Page 1

Service Manual

for DC-Inverter

KFR-26GW/ZBP & 34GW/ZBP

INVERTER WALL SPLIT

Technical specifications

Working range

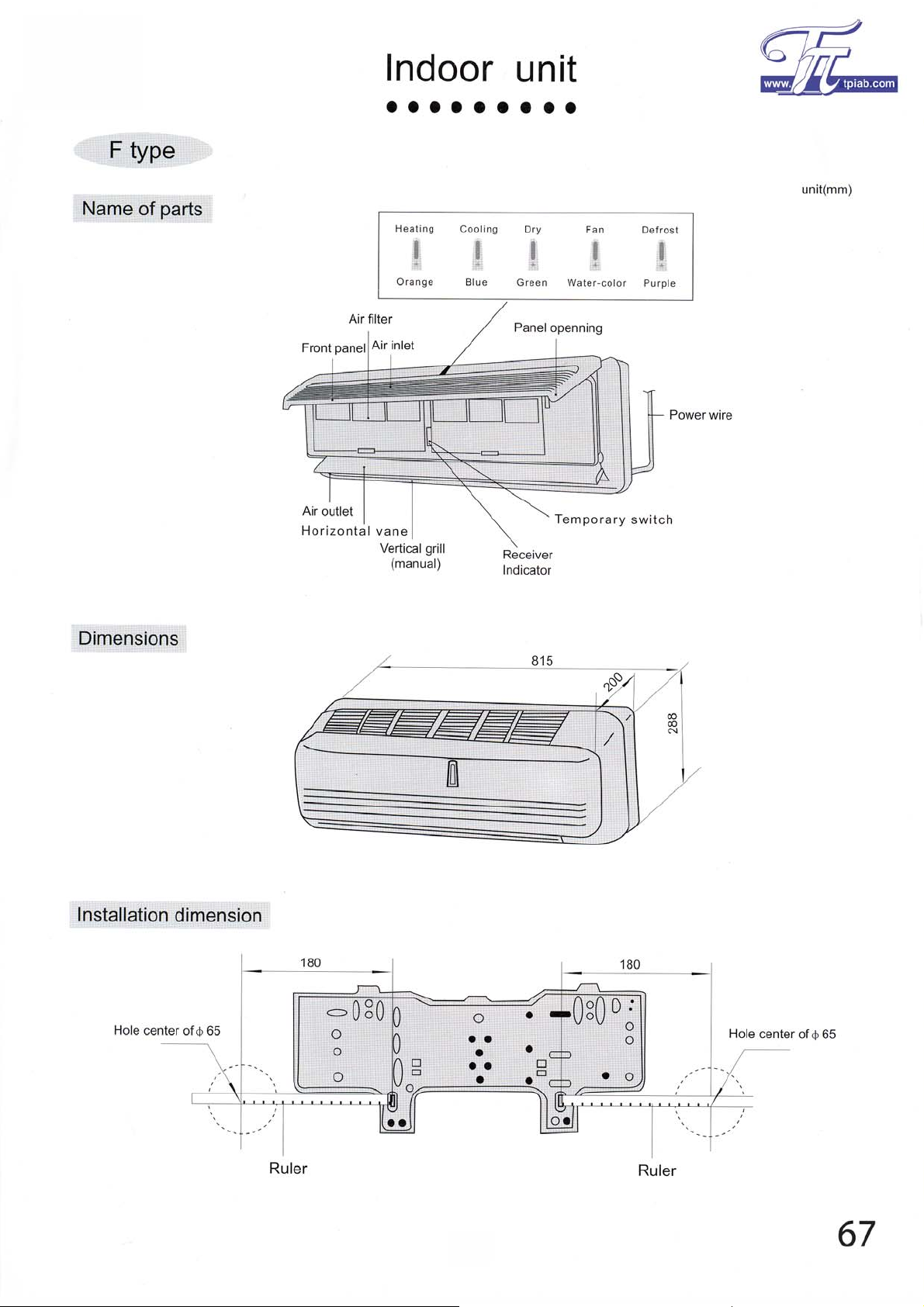

Indoor unit

Outdoor unit

Refrigeration cycle diagram

Main function

page 64

page 66

page 67

page 68

page 69

page 70

System control

Wiring diagram

Faults & self-diagnoses

Service parts list

page 71

page 78

page 80

page 85

64

Page 2

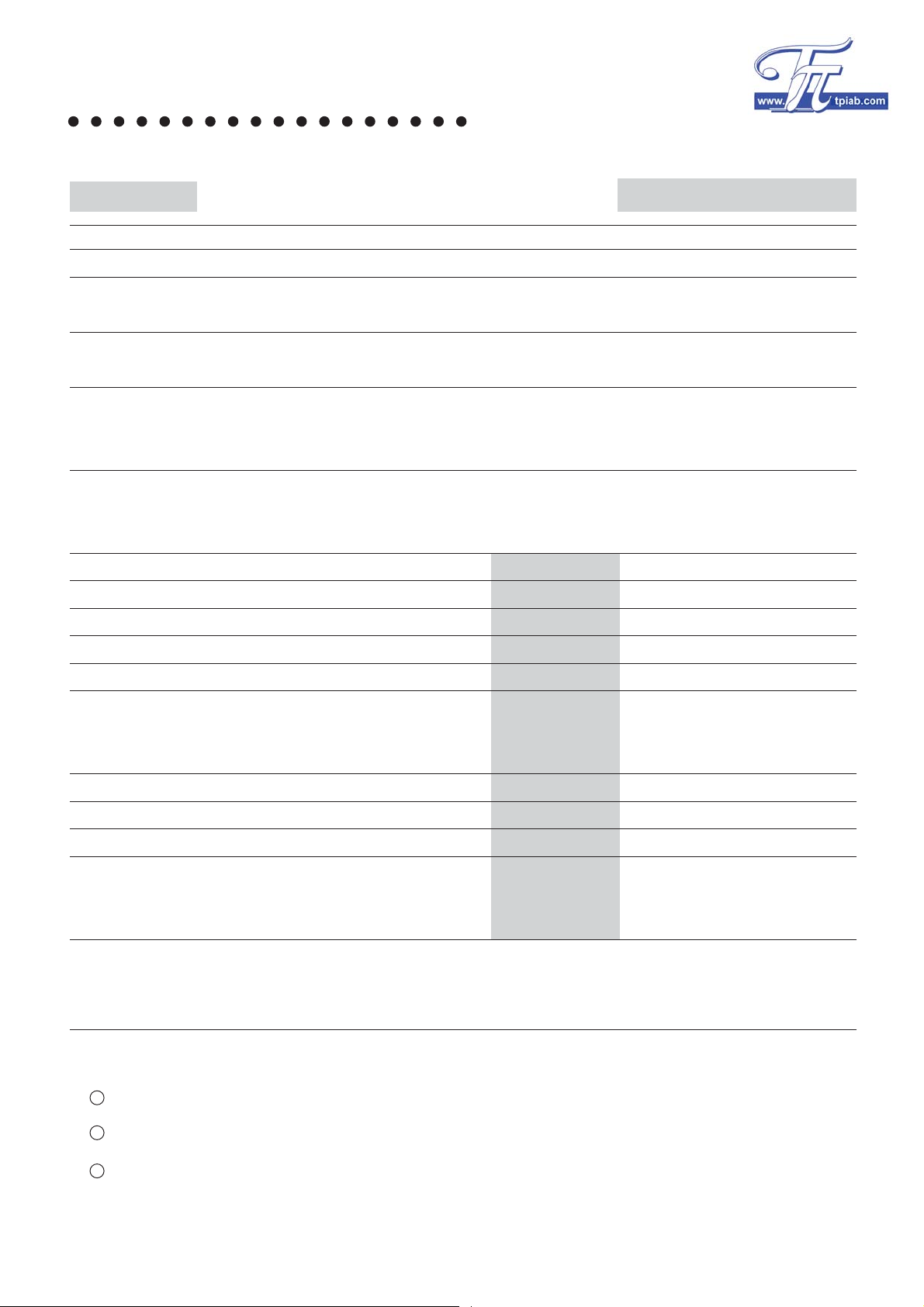

Technical specifications

Heat pump

Model

Cooling capacity

Heating capacity

Rated power input

Cooling

Heating

Rated current

Cooling

Heating

Operation frequency

Power

Air flow(indoor/high speed)

