Page 1

Scope

Plus!

Instruction Manual

440

Page 2

Page 3

42

TABLE OF CONTENTS

page

A. INTRODUCTION

1. Congratulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . .4

B. SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . .5

C. TECHNICAL DATA

1. Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . .7

2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

D. MEASUREMENT TECHNIQUES

1. Controls and Functions . . . . . . . . . . . . . . . . . .13

2. Step by Step Procedures:

a) Measuring DC Volts . . . . . . . . . . . . .15

b) Measuring AC Volts . . . . . . . . . . . . .16

c) Measuring DC Amps . . . . . . . . . . . .17

d) Measuring AC Amps . . . . . . . . . . . .18

e) Measuring Resistance . . . . . . . . . . .19

f) Measuring Diodes . . . . . . . . . . . . . .20

g) Continuity Buzzer . . . . . . . . . . . . . .21

h) Measuring Capacitance . . . . . . . . . .22

i) Measuring Frequency . . . . . . . . . . .23

j) Component Test . . . . . . . . . . . . . . .24

k) Logic Test . . . . . . . . . . . . . . . . . . . .26

E. SPECIAL DMM FEATURES & FUNCTIONS . . . .27

F. D MODE FEATURES & FUNCTIONS . . . . . . . . .29

G. WAVEFORM MEMORY & SETUP MEMORY . . .32

H. NORMAL MODE 440 APPLICATIONS . . . . . . . .35

I. TREND MODE 440 APPLICATIONS . . . . . . . . . .38

J. GLITCH CAPTURE 440 APPLICATIONS . . . . . .39

K. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . .40

L. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . .41

M. RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . .42

N. TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . .44

Page 4

5

A. INTRODUCTION

1. Congratulations!!

Thank you for purchasing TPI brand products. The

product you have just purchased in an innovative

new concept in Digital Oscilloscope/Multimeter

design – The Scope Plus. This hand-held meter is

easy to use and is built to last. It is backed by a

three (3) year limited warranty.

2. Product Description

The TPI 440 is a hand-held oscilloscope plus

autoranging DMM. The instruments large, backlit

LCD display shows a reading and waveform simultaneously. In addition to the standard functions of

ACV, DCV, ACA, DCA, Ω, Diode Test and Continuity

Buzzer; the 440 measures Frequency (Hz),

Capacitance, Logic and Component test functions.

The 440 also has RS232 output and software for

interfacing with a PC is offered as an optional

accessory.

The 440 comes complete with the following

accessories:

• 440 instrument

• Rechargeable batteries

• Set of standard test leads

• Charger/adapter

• Operating instructions

3

Page 5

64

3. EC Declaration of Conformity

This is to certify that model 440 conforms to the protection

requirements of the council directive 89/336/EEC, in the

approximation of laws of the member states relating to

Electromagnetic compatibility and 73/23/EEC, The Low

Voltage Directive by application of the following standards:

EN 50081-1 1992 Emissions Standard

EN 50082-1 1992 Immunity Standard

EN61010-1 1993 Safety Standard

EN61010-2-031 1995 Safety Standard

To ensure conformity with these standards, this instrument

must be operated in accordance with the instructions and

specifications given in this manual.

CAUTION:

Even though this instrument complies with the

immunity standards, the accuracy can be affected by strong radio emissions not covered in the

above standards. Sources such as hand held

radio transceivers, radio and TV transmitters,

vehicle radios and cellular phones generate

electromagnetic radiation that could be induced

into the test leads of this instrument. Care should

be taken to avoid such situations or alternatively,

check to make sure that the instrument is not

being influenced by these emissions.

Page 6

75

B. SAFETY CONSIDERATIONS

WARNING: Please follow manufacturers test procedures

whenever possible. Do not attempt to measure unknown

voltages or components until a complete understanding

of the circuit is obtained.

GENERAL GUIDELINES

ALWAYS

• Test 440 before using to ensure proper operation.

• Inspect the test leads before using to make sure there

are no breaks or shorts.

• Double check all connections before testing.

• Have someone check on you periodically if working

alone.

• Have a complete understanding of the circuit being

measured.

• Disconnect power to the circuit, then connect the test

leads to the 440, then to the circuit being measured.

NEVER

• Attempt to measure unknown high voltages.

• Attempt to measure current with the meter in parallel to

the circuit.

• Connect the test leads to a live circuit before setting up

the instrument.

• Touch any exposed metal part of the test lead assembly.

!

Page 7

86

INTERNATIONAL SYMBOLS

DANGEROUS VOLTAGE

AC (ALTERNATING CURRENT)

DC (DIRECT CURRENT)

REFER TO INSTRUCTION MANUAL

GROUND

FUSE

DOUBLE INSULATION

EITHER DC OR AC

!

Page 8

97

C. TECHNICAL DATA

1. Features and Benefits

Approvals Meets CE and IEC 1010 requirements.

True RMS Needed to accurately measure non-sinusoidal AC

voltage and current waveforms found on many controls

and circuits.

Auto Set 440 automatically sets-up the scope depending on the

magnitude of the signal being measured.

Real Time Tracks events as they happen.

Update

Glitch Finds spikes in signals.

Capture

Relative LCD displays the difference between the measured

Mode value and a stored value.

Trend Mode Graphs signals to find problems with circuits.

Record Records Min/Max and Average values. Time reference

Mode when value was obtained.

Compare Compares stored value with measured value for

Mode matching components.

Relative % Displays measured value as a percentage of stored

Mode value for checking component tolerances.

RS232 Output Transfers data directly to a PC while measuring.

Back Light Allows viewing in any light condition.

Autorange Automatically selects best range for measurement.

Low Battery Battery should be charged when battery symbol

Indication displays on LCD.

