Page 1

460 Handheld 20MHz

Digital Oscilloscope

User’s Guide

Test Products International, Inc.

9615 SW Allen Blvd.

Portland, OR 97005

Ph: 503-520-9197 ! Fax: 503-520-1225

E-mail: info@tpi-thevalueleader.com

The Value Leader

www.tpi-thevalueleader.com

TM

Page 2

Copyright © 2001

Test Products International, Inc.

All Rights Reserved

08/01

460 User’s Guide

ii

Page 3

Table of Contents

C1 - Introduction........................................................................................C1-1

Features ..........................................................................................C1-2

Specifications ..................................................................................C1-3

Scope Modes ........................................................................C1-3

Multimeter Modes ................................................................C1-5

C2 - Getting Started ..................................................................................C2-1

Equipment Needed ..........................................................................C2-1

460 Setup ........................................................................................C2-1

Measuring Voltage ..........................................................................C2-3

Measuring Frequency ......................................................................C2-3

Measuring Resistance......................................................................C2-4

Testing Continuity ............................................................................C2-4

Diode Test ........................................................................................C2-4

C3 - Operation............................................................................................C3-1

Principal Connectors and Keys ........................................................C3-1

Key / Screen Menus ........................................................................C3-3

C4 - Advanced Functions ..........................................................................C4-1

Triggering ........................................................................................C4-1

Trend Mode......................................................................................C4-1

Glitch Capture ..................................................................................C4-2

Saving Screens ................................................................................C4-2

Using the 10:1 Probe ......................................................................C4-3

10:1 Probe Compensation Adjustment ............................................C4-3

C5 - Using Adapters ..................................................................................C5-1

Temperature Adapter - A301............................................................C5-1

High Current Adapter - A251 / A256 / A296 ....................................C5-1

Low Current Adapter - A254 ............................................................C5-2

460 User’s Guide

iii

Page 4

Current Shunt Adapter - A130 ........................................................C5-2

Pressure Adapter - A620 ................................................................C5-2

PC Software & RS232 Cable - A404................................................C5-3

C6 - Safety Considerations ........................................................................C6-1

Instrument ......................................................................................C6-1

Environmental..................................................................................C6-2

Appendix A - Test and Calibration................................................................A-1

Appendix B - Maintenance Considerations ..................................................B-1

Appendix C - Glossary ................................................................................C-1

Appendix D - Optional RS-232C / PC Interface............................................D-1

Appendix E - Troubleshooting ......................................................................E-1

iv

460 User’s Guide

Page 5

Chapter 1

Introduction

This manual describes the TPI Scope Plus 460 and its functions. Normal and advanced functions

are covered in detail, as well as interactions with computers and other instrumentation. A full

chapter is also devoted to safety considerations, both instrument based and interactively. The following is a brief chapter and appendix summary:

Chapter 1 - Covers the introduction, features and Specifications.

Chapter 2 - Getting Started gets the new user up and running in the shortest time possible.

The basic functions are introduced in a hands on style designed to familiarize the

user with the keypad and screen display.

Chapter 3 - Explains all the normal functions of the TPI Scope Plus 460, including buttons,

menus, screen displays, and a sequencing guide for both external key actions and

their interaction with software driven menus.

Chapter 4 - Explains more advanced functions such as triggering, glitch capture, trend mode,

and saving screens.

Chapter 5 - Explains and illustrates uses of probes and adapters including pressure,

temperature, and current shunt adapters. This chapter also introduces general

aspects of the optional optically isolated RS-232 interface.

Chapter 6 - This important chapter details operating methods and tips designed to preserve

both the life of your instrument, and safety factors to prevent human injury. The

text is divided into Instrument and environmental safety subsections.

Appendix A - This appendix covers what to look for, and how to make simple tests to find out if

your TPI Scope Plus 460 requires replacement parts or calibration.

Appendix B - This Maintenance appendix gives tips on how to keep your TPI

Scope Plus 460 in top operating condition by assuring constant

peak performance. The appendix also covers battery servicing

and replacement.

Appendix C - A glossary describing the meanings of terms associated with the

460 and its working environment.

Appendix D - This appendix introduces and explains the powerful RS-232C

Interface option. All aspects are covered from Installation to

460 User’s Guide Introduction

C1-1

Page 6

Special Applications.

Appendix E - This Troubleshooting appendix covers problems that may arise

during installation or operation of your new TPI Scope Plus 460.

Features

The following features exist for the TPI Scope Plus 460:

"

20 MHz Bandwidth

Enough bandwidth to capture signals from AC/DC drive motors, sensors,

actuators, line and control voltages, UPS and industrial machines.

"

Sample Rate

A real time sampling of 25 megasamples/sec to capture spikes and dropouts of

industrial signals.

"

Dual Input

View two waveforms on the display for comparison and troubleshooting.

"

True RMS DMM

Includes a 4000 count True RMS DMM that measures AC/DC volts to 600V,

frequency to 20MHz, resistance to 20M Ohm, diode test and continuity audible

tone.

"

Autoranging

Autoranging capability across Voltage, Timebase and Frequency.

"

Bright LCD Backlight

Easy-to-see display in any light condition with user-adjustable backlight

brightness levels

"

Optically Isolated RS232 Output

Transfer data safely without any direct connections to your computer’s systems

security.

"

Optional Accessories

Temperature Adapter to measure temperature from -40 to 500

o

F (A301).

Pressure Adapter to measure pressure from -30 to 500psi (A620).

Protective Boot (A405).

Soft Carrying Case with Shoulder Strap (A905).

RS232 cable and software (A404).

Current Adapters:

o A254 - For measuring low current in milliamps

o A256 - Up to 400 AC/DC amps

460 User’s Guide Introduction

C1-2

Page 7

o A296 - Up to 1000 AC/DC amps

Specifications

Display:

Size 76mm X 76mm (3" X 3")

Pixels 240 X 240 pixels

LCD type STN Normally Gray or Black

Back Light CCFL

Memory:

Waveform Screens (2)

Setup User setup (1)

Power:

External Power Adapter (5.5V / 2A)

Internal Battery Ni-MH 1.2V X 4

Battery Operating Time More than 2.5 hours with bright backlight

Charging Time 10 hours

SCOPE MODES

Horizontal:

Samples per division 25 samples / div.

Time/division Equivalent sampling 50ns to 500ns/div

Real time sampling 1us to 2s/div

Modes Single, Normal, Auto, Glitch

Accuracy Real time sampling +/- (0.1% + 0.04 time/div)

Equivalent sampling +/- (0.5% + 0.08 time/div)

Vertical:

Sampling Rate 25 Mega samples per second

Bandwidth DC Coupled 1:1 shielded test leads ; DC to 10MHz

10:1 probe ; DC to 20MHz

AC Coupled 1:1 shielded test leads ; 10Hz to 10MHz

10:1 probe ; 10Hz to 20MHz

Resolution 8 bits

Channel 2

Coupling AC,DC,GND

Input impedance Approx. 1M Ohm

Sensitivity 50mV to 200V/div 1,2,5 sequence

460 User’s Guide Introduction

C1-3

Page 8

Accuracy +/- (3% + 0.05 range/div)

Display modes CH1, Dual

Maximum Input Voltage 600V

Trigger:

Position Ver 1; Fixed Position / Ver 3; Adjustable Position

Mode Free run, normal

Source Internal (CH1/CH2)

Slope Positive/Negative

Sensitivity Real time sampling .... 2 divisions or more

Equivalent sampling .... 3 divisions or more

Trend Plot:

Plot Time 30sec/div to 1-hour/div

Plot Data Type Max / Min Selectable

Temperature Measurement:

Optional Adapter A301 (k - Type thermocouple)

Range -40 F to 500 F

Accuracy +/- (1.5% + 5 digits)

Pressure / Vacuum Measurement:

Optional Adapter A620

Range Pressure 500 psi

Vacuum 30 inHg

Accuracy Pressure +/- (5% + 5 digits)

Vacuum +/- (1.5% + 5 digits)

Current Measurement:

Optional Adapter 1 A251 (AC AMPS)

Range 0 - 40A / 40 - 400A

Accuracy ( 0 - 40A ) +/- (2.0% + 10 digits , 50 / 60 Hz)

(40 - 400A) +/- (2.0% + 10 digits , 50 / 60 Hz)

Optional Adapter 2 A256 (AC/DC AMPS)

Range 0 - 40A / 40 - 400A

Accuracy ( 0 - 40A ) +/- (2.0% + 10 digits , 50 / 60 Hz)

(40 - 400A) +/- (2.0% + 10 digits , 50 / 60 Hz)

Optional Adapter 3 A296 (AC/DC AMPS)

460 User’s Guide Introduction

C1-4

Page 9

Range 0 - 400A / 400 - 1000A

Accuracy ( 0 - 400A ) +/- (2.0% + 10 digits , 50 / 60 Hz)

(400 - 1000A) +/- (2.0% + 10 digits , 50 / 60 Hz)

MULTIMETER MODES

DC Volts (CH1/CH2)

Range Resolution Accuracy

400mV 0.1mV +/- (0.5% + 5 digits)

4V 0.001V +/- (0.5% + 5 digits)

40V 0.01V +/- (0.5% + 5 digits)

400V 0.1V +/- (0.5% + 5 digits)

600V 1V +/- (0.5% + 5 digits)

AC Volts (CH1/CH2)