Noise(indoor/outdoor)

W

Btu/h

W

Btu/h

W

A

Hz

3

m /h

dB(A)

Refrigerant R410A

9000BTU 12000BTU

KFR-26GW/AZBP KFR-34GW/AZBP

2600(900~3200) 3500(1000~3700)

8870(3100~11000) 12000(3412~13000)

3400(1000~4000) 4100(1000~4500)

12000(3412~14000) 140003412~15400)

780(250~1100) 1020(260~1320)

950(250~1320) 1130250~1500)

3.7 4.80

4.5 5.30

28~95

220/240V/1/50Hz

520

İ42/52

Refrigerant(R410A˅

Refrigerant tube size

Liquid

Gas?

Connecting wire

Power wire

Drain hose(Indoor/Outdoor)

Dimension(WhHhD)

Indoor

Outdoor

Weight

Indoor

Outdoor

inch

mm

mm

mm

mm

kg

g

2

2

770 910

ʾ

1/4

ʾ

3/8

3

h1.0+1h0.75 3h1.5+1h0.75

3

h1.0/10A 3h1.5/16A

I. d¶16

815

h288h210

820

h540h320

10.5 10.5

32

1/4

1/2

35

Note

1

Rated cooling capacity under below conditions˖

Indoor temp:27ćDBˈ19ćWB˗Outdoor temp:35ćDBˈ24ćWB.High speed;4-meter connecting pipe.

2

Rated heating capacity under below conditions˖

Indoor temp:20ćDB;Outdoor temp:7ćDBˈ6ćWB.High speed;4-meter connecting pipe.

3

We get the noise under heating model meantime.The fan runs at high speed.

