Page 1

TPI Corporation

P.O. Box 4973

Johnson City, TN 37602

www.tpicorp.com

FSS-Series

Heavy-Duty Flat panel Emitter

Electric Overhead Infrared Heaters

FSS-14 FSS-43

FSS-31

IMPORTANT SAFETY INFORMATION

INSIDE

• Serious injury or death possible

• Read, understand and follow all safety

in fo rm ation and instructions in this manual

before using or servicing this product.

FSS-95

EXTREMELY HIGH TEMPERATURES ARE

PRESENT, DURING OPERATION. MAINTAIN

CLEARANCES FROM COMBUSTIBLES AS

STATED IN MANUAL.

• Retain these instructions for future use.

REFER TO COMPLETE INDEX OF

INFORMATION ON PAGE 2.

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 1 OF12

Page 2

IMPORTANT INSTRUCTIONS

1. Read all instructions before installing or using the heater.

2. This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Keep away

from combustible materials at minimum, the following required distances. DO NOT install closer

than 36 inches to a vertical surface or 24 inches to a ceiling. Heaters MUST BE SEPARATED by

more than 36 inches and 72 inches from any combustible surface in direct radiation path (87 inches

for FSS-19 Series).

3. Extreme caution is necessary when any heater is used by or near children or invalids and whenever

the heater is left operating and unattended.

4. Do not operate any heater after it malfunctions. Disconnect power at service panel and have heater

inspected by a reputable electrician before reusing.

5. Do not use outdoors.

6. To disconnect heater, turn controls to off, and turn off power to heater circuit at the main disconnect

panel (or operate internal disconnect switch if provided).

7. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause

an electric shock or re, or damage to the heater.

8. To prevent a possible re, do not block air intakes or exhaust in any manner.

9. A heater has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint or

ammable vapors or liquids are used or stored.

10. Use this heater only as described in this manual. Any other use not recommended by the

manufacturer may cause re, electric shock, or injury to persons.

11. SAVE THESE INSTRUCTIONS.

INDEX

General Description & Use Page 4

Specications Page 4, 5, 6

Installation Planning Pages 7, 8

Installation - Hanging Heaters Pages 8, 9

Installation - Wiring Pages 10, 12

Operation Page 11

Maintenance Page 11

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 2 OF12

Page 3

ATTENTION:

The table to the right provides

can be found throughout this

words are generally used in

this manual, refer back to this

signal word definition.

SIGNAL WORD DEFINITIONS

definitions of the signal words that

manual. These signal words are

used to express the severity of

the hazard at hand. The signal

conjunction with safety symbols

that correspond to the text for that

particular hazard. As you read

table when you are unsure of the

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury

WARNING indicates an imminently hazardous

situation which, if not avoided, could result

in death or serious injury

CAUTION indicates an imminently hazardous

situation which, if not avoided, may result in

minor or moderate injury

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation

which, if not avoided, may result in property

damage.

As dened in ANSI Z535-4-2002

THANK YOU!!

Thank you very much for selecting Fostoria’s overhead electric infrared heating equipment for your

comfort heating needs. These products were engineered with the most reliable components and

materials available and are equipped with features to assure ease of installation and maintenance.

The warmth you will now enjoy when using this heating equipment is created by a heat source; a at

panel emitter; that emits infrared energy in the form of heat, like the sun. This is an economical way

to heat because it heats people and objects, not the air, so you don’t need to heat a large area to feel

warm.

• Upon receipt of your shipment, check all cartons for visible damage.

• Claims for damaged material or shortages that were not evident upon receipt of shipment must

be reported to carrier and TPI Corporation’s customer service (800-251-0382) immediately.

• Any accessory items ordered for the heater will be shipped in separate cartons.