Range Resolution Accuracy

400mV 0.1mV 20Hz to 50Hz; +/- (2% + 20 digits)

4V 0.001V 50Hz to 1kHz; +/- (1% + 10 digits)

40V 0.01V 1kHz to 20kHz; +/- ( 2% + 10 digits)

400V 0.1V 40Hz to 400Hz; +/- (1% + 10 digits)

600V 1V 40Hz to 400Hz; +/- (1% + 10 digits)

Frequency (CH1/CH2)

Range Resolution Accuracy

100Hz 0.01Hz +/- (1.0% + 10 digits)

1KHz 0.1Hz +/- (0.5% + 5 digits)

10KHz 1Hz +/- (0.5% + 5 digits)

100KHz 10Hz +/- (0.5% + 5 digits)

1MHz 100Hz +/- (0.5% + 5 digits)

10MHz 1kHz +/- (0.5% + 5 digits)

20MHz 10kHz +/- (2.5% + 5 digits)

OHM (CH1 ONLY)

Range Resolution Accuracy

400 Ohm 0.1 Ohm +/- (0.75% + 5 digits)

4k Ohm 1 Ohm +/- (0.5% + 5 digits)

40k Ohm 10 Ohm +/- (0.5% + 5 digits)

400k Ohm 100 Ohm +/- (0.5% + 5 digits)

4M Ohm 1k Ohm +/- (1.0% + 10 digits)

20M Ohm 10k Ohm +/- (3.0% + 20 digits)

460 User’s Guide Introduction

C1-5

Page 10

Continuity (CH1 ONLY)

Range Resolution Accuracy

4 K ohm 1 ohm Beeps < 0.1 K ohm , +/- (2% + 5 digits)

Diode (CH1 ONLY)

Range Resolution Accuracy

4 V 1 mV Open circuit voltage < 5 V

Short circuit current < 5 mA

Reading accuracy; +/- (2% + 5 digits)

460 User’s Guide Introduction

C1-6

Page 11

Chapter 2

Getting Started

This chapter will get you started with the TPI Scope Plus 460. It will include initial power up, followed by a series of DMM and static tests. More detailed operations will be the subject of the

next chapter. Refer also to the chapters and appendices covering specifications and maintenance

if you run into problems outside the scope of this chapter. Also feel free to check with service

support using the phone numbers given at the beginning of this manual.

Equipment Needed

Required:

"

Fully operational TPI Scope Plus 460 with batteries fully charged

"

Set of probes with alligator clip attachments available

"

Set of fixed or variable resistances.

"

Set of fixed or variable inductances.

"

Set of fixed or variable capacitances.

"

Static or variable DC voltage source.

Optional:

"

Signal generator source with varied outputs

"

Random glitch or voltage spike generator

460 Setup

1. Use the tilt stand if necessary to set up the instrument in a readable position.

2. Switch the unit on by pressing POWER ON button for 3 seconds. If the unit will power

on, attach the power adapter. Initial charge of the battery must be made with 460 turned

on.

3. If the Power adapter is attached, check the battery level by pulling out the adapter and

checking if there is any change to the brightness of the display (For optimal performance,

the battery should be fully charged even with the Power adapter attached).

4. Check the Contrast. Refer to Figure 2-1, and press the USER button. Note the Contrast

menu button is displayed on the screen above F2. - Press F2 and note the menu item on

the screen is now darkened. Press the Up arrow to increase the contrast and the Down

arrow to reduce the contrast.

5. Check the Brightness (-there are ten levels). Refer to Figure 2-1, and press the

Brightness button (Sun Icon) to decrease the brightness. To increase the brightness,

continue pressing the brightness button until you have reached the bottom level, at which

460 User’s Guide Getting Started

C2-1

Page 12

3. Press F2 (below the

Contrast Label).

4. Press the Up or Down direction

arrows to change contrast.

2. Press the User

Button

1. Press the POWER ON

Button

Figure 2-1. Contrast Adjustment with Low Visibility

460 User’s Guide Getting Started

C2-2

Page 13

time it will revert to the maximum brightness level.

NOTE: The Brightness control effects the backlighting whereas Contrast

effects the intensity of the liquid crystal display (both for the tracing beams

and the text display).

6. You have now completed the basic setup. Press Ch A (Channel A), to exit the user setup

mode and ready the instrument for Multimeter operations.

Measuring Voltage

1. With the 460 set for Input A (Ch A button), use the down arrow to set the highlight on

DCV. Press Enter.

2. Press the green V key, and connect the probes to a DC Voltage source. The voltage will

appear in alphanumeric text at the top left of the screen. The trace line A should be

steady, but if there are any AC components present on the line it will also show these

(especially in the case of partially rectified AC).

NOTE: Pressing the Green key V selection first will ensure you are not

being limited by the millivolt range. If the voltage reading is then read as

a small value, use the mV side of the green rocker key to display the millivolt

range on the screen.

3. Disconnect the DC Voltage source and press Ch A (Channel A blue button). Use the Up

arrow to move the screen highlight to ACV. Press Enter.

4. Press the green V key, and connect the probes to the AC source. The voltage can be read

at the top left of the screen expressed as an RMS value. The trace line A will show the

shape of the AC voltage source.

Measuring Frequency

1. With the 460 set for Input A (Ch A button), use the down arrow to set the highlight on

Freq. Press Enter.

2. Connect the probes to a frequency source. The frequency will be shown in alphanumeric

text at the top left of the screen. The trace line A will show the nature of the frequency

source.

Notes on Trace Stability:

a). Ensuring that the Channel B trace is off when making frequency

measurements on the A channel, will reduce clutter on the screen, and make

the A trace easier to read.

460 User’s Guide Getting Started

C2-3

Page 14

b). Using the HOLD/RUN button will freeze the trace and allow waveform

characteristics to be measured precisely against the background grid.

Measuring Resistance

1. With the 460 set for Input A (Ch A button), use the down arrow to set the highlight on

OHM. Press Enter.

2. Connect the probes across the resistance source. The resistance value is shown in two

forms. First as alphanumeric text at the top of the screen. Secondly, the value is shown

visually against a calibrated bar. The value of the bar is shown at the base of the screen.

For instance, if a resistance of 12.00 K Ohms is being read, a bar of value 40K Ohms will

typically be displayed, and the actual value of the resistance will show as 12.00 against

that bar

Testing Continuity

1. With the 460 set for Input A (Ch A button), use the down arrow to set the highlight on

Beep. Press Enter.

2. Connect the probes across the source to be tested. If the line is closed (equiv. of short

circuit) or not offering more than 100 Ohms of resistance, the full beep will be heard, and

the bar will show the degree of resistance (if any).

Note: The continuity test function can also be used to test the resistance in

a path up to a value of 4K Ohms. The actual value will be shown alphanumerically in the top left of the screen, and also shown graphically against

a bar having a span of 0 to 4K Ohms

Diode Test

1. With the 460 set for Input A (Ch A button), use the down arrow to set the highlight on

DIODE. Press Enter.

2. Connect the probes across the diode in the +/+ direction. A total resistance should be

noted (The full bar shows no reverse current flow).

3 Connect the probes to the diode in the normal +/- direction. The bar display should show

an open or almost open condition. - Forward bias is shown against a scale of 2.0 volts

and is also displayed alpha-numerically at top left of the screen.

460 User’s Guide Getting Started

C2-4

Page 15

Chapter 3

Operation

This chapter provides a general overview of the tpi Scope Plus 460 from an operations point of

view. The keys and adapter connectors will first be identified followed by a pictorial description

of the key and screen menu functions.

