only supplied with AB6000

4.3 Technical Data

Traverse speed: 1 - 60 cycles per minute

Traverse speed accuracy: + / - 1% of set speed

Stroke length: 20 - 300 mm / 0.39 - 11.81 in

Stroke length accuracy: + / - 0.01 mm

Pump flow rate: 0.0 - 3.0 ml per minute / 0.0 - 0.79 GPH

Max. panel width: 70 mm

Max. panel length: 350 mm

Max. panel height: 35 mm

4.4 Dimensions and Weight

Depth: 490 mm / 19.3 in

Depth with pumps: 530 mm / 20.87 in

Width: 640 mm / 25.2 in

Height: 235 mm / 9.24 in

Weight: 30 - 35 kg / 66.14 - 77.16 lbs (depending on model)

4.5 Basic Unit

Power Supply: 24 VDC / 100 - 240 V / 50 - 60 Hz

Power consumption: max. 90 Watt

Display: 480 x 272 pixel TFT display

Control: 5-key navigation switch

(Mouse Keyboard optional)

Menu languages: English, Spanish, Chinese, Polish, German, French,

Italian, Japanese, Russian, Turkish

4.1 Name / Article

AB6000 TQC Scrub Abrasion and Washability Tester

AB6010 TQC Scrub Abrasion and Washability Tester Basic

4.2 Scope of Supply

| 10

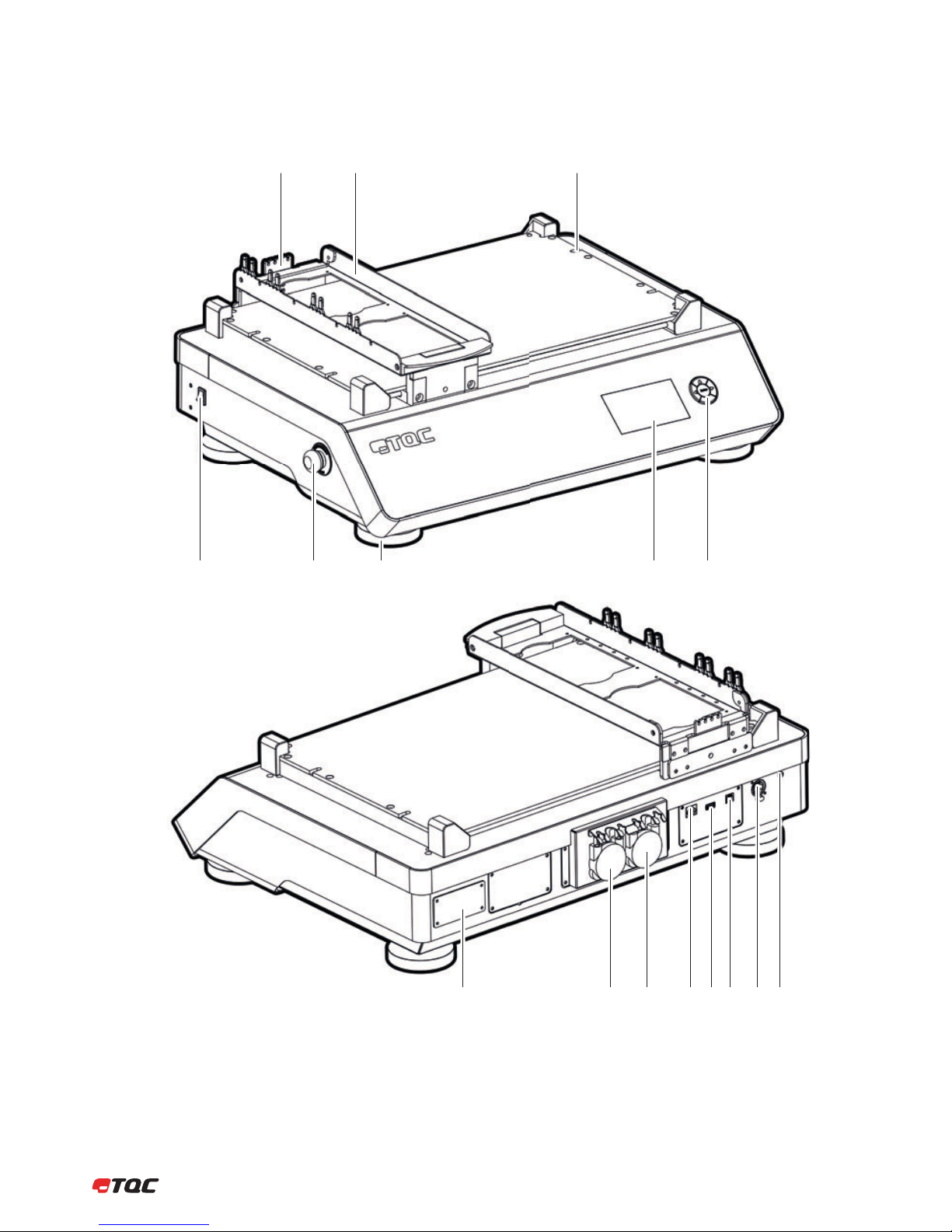

5 INSTRUMENT LAYOUT AND FUNCTIONS

Tube Holder

Tool Carrier

Fixture Screws

Power Switch

Emergency Button

Adjustable Feet

Full Color Display

5-key Navigation Switch

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

Machine ID-Tag

Pump AB

Pump CD

Ethernet

USB-A

USB-B

TQC Bus

Power Entry

45

910111213141516

678

12 3

5.1 Instrument Layout

11 |

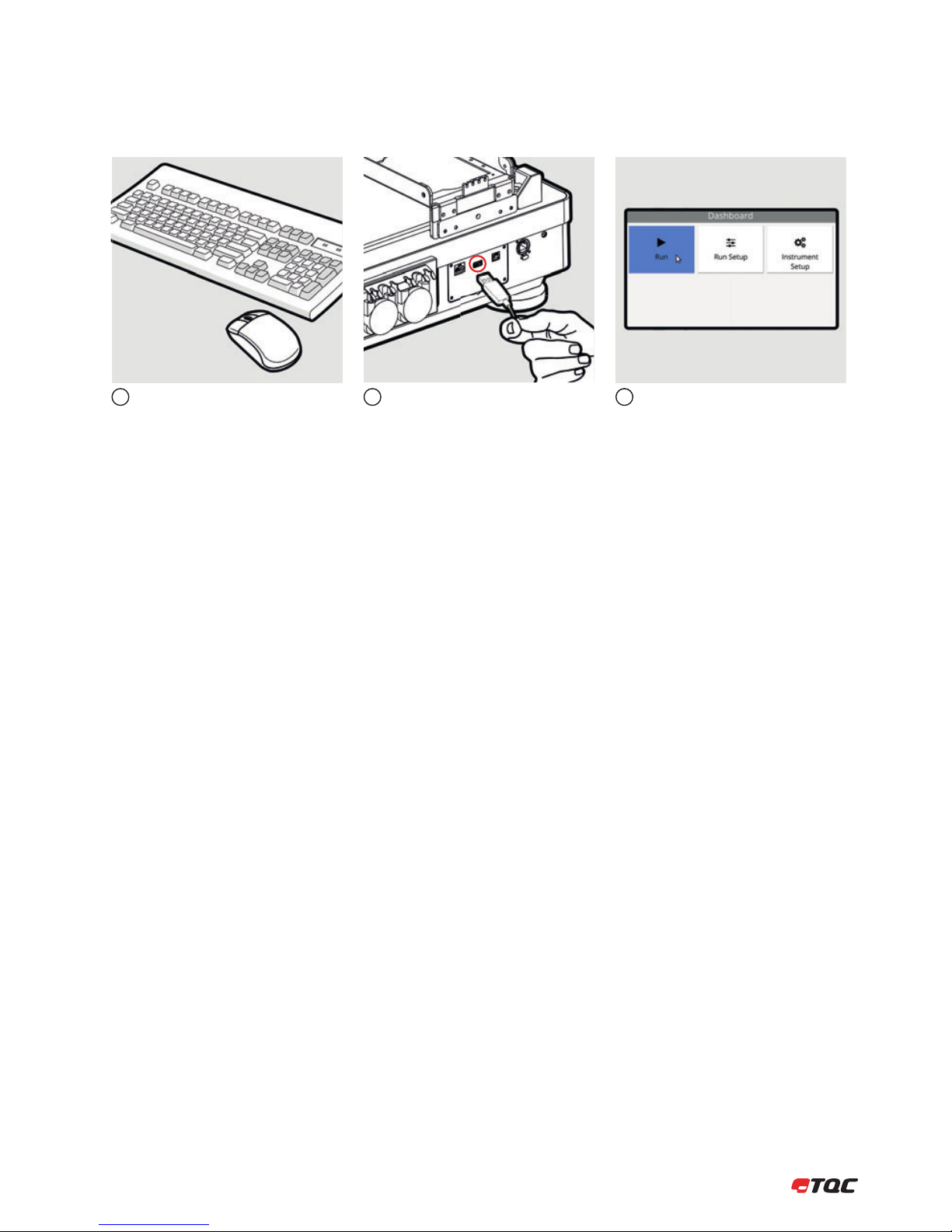

5.2 Connecting a Mouse and Keyboard

The instrument can also be controlled by a

mouse and/or keyboard.

Connect the mouse and/or keyboard to the

USB-A port at the back of the instrument.

Clicking the left mouse button behaves the

same as the OK button. (Not all input fields

can be controlled by a mouse.)

123

| 12

6 INSTRUMENT PREPARATIONS

The instrument has to be installed on a

sturdy table or work area.

Lift the Tool Carrier.

Connect the power cable to the machine

and a wall socket.