CHECKING YOUR SHIPMENT

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 3 OF12

Page 4

GENERAL DESCRIPTION & USE

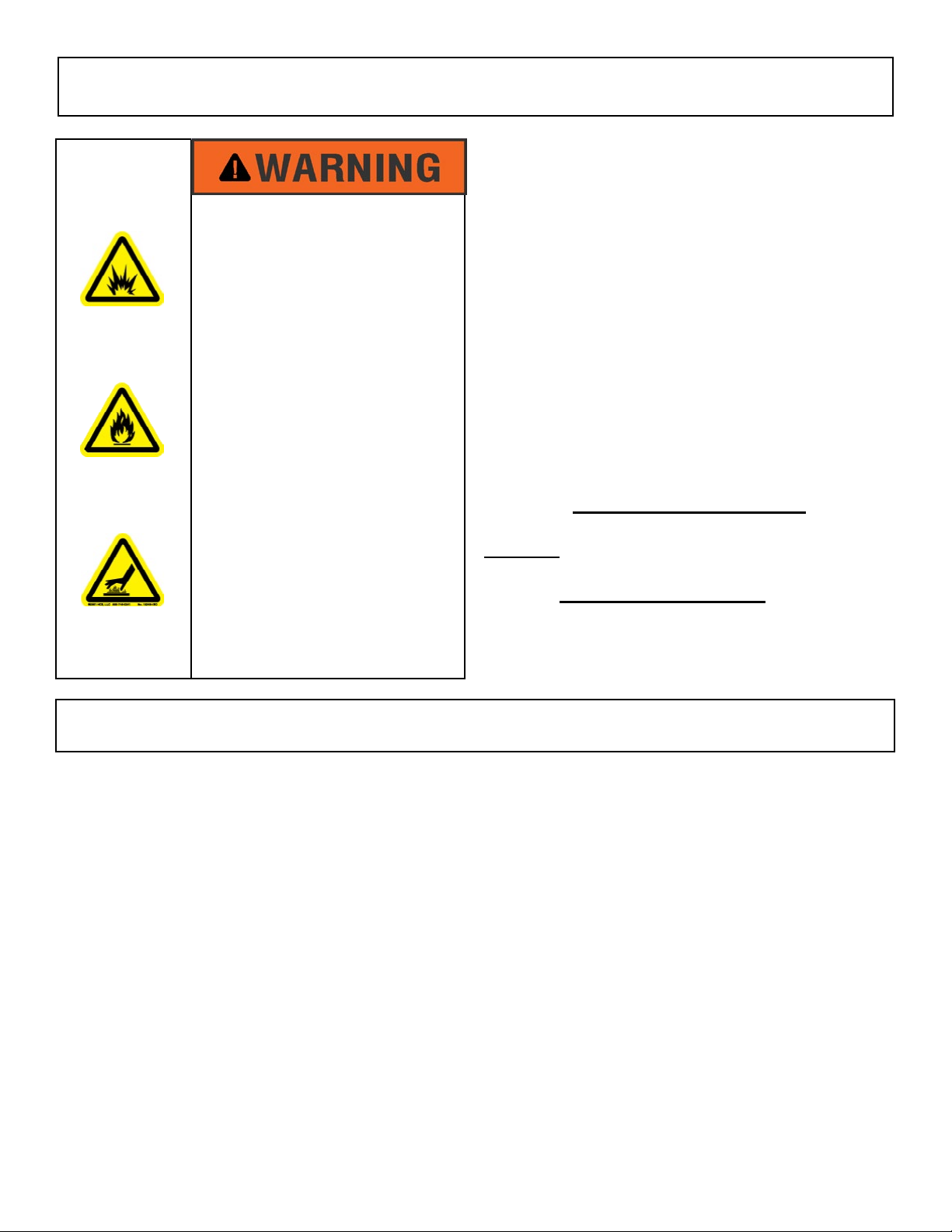

EXPLOSION HAZARD

FIRE HAZARD

BURN HAZARD

The Fostoria FSS-Series heaters provide

safe, efficient electric infrared heat for total

area heating or spot heating applications for

warehouses, steel mills, machine shops and

many other industrial applications They are

ideal for use in high vibration environments.

Using the “L” brackets on the top of the

housing these overhead heaters can be hung

by chain or rigidly mounted They operate

cleanly, emitting no fumes or odors.

