Page 1

5700 SERIES

CONFINED SP ACE

UNIT HEA TER

Horizontal or Vertical

Mounting

A TTENTION: Read carefully before

attempting to install or operate Unit Heater .

MAINTENANCE

MANUAL &

INSTALLATION

INSTRUCTIONS

R

T

E

E

T

K

N

I

FEATURES:

Forced air electric unit heater available in:

240/208 volt single phase, 5 kw and

240 and 480 three phase 5 kw.

240/208 single phase unit is factory wired for 5 kw.

The wattage may be changed by moving jumpers as

indicated in table 1.

24 volt control standard or three phase unit.

All units with “T” suffix provided with unit mounted

hydraulic thermostat.

Mounting bracket included with all units.

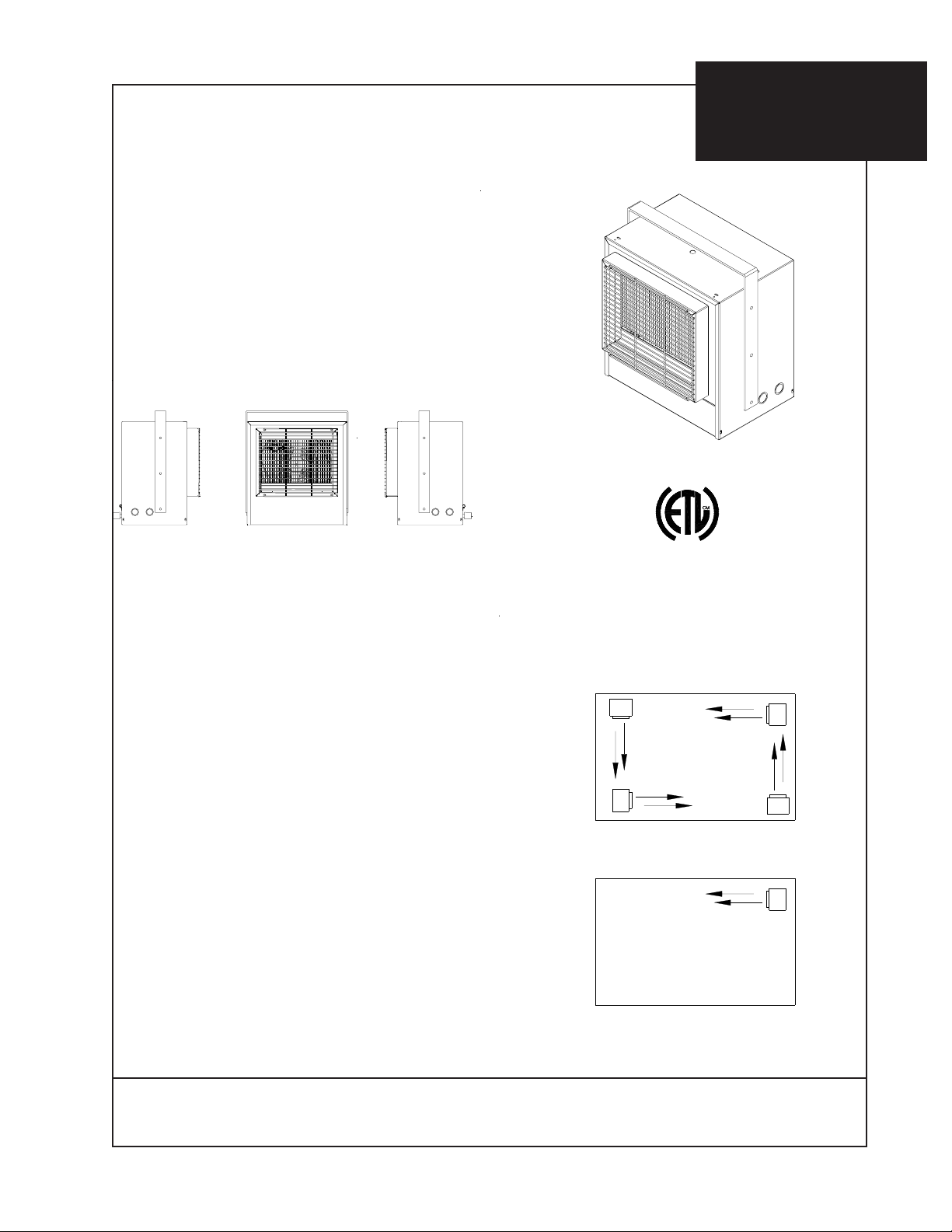

PROPER MOUNTING:

The heater(s) should be located along outside

walls or other areas of greatest heat loss. Multiple

heaters should be spaced to set up a generally

circular air movement, each heater supporting the

air stream of the other.