ʾ

ʾ

65

Page 3

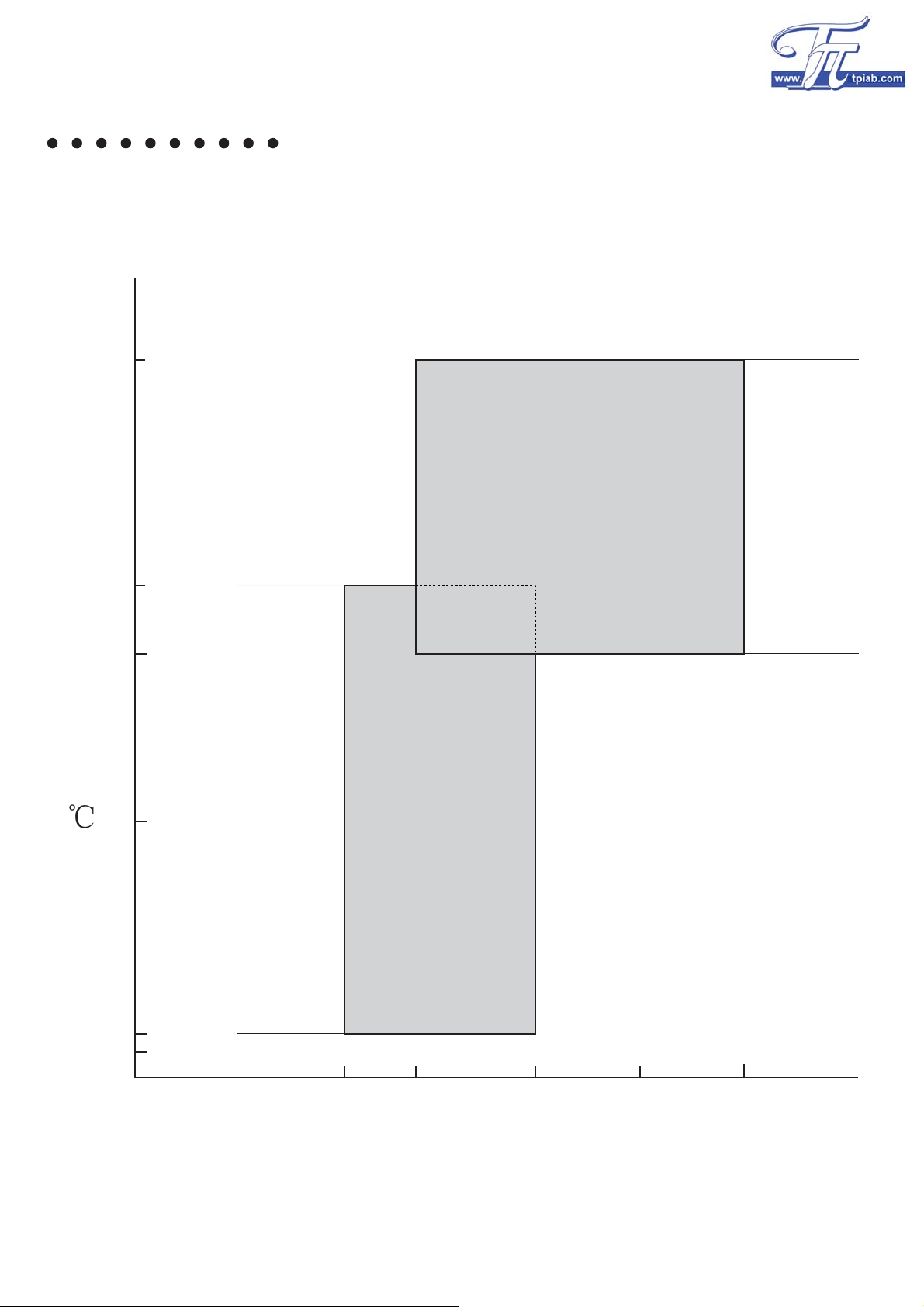

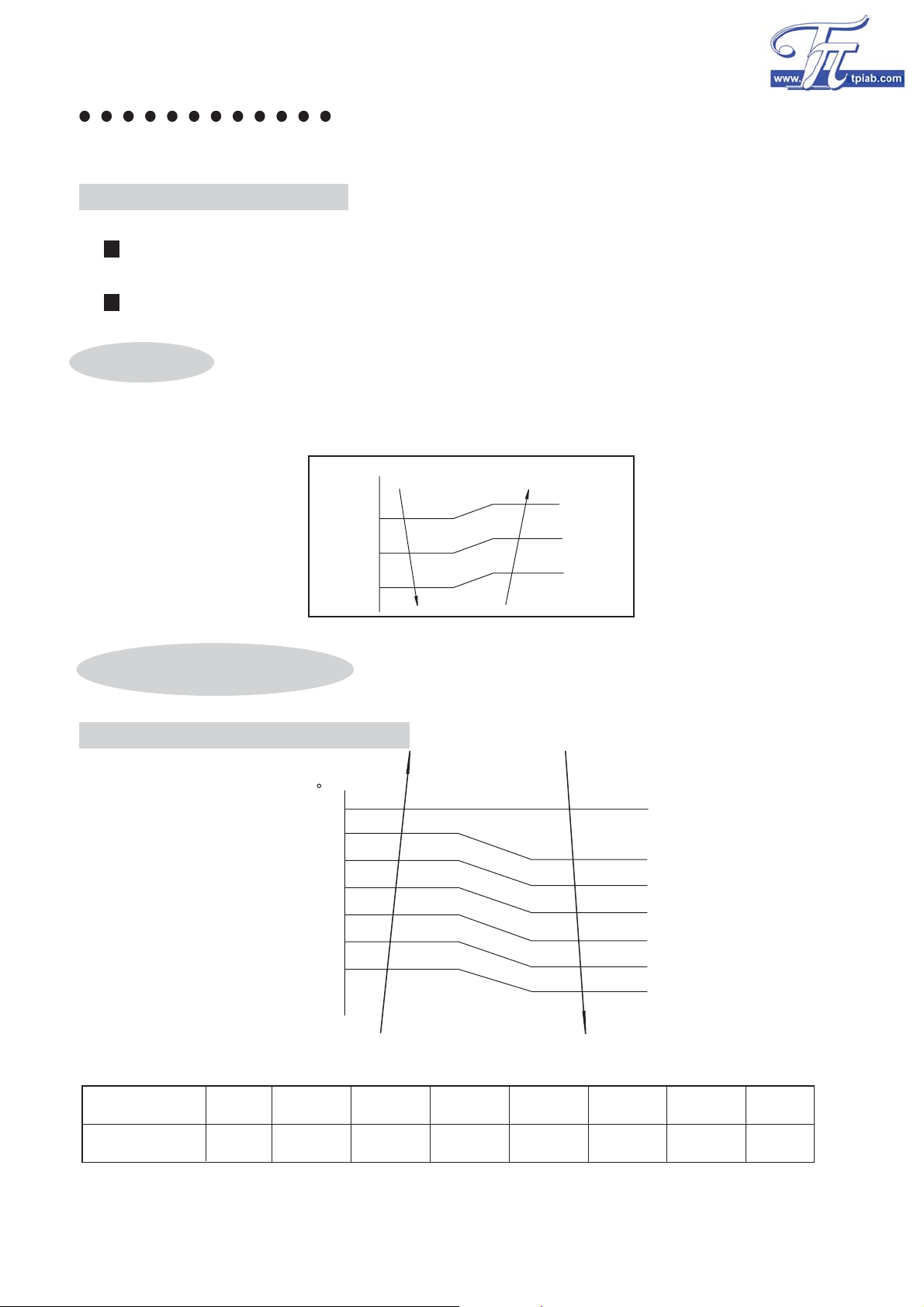

Working range

43

Max.operation temp

Cooling

Outdoor side temp.

24

21

Max.operation temp

Min.operation temp

ć

10

Min.operation temp

-7

-10

Heating

20 27 30 32

21

Indoor side temp.ć

66

Page 4

Page 5

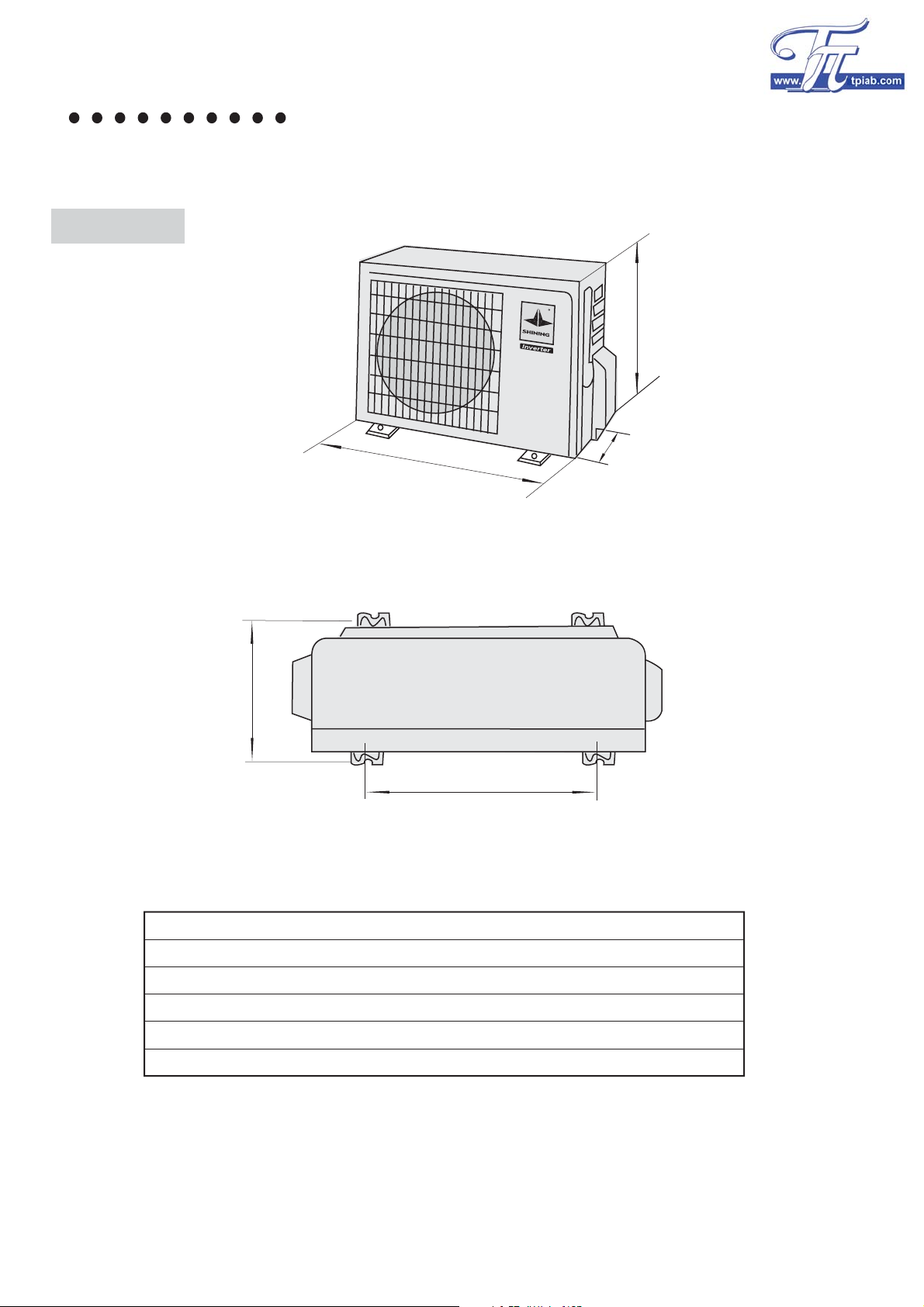

Outdoor unit

Outdoor unit

unit(mm)