• Serious injury or death may

occur

Applications where combustible materials and/or

personnel will be located near these heaters must

• Not for residential use.

adhere to the minimum clearance information

below

• Do not use outdoors.

REQUIRED CLEARANCES

• Use for comfort heating only

DO NOT install closer than 36 inches to

• Do not use locations

containing hazardous or

explosive atmospheres

a vertical surface or 24 inches to a ceiling.

Heaters MUST BE SEPARATED by more than

36 inches and 72 inches from any combustible

surface in direct radiation path (87 inches for

FSS-95 Series).

SPECIFICATIONS

• ETL listed for suspended, high-bay indoor applications (see table on next page)

• High-watt-density radiant heat with 60 degree heat pattern.

• Gold-anodized aluminum housing for good reectivity and corrosion resistance

• “L-brackets included for chain suspension or rigid-mounting.

• Designed for direct-wire, single or three-phase congurations (see table next page).

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 4 OF12

Page 5

SPECIFICATIONS (con’t.)

Heater

Models

FSS-1412-1 120; 1ph 12.1 N/A

Voltage

And Phase

Amps

1ph.

Amps

3ph.

Number

Of Elements

Watts Btu’s/Hr.

ETL

listed

cETLus

certied

Yes Yes

FSS-1420-1 208; 1ph 6.97 N/A Yes Yes

FSS-1424-1 240; 1ph 6.04 N/A Yes Yes

1 1450 4947

FSS-1427-1 277; 1ph 5.23 N/A Yes Yes

FSS-1448-1 480; 1ph 3.02 N/A Yes Yes

FSS-1457-1 600; 1ph 2.52 N/A Yes Yes

FSS-3120-1 120; 1ph 15.14 N/A

Yes Yes

FSS-3124-1 240; 1ph 13.13 N/A Yes Yes

FSS-3127-1 277; 1ph 11.37 N/A Yes Yes

1 3150 10,748

FSS-3148-1 480; 1ph 6.56 N/A Yes Yes

FSS-3157-1 600; 1ph 5.48 N/A Yes Yes

FSS-4320-3 208; 1 or 3ph 20.67 11.94

Yes Yes

FSS-4324-3 240; 1 or 3ph 17.91 10.36 Yes Yes

FSS-4327-1 277; 1ph 15.52 N/A Yes Yes

1 4300 14,672

FSS-4348-3 480; 1 or 3ph 8.96 5.18 Yes Yes

FSS-4357-3 600; 1 or 3ph 7.48 4.32 Yes Yes

FSS-9520-3 208; 3ph N/A 26.39

Yes Yes

FSS-9524-3 240; 3ph N/A 22.89 Ye s Ye s

FSS-9527-1 277; 1ph 34.3 N/A Yes Yes

1 9500 32,414

FSS-9548-3 480; 3ph N/A 11.44 Ye s Ye s

FSS-9557-3 600; 3ph N/A 9.54 Yes Yes

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 5 OF12

Page 6

SPECIFICATIONS (con’t.)