CONFORMS TO

ANSI/UL 1995

CERTIFIED TO

CAN/CSA C22.2 No. 236-11

EXPOSED

H

H

EXPOSED

EXPOSED

EXPOSED

L

I

S

E

T

110045

USC

D

H

H

H

IMPORT ANT : OWNER SHOULD RET AIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

FORM: 8396-7/13

Page 2

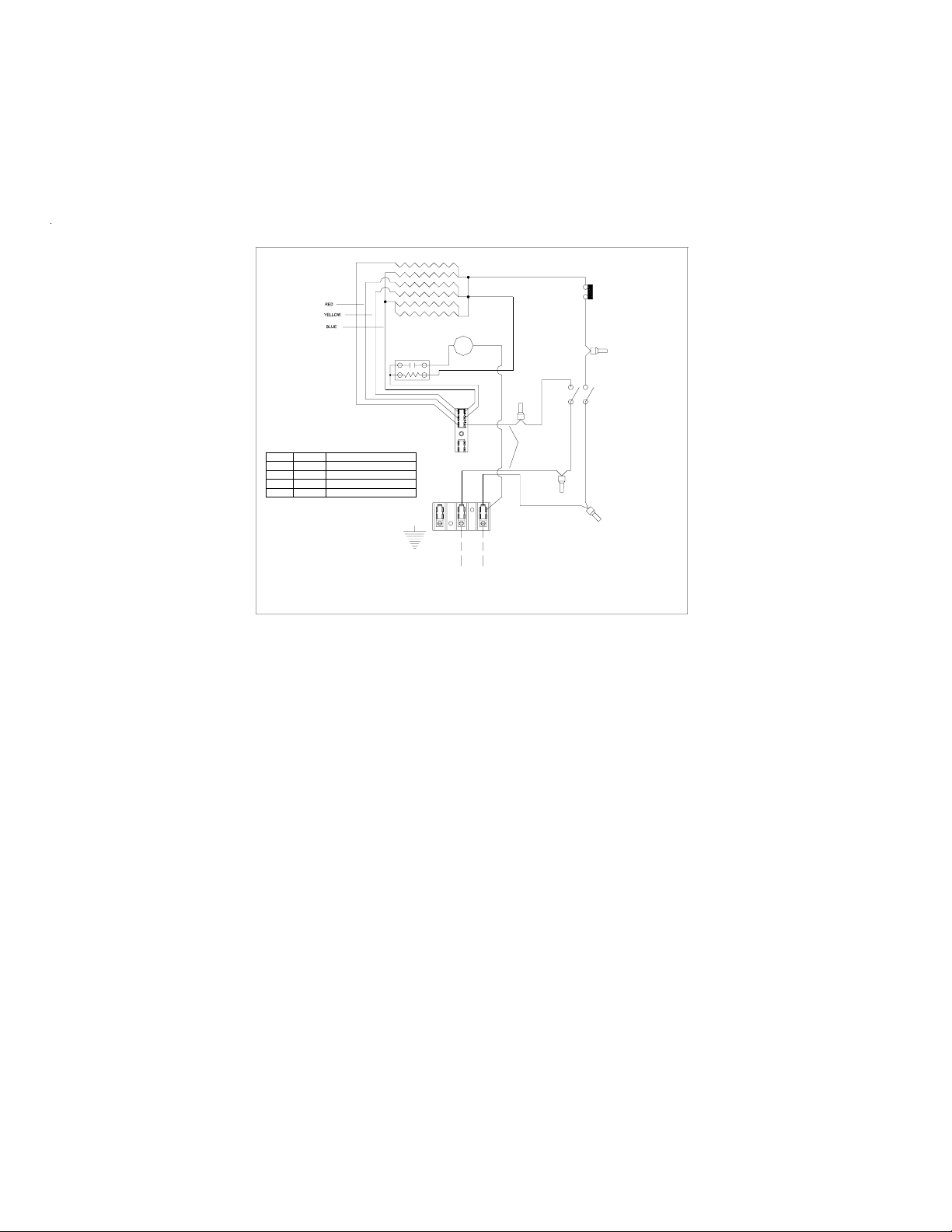

PRINCIPLES OF OPERATION

When the thermostat calls for heat, the elements are immediately energized, a fan delay brings on the fan

after the elements are heated allowing warm air to circulate. When the thermostat is satisfied, the elements are

de-energized and the fan purges the heater of residual heat.

The heater wattage may be field adjusted only on model HF5705T . Select the desired wattage from Table 1 and

move color coded jumpers as indicated.

ELEMENT

LIMIT

CONTROL

M

ABC

LTB

L2L1

240/208V 1?

BLACK

BLACK

RED

THERMOSTAT

RED

TABLE 1

WATTAGE ADJUSTMENT TABLE

VOLTS

WATTS

240/208

240/208

240/208

240/208

USE WITH MODEL NUMBER

NONE REQUIRED

5000/3750

BLUE JUMPER TO TERMINAL 'C'

4167/3120

BLUE AND YELLOW TO TERMINAL 'C'

3333/2500

BLUE,YELLOW AND RED TO TERMINAL ' C'

2500/1875

USE COPPER CONDUCTORS ONLY

CONTROL CIRCUIT WIRING MUST BE

NEC CLASS 1 RATED 600V

HF5705T

44503-001

FAN DELAY

ADJUSTMENT

INSTALLATION INSTRUCTIONS

All electric unit heaters are shipped fully assembled. Installation includes hanging the

unit and electrical wiring to the unit.

The wall and/or ceiling structure must be sufficient to support the combined weight of

the heater and any mounting bracket and accessories.

Be sure power source is de-energized before installing heater . Check heater voltage and

phase listed on heater data label on back of unit to make sure they are the same as the

electrical service supplied.