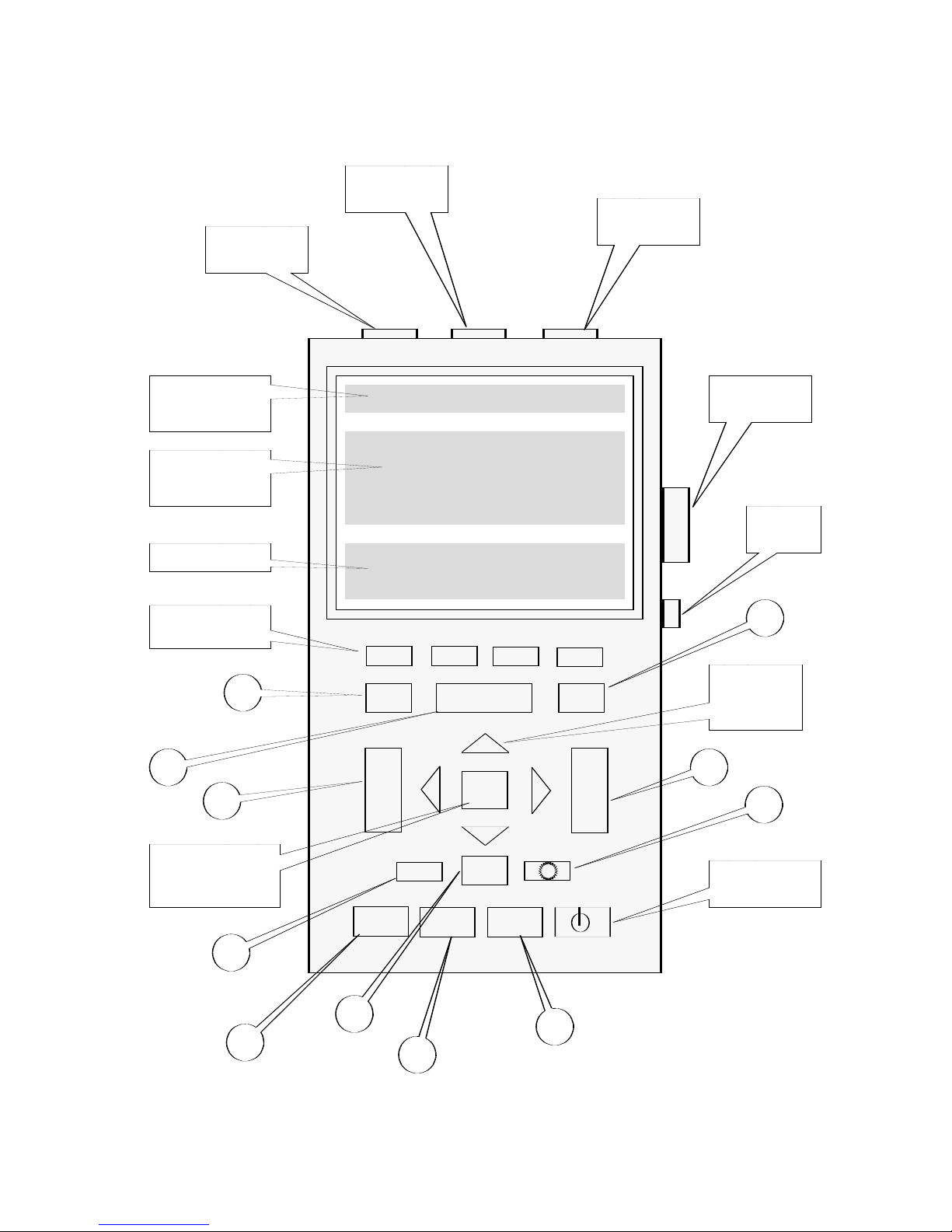

Principal Connectors and keys

Figure 3-1 shows the general layout of the front panel and side connectors. Many of the functions are straight forward and identified in the illustration. The numbered items in the diagram

need additional explanation and are detailed below:

1. Ch A

This key controls the display of oscilloscope Channel A. The first screen requires

the user to first identify the nature of the display, e.g., AC Volts, DC Volts,

Frequency, etc. Then, after pressing ENTER, the Channel A trace is displayed as

well as the correct alphanumerics.

2. Ch B

This key controls the display of oscilloscope Channel B. The first screen requires

the user to first identify the nature of the display, This list is different from

Channel A and includes specialized measuring scales such as

o

C, oF and Psi, etc.

After selecting the scale, press ENTER , and the Channel B trace is displayed.

3. S TIME nS

This rocker switch controls the oscilloscope timebase. Pressing the left side

decreases the sweep rate in 1, 2, 5, increments down to 2-seconds per division.

Pressing the right side speeds the sweep rate in increments up to 50-nano

seconds per division. Sweep Rate is displayed above the TRIGGER label at the

base of the screen

4. mV / V

This vertically orientated rocker switch controls the vertical sensitivity for the A

Channel oscilloscope. The scale is in 1, 2, 5, increments from 50mV to 200V

per vertical division. The readout is at the extreme left of the display just above

the A MOVE label.

5 mV / V

This rocker switch is identical to Callout #4 except applicable to Channel B. The

readout is at the extreme right of the display just above the B MOVE label.

6. <Sun Icon>

This is the brightness button. It controls the screen background intensity of the

460 User’s Guide Operation

C3-1

Page 16

backlit LCD screen. The button has ten cycles of brightness, after which it resets

to the first position.

Figure 3-1. 460 Front Panel layout

Ch A COM Ch B

F1 F2

F3

F4

Ch A

Ch B

S TIME nS

ENTER

mV

V

mV

V

AUTO

HOLD

RUN

SCOPE

USER SAVE

POWER ON

Channel B

Connector

Channel A

Connector

Common

(Ground)

RS-232C

Connector

Power

Plug

Alphanumeric

Display Area

Dual Trace

Display Area

Menu Area

Menu Function

Keys (F1-F4)

Highlight

Direction

Arrows

460 Power

Switch

Function

Acknowledge

Key

1

3

4

2

5

6

7

8

9

11

10

460 User’s Guide Operation

C3-2

Page 17

7. AUTO

This is the Auto Ranging and optimal setting button. In the AUTO mode, the 460

will sense the parameter being measured and automatically adjust the oscilloscope

timebase to suit. The button also toggles between AUTO and MANUAL modes.

Note that the previous manual settings are lost once auto mode has activated.

8. SCOPE

This is a dual function oscilloscope switch. Initial activation (Scope /S1)

sets the oscilloscope program to display the SCOPE INPUTS interactive

menu. Activating the SCOPE switch a second time, sets the program to

display the Channel A waveform, the Channel B waveform (if it is

switched ON), and the A / B MOVE, TRIGGER / TREND selection menu.

Pressing the switch a third time will toggle the program back to SCOPE

INPUTS.

9. HOLD / RUN

This is a toggle switch that allows the user to freeze the currently dis

played waveforms. Once frozen, the user can choose to record the

waveform using the SAVE key (see callout #11), or to press the HOLD /

RUN key a second time to unfreeze the display.

10. USER

This is a toggle switch that allows a user to interrupt most ongoing

programs to revert to a setup mode to adjust Contrast, RS-232C output,

or Power Down, and then revert to the original program by pressing

the button a second time. Note that the POWER DOWN menu selection

allows an automatic timed power down for special functions.

11. SAVE

This is a toggle switch that allows a screen save (traces only) for a

maximum of two saves and/or recalls. You can delete an existing capture,

or automatically overwrite to the selected memory. Pressing the button

a second time reverts to the original display.

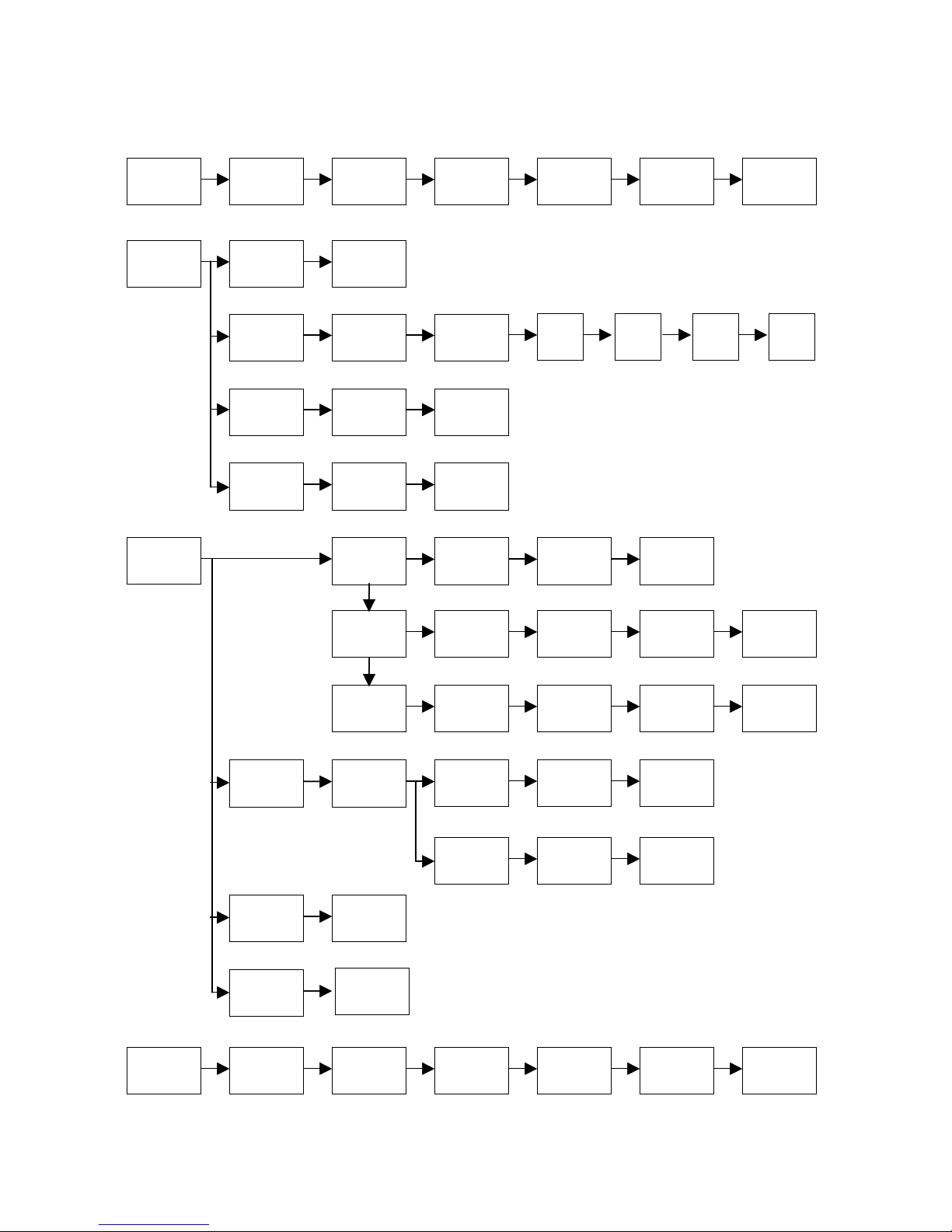

Key / Screen Menus

The following tables provide a graphical explanation of the key and menu interactions and menu

item sequencing. Most sequences begin with a key and are at the left of the diagrams. The colors of the keys are below the appropriate boxes.