Place the Test Beds and the Sample Clamp

Frames. Then close the Tool Carrier.

Place the Tool Holders first, then place the

Tools.

1

1

2

23

6.1 Installation

6.2 Tool Holders and Tools

6.3 Fluid Tubes

Mount the tubes in the bracket on the Tool

Carrier and place the correct tube at each

channel.

Connect the IN tubes from the pumps to

the fluid containers.

23

Connect the tubes to the fluid pumps. The

channels are marked on bracket.

1

13 |

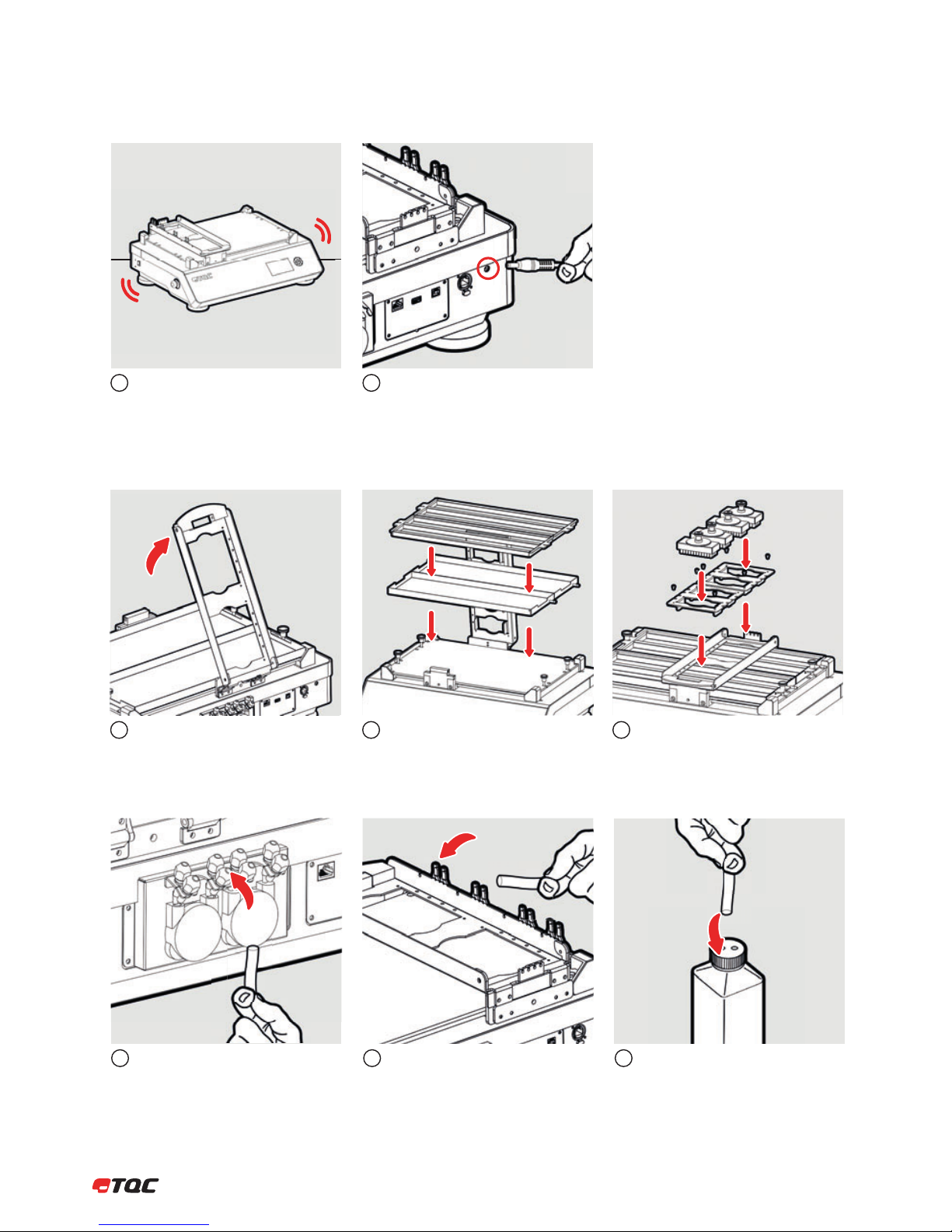

7 NAVIGATION

Use the 5-key button to navigate through

the interface. Red lights in the 5-key button

indicate possible actions for the selected

button.

You can change the selected button by

pressing the arrows on the 5-key button.

12

To confirm the selected button, press OK on

the 5-key button.

3

Select the input and press OK to edit the

value.

Use the and buttons to increase or

decrease the value. Hold the button to

increase or decrease in bigger steps.

Use the and buttons to select the

character.

Use the and buttons to change the

character.

Press OK to stop editing.

12

23

3

Select the input and press OK to edit the

value.

1

7.2 Number Input

7.1 Menu

7.3 Text Input

| 14

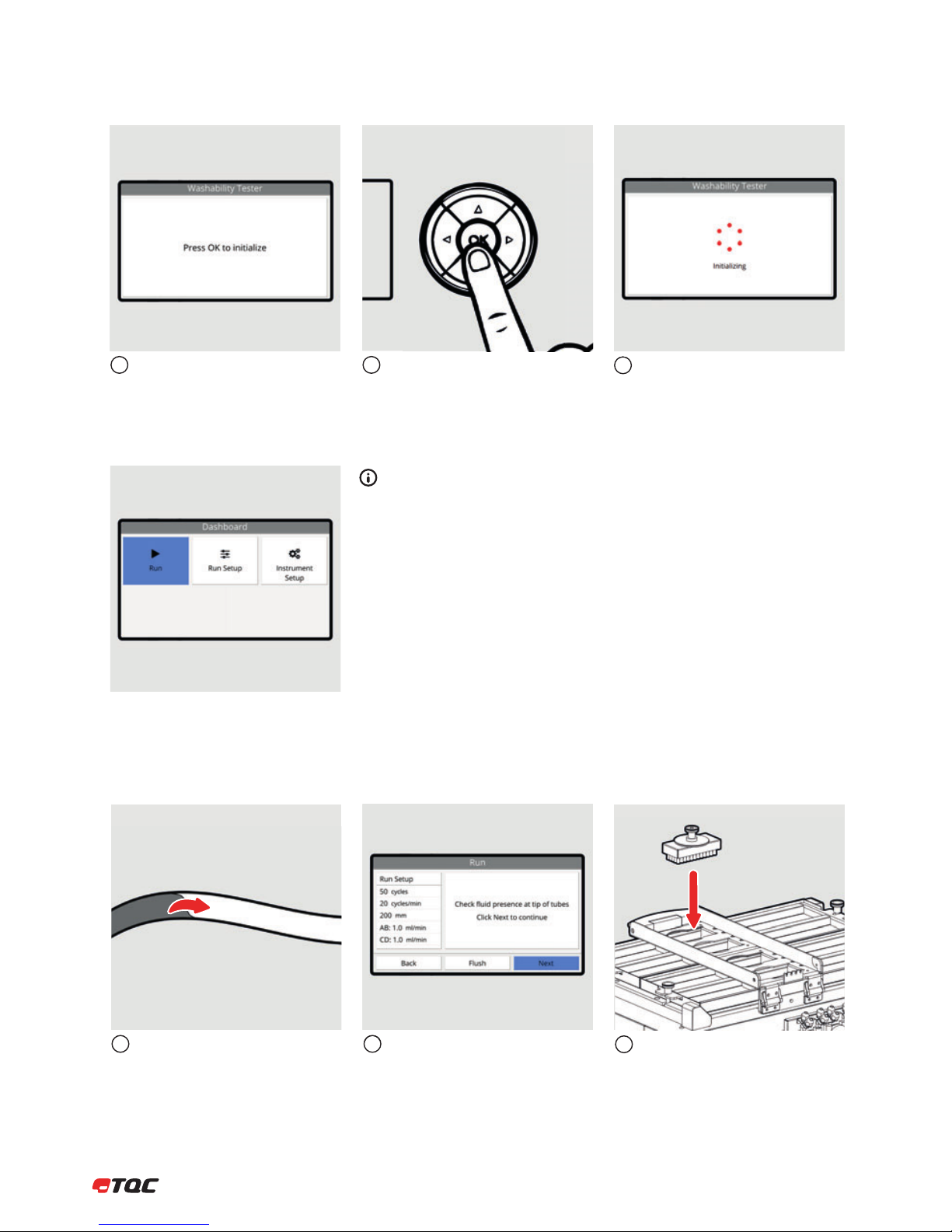

8.1 Starting the Instrument

8 OPERATION

Press OK to initialize the instrument.This screen will be displayed after turning

on the instrument.

The instrument will check the system

for any errors and the Tool Carrier will be

calibrated.

12

Run

Click to start a new run.

Run Setup

Run related settings.

Instrument Setup

All instrument related settings.

3

Check fluids presence at tip of tubes.

(AB6000 only)

Follow the instructions on the display.