Page 9

108

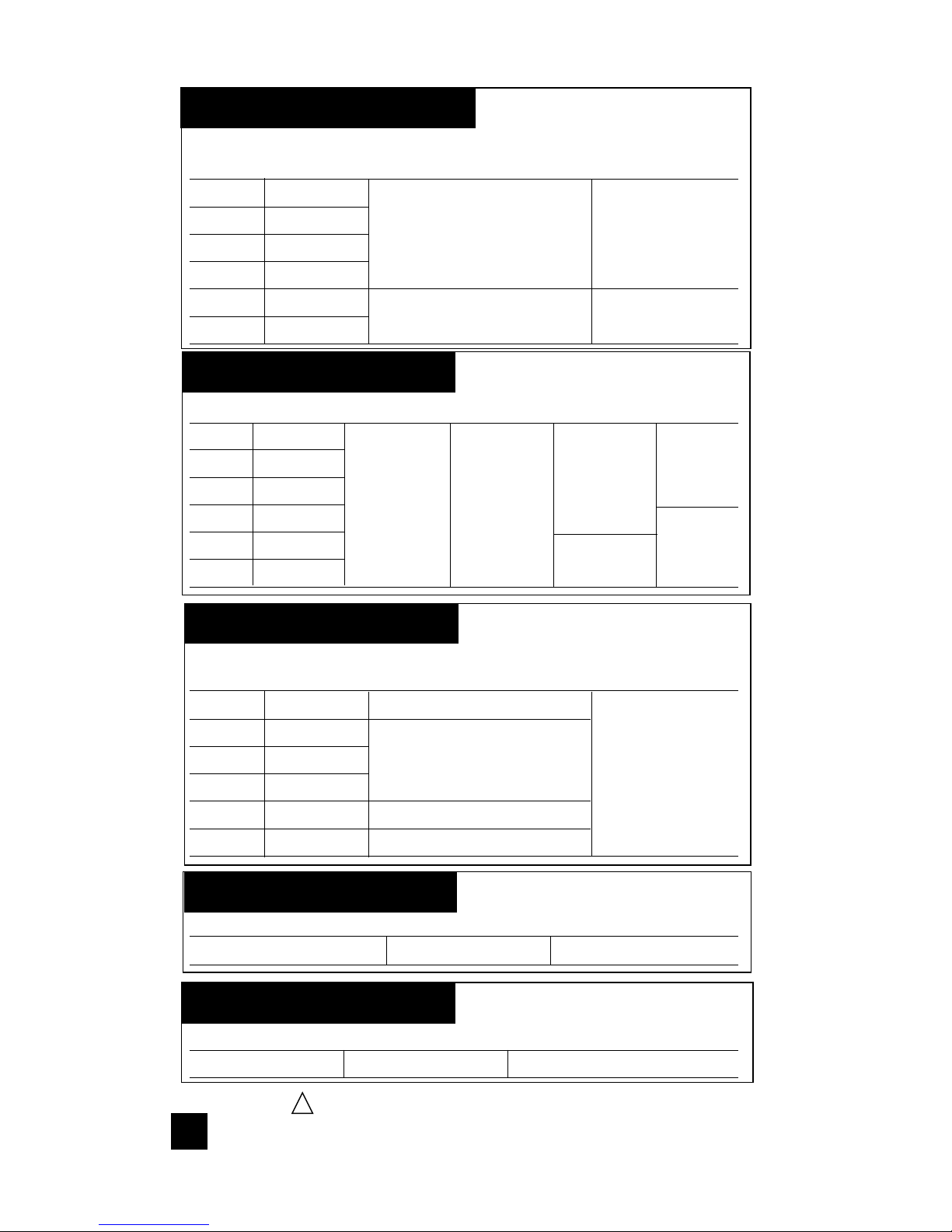

2. Specifications

IEC 1010 Over Voltage:

CAT II - 1000V

CAT III - 600V

Pollution Degree 2

OSCILLOSCOPE FUNCTIONS

Horizontal

Sample Rate 20 Megasamples/second

Record Length 256 in all modes(pixel).

Samples/Division 20

Update rate Real time.

Modes Single shot

Accuracy ±0.01%

Sweep Rate 1µS to 1S in 1,2,5 sequence

Vertical

Bandwidth 1 MHz

Resolution 8 Bits

Channels Single

Coupling AC, DC

Input Impedance 1.11 M Ohm

Accuracy ±3%

Max. Input Volts 1000 Vp-p

Page 10

119

OSCILLOSCOPE FUNCTIONS (cont.)

Triggering

Type Internal

Coupling AC, DC, Glitch Capture

Slope + or - edge

Internal Trigger 2/20 Division

Sensitivity

Other

Glitch Capture Over 0.05 Horizontal division,

0.25 Vertical division spike.

Minimum time 1µS.

Digital Trigger 0-512 Samples

Delay Time

Logic Test 3V & 5V CMOS, TTL

Display

Page 11

1210

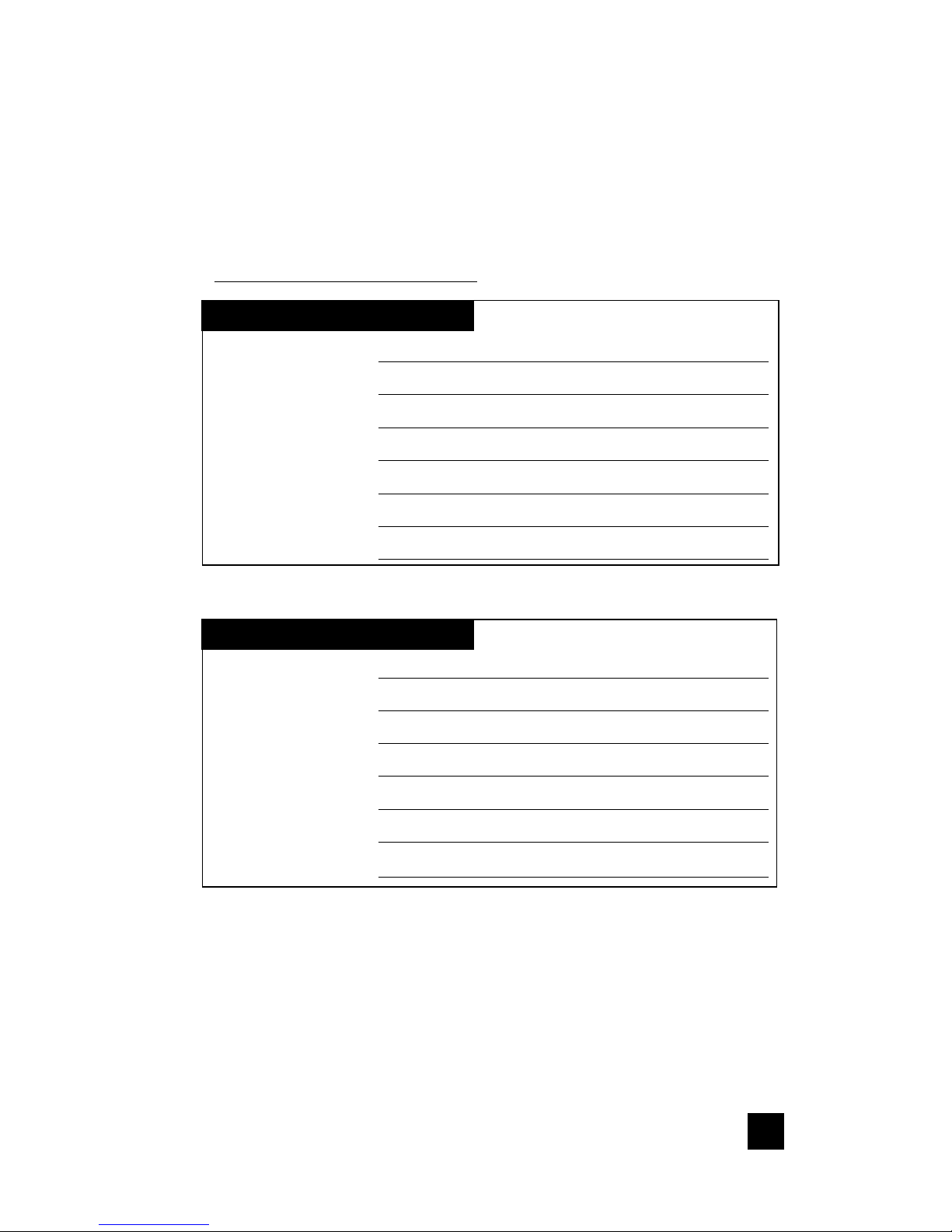

DIGITAL MULTIMETER FUNCTIONS

a. DCV

Range Resolution Accuracy Impedance

400mV 0.1mV ±0.3% of reading, more then 100MΩ

4V 0.001V ±2 digits 10MΩ

40V 0.01V

400V 0.1V

1000V 1V

b1. ACV (20Hz to 50Hz)