H

L2

W

L1

D

Dimension

W

H

D

1

L

L2

9000Btu

760

528

256

538

283

12000Btu

760

528

256

538

283

68

Page 6

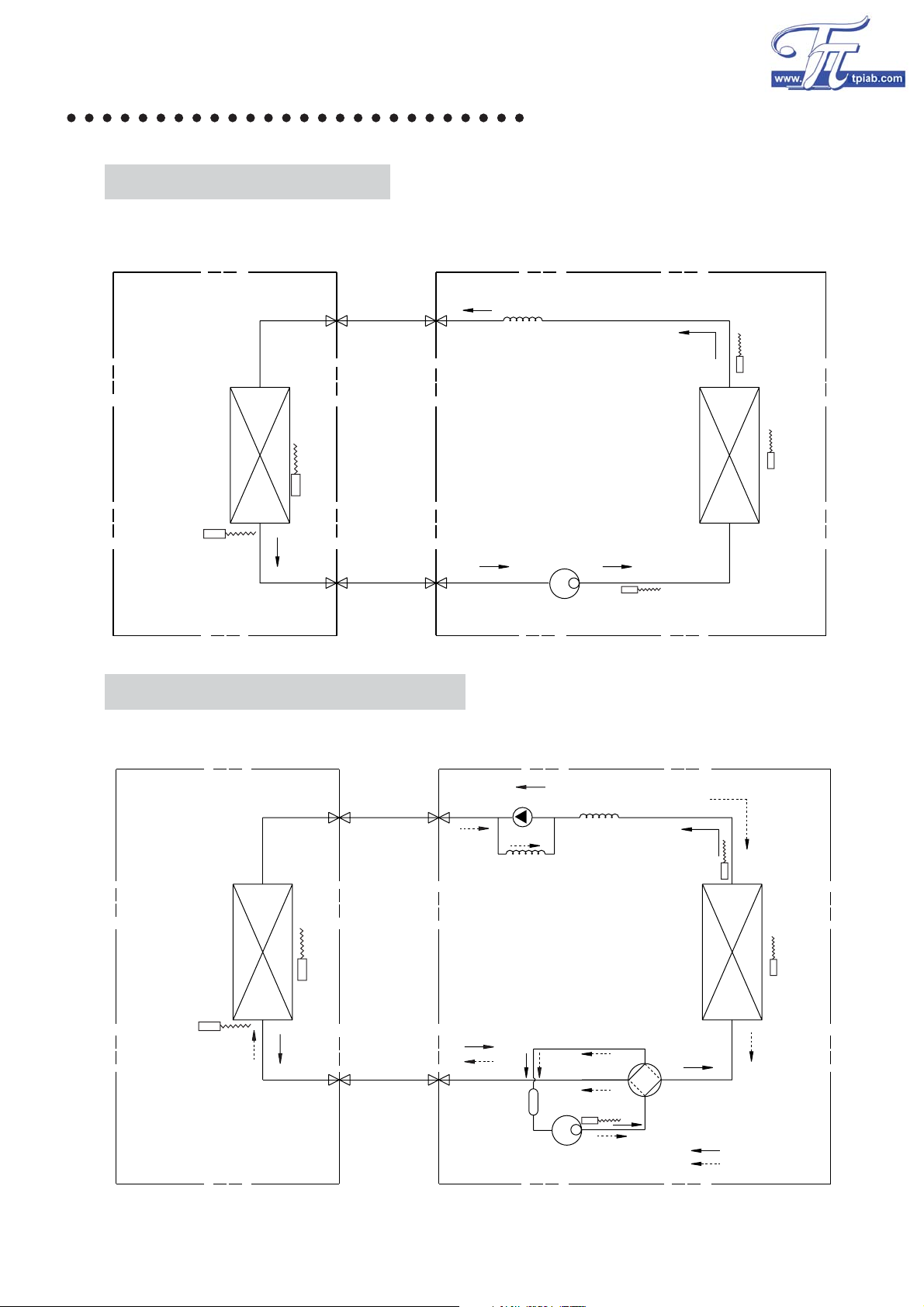

Refrigeration cycle diagram

COOLING ONLY MODELS

Indoor unit

Indoor

Exchanger

Indoor air thermo

Indoor

pipe

thermo

Liquid side

2-way valve

3-way valve

Gas side

Cooling capillary

Compressor

Outdoor unit

Outdoor

Exchanger

discharge thermo

Outdoor

pipe

thermo

Outdoor

air

thermo

COOLING AND HEATING MODELS

Indoor unit

Liquid side

2-way valve

Indoor

pipe

thermo

Indoor

Exchanger

Indoor air thermo

Gas side

3-way valve

Check valve(Heating model)

Heating capillary

Accumulator

Outdoor unit

Cooling capillary

discharge thermo

Outdoor

pipe

thermo

Outdoor

Exchanger

Outdoor

air

thermo

Reversing valve

(Heating model)

Compressor

cooling

heating

69

Page 7

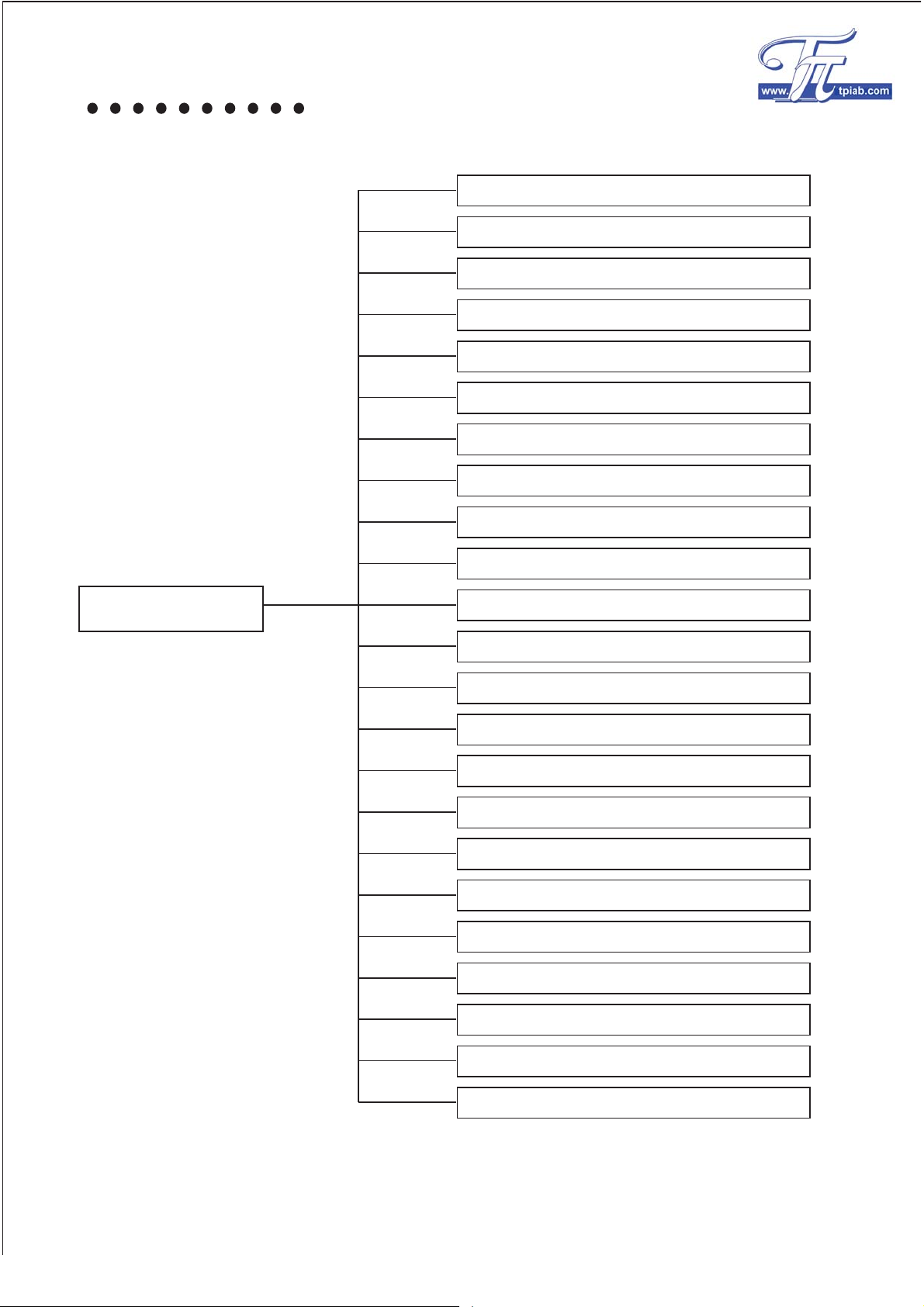

Main function

Cooling

Heating

Soft/dry

Auto operation

Temporary operation

Add and reclaim fluorine running

Sleep

24-hour timer

Vertical air direction adjustment

Main function

Vertical air direction adjustment

Capacity adjust(Inverter

Ice avoid(cooling model)

Cold air avoid(heating model)