12

Place and secure tools.3

8.2 Run

8.2.1 Run

15 |

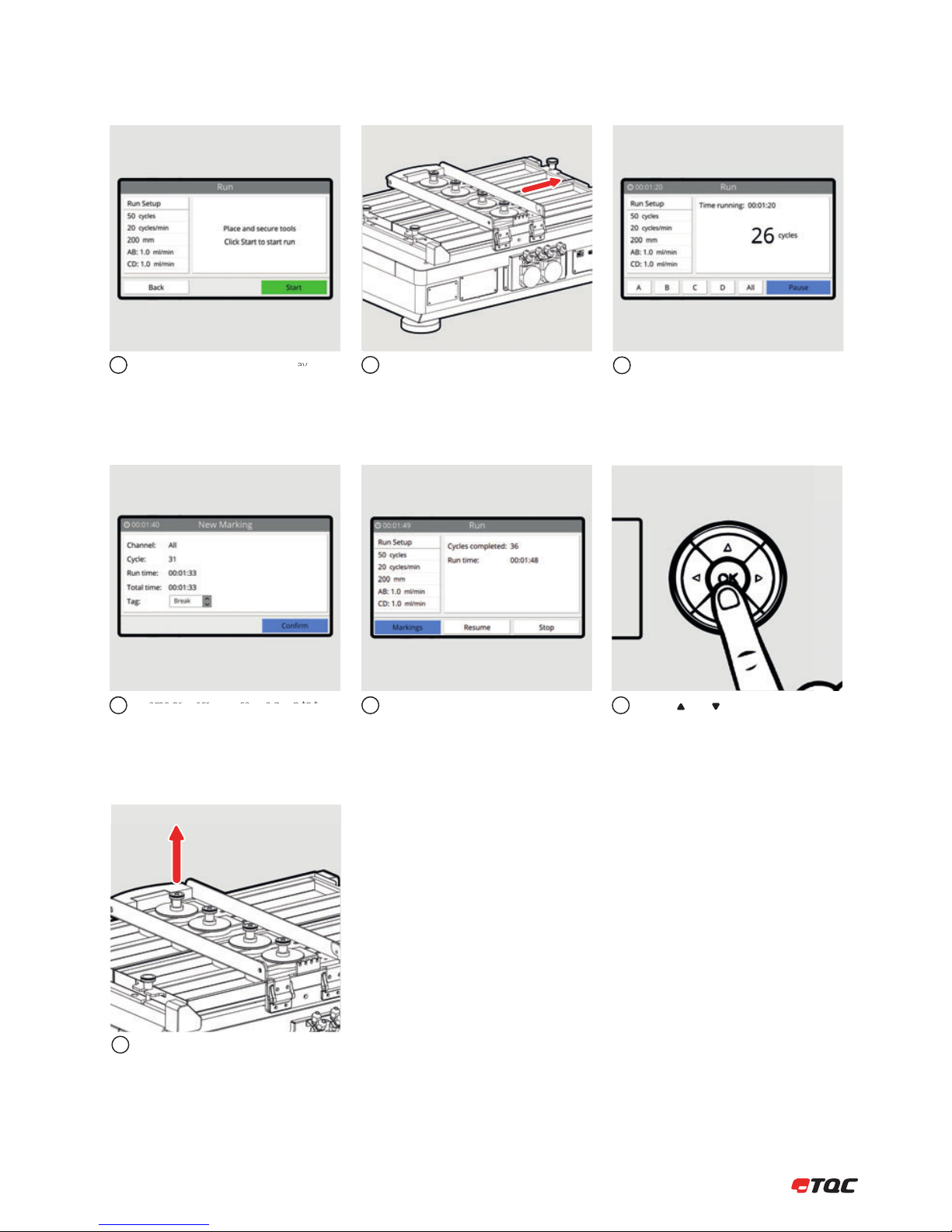

Follow the instructions on the display.

A name or description can be given to the

marking. Click Conrm to save the marking.

The Tool Carrier will now move. Stay clear

from moving parts!

4

7

5

89

Click A, B, C, or D to mark a single channel

at current cycles/time. Click All to mark all

channels at current cycles/time. Click Pause

to temporarily stop the test.

Click Markings to view all markings of the

current run. Click Resume to continue the

run. Click Stop to stop the run.

Use the and buttons to scroll through

the list of markings. Click Clear to erase all

current markings.

6

Tools may be removed when the Tool

Carrier has stopped moving.

10

| 16

8.2.2 Manual Movement

See steps 1 – 4 from chapter 8.2.1.

8.2.1.

Click Move Stroke to move the Tool Carrier

a single stroke. (from Left to Right or Right

to Left, depending on set Start Position)

12

Click Move Cycle to move the Tool Carrier a

single cycle.

3

Click Stop to stop the run.

4

Tools may be removed when the Tool

Carrier has stopped moving.

5

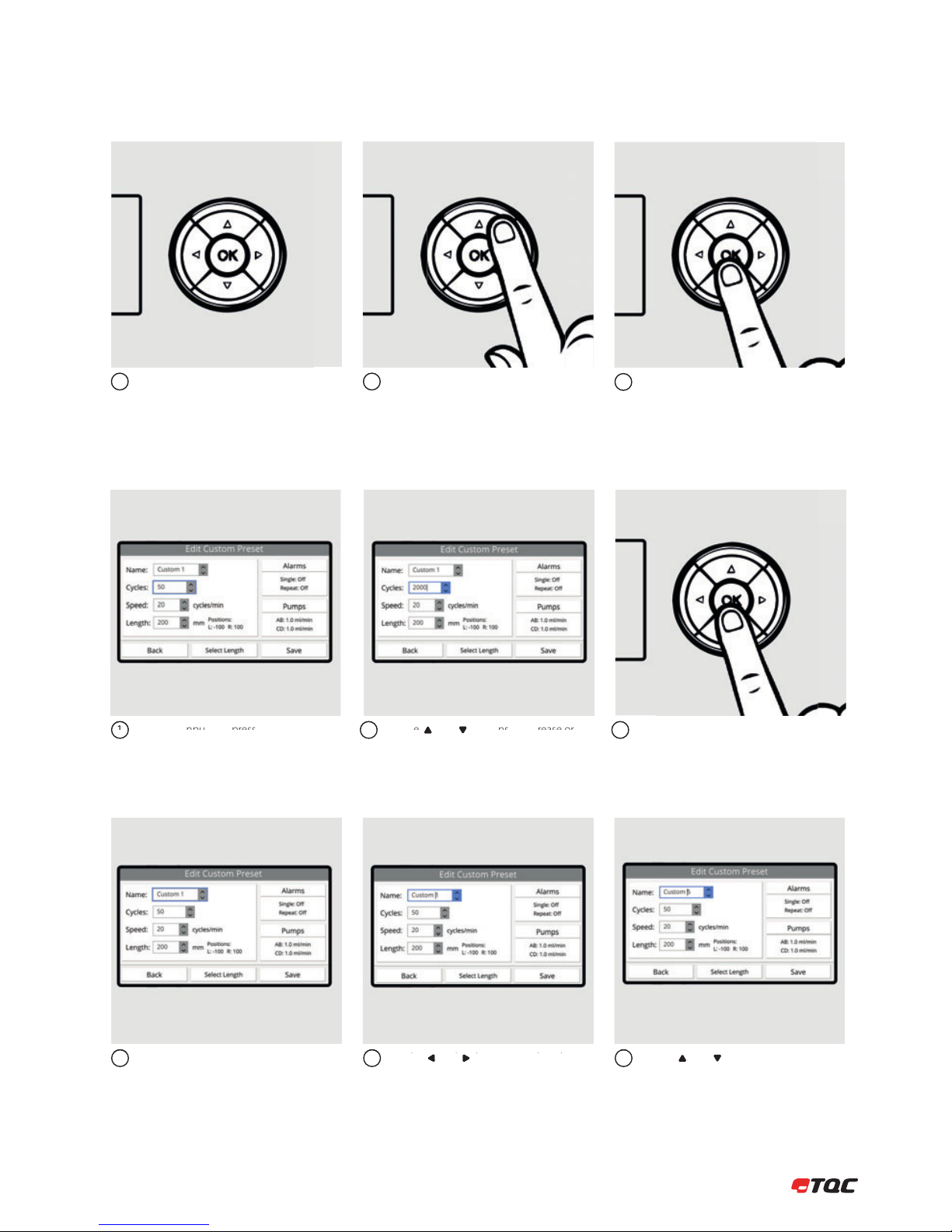

Run settings are set in Manual, Custom or

Standard. The red checkmark indicates the

active setup.

Click to set the movement start position to

Left or Right.

12

8.3 Run Setup

Run Setup

St

op

to sto

he run

.

4

17 |

Set the speed and length.

Click Alarms to configure the alarms

settings. Click Pumps to configure the

pumps settings. (AB6000 only)

If uncertain about the left and right

position, use Select Length to determine

the positions. See 8.3.7.

123

8.3.1 Manual

Click Select to use the manual setup.

Enable Manual Movement for manual

control of the Tool Carrier in a run.

45

Manual

Manual Movement

Instead of automatic movement, the user

can move the Tool Carrier a single stroke or

cycle by the click of a button. See 8.2.2 for

more information.

Single alarm will make a sound once at set

number of cycles. Enable Stop at alarm

to stop the Tool Carrier when an alarm is

triggered.

Repeat alarm will make a sound at set

interval.

Click Back to save the alarm settings.

123

8.3.2 Alarms

Ala

| 18

Enable or disable a pump.

Set the flow rate speed. Click Back to save the pumps settings.

123

8.3.3 Pumps

Click New to create a new custom preset.

Click to edit the selected preset.

Click to delete the selected preset.

The selected preset’s settings are listed on

the right.

12

Click Select to use the selected custom

preset.

3

8.3.4 Custom Presets

Similar to Manual, set the A, B, C, and D.

A name can be given to the custom preset.

Click Alarms to configure the alarms

settings. Click Pumps to configure the

pumps settings. (AB6000 only)

12

Click Save to save the new custom preset.

The new preset will be listed in the Custom

Presets menu.

3

8.3.5 New Custom Preset

19 |

Predefined presets according several

standards.

Click Select to use the selected standard

preset.

Click to edit the number of cycles.

123

8.3.6 Standard Presets

Move the tool carrier by using

the and buttons. Make sure the Tool

Carrier can move freely.