Range Resolution Accuracy Impedance

300mV 0.1mV

3V 0.001V ±1.5% of reading, 1.11MΩ

30V 0.01V ±10 digits

300V 0.1V

750V 1V

*NOTICE: Digit fluctuates at AC 20Hz~ 40Hz range. in 1~2 minutes

after input.

b2. ACV (50Hz to 1kHz, 1kHz to 10kHz)

Range Resolution Accuracy Impedance

300mV 0.1mV

3V 0.001V ±0.75% of reading, 1.11MΩ

30V 0.01V ±10 digits

300V 0.1V

750V 1V (N/A for 1kHz to 10kHz)

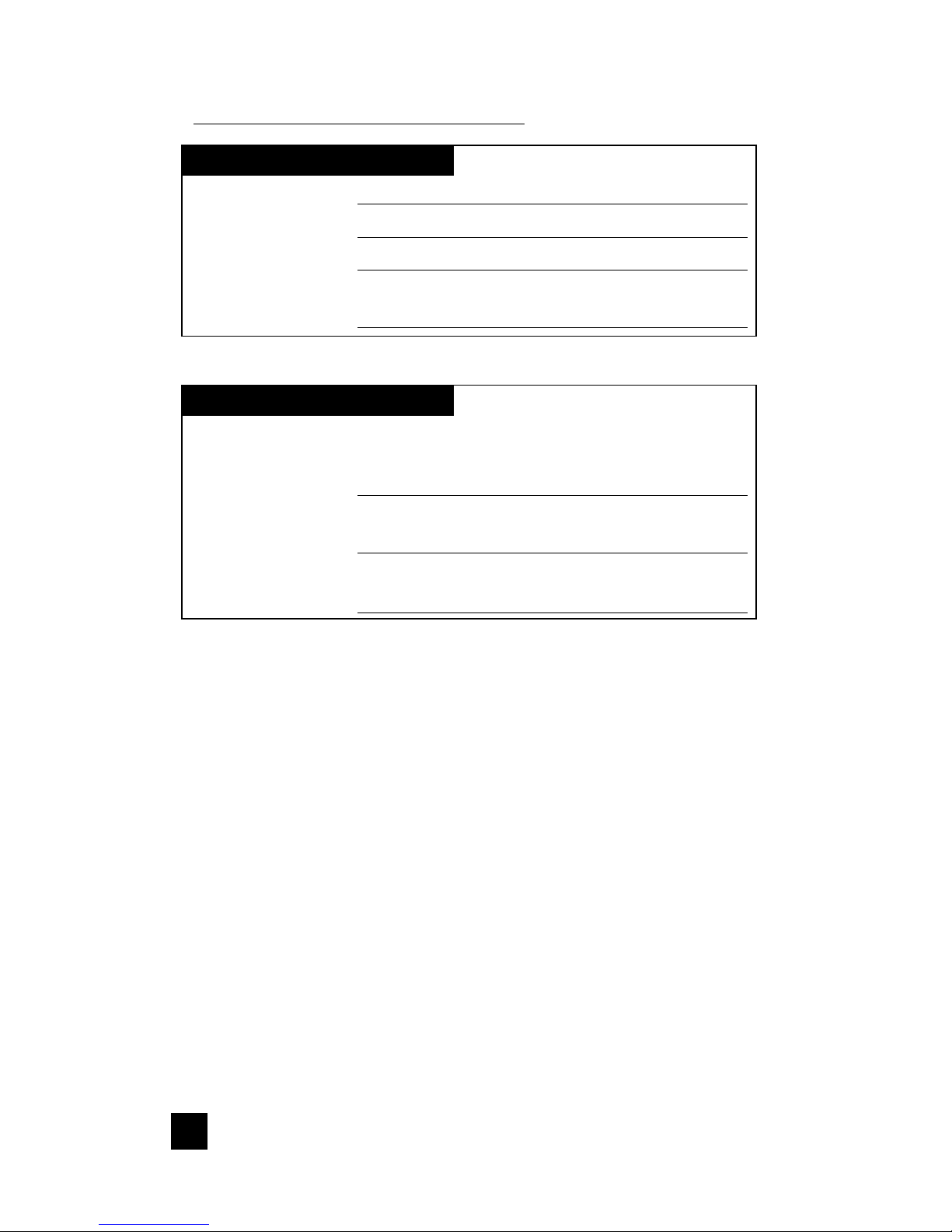

b3. ACV (10kHz-30kHz, 30kHz-100kHz, 100kHz-200kHz)

Range Resolution 10-30kHz 30-100kHz 100-200kHz Impedance

300mV 0.1mV

3V 0.001V ±2.5% of reading, ±4% of reading, ±10% of reading, 1.11MΩ

30V 0.01V ±30 digits ±200 digits ±300 digits

300V 0.1V

750V 1V N/A N/A N/A

Page 12

1311

*Warning: Use only correct size, voltage and current rated fuses.

Test Leads: Use only correct type and overvoltage category rating.

!

c. DCA

Range Resolution Accuracy Overload

Protection

400µA 0.1µA ±0.5% of reading, ±5 digits Fuse*(fast blow)