Auto defrost

Heating overload protection

Cooling

Current

Discharge temp protection

Compressor 3-minute protection

IPM

overload protection

protection

protection

Low voltage protection

Frequency control

Faults & self-diagnoses

70

Page 8

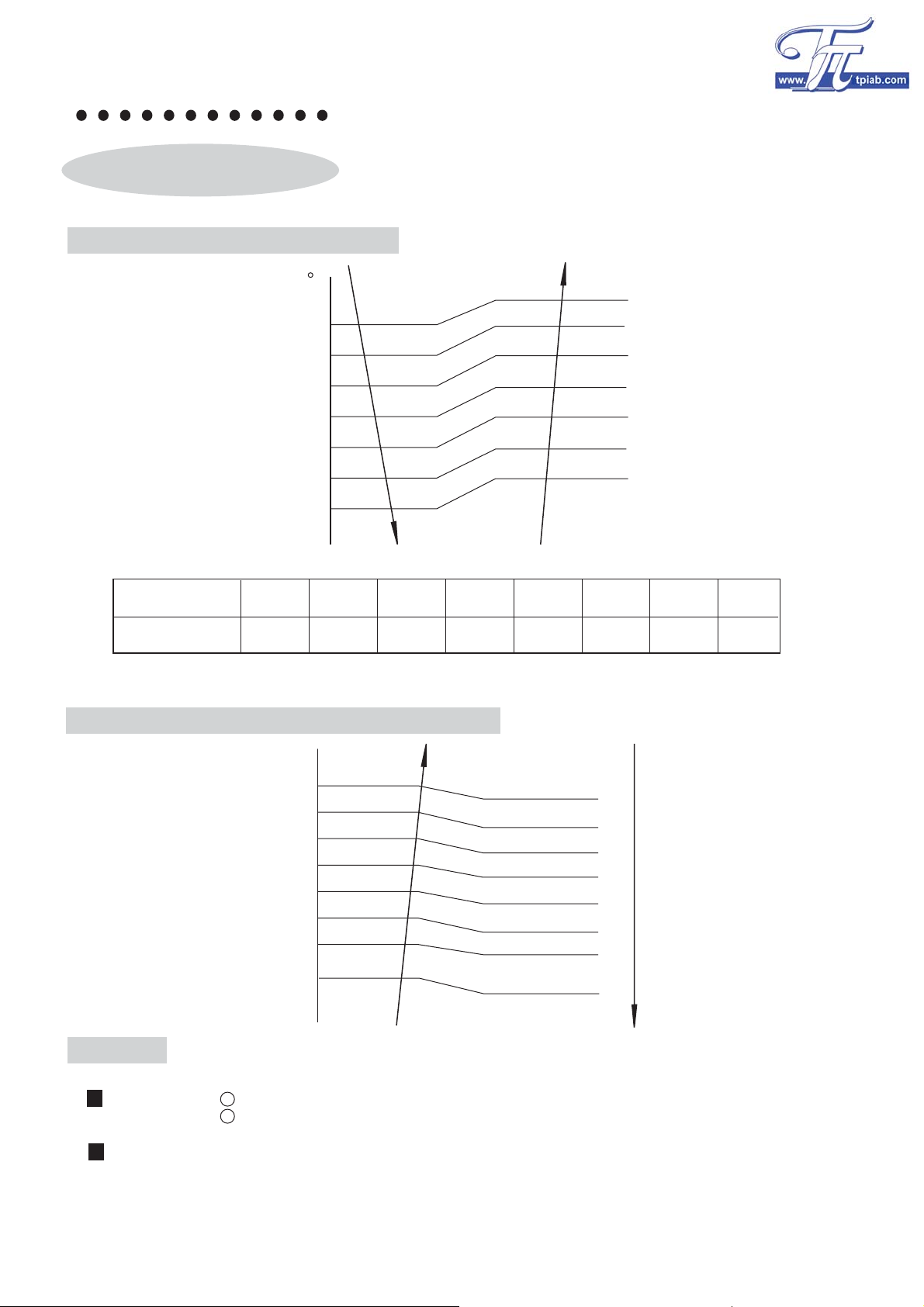

System control

Cooling operation

Frequency control by indoor temp

C

3.5

3.0

2.5

Indoor temp-setting temp

2.0

1.5

1.0

0.5

0.0

A

B

C

D

E

F

G

H

Temp range

Frequency(Hz)

ABCDE FGH

89 85 81 77 73 37 28 0

Limit of the most frequency by outdoor temp

45

44

41

40

37

36

30

29

24

23

18

17

12

11

0

-1

Compress OFF

Fmax= 55Hz

Fmax= 73Hz

Fmax= 81Hz

Fmax= 89Hz

Fmax= 81Hz

Fmax= 73Hz

Fmax= 55Hz

Fmax= 46Hz

Ice avoid

Inlet condition: evaporator temp downİ2ć,system is running on the lowest frequency(28Hz).

evaporator temp down˘0ć,compressor OFF.

Return condition:evaporator temp raiseı6ć and continuous 10 minutes,the frequency rise

to the most.

1

2

71

Page 9

System control

Cooling

overload protection

Inlet condition: condenser temp raiseı58ć,system is running on the lowest

frequency(28Hz).

condenser temp raiseı62ć,compressor OFF.

Return condition:condenser temp down˘54ć and continuous 10 minutes when condenser down <52ć,

the frequency rise to the most.

O

1

O

2

Soft/dry

Automatically choose running frequency according to the numerical value between room

temp and setting temp.(CMOS chip enact the temp to 24ć).

Indoor temp-setting temp˄24ć˅

3.5

3.0

2.5

2.0

1.5

1.0

55Hz

46Hz

37Hz

28Hz

Heating operation

Frequency control by indoor temp

C

-0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

Temp range

A BC D E FGH

Indoor temp-setting temp

H

G

F

E

D

C

B

A

Frequency(Hz)

95 90 85 78 70 38 30 0

72

Page 10

System control

Limit of the most frequency by outdoor temp

ć

33

31

27

26

22

21

18

17

14

13

10

9

F

F

F

F

F

F

F

max

max

max

max

max

max

max

=0Hz

=46Hz

=54Hz

=62Hz

=78Hz

=90Hz

=95Hz

Heating

overload protection

Inlet condition: evaporator temp raiseı55ć,system is running on the lowest frequency(30Hz).

evaporator temp raiseı62ć,compressor OFF.

Return condition:evaporator temp down˘47ć and continuous 10 minutes,the frequency rise

to the most.

Cold air avoid

1

2

evaporator

temp

37ć

35ć

33

ć

ć

18

15

ć

low speed

Setting speed

UL speed

Fan stop

73

Page 11

System control

Auto defrost

Inlet condition: (only meet one condition)

1

Condenser temp İ3ćcontinuous40min,and Condenser temp İ-6ćcontinuous more 3minDŽ

tempć

3

-6

ı40min ı3min

2

Condenser tempİ3ć continuous80min ,and Condenser tempİ-4ćcontinuousPRUH3min.

tempć

3

-4

ı80min ı3min

3

Condenser temp İ3ćcontinuous 120min ,and Condenser tempİ-3ćcontinuous more 3min.

tempć

3

-3

ı120min ı3min

Time

Time

Time

Return condition: (only meet one condition)

Condenser temp risingı15ć

1

2

Condenser temp risingı8ćand continuous more 80S.