Click Set Left Position to set the current

position as left position.

12

Click Set Right Position to set the current

position as right position.

3

8.3.7 Select Length

Use the and buttons to move the

Tool Carrier. Left and Right position for

irregular test objects can be determined.

1

8.3.8 Test Positioning

Standard Preset

s

| 20

Click Flush Both to start both fluid pumps.

Click Flush Pump AB or Flush Pump CD to

start one of the pumps.

12

Click Back to return to the Run Setup menu.

Active pumps will be stopped.

3

8.3.9 Flush System (AB6000 only)

yy

21 |

This menu contains all instrument related

settings and information about the system.

Select the desired language and click Back

to change the systems language.

12

Click Length to set the length unit. Options

are: Millimeter, Centimeter or Inch.

Click Flow to set the flow unit. Options are:

Millimeter per second or Gallons per Hour.

(AB6000 only)

12

9.2 Units

9.1 Instrument Setup Menu

9 INSTRUMENT SETUP

9.3 Alarms

O

Alarms will make no sound.

Single

Alarms will make a sound once.

Repeat

Alarms will repeat a sound, until turned off.

p

9.3 Alarm

s

| 22

Use the and buttons to change the

brightness level of the display.

Click Back to save the brightness level.

12

Information about the instrument is listed

here. When requesting support, always

provide the serial number and the versions.

(Versions may be different than listed here.)

Information about updating the system will

be given when an update is released.

Click Reset to reset presets.

123

9.5 System Information

9.4 Display Brightness

Click Reset Custom Presets to remove all

custom presets.

Click Reset Standard Presets to set the

standard presets to their default values.

Warning: this action cannot be reversed.

Saved presets will be lost.

12

9.6 Reset

y

23 |

The TQC Scrub, Abrasion and Washability Tester can be supplied with

2 types of test beds. Either one AB5176 covering the full width of the

machine or one or two AB5196, covering either half the width or the full

width.

Placement

Dependent on the model either two narrow or one wide test bed is placed

flat on the top plate of the Washability tester.

AB6000 and AB6010 can be used without the test beds when used for dry

abrasion testing. Following rules have to be applied:

- The sample shall not protrude from the test bed.

- The sample shall be positioned such that it will not move.

- The sample shall not block any of the movement of the TQC Scrub

Abrasion and Washability Tester.

In order to hold samples down the TQC scrub, abrasion and washability

tester shall be equipped with one of the following sample clamp frames.

These can be used on both test bed models AB5196 and AB5176. The total

machine can contain two frames at a time.

Placement

The sample frames are with the indentation on each side up such that

they can be fixed using the fixture screws of the TQC Scrub Abrasion

and Washability Tester. The Rubber seals beneath the clamping frames

are made out of Viton rubber. The chemical resistance of this rubber is

expressed in annex B.

The TQC Scrub, Abrasion and Washability Test is equipped with a universal

traverse as of 01-04-2016. Earlier models have a standard configurated

traverse containing tool holders equal in function to AB5041. Models

after 01-04-2016 have a configurable traverse allowing for a flexible

arrangement of the tools. The tool holders are linked to the tools in use

and the frames that are used. Please use the online Ordering Matrix to

select the proper tool holder in correlation to the clamping frame and tool

in use. The shown models are available and all have the same installation.

Placement

Place the tool holder in the designated part of the traverse and secure

it with the 4 screws supplied with each tool holder. Always make sure

the tool holder is properly secured with the guides for the tools facing

downward.beneath the clamping frames are made out of Viton rubber.

The chemical resistance of this rubber is expressed in annex B.

AB5196

Dimensions: 480x165x18 mm

ABAB5045

AB5041

AB5043

AB5176

Dimensions: 480x330x18 mm

AB5197

AB5042

AB5044

10.1 Test Beds

10.2 Sample Clamp Frames

10.3 Tool Holders

10 MECHANICAL

pp

T

T

AB519

7

| 24

The TQC Scrub, Abrasion and Washability Tester can be supplied with a wide range of tools. These tools are all selected and produced with the greatest care.

Please see the Ordering Matrix to select the correct tool for the appropriate standard. You can download the Ordering Matrix at

www.tqc.eu/en/product/tqc-scrub-abrasion-and-washability-tester/ under the tab documents.

10.4 Tools

The small sponge holder is supplied ready for use.

The sponge is a gentle tool to test the washability

of the coating. Often used for cleanability tests of

for example wall paints.

Placement

The AB5012 sponge tool is placed in the AB5042

or AB5041 holder and needs to fit comfortably in

the holder. The tool must be able to move freely

without friction in the holder. Always position

the tool facing the same way, to create the best

homogeneity in results. For replacement intervals

check the appropriate standard.

Scope of supply:

• Sponge

• Sponge Holder

• Weight 60 g / 0.13 oz

• Weight 100 g / 0.22 oz

• Fixation Screw

Specications Sponge Tool Complete

Mass: 508 g / 17.92 oz

Standards: ASTM D4213-92, ASTM D4828

Specications Sponge Tool Holder

Material: Stainless steel

Inner dImensions: 92x41 mm

Outer dimensions 94x43 mm

Scope of supply

• Wild boar brush

• Brush holder

• Weight

Specications Wild Boar Brush Tool Complete

Mass: 250g/8.82oz

Standards: DIN 53778

Specications Brush Holder

Inner dimensions: 92x41 mm

Outer dimensions: 94x43 mm

Material: Stainless steel

Specications Wild Boar Brush

Material: Wild boar hair

Mass: 60 g / 0.13 oz

Scope of supply

• Nylon brush

• Brush holder

• Weight 60 g / 0.13 oz

• Weight 100 g / 0.22 oz

• Fixation screw

Specications Nylon Brush Tool Complete

Mass: 454 g / 16.01 oz

Standards: ASTM D2486

Specications Brush Holder

Material: Stainless steel

Inner dimensions: 92x41 mm

Outer dimensions: 94x43 mm

The wild boar brush holder is supplied ready for

use. The brush is used to test scrub resistance of

coatings. The brushes are not worn in. This needs

to be done on the machine of the user.

Placement

The AB5010 Wild boar hair tool is placed in

the AB5042 or AB5041 holder and needs to fit

comfortably in the holder. The tool must be able

to move freely without friction in the holder.

Always position the tool facing the same way,

to create the best homogeneity in results. For

replacement intervals check the appropriate

standard.

The nylon brush brush holder is supplied ready

for use. The brush is used to test scrub resistance

of coatings. The brushes are not worn in. This

needs to be done on the machine of the user.

Placement

The AB5011 nylon brush tool is placed in the

AB5042 or AB5041 holder and needs to fit

comfortably in the holder. The tool must be able

to move freely without friction in the holder.

Always position the tool facing the same way,

to create the best homogeneity in results. For

replacement intervals check the appropriate

standard.

10.4.1 Small Sponge (AB5012)

10.4.2 Wild Boar Brush (AB5010)

10.4.3 Nylon Brush (AB5011)

25 |

The Abrasive Pad Holder is supplied ready for

use. The pad is used to test scrub resistance of

coatings. The pads cause an aggressive wear of

the coating.

Placement

The AB5013 Abrasive Pad Tool is placed in the

AB5042 or AB5041 holder and needs to fit

comfortably in the holder. The tool must be able

to move freely without friction in the holder.

Always position the tool facing the same way,

to create the best homogeneity in results. For

replacement intervals and maximum life please

check the appropriate standard.

Scope of supply

• Abrasive pad

• Pad holder

• Fixation screw

Specications Abrasive Tool Complete

Mass: 135 g / 4.76 oz

Specications Aluminium Pad Holder

Material: Aluminium

Inner dimensions: 92x41 mm

Outer dimensions: 94x43 mm

Scope of supply

• Clamp tool upper part with fixation screw

• Clamp tool lower part with rubber lining on the

bottom and a separate rubber lining for both

short sides

Specications

Universal Material Clamp Tool. Assembly of two black

anodised aluminum blocks with rubber lining into which

user-selected abrasive material can be clamped.

Dimensions: 75x40x80 mm

(without rubber lining on

the short sides)

Scope of supply

• TQC MEK / Crockmeter tool

• Weight

• Set of felts and Viton O-rings

Specications

Required Mass: 454 g

Standard Delivery: 200g

Order extra (not included): + 1x AB5065 (54 g)

+ 2x AB5015 (100g)

Required Mass: 900g

Standard Delivery: 200g

Order extra (not included): + 1x AB5015 (100g)

+ 3x AB5066 (200g)

The Universal Material Clamp Tool is designed to

hold abrasive media as sandpaper, cloth, towel

material, etc. The rubber lining on the bottom

create a uniform pressure on the bottom. The

rubber pads on each side allow for the size

adjustment to any thickness of cloth.

Placement

The AB5020 Universal Material Clamp Tool is

placed in the AB5042 or AB5041 holder and

needs to fit comfortably in the holder. The tool

must be able to move freely without friction in

the holder. Always position the tool facing the

same way, to create the best homogeneity in

results. For replacement intervals and maximum

life please check the appropriate standard.

The AB5060 MEK / Crockmeter is designed to

perform several types of MEK / Crockmeter tests,

depending on the configuration used. A full set

weighs 200g. The hollow fixation screw allows for

easy filling of the liquid reservoir in the stamp.

Placement

The AB5060 MEK / Crockmeter tool is placed in

the AB5042 or AB5041 holder and needs to fit

comfortably in the holder. The tool must be able

to move freely without friction in the holder.

Always position the tool facing the same way,

to create the best homogeneity in results. For

replacement intervals and maximum life please

check the appropriate standard.