4000µA 1µA F600V, 0.5A, 31CM

40mA 0.01mA

400mA 0.1mA

4A 0.001A ±0.75% of reading, ±5 digits F600V, 10A, 31CM

10A 0.01A

d. ACA

Range Resolution 20-50Hz 50Hz-3kHz 3-10kHz 10-30kHz

300µA 0.1µA ±1.0% rdg, ±0.75% rdg, ±2.0% rdg, ±2.0% rdg,

3000µA 1µA ±10 digits ±10 digits ±20 digits ±40 digits

30mA 0.01mA

300mA 0.1mA N/A

3A 0.001A N/A

10A 0.01A

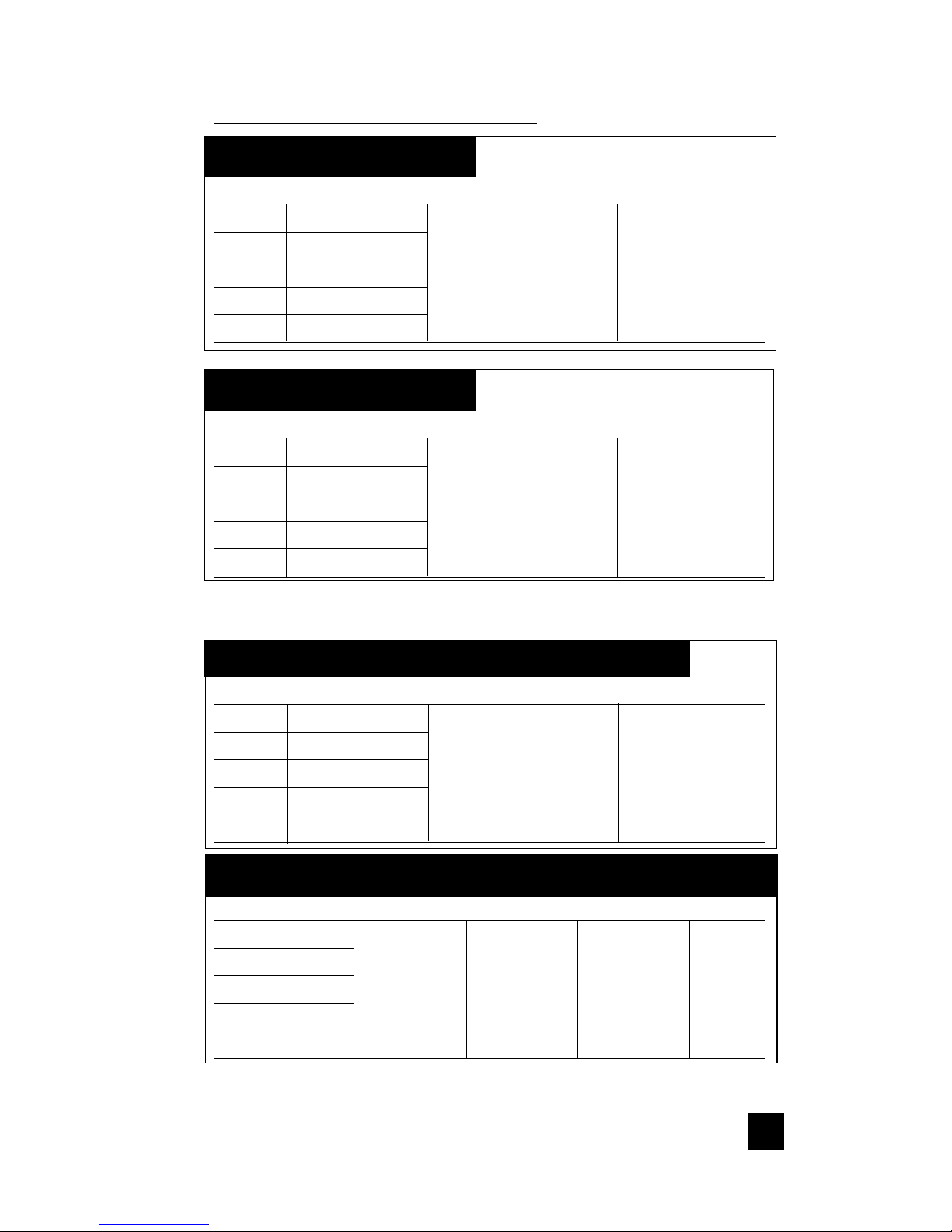

e. OHM (Resistance,Ω)

Range Resolution Accuracy Overload

Protection

400Ω 0.1Ω ±0. 3% of reading, ±10 digits 600V DC or

4kΩ 0.001kΩ ±0.3% of reading, AC Peak

40kΩ 0.01kΩ ±2 digits

400kΩ 0.1kΩ

4MΩ 0.001MΩ ±1.0% of reading, ±10 digits

30MΩ 0.01MΩ ±1.5% of reading, ±20 digits

f. Continuity Buzzer

Test Voltage Threshold Over Load Protection

3V 100 digits 600 V DC or Peak AC

g. Diode Test

Test Voltage Max Test Current Over Load Protection

3V Approx. 2.5mA 600 V DC or Peak AC

Page 13

1412

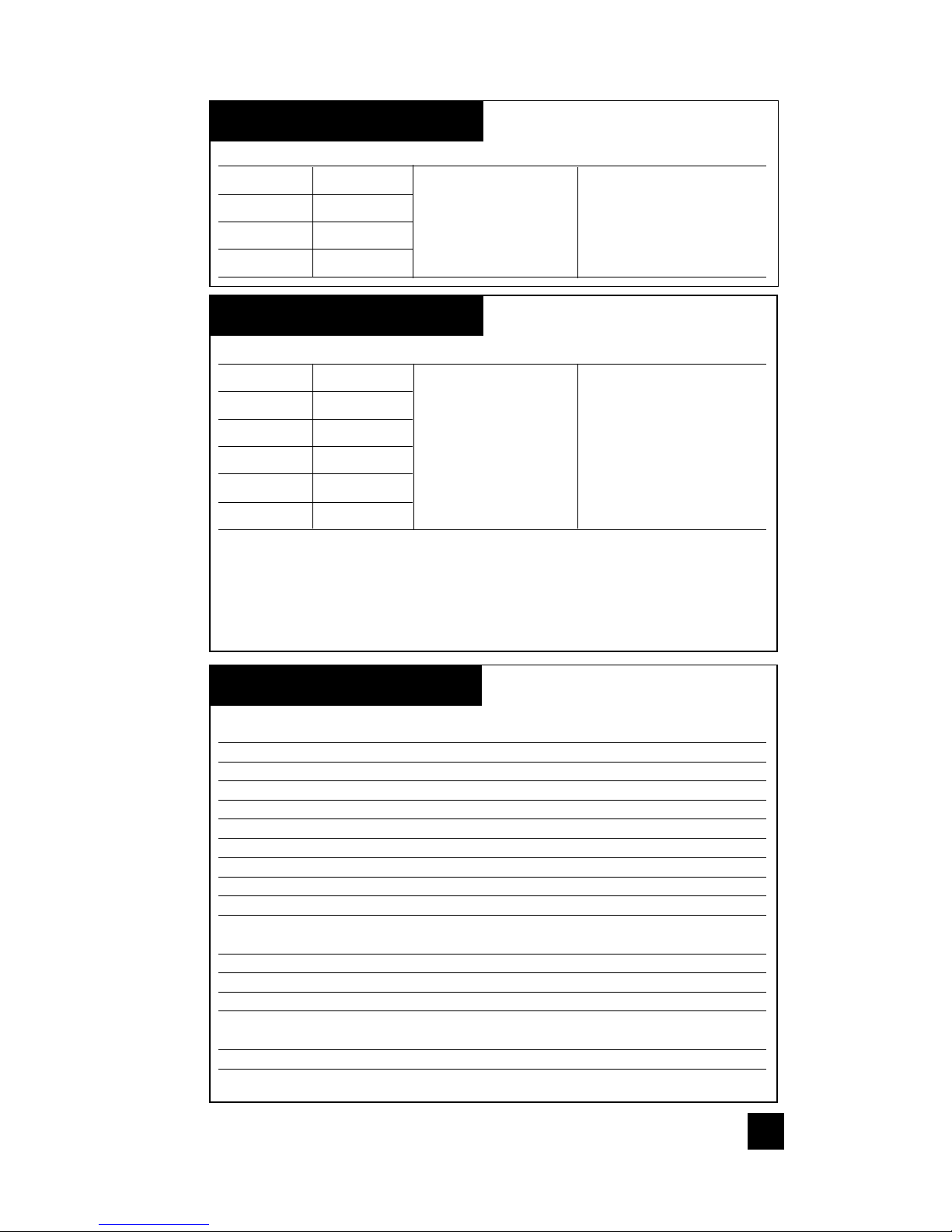

i. Capacitance

Range Resolution Accuracy Over Load Protection

400.0nF 100pF ±3% of reading, 600 V DC or Peak AC

4.0µF 0.001µF ±5 digits

40.0µF 0.01µF

400.0µF 0.1µF

j. Frequency

Range Resolution Accuracy Over Load Protection

100.00Hz 0.01Hz

1.0000kHz 0.1Hz ±0.05% of reading, 600 V DC or

10.000kHz 1Hz ±1 digit Peak AC

100.00kHz 10Hz

1.0000MHz 100Hz

2.0000MHz 100Hz

**Sensitivity(square wave)

1Hz below N/A

2Hz to 1kHz 1V

1kHz to 2MHz 1.5V

General Specifications

Max. Volt. between 1000V

any Input and Ground

Basic DC Accuracy 0.3%

Frequency Counter Range 2 MHz

Meter AC Bandwidth 200 kHz

Waveform Display Bandwidth 1 MHz

Fuse Protection mA: 0.5Amp/600VAC; A: 10Amp/600VAC

Display Type Super-twist LCD, 160 x 240 pixels

Operating Temp. 0° to 50°C (32° to 122°F)