3

Defrost continuous 10min

Defrost action

Max10min

10s

Compressor

4-way valve

Outdoor fan motor

Indoor fan motor

ON 78Hz

30s

46Hz

ON

ON

ON

ON

OFF

OFF

OFF

30s 20s

OFF

ON

ON

ON

ON

74

Page 12

System control

Auto operation

Once enter into auto operation model,the unit automatically choose one running model among

cooling, single blowing,heating according to the numerical value between room temp(TA) and

setting temp(TS).First enter into auto model,the CMOS chip enact automatically to 24ć

Sleep

Cooling

TA-TS˚1ć

ˉ1ćİTA-TSİˇ1ć

TA-TSİˉ1ć

Room temp

Sleep function start

0-1 hour

About +1ć

About +1ć

3 hours

cooling

single blowing

heating

Stop operation

after 8 hours

Time

Heating

Room temp

Sleep function start

0-1 hour

About -2ć

3 hours

Stop operation

after 8 hours

About -2ć

Time

Temperary operation

If there is a fault with the remote controller or you lose it,you can operate it by this function.

Press the temperary switch for more 0.5s,the unit will enter auto operation model.

75

Page 13

System control

Protection functions

Discharge temp protection

When discharge temp 105ć˘td˘115ć,the system limit the frequency to 30HzDŽ

When

discharge temp td˘95ć and continue 10 minutes,rescind the protection.

When

discharge temp td˚115ć,compressor OFF and compressor restart until td˘95ć.

115ć

Discharge temp

105ć

95ć

ON

Compressor

OFF

30Hz 30Hz

3-minute waiting

It should wait 3 minutes when we restart the compressor.

Compressor

OFFON

3min

Low voltage protection

Heating

ON OFF

3min

30Hz

ON

106Hz

73Hz

65Hz

45Hz

30Hz

0

158 160 162 168 170 172 178 180 182 185 190

v

76

Page 14

System control

Cooling

98Hz

73Hz

65Hz

45Hz

30Hz

0

Current

When current of outdoor Idown˘Ict˘Istop,the system reduce the frequency by 1Hz/s until Ict˘IdownDŽ

When Inorm˘Ict˘Idown,prohibit compressor frequency to rise and can raise until Ict˘Inorm.

When current of outdoor Ict˚Istop,compressor off.

IPM

When there is 3 times IPM protection within 30 minutes,it means IPM fault,compressor off.

protection

ICT

Cooling˄A˅

Heating˄A˅

protection

158 160 162 168 170 172 178 180 182 185 190

stop Idown

I

12.0 10.5

14.0 12.0

?I

10.5

norm

7.5

v

77

Page 15

Wiring diagram

Indoor circuit

Indoor FAN motor

Outdoor circuit

Stepping motor

CN307

CN312

&1

&1

RY301

CN306

Brown

White

?Orange

CN305

CN302

1234

Indoor pipe thermo

1L NPE

CN314

Blue

Brown

CN304

Indoor air thermo

Yellow/green

PE

N

L

2XWGRRU

3RZHU

Display and Receptor board

W

V

U

-

+

Capacitor

Only cooling:

No 4-way Reversing valve

Black

CN13

CN12

CN11

CN10

CN09

DC Inverter

Compressor

White

Red

CN08 CN02

IPDU

Reactor

&RPSUHVVRU

FDVHWKHUPR

15

CN06

CN01

CN500

CN07

?Brown

Blue

CN12

CN11

CN14

CN5

1

5

N'

FAN

Outdoor air thermo

Yellow/green

L'

CN4

CDB

CN10CN9

?Outdoor pipe thermo

4-way Reversing

Valve

CN3

CN15

CN2

Orange

?Brown

Blue

N

CN7

L

CN1

1L N

Indoor

78

Page 16

Wiring diagram

Main parts list

name of parts

Remote controller"

Fan motor capacitor

Room temp. sensor

Indoor coil sensor

Compressor(R410A)

Compressor(R407C)

Fan motor

˄PG˅

Step motor

Relay

Power wire

Micro computer

Fuse

4-way valve

Fan motor

models

9000Btu 12000Btu

Indoor unit

cooling & heating cooling & heating

220V/50HZ 0.23A 16W 220V/50HZ 0.23A 16W

1.2F/450V 1.2F/450V

25BYJ48-Bˈ12VDC 300

JQX-102F-012 JQX-102F-012

12VDC,20A 250VAC

CBB61,1.2F/450V CBB61,1.2F/450V

3h1.0mm /10A

R25=5.0K¡ , B25/50=3950K R25=5.0K¡ , B25/50=3950K

R50=20.92K¡ , B0/50=3877K R50=20.92K¡ , B0/50=3877K

B25/50=3950K B25/50=3950K

TMP87PH46N TMP87PH46N

T3.15A/250V T3.15A/250V

2

¡

25BYJ48-Bˈ12VDC 300

12VDC,20A 250VAC?

3h1.5mm /16A

2

Outdoor unit

DA89X1F-22FD

Winding resistance:0.88¡(20ć)

DHF-5 ?DHF-9

KF20-6M ,20W,6P ,0.32A

220V/50HZ , 2F /450V 220V/50HZ , 2F /450V

Temp protector inside

˖OFF:125ć

ON: 95ć ON: 95ć

DA89X1F-22FD

DA89X1F-22FDDA89X1F-22FD

Winding resistance:0.88¡(20ć)

KF20-6M ,20W,6P ,0.32A

Temp protector inside˖OFF:125ć

¡

)DQPRWRUFDSDFLWRU

&RPSUHVVRU

FDVHWKHUPR

?Outdoor pipe thermo

?Outdoor air thermo

Current protector(CT) 25A ?25A

Micro computer

IPM

Electrolytic capacitor

TMP87P809Nǃ

Reactor

Fuse

Cooling capillary

Heating capillary

2F /450V 2F /450V

R95=4.1877K¡ R95=4.1877K¡

R110=2.6325K¡ R110=2.6325K¡

R115=2.2734K¡

B95/115=4365K B95/115=4365K

R0=15.0K¡ ,R25=5.286K¡

B0/100=3450K

R0=15.0K¡ ,R25=5.286K¡ R0=15.0K¡ ,R25=5.286K¡

B25/50=3450K B25/50=3450K

TMP88PH47N

2S16DAI

400VAC 50/60HZ 1500F

19mH 23/10A

T20A 250V T20A 250V

3.0h1.5h600

3.0h1.4h630

R115=2.2734K¡

R0=15.0K¡ ,R25=5.286K¡

B0/100=3450K

TMP87P809Nǃ

2S16DAI

400VAC 50/60HZ 1500F

19mH 23/10A

3.0h1.6h700

3.0h1.5h750

TMP88PH47N

79

Page 17

Page 18

Page 19

Page 20

Faults & self-diagnoses

Faults and solution

No Main reasons

Faults content

Wire connecting plate broken

1

or jointing copper foil open

AC open circuit

The transformer broken

Can't adjust the indoor fan

Can't adjust the

indoor fan speed

2

speed under sleeping mode

(low speed)

Can't adjust the indoor fan

speed under dehumidifying

mode (low speed)

Battery power used up

Wrong battery connection

Caused by other light

(too near)

Use the remote control with

3

Remote control signal

transmitting or

receiving error

incorrect place or angle

Broken wire connecting

Signal receiver error

PCB of remote control error

Chip wrong action

?Diagnose Normal conditions Solution

Check by eyes

Connecting plate and copper

foil connected well

Check voltage of the

AC10~16V

transformer

Check if the units under

sleeping mode

Check the operation mode

The speed changeable except

sleeping mode

The speed changeable

except dehumidifying mode

Check the voltage of battery

Check the direction of battery

Check after turning off the light

Use the remote control within

the valid angle and distance

Check the wire connection

Check the signal receiver

Check the weld of signal

The total voltage should > 2.5V

Instruction in the battery box

The unit recover after turning

off the light

Signal transmits OK within

the valid angle and distance

No connection broken

Steady connection,touch well

No rupture and weld ill

receiver

Check the remote controller

Replace the signal receiver

and check it

Use temporary switch for

Remote controller transmit well

Signal receive successfully

The unit operate well

test

Try again after turning off

the power

The unit start to run after

restart

Chang the connecting plate or

repair the jointing copper foi

Change the transformer

Explain to user

Explain to user

Change the battery

Correct the direction of battery

Change the location of the light

Use the remote control

according to the User Manual

Change the connecting wire

Repair and correct the

connection

Change the signal receiver

Change the remote controller

Change the signal receiver

Change the PCB of remote

control

Anti-jamming to the chip

Solution to disturbance

4

The horizontal grill

action error

The compressor don't

start

5

Linkage construction fall off

The joint ends of the

horizontal grill fall off

Step motor error

Wrong wire connection

(Communication error)

IPM protection or default

Check the linkage parts

Check both ends of the

horizontal grill plate

Check the existence of

step motor

Check the wire connection

Turn off the power, discharge

the power of capacitor and

then test the current.