10.4.4 Abrasive Pad Tool (AB5013)

10.4.5 Universal Material Clamp (AB5020)

10.4.6 MEK / Crockmeter Tool (AB5060)

| 26

Scope of supply

• Sponge

• Sponge holder

• Weight 500 g

• Fixation screw

Specications Sponge Tool Holder

Material: Stainless steel

Inner dimensions: 90x75 mm

Outer dimensions 102x78mm

The Large Sponge Tool is supplied ready for use.

The sponge is a gentle tool to test the washability

of the coating. Often used for cleanability tests on

for example wall paints.

Placement

The AB5050 Sponge Tool is placed in the AB5043

holder and needs to fit comfortably in the

holder. The tool must be able to move freely

without friction in the holder. Always position

the tool facing the same way, to create the best

homogeneity in results. For replacement intervals

check the appropriate standard.

10.4.7 Large Sponge Tool (AB5050)

Scope of supply

• Cloth holder body

• Cloth holder frame

SpecicationsC Cloth Holder Body

Material: POM

Dimensions: 90x54*x30 mm

* Width of the block is 40 mm

Specications Cloth Holder Frame

Material: Anodised aluminium

Inner dimensions: 91x41x12 mm

Outer dimensions: 110x51x12 mm

The TQC Cloth Holder is supplied ready for use.

The tool is suitable for clamping flexible test

media around the test body. Allowing for a

smooth testing.

Placement

The AB5055 Cloth Holder can only be placed

in the AB5044 tool holder and needs to fit

comfortably in the holder. The tool must be able

to move freely without friction in the holder.

10.4.8 TQC Cloth Holder (AB5055)

Scope of Supply

• 4 metal shims with rounded corners

Specications

Material: Stainless steel

Dimensions: 0.25x12x158 mm

Please verify proper use of the shims by appropriate standard

and or specification.

Scope of Supply

• 2 glass plates with champhered edges

Specications

Material: Glass

Dimensions : 470x163x6 mm

The metal shim is usually placed in the middle

and underneath of the test sample. The small

elevation will increase abrasion at that point

hence test results are obtained more

quickly.

Some standards require all tests to be performed

on a glass test bed. This to ensure the flattest

and smoothest substrate for the test. Often the

glass bed is used together with the metal shims

for many ASTM standards.

10.4.9 Metal Shim (AB5025)

10.4.10 Glass Bed (AB5180)

27 |

Scope of supply

• 1 heavy weight support tool

• 1 fixture screw

Specications

Material: Stainless steel and plastic

Dimensions : 94x50x50 mm

(adjustable hight: 50 - 75 mm)

Mass: 14 g

When using top heavy tools the risk exists for a

tool to tip over due to the load, or the used

speed. Instable tools cause irregular wear and will

lead to non-reproducible results. A tipped over

tool can significantly scratch the sample and

damage it beyond use. The heavy weight support

tools are used to stabilize the tools by creating a

fixture point on the vertical axis of the tool. Per

tool 1 heavy weight support tool is required.

When a lighter weight is used, mount the

supplied spacers between the weight and the

tool.

10.4.11 Heavy Weight Support Tool (AB5032)

Scope of Supply

• AB5115 General tubing set

• 1 set of tubes suitable for installation between container

and pump and from the pump to the test area’s

• AB5113 Pump tubing kit

• 4 tubes for installation in the pumps

Specications

Pump tubing: BPT Pharmamed tube

Tubing to pump

and from pump : Tygon (at delivery PVC tube to the

pump)

Additional information

Waste / drainage

tube : Silicon tube

The TQC Scrub, Abrasion and Washability Tester

AB5000 and AB5005 are equipped with pumps

for the application of test liquids to the samples.

These tubes do require maintenance and timely

replacement depending on the liquids that are

pumped. The chemical resistance of the tubes is

covered in the chemical resistance table. The wear

of the tubes depends both on the abrasiveness

and aggressiveness of the media used. It is not

possible to predict the life expectancy of a

tube.

10.4.12 Tubing (AB5115 and AB5113)

| 28

• Though robust in design, this instrument is precision-machined.

Never drop it or knock it over.

• Always clean the instrument after use.

• Clean the instrument using a soft dry cloth. Never clean the instrument

by any mechanical means such as a wire brush or abrasive paper. This may

cause, just like the use of aggressive cleaning agents, permanent damage.

• Do not use compressed air to clean the instrument.

• Never bend or exert extreme forces on the tool carrier

• Generally the TQC Scrub Abrasion and Washability Tester does not require

any maintenance.

Make sure that no paint or other liquids are spilled on the

electronics or left in the tubing.

11.1 Disposal of Materials

Disposal of materials used in the operation of the instrument or for auxiliary

functions and exchanged items should be dealt with safety and in a manner

that will not harm the environment. Follow the local regulations.

11.2 Customer Service

Customer service is provided on request by

TQC – Molenbaan 19 , 2908LL Capelle aan den IJssel - The Netherlands,

T +31(0)10 7900100, F +31 (0)10 7900129 or by local representatives.

11 CARE AND MAINTENANCE

29 |

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and

any person using the product for any purpose other than that specifically

recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does

so at his own risk. Whilst we endeavor to ensure that all advice we give

about the product (whether in this manual or otherwise) is correct we have

no control over either the quality or condition of the product or the many

factors affecting the use and application of the product. Therefore, unless

we specifically agree in writing to do so, we do not accept any liability

whatsoever or howsoever arising for the performance of the product or for

any loss or damage (other than death or personal injury resulting from our

negligence) arising out of the use of the product. The information contained

in this manual is liable to modification from time to time in the light of

experience and our policy of continuous product development.

12 DISCLAIMER

| 30

ANNEX A | STANDARDS CONFIGURATION TABLE

Art. No. Description

MEK test / DIN 55654 / ISO 105-X12§4.2.1

ASTM D4828

ASTM D3450

ASTM D2486

ASTM D4213 (from 1996)

ASTM D4213-92

ISO 11998 / EN13300

DIN 53778

x

x

x

o

x

o

x

o

x

o

x

x

x

x

x

x

o

x

o

x

o

x

x

x

o

x

x

x

x

x

x

o

x

x

x

o

x

x

x

x

x

x

o

x

x

x

o

x

x

x

x

o

x

o

x

o

x

o

x

x

x

x

x

o

x

x

x

o

o

x

x

x

x

x

x

x

o

x

x

x

o

x

x

x

x

x

x

o

x

o

x

o

x

AB5000

AB5005

AB5210

AB5215

AB5196

AB5176

AB5045

AB5197

AB5041

AB5042

AB5043

AB5044

AB5010

AB5011

AB5012

AB5013

AB5020

AB5050

AB5055

AB5060

AB5014

AB5015

AB5030

AB5040

AB5032

AB5025

AB5027

AB5180

Scrub Test Basic Device

TQC Scrub, Abrasion and Washability Test 230 V

TQC Scrub, Abrasion and Washability Test 100 V

TQC Scrub, Abrasion and Washability Test Basic 230 V

TQC Scrub, Abrasion and Washability Test Basic 100 V

Test beds

Reservoir low, half

Reservoir low, full

Clamping frames

Wide channel single frame for low reservoir

Double narrow channel frame for low reservoir

Tool adapter (WARNING: The adapter must be compatible with the clamping frame)

Tool adapter “Double” for tools AB5012/5010/5011/5013/5020

Tool adapter “Single” for tools AB5012/5010/5011/5013/5020

Tool adapter “Single” for tool AB5050

Tool adapter “Double” for tool AB5055

Tools

Wild Boar Brush (250g/8.82oz) DIN 53778

Nylon Brush (454g/16.01oz) ASTM D2486

Sponge (232g/8.12oz)

Abrasive pad (232g/8.12oz) ISO 11998

Universal holder

Sponge tool, large, conform ASTM D4828 / D3450 (500g)(excl weights)

Cloth holder tool for detergents test

MEK Test / Crock meter

Accessories

Weight for Washability test 60g

Weight for Washability test 100g

Weight for Washability test 1000g

Weight for Washability test 500gr

Tool stabilization kit for heavy weights

Metal shims for ASTM D2486, for reservoir half (set of 4)

Metal shims for ASTM D2486, for reservoir full (set of 4)

Glass base conform ASTM D2486 (set of 2)

x = mandatory

o = optional

31 |

Art. No. Description

MEK test / DIN 55654 / ISO 105-X12§4.2.1

ASTM D4828

ASTM D3450

ASTM D2486

ASTM D4213 (from 1996)

ASTM D4213-92

ISO 11998 / EN13300

DIN 53778

x

o

x

x

xx

oxo

xxx

o

AB5016

AB5016

AB5017

AB5018

AB5018

AB5019

VF2316

VF2316

AB5140

AB5142

AB5141

AB5113

AB5113

Consumables

Abrasive pads for tool AB5013, set 5 pcs (Weight each appr. 3 g.)

Abrasive pads for tool AB5050, set 5 pcs

Wild boar brush for tool AB5010

Nylon brush for tool AB5011

Sponge pads for tool AB5050, set 5 pcs

Sponge pads for tool AB5012, set 5 pcs

TQC opacity scrub charts, black and white, 100 pieces

TQC opacity scrub charts black, 100 pieces.