Storage Temp. -20° to 60°C (-4° to 140°F)

Relative Humidity 0% to 80%: (0°-35°C/32°-95°F) 0% to 70%: (35°-55°C/95°-131°F)

Temp. Coefficient 0.1 x (Specified Accuracy) per °C for

temperature <18°C to >28°C

Power Supply Nicad Battery 7.2V, AA Cell x 8

Battery Life Time 5 Hours

Battery Charge Time 3 Hours

Safety Designed Pollution degree 2, Overvoltage Cat. II 1000V, Cat.

III 600V per IEC 1010, UL3111 and C22.2 No. 1010-1

Size (H x L x W) 52 x 220 x 100mm

Weight 1 lb. 6 oz

Page 14

1513

D. MEASUREMENT TECHNIQUES

1. Controls and Functions:

Push Buttons

F1-F5 Selects additional functions displayed across the

bottom of the LCD.

D Mode Selects digital scope mode with functions displayed

across the bottom of the LCD.

Hold A Freezes the analog reading on the LCD.

RGE Push once to select manual ranging, push again to

return to functions.

PROG Push once to select REC, REL% and COMPARE

functions. Once selected, use the EDIT button to set

parameters.

T.BASE Push once to select time base, push again to

return to functions.

MEM Push once to waveform and setup memory, push

again to return to functions.

Turn back light on and off.

Select help text.

Rotary Switch

OFF Turns the instrument off.

V Selects the DCV function.

V Selects the ACV function.

Ω Selects resistance or continuity buzzer function.

Selects the diode test function.

µA Selects DC or AC microamps.

mA Selects DC or AC milliamps.

A Selects DC or AC amps.

Hz Selects the Frequency function.

LOGIC Selects the Logic Test function.

➩

Page 15

1614

1. Controls and Functions: (cont.)

Selects the Capacitance function.

COMP Selects the Component Test function.

OFF Turns the instrument off.

Input Jacks

A Red test lead connection for current measurements

on the A function (AC and DC amps).

µmA Red test lead connection for current measurement

on the µA and mA functions (AC and DC micro and

milliamps).

COM Black test lead connection for all functions.

VΩ Red test lead connection for Volts, Ohms,

Capacitance, Logic and Component Test functions.

RS-232C Output

DB9on See section M on RS-232C interface.

top of 440

Page 16

1715

a. Measuring DC Volts (V)

CAUTION!

Do not attempt to make a voltage measurement if a test

lead is plugged in the A or µmA input jack. Instrument

damage and/or personal injury may result.

WARNING!

Do not attempt to make a voltage measurement of more

than 1000V or of a voltage level that is unknown.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

V COM VΩ 0.1mV 1000V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into COM input jack.

3. Plug red test lead into the VΩ input jack.

4. Set the rotary switch to the V function.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 440.

!

Optional DMM Functions (refer to page 27)

REL PEAK FREQ PERI FULL

HOLD AUTO

F1 F2 F3 F4 F5

PROG (refer to page 27)

REC REL% COMP EDIT EXIT

F1 F2 F3 F4 F5

Optional D Mode Functions (refer to page 29)

COMBO METER SCOPE TREND EXIT

F1 F2 F3 F4 F5

Page 17

1816

b. Measuring AC Volts

CAUTION!

Do not attempt to make a voltage measurement if a test

lead is plugged in the A or µmA input jack. Instrument

damage and/or personal injury may result.

W

ARNING!

Do not attempt to make a voltage measurement of more

than 1000V or of a voltage level that is unknown.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

V COM VΩ 0.1mV 750V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into the VΩ input jack.

4. Set the rotary switch to the V function.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 440.

!

Optional DMM Functions (refer to page 27)

REL PEAK FREQ PERI FULL

HOLD AUTO

F1 F2 F3 F4 F5

PROG (refer to page 27)

REC REL% COMP EDIT EXIT

F1 F2 F3 F4 F5

Optional D Mode Functions (refer to page 29)

COMBO METER SCOPE TREND EXIT

F1 F2 F3 F4 F5

Page 18

1917

c. Measuring DC Amps

CAUTION!

Do not attempt to make a current measurement with the

test leads connected in parallel with circuit to be tested.

Test leads must be connected in series with the circuit.

W

ARNING!

Do not attempt to make a current measurement of

circuits with more than 600V present. Instrument

damage and /or personal injury may result.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

µA COM mA 0.1µA 4000µA

mA COM mA 10µA 400mA

A COM A 1mA 10.00A

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug the red test lead into the mA or A input jack

depending on the value of current to be measured.

4. Set the rotary switch to the µA, mA or A function.

5. Connect test leads in series to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the current on the 440.

!

Optional DMM Functions (refer to page 27)

REL PEAK DC AC FULL

HOLD FREQ FREQ AUTO

F1 F2 F3 F4 F5

PROG (refer to page 27)

REC REL% COMP EDIT EXIT

F1 F2 F3 F4 F5

Optional D Mode Functions (refer to page 29)

COMBO METER SCOPE TREND EXIT

F1 F2 F3 F4 F5

Page 19

2018

d. Measuring AC Amps

CAUTION!

Do not attempt to make a current measurement with the

test leads connected in parallel with circuit to be tested.

Test leads must be connected in series with the circuit.

W

ARNING!

Do not attempt to make a current measurement of

circuits with more than 600V present. Instrument

damage and /or personal injury may result.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

µA COM mA 0.1µA 3000µA

mA COM mA 10µA 300mA

A COM A 1mA 10.00A

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug the red test lead into the mA or A input jack

depending on the value of current to be measured.

4. Set the rotary switch to the µA, mA or A function.

5. Push the F4 button

6. Connect test leads in series to circuit to be measured.

7. Reconnect power to circuit to be measured.

8. Read the current on the 440.

!

Optional DMM Functions (refer to page 27)

REL PEAK DC AC FULL

HOLD FREQ FREQ AUTO

F1 F2 F3 F4 F5

PROG (refer to page 27)

REC REL% COMP EDIT EXIT

F1 F2 F3 F4 F5

OPTIONAL D MODE FUNCTIONS (refer to page 29)

COMBO METER SCOPE TREND EXIT

F1 F2 F3 F4 F5

Page 20

2119

e. Measuring Resistance

WARNING!

Do not attempt to make resistance measurements with

circuit energized. For best results, remove resistor

completely from circuit before attempting to measure it.