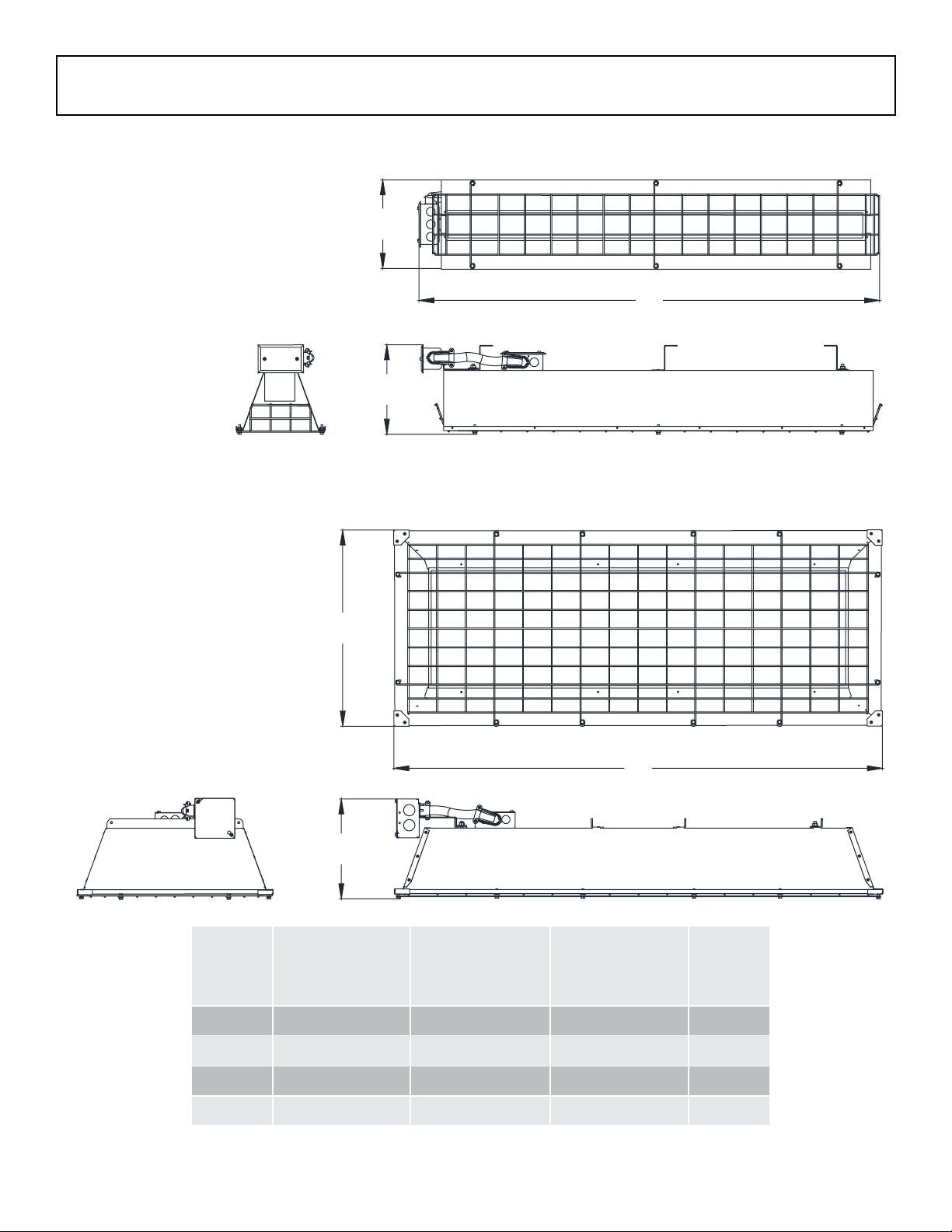

FSS-14, FSS-31

B

A

FSS-43, FSS-95

C

B

C

A

Model

Series

FSS-14 8-1/2 9 26 7

FSS-31 8-1/2 9 46 13

FSS-43 9-3/4 20 29 18

Dimension A

(inches)

Dimension B

(inches)

Dimension C

(inches)

Weight

(lbs.)

FSS-95 7-3/4 20 49 31

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 6 OF12

Page 7

INSTALLATION PLANNING

Fostoria’s at panel emitter heaters are equipped with heating elements that are manufactured using

materials with exceptional mechanical and thermal performance and are built with precise process

control to provide rugged and reliable infrared performance in challenging environments. It is our

understanding that these precision characteristics can change with time, specically in environments

with high humidity or where mechanical damage can occur, causing the internal electrical insulation to

weaken.

Installer Qualications

The installation and wiring of Fostoria MR heaters

must be performed by a licensed electrician.

FIRE HAZARD

Installer Responsibility

• Serious injury or death may

occur.

The National Electric Code (NEC) and local

codes and ordinances together with specications

provided by Fostoria comprise the information

needed for proper installation.

• Heater circuit load calculations

and circuit design must be

done by a licensed electrician

or engineer.