Note that the two Scope entries (Scope / S1 in Table 3-1, and Scope / S2 in Table 3-2) represent

the two sequential functions of the same switch.

460 User’s Guide Operation

C3-3

Page 18

DIODECHA

ACV

DCV

FREQ OHM BEEP

CHB

OFF ON

Blue

Blue

ACV DCV FREQ

1mV/A 10mV/A

100mV

/A

1mV/A 10mV/A

100mV

/A

1mV

/

o

C

1mV

/

o

F

1mV

/Psi

1mV

/inHg

ACA

DCA

SCOPE

/ S1

F1

F2

F4

A

ACV

DCV GND

GLITCH

MODE

AUTO NORM SINGLE

Brown

OFFB ACV DCV GND

PROBES

SELECT

SEL B 1:1 10:1

SEL A 1:1 10:1

Probe

Adjust

Enter

NOSAVE

SAVE

RECALL DELETE

SCREEN

1

SCREEN

2

Brown

Table 3-1. 460 User Function / Menu Interactions – Part 1

DIODECHA

ACV

DCV

FREQ OHM BEEP

CHB

OFF ON

Blue

Blue

ACV DCV FREQ

1mV/A 10mV/A

100mV

/A

1mV/A 10mV/A

100mV

/A

1mV

/

o

C

1mV

/

o

F

1mV

/Psi

1mV

/inHg

ACA

DCA

SCOPE

/ S1

F1

F2

F4

A

ACV

DCV GND

GLITCH

MODE

AUTO NORM SINGLE

Brown

OFFB ACV DCV GND

PROBES

SELECT

SEL B 1:1 10:1

SEL A 1:1 10:1

Probe

Adjust

Enter

NOSAVE

SAVE

RECALL DELETE

SCREEN

1

SCREEN

2

Brown

Table 3-1. 460 User Function / Menu Interactions – Part 1

460 User’s Guide Operation

C3-4

Page 19

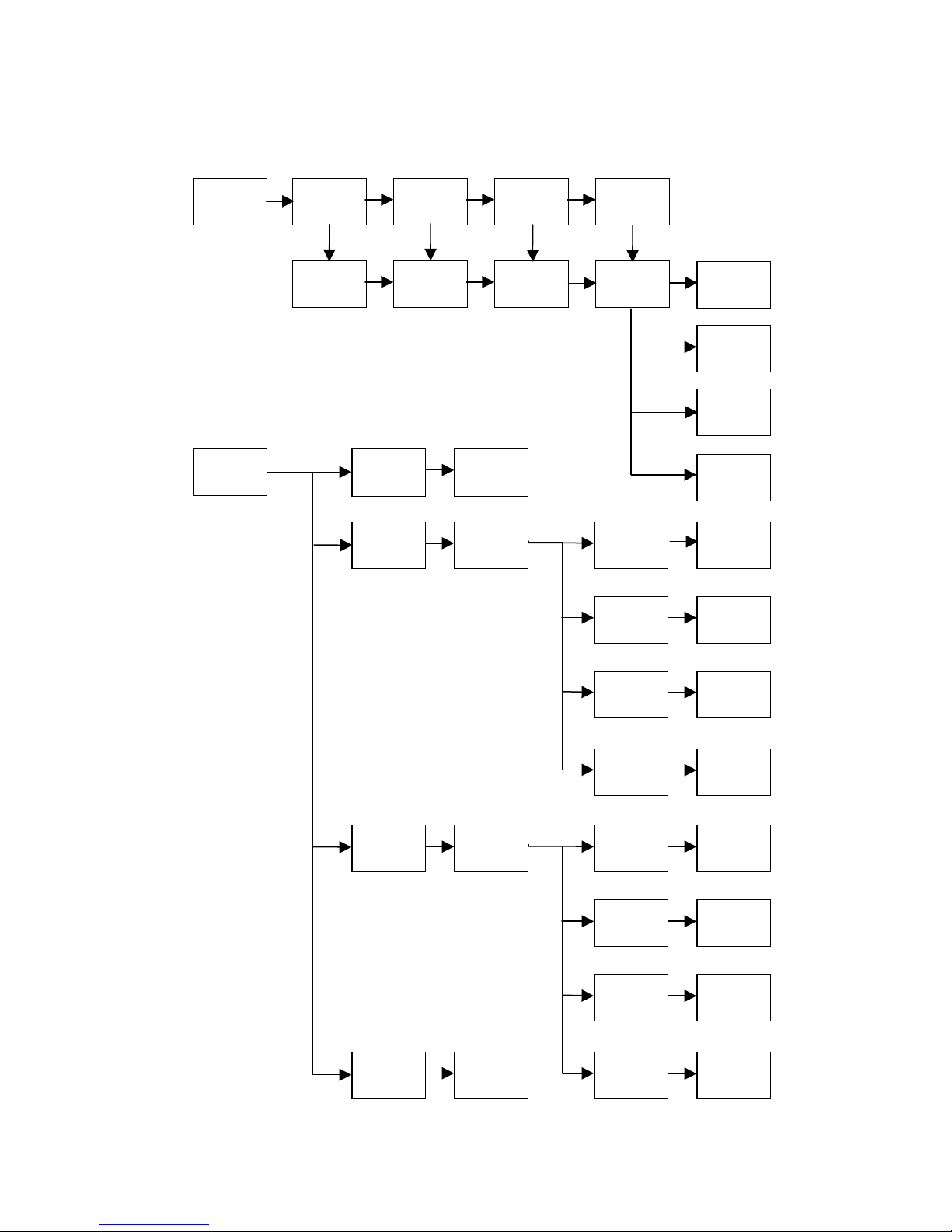

USER

F1

F2 F3 F4

EXIT

Brown

SCOPE

/ S2

F1

A

MOVE

F2

TRIGG-

ER

F1 EXIT

Brown

F2

SOURCE

A, B

F4

TRIG.

SLOPE

F3

TRIG.

LEVEL

Table 3-2. 460 User Function / Menu Interactions – Part 2

CON-

TRAST

RS-

232C

POWER

DOWN

F3

TREND

F1 EXIT

F2

MAX

F4

RE-

START

F3

MIN

F4

B

MOVE

AFTER

10 MIN

AFTER

20 MIN

AFTER

30 MIN

DIS-

ABLE

460 User’s Guide Operation

C3-5

Page 20

Page 21

Chapter 4

Advanced Functions

This chapter assumes the user has now become proficient with the general use of the tpi Scope

Plus 460, and is ready to utilize the more enhanced operations of the 460’s built-in oscilloscopes

and related logic circuits.

In this chapter we will look at triggering, trend mode and different aspects of capturing glitches.

We will also look at screen saves, use of the 10:1 probe and probe adjustments.

Triggering

Trigger level refers to the control of the threshold voltage amplitude level that is triggered from

the input signal, in turn synchronizing the waveform. Once the voltage exceeds or recedes the

trigger level, the meter will draw a trace of the signal with greater stability allowing the technician

to analyze the portion of interest more efficiently.

With Channel A on the 460 active, connect the Common and Probe Lead A to a signal source

(Sine Wave preferred), and proceed with the following steps:

1. Click SCOPE, then select A=ACU, Mode=Auto, B=Off. Then select ENTER

2. Move the highlight to TRIGGER and press ENTER

3. Use the mV / V Channel A rocker key to size the waveform.

4. With the highlight on TRIG. LEVEL, use the up and down keys to stabilize the waveform.

5. Observe that you have now stabilized the waveform without changing the frequency and

without intentionally freezing the waveform. So this is a stabilized live waveform suitable

for analysis or monitoring.

6 Use the SOURCE or TRIG. SLOPE highlight options in conjunction with the direction

buttons to modify the waveform.

7. Use the EXIT box (F1) to Exit from the trigger operation and / or to move the

waveform position on the screen.

Trend Mode

The Trend mode graphs signals over time to capture problems. This option has menu

boxes but is inactive on the current model of the 460.

460 User’s Guide Advanced Functions

C4-1

Page 22

Glitch Capture

The tpi Scope Plus 460 incorporates this feature for capturing intermittent or single event voltage

spikes occurring in a circuit. The spike is automatically detected, captured, and displayed for

analysis on the screen.

To perform this task as a test, you will need a signal generator with a spike or glitch generating

capability, or a means of imposing a glitch onto an otherwise stable signal.

With Channel A on the 460 active, connect the Common and Probe Lead A to a signal source

(Sine Wave preferred), and proceed with the following steps:

1. Click SCOPE, then select A=DCU, Mode=Glitch, B=Off. Then select ENTER

2. Use the up and down keys to center, or lower the waveform (-the spike will usually be

positive in test cases). Then introduce the spike (-this is usually a button on many test

signal generators).

3. If the 460 is performing correctly, you should now have the glitch on your screen,

complete with leading and trailing edges so that rise time as well as other parameters

can be measured.

4. Exit the glitch condition by selecting SCOPE, then change MODE = NORM, then press

ENTER.

Saving Screens

You can save any screen capture from Channel A, Channel B, or two instances of both channels

simultaneously. They can be recalled to the screen, or made available to your computer if you

also have the RS232 software option.