Check the heat sinker of the

IPM

The horizontal grill move easy

Both ends of horizontal grill

plate steady installation

1-3

1-2

575¡

1-4 1-5

575¡ 575¡ 285¡

L-N˖AC220V

1-N˖Being lined signals

Running: DC 2.5V

Stop: DC 12-18V

Overload current DC<2.5A

normal

data

Ğ

normal

data

Ğ

Test data

N

U

P

V

W

Test data

U

V

W

N

normal

data

530K

420K

normal

data

420K

Test data

N

U

P

V

W

Test data

U

V

W

N

Heat disperse well

Repair the linkage parts?

Confirm the joint ends well

connected

Change the step motor

Correct the wire connection

Change the IPM

Change the heat sinker

82

Page 21

Faults & self-diagnoses

No Main reasons "Diagnose

5

Faults content

Compressor don't

move

Electro-analysis capacitor

error

The fuse of the outdoor unit

broken

The compressor block

The compressor burnt

Commutating bridge error

Turn off the power, discharge

the power of capacitor and

then check it if there is

broken or transfiguration

Check by the current meter

Check the resistance by

the current meter

Check the 20A fuse

Turn on the power and

confirm the start

The compressor shake and

stop.

Check the existence R-S

R-C and S-C

Turn off the power, discharge

the power of capacitor and

then check the existence

Normal conditions Solution

No broken and transfiguration

Positive and negotive meter

pole connected with capacitor

terminals,multimeter needle

rotate completely,and then

slowly revent,change polavity,

the same result(while

oppositive polavity checked,

first discharging)

R=0 OK

R= Broken

Ğ

Can start

BH108/BG108˖1.18¡

BH103/BG130˖1.33¡

Test data

+

~

-

Test data

-

~

-

normal

data

-

+

Ğ

~

normal

data

+

+

10K¡

~

Change the electro-analysis

capacitor

Change fuse

Change compressor

Change compressor

Change the commutate

bridge

6

7

Indoor fan don't

move

Outdoor fan don't

move

Inductance error

Connecting broken

Burnt

Coil of the motor burnt

The temp sensor of indoor

coil open wire (when heating

operation)

Feed back error

Fan capacitor error

Connecting wire broken

Fan capacitor error

Relay error

Coil burnt

Check the resistance of the

inductance

Check it by eyes

Check it by the current meter

Test the resistance of 1-2

Check it by the current meter

Confirm by charge and

discharge of the capacitor

Check by eyes?

Confirm by charge and

discharge of the capacitor

Check by the current meter

Check by the current meter Change the motor

About 0.2 ohm

Steady connection

1~2

1~3 2~3

1010¡ 526¡ 485¡

20ć 25ć 30ć 35ć 40ć

7.3K¡ 5.8K¡ 4.7K¡ 3.8K¡ 3.1K¡

1~2 1~3 2~3

15.8K¡

16K¡

(positive)

(positive)

19K¡

(negotive)

17.1K¡

(negotive)

Steady connection

Same as Electro analysis

capacitor

No short circuit and open circuit

1~3 1~9 3~9

158¡

240¡

8.7K¡

(positive)

8.9K¡

(negotive)

392¡

Change the inductance

Repair and correct the

connection

Change the motor

Change the sensor

Change the motor

Change the capacitorSame as above

Repair and correct the

connection

Change the capacitor

Change the relay

83

Page 22

Faults & self-diagnoses

No

8

9

10

11

Faults content

4-way valve

don't work

(heating mode)

Abnormal high temp with

the compressor

Indoor temp sensor error

Outdoor temp sensor fault

Main reasons "Diagnose Normal conditions Solution

Connect wire broken

Coil short circuit or open

circuit

Insulation ageing

The valve can not move

Air inlet or outlet block

with the outdoor unit.

Refrigerant leakage

Discharge temp sensor error

Indoor heat exchanger sensor

error

Resistance abnormal Short

circuit or open circuit

Resistance abnormal Short

circuit or open circuit

Check by eyes or hands

Check the resistance

DC 500V insulation ageing

test

Don't heating after frequency

rise

Check by eye

Check the leakage

Resistance test 1-2

Resistance test 1-2

Resistance test 3-4

Resistance test 1-2

Connect OK

13K ohm between 1-3

>1000M ohm

can change normally

No block with Air in and out

No leakage

25ć20ć

25ć20ć

25ć20ć

25ć20ć

30ć 35ć

46.1K¡57.5K¡71.5K¡

30ć 35ć

30ć 35ć

30ć 35ć

37.2K¡

3.8K¡4.7K¡5.8K¡7.3K¡

3.3K¡4.0K¡5.0K¡5.3K¡

3.6K¡4.4K¡5.3K¡6.4K¡

40ć

30.2K¡

40ć

3.1K¡

40ć

2.7K¡

40ć

3.0K¡

Correct the connection

Change the coil

Change the coil

Change the valve

Confirm the air inlet and outlet

Fill in refrigerant

Change the discharge temp

sensor

Change the indoor exchanger

sensor

Change the indoor temp

sensor

Change the outdoor temp

sensor

Outdoor heat exchange

12

sensor error

Current inductance error

13

Voltage inductance error

14

Resistance abnormal Short

circuit or open circuit

Resistance broken

Current inductance fault

Resistance broken

Voltage inductance fault

Resistance test 1-2

Check the resistance

Creepage check to the

capacitor

Check the resistanc

Check the capacitance

leakage

30ć 35ć

25ć20ć

No open-circuit

Normal charge and discharge

with the capacitor

No open-circuit

Normal charge and discharge

with the capacitor

40ć

3.0K¡

3.6K¡4.4K¡5.3K¡6.4K¡

Change the outdoor heat

exchange sensor

Repair the resistance

Change the current

inductance

Repair the resistance

Change the voltage

inductance

84

Page 23

Service Parts List

Indoor Unit

REF.NO

Parts Name

Fan motor

1

Remote controller

2

Control board ass'y

3

Control board

4

Receiving & Indicator board

5

Power wire

6

Terminal (4P)

7

9000Btu

(heat pump)