MOUNTING THE HEATER

Select the mounting location. Be sure to observe the minimum mounting clearances as

shown in Figure 1.

The heater can be mounted either from the ceiling or wall depending on the application.

The mounting bracket is supplied with 3/8” holes, 10 inches on center for threaded rod

mounting or direct mounting to the structure.

The heater cabinet also has 3/8” weld nuts 10” on center to allow threaded rod mounting

without the bracket.

FORM: 8396-7/13

Page 3

MOUNTING CONTINUED

1. Install the mounting bracket in the desired location with threaded rod or hardware

that is appropriate for the mounting surface. If using threaded rod, two nuts, one on

the top and one on the bottom of the bracket along with a split washer is suggested.

2. Secure the heater to mounting bracket, using the 1/4-20 x 3/4” machine

screws and lockwashers provided.

3. Position the heater, aligning the bracket holes with the cabinet holes and secure

bracket to the cabinet with the 1/4-20 x 1/2” machine screws and nuts that are

provided. With the mounting bracket in the vertical position the 1/4” nuts are not

necessary , weld nuts are supplied in the cabinet.

MINIMUM INSTALLATION CLEARANCES:

SIDES, TOP AND BOTTOM 0 INCHES

REAR: 8 INCHES (203mm)

FRONT: 24 INCHES (610mm)

Dégagements minimums MONTAGE:

Côtés, le haut et le bas 0 pouces

ARRIÈRE: 8 pouces (203mm)

AVANT: 24 pouces (610mm)

FIGURE 1

5.1

14.6

0"

14.4

10.0

W

A

L

L

0"

FLOOR

8.0"

MIN. TO WALL

24"

MINIMUM

DISTANCE

FROM FRON T

TO ANY

OBJECT

FORM: 8396-7/13

Page 4

POWER CONNECTION

T o avoid possible electrical shock, be sure the electrical current is turned off at

the main switch prior to wiring or servicing of unit.