As an example of simultaneous capture, connect the Common and Probe Lead Ch A to one signal

source, then the Probe lead Ch B to a different signal source, and proceed with the following

steps:

1. Click SCOPE, then select A=ACU, Mode=Glitch, B=ACU. Then select ENTER

2. Use the up and down keys in conjunction with the A & B Move boxes at the base of the

screen to position both waveforms

3. Press the SAVE key, select SCREEN 1, and then select ENTER

460 User’s Guide Advanced Functions

C4-2

Page 23

NOTE: There may be no change to the screen after the last operation. This

is normal.

4. Press SAVE again, then select the menu item RECALL, then SCREEN 1, then ENTER.

5. You should now see your saved waveforms with the label RECALLED SCREEN 1,

immediately below the waveforms.

NOTE: The next screen save using the same screen number (e.g. Screen 1), will

overwrite the previous (Screen 1) save.

6. Select the on-screen EXIT to leave the Save program, then press SCOPE to reset the

scope parameters

Using the 10:1 Probe

The TPI Scope Plus 460 is also available with selectable attenuation probes (e.g. P/N SP60B).

These are usually in the form of a probe body with a 3-position switch, 1-meter co-axial lead terminating at the meter end with a BNC connector with an adapter for the 460 socket. This set-up

contains its own ground lead exiting from the probe body, and is supplied with a number of different probe tips.

Attenuation selection is X1, X10, and a ground reference position. Use of the 10:1 probe extends

the bandwidth to 100 MHz when used in the X10 position.

To use the 10:1 probe with the 460, press the SCOPE button, then the F1 key when the SCOPE

INPUTS / PROBES SELECT menu boxes are present on the screen.

With the 10:1 Adapter in the CH A socket, use the Up / Down keys to highlight 10:1 on the SEL A

side of the displayed Probe Selection menu box. Then select ENTER

When using the 10:1 probe on different dual oscilloscope channels, or from instrument to instrument, always perform the adjustment procedure which follows.

CAUTION: Do not use the 10:1 probe for resistance measurements.

10:1 Probe Compensation Adjustment

The following adjustment procedure will ensure that the displayed waveforms will be matched to

the correct division on the display.

There are two methods to compensate the 10:1 Probe. The first and recommended way is to

460 User’s Guide Advanced Functions

C4-3

Page 24

connect the probe to the 460 and set up a 1 KHz square wave using an external signal generator.

Method 1

1. Connect the 10:1 Adapter BNC connector to the Ch A socket on the 460.

2. Press the 460 SCOPE key. Then, when the SCOPE INPUTS display is present, press the

F2 key below the PROBE ADJUST selection box.

3. Attach the 10:1 Probe tip to the signal generator, and use the ground wire from the probe

body to connect with the signal generator ground.

4. With a square wave displayed on the 460 screen, adjust the trimmer located in the BNC

plug to maximize the squareness on the top and bottom of the square wave.

5. On the 460, press the F4 key, or the ENTER key to exit the program.

Method 2

1. Connect the 10:1 Probe BNC adapter to the Ch B input at the top of the 460. Then attach

the 10:1 Probe Tip with the Banana Adapter to the Ch A input.

2. Press the SCOPE key. Then, when the SCOPE INPUTS display is present, press the F2

key below the PROBE ADJUST selection box.

3. Following the instructions on the screen, use the screwdriver, supplied with the 10:1

Probe kit to adjust the trimmer in the BNC plug. Adjust the trimmer to obtain fully

squared edges on the displayed square wave.

4. On the 460, press the F4 key, or the ENTER key to exit the program.

460 User’s Guide Advanced Functions

C4-4

Page 25

Chapter 5

Using Adapters

This chapter covers general information on the accessories available for use with the tpi 460

Handheld Oscilloscope. For detailed information, please refer to the data sheets provided with

each adapter.

Temperature Adapter - A301

This adapter is used in conjunction with K-type probes to measure a variety of temperature targets with ranges from -40 to 500oF. tpi offers almost 20 different types of thermocouple probes

that work accurately with the A301.

The A301 (regardless of the type of thermocouple use, has a standard output of 1mV DC per

degree Fahrenheit. The range of the A130 is -40 to 500

o

F, therefore the output range is 960mV to

O.5V. On the 460 this equates to using the standard DCV scale on Channel A, or the 1mV/oF

scale on the B Channel (Press Ch B, make selection, and press F4 to Enter).

NOTE: The A Channel is recommended for this adapter, as the Ch A plug

orientation on the 460 allows the Adapter On/Off switch to face the user.

The A301 comes with a 9V battery and a standard 2-Pin plug that sockets directly into the top of

the tpi Scope Plus 460.

High Current Adapters - A251 / A256 / A296

o A251 - A clamp-on adapter that measures up to 400 AC amps.

o A256 - A clamp-on adapter that measures up to 400 AC and DC amps.

o A296 - A clamp-on adapter that measures up to 1000 AC and DC amps.

All three adapters have some common operating parameters. They should only ever be used on

a single wire. Clamping onto bundles or any more that one wire will result in erroneous readings.

Set up the 460 before making the test and ensure that power is initially off to the circuit under

test and that the input cable is inserted using the correct polarities.

On the 460, use ACV for making AC measurements, and DCV for making DC measurements. In

addition, use the V rocker button on he instrument to initially go to the highest voltage rating

when making an initial measurement (200V on both scales).

All the High Current measurement adapters use a 9V battery (supplied). If the battery runs low,

460 User’s Guide Using Adapters

C5-1

Page 26

the red LED will come on and remain on until it is exhausted or the battery is replaced.

Low Current Adapter - A254

This small clamp-on adapter measures currents one amp and below accompanied by voltages up

to 1000V in either AC or DC.

Plug the unit into the upper sockets of the 460. Use DCV on Channel A (Ch A) and convert 10mV

to 1.0 amp with the 254 set to 10mV/A and 100mV to 1.0amp with the 254 set to 100mV/A, or

Channel B (Ch B) and use either the 10mV/A DCA or 100mV/A selections (depending on the

appropriate A254 setting) to read both millivolts and equivalent amps at the top of the screen.

Be sure to plug the A254 into the correct sockets of the 460 for the channel being used.

CAUTION: This adapter is designed to measure currents up to 1 Amp.

Attempts to measure currents greater than 60 Amps could damage both

the adapter and the 460 measuring instrument.

The A254 uses a 9V battery (supplied), and includes a detachable instrument head socket (2-pin

to co-axial), and a zero adjust control.

Current Shunt Adapter - A130

This adapter is an inexpensive way of extending the current range of your tpi 460 Handheld

Oscilloscope to 30 amps.

The A130 comes with two probes and is used in series with the circuit to be measured. The unit

uses the power being measured and requires no batteries.

Plug the unit into the upper sockets of the 460. Use DCV on Channel A (Ch A) and convert

0.1mV to 0.1 amp, or Channel B (Ch B) and use the 1mV selection to read both millivolts and

equivalent amps at the top of the screen.

Be sure to plug the A130 into the correct sockets of the 460 for the channel being used.

NOTE: Channel A is recommended for the A130 adapter, as the Ch A plug

orientation on the 460 allows the Adapter On/Off switch to face the user.

Pressure Adapter - A620

This adapter can measure air densities from a vacuum of 30 inHg to a pressure of 500 psi.

Connect the adapter to the upper sockets of the 460. Use DCV on Channel A (Ch A) and convert

0.1mV to 1 psi for pressure and 1 inHg for vacuum, or Channel B (Ch B) using the 1mV/PSI or

460 User’s Guide Using Adapters

C5-2

Page 27

1mV/inHg selections as required.

On the A620, use the BAR switch position to measure vacuum or the X10psi position to measure

pressures from 1 to 500psi. Use the ZERO control only if you know the pressure to be zero and

stable, or at a standardized pressure.

The A620 uses a 9V battery (supplied) and includes a 1/4 inch NPT pressure port connection at

the end of a 2-Meter flexible cable.

PC Software and RS232 Cable - A404

This software allows the 460 to download data and waveforms to any computer environment running Microsoft Windows. The RS232 interface utilizes a fiber optic connection to shield the data

from electro magnetic radiation sources, and therefor from potential signal degradation.

Using the A404 package you can download data and put the information into spreadsheets and

charts for incorporating into reports and other documents. Reports from different units can also

be merged to produce one report.

In addition, graphs can be shown with the identification number of the instrument used, enabling

data to be cross-checked against calibration records helping to ensure full traceability.

Since live waveforms can also be transmitted to the computer via the RS232 connection, you can

compare stored waveforms to current waveforms for some types of fault recognition.

Refer to Appendix D for RS232 interactions with your personal computer.

460 User’s Guide Using Adapters

C5-3

Page 28

Page 29

Chapter 6

Safety Considerations

This chapter deals with various aspects of safety, both for personnel and the instrument. Also

included is a List of safety signals and their meanings.

Instrument Cautions

o Test the Instrument before using

o Check Backlighting and Contrast (this will also accomplish a quick test on the

battery level).

o Check both oscilloscope channels. - A simple standard waveform test will usually

accomplish this.

Check the Test Leads and/or Adapter

o If there is a break or intermittent in the test leads, it will have the same effect as a

malfunctioning instrument.

o Check the adapter using a known sample or set-up before using on the device or

environment under test.

o Test Connections

o Check the security and quality of both the adapter connections to the instrument and

DUT (Device Under Test) connector points.