The installer must furnish all materials that

have not been purchased from Fostoria or its

representatives. It is the installer’s responsibility

that the materials and methods of installation

result in a job that is workmanlike and compliant

with all applicable codes.

Preparations For Hanging Heaters

• Hardware to suspend these heaters from overhead supports (chain, “S”-hooks etc.) is not included

with the product. Make certain that the hardware to be used is capable of supporting at least twice

the total weight of the heater’s in question. Refer to the specications section of this manual for

product weights.

• Identify and use installation locations that are strictly compliant with the clearance-to-combustibles

requirements in the installation section of this manual.

• Mounting height is an important consideration to assure satisfaction with the heating performance

of infrared heaters. Fostoria has many years of practical experience in the successful application of infrared technology. For that reason, recommended mounting heights have been included

in the installation section of this manual. Please refer to this data and select installation points

where these recommendations can be followed.

`

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 7 OF12

Page 8

INSTALLATION PLANNING (CON’T.)

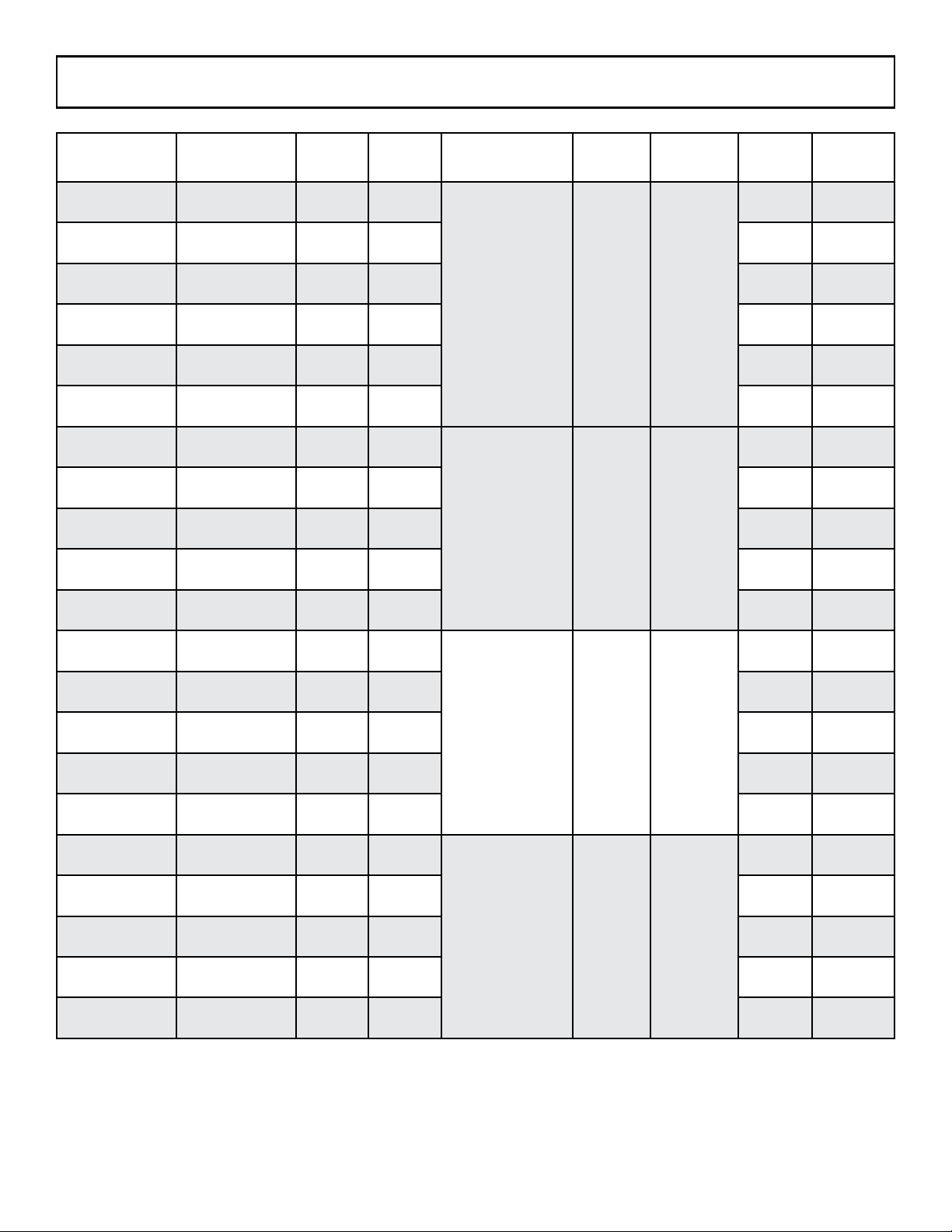

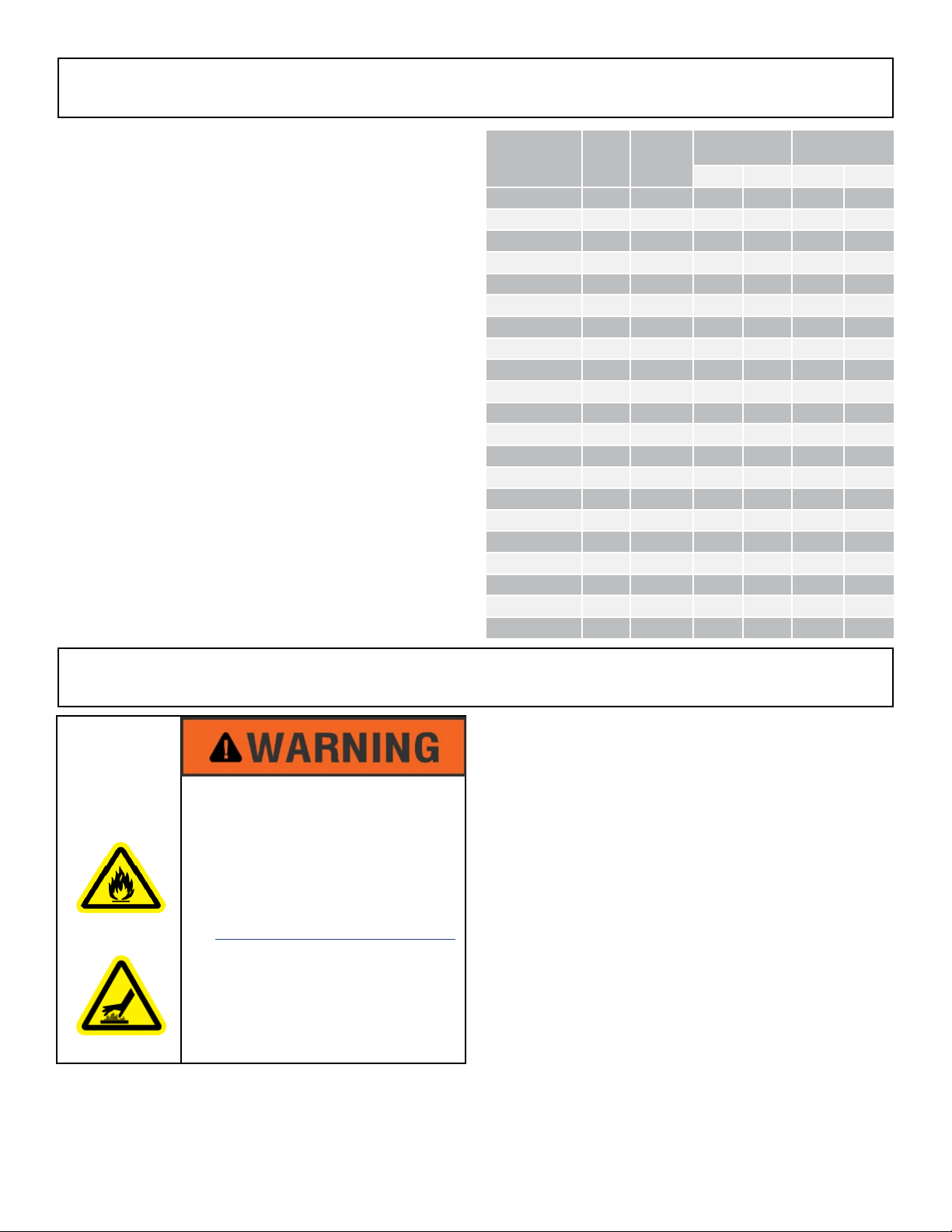

Supply Wire Size Recommendations

The table at the right is provided to assist the

licensed electrician in sizing the electric supply

wires required to deliver power to each individual

heater. All branch circuit supply wiring must be

copper, rated 90o C minimum and comply with all

local codes and the NEC.

All recommended wire sizes assume a 50ft.

maximum wire length.

Heater Model kW Volts

FSS-1412-1 1.45 120 N/A 12.08 N/A 12

FSS-1420-1 1.45 208 N/A 6.97 N/A 12

FSS-1424-1 1.45 240 N/A 6.04 N/A 12

FSS-1427-1 1.45 277 N/A 5.23 N/A 12

FSS-1448-1 1.45 480 N/A 3.02 N/A 12

FSS-1457-1 1.45 600 N/A 2.52 N/A 12

FSS-3120-1 3.15 208 N/A 15.14 N/A 12

FSS-3124-1 3.15 240 N/A 13.13 N/A 12

FSS-3127-1 3.15 277 N/A 11.37 N/A 12

FSS-3148-1 3.15 480 N/A 6.56 N/A 12

FSS-3157-1 3.15 600 N/A 5.48 N/A 12

FSS-4320-3 4.3 208 11.9 20.67 12 10

FSS-4324-3 4.3 240 10.4 17.9 12 10

FSS-4327-1 4.3 277/480 5.2 15.5 12 12

FSS-4348-3 4.3 480 5.2 9.0 12 12

FSS-4357-3 4.3 600 4.3 7.5 12 12

FSS-9520-3 9.5 208 26.4 45.7 8 8

FSS-9524-3 9.5 240 22.9 39.6 10 8

FSS-9527-1 9.5 277/480 11.4 34.3 12 8

FSS-9548-3 9.5 480 11.4 19.8 12 10

FSS-9557-3 9.5 600 9.5 16.5 12 10

Amps

3ph 1ph 3ph 1ph

Recommended

AWG Wire Size

INSTALLATION - HANGING HEATERS

FIRE HAZARD

BURN HAZARD