1. Remove the access panel, by removing four screws, two on the front and two on the

back.

2. Remove desired knockout on side or back of the heater .

3. Following the correct unit wiring diagram, connect the power supply and electrical

ground to the correct terminals using accepted practices recognized by local codes.

See T able 2 for minimum circuit requirement s.

4. Replace the access panel, tighten the screws to ensure a good seal to help prevent

dust and dirt from entering the control compartment.

TECHNICAL DATA TABLE 2

MODEL VOLTS WATTS PHASE AMPS SUPPLY WIRE

HF5705T

H3H5705T 240/208 5000/3750 3 12.04/10.4 12

P3P5705T 480 5000 3 6.1

240/208

Note: Supply wire must be 60o AWG minimum.

5000/3750

1

20.83/18 10

14

OPERATION

1. Restore power to the unit.

2. Turn the thermostat up to energize the unit. When the area reaches the desired

temperature, rotate the thermostat knob counter- clockwise slowly until the heat turns

off.

3. This 5700 series is provided with a fan delay/purge. When the heater is turned on,

the elements will heat up before the fan comes on (approx. 30 seconds). This allows

for warm air circulation. When the thermostat is satisfied, the elements will

de-energize and the fan will continue to run (approx. 30 seconds) allowing residual

heat to be purged from the heater .

4. The 5700 series is provided with an automatic limit control. In the event of an

abnormal situation such as fan failure or other over-temp. situations the limit control

will cycle the heater off. In the event of an over-temp situation, the heater should be

inspected to determine the cause and repaired by authorized personnel.

FORM: 8396-7/13

Page 5

Maintenance:

Caution: Make certain that the power source is disconnected before attempting to service or disassemble

any component. If the power disconnect is out of the line of sight, lock it in the OPEN position and tag to

prevent the application of power.

Electrical:

Once a year inspect the control panel wiring to make certain insulation is intact and all connections are tight.

Inspect all heater and relay contacts. If the contacts appear badly pitted or burned, replace the contactor/

relay.

Cleaning:

Clean the unit casing, fan and motor once a year. A dirty motor will tend to run hot and eventually will be

damaged internally . Any rust spots on the casing should be cleaned and repainted.

The element can be cleaned by removing the outer cabinet. Do not use any liquid to clean electric components.

Lubrication:

All units have fan motors that are permanently lubricated so that only occasional cleaning is required.

General Safety Information:

CAUTION:

Follow all local electrical and safety codes, as well as the National Electric Code (NEC) and the Occupational

Safety and Health Act (OSHA).

To avoid possible electrical shock, be sure the electrical current is turned off at the main switch prior to

wiring or servicing of unit.

If the power disconnect is not integral and is out-of-sight, lock it in the open position and tag to prevent

unexpected application of power prior to performing any service of maintenance on the unit.

The unit when installed must be electrically grounded in accordance with the National Electrical Code and

standard industry practice.

Make certain that the power source conforms to the requirements of your equipment. See Table 2 for

information as to wire and circuit size.

Check heater voltage and phase on rating label to confirm it is the same as the electric service supply.

Wiring diagrams of the heaters and supply connections are permanently attached to the heater access door.

All terminals are coded in accordance with the wiring diagram.

The wall/ceiling mounting structure and anchoring provisions must be of sufficient strength to support the

combined weight of the heater and mounting bracket.

FORM: 8396-7/13

Page 6

44503-002

ELEMENT

CONTACTOR

COIL

FAN

DELAY

L3L2L1

480V 3 PH

LIMIT CONTROL

M

CONTROL TRANSFORMER

LTB

THERMOSTAT

CTB

USE WITH MODEL NUMBER

P3P5705T

44503-003

ELEMENT

CONTACTOR

COIL

FAN

DELAY

240V 3 PH

LIMIT CONTROL

CONTROL TRANSFORMER

LTB

L3L2L1

T-STAT

CTB

USE WITH MODEL NUMBER

H3H5705T

FORM: 8396-7/13

Loading...

Loading...