NOTE:

To make accurate low ohm measurements, short the

ends of the test leads together and record the resistance

reading. Deduct this value from actual readings.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

Ω COM VΩ 0.1Ω 30.00MΩ

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into VΩ input jack.

4. Set the rotary switch on the 440 to the Ω function.

5. Connect the test leads to the circuit to be measured.

6. Read the resistance value on the 440.

!

Optional DMM Functions (refer to page 27)

REL FULL

AUTO

F1 F2 F3 F4 F5

PROG (refer to page 27)

REC REL% COMP EDIT EXIT

F1 F2 F3 F4 F5

Optional D Mode Functions (refer to page 29)

METER TREND EXIT

F1 F2 F3 F4 F5

Page 21

2220

f. Measuring Diodes

CAUTION!

Do not attempt to make diode measurements with circuit

energized. The only way to accurately test a diode is to

remove it completely from the circuit before attempting to

measure it.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

COM VΩ 0.001V 2.000V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into VΩ input jack.

4. Set the rotary switch to the function.

5. Connect black test lead to the banded end of the diode

and the red test lead to the non-banded end of the diode.

6. Reading on display should be between 0.5 and 0.8 volts.

7. Reverse test lead connections in 5 above.

8. Reading on the display should be OUCH (Overload).

NOTE: If diode reads 0 in both directions, diode is shorted.

If diode reads OUCH in both directions, diode is open.

Optional DMM Functions (refer to page 27)

POLA.

CHECK

F1 F2 F3 F4 F5

Page 22

2321

g. Continuity Buzzer

WARNING!

Do not attempt to make continuity measurements with circuit energized.

Instrument set-up:

FUNCTION BLACK RED

TEST LEAD TEST LEAD

Ω COM VΩ

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug the red test lead into the VΩ input jack.

4. Set the rotary switch to the Ω function.

5. Press the F2 button to activate the continuity buzzer.

6. Connect test leads to circuit to be measured.

7. Listen for the buzzer to confirm continuity.

!

Page 23

2422

h. Measuring Capacitance

WARNING!

All capacitance measurements are to be made on

de-energized circuits with all capacitors discharged only.

Failure to de-energize and discharge capacitors before

attempting to measure them could result in instrument

damage and/or personal injury.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

COM VΩ 0.1nF 400.0µF

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Remove capacitor from the circuit and discharge it.

3. Plug black test lead into the COM input jack.

4. Plug the red test lead into the VΩ input jack.

5. Set the rotary switch to the function.

6. Connect test leads to capacitor to be measured.

7. Read the capacitor value on the LCD.

!

Optional D Mode Functions (refer to page 27)

METER TREND EXIT

F1 F2 F3 F4 F5

Page 24

2523

i. Measuring Frequency

WARNING!

Never attempt a frequency measurement with a voltage

source greater than 600V. Determine the voltage of any

unknown frequency source before connecting the instru-

ment in frequency mode.

Instrument set-up:

FUNCTION BLACK RED MINIMUM MAXIMUM

TEST LEAD TEST LEAD READING READING

Hz COM VΩ 0.01Hz 2.0000MHz

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into the VΩ input jack.

4. Set the rotary switch to the Hz function.

5. Reconnect power to circuit to be measured.

6. Read the frequency on the LCD.

!

Optional DMM Functions

PERIOD

F1 F2 F3 F4 F5

F4 Period Push F4 to display the Period (1/time) of measured frequency.

Optional D Mode Functions (refer to page 29)

COMBO METER SCOPE TREND EXIT

F1 F2 F3 F4 F5

Page 25

26

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

j. Component Test

Use Component Test to measure the characteristics of a

passive component (in or out of circuit, no power applied).

The 440 provides an AC stimulus signal to the component and

plots the voltage drop against the current measurement. The

resulting pattern provides information about passive circuit

condition.

2Hz 20Hz 200Hz

F1 F2 F3 F4 F5

Diagrams are displayed on the LCD that can be used to roughly identify components being measured. The diagrams below

show typical signatures for the components that are indicated.

Some components may be difficult to distinguish due to similarities in pattern, however, the determination of a good or bad

component can be made.

NOTE: RESISTOR 0Ω RESISTOR 1kΩ

RESISTOR 10kΩ RESISTOR 20kΩ

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

RESISTOR 100kΩ RESISTOR 200Ω

24

Page 26

2725

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

NOTE:

DIODE FORWARD DIODE REVERSE

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

ELEC/CAP. 0.33uF ELEC/CAP. 47uF

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

METAL CAP. 0.22uF MYLAR CAP. 103

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TRIG LEVER: +00

1mS/DIV SLOPE:

+

TANTAL CAP. 0.47uF INDUCTOR

Page 27

2826

k. Logic Test

The logic state of IC’s can easily be determined with the 440.

Use the function buttons to select TTL, 3V CMOS or 5V CMOS

logic chips. The 440 will display high and low logic levels.

TTL 3V 5V

CMOS CMOS

F1 F2 F3 F4 F5

This function is designed to check the HI/LOW logic states of

IC’s and circuits by direction of the arrow on the LCD. For TTL

circuits, the arrow will point downward at or below 2.9 volts

and upward at or above 3.2 volts. For 3V CMOS the arrow will

point downward at or below 1.7 volts and upward at or above

2.0 volts. For 5V CMOS the arrow will point downward at or

below 3.1 volts and upwards at or above 3.4 volts. When the

BZ is also activated, the 440 buzzer will sound when HI logic

levels are measured.

Page 28

2927

E. SPECIAL DMM FEATURES AND FUNCTIONS

1. REL:{Range- ACV,DCV, OHM, DC/AC(µA,mA,A)}

REL stands for relative. When a reading is measured that is

wanted as a standard, pushing the REL function will display

the variance from the standard for all subsequent readings.

This is useful for matching components in circuits.

a) Obtain a stable reference reading on the 440.

b) Push the REL (F1) button on the 440.

c) The REL value will be displayed just above the function button

menu on the lower portion of the LCD.

d) Measure subsequent items.

e) The LCD will display the difference between the REL stored value

and the measured value.

2. PEAK HOLD:{Range- ACV,DCV, DC/AC(µA,mA,A)}

The 440 displays the MAX and MIN readings for the main

function being measured.

3. :(Range-OHM, DIODE, LOGIC)

Pushing the BZ button activates the Continuity Buzzer. The

buzzer sounds when the resistance measured is <100 Ohms.

Note: The following items are accessed by pushing the

PROG button on the 440.

{Range-ACV,DCV, OHM, DC/AC(µA,mA,A)}

REC REL% COMP EXIT

4. REC PRESS

REC REL% COMP EXIT

Pushing this button activates the Min/Max record function.

The minimum and maximum values of readings over a period

of time are displayed on the LCD.

Page 29

3028

5. REL%

REC REL% COMP EDIT EXIT

Pushing this button activates the REL% function.

EDIT PRESS

EXIT

A reference value is entered using the edit button and all

subsequent readings are displayed as a percentage to the

reference value.

6. COMP

REC REL% COMP EDIT EXIT

Pushing the COMP buttons enters the 440 into the Compare

Mode.

EXIT

A reference value is entered using the edit button and all

subsequent readings are displayed compared to the reference

value.

NOTE: The first line edited is the HI value. To access the line

for LO value, push the F1 key to scroll to the lower

line.