• Install heaters to comply with

REQUIRED CLEARANCES

listed above at right.

• Do not mount heaters

vertically.

REQUIRED CLEARANCES

DO NOT install heaters closer than 36 inches to a

vertical surface or 24 inches to a ceiling. Heaters

MUST BE SEPARATED by more than 36 inches

and 72 inches from any combustible surface in

direct radiation path (87 inches for FSS-95

Series).

HEATER HANGING ALTERNATIVES

One method of hanging the heaters (shown

below) is with hardware chain and “S” hooks. The

chain and “S” hooks must be either 14 or 16 gauge

for all models. The heaters also can be mounted

“xed” with angle iron, metal rods or metal straps.

Whatever means is used to mount the heaters,

the terminal box must be EVEN WITH or LOWER

THAN the horizontal plane of the heater housing.

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 8 OF12

Page 9

CHAIN HANGING

SERIES

FSS-14 8-10 Ft.

FSS-31 8-12 Ft.

FSS-43 10-14Ft.

FSS-95 12-16Ft.

Mounting Centers

RECOMMENDED

MOUNTING HEIGHTS

(In Inches)

CHAIN

S-HOOK

Fixed-Mounting

Series Dim. A Dim. B

FSS-14 14-1/4 2-1/2

FSS-31 34-1/4 2-1/2

FSS-43 18-1/4 12-3/4

FSS-95 36 3/4 12-3/4

B

A

B

A

FSS-14, FSS-31

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 9 OF12

FSS-43, FSS-95

Page 10

INSTALLATION - WIRING

ELECTRICAL SHOCK

HAZARD

• Serious injury or death may

occur.