Disconnect Power to the Circuit (Unless using Clamp-On’s)

o This step provides two safety factors. The first ensures that the operators hands are

not in the vicinity of dangerous voltages. The second allows you to check that the

instrument is set up to read the right values before power is present at the DUT.

o Understand the circuit being measured

o Failure to understand the circuit to be tested has the same level of risk as not setting

up the instrument before power is applied to the circuit. Namely the risk of too much

power for the level of measurement.

Keep the Instrument Non-Parallel to the Circuit

o If the instrument, or any substantial length of test cable is parallel to and/or in close

proximity to the bulk of the DUT or high current carrying cable, the test cable will

pick up some of the radiation and be affected by it. This is important when making

precise measurements or when seeking a stable waveform.

460 User’s Guide Safety Considerations

C6-1

Page 30

Personnel/Environmental Factors / Warnings

Assign a Checker

o Arrange to have someone check on you periodically. This is especially true of high

voltage environments. An unconscious worker stands a better chance of survival if

resuscitation is given in the shortest time after an accident.

Do not attempt to measure unknown voltages or currents

o With modern cabling, it is easy to assume that a small size wire or cable is carrying a

voltage or current that is less than actual. Either assumption can have disastrous

effects for both operator and instrument.

Do not touch any exposed part of the test lead assembly

o Some types of test leads have close to exposed metal parts that could potentially

come into contact with the body, especially hands or lead pencils and other

conducting items.

List of Danger/Warning Signals

The following are International Danger/Warning signals with an abbreviated explanation of their

meanings.

This label signifies that there is a distinct level of danger in

this area. This sign is usually accompanied with symbols

denoting the exact type of danger present.

This combination label signifies that a significant level of

danger exists in this area that can effect the eyes. This

symbol denotes that shaded goggles should be worn.

This combination label signifies that there is a distinct

possibility of a fire hazard in this area (--an explosion

symbol is sometimes substituted for the fire symbol in

similar situations). Do not carry combustible materials in

this area

460 User’s Guide Safety Considerations

C6-2

Page 31

This combination label signifies that there is a strong

possibility of electrical shock in this area. Proper attire,

and especially insulated footwear are required in these

areas.

This International symbol signifies that conditions exist that

could result in bodily harm. The symbol usually occurs in

conjunction with a symbolic description of the type of

hazard that exists.

This symbol indicates that there are open gears in the area

which could snag clothing and risk injury to the wearer.

Avoid wearing loose clothing and beware of test instrumentation with long leads attached.

This symbol indicates that a hazard exists in this area which

could effect exposed skin areas. The nature of this hazard

could be chemical of temperature based. Wear gloves at all

times and be careful of any other skin contact.

This International symbol indicates that a danger exists

which could damage equipment that you carry into the

area. Identify proper grounding and use in conjunction with

test equipment at all times

460 User’s Guide Safety Considerations

C6-3

Page 32

Page 33

Appendix A

Test and Calibration

This chapter is designed to re-affirm that your TPI Scope Plus 460 is functioning correctly and is

on a par with the original calibration. This test and calibration procedure can be used as an

annual test, goods inward (Acceptance) test, or re-affirmation test when readings have not been

expected ones.

Test Procedures

The TPI Scope Plus 460 has no built-in test programs, however, the following procedures can be

used to perform a quick functional check on most 460 operations. Procedural titles that are followed by an asterisk (*) are less important, and can be considered optional in cases where a

quicker spot test is required.

Initial Setup

The following tests should be made with an adequate battery charge and with the power charge

plug in place, and the RS232 cable disconnected. If the battery has previously been low, allow at

least 15-minutes for the battery charge to build up.

On power up (press and briefly hold the POWER ON button), allow a further 5-minutes for the

circuitry, and LCD screen to stabilize. After stabilization, press USER, then F2 to arrive at CON-

TRAST. Press ENTER, and use the Up / Down keys to adjust for optimal contrast. One way to do

this is to press the Up arrow until the background begins to darken and then backtrack down by

pressing the down arrow once. In any case , the waveform and alphanumeric characters should

both be black and stand out in strong contrast to the background

Check the brightness by pressing the blue button with the Sun icon. Continue pressing. After

10-counts, it should resume to maximum brightness.

If any of the above steps perform unsatisfactorily, you either have an undercharged battery, or a

malfunctioning LCD display. Check with the service department (see phone numbers on Page 1

of this document), before returning the unit.

A-1

460 User’s Guide Test and Calibration

Page 34

Sequencing Test

This test will verify that the internal multiplexors are correctly sequencing information to the display. Note that much of the sequence is dependent on the previous display, so many of these

steps will not work when separated from the overall context.

1. Press the USER key. The following menu bar should display at the base of the screen:

2. In the previous screen, use CONTRAST to make any necessary adjustment, then press

the SCOPE key. The following menu should display:

3. Press the F1 key. The following menu should display.

460 User’s Guide Test and Calibration

A-2

Page 35

4. Press SCOPE, then F2 (PROBE ADJUST). the following display should result.

5. Press ENTER to leave the PROBE ADJUST display, then complete the Scope input using

the ENTER button and Direction keys. Then press Ch A, ACV, then F3 (TREND). You

should get the following menu display:

6. Repeat the sequence for Step 6, except in the last step, press F2 (TRIGGER), instead of

F3. Follow by pressing ENTER -You should get the following menu display.

460 User’s Guide Test and Calibration

A-3

Page 36

7. Press F1 (EXIT) to leave the Trigger menu, then ENTER. Now press Ch B. The following

menu should result.

8. The previous screen shows the Channel B available selections. Click through the

sequence until you get to 1mV/Psi. Then finish the other selections and click ENTER. Check that the display shows Psi units at the top left of the screen. This is a spot check

on the sequence of one of the lists in this menu. You may choose to do this for the other

lists too (i.e.:ACA, DCA, etc.).

9. Press ENTER to exit with your selections from the previous screen, the press Ch A. The

result should show the selections available specific to Channel A, as depicted in the

following screen.

460 User’s Guide Test and Calibration

A-4

Page 37

10. Use the direction arrows to move down the menu to BEEP. Select F4 to acknowledge

selection. The following screen display should result.

11. Press CH A to return to the original Channel A menu, except this time use the direction

keys to move down to the DIODE selection. Press the F4 key to acknowledge selection.

The following display should result.

460 User’s Guide Test and Calibration

A-5

Page 38

12. Press the Ch B key, then F4 to acknowledge exiting the Diode Test mode. Select Ch B

a second time to bring the selection options up to the top of the menu. Then in the

Channel B menu, select ON, ENTER, ACV, ENTER. You should now have a dual trace

display. Press the SAVE key. This should give you the following menu selection.

13. In the screen save menu, select SAVE, F4 (ENTER), then SCREEN 1, F4. This will save

the first of the two possible saves in internal memory. Now repeat the screen save

function (SAVE key), except choose RECALL, F4, SCREEN 1, F4. A screen similar to

the following should result:

460 User’s Guide Test and Calibration

A-6

Page 39

14. Press the Ch B key. Select ON and ACV, then press F4 (ENTER) to enter the command.

You should get the following screen.

15. In the screen shown above, use the keys F1 and F4 to separate and position the two

traces from Channel A and Channel B in conjunction with the Up and Down arrow

buttons. Also note the Battery symbol in this depiction. The bars of the battery will

blink when the battery starts to get low. The battery symbol is replaced with a power

plug symbol whenever the power cord is attached.

16. Press the USER button, then F3 (RS-232C). Press the ENTER button. You should get

the following screen menu:

Battery

Check

460 User’s Guide Test and Calibration

A-7

Page 40

17. Select the correct baud rate for your computer and press F4 (ENTER). Refer to Appendix

D for other RS-232 interface details.

18. While still in the USER / CONTRAST Menu, select F4 to activate the POWER DOWN menu.

Then press ENTER. The resulting display should be similar to the following one:

19. Use he Up/Down arrow buttons to select 10-Mins, then press F4 to enter command.

Note the local time that the unit should switch off. If the unit switches off at any other

time, then the internal sequencer is incorrectly set and will need to be adjusted. Note

that you can continue to use the 460 in any way you choose up until it automatically

powers down.

20. This is the end of the general sequence test. If any problems were found with

sequencing, other column type lists that were not included should also be checked.

For general operational tests, refer to Chapters 2 and 4.

Calibration

Most calibration adjustments are carried out at the service facility or factory, however the following tests and adjustments can be made in the field. If you established that the instrument or

attachments are out of alignment and/or are not measuring within the confines of the specifications, call your local service representative or the number at the front of this manual for the correct address to return your parts to for test and calibration.

" Always use a known or reliable standard when making a test measurement. For instance,

when testing a resistance scale, use only high tolerance parts. E.g.: +/- 1%

" Check that the accessories such as test leads are the correct type for the entity being

measured (some test leads have their own specifications and are usually supplied with

the product.

460 User’s Guide Test and Calibration

A-8

Page 41

" Make sure that both the instrument and test leads are not close or parallel to electro-

magnetic sources which could be picked up by the 460 and/or the leads and which could

effect readings.

" Be sure that the ground (Common) for the entity being measured is the true ground.

" Check the specifications in Chapter 1 for the scale being measured

" Note that probes which are internally attenuated, usually have their own adjustment

procedure. Chapter 4 has an adjustment procedure for 10:1 probes.