Spare parts

Glass container 500ml

Glass container cap yellow

Glass container cap green

Pump tubes set of 4

Full tubing kit

| 32

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Acetaldehyde D D D A D

Acetamide D N/A D B B

Acetate Solvent D N/A D C D

Acetic Acid D N/A D C B

Acetic Acid 20% D A D B B

Acetic Acid 80% C N/A D B B

Acetic Acid, Glacial D N/A D B D

Acetic Anhydride D A D C D

Acetone D D D D D

Acetone, 50% water D N/A N/A A2 D

Acetyl Bromide D C D N/A N/A

Acetyl Chloride (dry) C C D C A

Acetylene A1 N/A A1 B A

Acrylonitrile B1 N/A D D D

Adipic Acid A2 N/A D N/A A2

Alcohols: Amyl A2 N/A D D A

Alcohols: Benzyl D N/A D N/A A

Alcohols: Butyl A2 N/A A2 B A

Alcohols: Diacetone B1 N/A B1 D D

Alcohols: Ethyl C N/A C B A

Alcohols: Hexyl A2 N/A A2 B C

Alcohols: Isobutyl A1 N/A A1 A A

Alcohols: Isopropyl A1 N/A D A A

Alcohols: Methyl A1 N/A A1 A C

Alcohols: Propyl A1 N/A A1 A A

Allyl Chloride D N/A N/A N/A A3

Aluminum Acetate (saturated) A A N/A D A

Aluminum Chloride A2 A A2 B A

Aluminum Chloride 20% A1 A A1 B A

Aluminum Fluoride A2 N/A A2 B A

Aluminum Hydroxide A2 A A2 N/A A

Aluminum Nitrate B2 A B2 B1 A2

Aluminum Potassium Sulfate 10% A2 A A2 A A

Aluminum Potassium Sulfate 100% A2 A A2 A A

Aluminum Sulfate A2 A A2 A A

Amines D N/A D B D

Ammonia 10% B1 a B1 N/A D

Ammonia Nitrate B a B N/A D

Ammonia, anhydrous A2 a B C D

Ammonia, liquid A1 a A2 N/A D

Ammonium Acetate A a A N/A A

Ammonium Bifluoride A N/A A2 N/A A

Ammonium Carbonate A2 a A2 C A

Ammonium Chloride A2 a A2 C A

Ammonium Fluoride 25% A N/A N/A N/A A

Ammonium Hydroxide A a A A B

Ammonium Nitrate A2 a A2 C A

ANNEX B | CHEMICAL RESISTANCE

|

Page 33

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Ammonium Oxalate A N/A A N/A N/A

Ammonium Persulfate A2 N/A A2 D A

Ammonium Phosphate, Dibasic A2 A A2 A A

Ammonium Phosphate, Monobasic A A A A A

Ammonium Phosphate, Tribasic A A A A A

Ammonium Sulfate A2 A A2 A A

Ammonium Sulfite A2 N/A A2 N/A D

Amyl Acetate D B D D D

Amyl Alcohol A2 D D D A

Amyl Chloride D C D D B1

Aniline C1-Fair C D B A

Aniline Hydrochloride B2 C D D A

Antifreeze (glycol–based) B N/A B B A

Antimony Trichloride A2 N/A N/A N/A A2

Aqua Regia (80% HCl, 20% HNO3) C1-Fair D D D B

Aromatic Hydrocarbons D D N/A D A

Arsenic Acid A1 N/A B A A2

Arsenic Salts A A A N/A A

Asphalt A2 N/A N/A D A

Barium Carbonate A2 A N/A N/A A

Barium Chloride A1 A B A A

Barium Cyanide D A N/A N/A A

Barium Hydroxide A2 A N/A A A

Barium Nitrate A A N/A B A

Barium Sulfate B1 A N/A A A

Barium Sulfide A2 A N/A A A

Beer A2 N/A A A A

Beet Sugar Liquids A2 N/A N/A A A

Benzaldehyde D D D D D

Benzene C1-Fair N/A D D A

Benzene Sulfonic Acid A D D D A

Benzoic Acid A N/A D B A

Bleach A N/A B N/A A

Bleaching Liquors A1 A N/A B A

Borax (Sodium Borate) A1 N/A N/A B A

Boric Acid A2 A A A A

Bromine C1-Fair D D D A

Butadiene C1-Fair N/A A D B

Butane C1-Fair A A D A

Butanol (Butyl Alcohol) C1-Fair D D B A

Buttermilk A1 N/A B A A

Butyl Amine D N/A D B1 D

Butyl Ether A2 N/A A2 D D

Butylacetate D B D D D

Butylene A1 N/A N/A D A

Butyric Acid B1 B D D B1

Calcium Bisulfide A2 A N/A C A

|

Page 34

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Calcium Bisulfite B A N/A A A

Calcium Carbonate A2 A N/A A A

Calcium Chlorate B2 A N/A N/A A

Calcium Chloride (30% in water) C A A A A

Calcium Chloride (saturated) A A N/A A A

Calcium Hydroxide B A B2 A A

Calcium Hydroxide (saturated) A A N/A A A

Calcium Hypochlorite B1 A A B A

Calcium Hypochlorite (saturated) A A N/A N/A A

Calcium Hypochlorite 30% A A N/A N/A A

Calcium Nitrate A2 A A2 B1 A2

Calcium Oxide B A C A B

Calcium Sulfate B2 A N/A N/A A

Calcium Sulfide A A N/A N/A A

Cane Juice A1 N/A A A A

Carbolic Acid (Phenol) D N/A B D A

Carbon Bisulfide D D D N/A A

Carbon Dioxide (dry) A2 A A B B

Carbon Dioxide (wet) A1 A A B B

Carbon Disulfide D N/A D N/A A1

Carbon Monoxide A2 N/A A A2 A

Carbon Tetrachloride D D D D A

Carbonated Water A N/A N/A N/A A

Carbonic Acid A2 N/A A A A

Catsup A N/A N/A N/A A

Cellulose Acetate D N/A N/A N/A D

Chloral Hydrate A N/A N/A N/A D

Chloric Acid A2 N/A N/A N/A N/A

Chlorine (dry) D C A D A

Chlorine Water A2 D N/A D A

Chlorine, Anhydrous Liquid D D B D A

Chloroacetic Acid B1 B A D D

Chlorobenzene (Mono) D D D D A

Chlorobromomethane D B N/A D A

Chloroform D C D D A

Chlorosulfonic Acid D D D D D

Chromic Acid 10% A2 A C C B

Chromic Acid 30% A1 A B C A

Chromic Acid 5% A2 A B C A

Chromic Acid 50% D A B C A

Chromium Salts A A A N/A N/A

Cider A N/A N/A B1 A

Citric Acid B2 N/A N/A A A

Copper Chloride A1 A A A1 A

Copper Cyanide A2 A N/A A A

Copper Fluoborate A A A N/A A

Copper Nitrate A2 A B N/A A

|

Page 35

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Copper Sulfate >5% A2 A N/A A A

Copper Sulfate 5% A2 A A A A

Creosote A N/A N/A D A

Cresols D D D D A

Cresylic Acid D N/A N/A D A

Cupric Acid A2 N/A A2 A1 A2

Cyclohexane D D D D A

Cyclohexanone D D D D D

Detergents A N/A A A A

Dextrin A N/A N/A N/A D

Dextrose A N/A N/A A A

Diacetone Alcohol D A N/A D D

Dichlorobenzene D N/A N/A D C

Dichloroethane D N/A D N/A C

Diesel Fuel A1 N/A D D A

Diethyl Ether D N/A N/A D D

Diethylamine D N/A A B A

Diethylene Glycol C1-Fair N/A C1-Fair B1 A2

Dimethyl Aniline D N/A D D D

Dimethyl Formamide D N/A D C C

Diphenyl Oxide D N/A D C A

Disodium Phosphate A N/A N/A N/A A

Dyes B N/A C N/A A

Epsom Salts (Magnesium Sulfate) A1 N/A B A A

Ethane A1 N/A A D A

Ethanol C C C B A

Ethanolamine D N/A N/A B D

Ether D C D D C

Ethyl Acetate D B D B D

Ethyl Benzoate D N/A D D A1

Ethyl Chloride D C D D A

Ethyl Ether D N/A D D D

Ethylene Bromide D N/A D D A

Ethylene Chloride D N/A N/A D B

Ethylene Chlorohydrin D A D C A

Ethylene Diamine D N/A N/A A B

Ethylene Dichloride D C D D A

Ethylene Glycol A A A A A

Ethylene Oxide D A A D D

Fatty Acids A C D C A

Ferric Chloride A A N/A B A

Ferric Nitrate A A N/A C A

Ferric Sulfate A A N/A B A

Ferrous Chloride A A N/A N/A A

Ferrous Sulfate A A N/A N/A B

Fluoboric Acid A D N/A N/A B

Fluorine D N/A D D C

|

Page 36

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Fluosilicic Acid D C A N/A B1

Formaldehyde 100% A D D B D

Formaldehyde 40% A D D N/A A

Formic Acid A1 A A B C

Freon® 11 A2 D A D B

Freon® 113 B D N/A D B

Freon® 12 A2 D A D B

Freon® 22 A D A D D

Freon® TF B D N/A D B

Fruit Juice A N/A A N/A A

Fuel Oils A2 N/A D D A

Furan Resin A N/A A D D

Furfural D N/A D D D

Gallic Acid B N/A D D A

Gasoline (high–aromatic) A D N/A D A

Gasoline, leaded, ref. B D D D A1

Gasoline, unleaded C2-Fair D D D A1

Gelatin B N/A A A A

Glucose A2 A A A A

Glue, P.V.A. C A C A B

Glycerin A A A A A

Glycolic Acid B N/A A A A

Grape Juice A N/A B A A

Grease A N/A A D A

Heptane C1-Fair N/A D D A

Hexane B1 N/A D D A

Honey A N/A A A A

Hydraulic Oil (Petro) A N/A A B A

Hydraulic Oil (Synthetic) A N/A A B A

Hydrobromic Acid 100% A1 D A D A

Hydrobromic Acid 20% B2 D A D A

Hydrochloric Acid 100% D A A1 D A

Hydrochloric Acid 20% A2 A A1 D A

Hydrochloric Acid 37% B B A1 B A

Hydrochloric Acid, Dry Gas A2 A N/A N/A N/A

Hydrocyanic Acid B N/A A C A

Hydrocyanic Acid (Gas 10%) A N/A A D A

Hydrofluoric Acid 100% C N/A D D B

Hydrofluoric Acid 20% B N/A A D A

Hydrofluoric Acid 50% B1 D C D B

Hydrofluoric Acid 75% C N/A C D B

Hydrofluosilicic Acid 100% B1 N/A D D A

Hydrofluosilicic Acid 20% A2 N/A A D A

Hydrogen Gas A2 N/A A C A

Hydrogen Peroxide 10% A1 A B A A

Hydrogen Peroxide 100% A B B B A

Hydrogen Peroxide 30% A1 A B B A

|

Page 37

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Hydrogen Peroxide 50% A1 A B B A