• Disconnect heater and lock out

from electrical supply before

installing or servicing.

• Always securely connect

green wire on heater to

bonding (green) wire from

electrical supply.

FOR ALL HEATERS

Wiring procedures and connections shall be in

accordance with the national and local authority

having jurisdiction. The FSS series heaters do not

have any on board controls and therefore must

be used in conjunction with an applicable control

center or be wired to a listed, properly rated safety

switch for on/off control.

Always disconnect the power at the circuit breaker or disconnect switch before installing electric

power to the heater. If the breaker or disconnect

switch cannot be seen from where you will be

working, lock it in the open position and tag it to

prevent unexpected application of power. Failure

to do so could result in fatal electric shock. Do not

depend on a thermostat or other switch as the sole

means of turning off power to the heater. When

bringing supply wiring to the heater always route it

away from the area directly above the heater and

away from the sides of the heater where temperatures may be dangerously high.

WIRING OF THE FSS SERIES HEATERS:

1. The FSS-14 and FSS-31 models are available

in single phase only. All FSS-43 and FSS-95

models (except the FSS-4327-1) and FSS9527-1) can be wired for single phase or three

phase applications. See wiring diagrams on

page 10.

2. Remove the cover from the terminal box.

3. Connect the lead wires to the 90°C rated supply wiring routed into the splice box with wire

nuts or other safe mechanical means. Black

and white supply leads can be connected to

either element lead wire. Be sure green lead

from supply and green (bonding) lead from the

terminal box are connected.

4. Reinstall splice box cover.

5. Apply power to circuit.

“Bonding is the intentional electrical connection

of all non-current carrying metal parts to the

equipment grounding (green) conductor of the

heater and then terminating this green conductor

to the green conductor of the power supply to form

a low-impedance path back to the power supply

so that safety devices (circuit breakers, fuses)

can quickly remove dangerous touch voltage from

these parts when a fault occurs.

Always securely connect the green conductor

from the power supply to the green conductor

of the heater.

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 10 OF12

Page 11

OPERATION

BURN HAZARD

• Serious injury or death may

occur.

• Allow heater to fully cool after

power is removed (may take

minutes) before touching or

working on it.

When power is provided to these heaters the

heater elements will take several minutes to

achieve full infrared output that can be conrmed

by an orange to dull red glow on the element

surface. The element under this condition is

operating between 1,500 and 1,600° F emitting

medium wavelength (approx. 3 microns or

millionths of a meter) infrared energy. This

energy, that can also be considered “radiation” is

not harmful, yet is very effective at heating

o

bjects and surfaces that are within the

line-of-sight of the elements and the heater’s

reective surfaces.

When power is provided or removed from these

heaters, you may hear unfamiliar sounds that are

caused by the expansion and contraction of metal

components in the heater. This is normal.

MAINTENANCE

Pre-Season Maintenance and Annual Inspection

T

o ensure your safety and years of trouble-free operation from the heaters, periodic service and

inspections must be done by a trained maintenance person or licensed electrician.

To obtain maximum performance from your heater(s) each year, we recommend the following be

performed at the start of the heating season:

1. Disconnect power to heater at main panel. Be sure that heating elements have cooled down.

2. Clean housing surfaces with a damp cloth.

3. Blow or dust off the element.

4. Repair or replace damaged power cables.

5. DO NOT hose-down these heaters.

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 11 OF12

Page 12

INSTALLATION WIRING (con’t.)

WIRING SCHEMATIC

FOR FSS-14, FSS-31 FSS-4327-1

AND FSS-9527-1 MODELS

L1

L2(N)

FOR ALL OTHER MODELS

1

2

3

4

FOR 3PH OPERATION

L1-1 & 4,L2-2,L3-3.

FOR 1PH OPERATION

L1-1 & 3, L2(N)-2 & 4.

ISSUE DATE 07-2015 REV. DATE ------------ REV. LEVEL: - ECO 1-7090 OIPM P/N 8419 PG 12 OF12

Loading...

Loading...