460 User’s Guide Test and Calibration

A-9

Page 42

Page 43

Appendix B

Maintenance

This chapter covers basic maintenance for the hand-held TPI Scope Plus 460. These procedures

include general inspection, use and inspection of probes, and battery check and replacement.

Note that attempts to perform maintenance beyond the scope of this document, especially alterations to interior settings, may result in a default of your warranty coverage.

General Inspection

The following steps are recommended, but the sequence is not critical. If all steps are performed, and the instrument is malfunctioning, note the conditions on a label and attach it to the

instrument. Prepare the unit for mailing in to the address given at the front of this document, but

please call the service department before shipment.

1. Check the exterior of the instrument for damage and existence and functionality of the

carrying handle and back support flap.

2. Check the back of the instrument for any loose or missing screws, and any obvious

interior rattles. Note: Do not shake the instrument vigorously. A gentle rocking is

sufficient to check for loose parts.

3. Check the display face plate for nicks and scratches that could cause interference with

viewing waveforms.

4. Check the plug sockets at the top of the instrument for discoloration or burns, etc.

5. Check the key markings and silk screening above the display (Ch A / COM / Ch B), for

readability.

6. Connect the power adapter to the 460, and allow 10-minutes for the circuitry to stabilize.

Then press USER > CONTRAST and use the arrow keys and sun icon button to adjust for

optimal brightness and contrast. If the brightness and/or contrast are slightly out, the

internal battery may be undercharged. If the unit has been in service for a long time and

the display is very dim, you may need to replace the battery (see instructions on battery

checks and replacement later in this chapter).

Probes

The 460 comes with one set of probes and can be used with a number of other probes available

as optional extras. Most of the probes come with their own specifications and instructions, so

only general maintenance information will be included here. Please note the following points.

B-1

460 User’s Guide Maintenance

Page 44

1. The bandwidth of the 460 is 20 Mhz. Not all probes have this much bandwidth. If you

use probes with lesser bandwidth, the measurements and waveform interpretation may

be inaccurate. Check the specifications of the probes you receive before using them.

2. The ground potential in the shield of most co-axial type probes is the same potential as

the “Common” potential. This means that if you use the convenience ground outlet in

the body of many probes, it will have the same effect as using a separate wire from the

“COM” outlet of the 460.

3. The normal attenuation in probes is, for all practical purposes zero, these are the

probes referred to as 1:1 probes. Another commonly used probe is the 10:1 probe.

The 10:1 probe is attenuated (sometimes switchable) to read only one tenth (1/10th) of

the potential that the probes detect at the probe tips. The 460 has an internal ability to

read 10:1 probes correctly, as long as the instrument is correctly set (SCOPE > F1 > 10:1

> ENTER) . Note that you can set up the two channels of the 460 for different probe

sensitivities.

4. The 10:1 probe requires a minor adjustment (because of the internal attenuation circuit)

whenever you set the probe up, or use the same probe on a different channel. This

adjustment is so that the displayed waveform will accurately represent the shape of the

waveform being measured. The adjustment is usually made via a trimmer (variable

capacitance) in the head of the adapter at the instrument end. Refer to Chapter 4 (10:1

Probe Compensation Adjustment), for instructions on making the adjustment.

Battery Check and Replacement

The 460 uses a rechargeable 4.8V Ni-Cad battery (4-cells @ 1.2V, 1.4Ah). The battery should last

through many recharges before losing the capacity to hold a charge. Should the latter case happen, the best option is to replace the battery. The following steps will guide you through this

process.

Disassembly:

1. Disconnect the power charging plug and all connectors and cables. Then check that

power for the instrument is off. If the battery compartment cover is hot, you may wish

to let the instrument cool before performing the next step.

2. At the back of the instrument, remove the two screws near the base of the support flap.

3. Turn the instrument over so that the battery cover and battery fall into the palm of your

lowest hand. If they do not come out on their own, give a slight up and down shake to

the instrument. However do not use excessive force.

B-2

460 User’s Guide Maintenance

Page 45

4. Reverse the instrument again, so that you can see the battery connections entering the

instrument. Gently pull the leads back and downwards so that the plug releases without

catching onto the inside of the case.

5. Note the battery type that you have just removed as a double check with the type you

are going to replace it with.

6. If you are going to dispose of the old battery, mark it for proper disposal. Ni-Cad

batteries should not be incinerated in standard incinerators or crushed.

Assembly

1. The 460 uses a TPI A006 replacement 4.8V rechargeable Ni-Cad battery. Unpack and

check the battery type and the existence of a 4-pin plug on the end of the leads. The

battery comes uncharged and will need to be fully charged after installation.

2. Refer to Figure B-3 and install the connector into the battery compartment socket.

Note that the red leads are to the right of the connector. The leading edge of the

connector is best inserted slightly upward and forward.

3. Refer to Figures B-2 and B-3, and install the battery into the compartment, connector

end first. Fold the wires in a single fold to the left, keeping the wires at the top of the

compartment.

4. Check the wires are inside the perimeter of the battery case housing and replace the lid

above the battery. Insert slight pressure on the lid to determine if the wires are properly

folded inside. Insert the two screws and tighten down without using excessive force.

5. Turn the unit over and insert the power charging plug. Set the instrument aside to fully

charge. --Typically 12-hours for the initial charge.

6. Refer to Chapter 2 and perform the 460 setup with special emphasis on setting up the

initial contrast setting. Note that even after fully charging the batteries, a low contrast

setting may make the screen difficult to read until adjusted.

B-3

460 User’s Guide Maintenance

Page 46

Use single loop U configuration between connector

and battery outlet.

Fig. B-1. Pre-install

Battery Wire position

Fig. B-2 Battery Wire

position after installation

Fold wire within confines of

inner battery compartment

Fig. B-3. Battery Connector

position before insertion.

Note topside position of

guide bar, and location of red

wires to right side.

B-4

460 User’s Guide Maintenance

Page 47

Appendix C

Glossary

The following terms are pertinent to the TPI Scope Plus 460 and the environment in which it

typically works. The meanings in other environments may be different to those described here.

Cross references in this glossary are identified with an asterisk (*).

Active Power A power measurement in Watts that is derived by

multiplying the voltage portion of the signal by the current

that is in phase with that voltage.

Analog Output A non-digitized signal such as those used to drive an oscilloscope.

Apparent Power The product of the voltage applied times the current flow. The unit

of measure is VA (Voltamperes), and the term is only applicable to

Alternating Current (AC) circuits.

Auto Hold The action by a measuring device to (on command) wait until a

reading has stabilized before storing that reading and making

it available for display.

Auto Ranging Ability of a measuring device to automatically select the

appropriate range of measurement.

Auto Set A command to the measuring device (AUTO on the 460) to go from

manual to automatic setting based on the magnitude of the signal

being measured.

Bandwidth The frequency range over which the instrument operates efficiently.

CCFL Acronym for Cold Cathode Fluorescent Lighting. -- The type of

backlighting used in several tpi instrument displays to light the

back of the LCD* screens.

Cold Junction A circuit in a measuring device which automatically resolves

Compensation the difference between an ambient reference (used when the

device was calibrated), and the actual operating temperature of

of the measuring device.

Conductance The reciprocal of resistance expressed in terms of Siemans

(formally mhos).

460 User’s Guide Glossary

C-1

Page 48

Contrast The level difference between light and dark.

Continuity Beeper Audible tone emitted from a meter when the resistance falls below

a preset threshold value (typically 100 Ohms).

Cosine F Voltage and Current do not always happen together, often there is a

difference. The difference is an angle between 0 and 90, termed F.

The greater e angle, the bigger the difference between True and

Apparent Power and the smaller the Power Factor. If Voltage and

Current happen at about he same time, F is small, the values of

True and Apparent Power are close, Power Factor approaches 1.

Criterion Sound Level The eight hour average weighted sound level, expressed in dB, that

Level corresponds to the maximum permitted daily exposure to noise

as prescribed in national and state regulations.

Data Acquisition The ability of an instrument to acquire measurement information

as it occurs, and to be able to store it, for future retrieval or

transmission.

Data Logging Typically, the ability of an instrument to store information in non

volatile memory for use later (on demand) for analysis and report

generation.

Data Hold The temporary storage function of a measuring device which holds

a displayed value when a user presses a key or button.

Decibels The unit of measure expressed as dB’s, used when measuring the

level of sound. Every 3dB represents approximately double the

power or sound level, hence 53dB is twice as loud as 50dB. dBm

refers to decibels above one milliwatt.

Differential In dual input measuring devices, differential is the displayed

difference between the two inputs (Input A - Input B = Differential).

Diode Check A function of a measuring device in analyzing the operation of a

diode. The probe leads are attached to either side of the diode and

the user is alerted visually and/or audibly as to the diode’s integrity.

Display Counts The number of display units a meter or other device can indicate.

For example, a 3-1/2 digit display can indicate from 0 - 1,999 and

a 4-1/2 digit display can indicate from 0 - 19,999. If a meter is

bi-polar it can indicate positive and negative depending on the

460 User’s Guide Glossary

C-2

Page 49

polarity of the signal being monitored

Duty Cycle The ratio of the working time to the total time of a pulse train

expressed as a percent.

Elapsed Time The period of time between the start of a measurement series to

the last measurement observed or recorded.

Electric Power The measure of electric energy whose unit is the Watt.