Page 30

3129

F. D MODE FEATURES AND FUNCTIONS

1. TREND {Range-Cap., Freg., ACV,DCV,

AC/DC(µA,mA,A)}

The TREND mode allows you to measure a specific function

for a predetermined length of time so you can look for trends

in the circuit being monitored. The following functions are

enabled when TREND mode is entered.

RS232 TIME TREND RE-

SET TYPE START

F1 F2 F3 F4 F5

a) RS232 Enables the RS232 port on the top of the

440. Allows for interface between the 440

and a PC.

b) TIME SET Allows you to edit the time per division for

the trend graph.

SLOW FAST EXIT

F1 F2 F3 F4 F5

Slow or Fast selects the interval to use on

the horizontal scale as data points are plotted on the trend graph. (Seconds: 1, 2, 5,

10, 15, 30, 45; Minutes 1, 2, 3)

c) TREND TYPE

AVG SAMPLE EXIT

F1 F2 F3 F4 F5

Average: Plots the average of all samples

taken by the 440 during the plot interval.

Sample: Plots the last sample taken by the

440 at the time the data point is plotted.

d) RE-START Starts plotting a new trend graph as new

samples are acquired. Primary readings

are displayed and plotted; there are no

secondary readings in Trend Mode.

Page 31

3230

NOTE: The following is an example of setting up TREND mode

for a 10 ACV signal:

Push the D MODE button and then the TREND(F4) button. Set

the sampling time by pushing the TIME SET(F2) button to the

desired rate. Push EXIT to return to previous menu.

Push the TREND TYPE(F3) button. select from the following:

AVERAGE(F1)-Draws plot of the sampled data at the end of

the sample time.

RESTART starts the plotting process retaining the above settings.

Display will show all data points in recording time.

Page 32

3331

2. SCOPE (PRESS D MODE)

Pushing the SCOPE button (F3) enters the 440 in the oscilloscope mode. The following function is displayed:

TIME TRIG SINGL GLITC FULL

BASE H CAP AUTO

F1 F2 F3 F4 F5

a) TIME BASE Allows the user to adjust the time base for

the displayed waveform. Push the F2 button

to decrease the time and F3 to increase the

time {sweep speed(1, 2, 5, 10, 20, 50uS,

0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 50mS, 0.1, 0.2,

0.5, 1S)}. F5 exits the menu.

SLOW FAST EXIT

F1 F2 F3 F4 F5

b) TRIG Allows the user to set the slope and level of

the trigger. Push F1 to set the slope + or -;

push F2 to increase trigger level; push F3 to

decrease the trigger level. F5 exits the menu.

SLOPE UP DOWN EXIT

F1 F2 F3 F4 F5

c) SINGL This mode will force the 440 to show one

single sweep of the measured parameter

based on the time and trigger settings.

d) GLITCH CAPTURE An excellent troubleshooting tool for

finding spikes in circuits. Set the trigger to a

level above the normal peak value of a circuit

and let the 440 baby-sit the line until a spike

is encountered. The 440 will display only

this event showing a problem with the line.

Page 33

34

G. WAVEFORM MEMORY & SET-UP MEMORY

WAVEFORM MEMORY: 8 Pages (locations)

Set-up Memory: 8 Pages (locations)

1. Using Waveform Memory

a) Press MEM Key( V, V, µA, mA, A )

RANGE RANGE WAVE SETUP EXIT

UP DOWN MEM MEM

F1 F2 F3 F4 F5

F3: Waveform Memory

F4: Setup Memory

b) Press WAVE/MEM Key

PAGE PAGE SAVE LOAD EXIT

UP DOWN

F1 F2 F3 F4 F5

F1, F2: Page Up, Down; Select Memory Location

(0,1,2,3,4,5,6,7 Page)

F3: Save the present waveform to a memory location

F4: Load and Display from selected Memory

2. Using Set-up Memory

a) Press MEM Key( V, V, µA, mA, A )

WAVE SETUP EXIT

MEM MEM

F1 F2 F3 F4 F5

F1, F2: RANGE UP, DOWN

F3: Waveform Memory

F4: Setup Memory

b) Press MEM Key( , Hz, Logic, , COMP )

SETUP EXIT

MEM

c) Press MEM Key(OHM)

SETUP EXIT

MEM

Page 34

3533

d) Press SETUP/MEM Key

PAGE EDIT SAVE LOAD EXIT

UP

F1 F2 F3 F4 F5

F1: Page Up, Down; Select Memory Location

(0,1,2,3,4,5,6,7 Page)

F2: New Edit (Range, Contrast, D Mode, Baud Rate, etc.)

F3: Save the present setup status

F4: Load and setup from selected Memory

e) EDIT Press

NEXT

EXIT

NEXT: Menu selection

, : Mode level and function selection.

f) Adjusting REL% and COMP reference value is as follows

1. Enter the REL% key COMP mode by pushing PROG key

2. Push the REL% key(F2) to adjust REL% reference value

and then push EDIT key(F4).

3. Set the digit by right and left direction key and set the

figure by up to down direction key and then push the

EXIT key.

4. Enter the COMP mode by pushing F3 key and push the

EDIT key(F4).

5. Set the digit by right and left direction key and set the

figure by up and down direction key and then push the

EXIT key(HI,LO,setting).

6. Push the RGE key and SETUP/MEM key.

7. Save the adjusted value with page up key(F1) to memory

page.

Page 35

3634

Measure DC Drive Motor Current

The 440 can measure the start-up, running and

drop-out current of DC drive motors. Connect the

440 in series with motor and controller at the

controller, and proceed by following instructions

to measure DC amps.

Page 36

3735

H. NORMAL MODE 440 APPLICATIONS

Note: Scope sets up automatically for all applications

below. For best performance, leave 440 in

default COMBO scope/DMM mode.

1. Industrial Motor Control

a) Start-up inrush current

b) Waveform symmetry

c) Variable frequency drive signals

d) Pulse width modulation

e) Noise

f) AC and DC speed control signals

2. Power Quality

a) Noise on industrial feeds

b) AC voltage waveshape

c) Current waveforms

3. NC Machines

a) Power quality

b) Sensor outputs

c) Control circuits

d) Safety circuits

e) Calibration and adjustments

4. Uninterruptible Power Supplies

a) Sensing and monitoring circuits

b) Output waveforms

c) Current waveforms

5. Audio

a) Public address feeds

b) Amplifiers

c) Mixers

d) Preamps

Page 37

3836

H. NORMAL MODE 440 APPLICATIONS (cont.)

6. Video

a) Horizontal and vertical scan rates

b) Z axis blanking

c) Sync pulses

d) Luminance

7. Factory Automation

a) Robot control signals

b) Machine Vision

c) Machine and control sensing circuits

d) Calibration of positioning systems

e) Analog controllers

f) Servo controls

8. Line Conditioners

a) Quality

9. Voltage Regulators

a) Noise

b) Stability

10. Inverters

a) Waveform Quality

Page 38

3937

Monitoring Power Quality

The 440 can monitor power quality on branch circuits

from the breaker box. This helps to identify existing

or potential circuit instability. Connect the 440 at the

breaker box and follow instructions to measure AC

Voltage.

Page 39

4038

I. TREND MODE 440 APPLICATIONS

The 440 trend mode is used to look at signals over a

period of time to see if they changes or get interrupted.