Hydrogen Sulfide (aqua) B1 N/A A C D

Hydrogen Sulfide (dry) A2 N/A A C D

Hydroquinone B N/A N/A N/A B

Hydroxyacetic Acid 70% D N/A N/A N/A A

Ink C N/A C N/A A

Iodine A A A N/A A

Iodine (in alcohol) A A N/A N/A N/A

Iodoform A N/A C N/A N/A

Isooctane A1 N/A D D A1

Isopropyl Acetate D N/A D D D

Isopropyl Ether B N/A D D D

Isotane A N/A N/A N/A A

Jet Fuel (JP3, JP4, JP5, JP8) C N/A D D A

Kerosene A2 D D D A

Ketones D D D N/A D

Lacquer Thinners D B D D D

Lacquers D N/A A D D

Lactic Acid B1 A A A A

Lard A1 N/A D B A

Lead Acetate B A B A D

Lead Nitrate A2 N/A A2 B1 A2

Lead Sulfamate B N/A N/A B A

Lime B N/A A N/A A

Linoleic Acid A2 N/A A2 B1 B1

Lithium Chloride D N/A A2 A1 A1

Lubricants B2 N/A B D A

Lye: Ca(OH)2 Calcium Hydroxide B2 N/A B2 A B1

Lye: KOH Potassium Hydroxide B N/A B C B

Lye: NaOH Sodium Hydroxide A N/A B A1 B1

Magnesium Bisulfate A2 N/A A2 N/A N/A

Magnesium Carbonate B N/A N/A N/A A

Magnesium Chloride B A N/A A A2

Magnesium Hydroxide A2 N/A A A A

Magnesium Nitrate A2 N/A A N/A A

Magnesium Sulfate (Epsom Salts) A1 A A A A

Maleic Acid A2 N/A D N/A A

Malic Acid A2 A A B A

Manganese Sulfate C A A1 A1 A2

Mayonnaise D N/A D N/A A

Melamine D N/A D C A

Mercuric Chloride (dilute) A A D N/A A

Mercuric Cyanide A A N/A A A1

Mercurous Nitrate A A A2 N/A A1

Mercury A A A N/A A

Methane B A A D A

Methanol (Methyl Alcohol) A1 A D A C

|

Page 38

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Methyl Acetate D N/A D D D

Methyl Acetone D N/A A N/A D

Methyl Alcohol 10% A1 N/A A1 A C

Methyl Bromide D N/A D N/A A

Methyl Butyl Ketone A N/A N/A D D

Methyl Cellosolve D N/A C D D

Methyl Chloride D C D D A1

Methyl Dichloride A N/A N/A N/A A1

Methyl Ethyl Ketone D D D D D

Methyl Isobutyl Ketone D N/A D D D

Methyl Isopropyl Ketone D N/A N/A C D

Methyl Methacrylate A N/A N/A C D

Methylamine D N/A D N/A D

Methylene Chloride D N/A D N/A B

Milk A2 N/A A A A

Mineral Spirits A N/A D D A

Molasses A N/A A N/A A

Monoethanolamine D N/A D B D

Motor Oil B N/A D N/A N/A

Mustard B N/A B N/A D

Naphtha A1 D D D A

Naphthalene D N/A D D A

Natural Gas A N/A A A A

Nickel Chloride A A B A A

Nickel Nitrate A A A2 N/A A2

Nickel Sulfate A A A A A

Nitrating Acid (<1% Acid) D N/A D N/A N/A

Nitrating Acid (<15% H2SO4) D N/A D N/A N/A

Nitrating Acid (<15% HNO3) D N/A D N/A N/A

Nitrating Acid (>15% H2SO4) D N/A D N/A N/A

Nitric Acid (20%) A1 A D D A

Nitric Acid (5 to10%) A1 A D C A

Nitric Acid (50%) B1 A D D A

Nitric Acid (Concentrated) B1 D D D A

Nitrobenzene D D D D B

Nitromethane B2 N/A D D D

Nitrous Acid A A A N/A B

Nitrous Oxide A N/A A N/A B

Oils: Aniline D C D D C

Oils: Castor A N/A A A A

Oils: Cinnamon D N/A N/A N/A A

Oils: Citric B N/A D N/A A

Oils: Coconut A1 N/A A A A

Oils: Cod Liver A1 N/A N/A B A

Oils: Corn B N/A B A B

Oils: Cottonseed B2 N/A B A A

Oils: Creosote C N/A N/A D A

|

Page 39

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Oils: Crude Oil A N/A N/A N/A A

Oils: Diesel Fuel (20, 30, 40, 50) B N/A A D A

Oils: Fuel (1, 2, 3, 5A, 5B, 6) A2 N/A A C B

Oils: Hydraulic Oil (Petro) A N/A A B A

Oils: Hydraulic Oil (Synthetic) A N/A A B A

Oils: Linseed A2 C A A A

Oils: Mineral B D B C A

Oils: Olive C C B D A

Oils: Orange C1-Fair C N/A D A

Oils: Palm A C N/A N/A A

Oils: Peanut A1 C A A A

Oils: Pine D C D D A

Oils: Rosin C1-Fair C N/A N/A A

Oils: Sesame Seed A C A N/A A

Oils: Silicone A C A C A

Oils: Soybean A1 N/A B A A

Oils: Transformer B N/A N/A B A

Oils: Turbine A1 N/A A D A

Oleic Acid C2-Fair C D D B

Oleum 100% D N/A C D A

Oleum 25% D N/A A D A

Oxalic Acid (cold) B B B B A

Ozone B B A A A

Palmitic Acid B1 C D D A1

Paraffin B N/A D N/A B

Pentane A N/A A D A

Perchloric Acid C A N/A D A

Perchloroethylene C1-Fair C D D A

Petrolatum B N/A B D A

Phenol (10%) C1-Fair A B D A

Phenol (Carbolic Acid) D A B D A

Phosphoric Acid (<40%) B A A C A

Phosphoric Acid (>40%) B A A D A

Phosphoric Acid (crude) B2 N/A D D A

Phosphoric Acid (molten) D N/A D N/A N/A

Phosphorus A1 N/A B1 N/A N/A

Phosphorus Trichloride D N/A A N/A A1

Photographic Developer A N/A A B A

Photographic Solutions A N/A A2 A B1

Phthalic Anhydride D N/A D N/A A

Picric Acid D A A D A

Plating Solutions: Antimony Plating 130°F A A N/A N/A A

Plating Solutions: Arsenic Plating 110°F A A N/A N/A A

Plating Solutions: Brass: High-Speed Brass Bath 110°F A A N/A N/A A

Plating Solutions: Brass: Regular Brass Bath 100°F A A N/A N/A A

Plating Solutions: Bronze: Cu-Cd Bronze Bath R.T. A A N/A N/A A

Plating Solutions: Bronze: Cu-Sn Bronze Bath 160°F D A N/A N/A A

|

Page 40

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Plating Solutions: Bronze: Cu-Zn Bronze Bath 100°F A A N/A N/A A