E.g.: 1 Horsepower = 746 Watts. It is derived by multiplying the

applied voltage by the current passing through the circuit

Emissivity A term related to temperature measurement using Infrared

radiation. Errors in IR measurements can occur based on the

color, shape, and presence of reflection on the measurement

surface. A wide emissivity adjustment should be available on a

IR thermometer to allow the user to compensate for these types

of errors.

EMF/Electromagnetic Waves generated by a magnet configuration usually consisting of a

Radiation coil wound around a steel core. The core is strongly magnetized

when current flows through the coil. Video Monitors, power lines,

and wire harnesses are a few of the devices which produce electromagnetic radiation.

Glitch Capture The ability of an instrument to listen for and capture spikes that

occur in signals. The resulting captures are usually sent directly to

the screen for display.

Go/No Go Alarm An output from a meter or controller which is used to indicate

when a preset measurement point has been reached or exceeded.

On the tpi 460, the continuity checker is a form of Go/No Go alarm

Kelvin Connection A four wire method of connecting test leads which is designed to

eliminate or greatly reduce the effect of lead and contact resistance

and thus permitting accurate measurements of low resistance.

LCD Acronym for Liquid Crystal Display. Liquid crystal is a liquid that

is not isotopic, that is, it forms patterns when polarized. The

orientation of the molecules of the liquid are arranged by the

meter to form the display.

LED Acronym for Light Emitting Diode. An electric current is passed

through the diode causing illumination. When used for alphanumeric display purposes, the LED’s usually have seven segments

460 User’s Guide Glossary

C-3

Page 50

per digit Orange, yellow and Green are common LED colors.

Load A device that is driven by the output of a meter or other measuring

or control equipment. An example of a load is a resistor being

measured by a multimeter. The resistor “loads” the meter since it

becomes part of the measuring circuit.

Microprocessor Integrated circuits which perform many instructions per second

for functions such as mathematical equations,data storage, display

updates, etc. Microprocessors are at the heart of computer

accuracy, repeatability and speed. Also called CPU’s (Central

Processing Units).

Min/Max A function of a measuring device which records (saves) the highest

and lowest reading it has encountered since being reset (cleared)

or powered up.

Multiplexer A device that sequences access to a communication port. Several

different devices can share a single COM port on a computer if

they are multiplexed.

Overload A signal that is greater than that which a measuring device can

accurately or safely accept. Many meters have overload protection

in the form of a fuse, or similar device, to protect the meter from

overload input.

Over Range Visual display alerting the user that the signal present at the

Indication meter’s input is out of range.

Peak Hold The ability of a measuring device to hold the highest reading until

the user clears the display. Also known as Peak Detect.

Relative Mode Displays the difference between the measured value and the stored

value.

Relative % Mode Displays measured value as a percentage of stored value for

checking component tolerances.

Power Factor This is the ratio of Watts to VA, or True Power* divided by

Apparent Power. This can be expressed as a decimal or

percentage, i.e. : PF=0.65 or PF=65%. True Power is never

greater than Apparent Power, so the Power Factor is never greater

than 1. Power Factor may also be expressed as Cosine F*

Probe Select Most probes are only mechanically different. However when they

460 User’s Guide Glossary

C-4

Page 51

differ electrically they will effect metering. The most common

electrical difference is a change in attenuation. tpi probes typically

come with attenuations of either 1:1 or 10:1.

Probe Adjust For the meter to read accurately, the DUT and input capacitances

should match. Probe adjust allows a capacitance compensation to

be made whenever a change of probes or oscilloscope input

is made.

Psychrometers A relative humidity measuring device which has two thermometers.

(Wet Bulb) One of the thermometers measures ambient temperature (dry

bulb), the second measures the temperature of an element

surrounded by a fibrous material saturated with water (wet bulb).

Reference tables are than used to determine relative humidity.

Real Time Update The tracking of events as they happen.

Recall Mode To bring back from memory and display a previously recorded

waveform.

Resolution The smallest value a display device can indicate. For example, if a

device can display 0.0 to 100.0 RPM, the smallest measurement,

and therefore the resolution, is 0.1 RPM

Response Time The rate at which a measuring device responds to a change in the

measured variable

RH Capacitance Probe A capacitive device that senses relative humidity The meter used

with such a probe senses the change in capacitance based on the

moisture encountered by the capacitor’s dielectric and displays the

relative humidity based on this capacitance value.

RH Resistance Probe A resistive device that senses relative humidity The meter used

with such a device monitors the resistance of the probe which

changes proportionally to the amount of moisture encountered.

The meter then displays the relative humidity based on this

resistive value.

RMS See “True RMS”

RTD A temperature measurement device whose resistance is

proportional to temperature.

Single Phase A single alternating current source such as a typical AC wall outlet.

Three-phase on the other hand, provides three separate alternating

460 User’s Guide Glossary

C-5

Page 52

signals.

Thermistor A resistive temperature measurement device whose resistance

decreases as the temperature increases. A thermistor is a stable,

compact and rugged two terminal ceramic-like semiconductor

bead.

Thermocouple A 2-wire temperature measurement sensor constructed of two

dissimilar metals which form a junction. Current flows from one

metal to the other in proportion to temperature. A millivolt signal

is then measured by a thermometer or other display device

temperature.

Threshold Sound levels below this point (also called Threshold Cutoff), are

excluded from dosimeter measurements. National and state

regulations determine the threshold level.

Transistor Test A function of a measuring device which can be used o check the

operation of a transistor. The leads of a transistor are inserted into

a receptacle and the meter indicates whether the device is

operational or not.

Trend Mode The function of graphing signals over time to capture problems.

Trigger Selection The basis and point at which the oscilloscope begins its tracking.

Usually selected on the basis of AC, DC, or Glitch Capture, with

slope edge, level, and sensitivity selectable.

True Power Electric power, measured in Watts.

True RMS Voltmeter A Voltmeter that measures an AC sine wave (voltage and current)

and displays the rout mean square (rms) of each waveform cycle.

Important when measuring true power, and on the non-sinusoidal

waveforms found in many circuits and controls.

Watt The unit of measure for electric power. 1-Horsepower = 746 Watts.

Zero Adjust Ability of a meter to be calibrated to a null or “zero” reference

ensuring accurate readings in all ranges.

460 User’s Guide Glossary

C-6

Page 53

Appendix D

RS - 232C / PC Interface (Optional)

The RS-232C / PC Interface is a powerful tool for downloading instrument data, especially waveforms to your PC for subsequent program integration. In addition you are able to view your

waveforms on a larger scale, on a clearer grid and in a color of your choice. This appendix is

divided into the following sub-sections:

" Installation

" Set-Up

" File Management

" Print Management

" Controlling the A460 from the PC

" Archiving

" Special Applications

Installation

The RS-232C package comes with an optically isolated RS-232C connector/cable assembly to fit

the standard 9-Pin RS-232C Communication Port (Com Port) on your PC, and two 3-1/2

diskettes for the software. Use the following procedure for initial installation into any PC running

in a Windows environment.

1. Connect the 2-pin optical end of the cable assembly into the side socket of the

460. Connect the other end to the Com Port of the PC. Tighten the screw of

the Com Port plug.

2. Insert the first software installation disk, and use the mouse to select Start ->

Run. Enter A:\SETUP.EXE into the Open box and select OK. Repeat for the

second installation disk. You should have a screen similar to the one shown in

Figure D-1

Set-Up

After software installation, you will have the display but not necessarily the trace and other data

capture information. Use the following steps to bring up the data:

1. Set up the active display colors by selecting Color Set Up in the Printer section

of the display. Select the color box next to Background. In the resulting display,

select a box or color band and then click OK. Repeat for Grid and Graph, then

click OK to exit from the Graph box.

460 User’s Guide RS-232C / PC Interface

D-1

Page 54

Figure D-1. Basic 460 RS-232C display

2 Assign a save identifier for both channels. To do this, select the Save button for

Channel 1. Click the entry box and enter an identifier (See Figures D-2 and

D-3). Then click Ok. Repeat for Channel 2 with a different identifier.

3. Select the Start button. If the Comm Port selection is correct there should be a

display.

4. If no display is present (a center trace line should exist even if there is no wave

form), click the Stop button twice to ensure that it is not in a hold position.

3. If there is still no display present, click Stop, then select Comm Port 1, then

click Start. Repeat this for the other port numbers if necessary.

4. If there is still no display present, click Stop, then select a different Baud rate,

then click Start. Repeat this for the other baud rates if necessary

5. If there is still no display present you may have a cabling problem. If you do

now have a display, continue with File Management.

File Management

1. Save a file to the default folder, or use the File Browser to select any folder,

then enter the identifier in the entry box. You can also type the complete save

sequence string directly into the save entry box if you know the path names

2. To restore a previously saved file into the display area you will need to use

Load, however you will first have to Stop the current display.

460 User’s Guide RS-232C / PC Interface

D-2

Page 55

Figure D-2. Save Input Display

Figure D-3. Waveform Display with Identifiers

3. Press Load for Channel 1, and enter the load identifier into the entry box. Use

the Browser utility if needed. Then click Ok. (See example in Fig. D-4). The

result will be the waveform previously recorded.

4. Repeat for Channel B as required. Note that the Print option for the Data View

dialog box is for the data entry only (not the waveform).

Channel 1 Identifier

Channel 2 Identifier

460 User’s Guide RS-232C / PC Interface

D-3

Page 56