Set-up the 440 as follows:

Set-up Procedure:

1. Set the rotary switch to the desired function depending

on the device being measured (ACV, DCV, ACA,

DCA,Cap,Freq).

2. Push the button to manually select the correct range by

pushing the F1 or F2 buttons then push EXIT.

3. Press the D MODE button.

4. Press the TREND (F4) button.

5. Set TIME SET (F2) and TREND TYPE (F3) for the trend

being measured and RESTART (F4) press.

6. The 440 will display the trend graph on the LCD.

Applications:

1. Industrial Furnace Controls

2. Climate Control

a)Waveform quality

Page 40

4139

J. GLITCH CAPTURE 440 APPLICATIONS

The 440 Glitch Capture feature can be used to look at

the applications listed below. Set-up the 440 as follows:

Set-up Procedure:

1. Set the rotary switch to the desired function depending

on the device being measured (ACV, DCV, ACA, DCA).

2. Push RGE button to manually select the correct range by

pushing the F1 or F2 buttons then push EXIT.

3. Press the D MODE button.

4. Press the SCOPE (F3) button.

5. Adjust the TIME BASE (F1) and TRIGGER LEVEL(F2).

(Note: Trigger level must be set slightly above normal

signal level to capture a spike.)

6. Push GLITCH CAP (F4).

6. 440 will display the waveform measured when triggered.

Applications:

1. Industrial Motor Controls

a) SCR trigger pulses

2. Power Quality

a) Machine Start-up

b) Power quality interference and noise

3. Programmable Logic Controls

a) Input and output signals

b) Control signals

c) Signal conditioning circuits

d) Communication lines

e) Power supply

4. Uninterruptible Power Supplies

a) Switching circuits

5. Industrial Lighting Controls

a) SCR’s

b) Solid State circuitry

6. Line Conditioners

a) Noise

b) Quality

Page 41

4240

K. ACCESSORIES*

Standard Accessories Part No.

Charger/Adapter A401

Test Lead Set A050

7.2 V Battery Pack A004

Optional Accessories Part No.

Deluxe Carrying Case A900

Software and RS232 Cable A402

Fuse, 0.5 Amp A104

Fuse, 10 Amp A110

Temperature Adapter A301

Pressure adapter A620

AC amp adapter (0~400) A251

AC/DC amp adapter (0~400) A256

AC/DC amp adapter (0~1000) A296

Deluxe test lead set TLS2000B

Screw-on alligator clips A150

CO adapter (0~1999ppm) A701

CO adapter w/Alarm A702

CO Adapter w/Push button zero A711

Thermocouple adapter A115

*These accessories have not been evaluated by UL and are not

considered as part of the UL Listing of this product.

Page 42

4341

L. MAINTENANCE

1. Battery Replacement: The 440 battery pack needs

replacement when it will no longer hold a charge. Battery

is replaced as follows:

a. Disconnect and remove all test leads from live circuits

and from the 440.

b. Remove the five screws from back of the housing.

c. Carefully pull apart the front and rear instrument

housing.

d. Remove old battery pack and replace with new.

e. Reassemble instrument in reverse order from above.

W

ARNING:

• Replace old battery with new 7.2V battery pack.

• Make sure that replaced battery part number is A004.

• To charge the battery, battery eliminator ‘A401’ should be

used.

2. Fuse Replacement: Both the A and µmA input jacks are

fuse protected. If either does not function, replace fuse

as follows:

a. Disconnect and remove all test leads from live circuits

and from the 440.

b. Remove the five screws from the back of housing.

c. Carefully pull apart front and rear instrument housing.

d. Remove old fuse(s) and replace with new fuse(s).

e. Reassemble instrument in reverse order from above

3. Cleaning your 440:

Use a mild detergent and slightly damp cloth to clean the

surfaces of the 440.

Page 43

44

M. OPTIONAL RS232 COMMUNICATION AND

SOFTWARE INSTALLATION /OPERATION GUIDE

HARDWARE REQUIREMENTS

• IBM PC or compatible.

• Microsoft Windows version 3.X or Windows 95.

• Serial communications port.

SOFTWARE INSTALLATION.

1. Insert the 3.5” floppy disk provided in to disk drive

A(B).

2. WINDOWS 3.1

From program Manger Click “File”

Click “RUN” and type A(B):\SETUP.EXE

Click the “OK” button or press enter.

3. WINDOWS 95

Click start

Click “RUN” and type A(B):\SETUP.EXE

Click the “OK” button or press enter.

4. “Initializing setup” will be displayed.

5. “Install to C:\VDMM box will be displayed.

This is the default location for this program. If you

would like to install this program into a different

directory type in the new directory at this time.

6. Press the “continue” button.

7. The installation status will be displayed

This shows the progress of the installation.

8. “Scope Plus Installation is complete!” will be

displayed when the installation program is complete.

Press “OK”

The program been completely installed and is ready for use.

ESTABLISHING COMMUNICATION BETWEEN SCOPE

PLUS AND YOUR PC.

1. Double click the “scope plus” icon.

2. Connect the 9 pin male connector of the RS232 cable

to a top of the 440.

Connect the 9 pin female connector of the RS232 cable to

a serial COM port on your computer.

3. Select the COM port that is being used in the”COM ports”

box.(com port 1,2,3 or 4)

42

Page 44

4543

4. Click the “START” button in the “Communication” box.

The scope plus will being to communicate with the computer

at this time and readings will be displayed in the upper left

corner of the screen.

Click “Stop” to cancel.

DESCRIPTIONS

START Begins communication between the Scope

plus and the PC.

STOP Ends communication between the Scope plus

and the PC.

DATE Current date based on internal clock.

TIME Current time based on internal clock.

S/TIME Use to set the sampling time.

COMM PORTS Select the communication port being used .

BAUD RATE Select the baud rate.

SAVE IN FILE MANAGEMENT(DMM/SCOPE)BOX.

: Stores recorded data to a specific file for meter(scope).

LOAD IN THE FILE MANAGEMENT(DMM/SCOPE)BOX.

: Retrieves saved data from a specific file for meter(scope).

WAVEFORM MEMORY LOAD BOX.

: Retrieves saved waveform memory from the scope plus.

PRINTER BOX.

: RDG DATA Start/stop printing data.

SCREEN Print main screen.

Page 45

4644

N. TROUBLE SHOOTING GUIDE

Problem Probable Causes

Does not power up

• Dead or defective battery

• Broken wire from battery

pack to PCB

Won’t display current readings

• Open fuse

• Open test lead

• Improperly connected to

circuit under test

Page 46

Test Products International, Inc.

9615 SW Allen Blvd., Ste. 104

Beaverton, OR USA 97005

503-520-9197 • Fax: 503-520-1225

tpiusa@testproductsintl.com

Test Products International

15/23 Greenhill Crescent

Watford Business Park

Watford England WD1 8QU

Tel: 01923 693300 • Fax: 01923 693301

Test Products International, Ltd.

342 Bronte Road South, Unit #9

Milton Ontario Canada L9T5B7

Tel: 905-693-8558 • Fax: 905-693-0888

Visit us on the World Wide Web at

www.testproductsintl.com for additional

product information.

Loading...

Loading...