Electrical Parts

AAQ022123002

ABK260234202

ABK251326100

ABK251326101

AAK161328102

AAX161328002

AAU161328002

R410A

Parts No

Q'TY Q'TY

1

1

1

1

1

1

1

12000Btu

heat pump

AAQ022123002

ABK260234202

ABK251334100

ABK251334101

AAK161328102

AAX161328002

AAU161328002

1

1

1

1

1

1

1

8

Temp.sensor indoor

9

Evaporator temp.sensor

10

Step motor

11

Installation plate

12

Air-outlet ass'y

13

Motion link

14

Horizontal eliminating vane A

15

Horizontal eliminating vane B

16

17

Vertical eliminating vane

18

Drain plug

Drain hose

19

Front panel

20

AAD161328010

AAD161328010

AAQ160245003

Construct Parts

AAE160245001

ABC260234101

AAC140226126

AAC140226124

AAC140226125

AAC140226123

AAC140226134

AAF260235019

AAC140226101

12

1

1

1

1

1

1

2

2

2

1

1

1

AAD161328010

AAD161328010

AAQ022123002

AAE160245001

ABC260234101

AAC140226126

AAC140226124

AAC140226125

AAC140226123

AAC140226134

AAF260235019

AAC140226101

1

1

1

1

1

1

2

12

2

2

1

1

1

21

Front frame

AAC140226105

1

AAC140226105

1

85

Page 24

Service Parts List

Indoor Unit

REF.NO

Parts Name

Nail lid

22

Indicator signal cover

23

Indicator signal

24

Basing ass'y

25

Air filter

26

Bearing asss'y

28

29

Cross flow fan

30

Control box

bracket

9000Btu

only cooling

Parts No

Q'TY Q'TY

9000Btu

heat pump

AAC140226106

AAC140226103

AAC140226104

AAC140226108

AAC140226107

AAC140226135

AAY160245002

AAC140226115

2

1

1

1

2

1

1

1

12000Btu

only cooling

R410A

12000Btu

Q'TY

heat pump

AAC140226106

AAC140226103

AAC140226104

AAC140226108

AAC140226107

AAC140226135

AAY160245002

AAC140226115

Q'TY

2

1

1

1

2

1

1

1

Receiving and indicating board bracket

31

32

Sensor bracket

Distribution tubing fixed plate

35

Motor fixed plate

38

Evaporator induced tube ass'y

39

40

Evaporator ass'y

AAC140226120

AAC140226136

AAC140226112 AAC140226112

AAC140226114 AAC140226114

1

1

AAC140226120

AAC140226136

1

1

Cycle parts

AAB140226100

AAN260226100

1

1

AAB140226100

AAN260235100

Printing parts

1

1

1

1

1

1

44

45

46

Name plate

Wiring diagram

Inventer sign

ABT251326005 ABT251334005

ABL260234002

AAI161328015

1

1

1

ABL260234002

AAI161328015

86

1

1

1

Page 25

Service Parts List

Outdoor Unit

REF.NO

Parts Name

Fan motor

1

IPDU basing board ass'y

2

Control basing board ass'y

5

Discharge temp.sensor

7

Temp.sensor outdoor heater exchanger

8

9000Btu

only cooling

R410A

Parts No

9000Btu

Q'TY Q'TY Q'TY Q'TY

heat pump

Electrical Parts

ABQ251334001

AAK161328105

AAK161328104

AAD161328003

AAD161328014

12000Btu

only cooling

1

1

1

1

1

12000Btu

heat pump

ABQ251334001

AAK161328105

AAK161328104

AAD161328003

AAD161328014

1

1

1

1

1

9

Ambient air Temp.sensor outdoor

Terminal (4P)

10

Compressor wire

12

Electrolytic capacitor

14

4-way valve coil

16

Reator

17

Base ass'y

18

Base seal A

19

Base seal B

20

Compressor bottom cover

21

AAD161328013

AAU161328001

AAX161328012

AAR161328001

AAB162145301 AAB162145301

AAD161328001 AAD161328001

Construct Parts

AAE251334500

AAF160245401

AAF160245402

AAF141226101

1

1

1

1

AAD161328013

AAU161328001

AAX161328012

AAR161328001

1

1

1

1

5

1

AAE251334500

AAF160245401

AAF160245402

AAF141226101

1

1

1

1

1

1

1

1

5

1

88

Page 26

Service Parts List

Outdoor Unit

REF.NO

Parts Name

Compressor damping rubber

22

Valve base

23

Valve bolt

24

Compressor damping pad

25

Compressor damping nut

26

27

Motor angle

Motor angle seal A

28

Motor angle seal B

29

Propeller fan

30

9000Btu

only cooling

R410A

Parts No

Q'TY Q'TY Q'TY Q'TY

9000Btu

heat pump

ABG251334002

AAE160245102

AAG150270001

AAG022123020

AAG160245003

AAE251326502

AAF141226406

AAF141226407

AAY160245001

12000Btu

only cooling

3

1

4

3

3

1

1

1

1

12000Btu

heat pump

ABG251334002

AAE160245102

AAG150270001

AAG022123020

AAG160245003

AAE251326502

AAF141226406

AAF141226407

AAY160245001

3

1

4

3

3

1

1

1

1

Fan fixed nut

31

Bulkhead

32

Sound proof cover A

34

35

Sound proof cover B

Compressor top cover

36

Control box

37

IPDU bracket

38

Heat sinker

39

Bulkhead seal A

40

Bulkhead seal B

41

Condenser seal

44

AAG022123018

AAE130226106

AAF141226103

AAF141226104

AAF141226102

AAE161328109

AAE161328125

AAD161328005

AAF161328403

AAF161328404

AAF161328405

1

1

1

1

1

1

1

1

1

1

1

AAG022123018

AAE130226106

AAF141226103

AAF141226104

AAF141226102

AAE161328109

AAE161328125

AAD161328005

AAF161328403

AAF161328404

AAF161328405

1

1

1

1

1

1

1

1

1

1

1

Right side plate

45

AAE260235503

1

AAE260235503

1

89

Page 27

Service Parts List

Outdoor Unit

REF.NO

Parts Name

Right side plate seal A

46

Right side plate seal B

47

Wire fixed board

49

Front panel

50

Fan guard

51

Handle

52

Temp.sensor bracket outdoor

53

Air-inlet grill

54

Covering plate

55

9000Btu

only cooling

R410A

Parts No

9000Btu

Q'TY Q'TY Q'TY Q'TY

heat pump

AAF141226409

AAF141226410

AAE160245107

AAE160245101

AAC160245203 AAC160245203

AAC160245205

AAC161328201

AAC160245204

AAE160245104

12000Btu

only cooling

1

1

1

1

12000Btu

heat pump

AAF141226409

AAF141226410

AAE160245107

AAE160245101

1

1

1

1

11

1

1

1

1

AAC160245205

AAC161328201

AAC160245204

AAE160245104

1

1

1

1

Control box cover

56

Compressor ass'y

57

Terminal cover

58

Terminal cover gasket

59

Terminal cover nut

60

61

Ruber-washer

Condenser ass'y

62

4-way valve ass'y

63

Capillary tube ass'y

64

65

2 - way valve(7/16'')

3 - way valve(5/8'')

66

3 - way valve(3/4'')

67

7/16'' nut

68

Dž

5/8 nut

69

AAC161328201

Cycle parts

ABP251334001

AAF141226102

AAF141226101

AAG022123016

AAG022123024

AAN251334200

ABB251334300

AAM161326001

ABZ251326703

ABZ251326704

AAB022123802

AAB022123702

1

1

1

1

1

1

1

1

1

1

AAC161328201

ABP251334001

AAF141226102

AAF141226101

AAG022123016

AAG022123024

AAN251334200

ABB251334300

AAM161328001

ABZ251326703

1

0

1

ABZ251334704

AAB022123802

1

1

1

1

1

1

1

1

1

1

1

0

1

1

0

90

Page 28

Service Parts List

Outdoor Unit

REF.NO

Parts Name

Valve top (big)

72

Drain plug

74

75

Capacitor fixed clip

Name plate

76

Wiring diagram

77

9000Btu

only cooling

R410A

Parts No

9000Btu

Q'TY Q'TY Q'TY Q'TY

heat pump

AAB160245702

1

ABF260234001

01

1

AAE160245108

Printing parts

ABT251326006 ABT251334006

1

ABL161328004

1

12000Btu

only cooling

11

11

1

1

12000Btu

heat pump

AAB160245702

ABF260234001

01

AAE160245108

1

ABL161328004

1

1

1

1

1

78

Inventer label

1

ABT251334018

1

1

ABT251334018

1

91

Loading...

Loading...