Plating Solutions: Cadmium: Cyanide Bath 90°F A A N/A N/A A

Plating Solutions: Cadmium: Fluoborate Bath 100°F A A N/A N/A A

Plating Solutions: Chromium: Barrel Chrome Bath 95°F A A N/A N/A C

Plating Solutions: Chromium: Black Chrome Bath 115°F A A N/A N/A C

Plating Solutions: Chromium: Chromic-Sulfuric Bath 130°F A A N/A N/A C

Plating Solutions: Chromium: Fluoride Bath 130°F A A N/A N/A C

Plating Solutions: Chromium: Fluosilicate Bath 95°F A A N/A N/A C

Plating Solutions: Copper (Acid): Copper Fluoborate Bath 120°F A A N/A N/A A

Plating Solutions: Copper (Acid): Copper Sulfate Bath R.T. A A N/A N/A A

Plating Solutions: Copper (Cyanide): Copper Strike Bath 120°F A A N/A N/A A

Plating Solutions: Copper (Cyanide): High-Speed Bath 180°F D A N/A N/A A

Plating Solutions: Copper (Cyanide): Rochelle Salt Bath 150°F D A N/A N/A A

Plating Solutions: Copper (Misc): Copper (Electroless) A A D N/A A

Plating Solutions: Copper (Misc): Copper Pyrophosphate A A N/A N/A A

Plating Solutions: Gold: Acid 75°F A A N/A N/A A

Plating Solutions: Gold: Cyanide 150°F D A N/A N/A A

Plating Solutions: Gold: Indium Sulfamate Plating R.T. A A N/A N/A A

Plating Solutions: Gold: Neutral 75°F A A N/A N/A A

Plating Solutions: Iron: Ferrous Am Sulfate Bath 150°F D A N/A N/A A

Plating Solutions: Iron: Ferrous Chloride Bath 190°F D A N/A N/A A

Plating Solutions: Iron: Ferrous Sulfate Bath 150°F D A N/A N/A A

Plating Solutions: Iron: Fluoborate Bath 145°F D A N/A N/A A

Plating Solutions: Iron: Sulfamate 140°F A A N/A N/A A

Plating Solutions: Iron: Sulfate-Chloride Bath 160°F D A N/A N/A A

Plating Solutions: Lead Fluoborate Plating A A N/A N/A A

Plating Solutions: Nickel: Electroless 200°F D A N/A N/A A

Plating Solutions: Nickel: Fluoborate 100-170°F A A N/A N/A A

Plating Solutions: Nickel: High-Chloride 130-160°F D A N/A N/A A

Plating Solutions: Nickel: Sulfamate 100-140°F A A N/A N/A A

Plating Solutions: Nickel: Watts Type 115-160°F D A N/A N/A A

Plating Solutions: Rhodium Plating 120°F A A N/A N/A A

Plating Solutions: Silver Plating 80-120°F A A N/A N/A A

Plating Solutions: Tin-Fluoborate Plating 100°F A A N/A N/A A

Plating Solutions: Tin-Lead Plating 100°F A A N/A N/A A

Plating Solutions: Zinc: Acid Chloride 140°F A A N/A N/A A

Plating Solutions: Zinc: Acid Fluoborate Bath R.T. A A N/A N/A A

Plating Solutions: Zinc: Acid Sulfate Bath 150°F D A N/A N/A A

Plating Solutions: Zinc: Alkaline Cyanide Bath R.T. A A N/A N/A A

Potash (Potassium Carbonate) A A A N/A A

Potassium Bicarbonate A A A A1 A

Potassium Bromide A N/A B A1 A

Potassium Chlorate A N/A B B A

Potassium Chloride A N/A A A A

Potassium Chromate A N/A B N/A A

Potassium Cyanide Solutions A N/A A A A

Potassium Dichromate A N/A N/A A A

|

Page 41

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Potassium Ferricyanide A N/A B N/A A

Potassium Ferrocyanide A N/A B N/A A

Potassium Hydroxide (Caustic Potash) A1 A B C B

Potassium Hypochlorite B1 N/A B1 N/A N/A

Potassium Iodide A2 A B N/A A

Potassium Nitrate A N/A A A A

Potassium Permanganate A1 N/A B N/A A

Potassium Sulfate A2 N/A A A A2

Potassium Sulfide A2 N/A N/A A A

Propane (liquefied) A1 N/A N/A D A

Propylene B1 N/A A D A1

Propylene Glycol C1-Fair N/A A A A

Pyridine D C D D D

Pyrogallic Acid A N/A N/A N/A A

Resorcinal C N/A C N/A A1

Rosins C1-Fair N/A N/A A A

Rum A N/A N/A A A

Salicylic Acid B1 N/A B1 N/A A1

Salt Brine (NaCl saturated) A N/A N/A A1 A2

Sea Water A2 N/A N/A A1 A

Silicone A A N/A C A

Silver Nitrate A1 A B A A

Soap Solutions A B A A A

Soda Ash (see Sodium Carbonate) A A N/A A A

Sodium Acetate B1 N/A A D D

Sodium Benzoate B1 N/A B1 N/A A1

Sodium Bicarbonate A2 N/A B A A

Sodium Bisulfate A2 A B A A

Sodium Bisulfite A2 A B A A

Sodium Borate (Borax) A2 N/A N/A A A

Sodium Bromide B2 N/A B2 N/A A1

Sodium Carbonate A2 A B A A

Sodium Chlorate A1 B B C A

Sodium Chloride A2 N/A B A A

Sodium Cyanide A2 N/A A A A2

Sodium Ferrocyanide A A A N/A A

Sodium Fluoride A2 N/A D N/A A

Sodium Hydrosulfite C B A C A

Sodium Hydroxide (20%) A A A1 A2 C

Sodium Hydroxide (50%) A N/A C A1 D

Sodium Hydroxide (80%) A N/A C A1 D

Sodium Hypochlorite (<20%) A N/A C B A1

Sodium Hypochlorite (100%) B N/A N/A B A1

Sodium Iodide A N/A N/A N/A C

Sodium Metaphosphate A N/A N/A A A

Sodium Metasilicate A N/A N/A N/A A

Sodium Nitrate A2 A B D A

|

Page 42

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Sodium Perborate A2 N/A N/A B A

Sodium Peroxide B2 N/A N/A D A

Sodium Polyphosphate A1 N/A N/A D A

Sodium Silicate A2 A B A A

Sodium Sulfate A2 A A A A

Sodium Sulfide A2 A B A A2

Sodium Sulfite A2 A A A A2

Sodium Tetraborate A2 N/A N/A A A

Sodium Thiosulfate (hypo) A2 N/A N/A A A

Stannic Chloride A2 N/A N/A B A

Stannous Chloride A1 N/A A B A

Starch A N/A N/A N/A A

Stearic Acid B2 C D B A1

Stoddard Solvent C1-Fair N/A C D A

Styrene D D N/A D B

Sulfate (Liquors) B N/A N/A B A1

Sulfur Chloride C1-Fair N/A D C A

Sulfur Dioxide A1 N/A A B A

Sulfur Dioxide (dry) A2 N/A A B A

Sulfur Hexafluoride B N/A N/A B N/A

Sulfur Trioxide A N/A A B A

Sulfur Trioxide (dry) A1 N/A B B A

Sulfuric Acid (<10%) A1 A A C A

Sulfuric Acid (10-75%) A1 A C D A2

Sulfuric Acid (75-100%) D D D D A1

Sulfuric Acid (cold concentrated) D D D D B

Sulfuric Acid (hot concentrated) D D D D A2

Sulfurous Acid A2 A B D A

Tannic Acid A1 B B B A

Tanning Liquors A1 A B B A

Tartaric Acid A1 A B A A

Tetrachloroethane C N/A N/A D A

Tetrachloroethylene D N/A N/A D A

Tetrahydrofuran D N/A N/A D D

Tin Salts A A A B A

Toluene (Toluol) D D D D A

Tomato Juice A N/A N/A N/A A

Trichloroacetic Acid B B A D C

Trichloroethane C N/A D D A

Trichloroethylene D D D D A

Tricresylphosphate D N/A D C A2

Triethylamine B N/A A N/A D

Trisodium Phosphate A N/A A A A

Turpentine D D D D A

Urea D A B B A

Uric Acid A A A N/A N/A

Urine A N/A N/A N/A A1

|

Page 43

Explanation of Footnotes

1. Satisfactory to 72ºF (22ºC)

2. Satisfactory to 120ºF (48ºC)

Ratings - Chemical Eect

A = Excellent.

B = Good -- Minor Effect, slight corrosion or discoloration.

C = Fair -- Moderate Effect, not recommended for continuous use. Softening, loss of strength, swelling may occur.

D = Severe Effect, not recommended for ANY use.

N/A = Information not available.

Chemical

BPT Pharmed tube

PVC

Tygon

Silicone

Viton

Varnish D N/A D D A

Vinegar B N/A A1 A A

Vinyl Acetate D N/A D D A1

Vinyl Chloride D N/A D N/A A1

Water, Acid, Mine B N/A N/A B A

Water, Deionized A2 A A2 N/A A1

Water, Distilled A2 A B C A

Water, Fresh B A B B A

Water, Salt B A B B A

Whiskey and Wines A2 N/A C A A

White Liquor (Pulp Mill) A2 N/A N/A A A

White Water (Paper Mill) A N/A N/A N/A A

Xylene D D D D B

Zinc Chloride B D A B A

Zinc Sulfate A2 N/A A A A

45 |

ANNEX C | OPERATOR QUALIFICATION LIST

Date Name Signature SignatureInstructed by

Supervisor list (allowed to perform lamp replacement and such).

Date Name Signature SignatureInstructed by

Operator list.

47 |

ANNEX D | MAINTENANCE LIST

Date Action Name Signature

Installed at test location.

First run performed.

TQC Korea

Bldg Star Plaza, #805

Kimpo-Hangang-8-Ro 410

10071 Kimpo-Si, Gyeonggi-Do

South-Korea

+82 (0) 31 982 7074

+82 (0) 31 997 0827

jongsun@tqc.kr

www.tqc.eu

TQC UK

Po Box 977A

Surbiton, KT1 9XL

England

+44 208 255 0143

-

janet@tqc.eu

www.tqc.eu

TQC B.V.

Molenbaan 19

2908 LL, Capelle aan den IJssel

The Netherlands

+31 (0) 10 – 7900 100

+31 (0) 10 – 7900 129

info@tqc.eu

www.tqc.eu

TQC GmbH

Nikolaus-Otto-Strasse 2

Hilden, D-40721

Germany

+49 (0)2103-25326-0

+49 (0)2103-25326-29

info.de@tqc.eu

www.tqc.eu

TQC-USA Inc.

4053 S. Lapeer Road / Suite H

P.O. Box 108 Metamora, Michigan 48455

USA

+1 810-678-2400

+1 810-678-2422

joel@tqc-usa.com

www.tqc-usa.com

TQC ITALIA s.r.l.

Via Cesare Cantu’ ,26

SEREGNO, (MB) 20831

Italy

+39 0362-1822230

+39 0362-1822234

info@tqcitaly.it

www.tqc.eu

TQC Norge AS

Øvre Langgt. 26

Tønsberg, 3110

Norway

+47 333 10220

+47 333 10221

info@tqc.no

www.tqc.no

Loading...

Loading...